LJC

Members-

Posts

29 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Glen Allen, VA

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

Canute reacted to a post in a topic:

Chesapeake Bay Box Stern Workboat by LJC - Wye River Models

Canute reacted to a post in a topic:

Chesapeake Bay Box Stern Workboat by LJC - Wye River Models

-

robert952 reacted to a post in a topic:

Chesapeake Bay Box Stern Workboat by LJC - Wye River Models

robert952 reacted to a post in a topic:

Chesapeake Bay Box Stern Workboat by LJC - Wye River Models

-

yvesvidal reacted to a post in a topic:

Chesapeake Bay Box Stern Workboat by LJC - Wye River Models

yvesvidal reacted to a post in a topic:

Chesapeake Bay Box Stern Workboat by LJC - Wye River Models

-

Harvey Golden reacted to a post in a topic:

Chesapeake Bay Box Stern Workboat by LJC - Wye River Models

Harvey Golden reacted to a post in a topic:

Chesapeake Bay Box Stern Workboat by LJC - Wye River Models

-

ccoyle reacted to a post in a topic:

Chesapeake Bay Box Stern Workboat by LJC - Wye River Models

ccoyle reacted to a post in a topic:

Chesapeake Bay Box Stern Workboat by LJC - Wye River Models

-

JacquesCousteau reacted to a post in a topic:

Chesapeake Bay Box Stern Workboat by LJC - Wye River Models

JacquesCousteau reacted to a post in a topic:

Chesapeake Bay Box Stern Workboat by LJC - Wye River Models

-

robert952 reacted to a post in a topic:

Chesapeake Bay Box Stern Workboat by LJC - Wye River Models

robert952 reacted to a post in a topic:

Chesapeake Bay Box Stern Workboat by LJC - Wye River Models

-

robert952 reacted to a post in a topic:

Chesapeake Bay Box Stern Workboat by LJC - Wye River Models

robert952 reacted to a post in a topic:

Chesapeake Bay Box Stern Workboat by LJC - Wye River Models

-

Ryland Craze reacted to a post in a topic:

Chesapeake Bay Box Stern Workboat by LJC - Wye River Models

Ryland Craze reacted to a post in a topic:

Chesapeake Bay Box Stern Workboat by LJC - Wye River Models

-

Ryland Craze reacted to a post in a topic:

Chesapeake Bay Box Stern Workboat by LJC - Wye River Models

Ryland Craze reacted to a post in a topic:

Chesapeake Bay Box Stern Workboat by LJC - Wye River Models

-

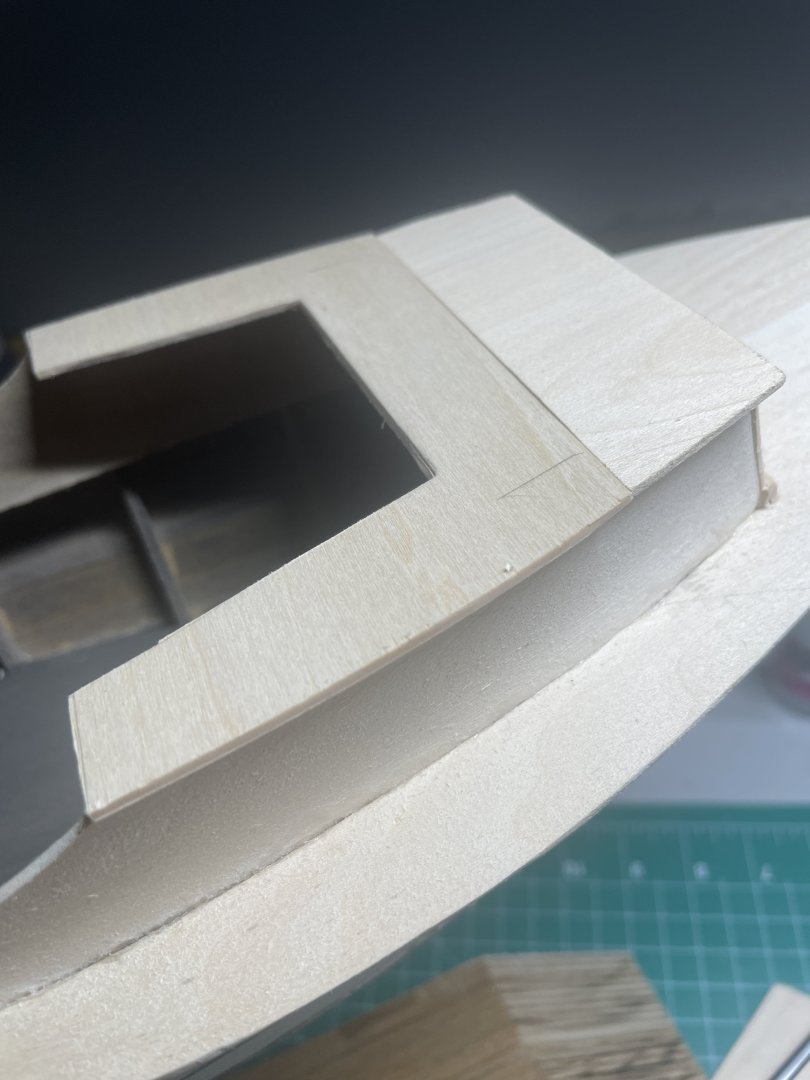

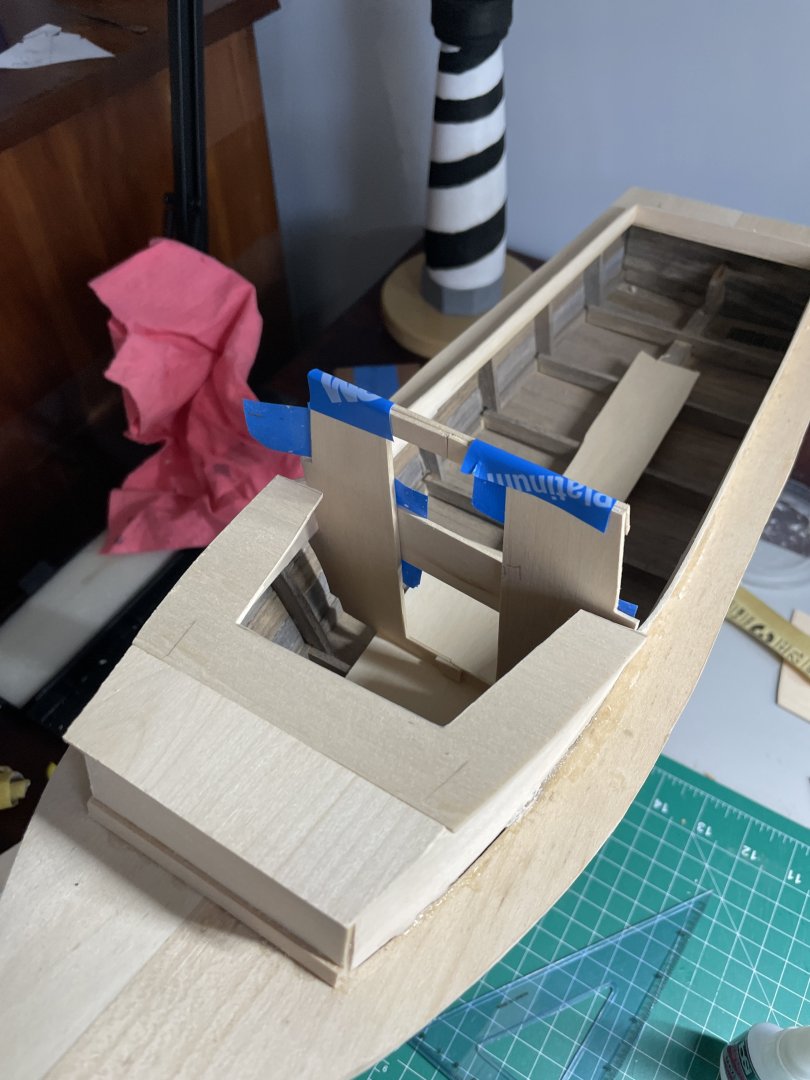

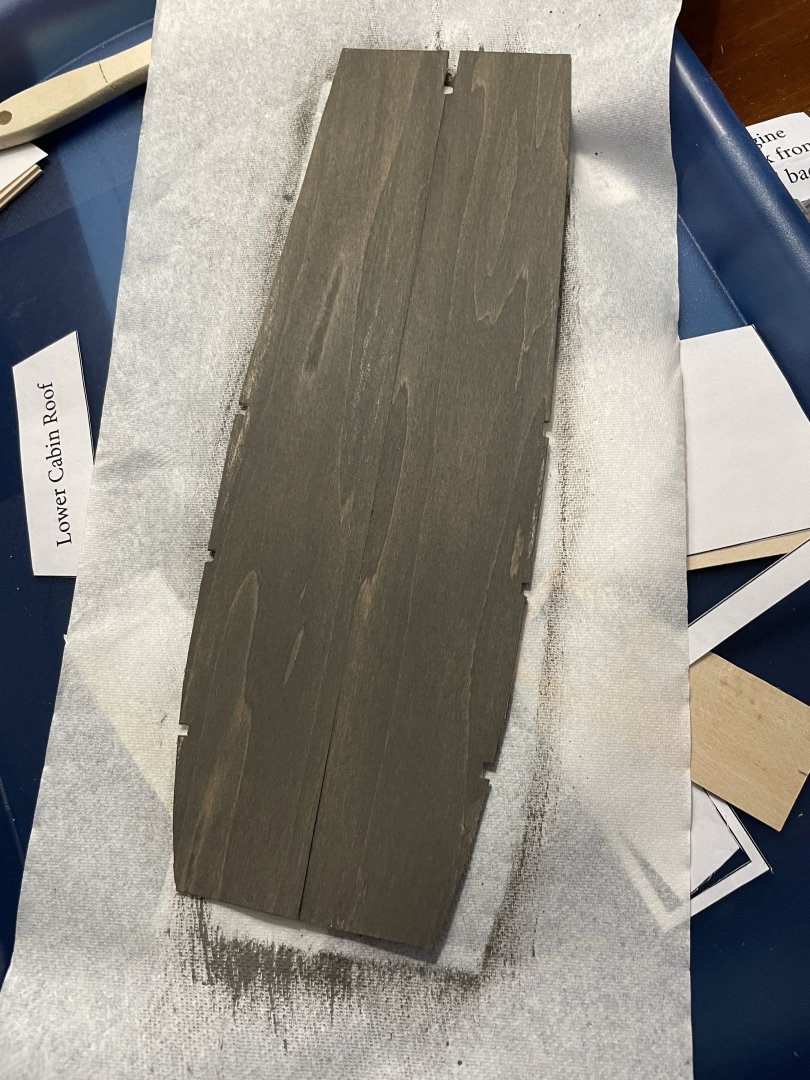

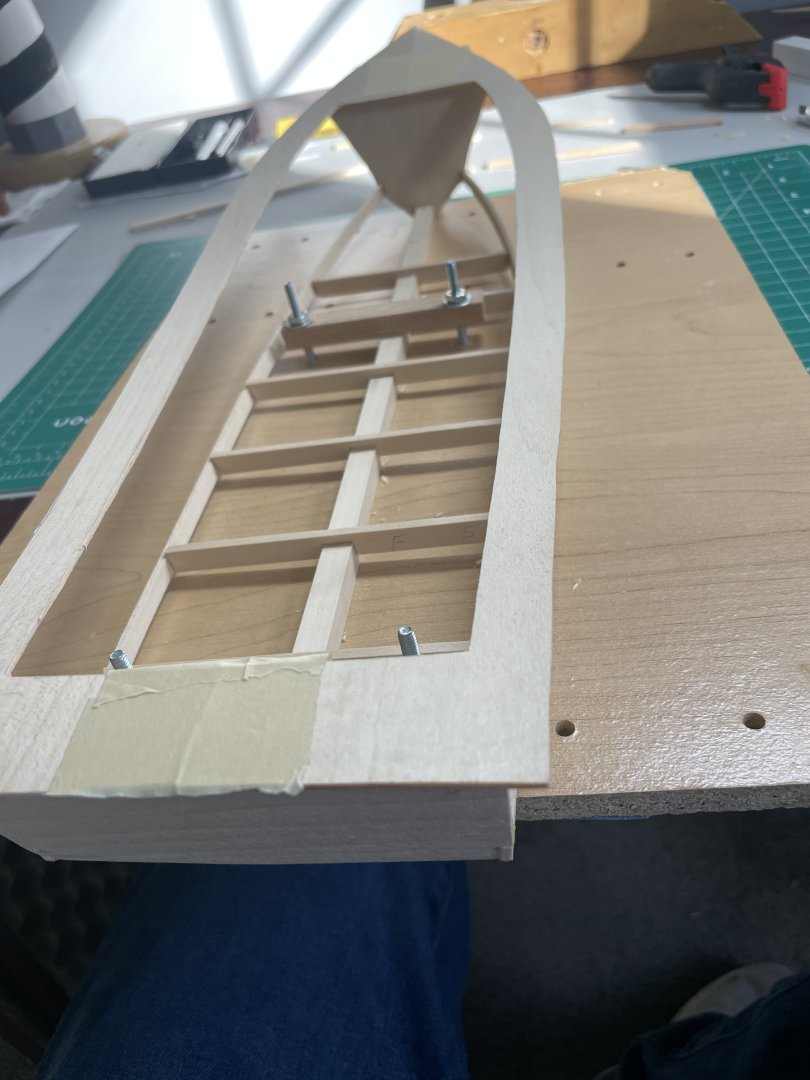

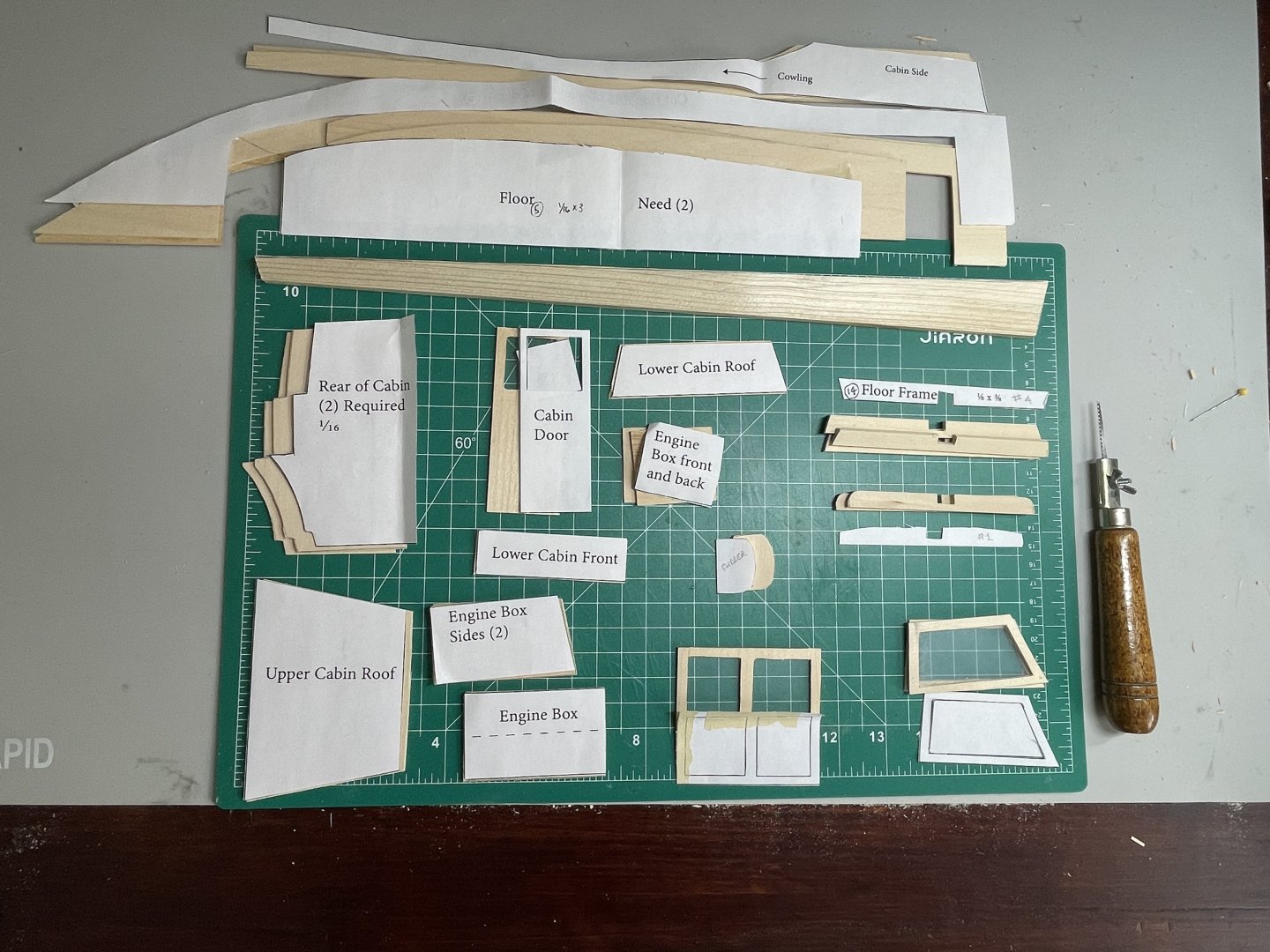

I prepared the cowling by soaking and shaping. I was concerned that trying to glue the cowling to a 1/16 inch thick deck board was gonna be next to impossible. I added support plates under the deck at the bow, stern, and on either side midship. It turns out that this worked OK – I could’ve used more support along both sides. Any overhang on the support can be trimmed flush with the cowling. I had to recut the lower cabin front to fit as the plans were too short. As an afterthought, cutting many of the pieces early may result in ill fitting situations although this is the first to short (several have been long). The lower cabin roof was installed. I needed to add to the roof in order to get back to the rear of the cabin and to have someplace for the front and side windows of the upper cabin to sit on. Had to make adjustments to the rear cabin on each side to fit the hull and cabin roof line. I assembled the rear cabin and decided to cut a space for the door out of the center. I added supports on the top and bottom of the rear cabin in order to join the two pieces together. Before I finish up the cabin, I need to decide on what accessories for the cabin I want if any. I’m thinking as a minimum a helm and seat in the cabin and also some pre-cut items for the deck. If that’s the case, I’ll have to find some to order before I complete the cabin build. Build time 4.5 hours.

-

Next step is building the cabin. And looking at the instructions that’s all there was “build the cabin.“ Needing to have the cockpit floor installed before the cabin, I fit that and stained it using Graystone (General Finishes). I also stained the interior hull Aged Barrel (Minwax). I’ll need to clean up the bleed through on the outside of the hull. Build time 1 hour.

-

LJC reacted to a post in a topic:

Chesapeake Bay Box Stern Workboat by LJC - Wye River Models

LJC reacted to a post in a topic:

Chesapeake Bay Box Stern Workboat by LJC - Wye River Models

-

LJC reacted to a post in a topic:

Chesapeake Bay Box Stern Workboat by LJC - Wye River Models

LJC reacted to a post in a topic:

Chesapeake Bay Box Stern Workboat by LJC - Wye River Models

-

LJC reacted to a post in a topic:

Chesapeake Bay Box Stern Workboat by LJC - Wye River Models

LJC reacted to a post in a topic:

Chesapeake Bay Box Stern Workboat by LJC - Wye River Models

-

LJC reacted to a post in a topic:

Chesapeake Bay Box Stern Workboat by LJC - Wye River Models

LJC reacted to a post in a topic:

Chesapeake Bay Box Stern Workboat by LJC - Wye River Models

-

LJC reacted to a post in a topic:

Chesapeake Bay Box Stern Workboat by LJC - Wye River Models

LJC reacted to a post in a topic:

Chesapeake Bay Box Stern Workboat by LJC - Wye River Models

-

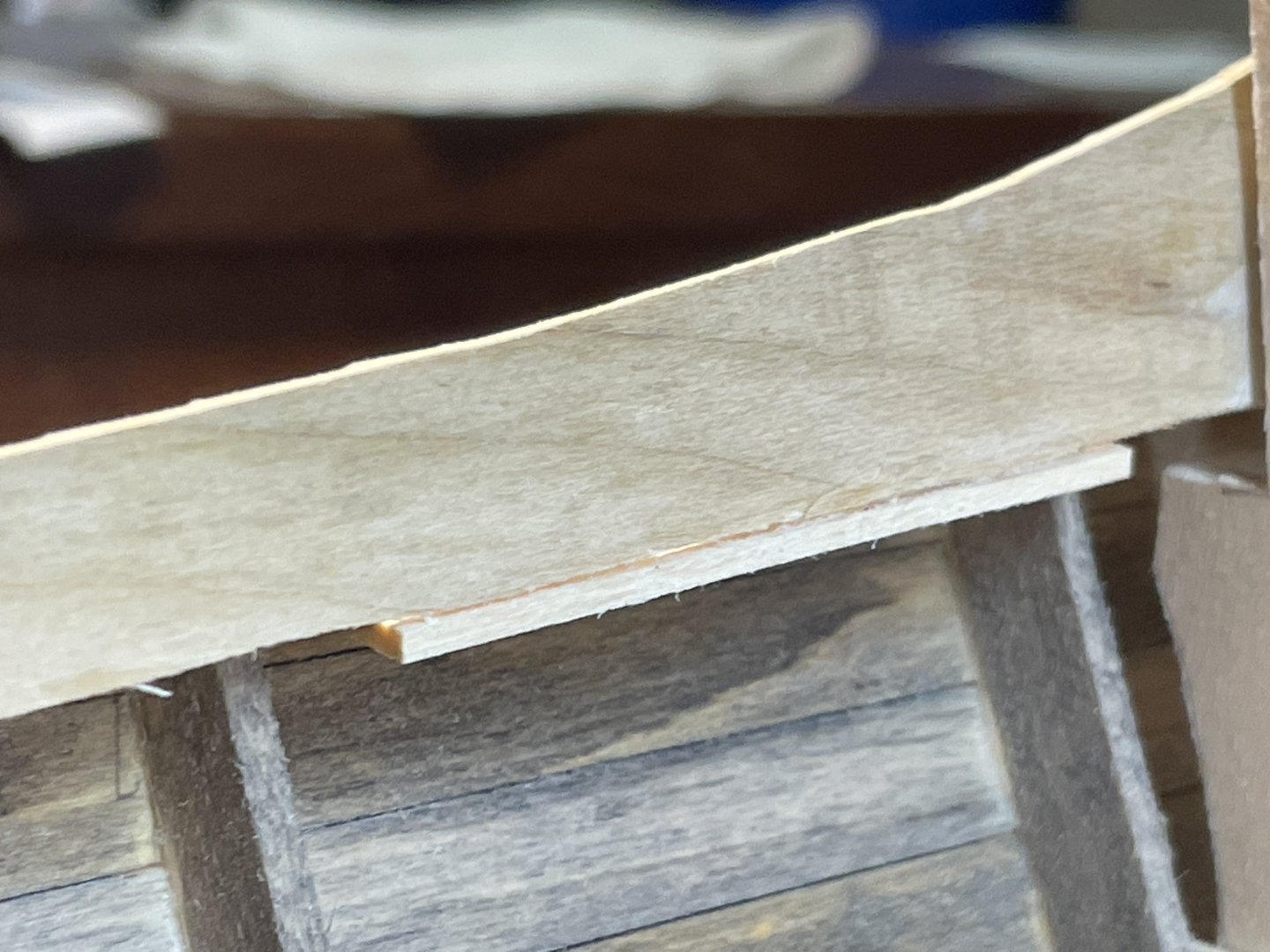

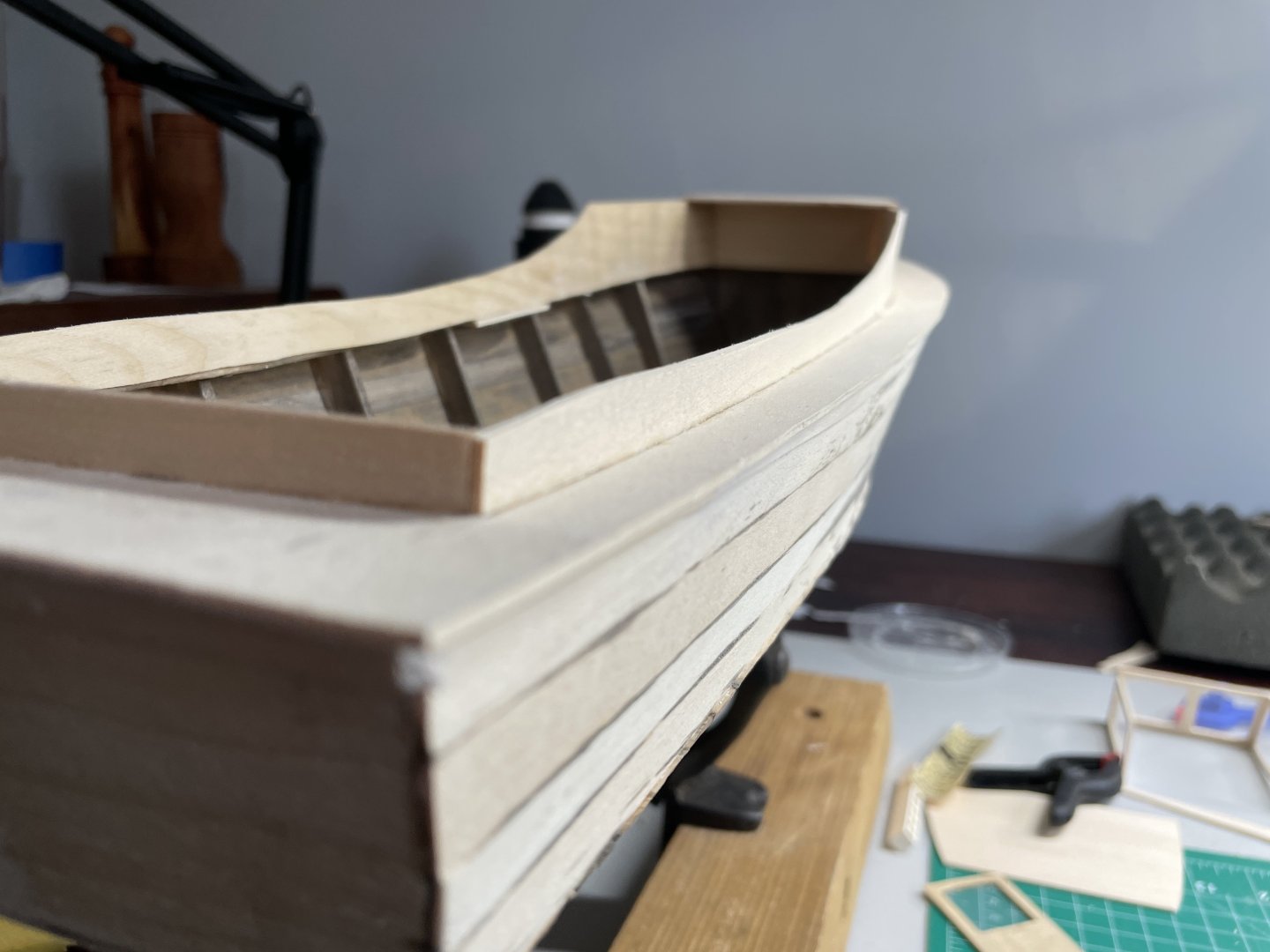

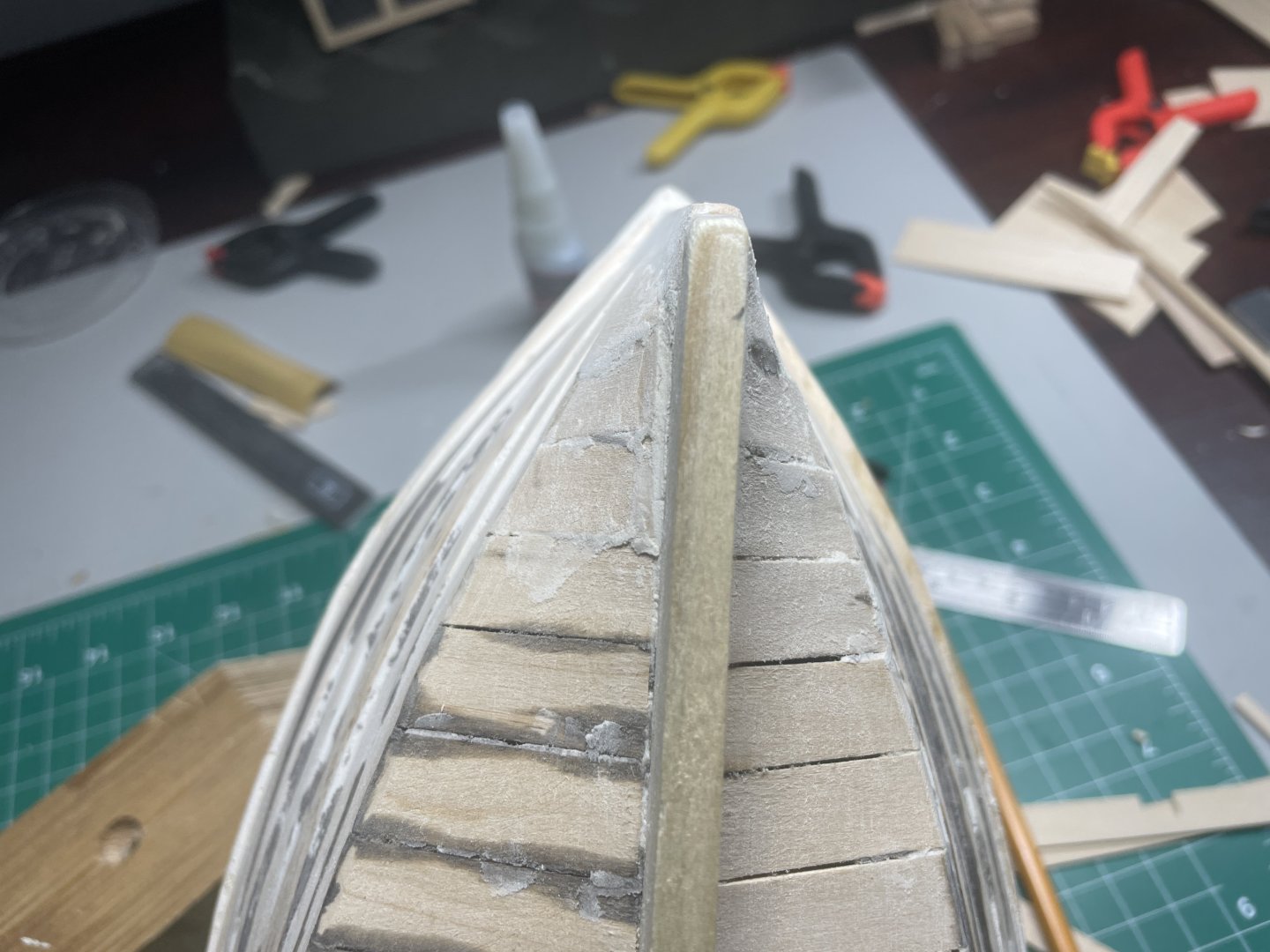

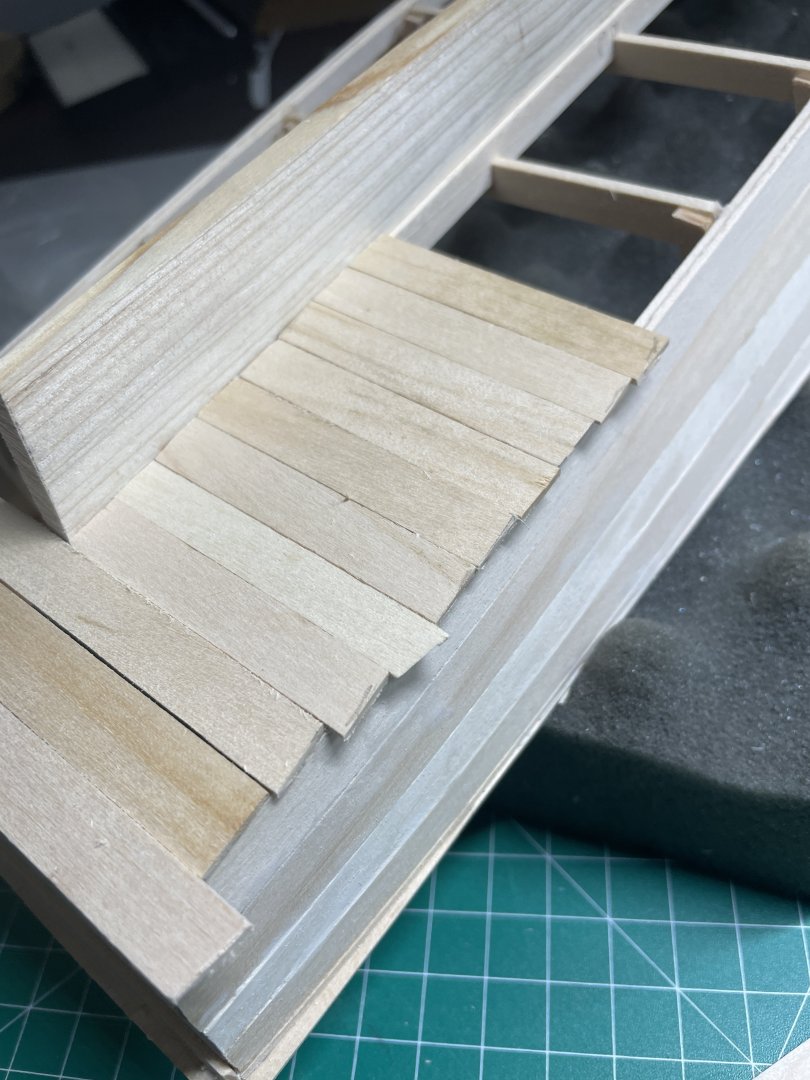

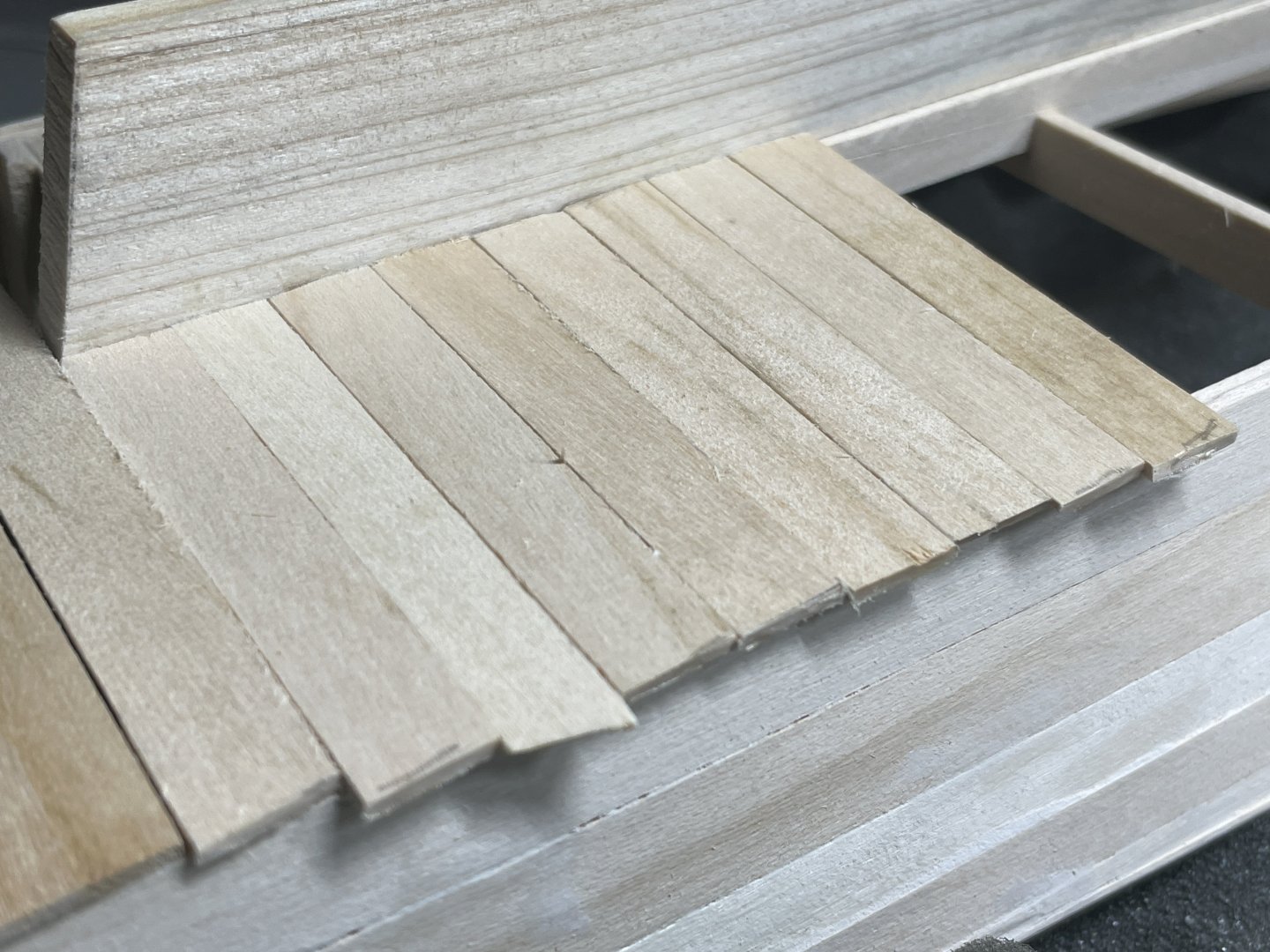

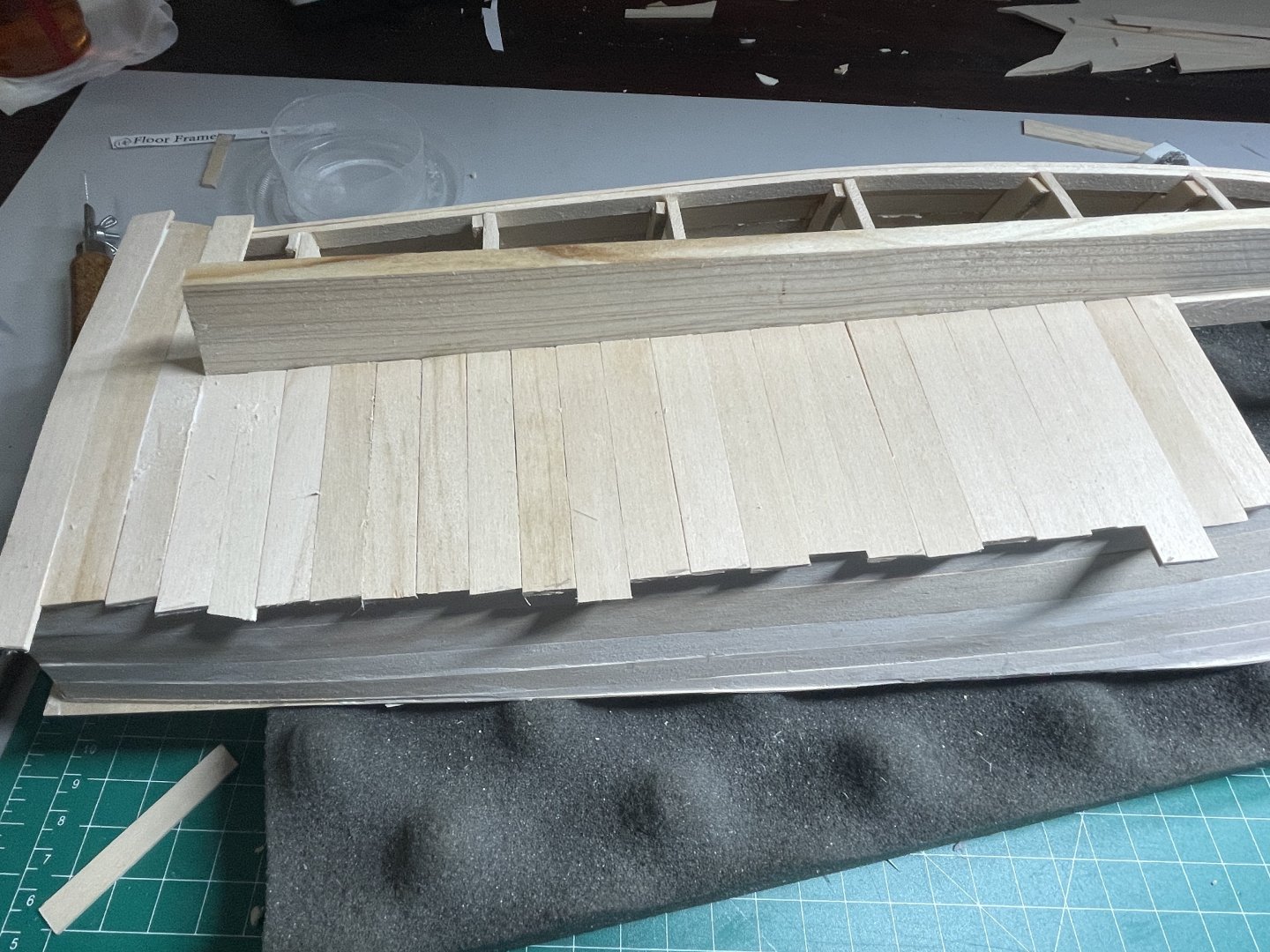

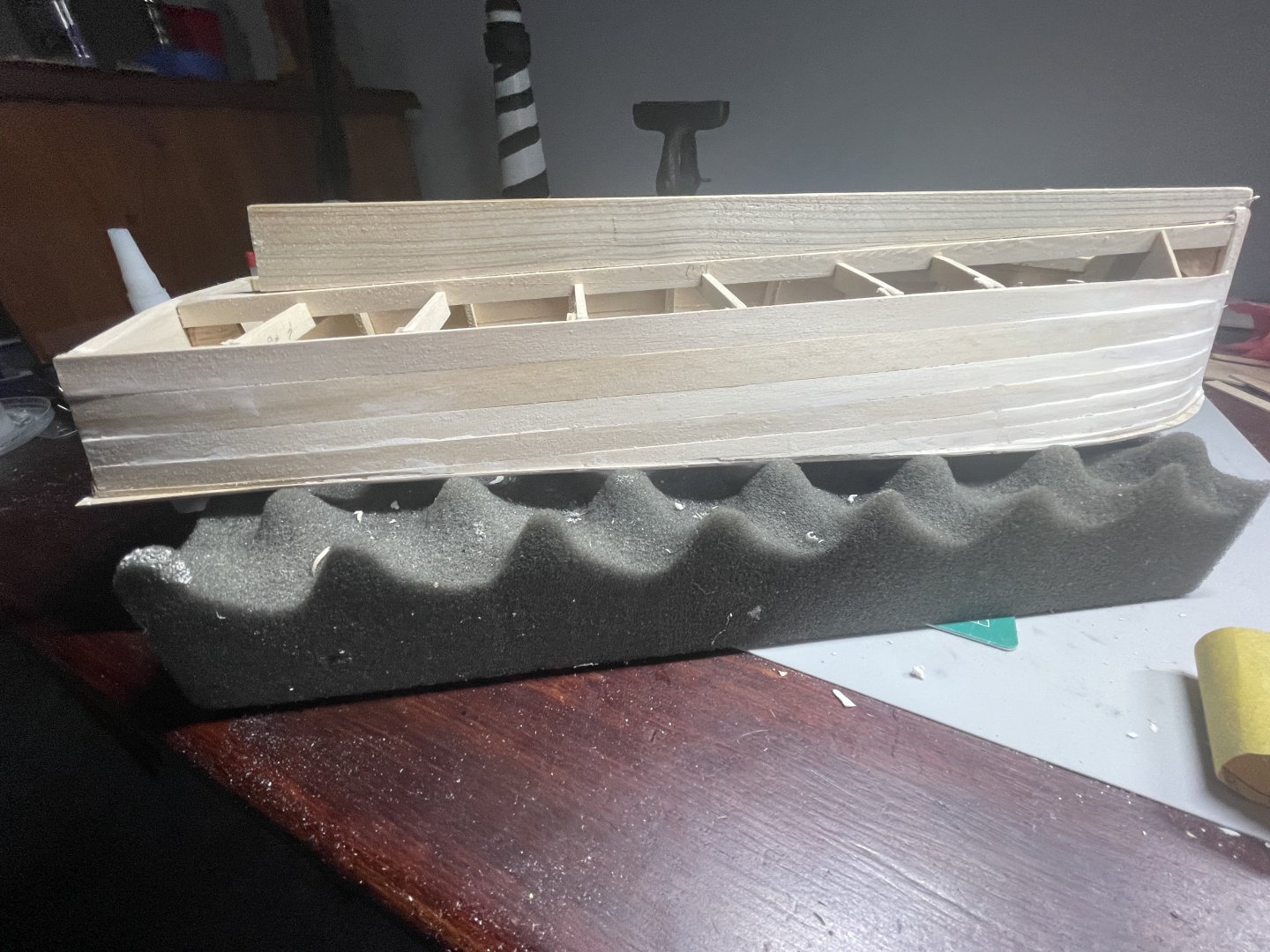

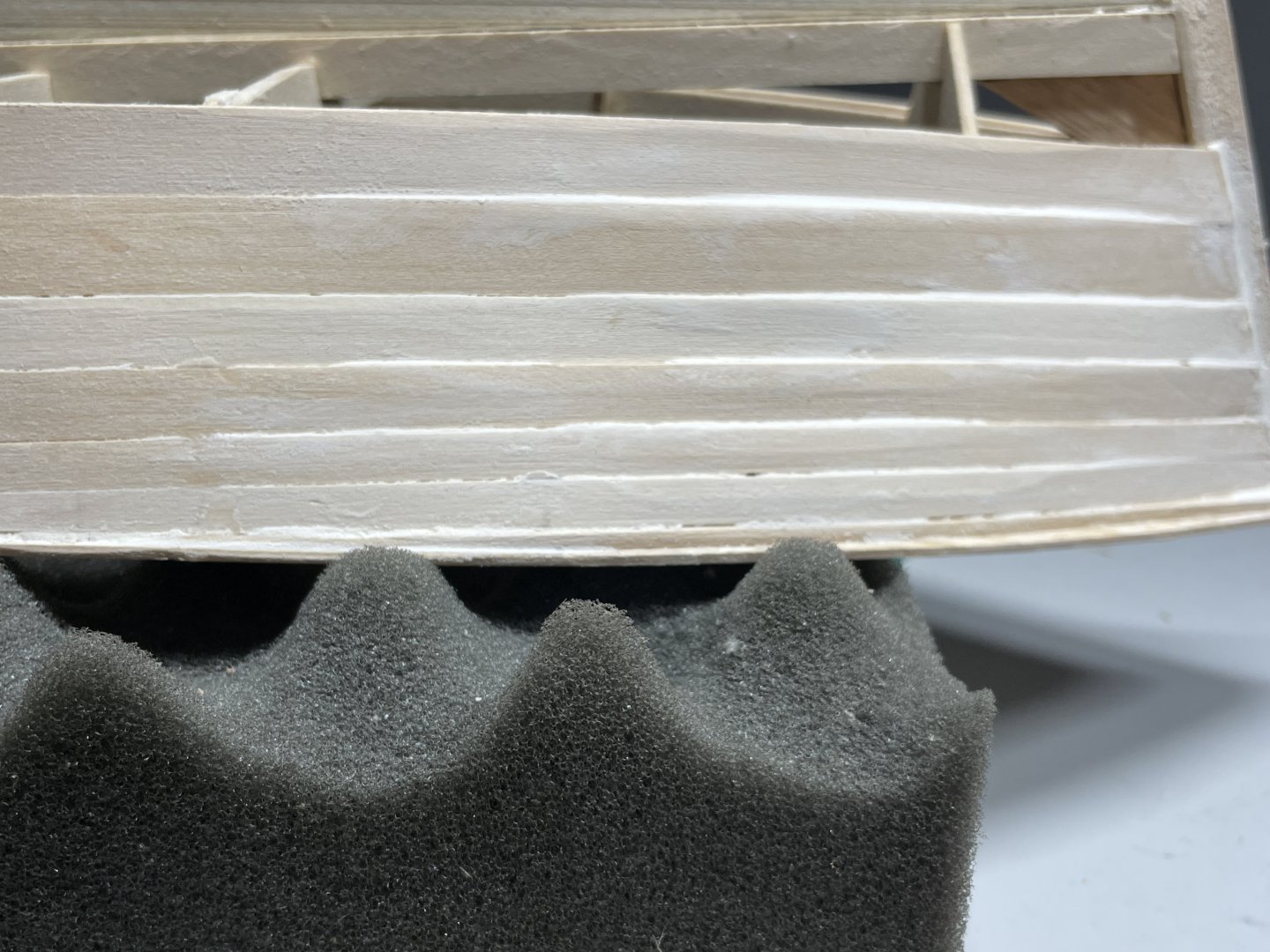

Individually fit bottom planks. Fitting planks for the bow will require soaking and shaping. I did that with 2 planks and it seemed to work. I’m pleased with how the bottom looks, hope it won’t be too hard to trim all the overhang. I don’t think it will need much filler. I’ll work on the bow next. Build time ~2.5 hrs

-

LJC reacted to a post in a topic:

Chesapeake Bay Box Stern Workboat by LJC - Wye River Models

LJC reacted to a post in a topic:

Chesapeake Bay Box Stern Workboat by LJC - Wye River Models

-

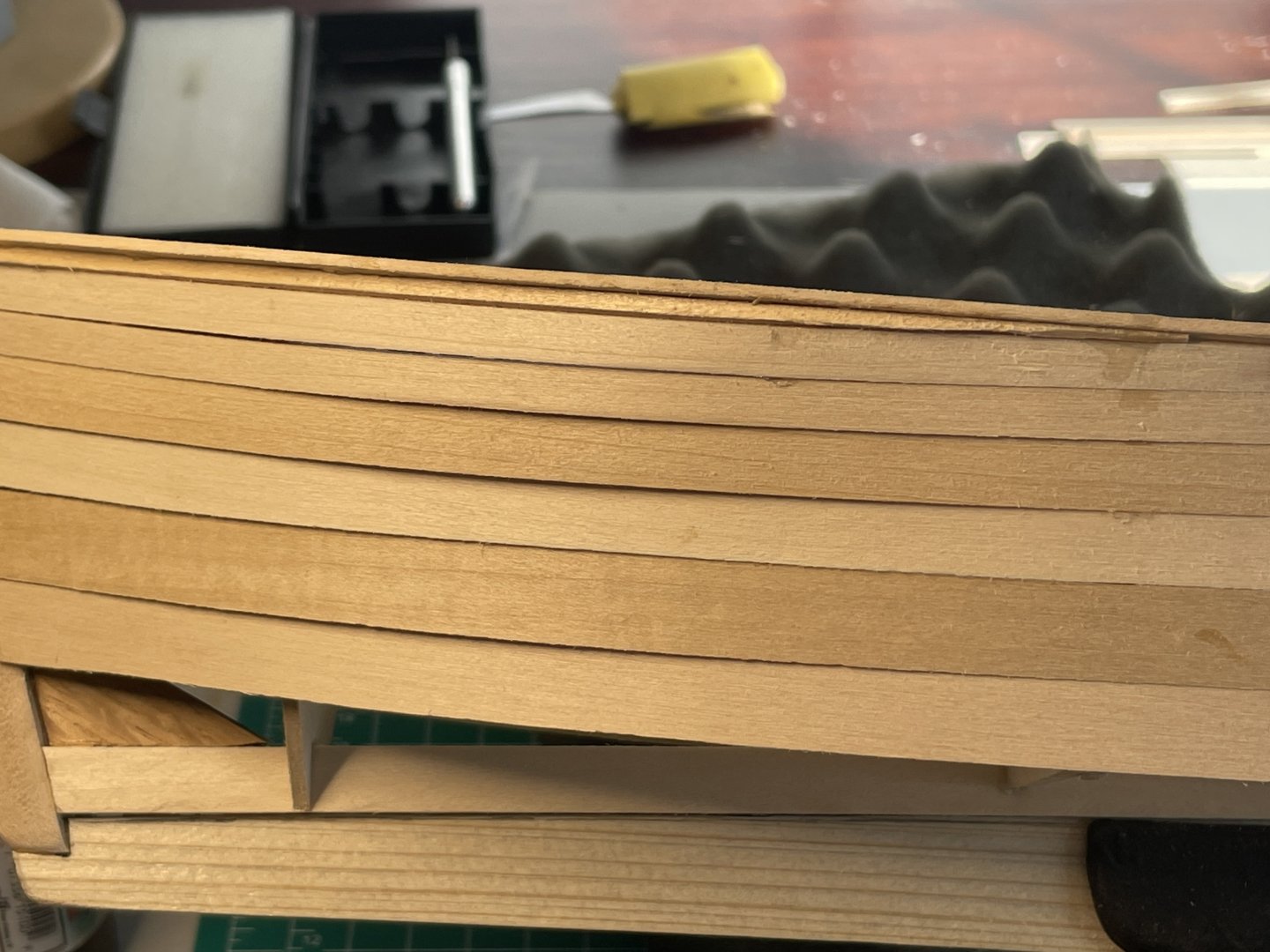

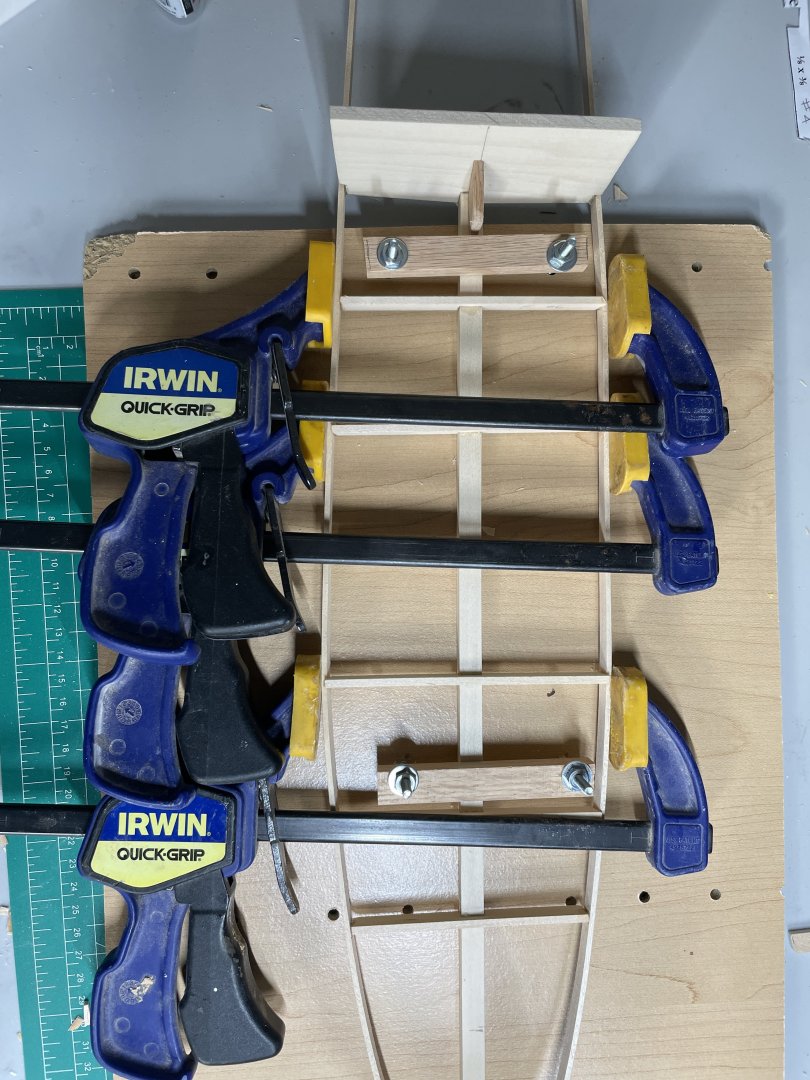

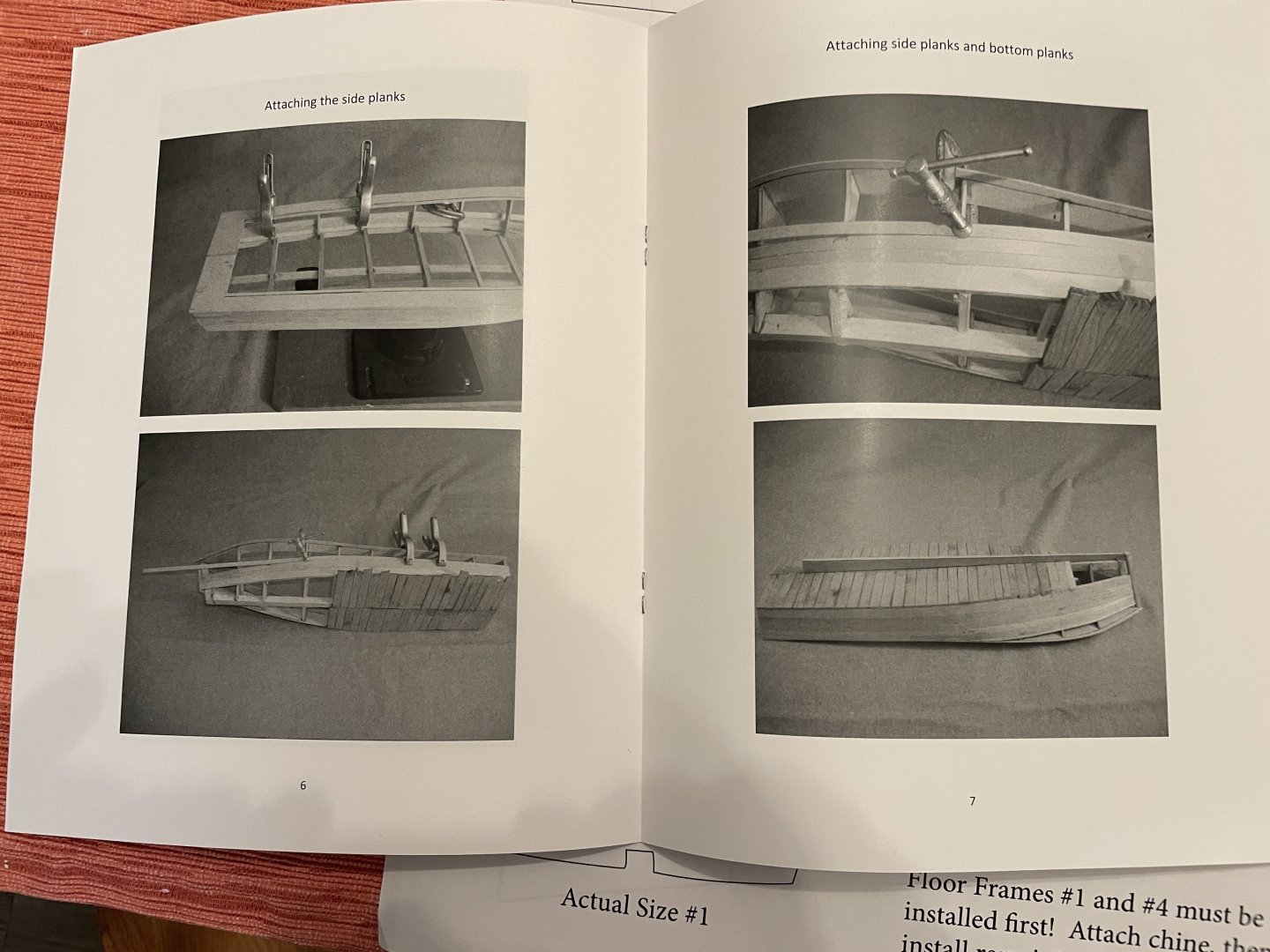

Cut floor frames for the other 4 members which had to be individually fit to the chine on the port and starboard side. Positioned and glued remaining frames to the keelson and chines. Several of the floor frames were high so were plained down so the floor will lie flat. Next, the 2 pieces of the deck were joined with a cross brace at the bulkhead and at the transom. Positioned and glued the deck to the bow stem, bulkhead and transom. Shaped the keel to fit flush to the keelson and glued. Cut and glued individual deck supports at each floor frame. The angle and position of these braces relative to the edge of the deck needs to be consistent so that when all planks are attached, their position relative to the deck is consistent. Installed one 1/2” hull plank to each side. In review of material provided, determined that 1/8” wide strips were provided instead of 3/8” wide. I will need additional 24” strips of 1/2” or 3/8” wide to complete the hull planks. Time for this build ~4 hours.

-

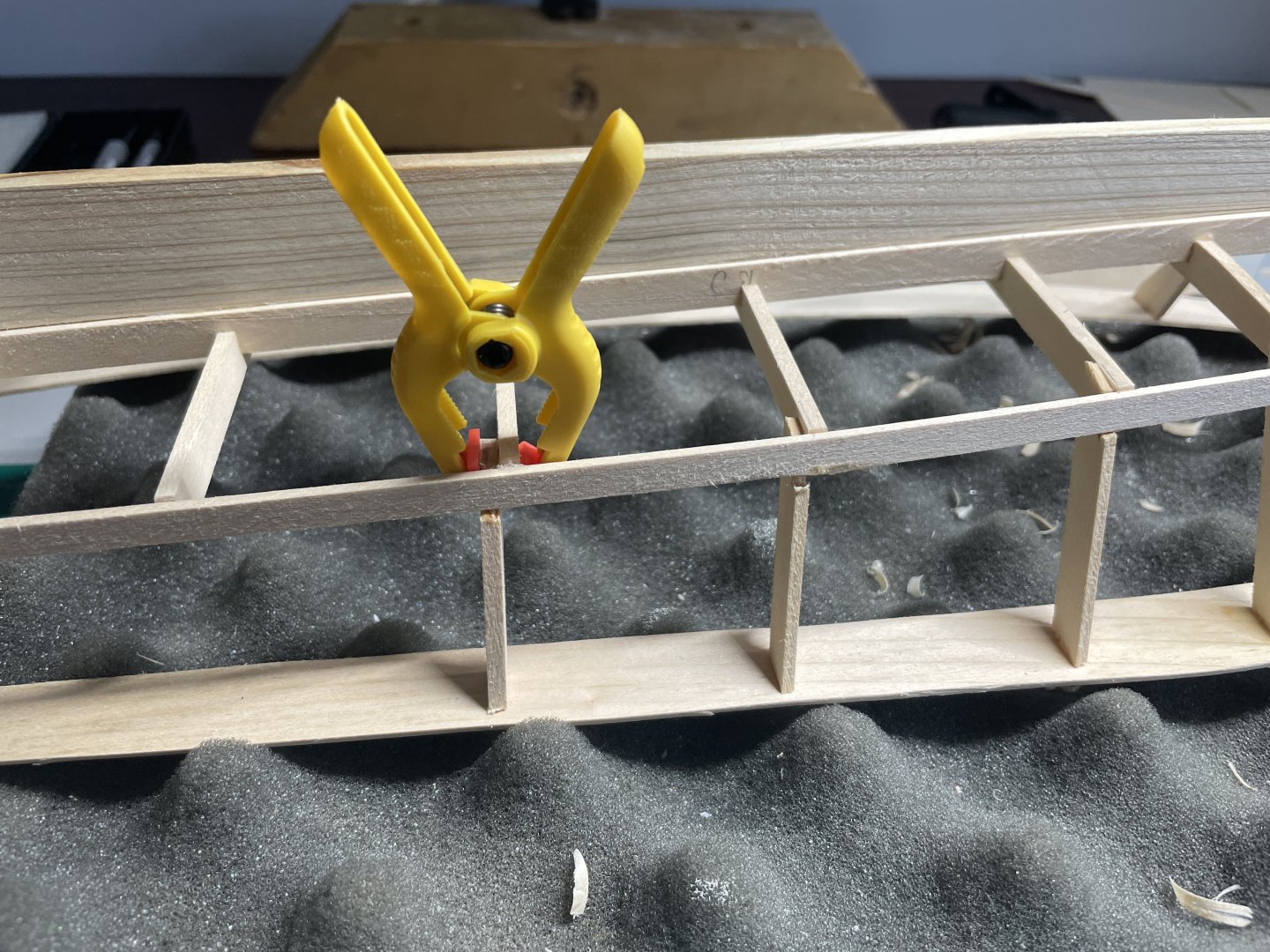

I built a table which allowed me to clamp the keelson for this part of the build. Installed the bow stem, bulkhead and the transom to the keelson. The plans called for floor frames number 1 and 4 to be installed first so that they align to the chine. I glued the chine to the bow stem, # 1 and 4 frames and the transom. Time for this build ~3 hours.

-

LJC started following Chesapeake Bay Box Stern Workboat by LJC - Wye River Models

-

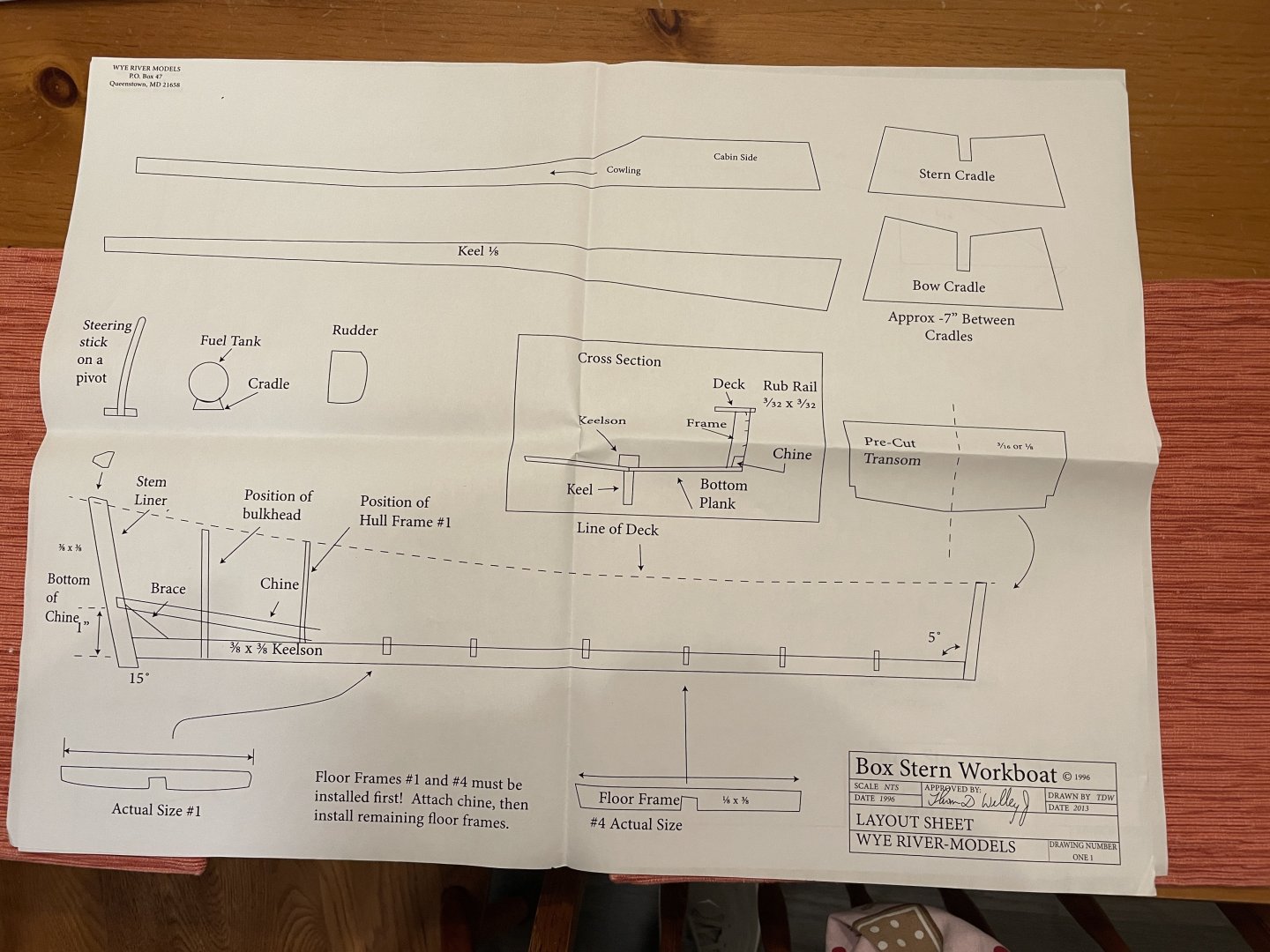

I saw this model and wanted to put it on my build list since these boats frequented Hampton Roads where I grew up. I also spent time on one of these boats that the Virginia Institute Marine Science chartered while we studied the changes that hurricane supplied freshwater had on the local rivers and Bay. Having some unexpected time off from my part-time job, I decided to start this model for my second build. I was a little concerned because I only saw one build log for the box stern and the log only documented part of the build. The kit arrived with an instruction manual (just pictures with no detail building instructions) and drawings along with a material list and supplies. I spent time reviewing the material list and handwritten changes to the list that didn’t jive with the material supplied. The material question was 1/16 x 3/8 strips of Balsawood, which is readily available so I don’t expect to have a problem. Review time ~1.5 hours

-

I’ve now finished the lobster smack and I’m pleased with my first build. Overall, my build time on this model was about 45 hours. I’m looking to order my next model and hopefully will do a better job of posting my build log as I go. Thanks to the many members who posted hints that help my build. Here are a couple of pictures of the final product.

- 18 replies

-

- muscongus bay lobster smack

- Model Shipways

-

(and 1 more)

Tagged with:

-

I tried several schemes to create coils for the jib line with little success. A search on model ship world got me to a jig that a member named Redshadowrider posted in message 326 on November 29, 2024. This worked well. Thanks.

- 18 replies

-

- muscongus bay lobster smack

- Model Shipways

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.