-

Posts

150 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by TerryPat

-

When your son posted his kit here on MSW was it a build log? I'd like to see it. When my son said 2 kits Terry It was in reference to an old Monty Python bit, 2 sheds Jackson, which we're both fans of. A good laugh. Will your 2nd kit be your son's kit? Looking forward to that. Thanks 2 kits Rick!

- 58 replies

-

- Endeavour

- j-class yacht

-

(and 1 more)

Tagged with:

-

- built and Installed the mast. -installed mast shtouds -built the boom -glued deck structures in place -added plenty of deck bling.. It's a crowded deck -Installed blocks. Next steps will be rigging and deciding full sail? No sails? Or furled main sail on the boom only? 🤔

- 58 replies

-

- Endeavour

- j-class yacht

-

(and 1 more)

Tagged with:

-

Many builders did the railing after planking like you're describing and did fine. My brain better aligned with the writers of the instructions I spen a lot of time with that railing. I wanted to be sure the size and overhang was correct before I started planking. Particularly in the stern section. I made sure that the laser cut stern rail piece fit properly with the correct amount of overhang around the sides and back of the stern.

-

I followed the recommend path in the instructions. One reason was because of my burned stanchions that you can see in my log. I wanted to get that all sorted out before going further. I also thought it would be good to start the first plank hard against the bottom of top rail and then plank downward to the first belt line as defined in the planking instructions. So, for making the railing and marking the overhang i pinned a temporary plank against the stanchions and then marked the hull line along the bottom of my top rail piece. I made sure I had at least of 1/16 inch overhang beyond that marked line. I then installed the railing and cut the many little stanchions and the fitted them between the rail and waterway. Tedious, but what isn't in this hobby. I then cut away my burned stanchions and replaced them.

-

I appreciate the comments.. Thank you! I saw your 1:35 version. Beautiful ! I like your treatment of the stern and the sort of herringbone plank ends on the deck. I haven't found your 1:80 version yet

- 58 replies

-

- Endeavour

- j-class yacht

-

(and 1 more)

Tagged with:

-

Seriously? I've been looking at the Cisson V8. Expensive but YOLO. I'm seriously considering it. I think I have to order direct from China. Did you order from Sterling? PM me if you don't want to clutter your build log

-

I better be following this one..😃 Great bargain! I wonder how old the kit is? Your kit shows it's double planked. Mine is not. I bought mine direct from Model Expo a few months ago. From what I can see from your pics the wood in your kit looks really nice. Mine?.. not so much. To be fair, Model Expo is using better wood after mine was put together.. They told me so. Anyway, congrats on a nice kit! I think overall it's a fantastic kit. It's nicely scaled and fun to build. You'll have fun

-

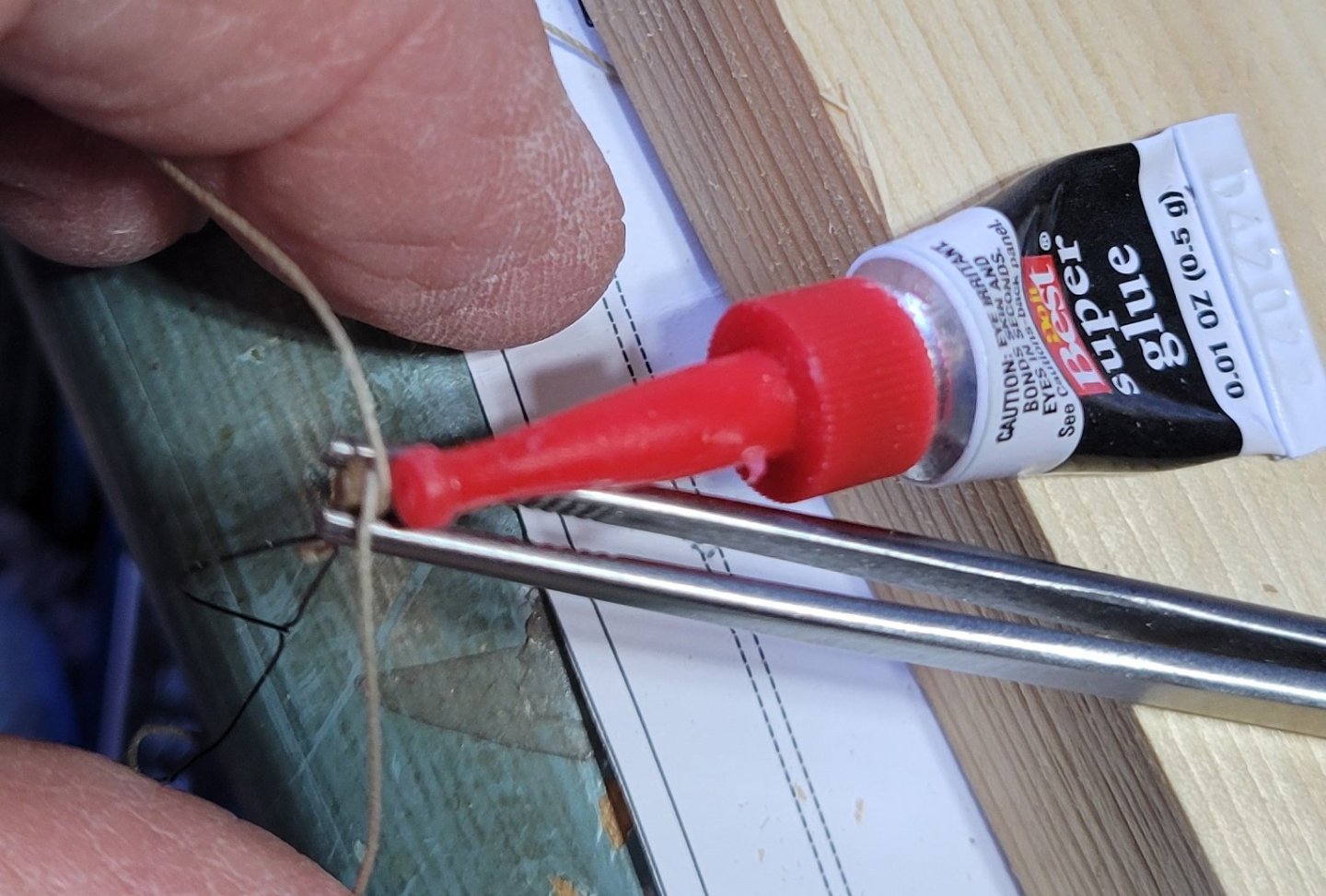

Excellent idea with the super glue! The hull looks fantastic. Nice job around the keel. You'll have a nice base for the second planking

-

It looks good at the stern. Sounds like you have a plan to fix the gaps. Some chunks of scrap wood and/or filler? That bender tool looks pretty handy. First time I've seen one. Cool !

-

Thanks Rick! I hope to have it complete by spring

- 58 replies

-

- Endeavour

- j-class yacht

-

(and 1 more)

Tagged with:

-

Living the life my friend! That whiting is excellent eatin'! Keep in touch with those of stuck up here in the snow. I will be getting in a couple of weeks in Florida to thaw out soon. Enjoy!

- 58 replies

-

- Endeavour

- j-class yacht

-

(and 1 more)

Tagged with:

-

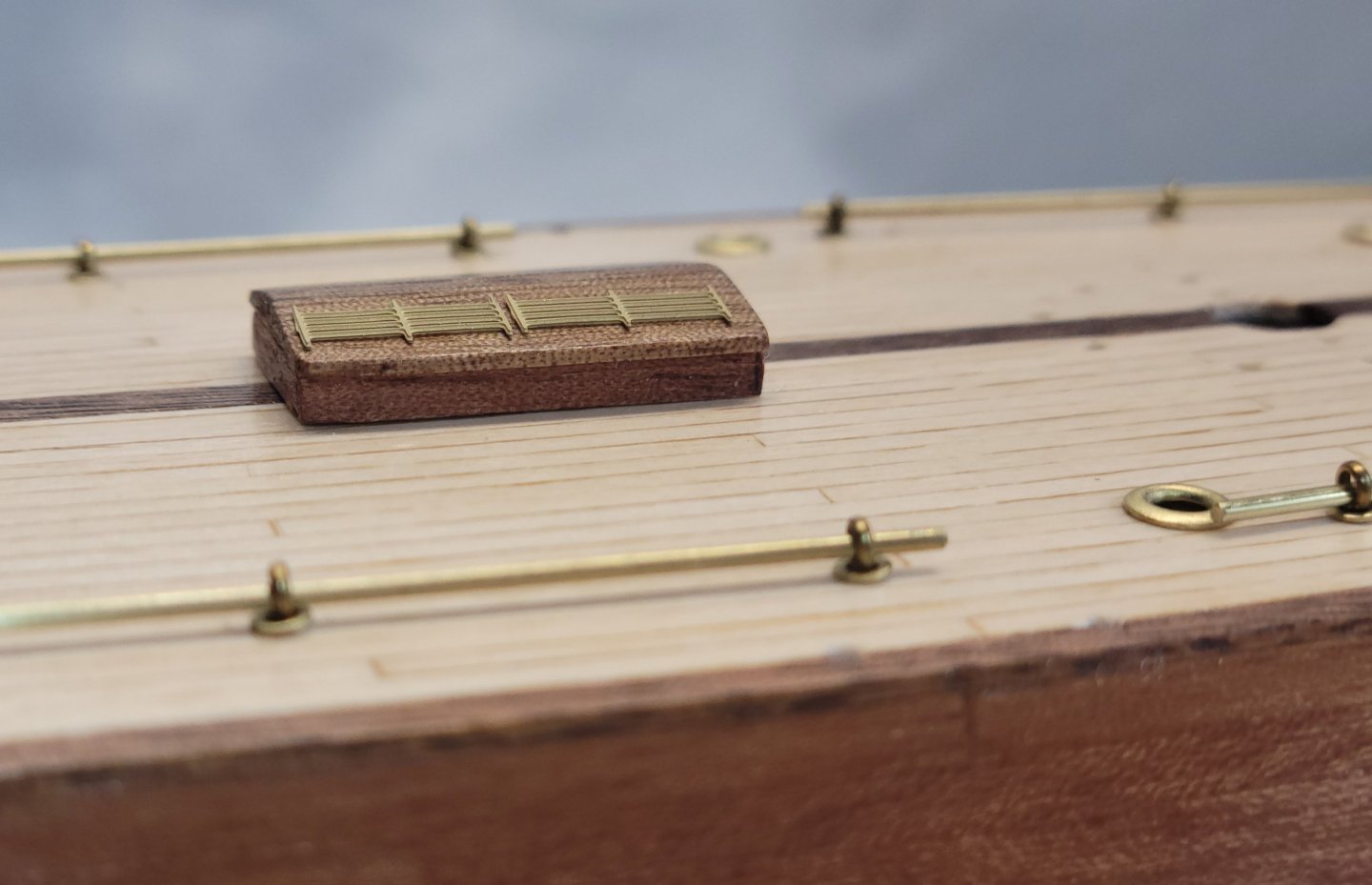

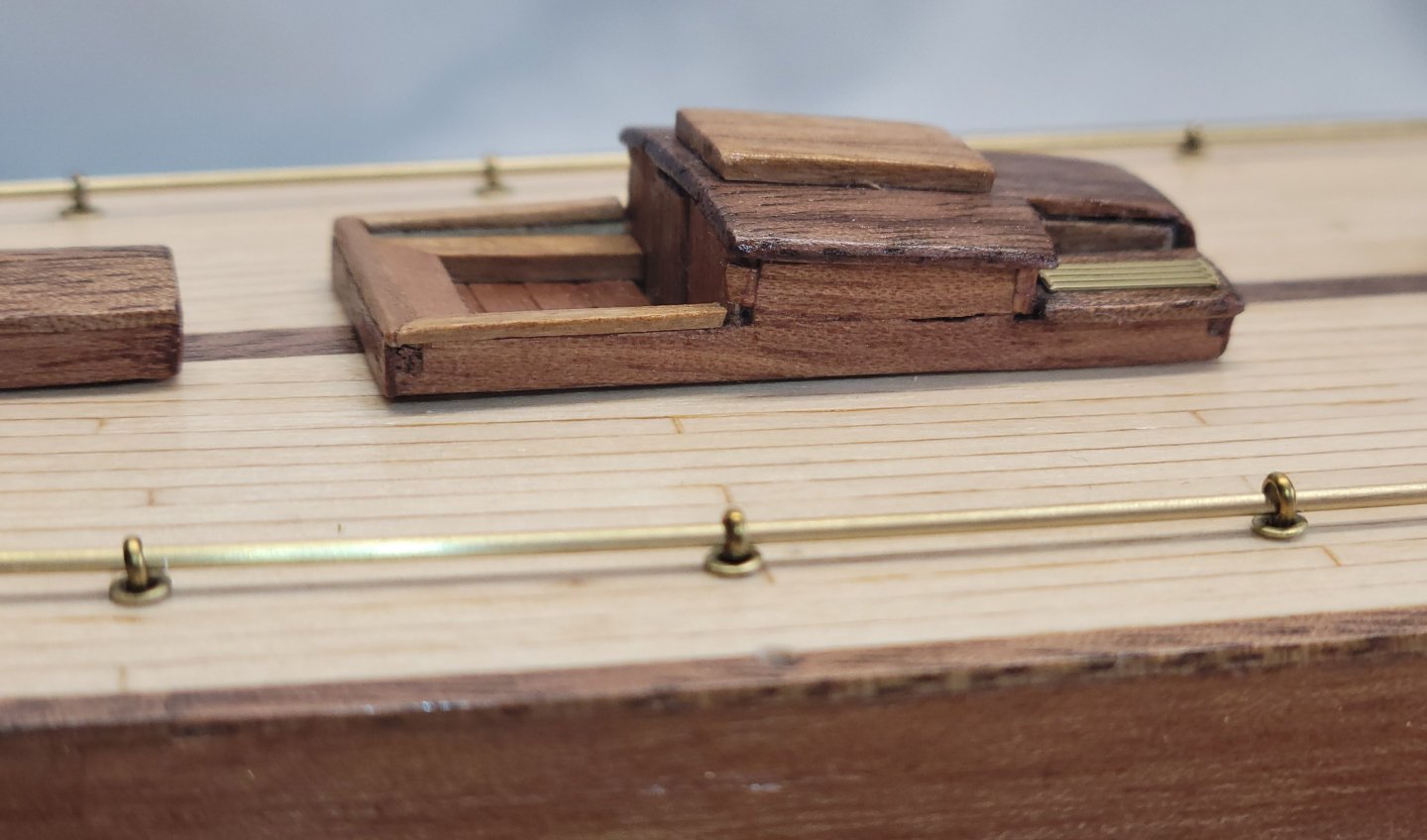

Build update: Progressing slowly. -drilled all holes in the deck using the included template. I was a little nervous to drill holes along the outer hull rails but it went very smoothly. Had to make up 29 stropped blocks to attach to the deck for rigging. After a lot of searching for stropping methods I settled on a method inspired by Olha Batchvarov in one of her YouTube videos. My methed differs where she used thin black line or thread and I used 32 guage black annealed wire. And her results were much better than mine. But good enough. I made a tying jig with a drill bit into a block of wood. - I built up deck structures using the supplied laser cut pieces except for the roofing which I replaced with walnut pieces. I didn't cut openings for skylights and windows. I may paint black under the skylight and window brass grates to simulate openings. We'll see. I covered the sides of the structures with left over walnut planking. -Installed the brass hand railing. In the following pics nothing is glued down. All for now

- 58 replies

-

- Endeavour

- j-class yacht

-

(and 1 more)

Tagged with:

-

@Admiral Rick i wish I was as organized as you. I go hunting for parts as needed which can be an annoying chore.

- 58 replies

-

- Endeavour

- j-class yacht

-

(and 1 more)

Tagged with:

-

Thanks, Rick. I appreciate the nice comment

- 58 replies

-

- Endeavour

- j-class yacht

-

(and 1 more)

Tagged with:

-

That looks great! I haven't done that yet. Glad you did. I'll look back on what you did when I get to it

-

Aye aye Admiral.. Back to work! I'm looking forward to following your Bluenose build

- 58 replies

-

- Endeavour

- j-class yacht

-

(and 1 more)

Tagged with:

-

Thank you so much, Ellie I'm glad you're back! You have such a good start going. I can't wait to see what you create

- 58 replies

-

- Endeavour

- j-class yacht

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.