-

Posts

535 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Amalio

-

-

-

Thank you very much to all for your comments. I believe, that what important mas of this of the naval model-maker is the great adventure that he supposes. The quantity of new things that we are incorporating in every model. And now, a bit of philosophy: the aim the model can never be end, but enjoy his construction

-

-

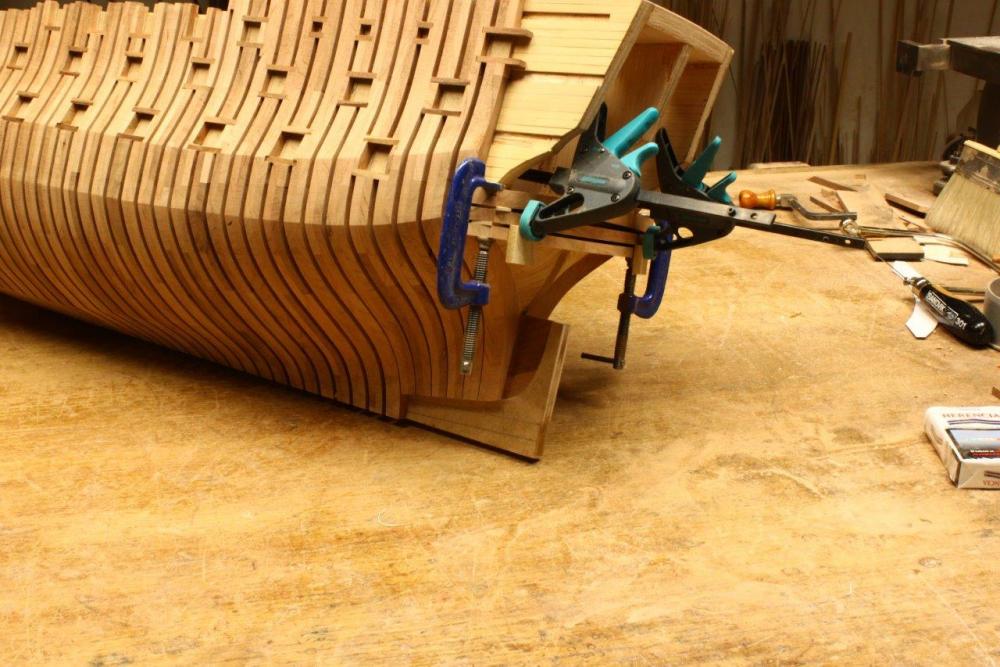

The mold can be had prepared in approximately one month. We have to bear in mind that to the forms that give us in the plane, it is necessary to discount the thick ones, both of the frames and of the keel, and do checkings with insoles of carton both to port and to starboard. To never forget that what we are going to do is the form of the interior of the hull.

-

It is a way of constructing that it is very trustworthy and comfortable since in the first phase, only we have to worry about the adjustment of the frame in his interior form. The exterior we it will fit when we have a group of complete finished frames. Of this form the thickness of the frame is controlled very well, without fear of remaining without wood especially in the zones of prow and stern. In addition, we can do any movement with the whole structure without dread to which nothing messes up of his site

-

-

-

It is a pleasure for my, to show my work in a site where it is so many teachers of the naval model-maker.

-

When I began it did not know it. Until I received a warning. It seems to me likely that like that is.

-

The mold will be extracted, when the exterior lining is put. It is necessary to extract it to chunks, and always from the center of the ship towards the ends. I ask you a bit of patience because everything will come. Thank you very much to all.

-

-

Thank you very much Adrian.

-

-

I am sorry. The translators, sometimes, do not work well. I do not understand what you want to say to me.

-

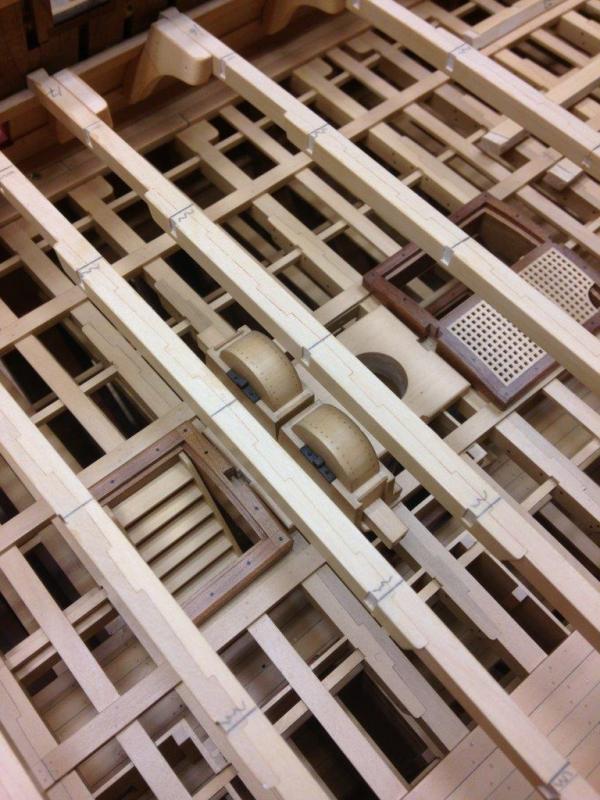

The tables of the interior lining are stuck to the mold, only in some points. All the tables are stuck by tail in his singing (Titebond). In some occasions I use warm tail to hold the lining to the mold, but only in isolated points.

-

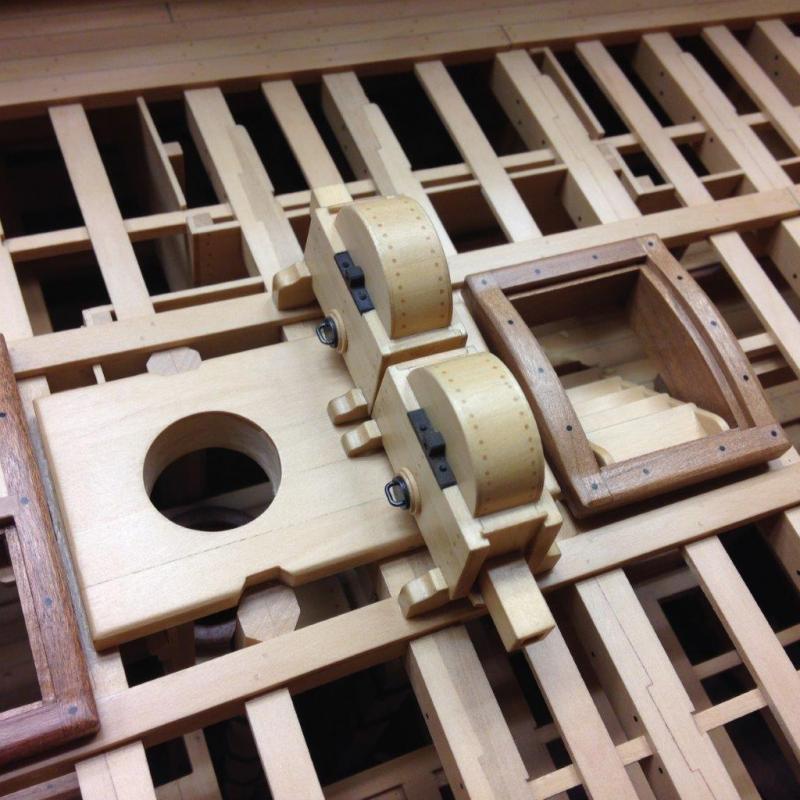

. Good days. The tables where I am sticking the frames, are actually, the interior lining of the hull. Hereby, we manage to have fact one of the most inconvinient things .of doing that it is the interior lining of the ship.

-

-

Thanks you very much.

-

-

These are the first ones that I have. I do not have photos of the construction of the interior mold, because it did not seem to me that they had a special interest. Hereinafter there will be photos in which it is possible to see the interior, when one takes the mold. Thank you very much.

-

Sorry, it's not easy for me.

-

Good Morning. The model is built to 1/48 scale and will be cherry wood used for the entire hull structure, frames, keel and small details of the covers, amarelo for the lining of the dead above the waterline work, and everything else, American boxwood. A greeting.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.