-

Posts

357 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by BRiddoch

-

Hello all, Since my last posting I have completed the thwarts and have started working on the aft seats and locker. I used boxwood on all the thwarts. Again, this was done to get a clean line with the scriber. Bob R.

- 100 replies

-

- model shipways

- 18th century longboat

-

(and 1 more)

Tagged with:

-

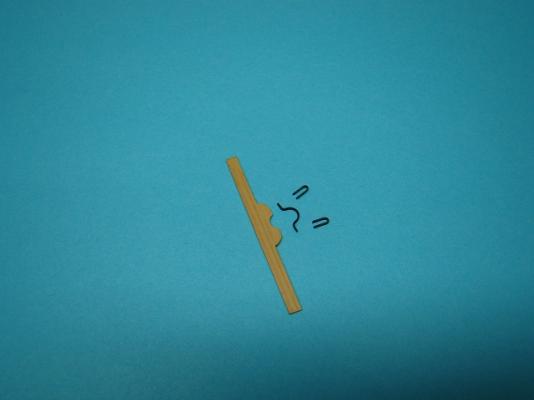

Hello all, It has been a while since my last post. Had a few family matters back east that required my attention. I'm home in San Diego now and back to building. While I was in Boston my new Byrnes Disc Sander arrived at home in San Diego. Nothing better that the anticipation of opening the box. Anyway, I am working on the Gunport lids. I am doing 7 at a time to break up the monotony. Small hinges are attached to the upper lids and painted white. False cannons are also added. Bob R.

-

Thanks Bob. I just can't deal with the basswood. I could not get a good groove. Bob R.

- 100 replies

-

- model shipways

- 18th century longboat

-

(and 1 more)

Tagged with:

-

Thanks Mike. I am in Seattle for the week but looking forward to getting home and working on both of my projects. Bob R.

- 100 replies

-

- model shipways

- 18th century longboat

-

(and 1 more)

Tagged with:

-

Added the strip below the frieze and the thwart supports. I used boxwood and was able to create a nice distinct groove. Bob R

- 100 replies

-

- model shipways

- 18th century longboat

-

(and 1 more)

Tagged with:

-

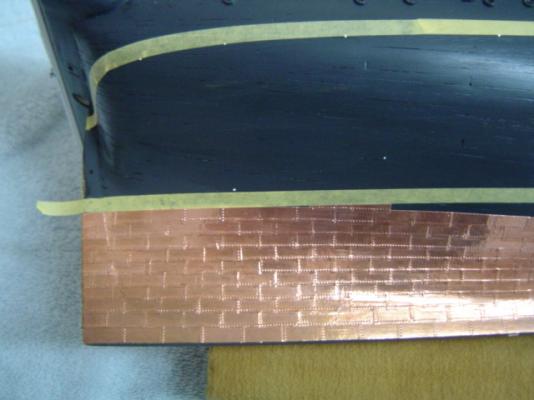

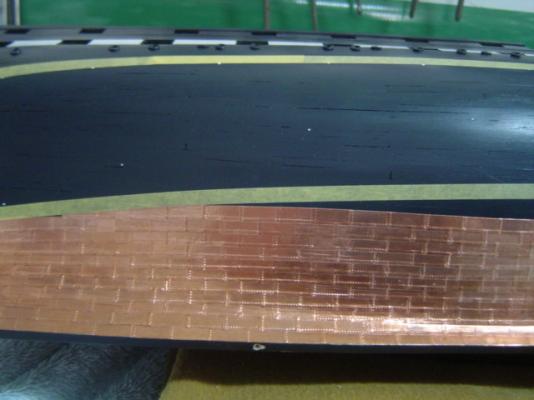

I am afraid I cannot speak intelligently on the properties of the tape or adhesive. Luckily I did not have the problem of "curl-up". I used a small piece of 3/16" x 3/16" basswood as a burnisher to press the tape down over both the wood and the lap over onto other pieces of tape. To date it still holds. I did not use a sealer as I am told that it tends to dull the appearance of the copper. Bob R.

-

JSGerson, I don't know the life span of the copper tape, but I can tell you this, it certainly sticks. It is difficult to work with but I had no problems with it sticking. I think the key is surface prep. You also need to avoid touching it. Once I had a few dozen plates applied, I used Armor-All Glass Cleaner to wipe it down with a lint free cloth. Bob R.

-

Looks great Mike. Looked even better in person. You should start a build log for the Fly. Bob R.

- 55 replies

-

- 18th century longboat

- model shipways

-

(and 1 more)

Tagged with:

-

Installed the floorboards and platforms. Most of my modeling has been taken up by copper plating the Constitution. I will start catching up with the group. Bob R.

- 100 replies

-

- model shipways

- 18th century longboat

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.