-

Posts

897 -

Joined

-

Last visited

-

Rudolf reacted to a post in a topic:

Charles W Morgan 1841 by toms10 - FINISHED - 1:96 - POB

Rudolf reacted to a post in a topic:

Charles W Morgan 1841 by toms10 - FINISHED - 1:96 - POB

-

Rudolf reacted to a post in a topic:

Charles W Morgan 1841 by toms10 - FINISHED - 1:96 - POB

Rudolf reacted to a post in a topic:

Charles W Morgan 1841 by toms10 - FINISHED - 1:96 - POB

-

Rudolf reacted to a post in a topic:

Charles W Morgan 1841 by toms10 - FINISHED - 1:96 - POB

Rudolf reacted to a post in a topic:

Charles W Morgan 1841 by toms10 - FINISHED - 1:96 - POB

-

Hi Jack thanks for the compliments throughout my build log. Sorry you won’t be at the conference. I know how “real life” can get in the way. See you at the he next one! Tom

- 197 replies

-

- Whaling Bark

- Charles W Morgan

-

(and 1 more)

Tagged with:

-

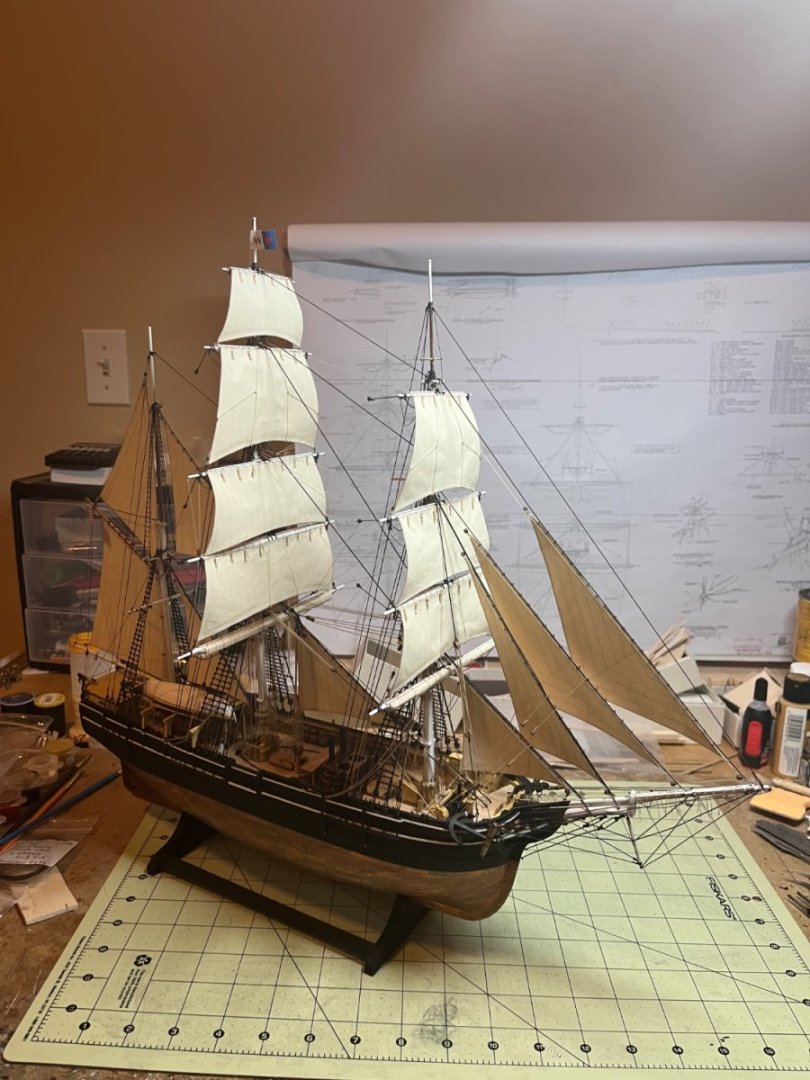

Well I guess it’s a wrap. I completed my Charles W. Morgan today. It has been an educational and fun 2 year journey. Thanks to everyone here on MSW for all the support. Not sure what my next build will be. I will take a break for a bit. I still have a 9000 piece puzzle of the Battle of Algiers. That will be a good project to take a break with. Here are some final pics. I need to figure out how to make an album and mark the build log finished. Happy modeling!

- 197 replies

-

- Whaling Bark

- Charles W Morgan

-

(and 1 more)

Tagged with:

-

We the day finally came, all the sail rigging is complete. The only things left to do is rig the cutting stage, attach the davits and then rig the whaleboats to the davits. Sounds simple enough…..yeah right!😂🤪😜😁 The light at the end of the tunnel is getting brighter! 😁 Tom

- 197 replies

-

- Whaling Bark

- Charles W Morgan

-

(and 1 more)

Tagged with:

-

Sails on the foremast installed and rigged except for the braces. Time to start on the main mast sails. Seems like there is always something cropping up to be done. I still have to install all the davits and whaleboats! I don’t think this model will ever be completed! 🤪😂 I am hoping to finish in time for the Northeast Joint Conference ant the end of April. Allowing for life getting in the way it is going to be very close! 🤪😜😁 Tom

- 197 replies

-

- Whaling Bark

- Charles W Morgan

-

(and 1 more)

Tagged with:

-

Hi Allen, Yes you are correct. You need to have bare wood for the stain to soak into the wood. You can seal it afterwards with urethane or shellac if so desired. There is a product you can apply to wood before staining called a leveler. It is a watery substance that is intended to help level out the color when applied to wood with coarse or varying grain texture on large surfaces. I don’t think it is necessary with the types of wood we use and relatively small surface areas. Tom

-

All the fore-aft sails except the gaff and spanker sails are installed as well as a furled fore sail. I will continue with the fore mast yards and work my way aft. Tom

- 197 replies

-

- Whaling Bark

- Charles W Morgan

-

(and 1 more)

Tagged with:

-

Finally got my first sail up along with the fore yard. All the hanging coils of rope waiting to be belayed will slowly start to disappear and become orderly…..I hope. 🤪 Tom

- 197 replies

-

- Whaling Bark

- Charles W Morgan

-

(and 1 more)

Tagged with:

-

John, I ended up cross tying the battens just for appearance. I think the knot adds a bit of realism instead of just a flat intersection of the batten and the shroud. The port side is complete! Only another 268 more to go on the starboard side but who is counting! 😂 Hope everyone has a great holiday season. 😁 Tom

- 197 replies

-

- Whaling Bark

- Charles W Morgan

-

(and 1 more)

Tagged with:

-

Hi Brian, I just cut off enough line to get from where the line starts to where it gets tied off and then add about another 1 1/2” for tying off to the belaying pin. One end is usually fixed to a block or eye, then run through whatever blocks are hanging under the tops, trees, etc. the loose end is just coiled up by wrapping it around my finger and then putting a small strip of the sticky note pad paper around it to kind of keep things organized. I also write down what line it is on the paper so I don’t have to go back and retrace which line is which. Tom

- 197 replies

-

- Whaling Bark

- Charles W Morgan

-

(and 1 more)

Tagged with:

-

Hi John They are glued in place. I may cross tie them later just for appearance. Tom

- 197 replies

-

- Whaling Bark

- Charles W Morgan

-

(and 1 more)

Tagged with:

-

Managed to get all the lower rat lines or should I say “rat slats” since these are wooden. The upper ones will be rope so I see many clove hitches in my future. 🤪😜. Actually at 1:96 scale, I think I will do some test lines to see if the knots will look too bulky. The rats will be done with .005” diameter thread to maintain scale but I don't want the knots to be the dominant feature. The picture is a bit cluttered in the background and there are coils of rope with labels hanging everywhere but you get the idea. 😁 Tom

- 197 replies

-

- Whaling Bark

- Charles W Morgan

-

(and 1 more)

Tagged with:

-

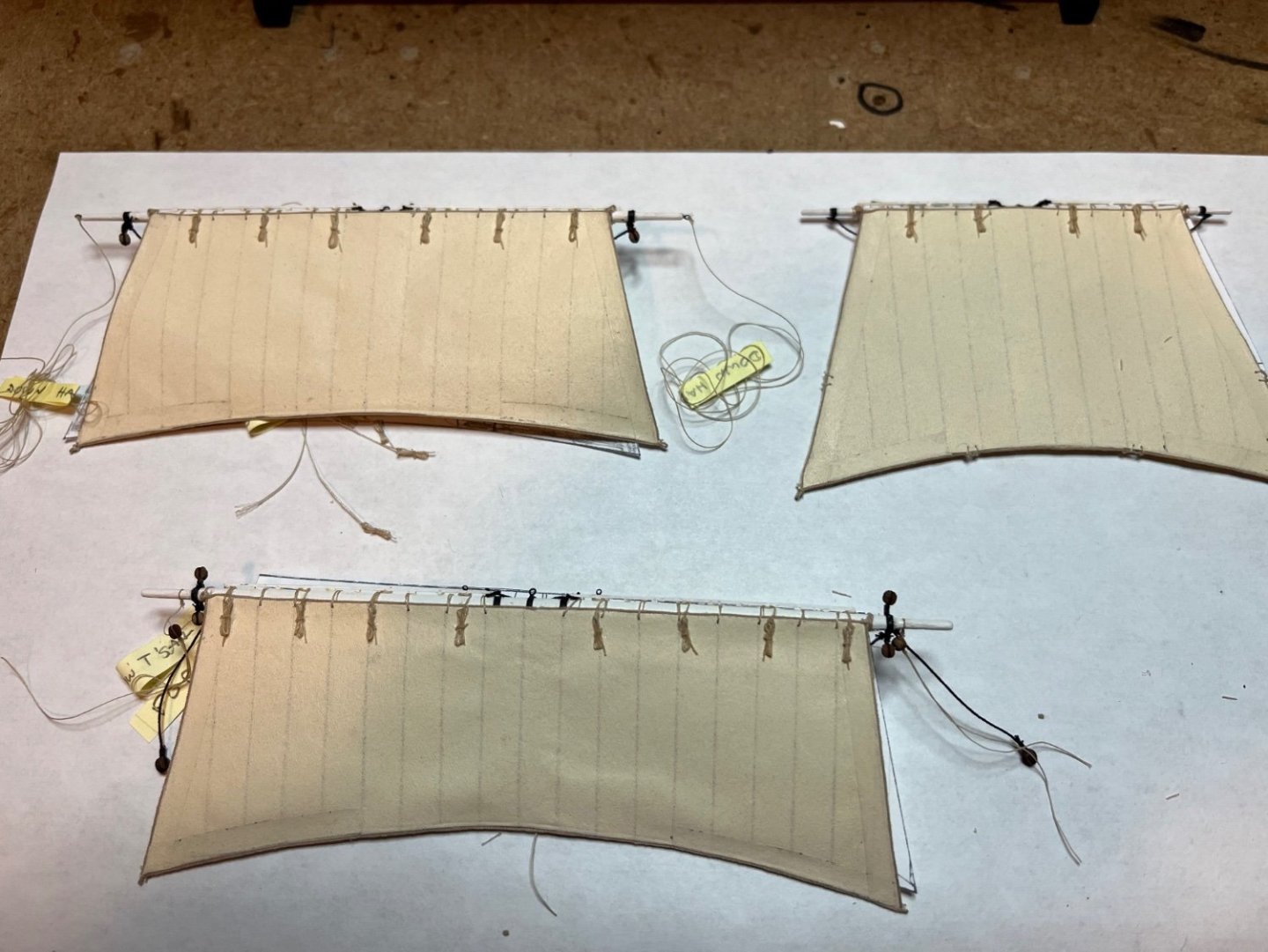

I make mine out of silkspan. As mentioned earlier, material is a bit too much out of scale at most scales used especially if you are going to use a sewing machine for seams. There are some basic instructions on how I make them on my Leopard and currently in progress Morgan builds. Dre the links in my signature. Tom

-

Hi John From what I read, I guess early on they used to carry the gasket ropes up with them when furling sails. I guess somebody got smart and just left them tied to either the yard or jackstay if there was one. Tom

- 197 replies

-

- Whaling Bark

- Charles W Morgan

-

(and 1 more)

Tagged with:

-

Managed to get all the sails except for the main and fore course sails bent to their respective yards. Also made some gaskets and hung those from the jackstays just for some added detail. Here are pics of the fore sails. and a close up of one of the gaskets. Still have to do all the hanks on the stay sails and bend the top gaff and spanker sails to their yards. Seems like their is always something else to do when working with sails. Tom

- 197 replies

-

- Whaling Bark

- Charles W Morgan

-

(and 1 more)

Tagged with:

-

Thanks Rick. Hope your family has a great Thanksgiving. Tom

- 197 replies

-

- Whaling Bark

- Charles W Morgan

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.jpg.d84ec4dad1d7791e855dca06210ab6f3.thumb.jpg.f45209242e851d4409eca1a09293165b.jpg)