wilnatp

-

Posts

25 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by wilnatp

-

-

Congratulations. She looks great!

-

Spent 6 hours last night rigging. Photos will follow in the next couple of days. Still have about 1.5 hrs left in the rigging - needing to add the square sails and shrouds/ratlines.

I am currently debating whether or not to set the course sail and the topsail or just the topsail. I've seen both configurations on this model, but am leaning toward just the topsail so as to provide a bit more viewing of the deck and rigging.

@Mike, I really like the way that your sea turned out and have been going back and forth on adding it. I've decided against it for this build, but have saved a few clear bottles just to practice putting sea into.

I tried fitting the ship into the bottle without the masts and it was TIGHT. I'll be filing out some of the neck to make the fit a touch easier. -

Great work so far. Looking forward to seeing how easily she goes in. I am nervous for getting her to settle onto the stand and its pegs.

-

Carl and Mike. Thanks for the support. I am moving on to rigging now. Your build logs have been great resources for me.

-

I got the keel glued in (in its deeper slot now) and painted the hull again. Trimming up to the bulwarks and coating the keel.

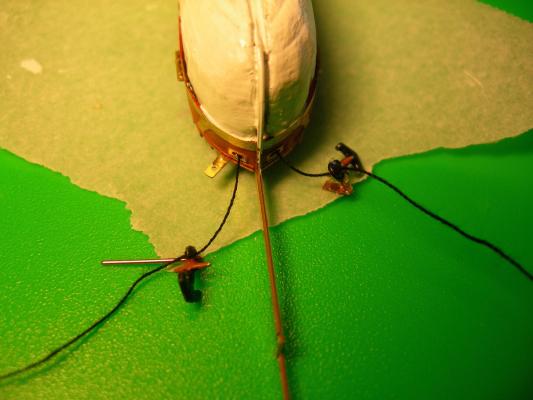

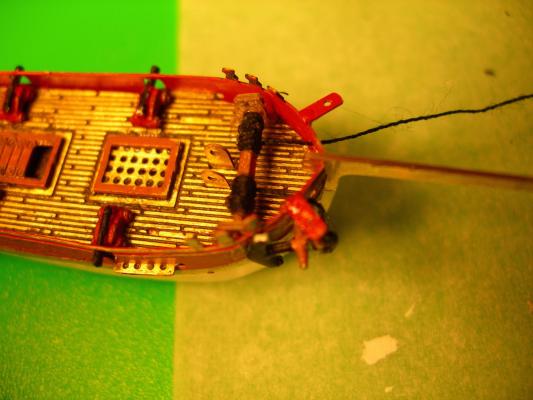

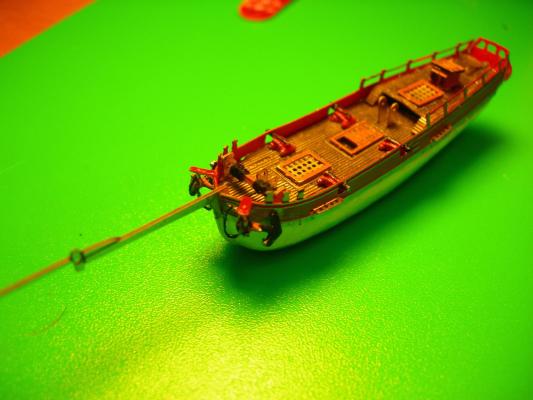

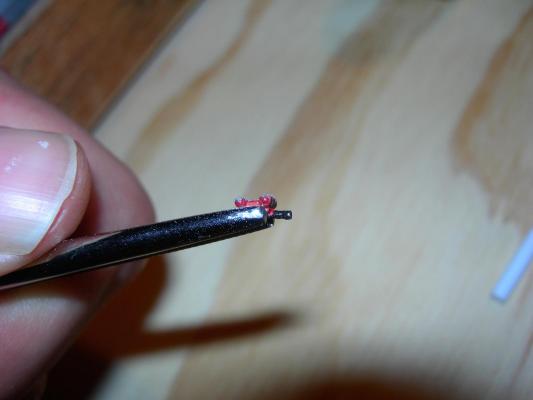

The anchors are to be tied on to the anchor line and then a copper eyebolt attached, the end of which runs into the cathead. I decided to not tie the anchors on. Instead I doubled the line back through the anchor. I attached the eyebolt, I was able to slide the anchor up and down the line to make it as short or as long as needed. This worked well for me to hold the anchor in place and get the slack line to the desired length. I attempted to slip the copper eyebolt up through the cathead and ended up breaking off the cathead. In this photo, the anchor on the right shows the cathead and the eyebolt glued to it.

Once dry, I used CA to reattach the cathead to bulwark. I also glued the anchor to the bulwark. When this dried, I was able to glue the line to the anchor and then cut it off. The plans show the anchors hanging, but I wanted them to be up as if they were lashed.

Got both hauled up and glued.

Here they are from the end of the bowsprit.

- Duanelaker, gjdale, IgorSky and 1 other

-

4

4

-

Final details on the deck house.

Attached the deck house and installed the cannon.

Prepared the winch. Used CA to glue thread onto the ends and wrapped the thread. I substituted the kit white thread for black cotton sewing thread. Same diameter but I like the black better.

Next up is attaching the winch to the deck - FORWARD of the mast step. This isn't accurate to the original, but necessary for the mast to be lowered far enough to fit into the bottle. I played around with a few ways of leaving the winch unglued and thus movable so that it could be glued in aft of the mast after insertion, but there wasn't enough slack in the anchor lines.

Keel was glued into place (with a lot less sticking out below the hull).

And then anchors were attached to the catheads.

Now you're caught up. I am waiting for Brass Black to arrive in the post so that I can blacken the yards and masts. I don't want to pain them as I am nervous that the coverage will either be too thin or too think and interfere with the raising ceremony.

-

Bulkheads were painted while still attached. Now they are removed from and CAREFULLY Bent to shape. The quarterdeck brass is glued on.

Now the quarterdeck is glued on, the bulwarks glued on, and the transom.

Fitting now showed that there wasn't a deep enough keel cut. The keel slot was deepened. Also needed to cut it deeper on the bow section.

Anchors were painted. I painted the cross bar brown as well.

-

-

I painted the deck pieces and then sanded off the paint. This allowed the lines between the "planks" to be filled with paint.

First time didn't take, so I had a second go at it. Then I painted the deck grating and glued them to the deck while it was still attached, making holding the small pieces much easier.

Glued the quarter deck to the hull. (But cut it off later when upon sizing i noticed that it was a bit too high)

Note the small gap between the bowsprit and the hull. This ends up not being enough - more on that later.

A view of the fit from the bottom. Again, I later realized that keel slot wasn't deep enough.

Now gluing on the first layer of brass decking.

-

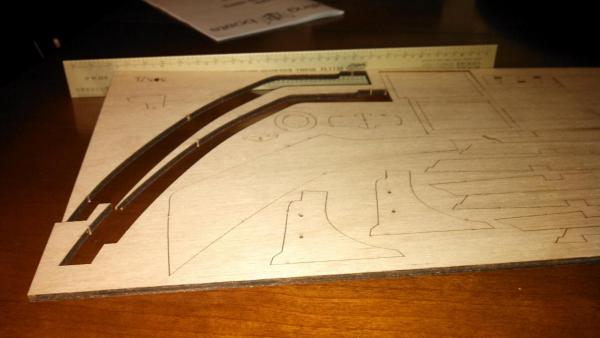

Per other builds - especially S. Kahn's - I cut the channel for the keel early on. See page 21 of the blog.

(NOTE: I don't recall what I did that got red on the hull here...)

Painted the deck back under the hatch areas.

Removed some of the hull decking to fit the quarter deck. Checking fit with the keel as well.

Painting the deck fittings prior to removing them from the brass. This was a lot easier with them attached.

-

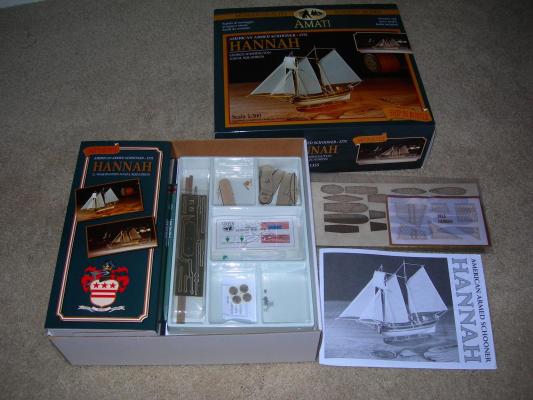

Started this kit about a year ago and took some photos, but didn't start my log. Life got busy and now I am back at the build and posting my log.

Available from Seagifts

Product Description (Copied from Seagifts) -- Wood model boat kit from Amati. All wooden parts are precut, for more accurate assembling, decks, and keel are photoetched, guns are metal casted. The kit includes: wooden hull, decks, masts, and skylights, glass bottle with wooden cap, cloth sails, and instruction booklet.Intermediate Skill Level:

Boat Length: 4-1/4", Height: 3-1/2", Scale 1:300Opening the box...

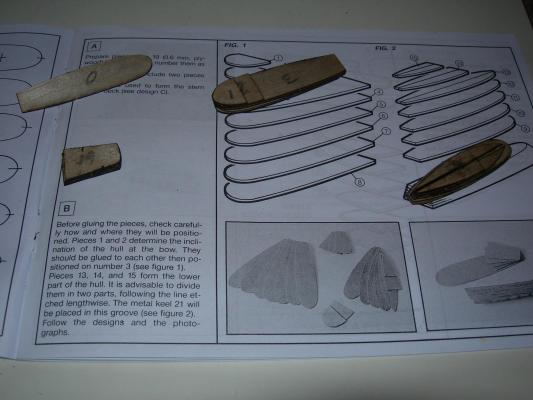

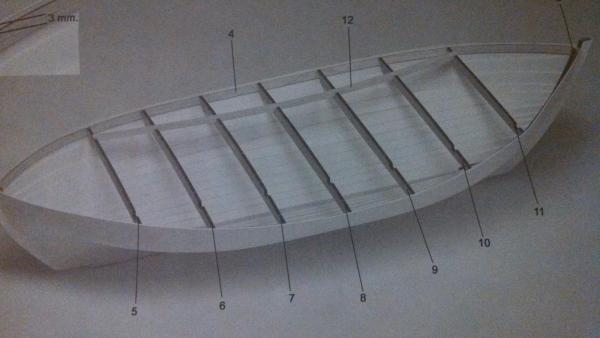

First step is to number each layer of the hull.

Then glue them together.

Sanded the hull, then painted, then sanded some more. At this point, there is the hull and the quarter deck as two separate pieces.

-

Thanks for the thoughts Hexnut. Due to the scale (1/15), most of my blocks are relatively large so super thin paint isn't a necessity; however, I test painted some Rust-oleum I had on hand. It was OK, but not was thin as I would like. I am going to look at getting some Tamiya when I get to the hobby store this weekend.

-

Now that the epoxy has dried, it is time to insert the support beams. The instructions show the beams on end it looks like. As best I can tell, they rise above the cross members.

Due to the concave nature of the deck (stem to stern) this would put a lot of stress on the support beam to bend it in such a way. In the photo, it may look like the beam is warping away from the deck, but it is indeed straight. (Optical illusion from the camera lens.)

There is room in the slots to fit two support beams side by side, or one on its side. Anybody see a problem with laying the beam on its side? It seems to follow the curvature of the deck better and allows for a continuous surface across the cross members.

In this photo the beam on the bottom is on its side and the beam on the top of the picture is on its end.

I am thinking I'll wait on placing the deck to see if hear back from the distributor on the deck planks that are missing. Additionally, I think I want to get my R/C components in or at least mapped out before making hull access harder.

The next few days will be busy with real life and work, but I am going to try and paint the plastic blocks that were included with the kit. Any recommendations on paint? I was planning to use a indoor/outdoor spray paint to get quick, even and light coverage that'll hold up to the wet sailing environment. Something like the product below?

-

As seen in the second photo in the post above, I had the cross braces in place while the epoxy set to hold the shape of the hull. Seen below, the braces do stretch the ABS hull a bit to get a tight fit.

Close up here

I used epoxy to glue in the cross braces and bit of tape to keep them aligned where they needed to stay.

While I waited for that to dry, i glued up two of the three deck hatches along with the mast step.

-

Saw the kit for sale last week at a local shop for $99. Haven't seen one built, but I think it would look great in a shadow box. Beyond a few completed photos and a kit on eBay, I couldn't find much info online.

This site shows great photos of the kit as well as a comprehensive history which is copied from the kit's manual. http://www.lacornamusa.com/blog/?p=73

Let us know if you proceed with this build!

[edit for spelling]

-

This book is now selling for about $40 used. http://www.amazon.com/Introduction-Radio-Controlled-Sailing-Models/dp/1900371200

Is it worth the $40? I am needing some basic information on the control aspects especially related to gaff rigs. The model I am building isn't extremely complex sail-wise, but there aren't manufacturer instructions on configuration of the the R/C components.

Thanks for your thoughts.

-

@Alistair thank you for your thoughts. There were only a few pieces which were warped and needed adjustment. These were the stem and stern posts. They flattened out well enough using your method. I placed then between two sheets of glass i had which helped prevent staining and ensured a flat surface.

After my detailed inventory, I have concluded that everything was included and to spec. except the deck planking. I am missing 42 strips of deck planking. Via a bright green sheet in the kit, Billings advised me to contact their US distributor - Great Planes Model Distributors. Considering the age of the kit, I checked Billing Boats' website as well as Google and found that Ages of Sail might be my best bet. Fired off an email, we'll see how that progresses. In the worst case, I'll make my own deck planks.

Progress tracker:

- Trimmed the excess plastic from the hull form.

- Washed the hull with soap to remove any oils etc. and prep for painting.

- Sanded and assembled the stand for the ship

- Flattened and then installed the stem and stern posts in the hull using Gorilla glue. The posts were too thick for the slots in the hull so i sanded them down a little. I did leave them a bit big so that the fit very snug. I used Gorilla glue because i wanted the glue to bond and fill any air space i had left due to an imperfect fit. Once i got the posts installed I held the boat in profile to the light and could see their dark shape filling the slots fully/adequately such that I was confident they were fully in place.

- Installed the framing strips. These run the length of the hull, 3mm from the top of each side. These strips will then hold the cross braces which will support the decking. I used epoxy to hold the strips in place. I broke on strip upon install but was able to epoxy the break and still get it all in place. The cross braces really help to provide shape to teh hull. The fit tightly into place with pressure alone. In placing them, there is noticeable movement of the hull sides, soI let them in place while the framing strips are drying to encourage proper shaping of the strips. Once those dry (i.e. while I am at work), I'll be able to glue the cross braces in place.

-

Greetings,

This is my first build log, and I currently have 3 ships in dry dock. I am working on a Hannah SIB (1/3 completed, and build log pending), MSW Fair American (still on the lofting floor), and this Billings Boats Karoline model.

Karoline was a Dutch Potato Boat in the winter and a fishing boat in the summer. The kit consists of an ABS hull with brass and plastic fittings and cloth sails. Length: 1080mm / 42.5in Beam: 330mm / 13in Scale: 1/15

I picked this up this week from a local Hub Hobby in MN. The kit had been on the shelves for a LONG time. I saw it there 5 years ago and almost bought her but decided against it. I have regretted the decision, but was excited to see it still there and at discount. Not sure how long they have had it, but from what I can tell, the model is from the '80s. The factory plastic wrap was still on the box, but had some rips and moving the box produced quite a clatter of pieces inside. The helpful cashier allowed me to open the box and inspect all the pieces prior to purchase to ensure nothing was broken or obviously missing.

Fast forward two nights. Last night, in my spare moments I decide to do a detailed inventory of the parts and instructions etc. Pretty basic instructions in the "Ikea fashion" of lots of picture with hardly any text. Shouldn't prove to be too complicated of a build; however, rigging might be a bit of an issue. As I started to work on the hull (which is molded plastic and will receive wood framing for the deck and gunwales), I noticed my first challenge. The sheet of plywood pieces is warped.

The missing pieces there are the stem and stern posts which have some torque to them as well.

Any thoughts on how to flatten this piece of wood?

Thanks for your help.

The plan for tonight after work will be to cut the excess plastic off of the hull and wash it to have it ready for painting when the time comes.

Yours,

Nathan

EDIT: Added more photos.

Unboxing: -

Wallyh,

It looks like you may have already made up your mind, but i just came across this post from KenW this week, and though I would share.

As you see in post #121 from his Fair American build, he added a companion way. I really like the way it looks and am considering doing the same on mine.

Cheers!

Nathan

-

Figuerres,

I hope that all is well. I was wondering if you could post more info and maybe picture regarding your lighting? I am interested in the idea of making a 'real' cabin as you are doing and I have really been kicking around the idea of lighting the kit, but have no experience with lighting models.

What and where is the power supply?

What kind of components did you order for lights, wiring, switches etc.?

Is there some book or article I should be reading to get a more knowledge on the subject?

Thank you for sharing your build with us.

Nathan

-

Great work Ken. The stern painting is very well done!

Thinking I might do some model work tonight myself. Here in MN it is -17 (wind chill to -43) with blowing snow. Makes me imagine the horror experienced by Franklin's Erebus and Terror and the lost expedition.

-

Silly question, but can you please expand on why you are using the pencil? And where you are using it?

I am new to wooden models and researching before striking out on my first wooden build.

Thank you,

Nathan

-

@Ulises Victoria - That is a great idea. When sewing clothes for my other hobby, I use wax on the thread to help it slide through the cloth but also protect the thread from sweat. I'll try this out on my next build.

@Daniel - Using wallpaper glue is a new idea. Thanks for that tip!

Thanks all for the great input. Keep it coming if you have additional thought!

Nathan

-

I have scratch built a wood model without much detail and built a plastic kit model. In both instances, the rigging on the ships has started to sag over time. The initial knots are tight (most with spots of glue) but where there was once a taut line, the lines sag. This is the case for both running and standing rigging but mostly the standing rigging.

Is this due to the type of thread or how I prepped it, or is this just part of the entropy? Can it be prevented or staved off or is option to rerig the ships?

Also, is there type of glue that you like to use on your rigging if glueing knots or anchor points that doesn't show as shiny?

Thanks!

Nathan

Lifeboat RS1 Colin Archer by IgorSky - BOTTLE - scale 1/230 - Finished

in - Build logs for subjects built 1851 - 1900

Posted

Beautiful project. What did you use for sea in the bottle? It is a lovely color and texture!

Nathan