-

Posts

197 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Yabuhebi

-

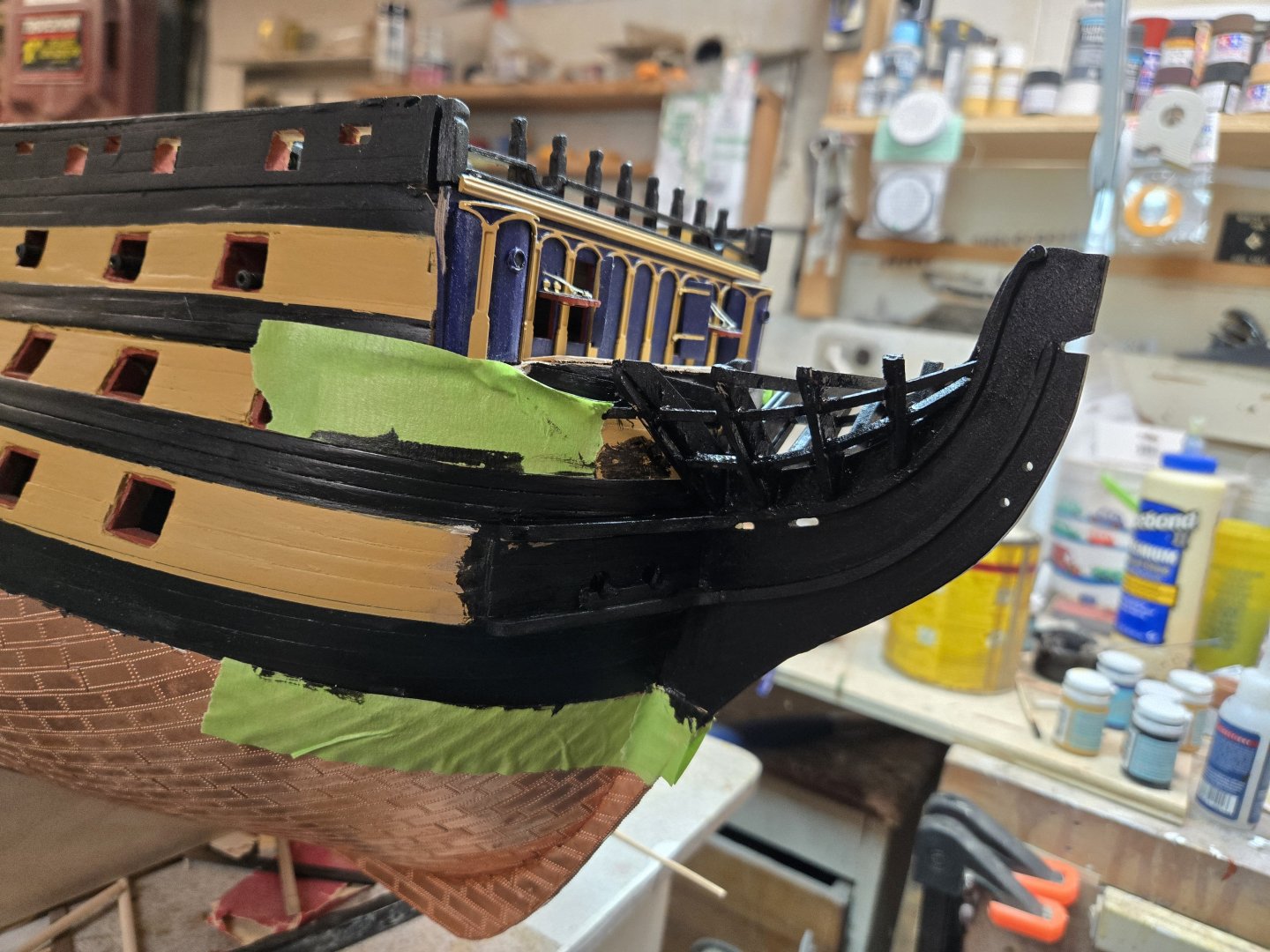

It's been a very bust weekend. I spent a lot of time working on the boat and enjoyed the challenges. Not the end results! But it's strangely enjoyable! I taped off some areas I wanted protected and painted the bow assembly all black. I didn't post pictures because the paint was still a bit wet and the lighting doesn't always help in the basement. Honestly, all black, things looked pretty good. I could see though that I had made a mistake as I was painting. There are some VERY tight spots and it was going to be a messy pain to get into them.

-

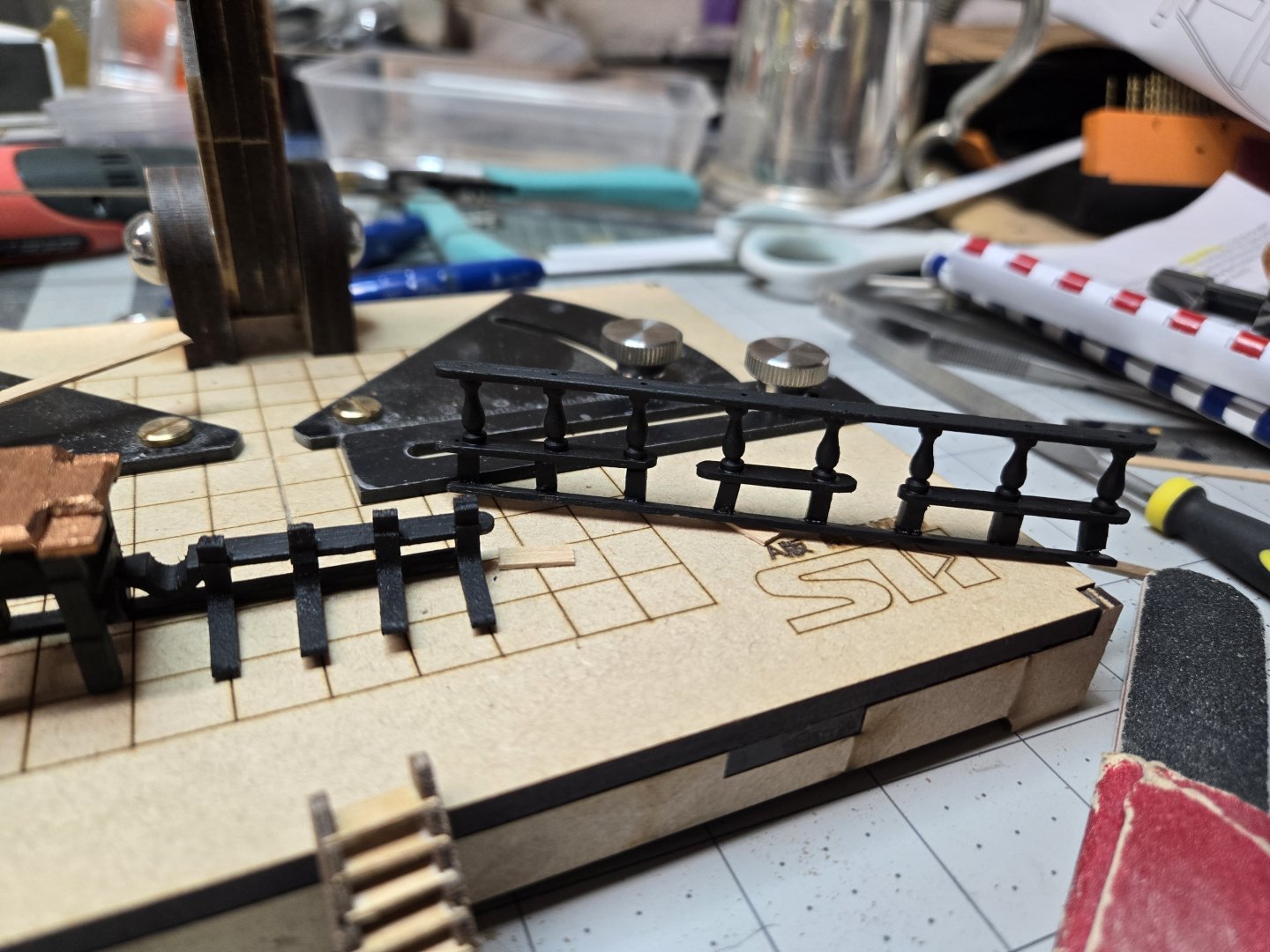

Alrighty, back to work! I think I tackled some cannon work because I was afraid to begin work on the bow. I thinned a regular toothpick and sanded all the wheels round, or round like. The larger ones came out a bit better. Once I was done with that, I painted all the axles black. I also put the carronades together. They went fine, I broke the axle ring on one of them, they are plastic and kind of cheap at that. No worries, it's under the cannon. I'll post pics when I complete the other 12. I also added the tackle rings to each of the 12 cannon bases. Next was the bow. I had had an issue with how to place #107, the aft/largest head timbers. 107 doesn't fit through the slot in the stem. I had to trim a bit off one of the bottom slots where it slides onto the stem and then it slid right through. When doing the others I had to cut the tips so that the others sat flush, level and flat. I glued them with white glue and let them dry. I also add the 5mm scrap walnut strips to #'s 108 & 109. They go across the front of these are create ledges for the two beakhead platform pieces. I The instructions then said to use 2x2mm beach to run the rails across these head timbers. The head timbers have little notches in them. I could not find any 2x2mm beach in my kit. There is a single pieces of 2x3 and there is no mention of a 2x3 beech wood in parts list, 2 pieces of 2x3 walnut but not beech. So I assume this is the pieces. The problem for me is the 3mm. It doesn't fit in the notches and when laid sideways sticks out farther. Is that an issue? I installed the horizontal rails. The next step are the vertical rails. I was confused, there really isn't any mention of these vertical rails, only that they are capped with trimmed down walnut strips that are painted blue. When looking at the pictures, it looks like these vertical rails are wider than 2mm so the trimmed down they create the 3-D look. Running the beech vertically, created problems as the head timbers sit almost, if not directly flush against the top curved rail. So installing the vertical rails makes their bottoms stick out. I haven't seen any build pics of this....in fact, it almost looks like the horizontal rails are installed on the inside of the head timbers and then the vertical rails sit flush against it. Notches don't match that theory, but a lot of pics seem to suggest that.... Well, I moved forward and installed the horizontal rails first and then added the same size wood as vertical rails. I trimmed the bottoms to taper into the curved trim rail. I don't know, it just doesn't look like other builds and I don't know what I did wrong. As I write this, it appears to me that perhaps the vertical rails need to be 'slotted' to fit OVER the horizontal rails , then they would create the illusion that the head timbers are bigger than they are. I plowed ahead and while I was writing this, I was half tempted to go downstairs and pull out the vertical rails and redo them with slots so they fit better. Then I decided that only the outer rails will be visible because they will be painted yellow while all the internal structures are black and thus hidden. Once I was done, I sanded everything and also drilled the anchor cable holes. I didn't have a 6mm drill bit close by, so I used a 5.8mm. When drilling one of the port holes (on the hawse piece that I made) I broke it. I've glued it back. When it was done, I painted everything black. That may have been a mistake. I have no issue with taping everything when the black is done to paint the yellow, but there are some very hard to reach spaces for the black. I will post the pics of the final outcome once it's all painted. I have pics of the bow all black, but because it's so black, there is very little detail right now without editing them.

-

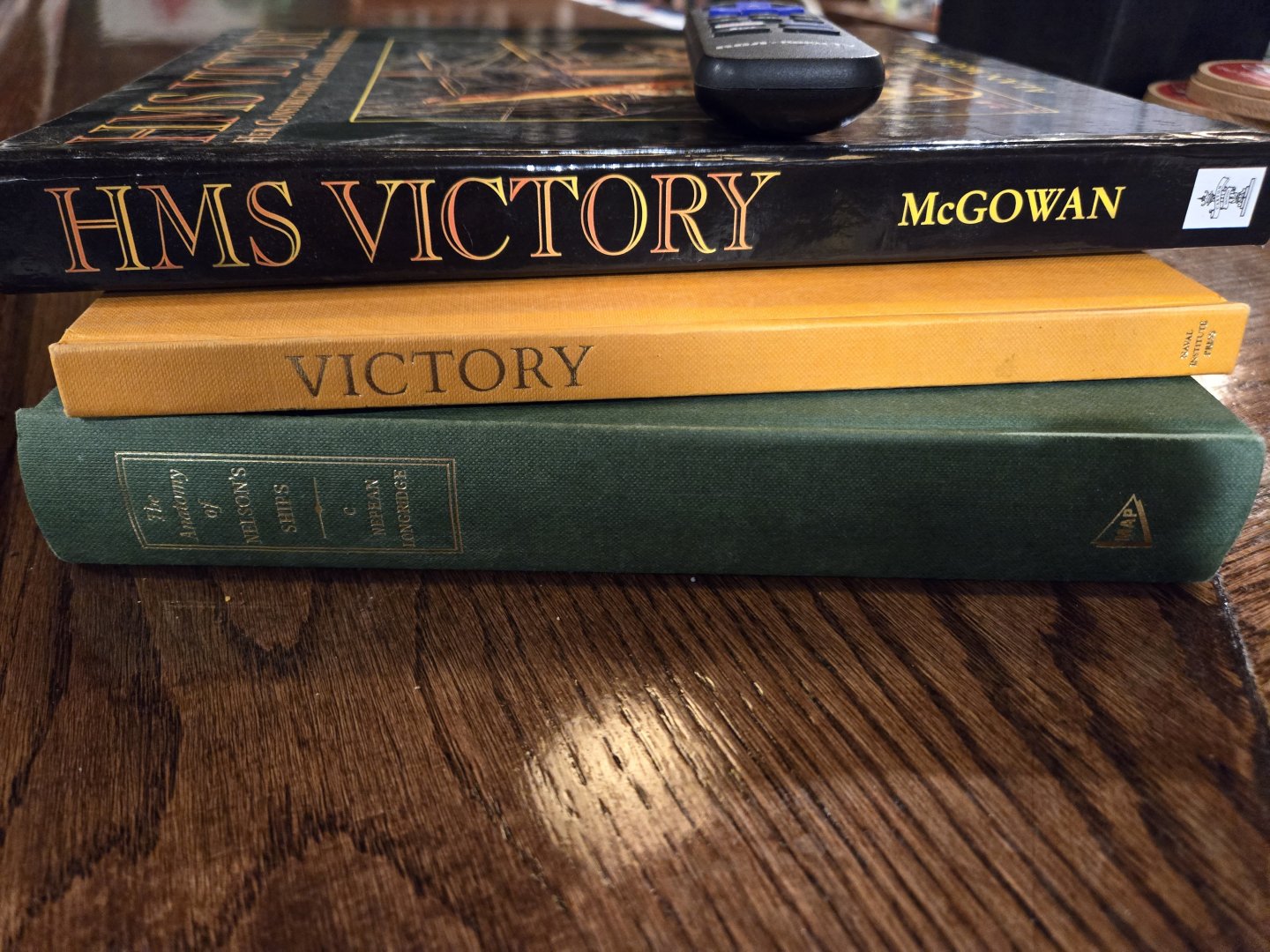

Hello everyone! I have done a bit more and will add that below. However, last night I spent a lot of time searching builds for help on the bow. I thought that having a list of what I use for this model might help new builders when they begin this journey. I am going to attach this to the first page too. I use 3 books and they are a tremendous help. I looked for used versions. Longridge's took some time. The book has many pull out plans that help with any model's build and I wanted to be sure the book I bought had them intact. I included Google links. Used Books Anatomy of Nelson’s Ships – Longridge, Nepean HMS Victory – McGowan The 100 Gun Ship Victory – McKay I use many videos, and many listed below have dedicated playlists that help keep their HMS Victory builds separate from their other work. YouTube Video Blogs Wooden Ships – Greg Wislon Just A Good Place This is a Spanish blog for Artesania Latina model Johns Wooden Ships - John Aliprantis Many blogs of wooden ship models including HMS Victory (NOT Caldercraft) John Builds Iconic Military Models – John Mansell Huge playlists for 2 different HMS Victory models Olha Batchvarov – Olha HUGE database of builds, how to’s and more including DeAgostini version Paul Vickers – Paul Vickers There are only 8-9 videos before he stopped posting. So good for a new starter only I am a member of two model ship builder sites. Both are great and offer so many tips, hints, links, etc. Ship of Scale The site has an advanced search enabling you to input exact issues you want to research and the ability to 'watch' build logs and get notifications when the builder adds new content. Paulv1958 – Paul Vickers Hasn’t done much and incorporates the use of his YouTube blog Traumadoc – As of 11/8/24 he is finishing up stern and hammock rails. I believe he is a novice builder just like me, but has done remarkable work while juggling a full-time job and taking the time to log his work. Peterg – Major blog with high quality build, including lighting and custom features. As of 11/8/24 on quarterdeck w/ cannons Serikoff – Sergey Custom built HMS Victory using Mantua plans. Just started builders log in October, 2024 but has brought it up to date with what he has done. He provides EXTENSIVE information concerning his build, how to’s and more. Julian – Occre model, but has similar build issues that will help Y.T. – Mamoli scale 1:90 Model Ship World A great site, a lot of interaction between builders, a great search engine and the ability to monitor other builders as they add content. Kiwiron – Ron As of 7/24 completed quarterdeck, stern, bow and more Robert29 Finished Caldercraft HMS Victory – one of the best builds I have seen and use extensively while doing mine. Charter33 As of 5/24 he has finished quarterdeck and is working on outerhull trim and deadeye platforms. Very good build, meticulous Heinz6672 Wood only (no paint) museum quality work, but stopped posting while doing rigging around 2020 Paulb – Paul Last posts around 2023 with work on standing rigging. Very detailed work There are many other blogs on both sites and searching will also pull many recommendations for help on various tasks needed during the build. I didn't include links to topics such as laying hull planking, deck planking, rigging tips, making rope, etc. These are things each builder will have to do to get to know the process. I am a NOVICE builder with just one model under my belt. A plastic large scale model of the Titanic. It took me a year to build and that was pretty quick given that I have a lot of time as I'm retired. In addition to the above, I spend a lot of time searching specific issues when needed. When working on cannons, I would search keywords: cannons 1700 era ships, hms victory cannons, cannon rigging, cannon tackle. Once Google provided me with their search, I would save pictures for future reference. Hope this helps and good luck! Chris

-

After that, I spent the better part of the afternoon and evening plotting my attack of the first bow installations. I couldn't use the planking on the hull as I didn't quite have everything even, so I had to individually judge every piece before installing. The first 4 pieces are the curved upper rails that are glued to the stem. The top upper rail sites above the gammon slots. To make sure they remained clear, I put a few pieces of deck material in the slots so the upper rails would rest on them. I noticed that on the real boat, the upper rail has some relief lines and a decoration on top. I took a little brass pin and cut it down and put it there, it's not huge but will give a little detail. I saw one builder who took a nail or small/larger than normal pin and used it to score these rails to give them the grooves. I didn't do that, but it is an interesting idea! Once the upper rails were attached, I began to work on the hair brackets and the lower bow cheek rail....the names these things have!!!!! I had to drastically sand down the 2nd planking and wales to create enough room for these 'brackets'. Using a combination of my Dremel, small chisel, sand paper and files I was able to clear out the hull. After, I also had to sand the 2 pieces on their backside to get them to fit. I used 1.x5mm walnut planking to fill in-between the brackets. Once installed I added walnut putty to smooth everything. I'll sand them clean. Over all this are the hawse hole bolsters. These are the guides for the large anchor cables that would go though the holes to the lower deck capstans. Sadly, I lost one of them! When cutting earlier pieces, I must have cut one of the bolsters free and put it somewhere for safe keeping. I will find it when I start my next ship in a few years!!!! I cut out a block and did the best I could to duplicate it. Hopefully, black paint and cable will hide any failures on my part. I am happy that the brackets appear level and in line with each other on each side. I did look ahead a bit. There are 4 head timbers that are attached to the top of the stem. The largest, #107 looks like it must fit THROUGH a slot in the stem. Except I can't figure out how that works. My only thought is that I have to cut it in half. There must be a way and I will search tomorrow. Thanks for all the likes, this model won't be a ribbon winning endeavor when done, but as a first timer, I am happy that I've gotten this far and that she isn't a shambles!!! ...yet! My best to all; Chris

-

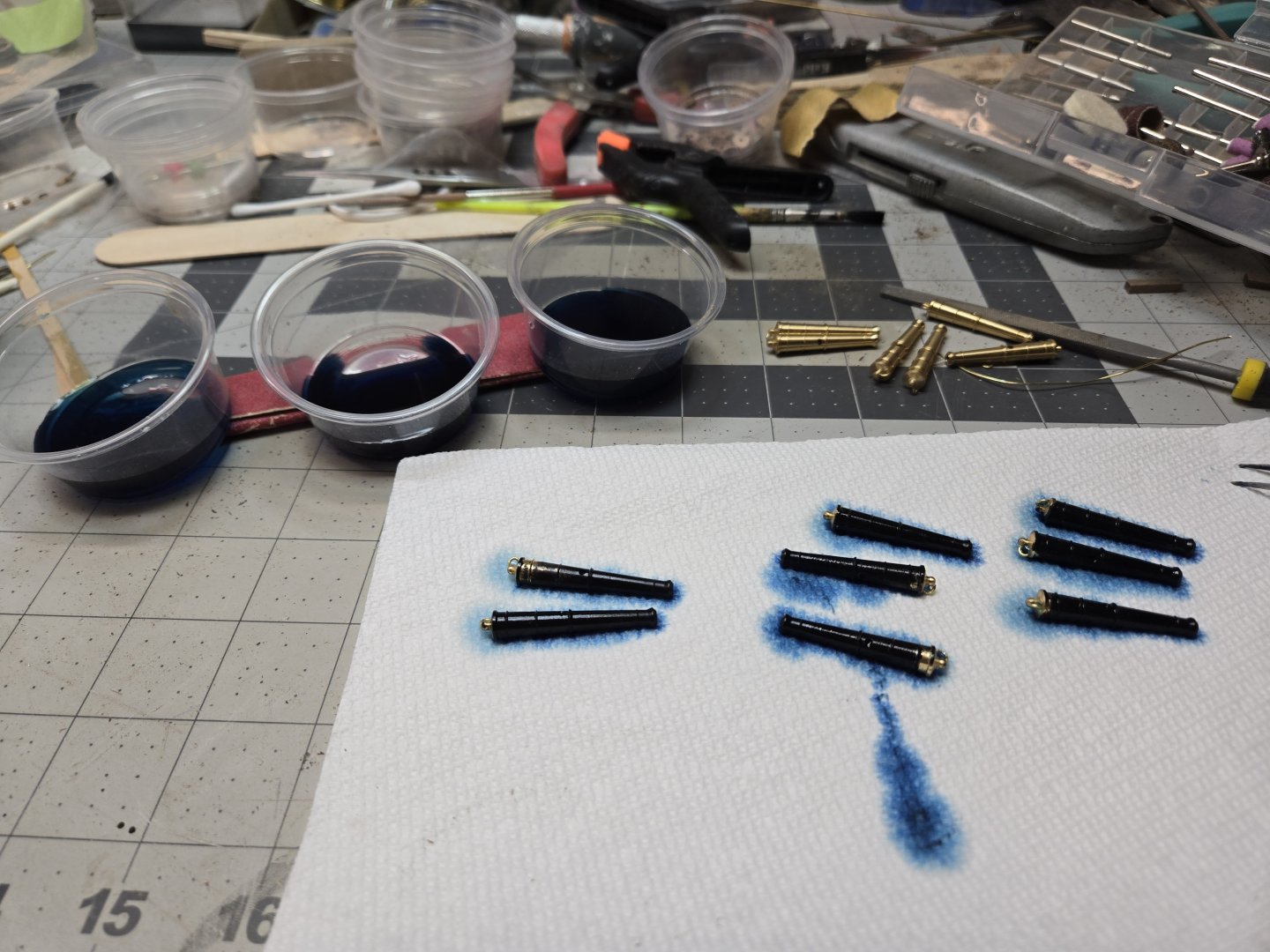

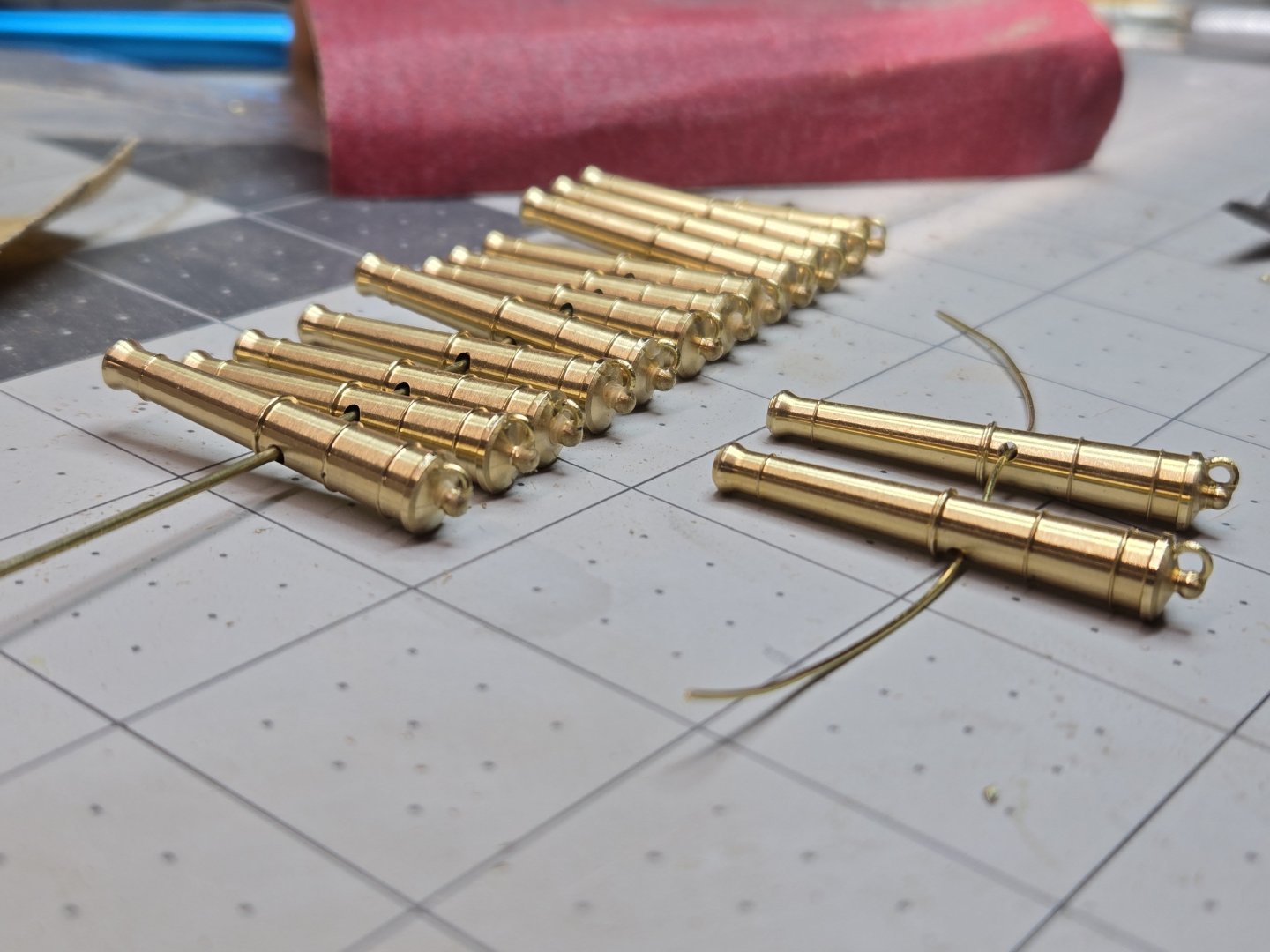

After getting the beakhead work done, I had to wait for the paint to dry so I worked on the cannons. I blackened the cannons and true to form, the ends would not take the bluing. The CA glue was a barrier. In this model the carronades are plastic, the manual stated they were cast. I built the carronade bases and put 2 coats of paint on all the cannon bases. Once the cannons were dry, I tried painting the breech sides. For some reason, the paint was gunking up to the points that I had to constantly clean the brush....this didn't happen when I did the first 30. Since I had erroneously used up all the iron black, I used a black iron Tamiya paint I had. Tamiya's color is a bit grayer. I'll circle back around in a day after they have dried.

-

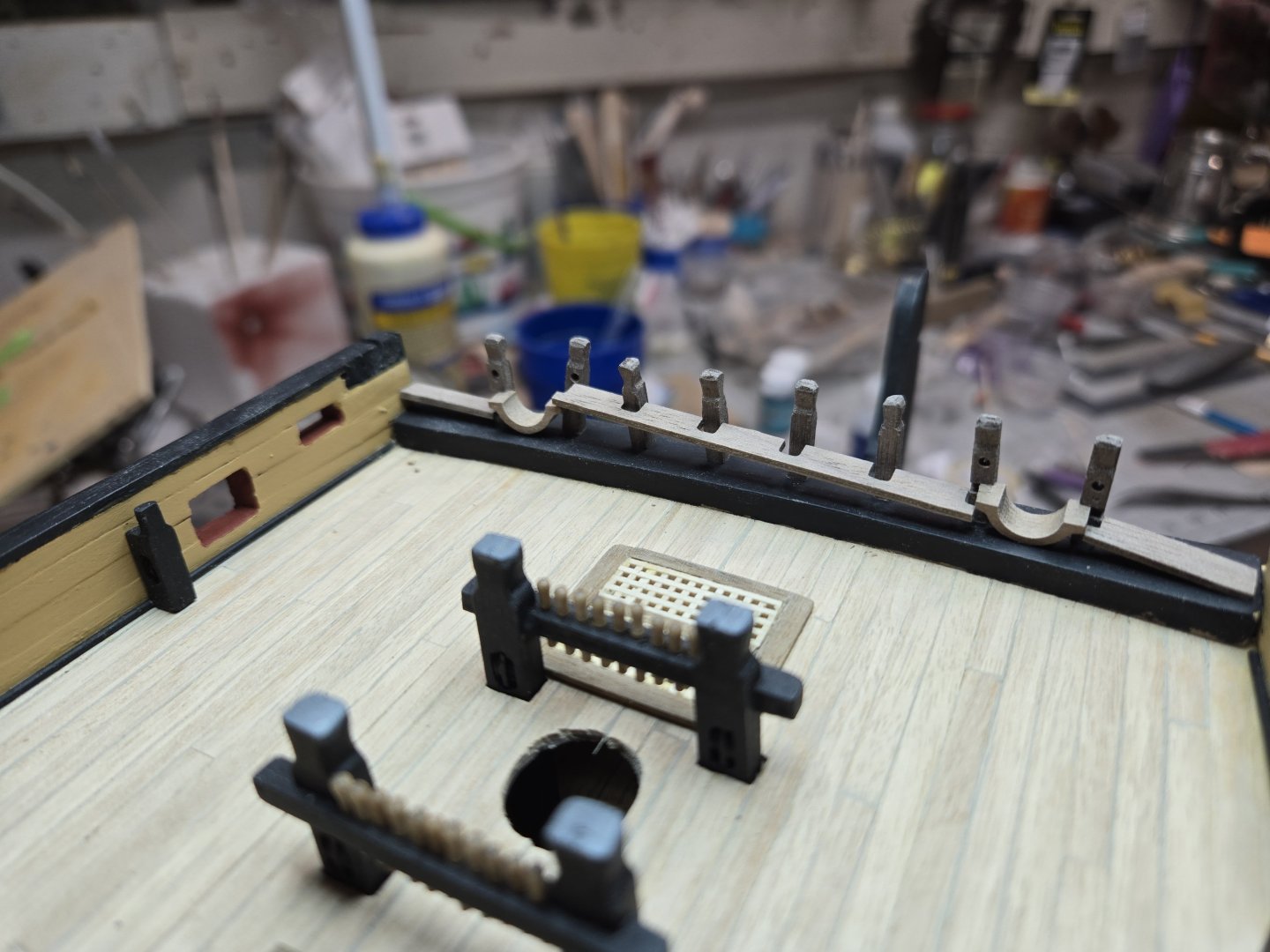

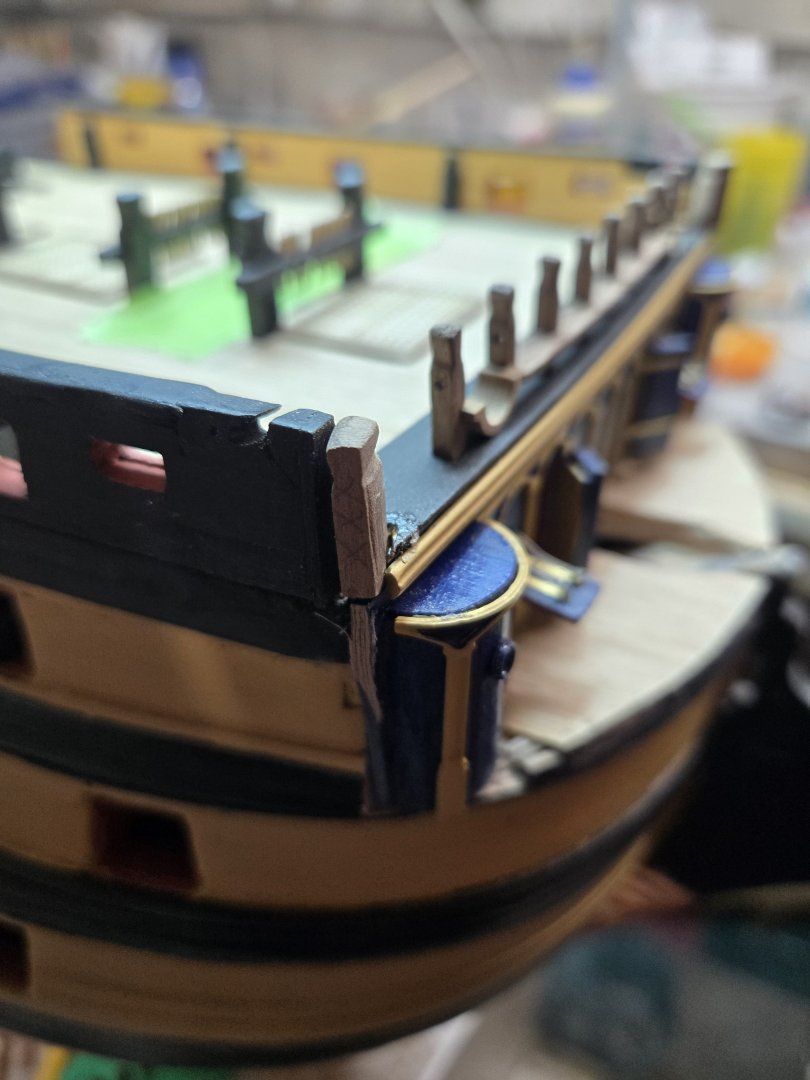

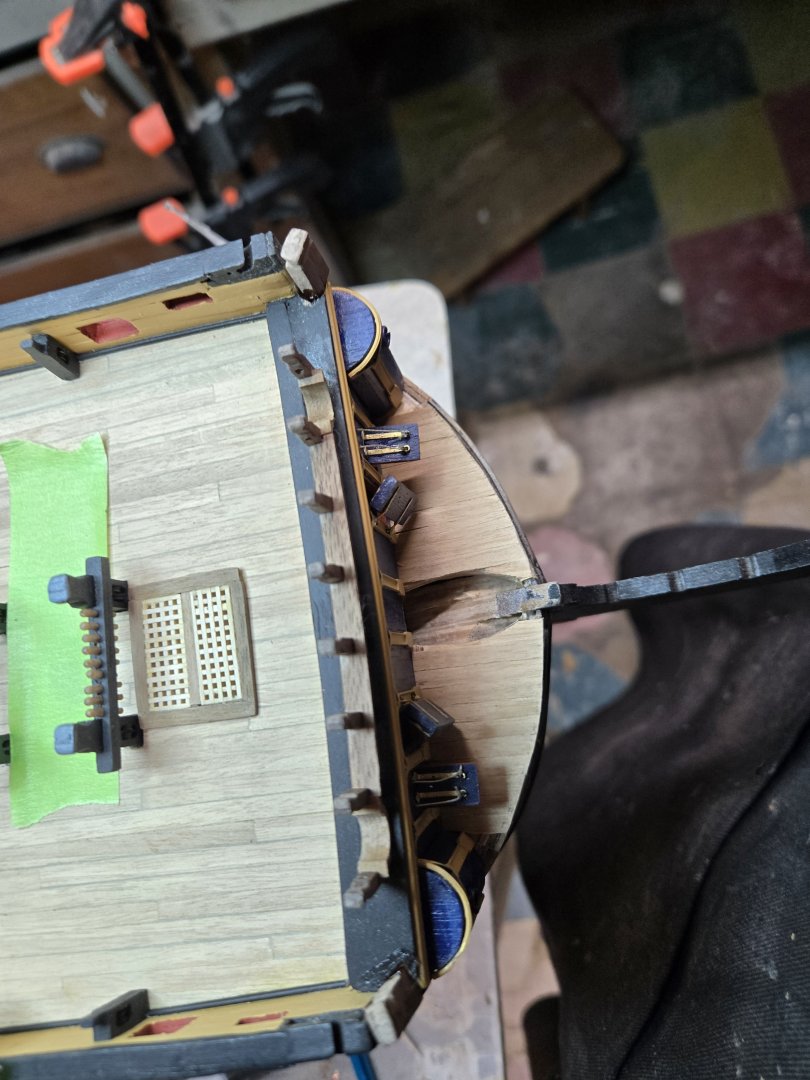

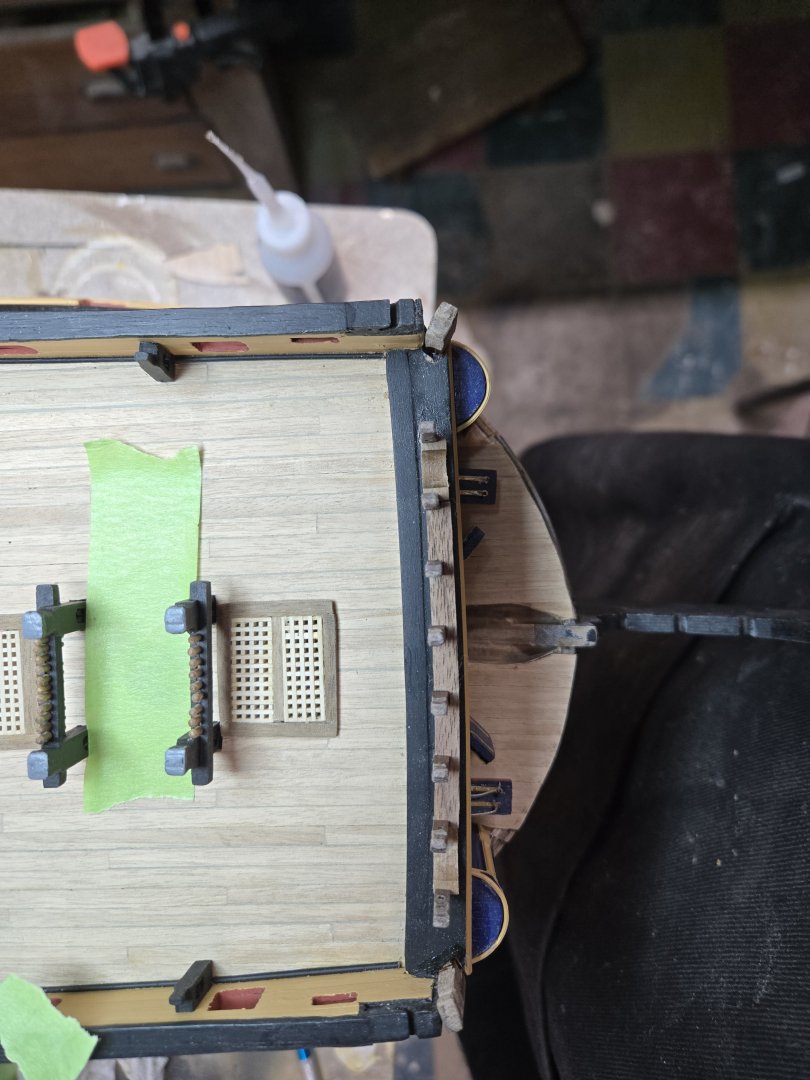

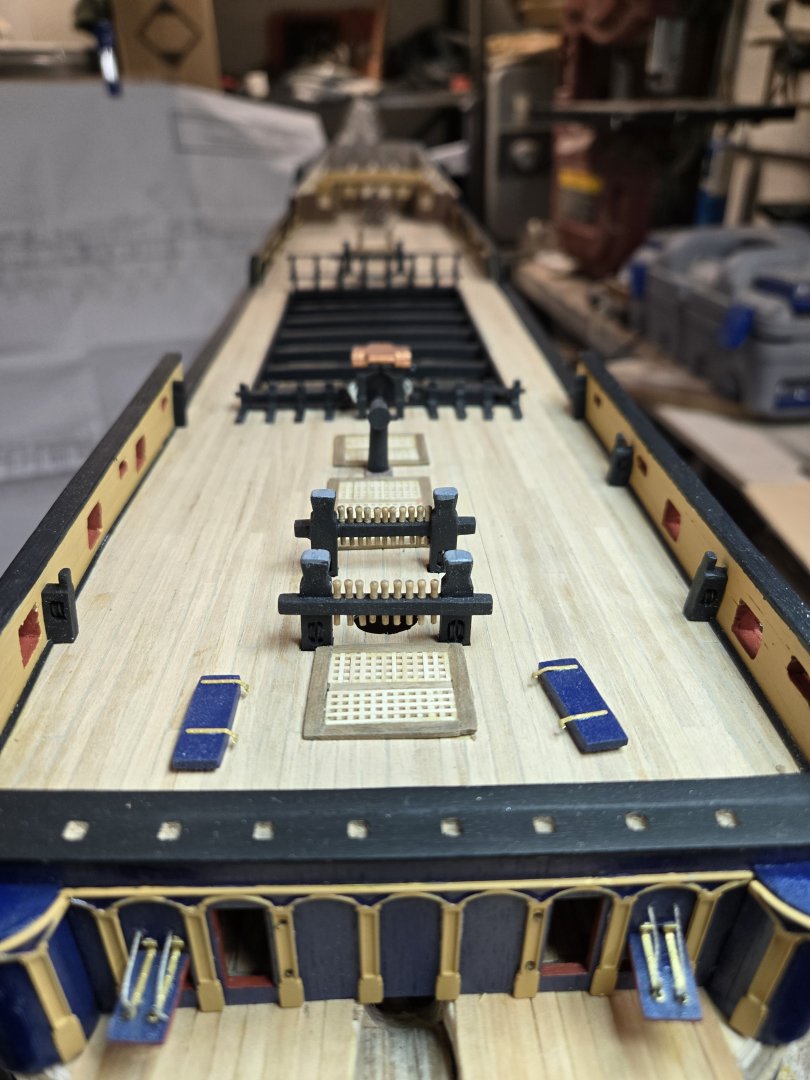

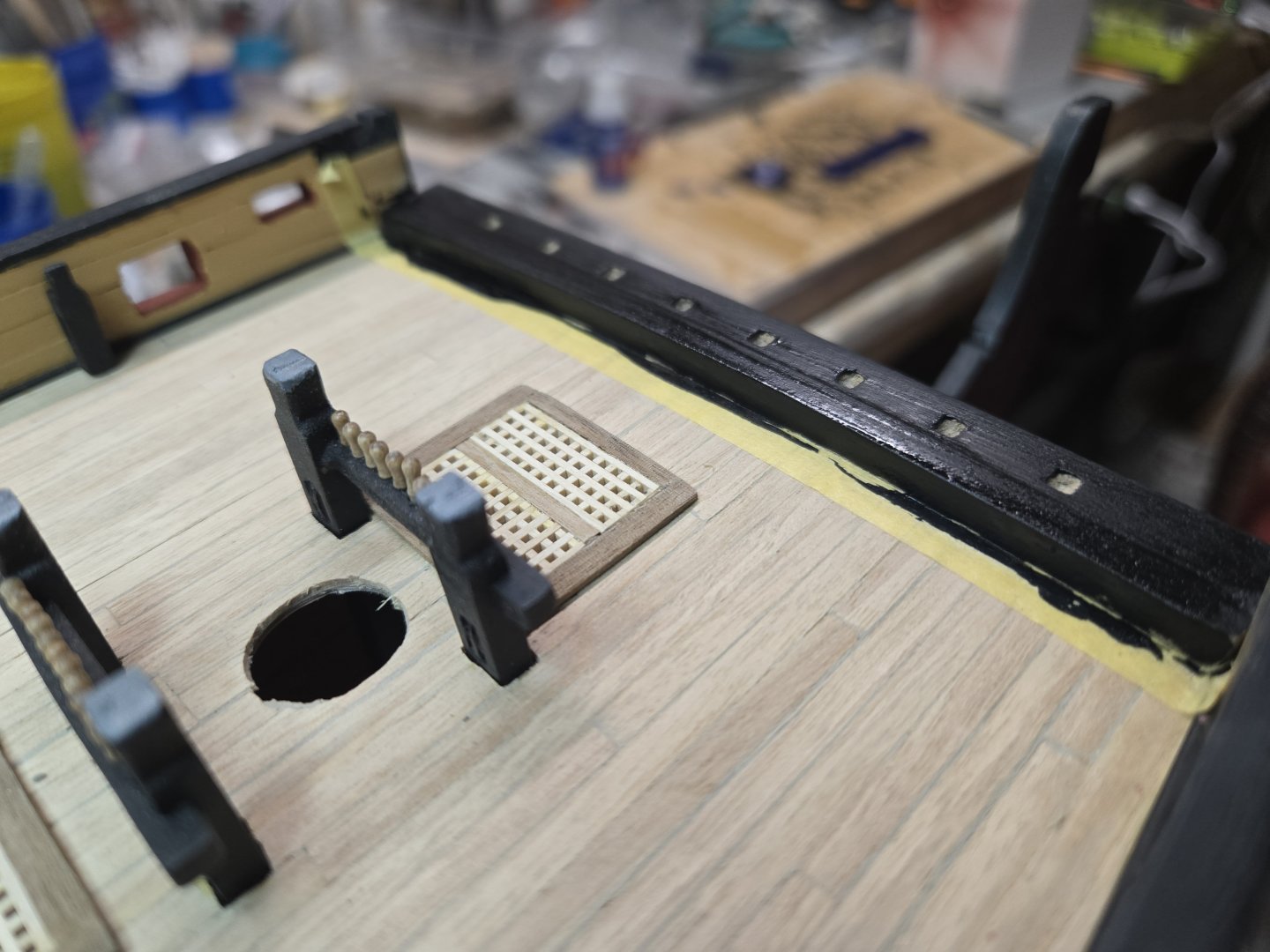

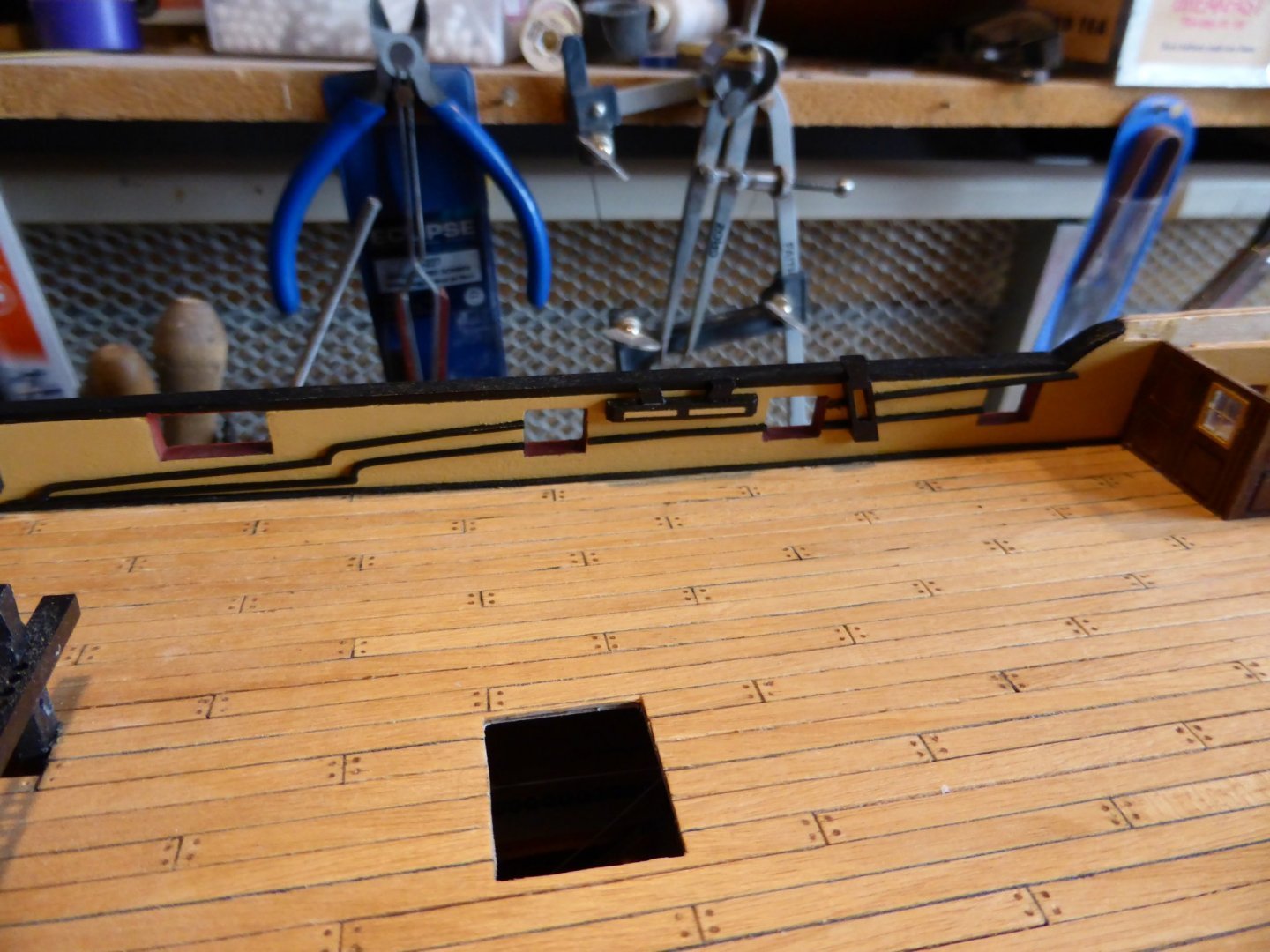

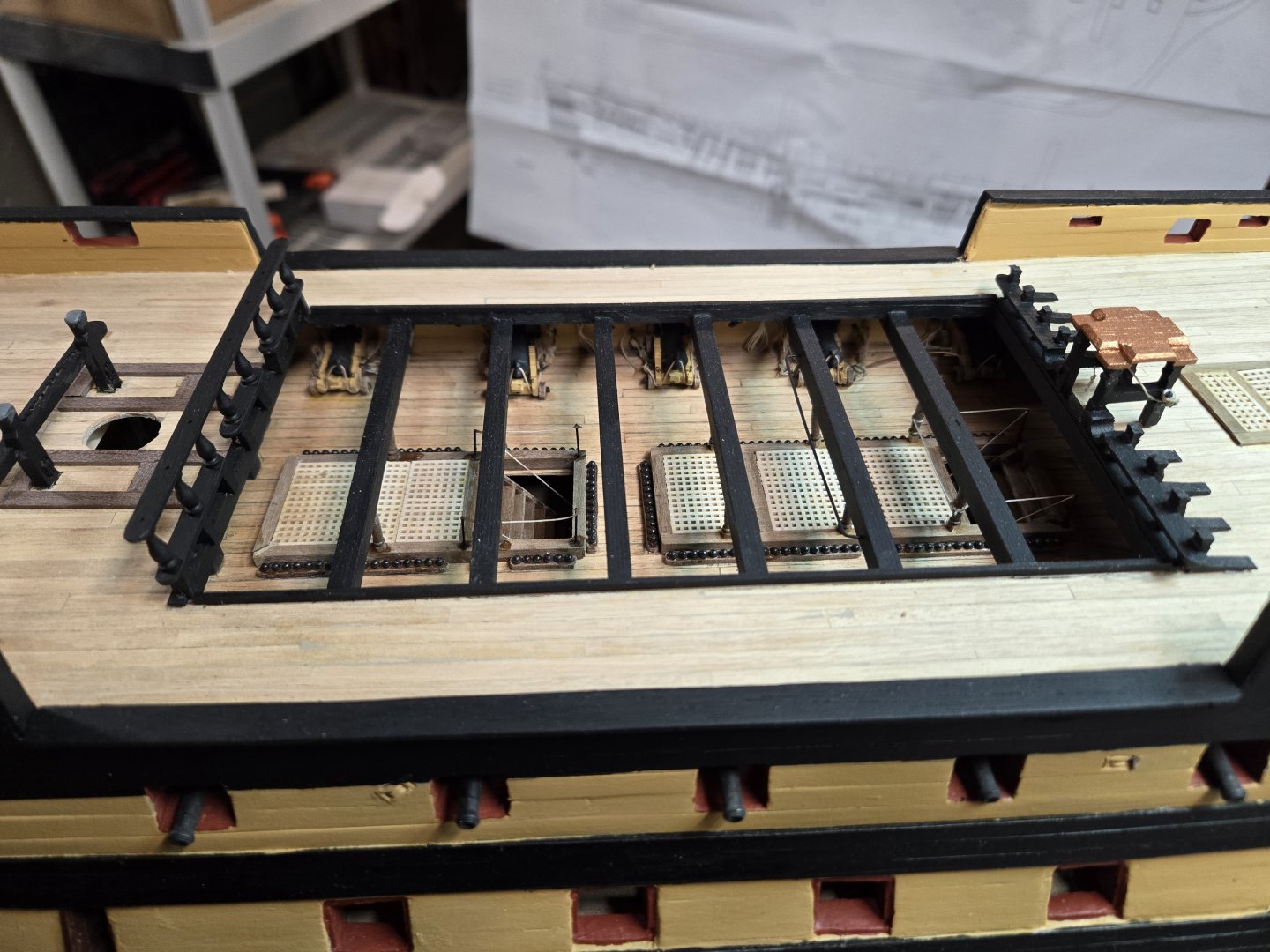

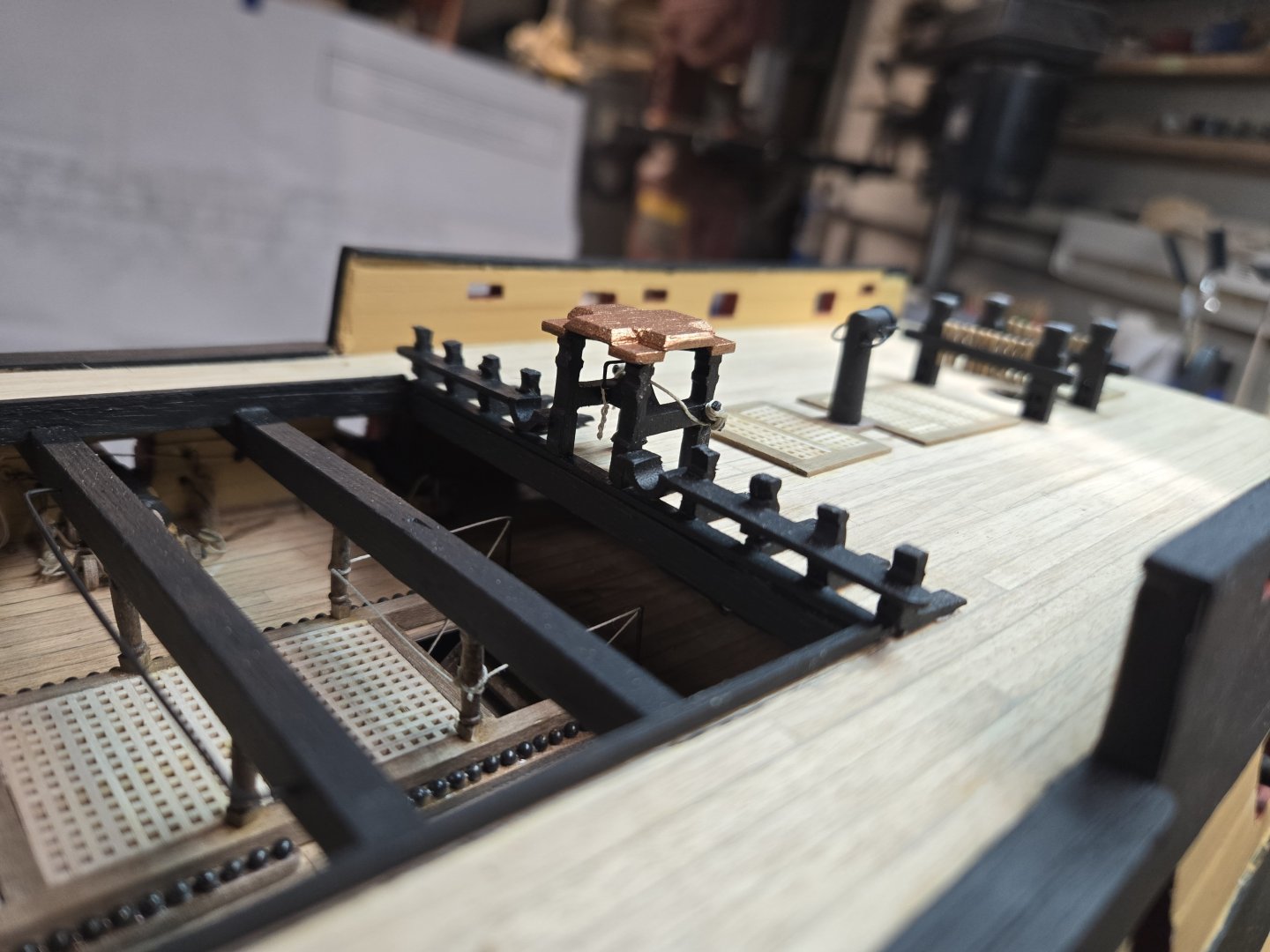

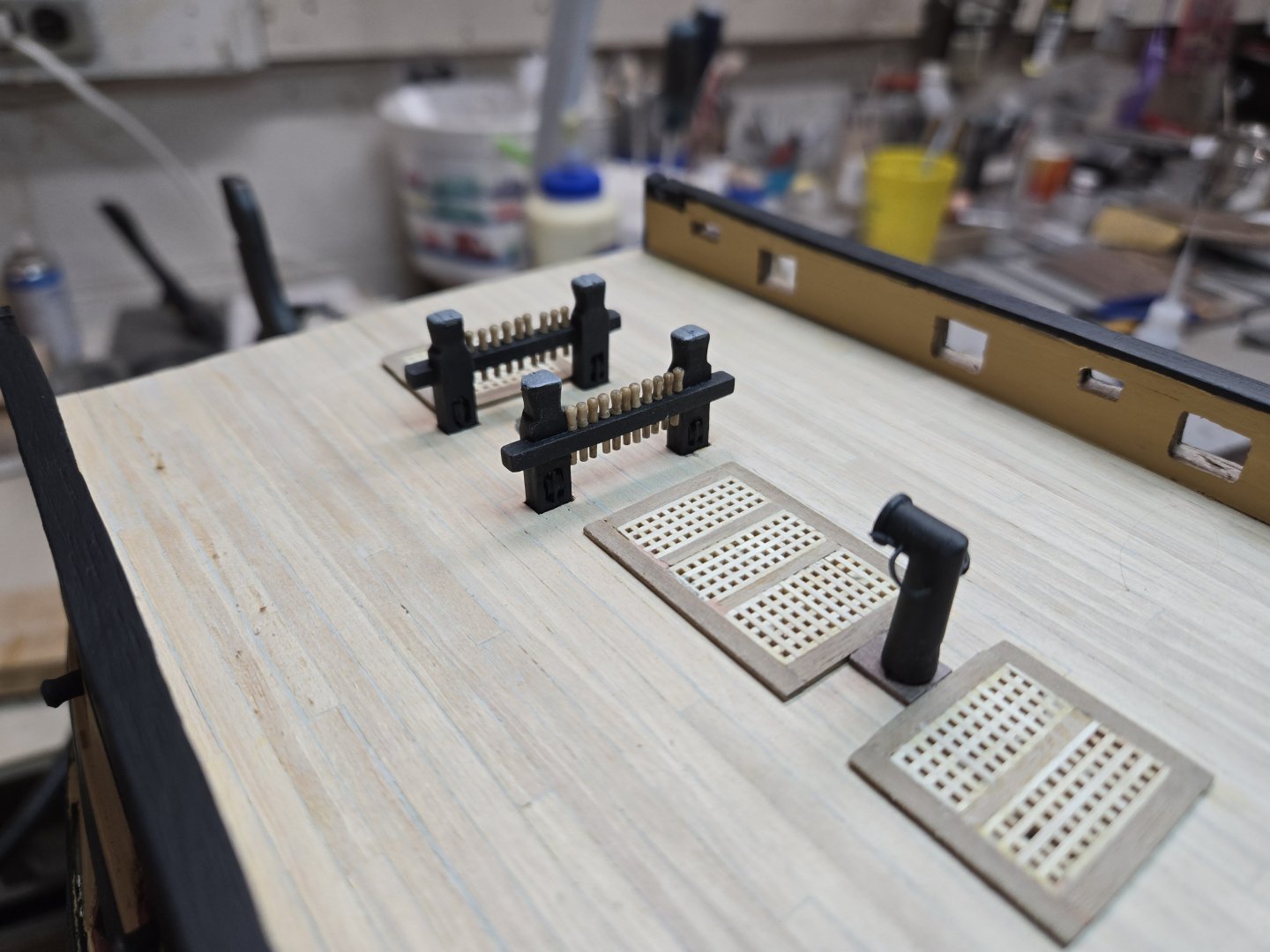

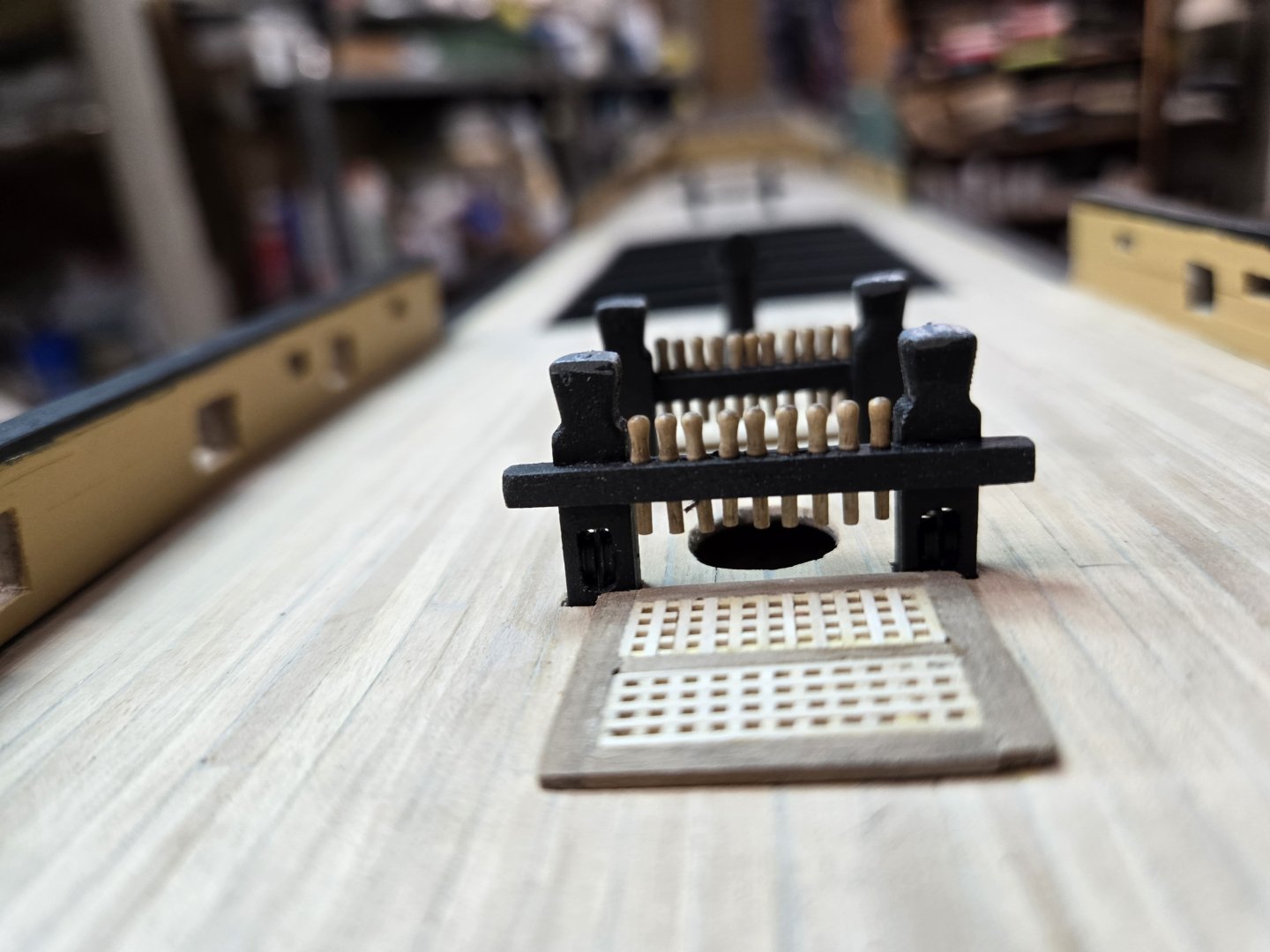

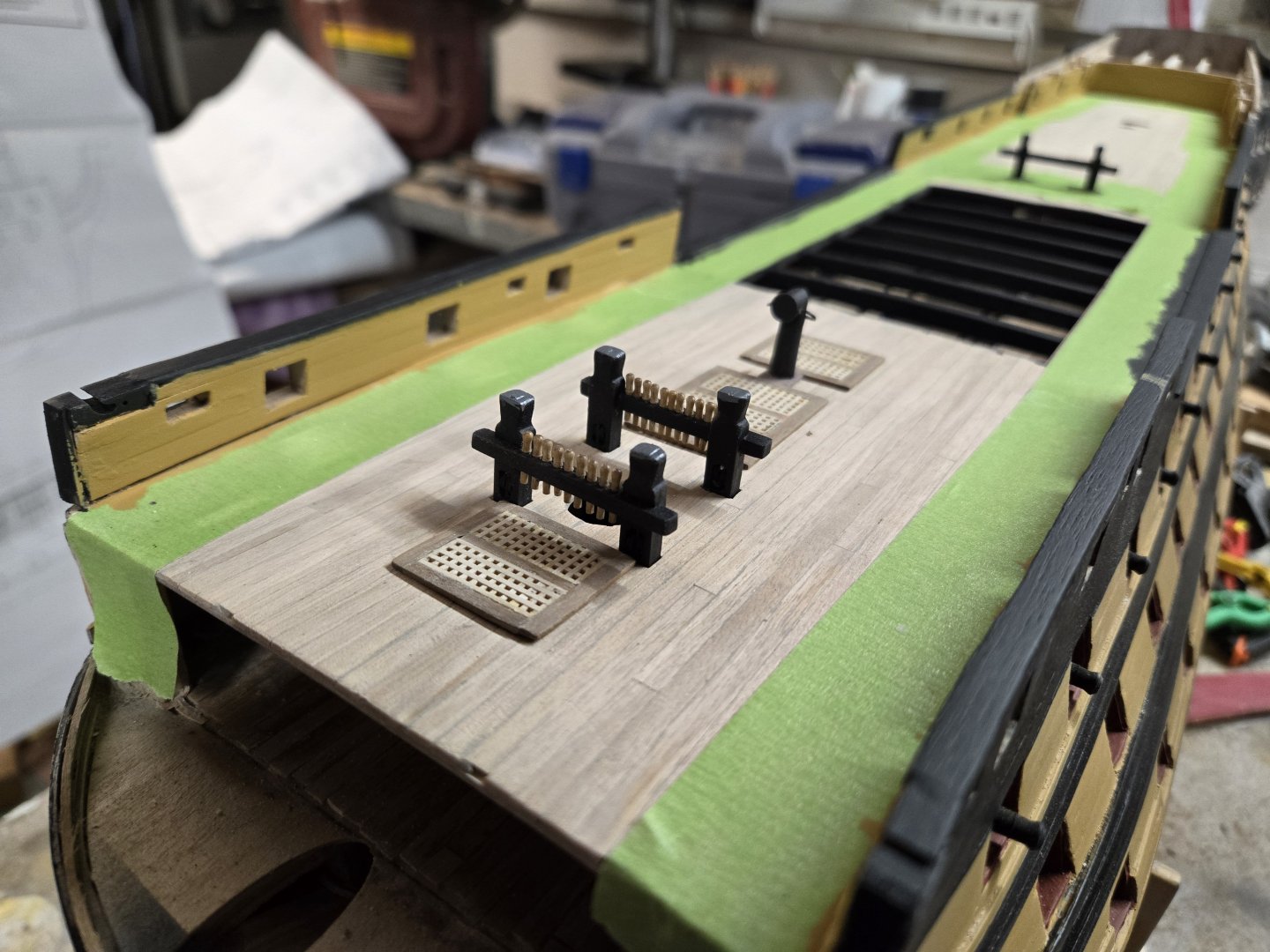

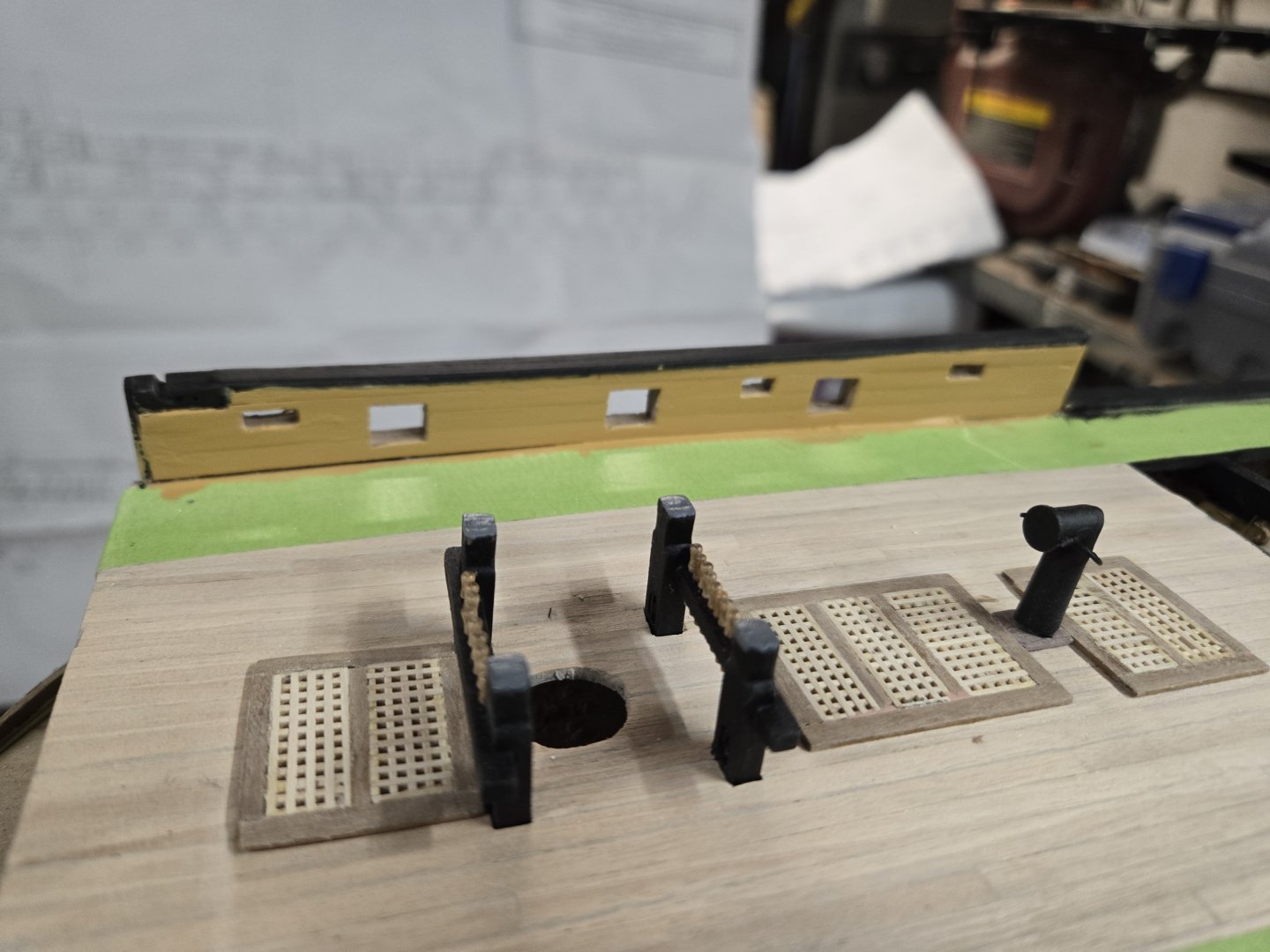

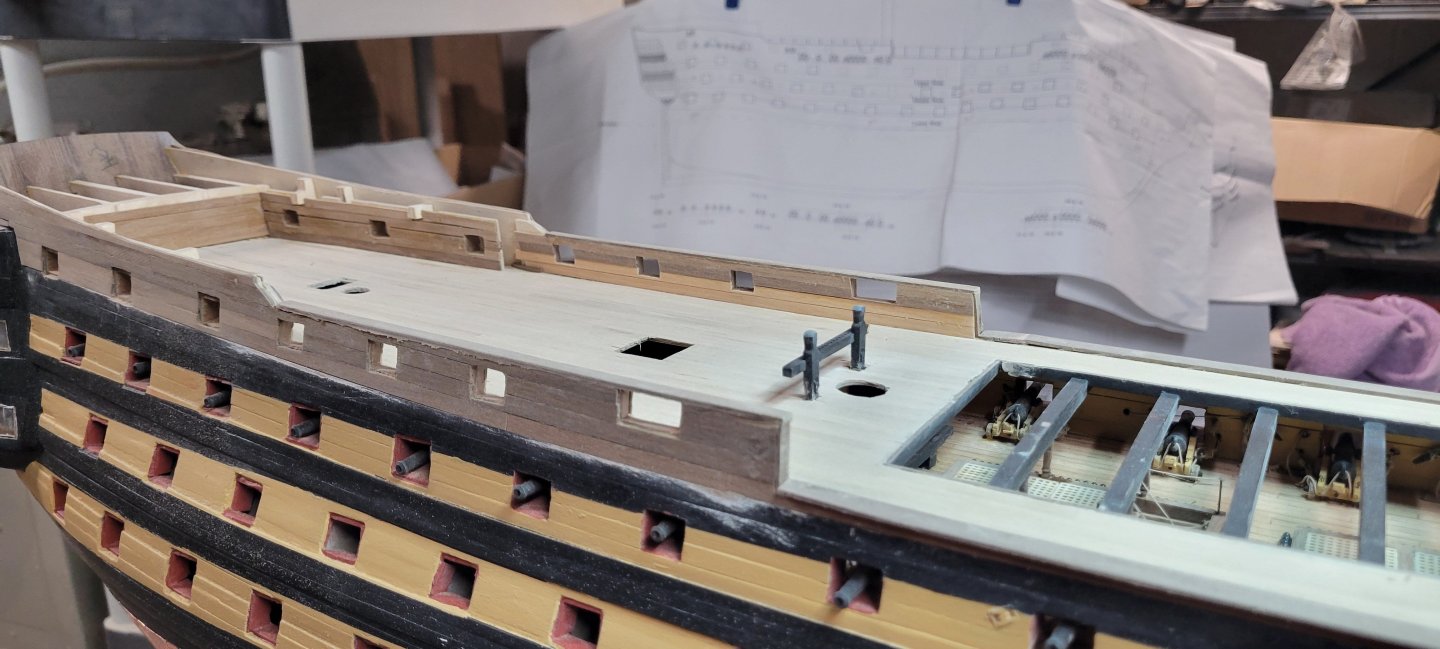

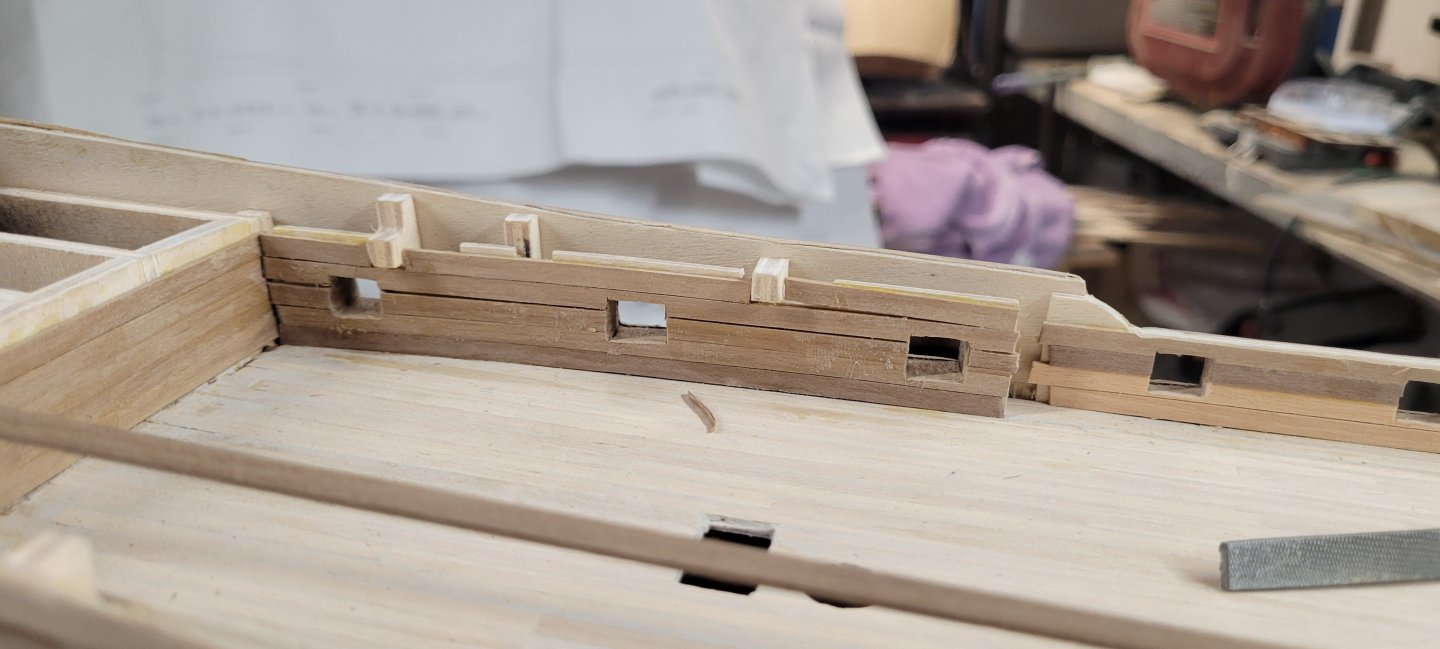

With no chores looming till all the leaves fall up hear in Northeast NY, I have spent a lot of time working on the boat! I installed the hatches and doors to the beakhead, laid the planking and put a few coats of matt finish on the deck. I started working on the Beakhead Cap Assembly. Many of the available blueprints had 6 of the 8 timberheads equipped with sheaves. They were too small for me to drill 2 holes and then create a hole for a sheave. I've seen other builds, but I couldn't see a way. I do have a drill press and thought I might be able to drill 2 small holes, but then I would be afraid to cut away the excess and break the timberhead...they are that small. I did drill a hole to perhaps accept any line while rigging. But once again, I didn't read the instructions...a common theme with me!!!! The previous assemblies had part #63 in such away that the timberheads needed to face aft. That isn't the case here, so my holes are useless! I didn't add the outside pieces because I wanted to add a thicker main rail inner timberhead. This is the one that will accept bow main rail and create a larger timberhead in each forward corner. Once I built these 'super' timberheads, I had to cut away some of the decking to get them to fit at the right angle. I taped the main rail inner to the stem and the side to get a feel for the angle they had to be installed to. Once done, I was able to cut away the end pieces of the cap assembly and paint it all black.

-

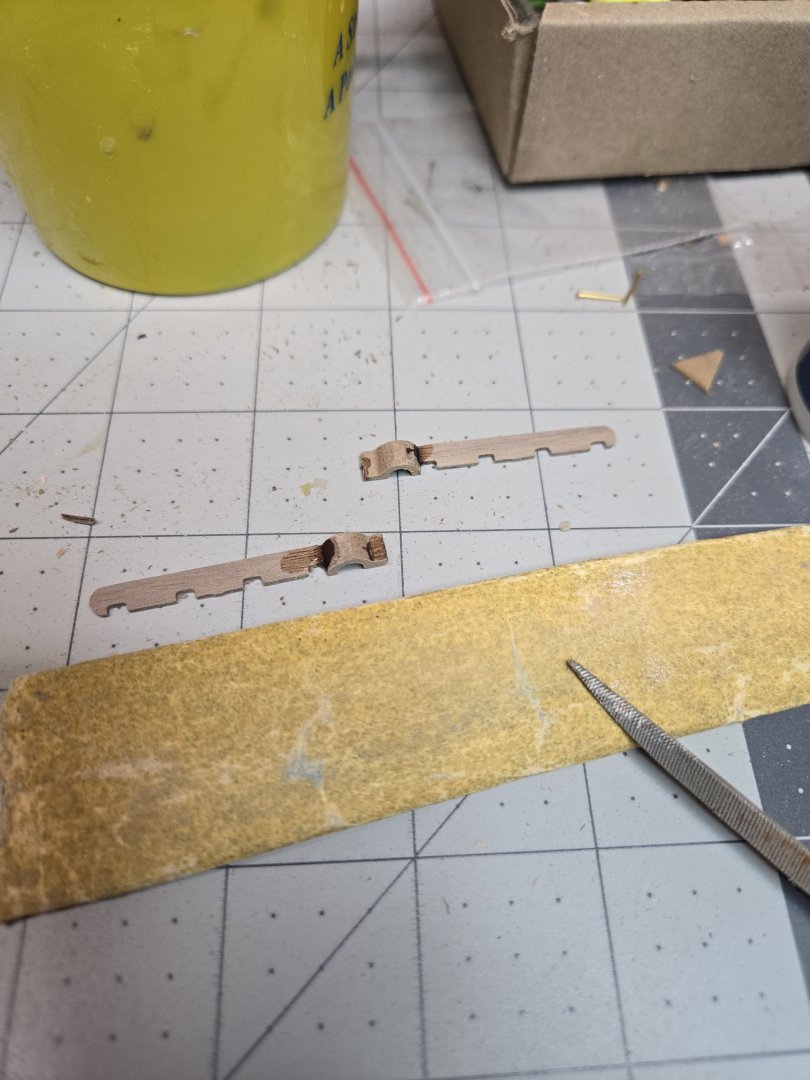

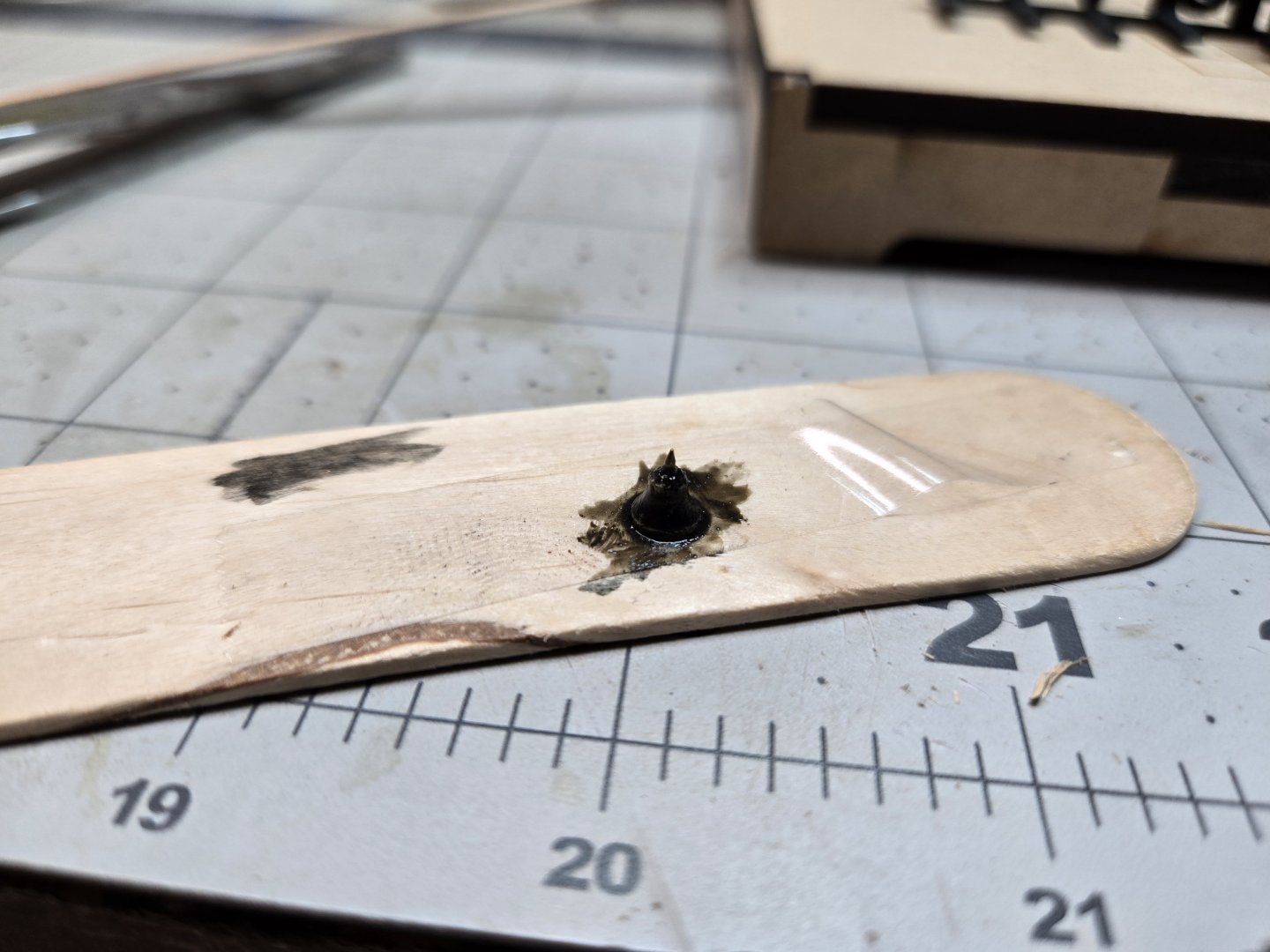

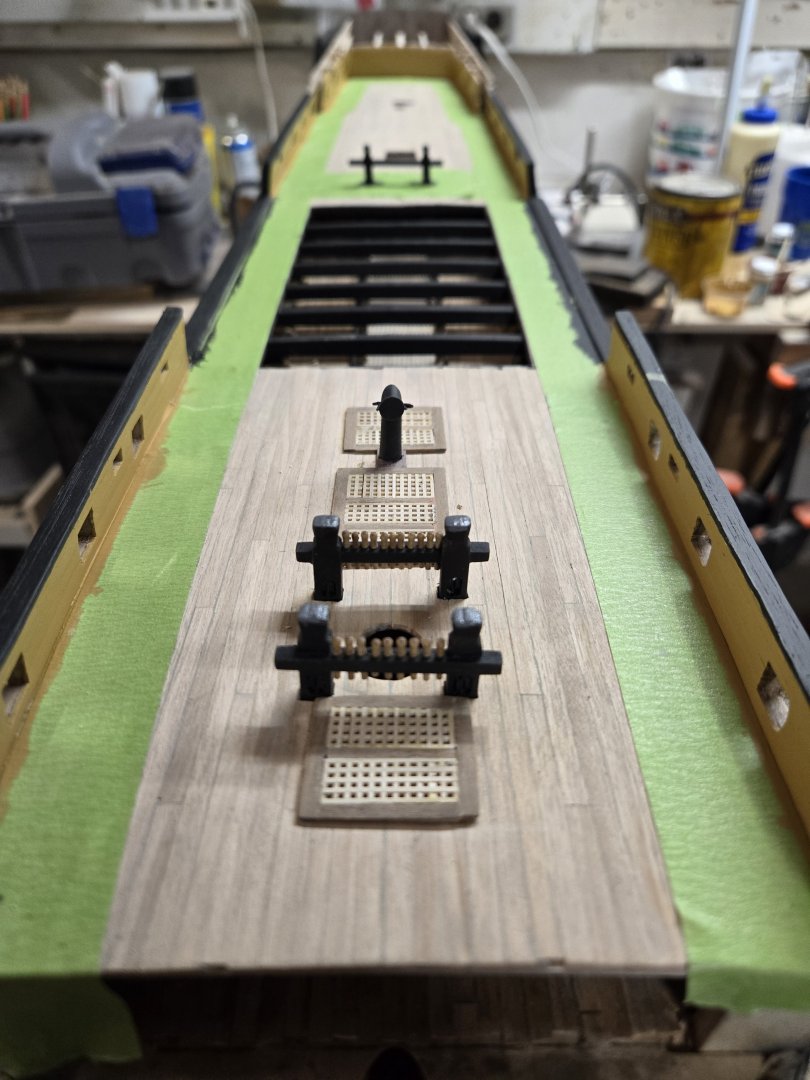

While waiting for all that to dry I plunged into the 14 cannons for the quarterdeck. There are 12 regular sized 12pounders and 2 long 12pounders. Also, there are 2 longer carriages for those 2 cannons....keep an eye on them! Cut them all out, sanded them clean. Next I cut out the axles. I remember receiving a post on the Ship of Scale site from AllanKP69 who suggested I use a drill chuck to round out the square axles so the wheels fit on them. I used a chuck that holds 1.7mm drill bits in my cordless Dremel style tool. It actually did the job! Some easier than others, but it would just grind down the square into a circle and the wheels will fit perfectly!!!! It is a rechargeable device and I had to keep it on the charger when doing this. I also wanted to add breeching rings to these cannons. I think they will be very visible and wanted that look. I have .64mm brass wire, it is too big but I wound it around a 1.7mm drill bit and then cut them into little ringlets. From there, I had to cut them into half or one-third moons. Gluing them to the back of the cannon was hard. Using CA glue, it gets all over the place and is very frustrating!!!!!! When I blacken the cannons, the brass wire won't blacken so I'll have to touch it up after. I also collected all the pieces for the 2 cannonades. I'll begin working on them tomorrow!

-

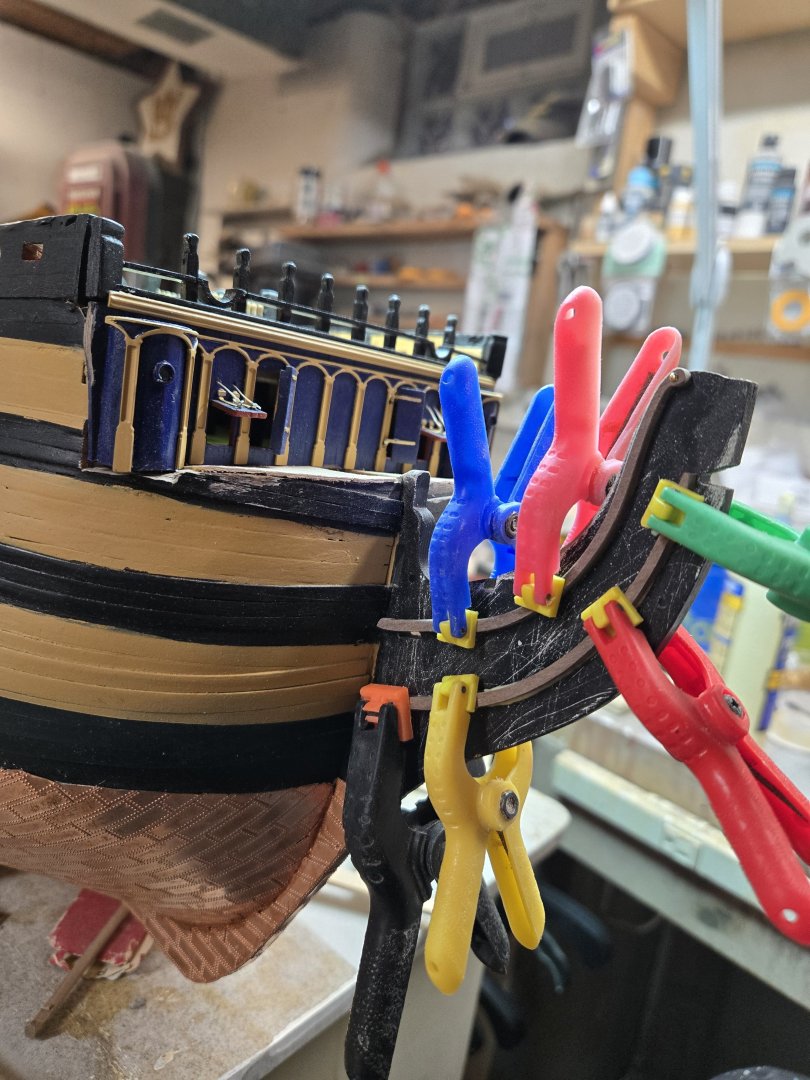

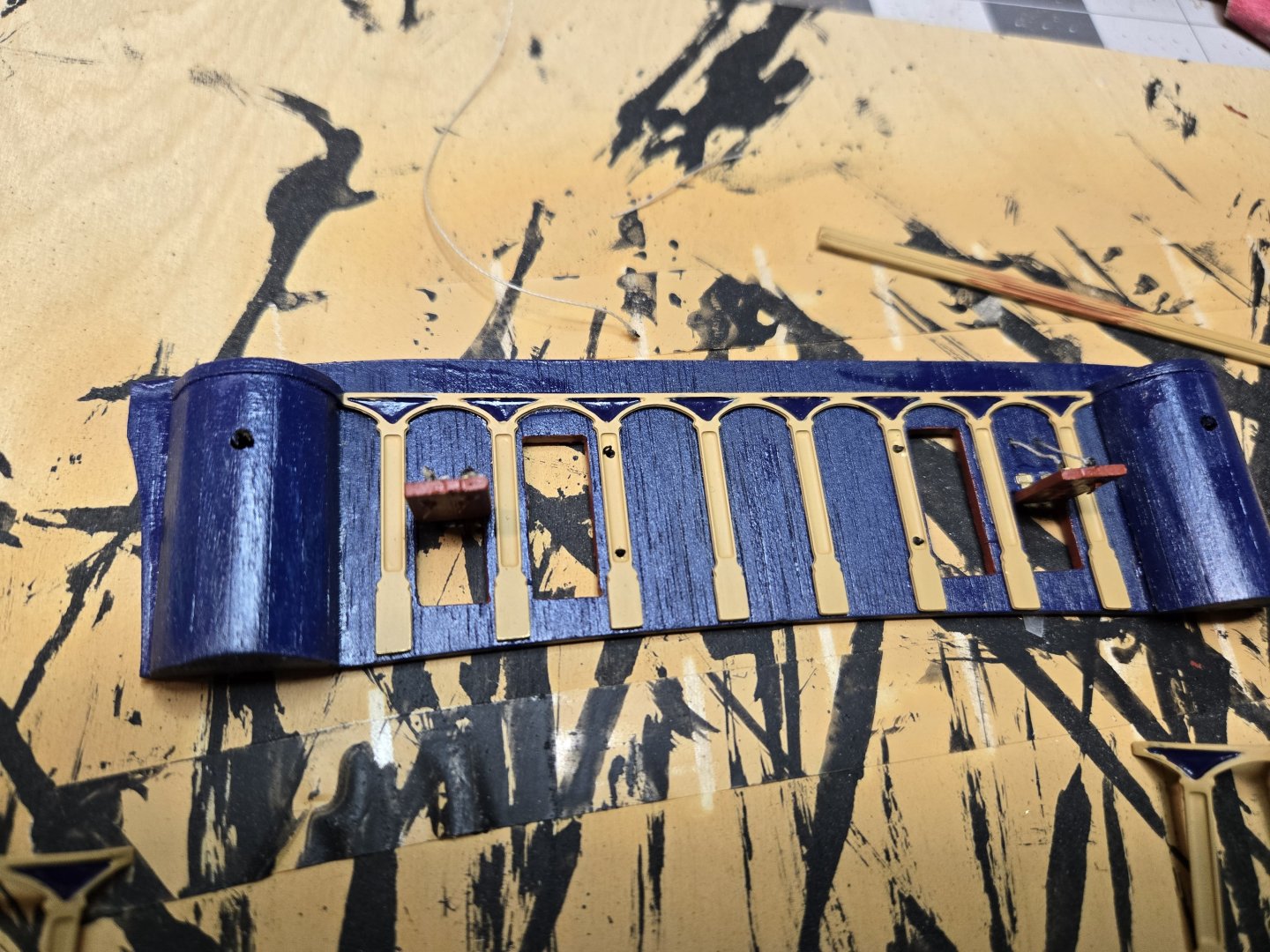

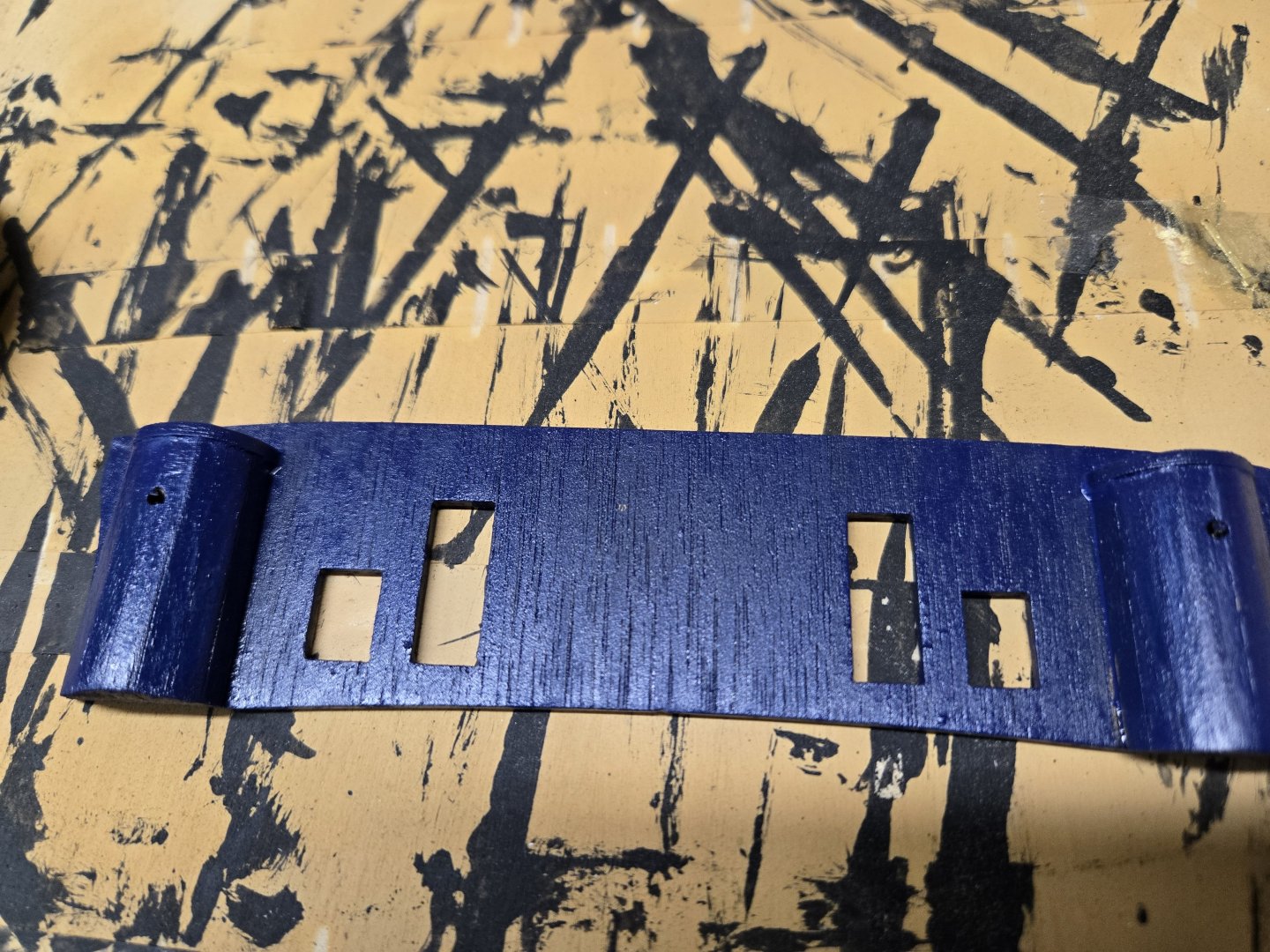

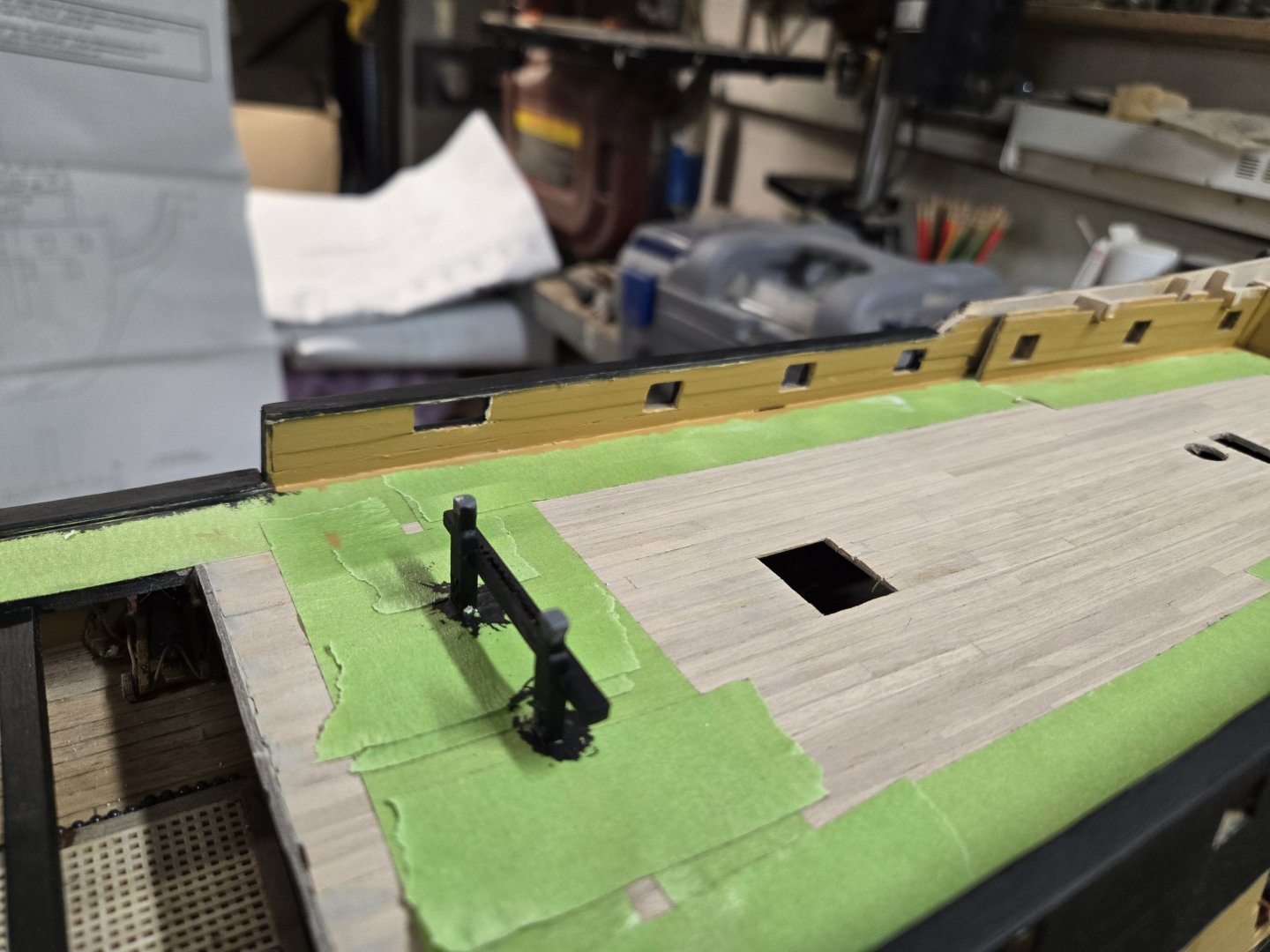

Back to working on the beakhead. I was able to get the bow deck all sanded down. I also added 2-3 coats of yellow ochre to the pilasters. Once dry, I added blue ochre to the tops. I ended up cutting about half the hairs off of a fine paint brush. This helped a bit. For some reason the blue paint is a bit more 'runny' than the others. Perhaps because the container is new, while the others have been used. I did more research online. There are very few actual live pictures of the bow looking to the stern. I couldn't find many good shots of the beakhead and all the detail it contains. I did post 2 that I like I painted the hatch and door sills red and the back of the 2 doors yellow. I installed the hatches open and used 2 lines to keep them open. It looks like a recent live picture shows that there is only one line to open and shut these hatches. Oh well!!!! Once I had touched up everything for the 5th time, I was able to glue (using white glue) the whole piece to the 1st bulkhead. It fit good, but I had to use a long pipe clamp to squeeze it tight on each end to the hull. A little touch up after did the trick. Once it had dried, I was able to lay planks down. Reading ahead, it appears that there the beakhead platforms help to hide the forward edges of the planking. I did not install the doors yet as I want room to sand the plank and finish it. I think the directions shouldn't be telling people to install all these pieces and then add to them on the boat.

-

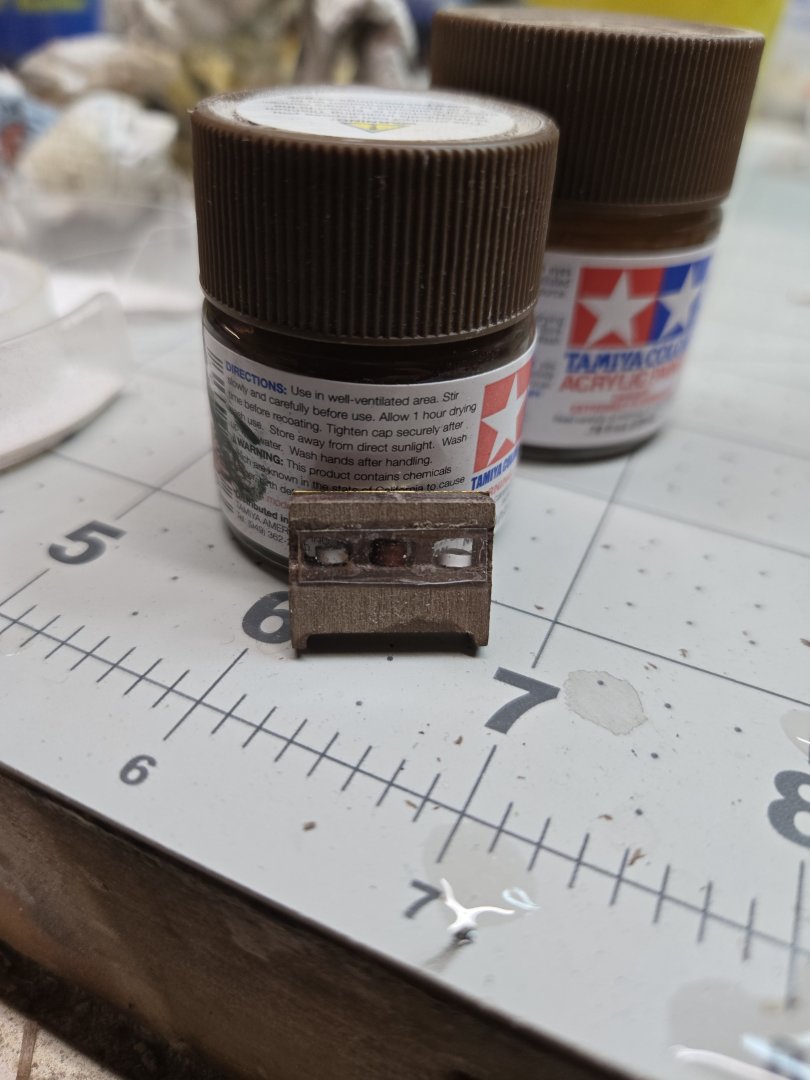

While working on the beakhead I noticed the need for copper eyelets. Both for the hinges to the doors and for the cannonades that are to be built next. Looking ahead they will be used extensively during the rigging. However, they are a MUCH better size than the .64mm wire I have. This picture was my first attempt. The sizing is much better. Still a bit too big. I hate closeups of model work. Thinks look great from afar, but the shear miniature scale amplifies any defects or poor paint/glue work. I also have to straighten out the top of the wheel post. I won't be visible when the poop deck is installed, but I will fix it!

-

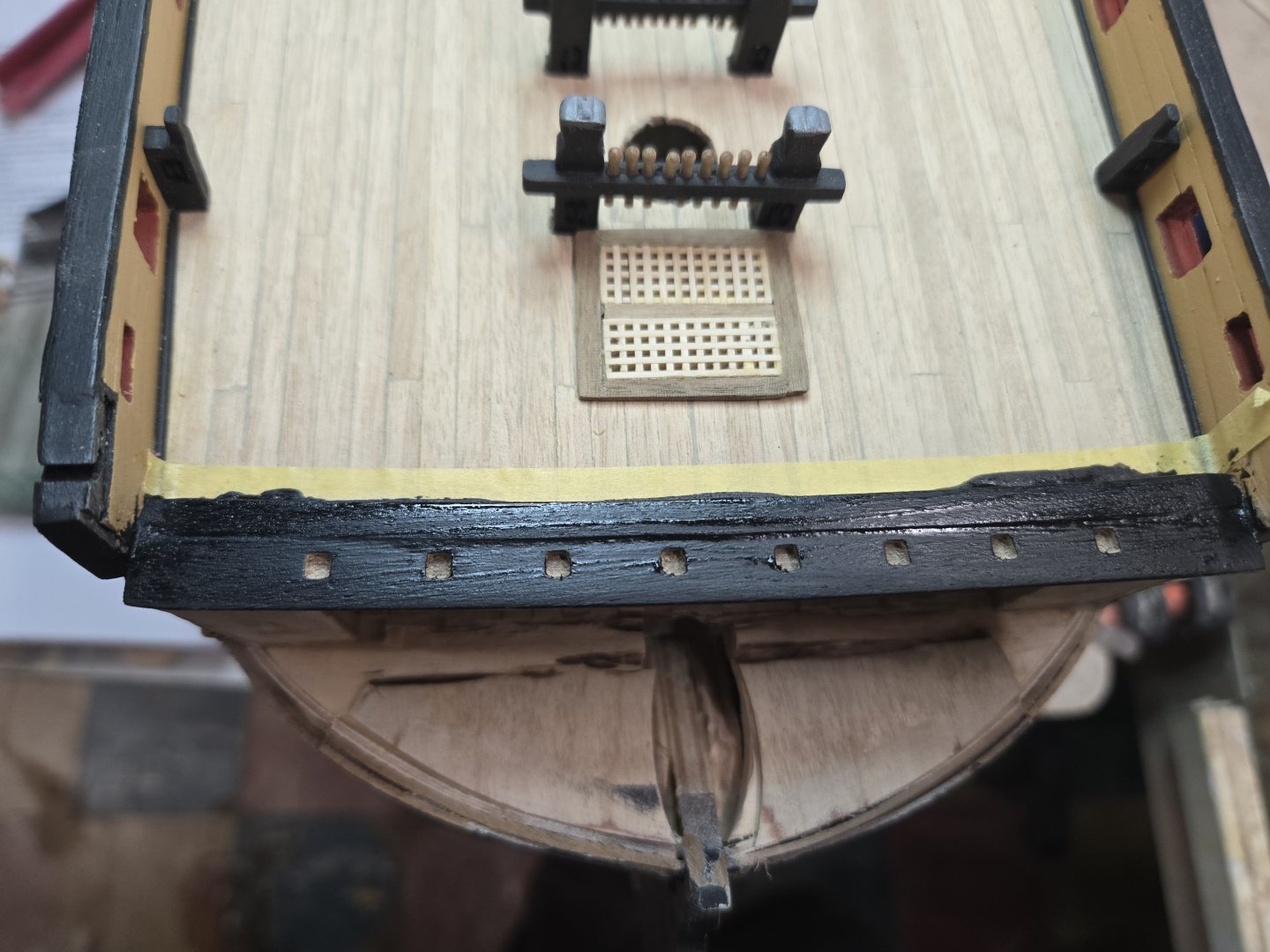

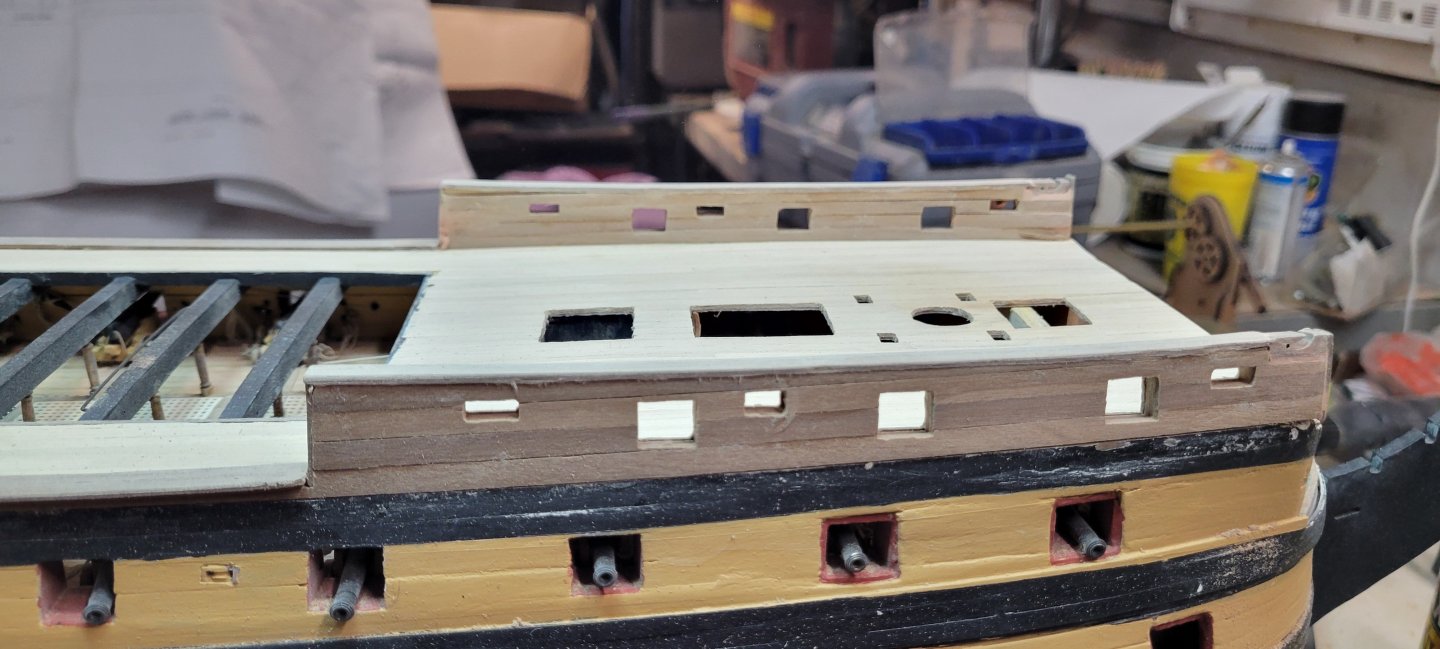

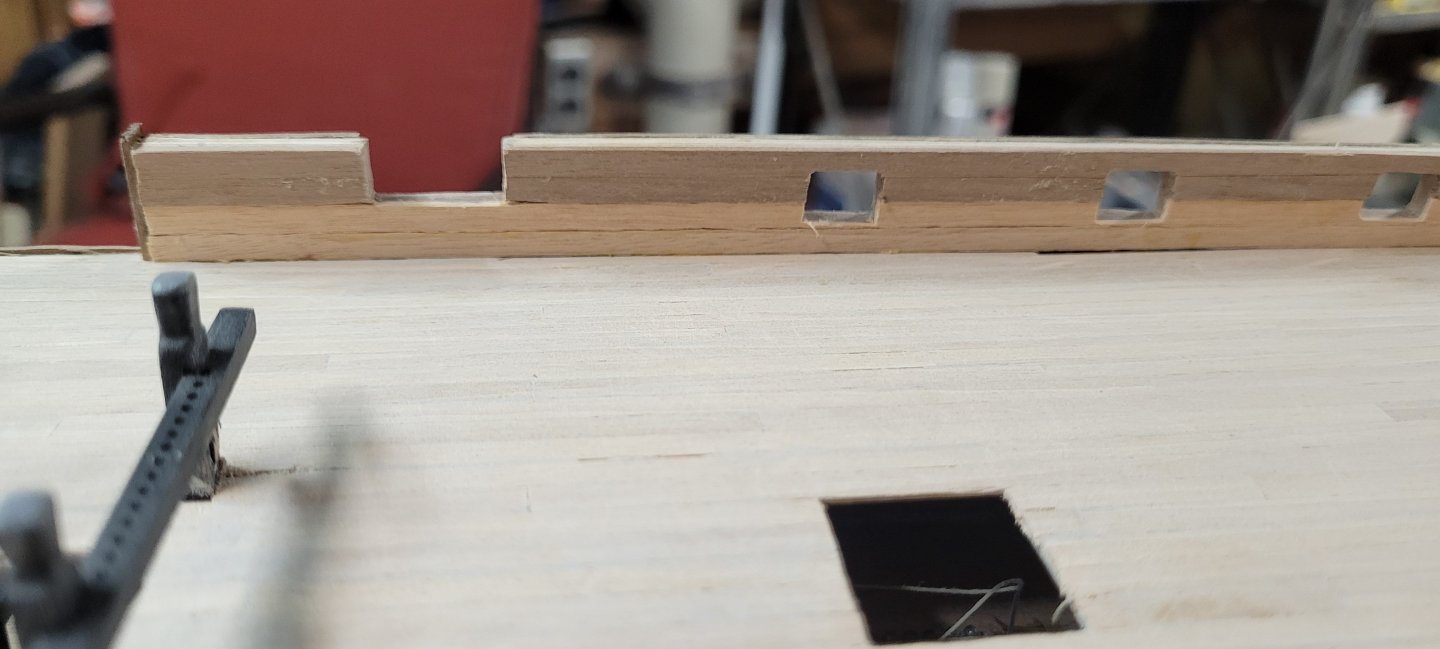

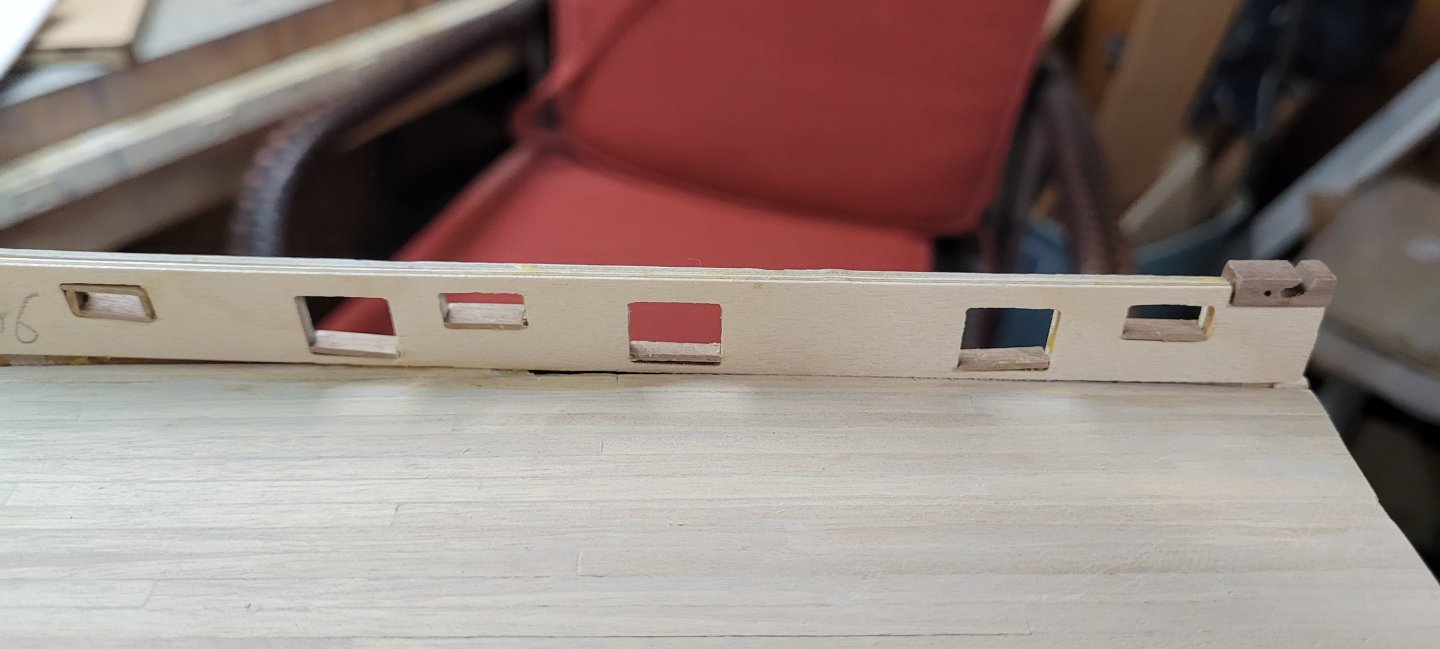

Getting the beakhead in place has been very hard! The directions while after the fact are quite specific, building something by words alone isn't the best way. I spent a lot of time looking up various parts in the part manual to see what the piece looks like and then trying to figure what they wanted. Then going back to all of the builders and view what they did. Sadly, many quickly if at all glossed over this aspect of the build. I chose NOT to install the beakhead to the bow. It's a good thing because I would have done it wrong. First, there are 3 pieces that lie on the quarterdeck at the very front. A thick 5mm cattail and a thinner 3mm cattail. You place the 3mm piece that it is FLUSH with the front of the ship. Behind that is laid the 5mm piece. This creates a step down 'slot'. The idea here is that once the beakhead is installed flat against the bulwarks there is a bulkhead plank shear that lays in that slot and overhangs the beakhead. This is the plank that has all the little square holes in it. That shear has a bow in it. On my build there is no curve to the front, it is straight across. There is no way to get clamps on this piece. I tried soaking it, but couldn't figure a way to glue and clamp. In the end I just used CA glue and it set up rather quickly while I held it in place. Getting the beakhead to fit took a lot of sanding and shaping. I had to sand down the bow deck sides and I also sanded down the beakhead top and bottom to get it to fit. I did sand a little too much off the top of the beakhead but I believe the crown molding will cover it....heh. I also saw a builder use a socket from a ratchet set. I used a 1/2" and worked ok. I didn't bother using a pipe clamp, I just held on to one piece with rounded needle nose pliers to get that final bend. Once done, i gathered all the doors, window hatches, trim, hinges, etc and painted them. Building is next and I will keep you posted!!!!

-

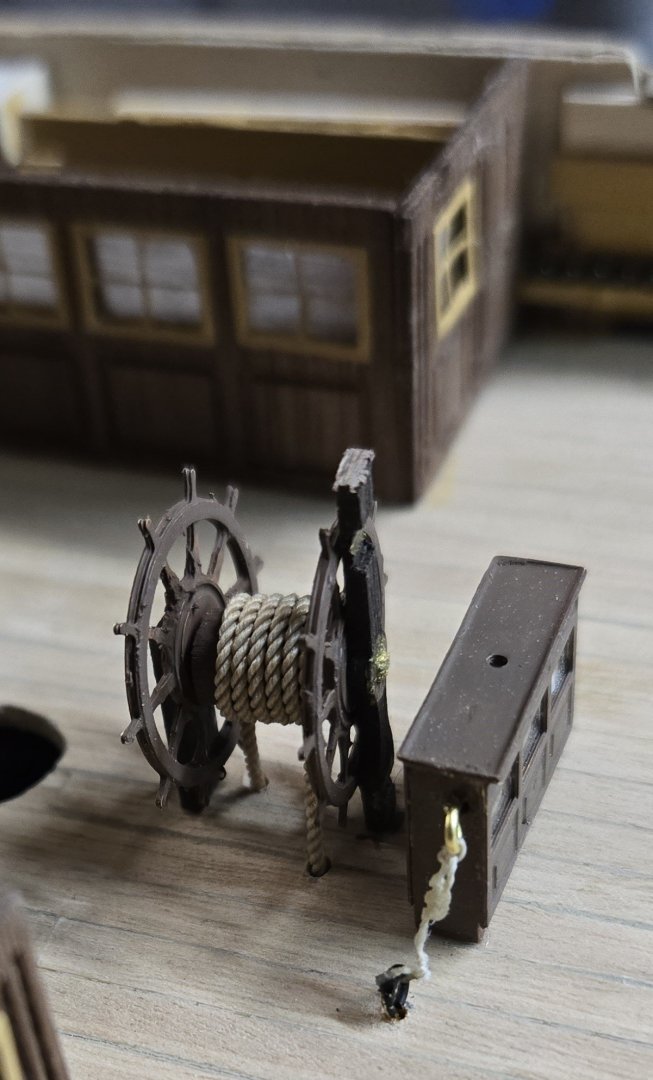

Worked on finishing the binnacle and the ships wheel. I added the chimney today and post it later. Today I was working on the bow and beakhead....that's another post!!!! I had to dig out the blue paint....I had bought the Admiralty's full paint set from the Ship Wright's Store almost a year ago. The only colors I've used to date have been the red and yellow ochre and black. Unfortunately, I didn't really read the black label and just grabbed the 2nd bottle of black when I needed and I guess there are 2 dull black and 1 iron black. I have been using the iron black to paint all of the kevels and the top section of gun ports. I haven't noticed a difference in shading, but it just didn't occur to me to think there were 2 shades!!!! Also, the paint kit came with brass/gold, copper and wood/walnut. Damn!!!! I have my own versions from various vendors and they look good...but again I just never thought! Oh well!!!! So on to this episode's installation. I created rings to secure the binnacle, but they are a bit out of scale. I painted the deck rings black (um....iron black!!!!) and left the rings on the binnacle their natural brass. For the wheel, I used a red brown paint I have and added some black to darken it. I used this mix to paint part #342, the forward pillar that holds the wheel. After it dried, I added a bit of gold paint to try and simulate some trim. For the wheel, spool and rear support I used the same brown I painted the binnacle. For the steering rope, I used the same after market rope I'm using for the cannon. Rope of Scale has such wonderful looking rope, it just screams authentic! It was fairly easy to rig the rope for the wheel and it's just fed through the holes. Actually, the wheel will turn a bit and looks great.

-

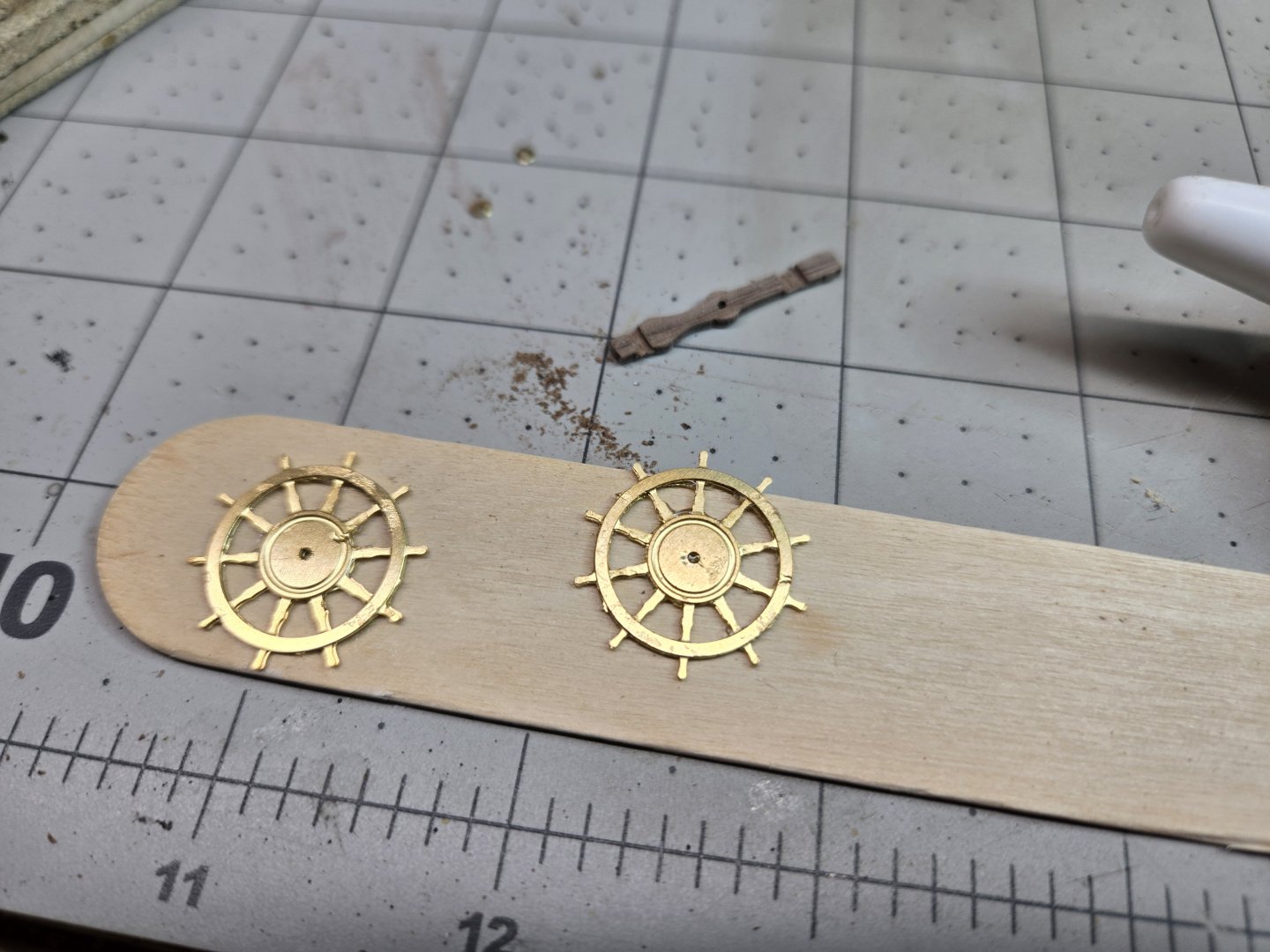

Working on ship's wheel and binnacle. I wasn't aware, but the bulk of the binnacle is just a piece of stock walnut covered by PE. I was able to file a groove in the front for glazing. It's possible that the kit comes with it, but I had some extra laying around. Again, used canopy glue to attach it to PE. I also started on the wheel and you have to glue 4 pieces of PE wheel together to create a fore and aft wheel. I used E6000 glue for this, it allows you to move the pieces around till they fit right. Regular CA glue just sets too fast. The E6000 does leave a bit of mess that has be cleaned up after it dries, but is good for PE to PE work. I also cut some little pieces of that styrene tubing and added to the interior of the binnacle. The outer cabinets housed compasses and I assume the middle was some type of light or lantern...hence the chimney! It's just a very tiny bit of detail that may or may not be noticed.

-

Working on the kevels, belays and cannon holders are pretty straight forward. I would recommend adding the cannon balls to the holders BEFORE installing on bulwark. I think that would be much easier. I also have some styrene tubing that I painted black and added to base of inner bulwarks. It's not quite what I was looking for, but it adds some depth. Another builder spent a lot of effort adding some additional detail to the interior aft bulwarks. He used wiring and soldered them together. I may try to do the same using my styrene, There is a lot going on there, but I am going to take a stab at it.

-

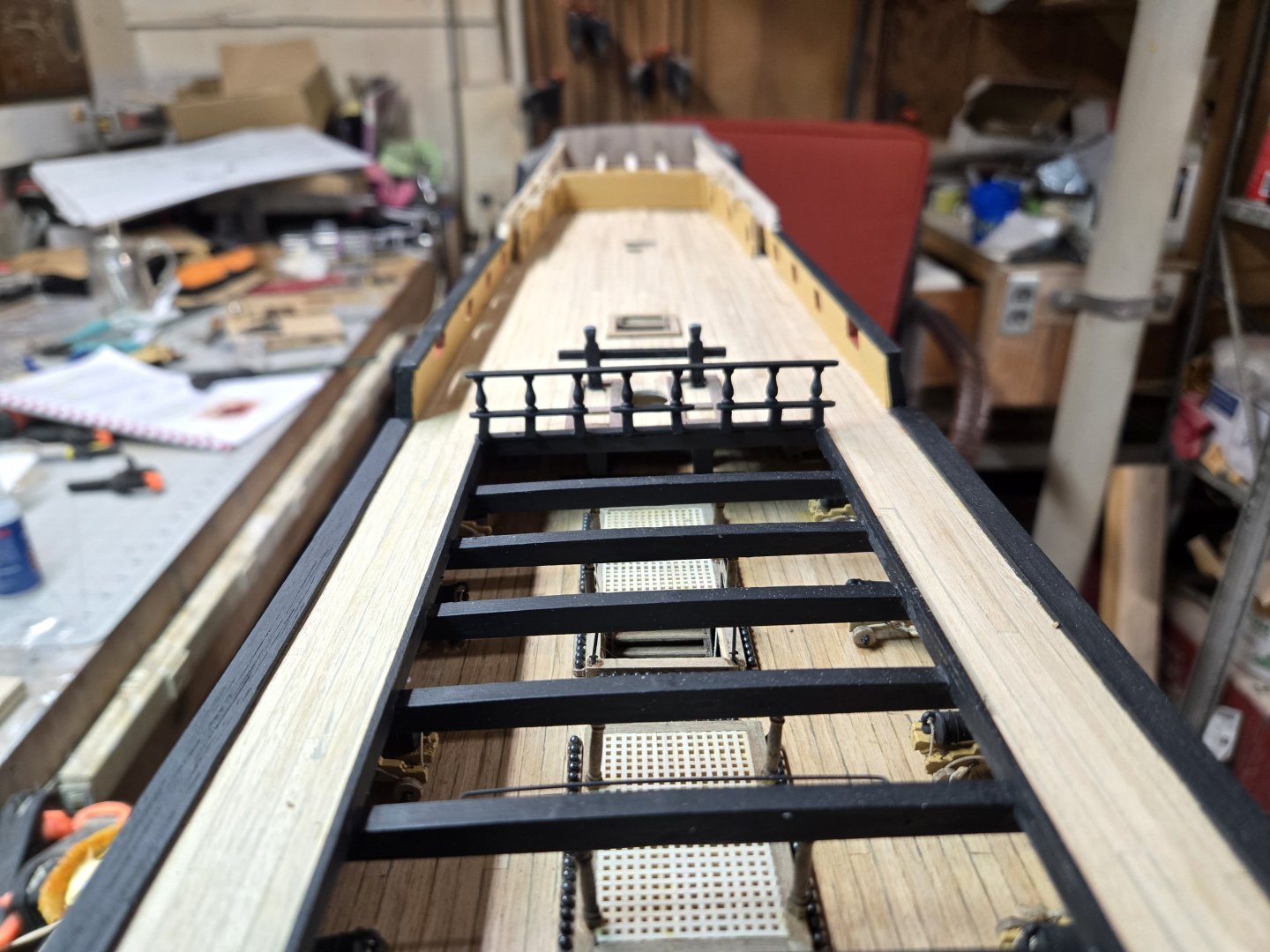

The 3 forecastle kevels have sheaves in them, so I drilled 2 holes in each and cut them out. I have 4mm brass sheaves that I blackened and when they were all painted, I squished them in. I know that is not a very technical way to do it, but squish I did! Next I worked on the admiral screen. I had put a coat of stain on the panels to darken them. To create the window glazing, I have left over acetate from another model. I sanded both sides of the acetate to create a cloudy look and then used a canopy glue...this won't fog and dries kind of clear...kind of. I added little brass rings for the doors. They may be a bit oversize, but add some color. Once the window frames were painted and installed that glazing added, I installed the screen. I did use a piece of 4x4mm scrap on the back to help secure the main screen. The directions call for 6 PE stanchions but for some reason I think I am starting to run low. Counting ahead, I have enough for around the skid beam and I think there may be a few more later on. So I used 2 on the stairs themselves and just used 4 pieces of 1.5x1.5mm stock. Once dry, I rigged the railing lines...This stairs will be fairly hidden so I am not too uptight about how it looks. I just LOVE my stairway work for the quarter deck down!!!! Very happy.

-

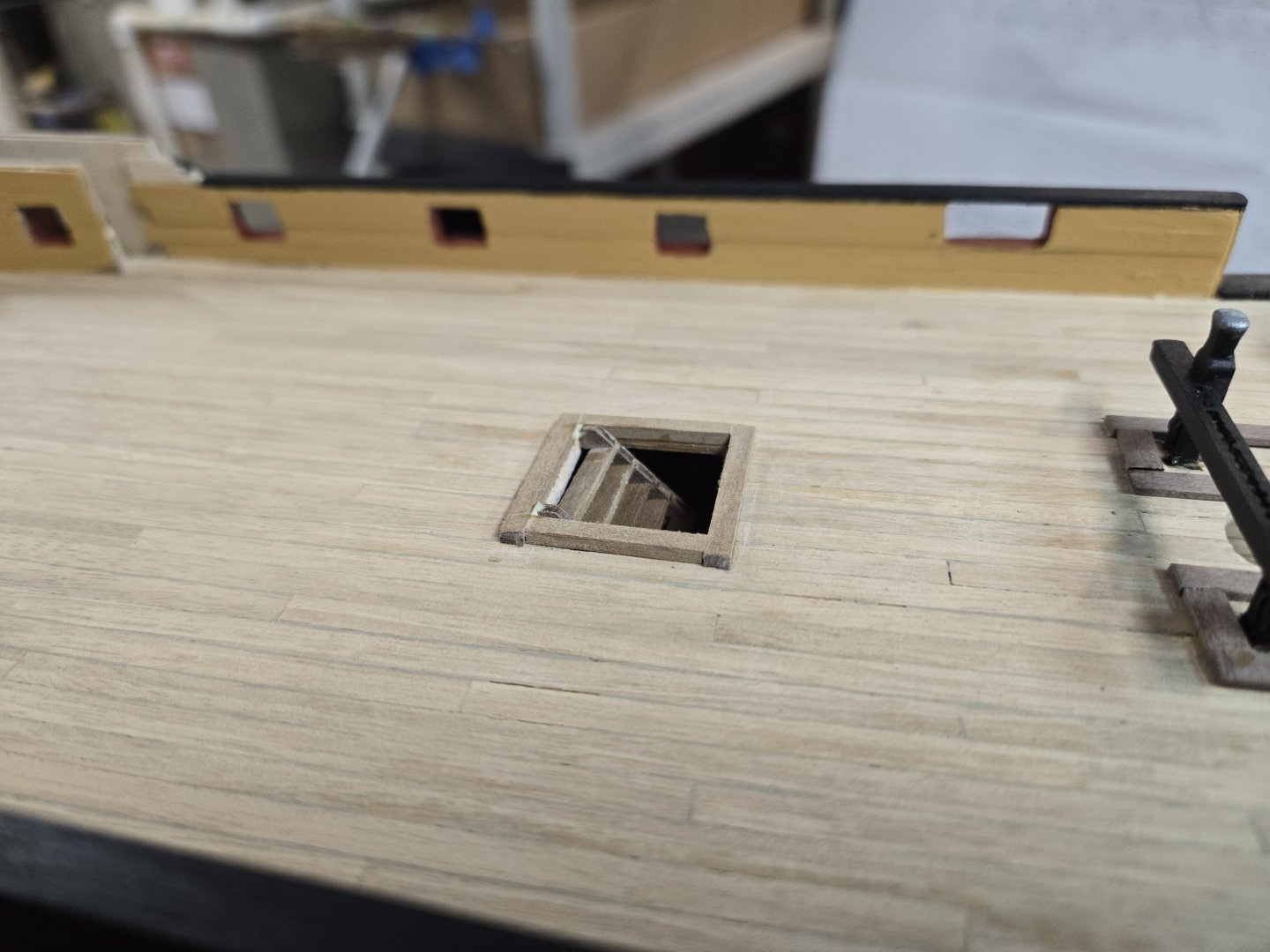

These are the 3 books I use. I was lucky enough to find them used on various sites and The Anatomy of Nelson's Ships has many pull out blueprint/plans that were all intact....very lucky! A couple of things, the first are the rigging openings around the main mast. There should be access to the lower deck and I planked over it! I was so engrossed in getting that bitt/brace in place that I just plowed up while laying planks and didn't stop to think. Now I had read ahead so many times and had planned what I was going to do to install the little cross member. Oh well. I did see one building pic where this opening was covered by gratings. Luckily, I have more grating coming from JoTika and I might take a look at whether it's worth it or not. Next I worked on the main companionway staircase. I was able to take the 1.5x1.5 square stock and twirl in my fingers between sandpaper and get it down to amount 1mm with a little roundness too! I also soaked it to get it to bend, but when I finished it, it was more like an escalator bend than the angle bend the instruction wanted. Also, my installation of the columns were just atrocious after I assembled it and took some pics. P. U. !!!! The next day after a fitful night of nightmares, I broke it all apart and reset the columns. I was very happy with that....until I started fretting about the bad bend in the railing. So I was able to get them both off and decided to break them, give them a coat of white glue and reinstall them. Now I am happy. Perhaps I will add a coat of matt finish to it to hide all the CA glue marks! Finally, I started cutting out all of the side bulwark kevels, cannon ball holders, belay pin holders, etc. I tried to lay them on the deck to get an idea where they go...then moved the picture off my phone!

-

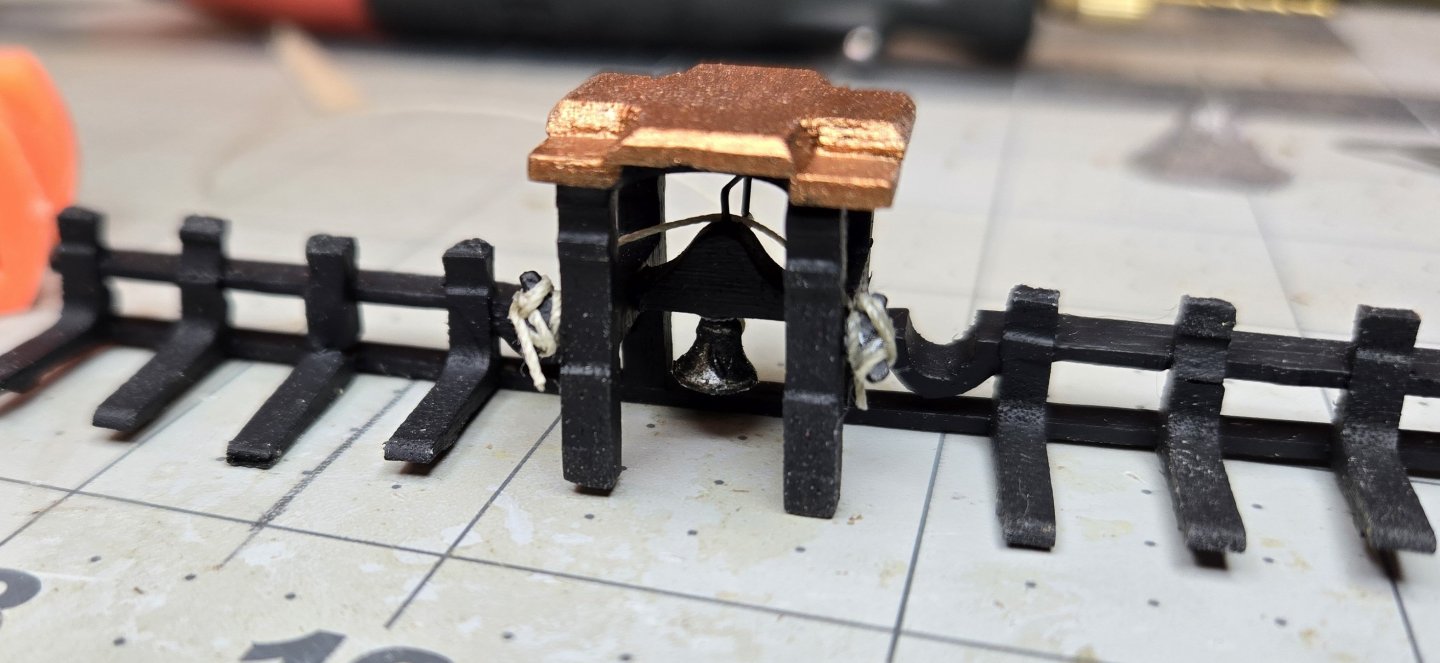

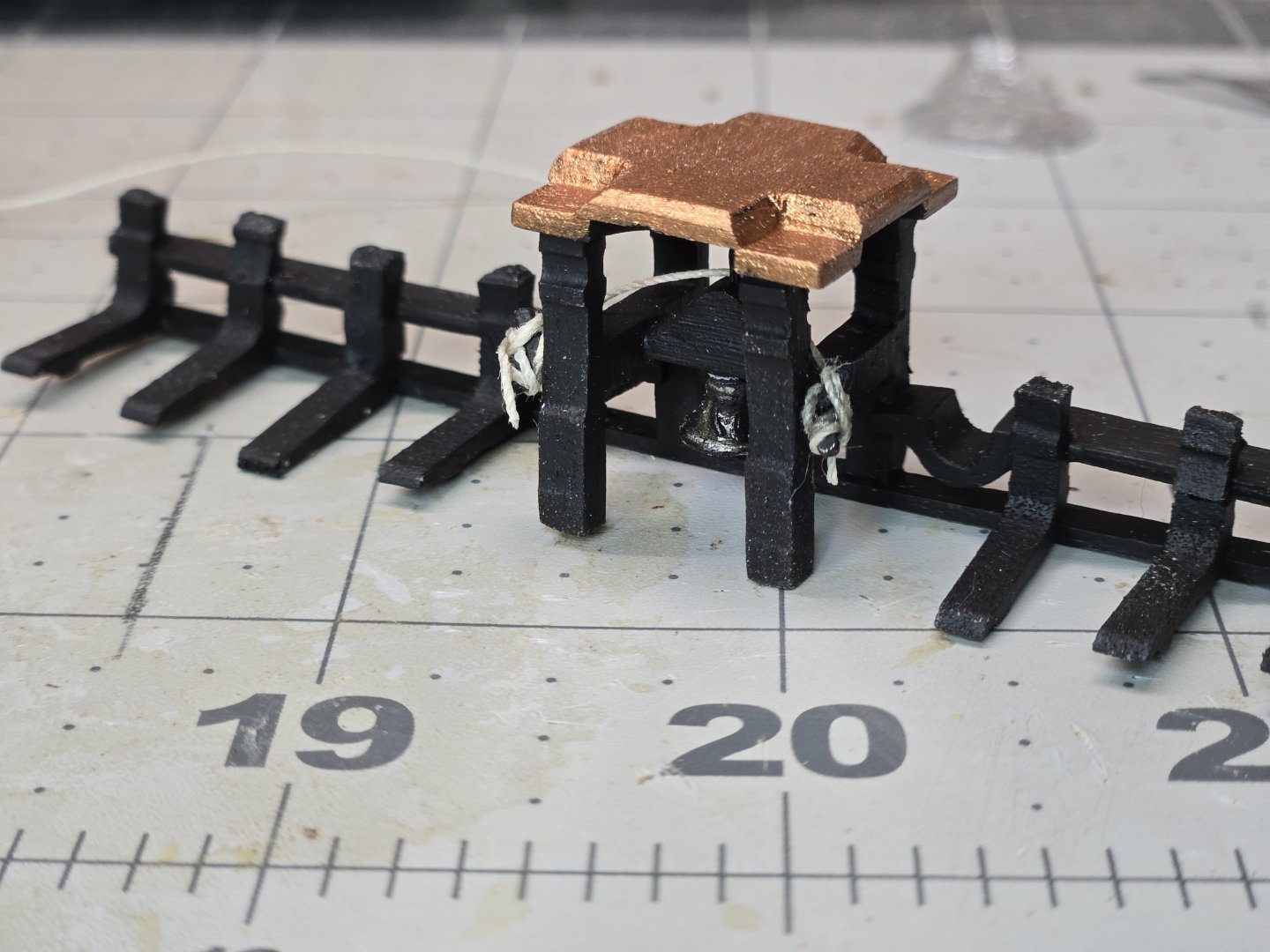

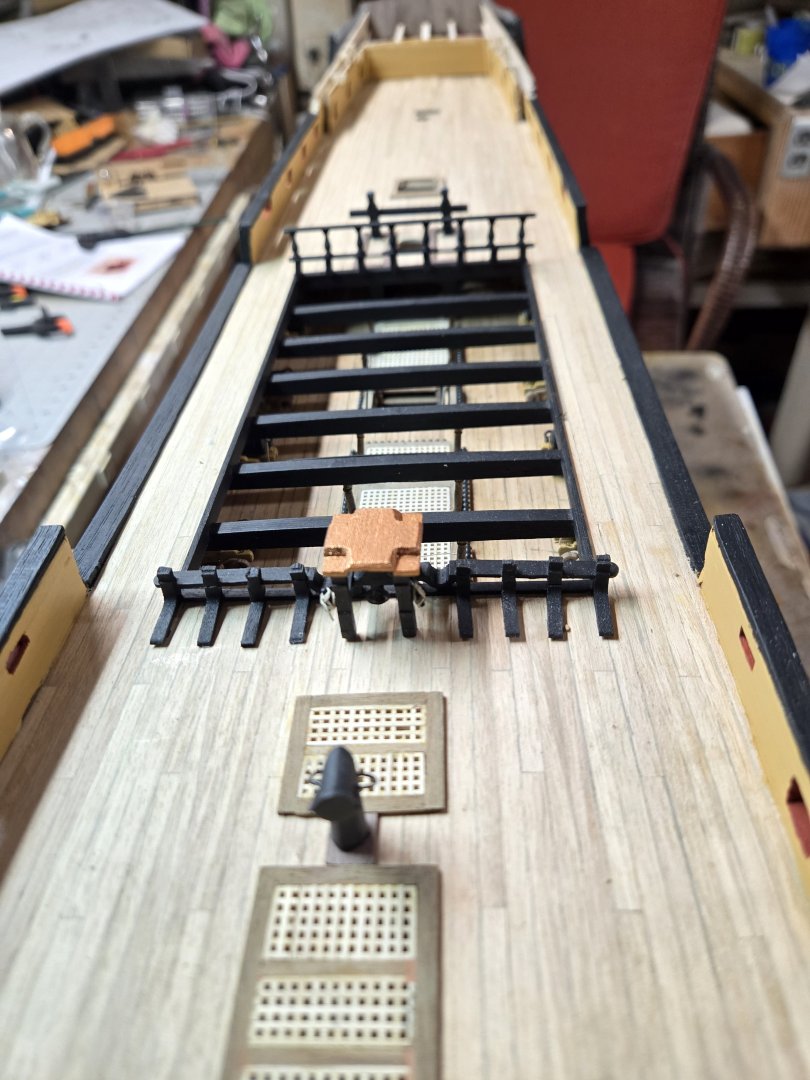

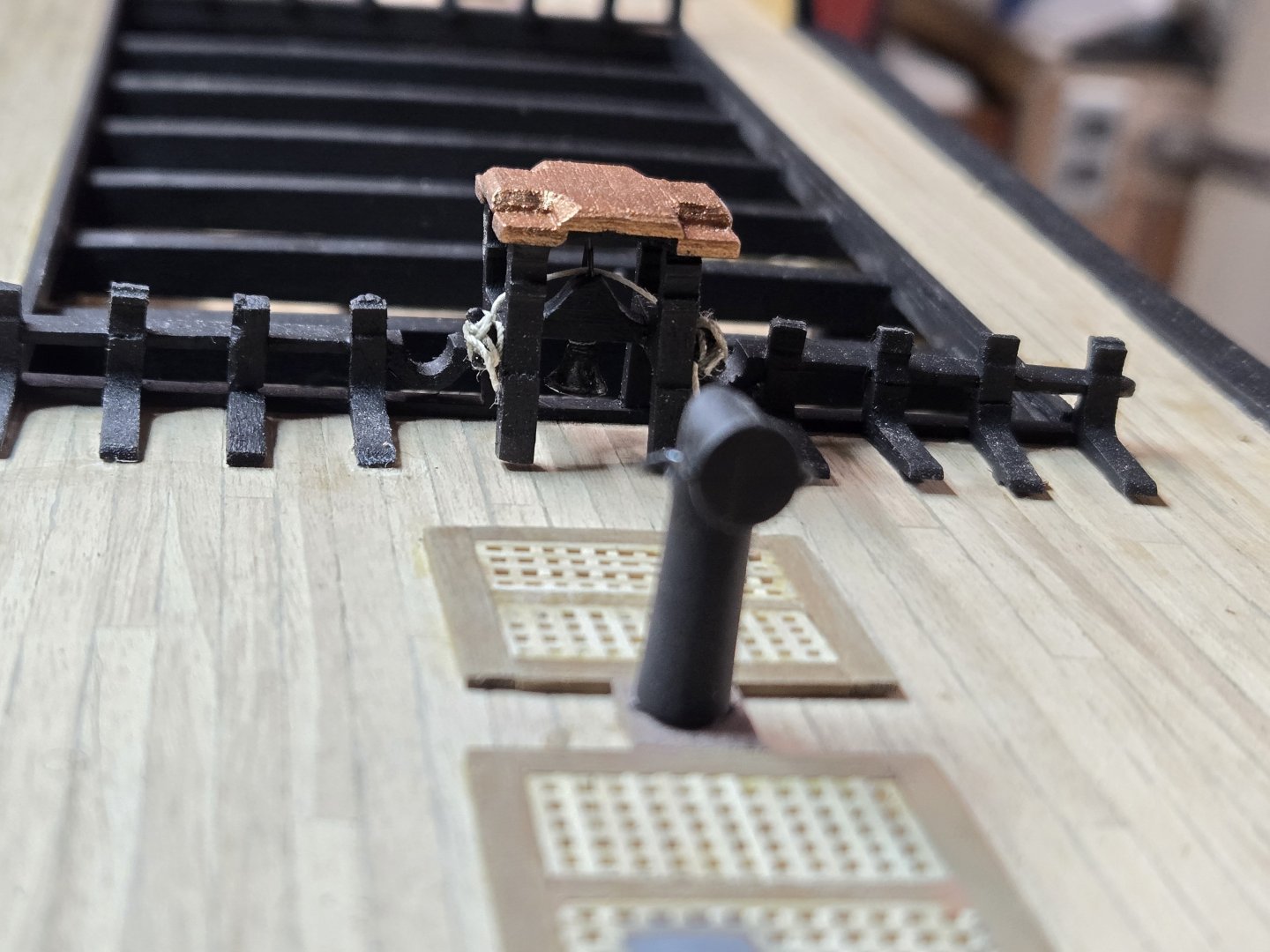

I finished the belfry and I love how it looks. I used Tamiya copper paint on the roof and it's perfect for me. One thing I have mentioned elsewhere. The plans call call for the rope that would ring the bell to face towards the bow. However, I have a picture that shows the belfry handle facing the stern. Now that doesn't really make sense, as you'd have to lean over the opening created by the skid beam to ring the bell....every 4 hours. But i'm sticking with the pic!!!! I was able to add the ropes that keep the bell secure to the cleats and I think they look pretty good! Laying the belfry to the deck took some wrestling. I had to add some weight to the supports to get them to stick. Probably not the smartest move, but they stick! After, I added the 1.5x1.5mm strips to the skid beam sides and touched it all up with black paint. The directions also call for two 'ships waist balusters'. These are cast pieces and they fit in the aft corners of the skid beam and will act as a railing from the aft stairs to the barricade. I will provide pics when I set them up. They are obscure in the photos provided in the directions and can get lost in the full size plans. Added coaming around the main mast bitt/bracing. I made a mistake here. When I added the quarterdeck and fitted these braces, there was a significant hole in that part of the deck. In my exuberance, I covered those holes! Except the mast one of course. Now I see that these are rigging openings. On the real ship, main halyards and clew lines would be run down to the lower decks.... I coamed out the 'openings' and I I have extra grating material coming, so I may use that to cover these. Finally, I added a 2nd coat of matt finish to deck and I also added a coat to external hull sides to help protect them. Can't wait to get back down there!

-

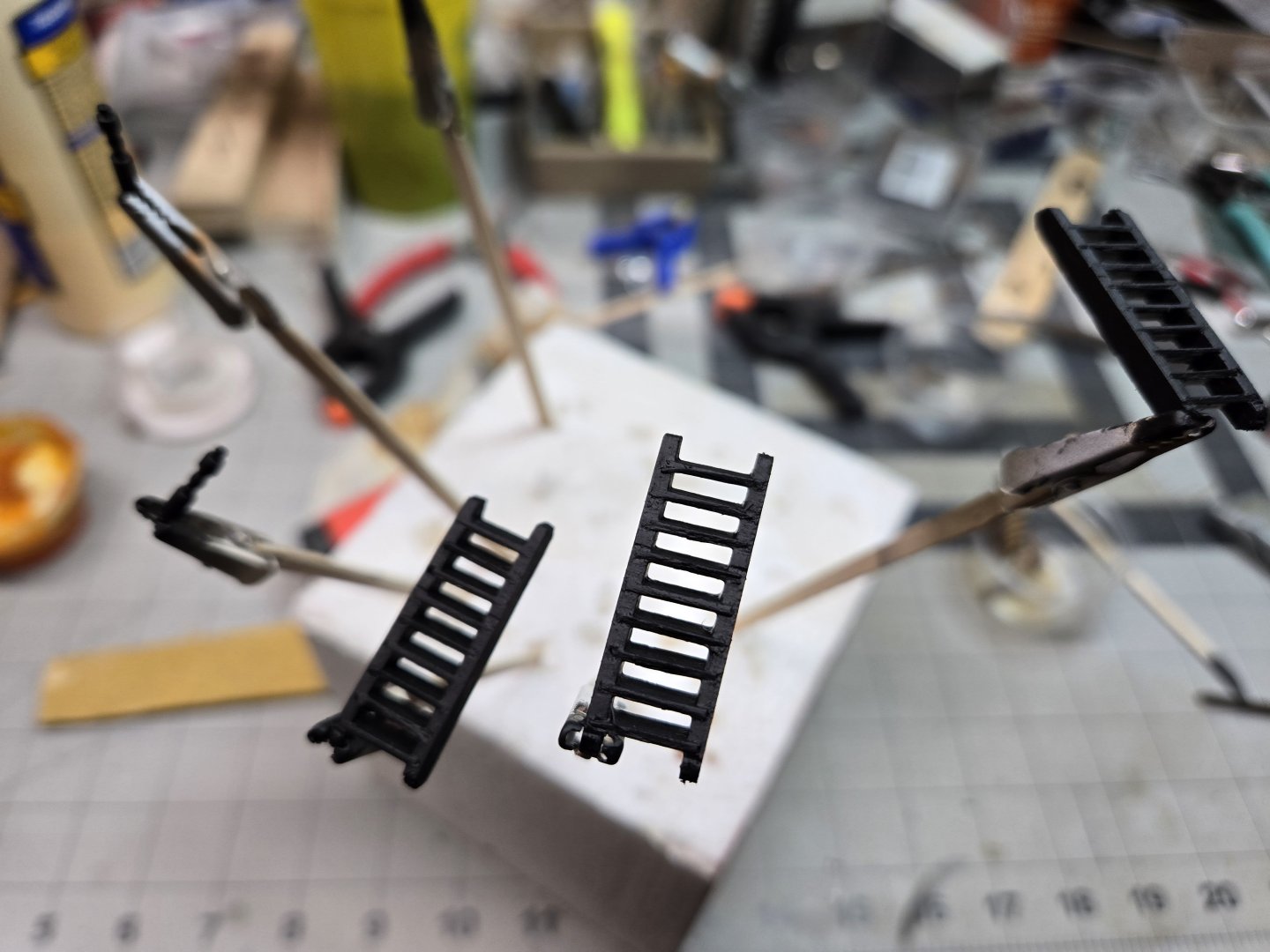

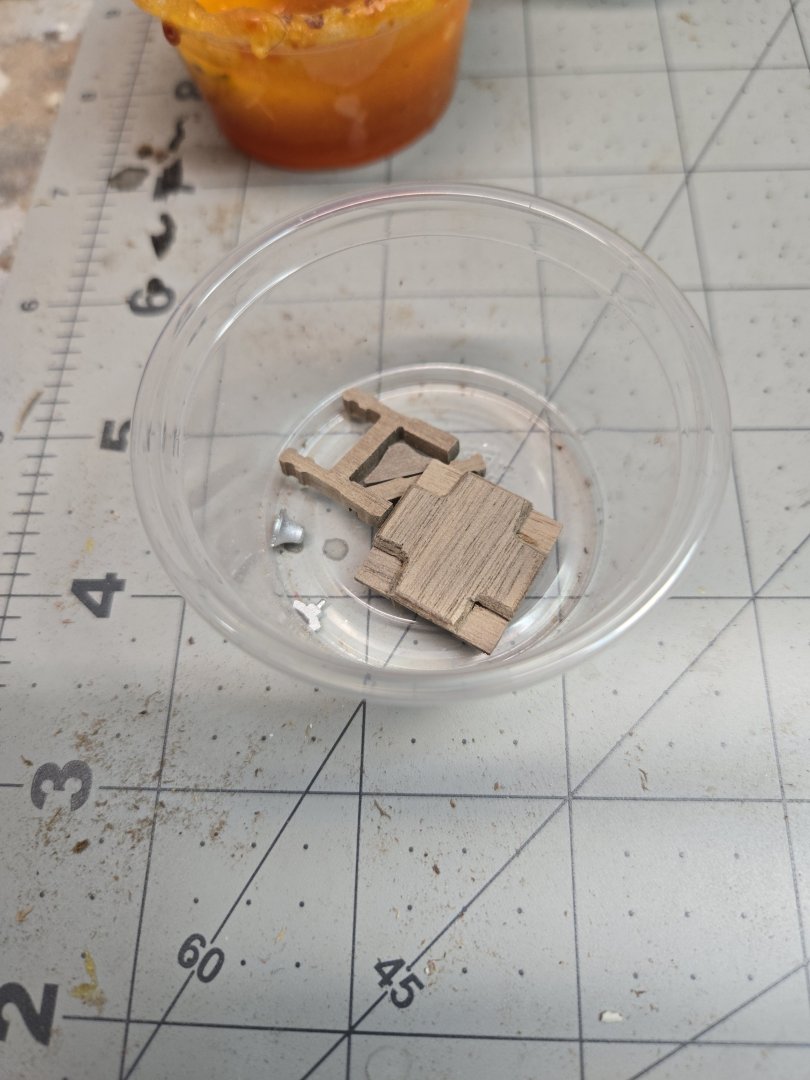

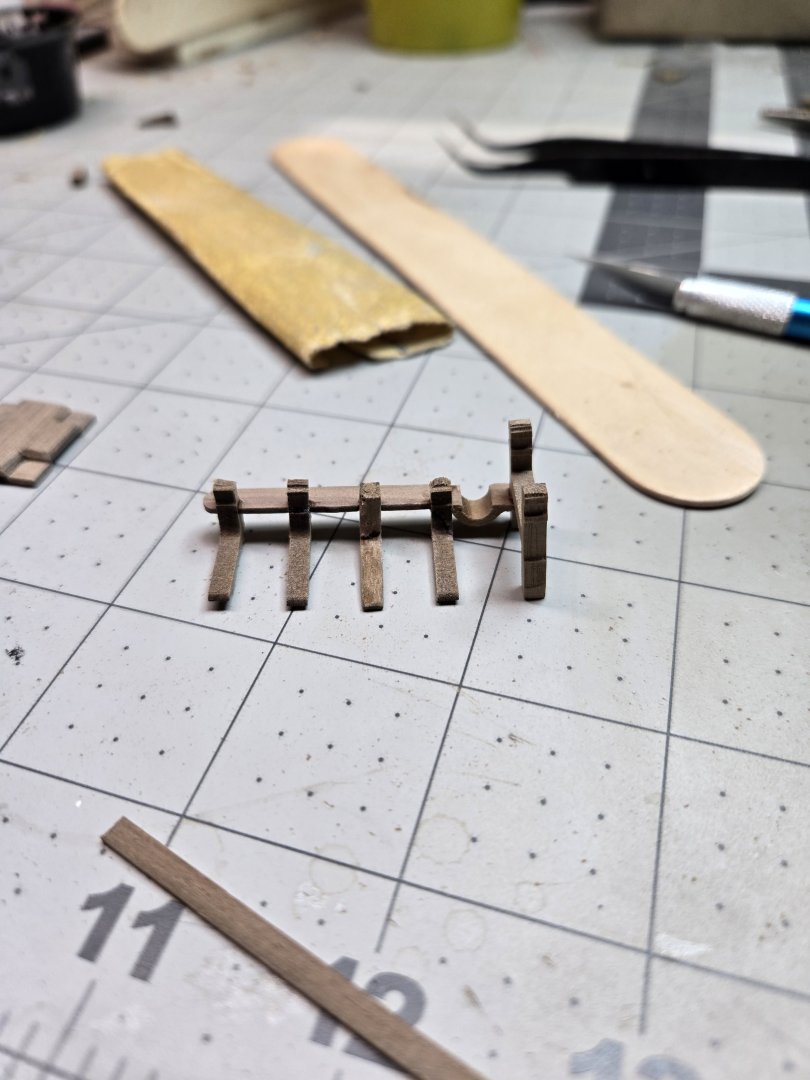

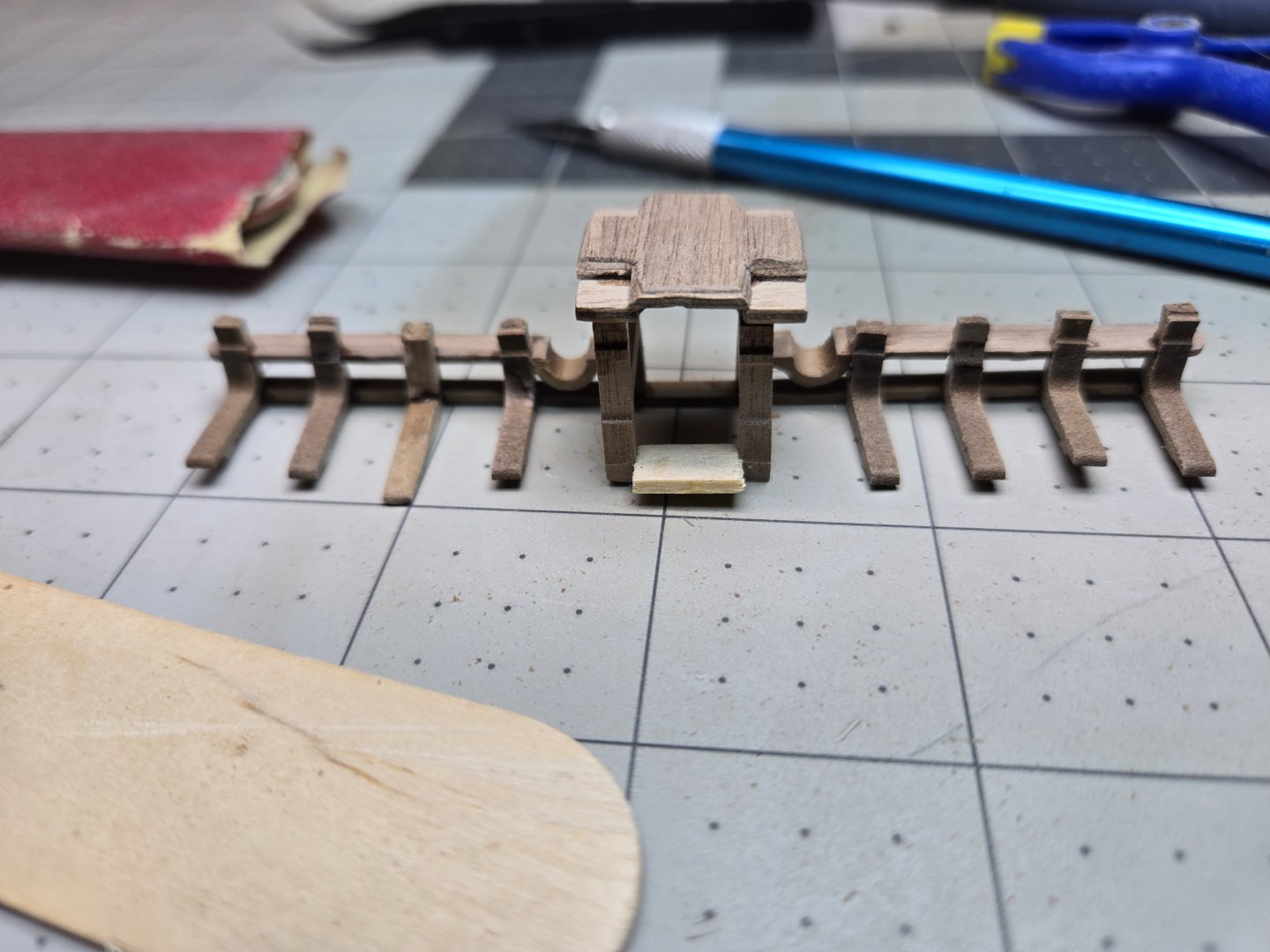

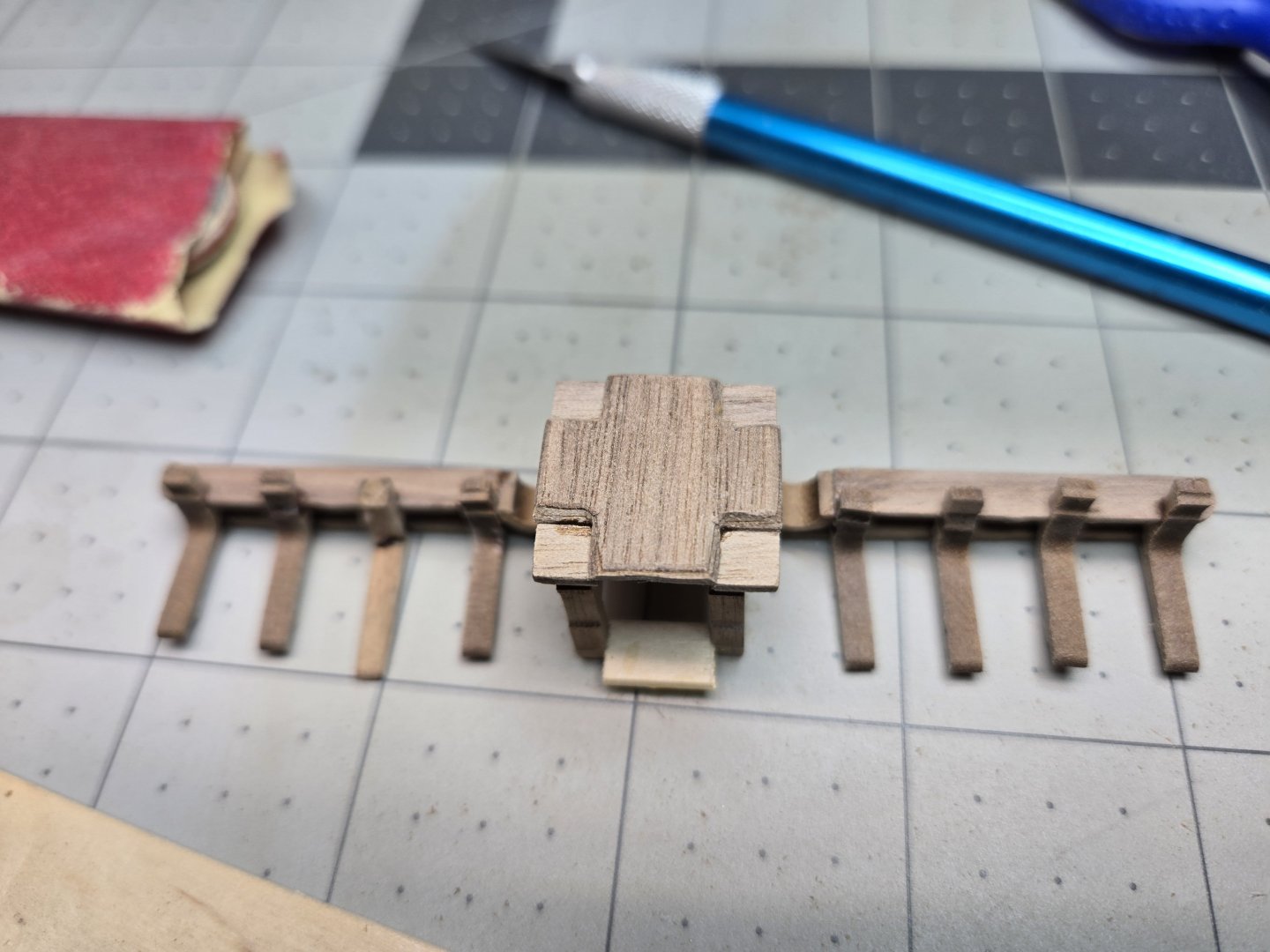

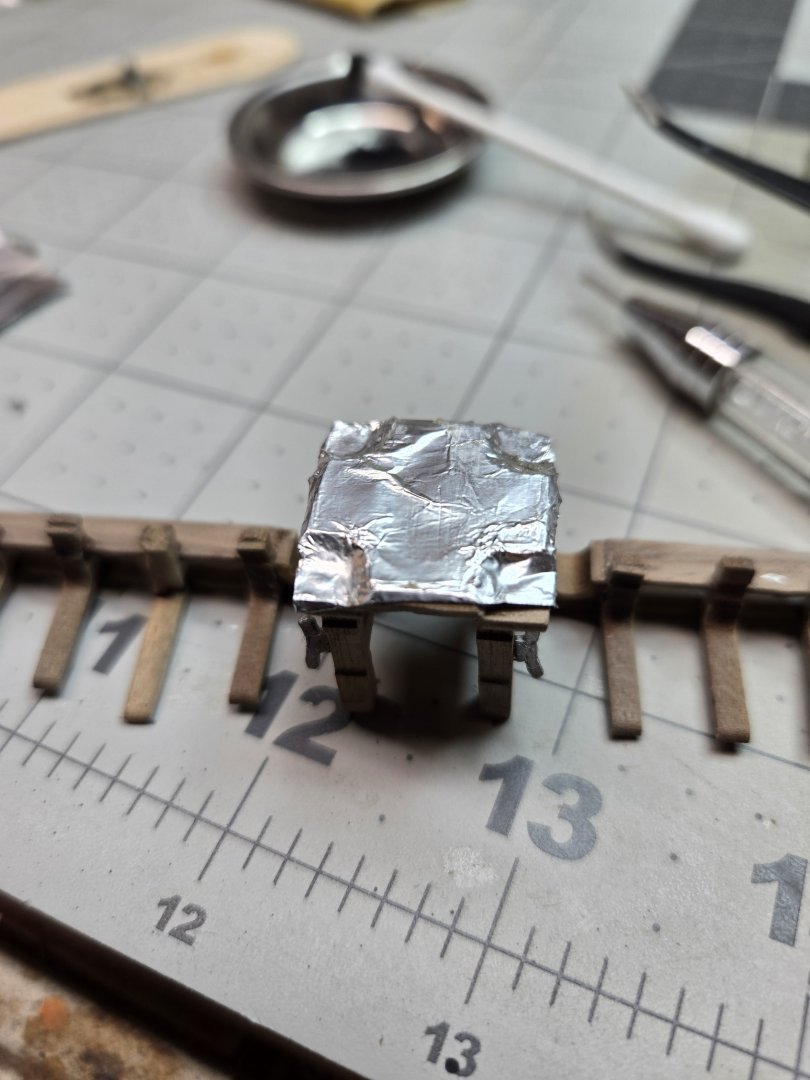

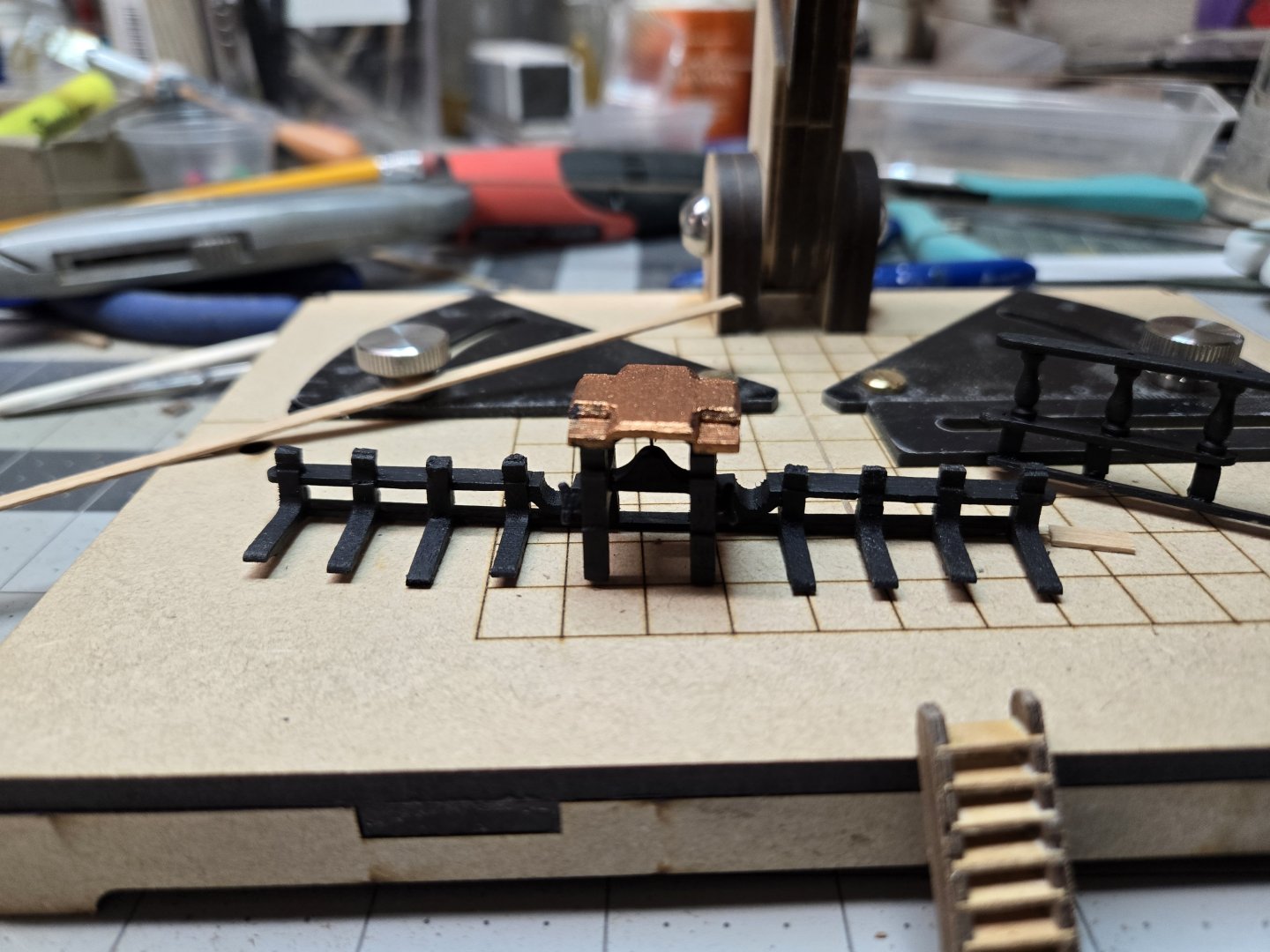

Next was the belfry assembly. Very tough. The breast beam supports are very fragile and a few of them exploded despite my carefulness in cutting them out. One was beyond repair and I tried to create a duplicate. They are so small that regular tools won't work. I had to glue 2 pieces together and then carefully whittle them away to something that 'looked close'. The supports also have cutouts to accept the cross bars. I had to sand them a bit thinner to make sure they wouldn't break. Getting them all to fit and fit flat was tough. You can see there is a bit of waviness in my final result. Sadly, I experimented with creating a metal roof for the belfry. I saw one build who created his own jig and hammered a thin piece of copper into a nice roof. That looked sweet. I thought I could fake it using tin foil. I just couldn't get it to smooth out and I didn't want to actually glue it down and ruin the roof. I then became concerned wondering if it would even take paint....which it wouldn't so I tanked the whole thing. The bell is cast...something. I hesitate to call it metal. I have a nice Vallejo bronze paint, but it wouldn't take it until I gave it coat of metal etch (Mr. Metal). The final result of the bronze isn't quite what I hoped for, but I suppose old or sea aged bronze would be closer to black. So perhaps it's ok! See that ladder!!! Almost perfect. However, the plans call for the 1x5 walnut. I don't know why, but that is way too thick for the side rail grooves. The decking material is perfect and since these 4 ladders will be painted, they will be fine.

-

Got the inner bulwarks all painted as well as the outer hull and all the caps. One thing are the belaying pins. They are way too big for the holes in the bitt/bracing. I was able to drill a hole using a 1mm bit but it does make a mess of the bitts. The drill did fine on one of the bitts but the other 2 got a bit chewed up...sorry for the pun! Also, the kit was short belaying pins. I've had a few other items missing in the kit and I think it was a case of JoTika being back logged when I ordered my kit and it may have been rushed. No big deal, I ordered a few bags of pins and they will be here in a week or so. Despite the fragileness of the bitts, the pins fit fine. I added a coat of matt finish to deck and while it's wet, I love the look. After it dries, it tends to revert to a more whiter color.

-

Getting close to current (as of 10/30/24) I taped off the interior deck and painted all of the raw decking. I thin the paint a bit and put on 2-3 coats where needed. I did this to keep any brush strokes to a minimum. I installed the coaming and the stove chimney. I will take a close up pic of that detail.... I plan on adding a small piece of black trim to base of interior bulkhead, just thinking about what I'll use. It would be nice if I could make it into a 'quarter round' piece of shoe molding. I suppose I could cut something about 1mm in width and then scrape it into that shape....hmmm. Once I do that, I will had a few coats of matt finish to this deck and then blow out all of the dust once it dries. I started gathering the pieces of the belfry and barricade. A lot of very small pieces that require patience to cut out. Like the mast base rings, a lot of them are VERY delicate and will break if pushed too far.

-

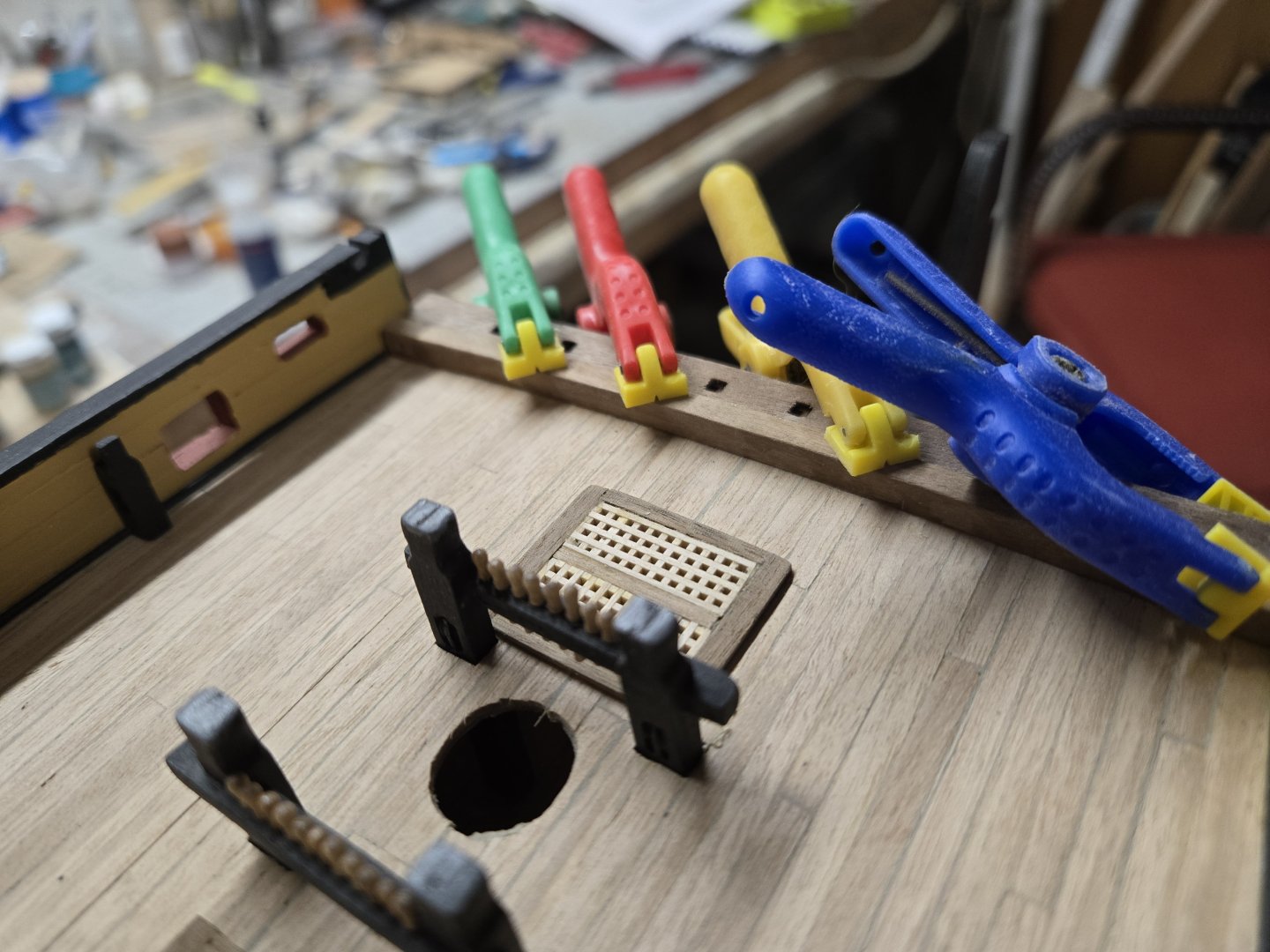

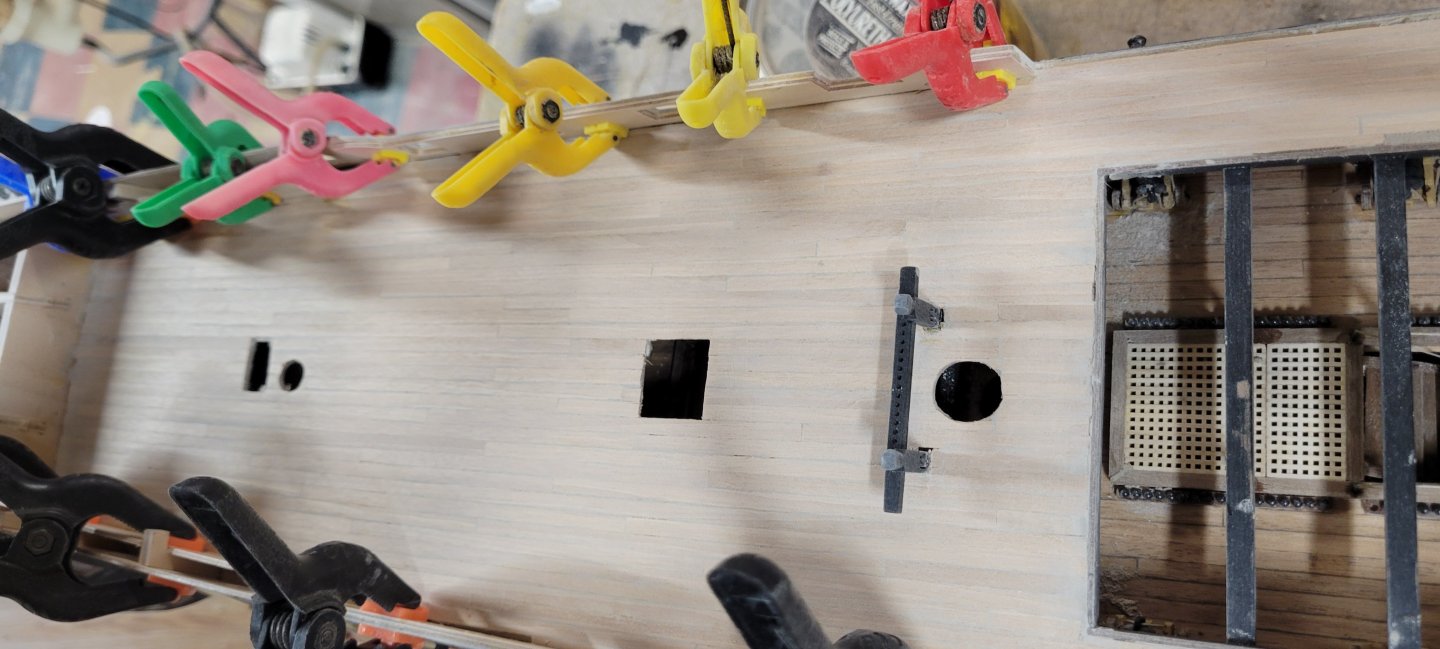

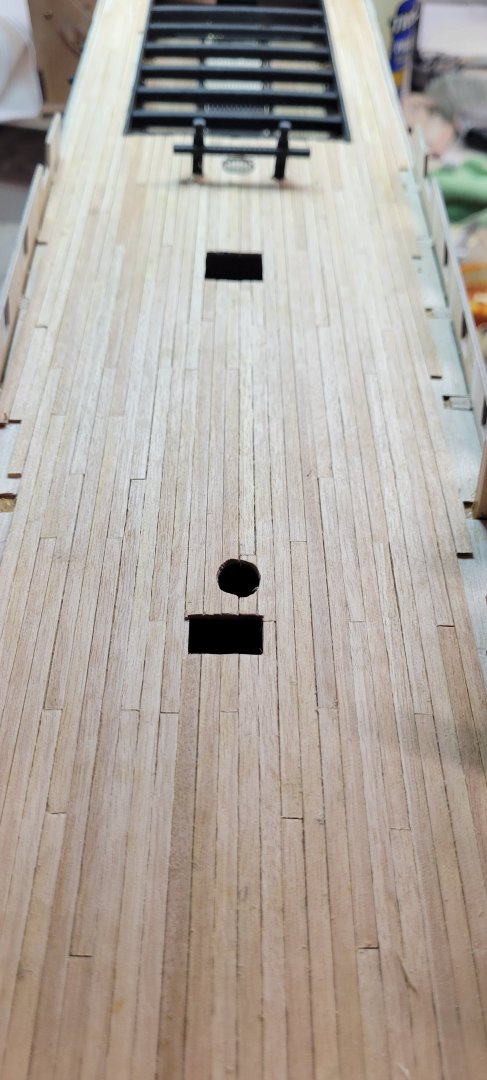

Working on the forward coamings and the fore bitt/bracing. I didn't think I had enough grating material to do these. I thought when I did the lower ones, I had made extra and tore my work shop apart looking for them to no avail. I ended up ordered more from Jotika. After I built what I had and it was enough. So I probably never did build extra, but there is just enough for these hatches. Thankfully, my US based credit card didn't work in the UK so no worries! They look ok. Some of the gratings broke and I am not 100% happy with the coaming work. I opted NOT to install them to the deck and trim around it. I think it's easier to build them in full and then fit them onto deck. I also added sheaves to the bitt/bracing. I drilled 3 holes and then carefully cut away until I had a hole large enough for two 4mm sheaves. I'll use a small piece of styrene in between. They look pretty good. I also added handles and a bit of wire to the chimney to look like the push rods that open the front. Once painted it looks fine, the handles are a bit out of scale, but will do.

-

Next were the caps for the bulwarks. There are 3 on each side. The forward piece (393), the stern piece (391) and the piece that lays on the deck between to fore and poop decks (392). I had them numbered, I just wish they were installed in numercial order....stern 391, mid 392, fore 393. But it was not to be and I mis-installed them. I suppose that will be the greater benefit of my log...."Tales of a builder who doesn't follow simple instructions" I ended up putting the mid cap on one of the stern rails and because it was so much longer, I cut away the excess. Now I had installed the forward caps correctly and there is a but of extra that I cut away, so while doing the stern, I just assumed the same thing. Once I saw my mistake when laying the middle pieces, I was able to pull away the stern and fix the installation. I did have to add a small piece which won't be visible once painted. There seems to be a LOT of extra width in these pieces that needs to be sanded flush. Honestly, it looks like they would like a bit of overhang, but the directions and all of the builder logs I have looked at show them flush. That's a lot of sanding. Either way, it's done.

-

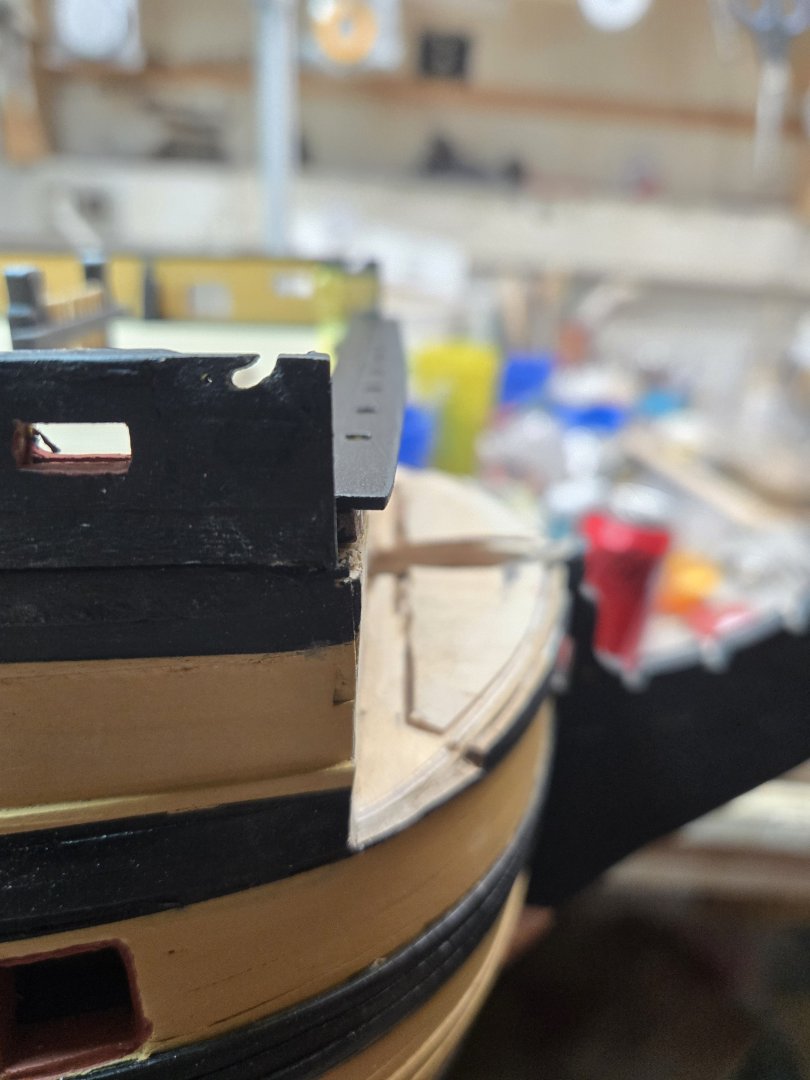

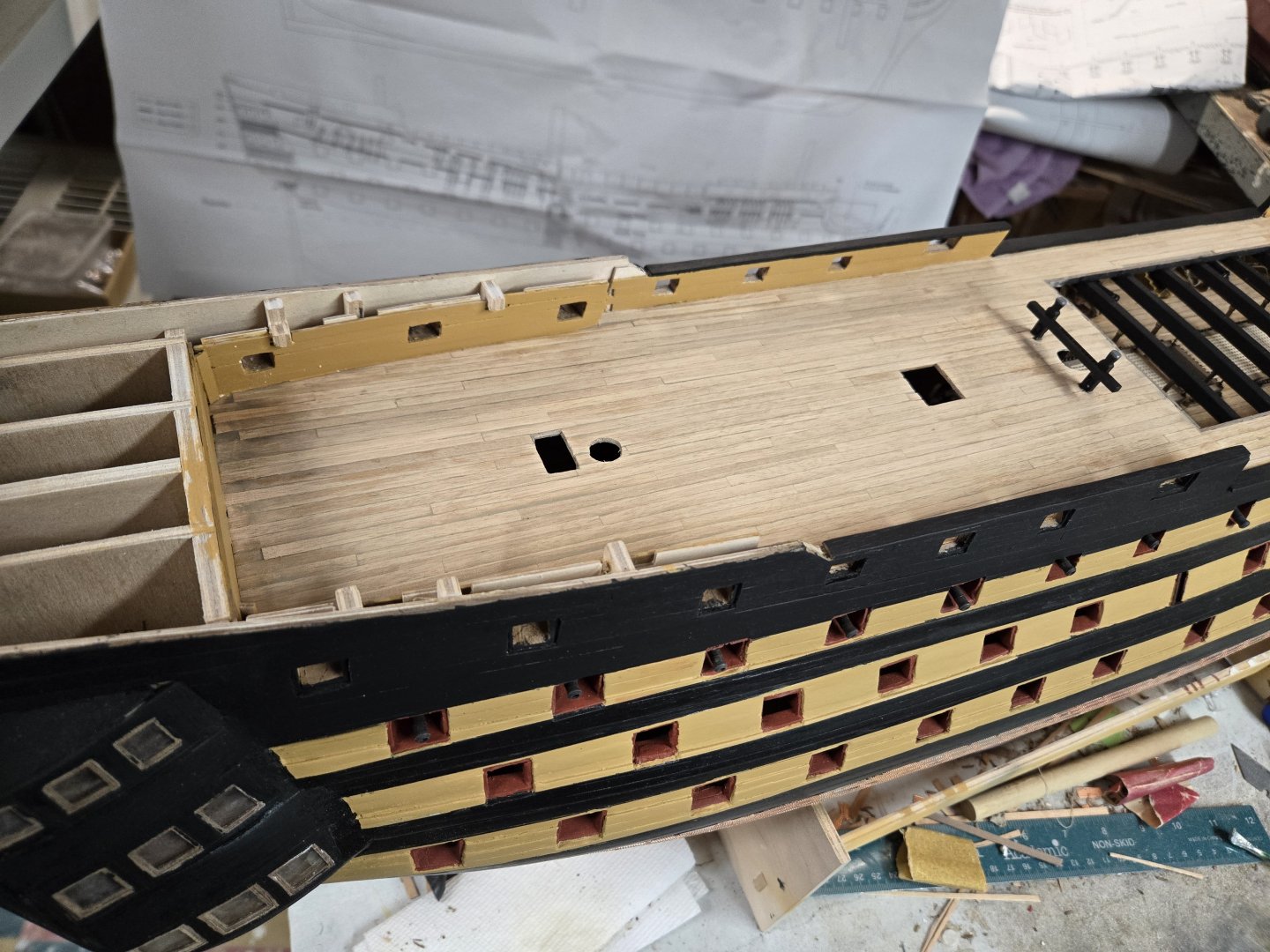

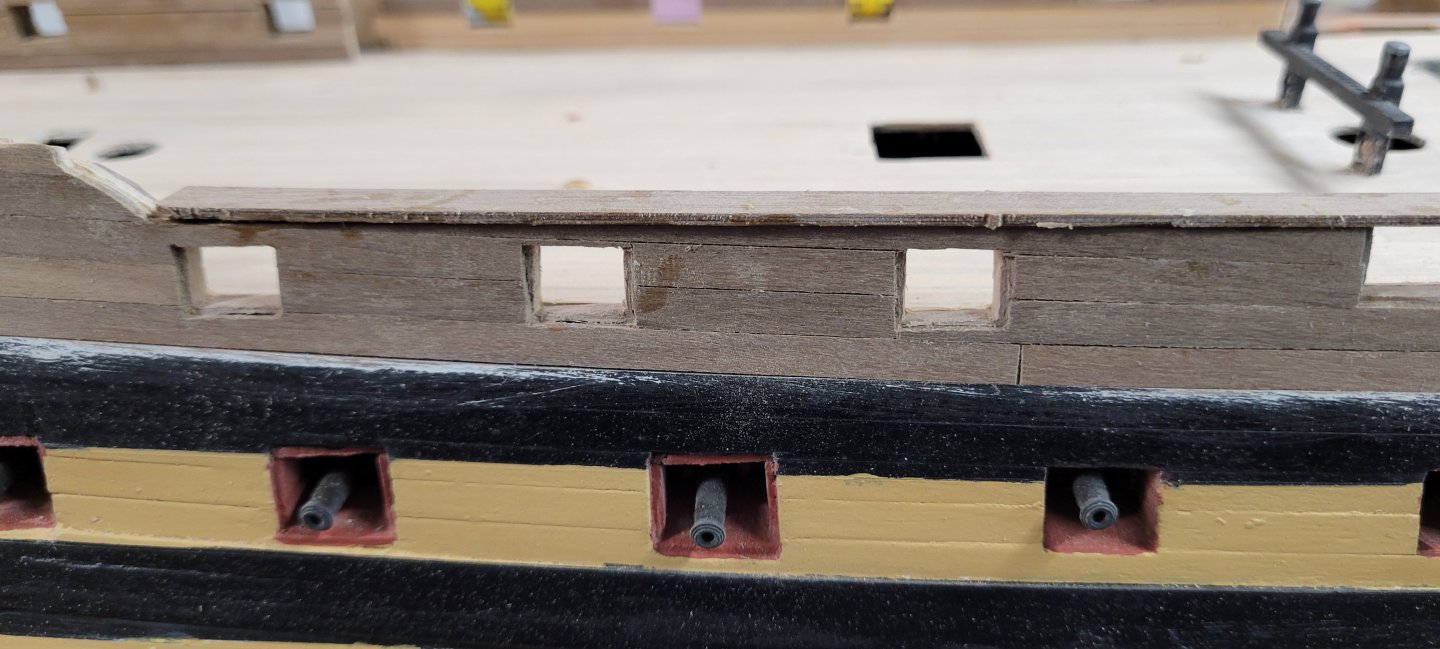

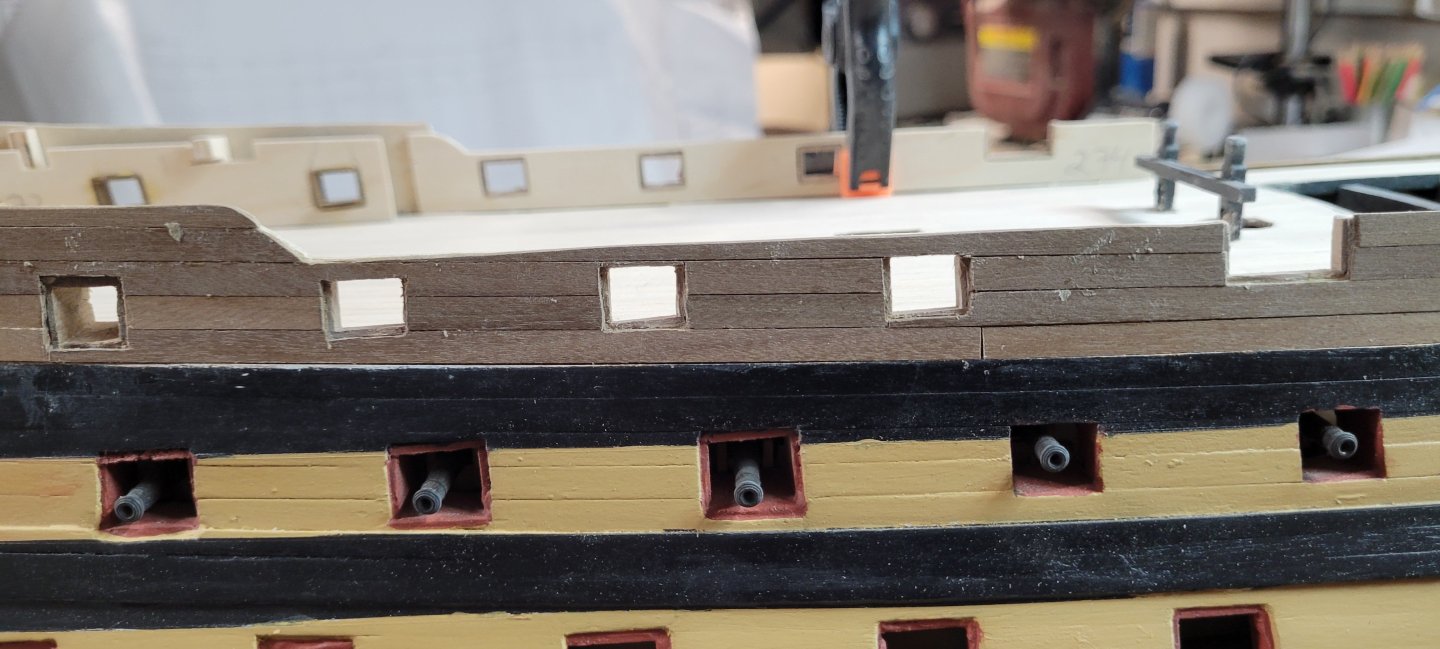

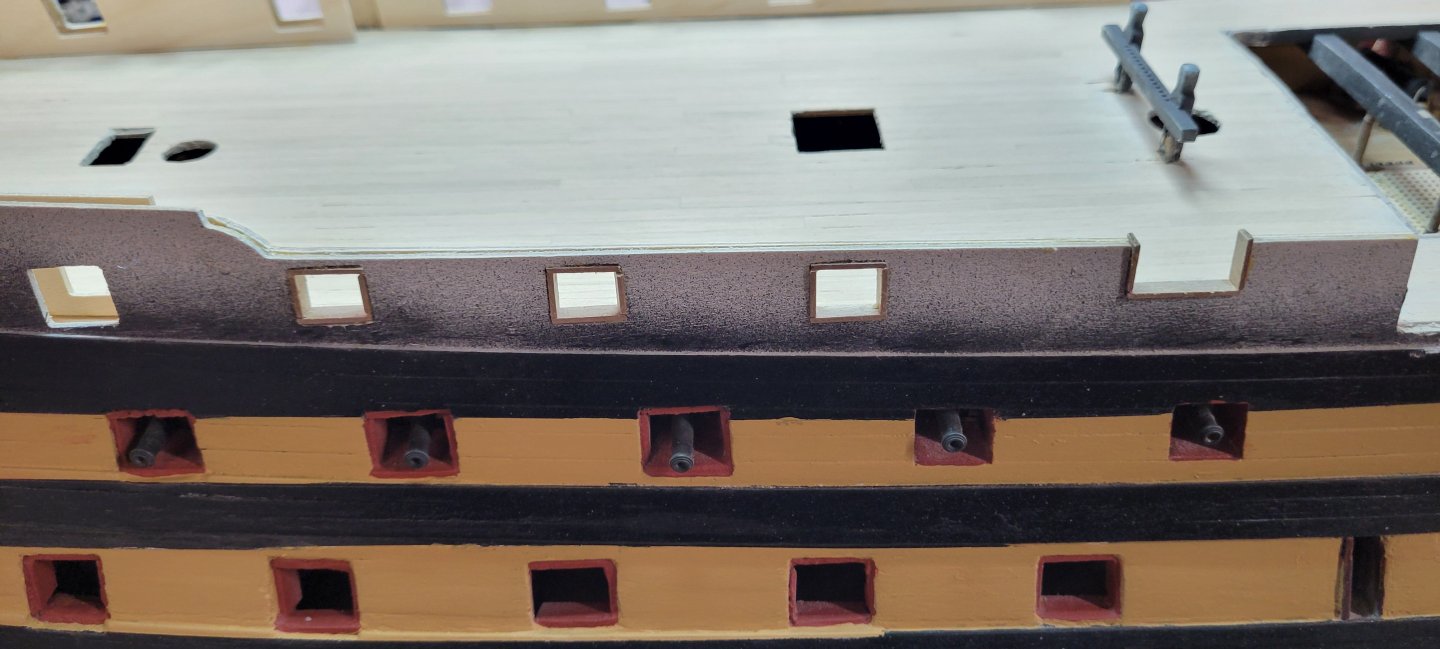

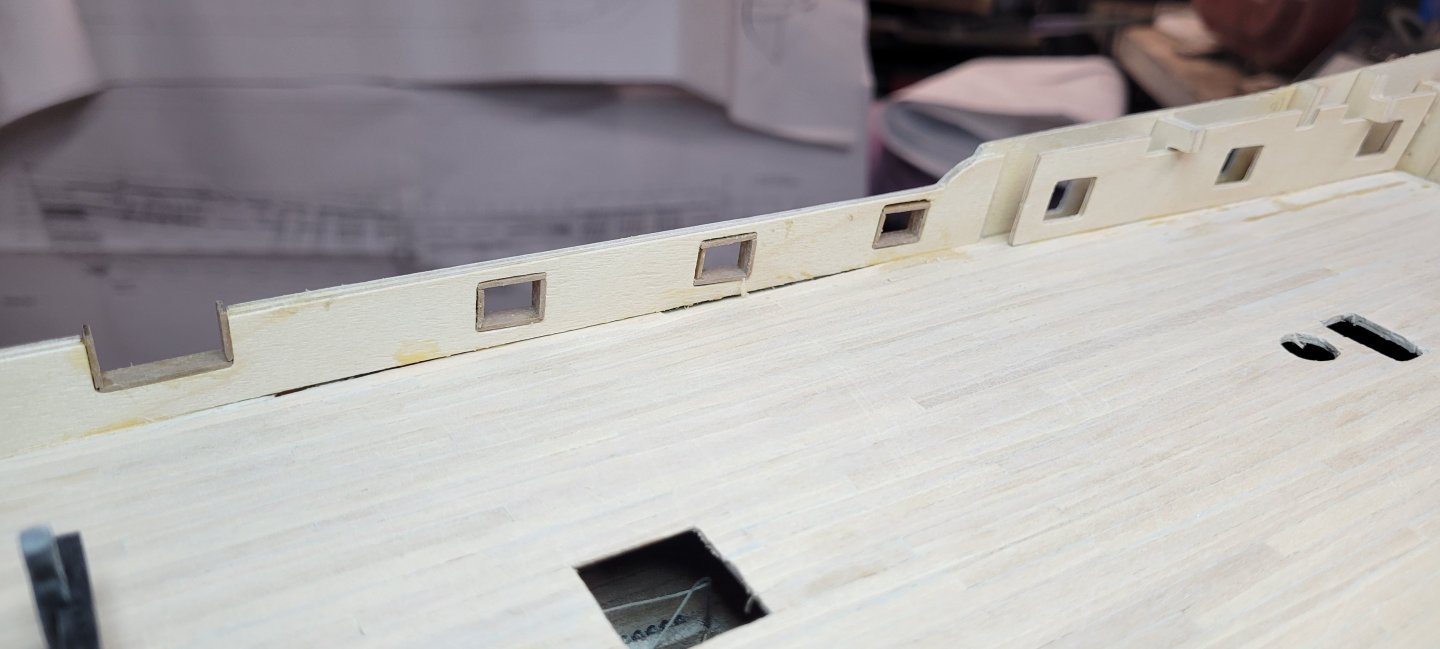

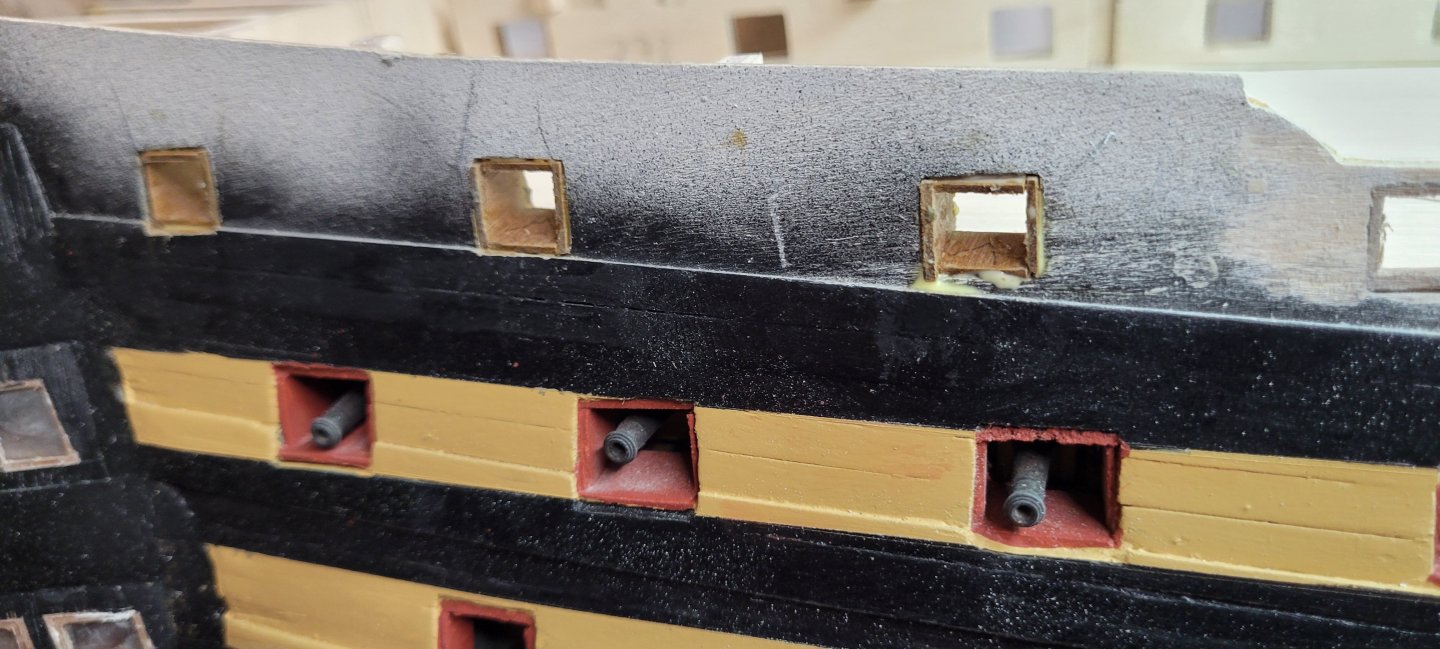

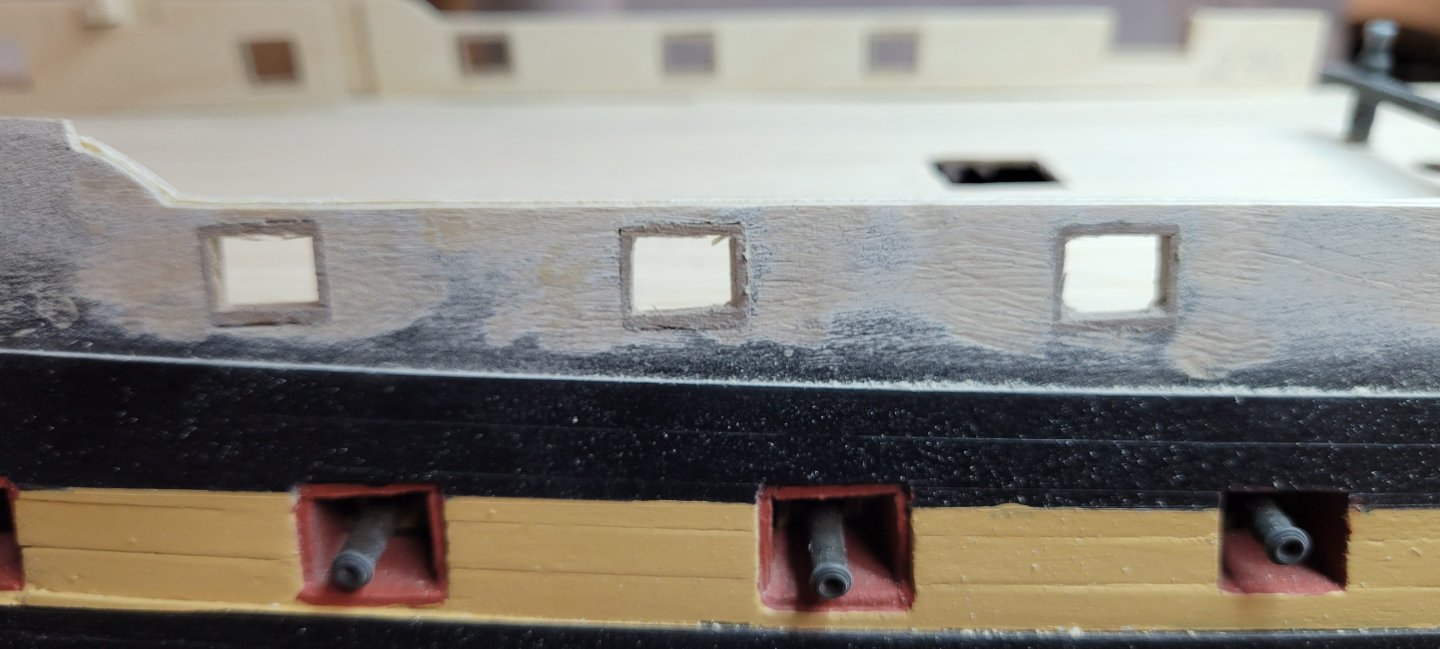

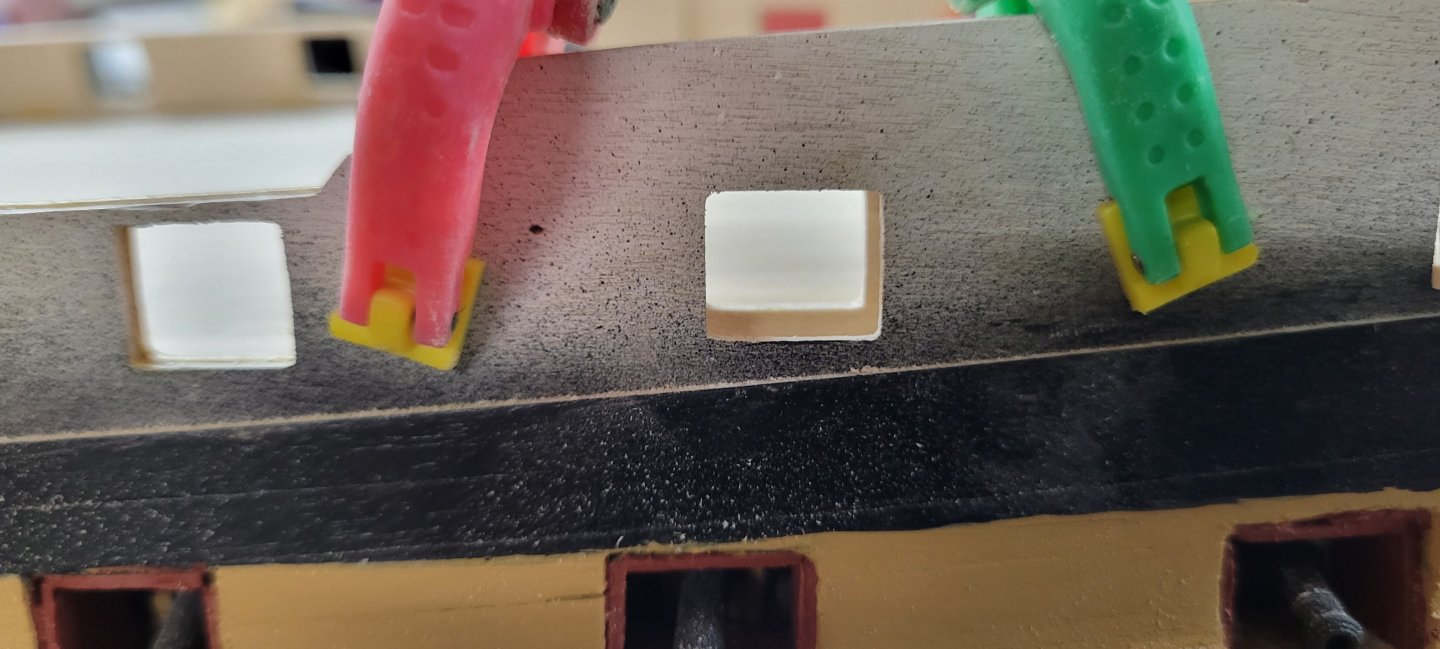

Adding the side planking took the most time. I would add a few rows to either the inside or outside. Just enough to leave the opening of a particular gun port visible. Once dry, I would cut away the planking covering the port. Then I would add another row or two. I did lose my way (again) when cutting out the gun ports. With the exception of the 3 at the stern, all the gun port liners should be flush to the side planking. The 3 at the stern need to be recessed by 1mm. On one side, I cut the planking so there was a recess where it shouldn't be. I'll see if paint will cover it. Once they were done, I squared them with a small flat file and small square file.

-

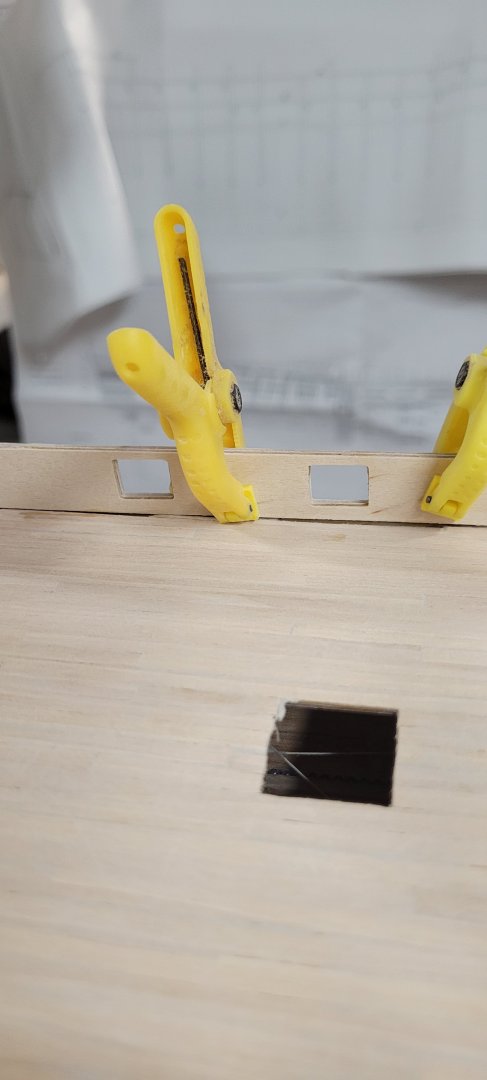

The next step was adding the gun port liners to inner bulkheads. I did break off one of the forward gun ports when I rested my hand on it. I ended up gluing a piece of the original planking to it and then using that extra piece to re-glue it to the hull. The problem was that the deck tapers at the bow and it was hard to get that bend in the piece. I ended up using some clamps, paint cans and more to get it in tight. I think I may need to do some sanding when I begin working on the bow. We shall see!!!! The gun ports actually lined up pretty good and there weren't any issues.

-

Hello! First, once again thank you for the kind remarks from everyone. Ron...I have all your pics from your log saved and they have been a tremendous help and a perfect addition to the kit's instructions. I doubt I'd be as far as I am without your log! So, I finished planking the quarterdeck. While the starboard side laid out as I wanted, the port side went a bit astray. Because of the hatch openings on the forward part, I lost my way keeping track of plank breaks. Instead of a break every 5 planks, it ended up being every 4 and in some cases 3. It's not something you will notice unless you're a rivet counter, but it is there and bothers me because this model requires a higher level of concentration, especially when I begin to tackle areas like the stern, bow and finally the rigging. If I can't get the decking right, I shudder to think what will happen when I get to those points (which are coming sooner than I think!) I did add the wood filler/stain again and while it looks bad at first, I can tell you it is not bad as of today (which is about 9 days after these pictures were taken). The only bad thing is the amount of dust I am creating doing this. I have an air compressor, just hope I glued those cannons down!!!! I ran the decking up to the side bulwarks so when I add the interior planks it will cover them. I did misread the instructions and thought I was going to coam/trim around the skid beam with a 3mm piece, but after the fact I saw it was only the longer sides and it is a 1.5x1.5 piece. I did leave a little too much space while laying the deck. I think I'll be ok as the belfry and barricade will cover that!

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.