dogface

Members-

Posts

26 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by dogface

-

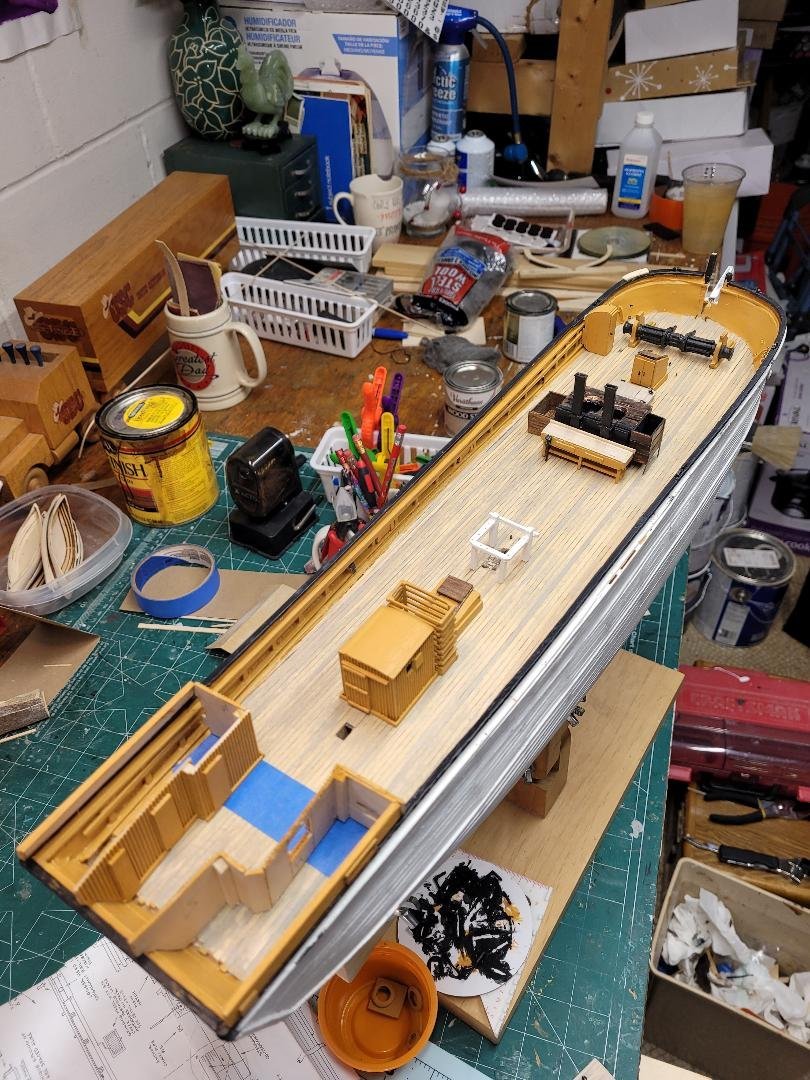

Just an update on where I'm at on my CWM build. As noted by other CWM builders, this model is quite difficult and can be overwhelming at times. here are some pics of the deck furniture I got done. I may re-do some pieces. Also, I tried the skylight 3 times without success. will probably try it again though.

-

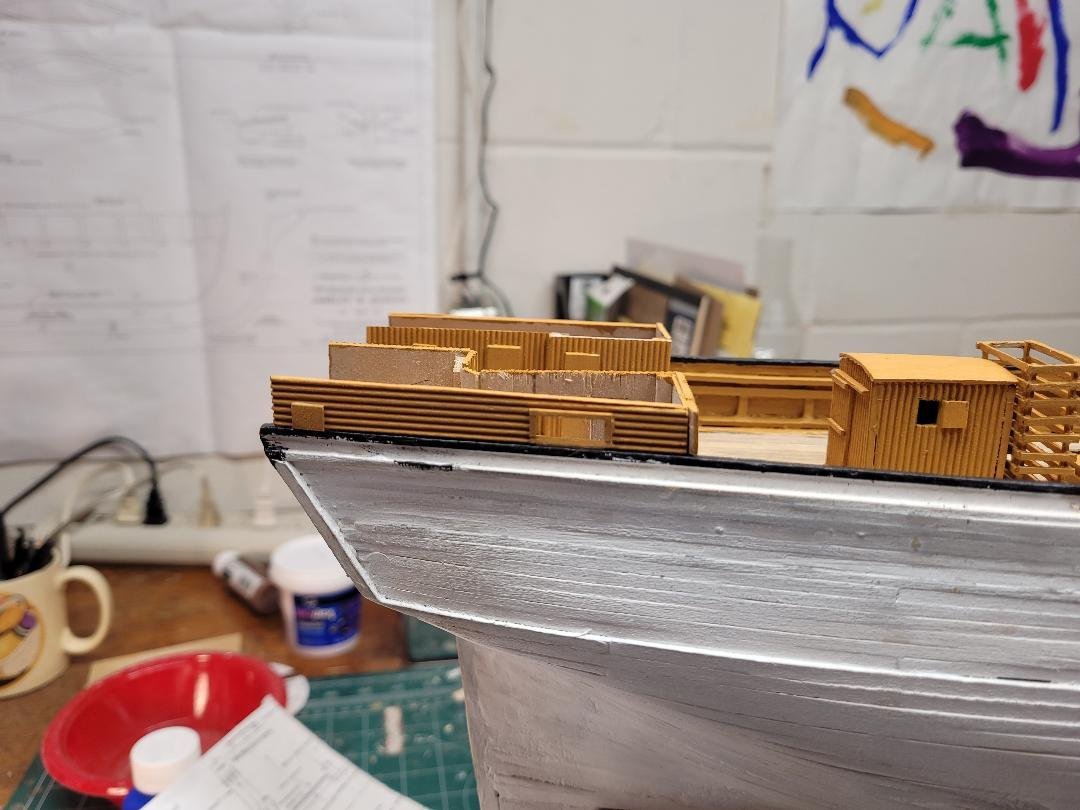

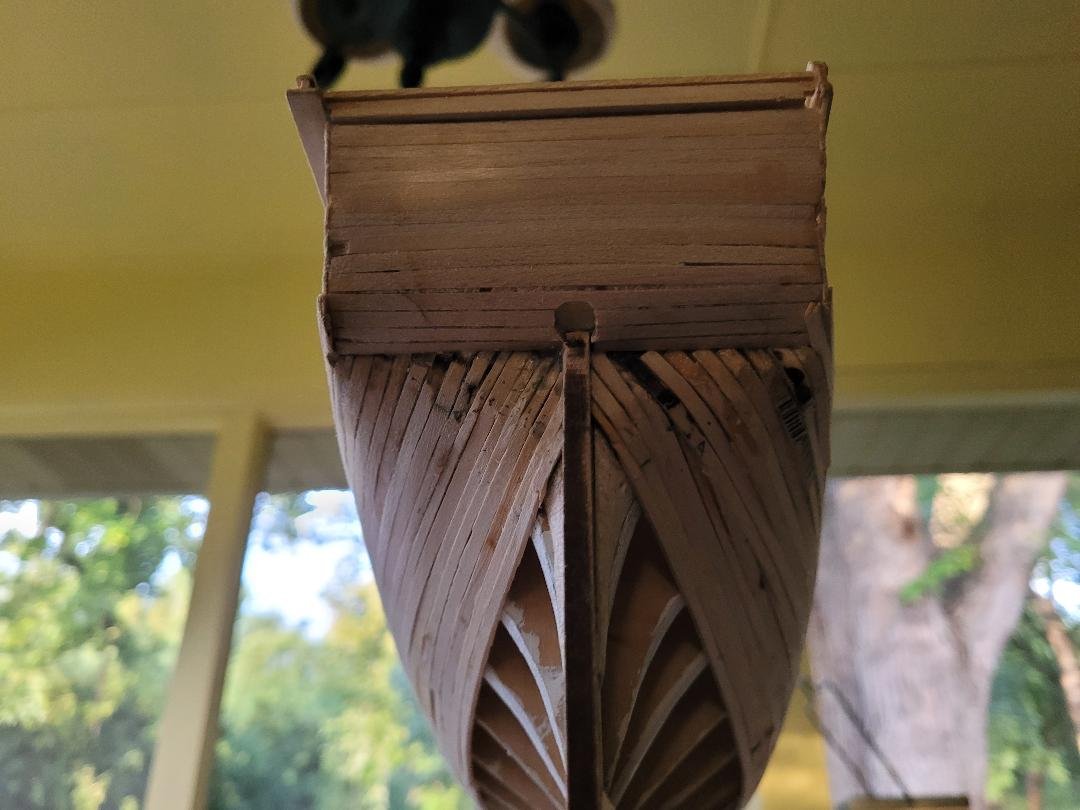

I have completed planking band 'A' on the port side. Pretty rough I know but it's about the best I can do right now. I'll add some filler and make it look as best I can. I'll add a 1/16 strip where the planksheer juts out from the hull. My wale line is not great but like I said, it's the best I can do. There is almost no tolerance for error on this build, and like I said, it's somewhat beyond my skill level. I only use hand tools. I'm actually pleased at how I was able to get the planks to bend into the transom area at the stern. Studied several videos regarding how to bend wood; Chuck Passaro's work is especially helpful. Anyway, comments and advice always welcome. Thanks! Jon

-

Thought I would post again to let you know I haven't given up on this build. I may be in over my head with the CW Morgan, but I've wanted to build her for a long time. Regarding the issues with the planksheer in my earlier posts, I basically started over and have posted photos. Don't judge me too harshly, I know there are some incredibly skilled modelers on this forum, and their build logs have been very helpful for me! BTW, the parts people at Model Shipways were very gracious in sending me several replacement parts. I appreciate their customer service. Anyway, here's where I'm at now.

-

JJ, thanks for the good advice and encouragement. I restarted the whole thing over and have been studying planking videos and practicums. Cisco, I agree that soaking and bending works well, and steam works really well. I lose a lot of wood too! Keep working at it; once youy figure out what works, it gets much easier. Jonb

-

I decided to basically start the build over. The planking was not going well and instead of trying to fix everything, I ordered new bulkheads, keel and some new wood strips from Model Shipways (they have been great with free replacement parts). Since I'm not that far into the build I would rather start over than fix all the mistakes I've already made. Jon

-

great work Tom. very helpful as you are a bit ahead of me. Jon

- 200 replies

-

- Whaling Bark

- Charles W Morgan

-

(and 1 more)

Tagged with:

-

also, I started the planking. I'm moving slowly, looking t other build logs and trying to follow Chuck Passaro's planking videos re: edge bending. I'm having a hard time at the stern because the planks not only bend but they twist to meet the counter. not sure what I'm doing wrong? comments welcome as always.

-

I decided to fill the plankshear gap by placing a wider strip along the side, and the shape it: the plankshear is still wider than it should be but I'll have to live with it. Looking at the profile view, (pic 3), it's about the best i can do. I don't have power tools to cut wood, so it's just me, an exacto blade, and sandpaper.

-

I'll post pictures when I get it figured out. I think I will end up having a wider plank shear amidship than is proper, and then taper it down to 1/16" square toward both the bow and the stern as the plans indicate. Hopefully, I'll be able to hide the mistake among all the other items placed on the outer hull, chainplates, rigging etc.

-

Hey everyone, Thought I should start my own build log for my Charles W. Morgan. However, when I started the build, I hadn't really looked at other build logs and of course by the time I did, I had already made an embarrassing mistake. The pictures below show the error -- I neglected to make sure the plankshear on both port and starboard sides ran out past the the bulkheads. You can see the gap formed between the upper planking and the outside of the bulkheads where the plankshear should be covering the bulkheads, especially amidship. Did I make a fatal mistake and should I start over? That is, should I tear out the planking, the stanchions, the main rail, and the plankshear, and do it over? Or if I fill the gap and place an artificial plankshear on the hull using a 1/16 square strip, could I "hide" the gap, or will I run into too many problems as the build progresses? Thanks, Jon

-

hey Tom, thanks for the quick response. yours is a good log for me to follow. Im sure I will have additional questions (if you don't mind)! Jon

- 200 replies

-

- Whaling Bark

- Charles W Morgan

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.thumb.jpg.c6ec69232688abd5c5dfc36669f11855.jpg)