Dsmith20639

NRG Member-

Posts

254 -

Joined

-

Last visited

About Dsmith20639

- Birthday 01/21/1945

Profile Information

-

Gender

Male

-

Location

Solomons Maryland

-

Interests

Wooden ship models, Pocher Auto models, woodworking, turning.

Recent Profile Visitors

-

wtimlen reacted to a post in a topic:

Chesapeake Bay Skipjack by Dsmith20639 - FINISHED - Horizon - 1/32

wtimlen reacted to a post in a topic:

Chesapeake Bay Skipjack by Dsmith20639 - FINISHED - Horizon - 1/32

-

Dsmith20639 reacted to a post in a topic:

Fifie by Ken_2 – FINISHED - Amati/Victory Models – 1:32 - Scottish Motor Fishing Vessel

Dsmith20639 reacted to a post in a topic:

Fifie by Ken_2 – FINISHED - Amati/Victory Models – 1:32 - Scottish Motor Fishing Vessel

-

Ken_2 reacted to a post in a topic:

Fifie by Ken_2 – FINISHED - Amati/Victory Models – 1:32 - Scottish Motor Fishing Vessel

Ken_2 reacted to a post in a topic:

Fifie by Ken_2 – FINISHED - Amati/Victory Models – 1:32 - Scottish Motor Fishing Vessel

-

Dsmith20639 reacted to a post in a topic:

Fifie by Ken_2 – FINISHED - Amati/Victory Models – 1:32 - Scottish Motor Fishing Vessel

Dsmith20639 reacted to a post in a topic:

Fifie by Ken_2 – FINISHED - Amati/Victory Models – 1:32 - Scottish Motor Fishing Vessel

-

Scottish Guy reacted to a post in a topic:

Professional Building Slip - Hobbyzone

Scottish Guy reacted to a post in a topic:

Professional Building Slip - Hobbyzone

-

Dsmith20639 reacted to a post in a topic:

Sloop Speedwell 1752 by Rustyj - Syren Ship Model Company - 1:32 Scale - POF Sloop

Dsmith20639 reacted to a post in a topic:

Sloop Speedwell 1752 by Rustyj - Syren Ship Model Company - 1:32 Scale - POF Sloop

-

Dsmith20639 reacted to a post in a topic:

Fifie by Ken_2 – FINISHED - Amati/Victory Models – 1:32 - Scottish Motor Fishing Vessel

Dsmith20639 reacted to a post in a topic:

Fifie by Ken_2 – FINISHED - Amati/Victory Models – 1:32 - Scottish Motor Fishing Vessel

-

Dsmith20639 reacted to a post in a topic:

Sloop Speedwell 1752 by Chuck - Ketch Rigged Sloop - POF - prototype build

Dsmith20639 reacted to a post in a topic:

Sloop Speedwell 1752 by Chuck - Ketch Rigged Sloop - POF - prototype build

-

Dsmith20639 reacted to a post in a topic:

Fifie by Ken_2 – FINISHED - Amati/Victory Models – 1:32 - Scottish Motor Fishing Vessel

Dsmith20639 reacted to a post in a topic:

Fifie by Ken_2 – FINISHED - Amati/Victory Models – 1:32 - Scottish Motor Fishing Vessel

-

Dsmith20639 reacted to a post in a topic:

Sloop Speedwell 1752 by Chuck - Ketch Rigged Sloop - POF - prototype build

Dsmith20639 reacted to a post in a topic:

Sloop Speedwell 1752 by Chuck - Ketch Rigged Sloop - POF - prototype build

-

mtaylor reacted to a post in a topic:

Books for Sale

mtaylor reacted to a post in a topic:

Books for Sale

-

Some books sold, here's what's left. Title Price Date Author The National Watercraft Collection 7.00 1960 Howard L. Chapelle Model Power Boats 15.00 1929 Edward W. Hobbs Building and Operating Model Ships 7.00 1965 Walter A. Musciano Ship Modeling Techniques 25.00 1990 Portia Takakjian Historic Ship Models (2) 4.00 1073 Toby Wrigley Ship Models Illustrated (3) 4.00 1943 F. Ward Hartman Prisoner of War Ship Models 10.00 1987 Ewart C. Freeston Planking the Built-Up Ship Model 5.00 1987 Jim Robert’s American Ship Models 5.00 1942 V.R. Grimwood Plank-on-Frame Models Volume II 20.00 1998 Harold A. Underhill Ship Models in Miniature 7.00 1975 Donald McNarry Down-Easter building a model of the Benjamin F. Packard 6.00 1954 Roger Weare Brandon Ship Modeling from Scratch 3.00 1994 Edwin B. Leaf The World of Model Ships and Boats 3.00 1971 Guy R. Williams Scale Model Ships 12.00 1951 Bernard Reeve and P.W. Thomas Building Model Ships from Scratch (3) 4.00 1977 Kent Porter Watercraft Modeler’s Handbook 8.00 1988 Benjamin Langford Jr. Miniature Boatbuilding 20.00 1928 Albert C. Pritchard Ship Model Making: Clipper Ship 10.00 1926 E. Armitage McCann

-

Vlax reacted to a post in a topic:

Books for Sale

Vlax reacted to a post in a topic:

Books for Sale

-

CiscoH reacted to a post in a topic:

Books for Sale

CiscoH reacted to a post in a topic:

Books for Sale

-

woodartist reacted to a post in a topic:

Fifie by Dsmith20639 - FINISHED - Amati - 1/32 scale

woodartist reacted to a post in a topic:

Fifie by Dsmith20639 - FINISHED - Amati - 1/32 scale

-

I am in the process of cleaning up my library. As a result, I have the following list of books for sale. If interested send me a PM, the first message received will be the buyer. Once I have your response and location I will respond with the total including shipping cost. Look up the titles on ebay or bookfinder for comparison. You can also make an offer. If you prefer I can ship first and you can pay me after receiving the items. Title with a number in parens, like (2) indicate multiple copies available. Title Price Date Author The National Watercraft Collection (2) 7.00 1960 Howard L. Chapelle Model Power Boats 15.00 1929 Edward W. Hobbs Building and Operating Model Ships 7.00 1965 Walter A. Musciano Ship Modeling Techniques 25.00 1990 Portia Takakjian Historic Ship Models (2) 4.00 1973 Toby Wrigley Ship Models Illustrated (3) 4.00 1943 F. Ward Hartman Prisoner of War Ship Models 10.00 1987 Ewart C. Freeston Planking the Built-Up Ship Model 5.00 1987 Jim Robert’s The Colonial Schooner 1763-1775 8.00 1981 Harold M. Hahn American Ship Models 5.00 1942 V.R. Grimwood Rigging Period Ship Models 15.00 2018 Lennarth Peterson Plank-on-Frame Models Volume II 20.00 1998 Harold A. Underhill Ship Models in Miniature 7.00 1975 Donald McNarry Down-Easter building a model of the Benjamin F. Packard 6.00 1954 Roger Weare Brandon Ship Modeling from Scratch 3.00 1994 Edwin B. Leaf The World of Model Ships and Boats 3.00 1971 Guy R. Williams Scale Model Ships 12.00 1951 Bernard Reeve and P.W. Thomas Building Model Ships from Scratch (3) 4.00 1977 Kent Porter The History of American Sailing Ships 6.00 1935 Howard I. Chapelle The Bomb Vessel 15.00 1994 Chris Ware Watercraft Modeler’s Handbook 8.00 1988 Benjamin Langford Jr. Miniature Boatbuilding 20.00 1928 Albert C. Pritchard The Cutty Sark 20.00 1975 C. Nepean Longridge Ship Model Making: Clipper Ship 10.00 1926 E. Armitage McCann

-

chris watton reacted to a post in a topic:

Fifie by Dsmith20639 - FINISHED - Amati - 1/32 scale

chris watton reacted to a post in a topic:

Fifie by Dsmith20639 - FINISHED - Amati - 1/32 scale

-

I think I made note of most of the problems with the kit as they occurred in my build log. Let me know by replying here if and when you start your build log and I will follow along and try to answer any questions you may have. As noted, I hated the MDF and the row boat was a challenge in itself. The kit is BIG. Planking the hull posed problems because off the thickness of the planking material so the final results were not up to my normal standards, but I thought the pictures on the box with exposed wood planks were unrealistic and that's why I fully painted the hull, also painting covers up a lot of minor mistakes. The final steps of finishing the model, rigging the masts, etc. is not difficult but the instructions at the end of the manual are sorely lacking compared the the rest of the manual (just a series of pictures with no commentary) and a few steps obviously omitted. By the way, I have Parkinson's disease so I understand your concerns about a hand tremor. Just go slowly, don't rush, and don't give up. Good luck !

-

Ken_2 reacted to a post in a topic:

Fifie by Dsmith20639 - FINISHED - Amati - 1/32 scale

Ken_2 reacted to a post in a topic:

Fifie by Dsmith20639 - FINISHED - Amati - 1/32 scale

-

Dsmith20639 reacted to a post in a topic:

Fifie by Ken_2 – FINISHED - Amati/Victory Models – 1:32 - Scottish Motor Fishing Vessel

Dsmith20639 reacted to a post in a topic:

Fifie by Ken_2 – FINISHED - Amati/Victory Models – 1:32 - Scottish Motor Fishing Vessel

-

Ryland Craze reacted to a post in a topic:

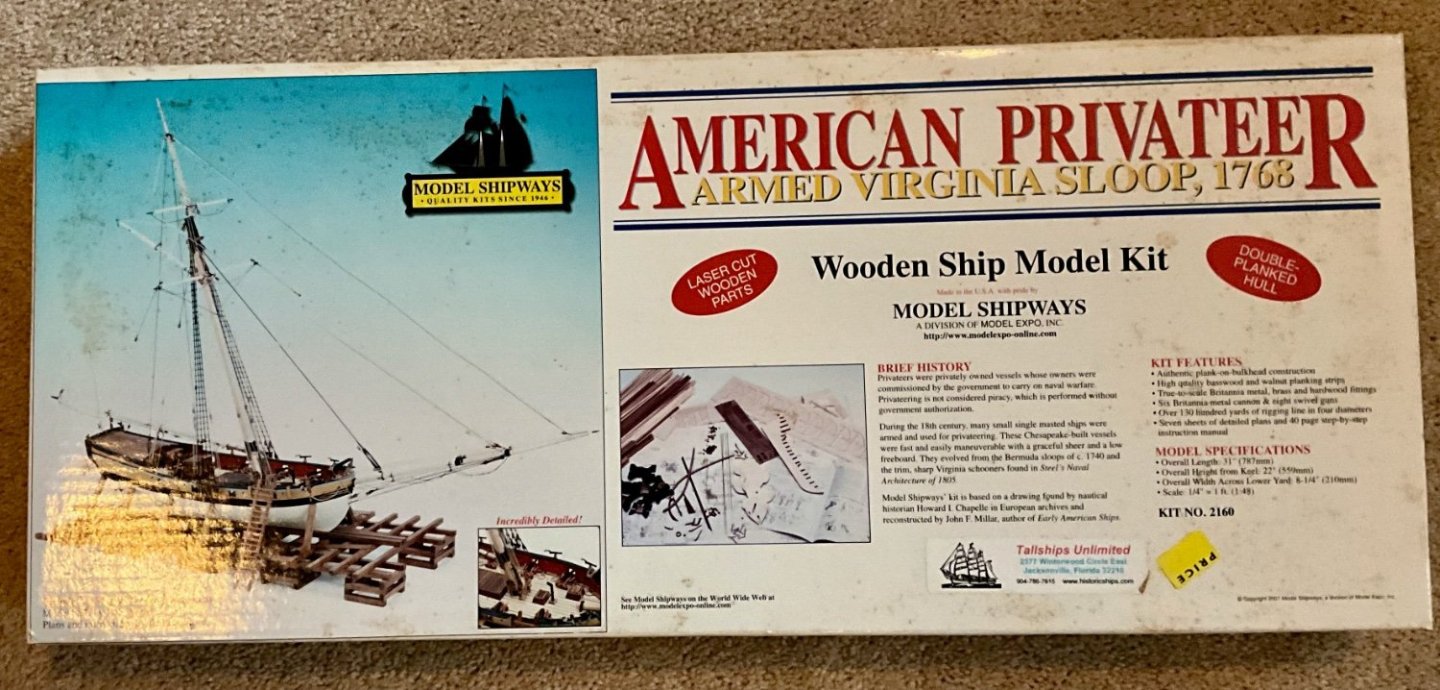

Armed Virginia Sloop by Dsmith20639 - Model Shipways - 1:48

Ryland Craze reacted to a post in a topic:

Armed Virginia Sloop by Dsmith20639 - Model Shipways - 1:48

-

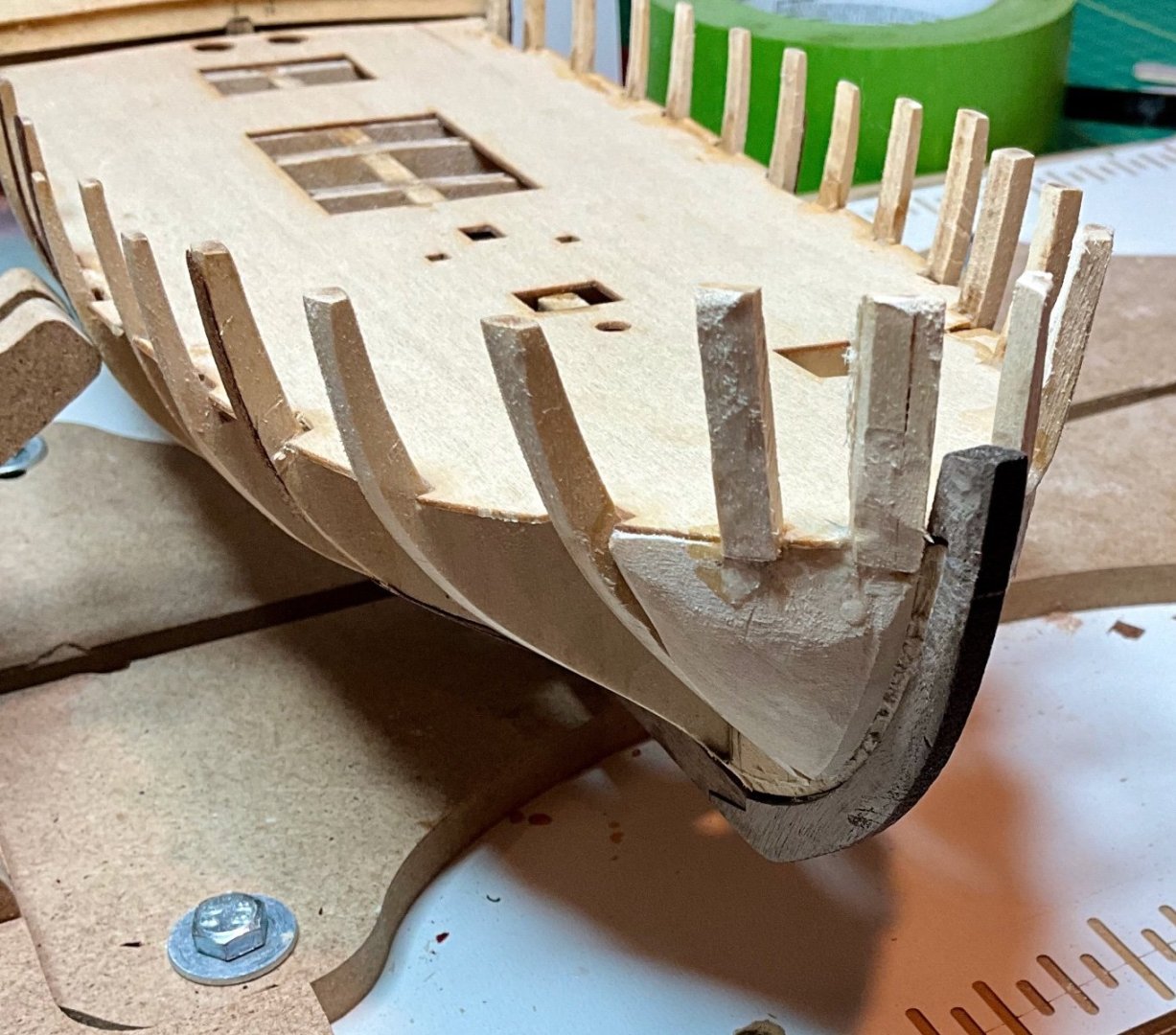

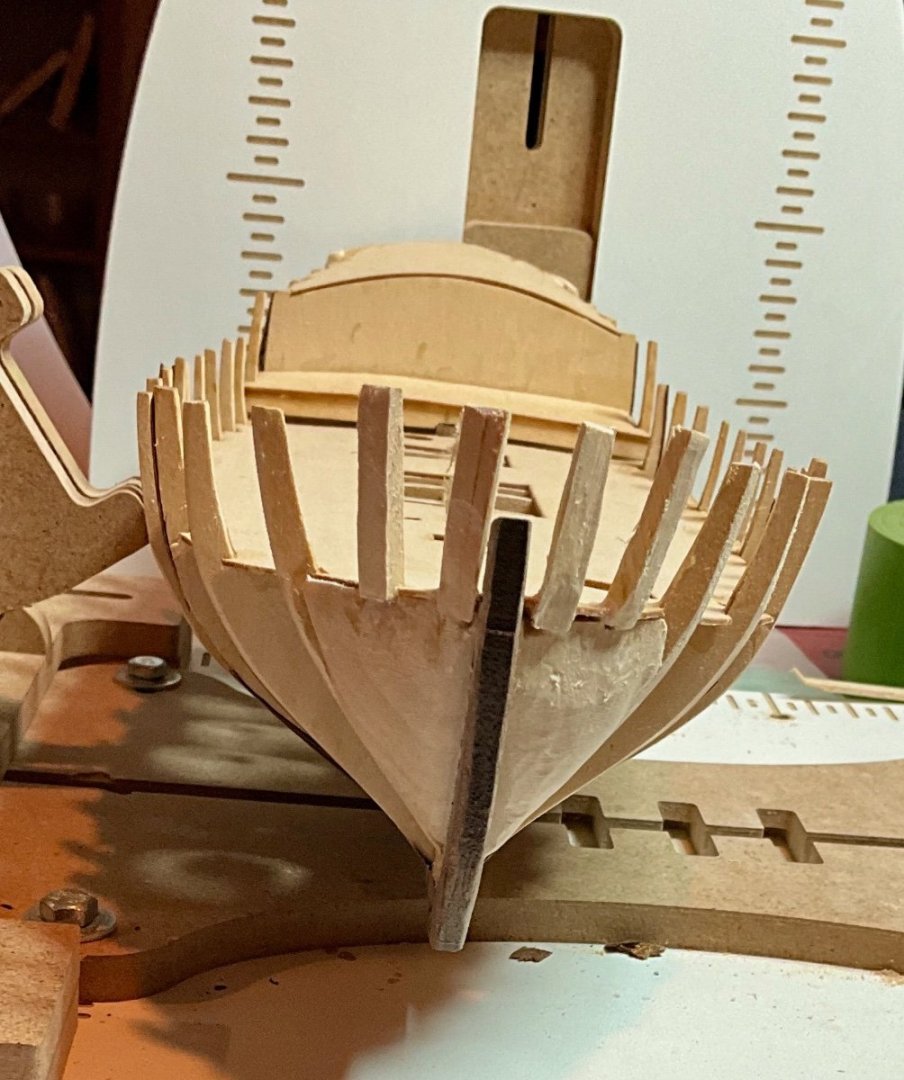

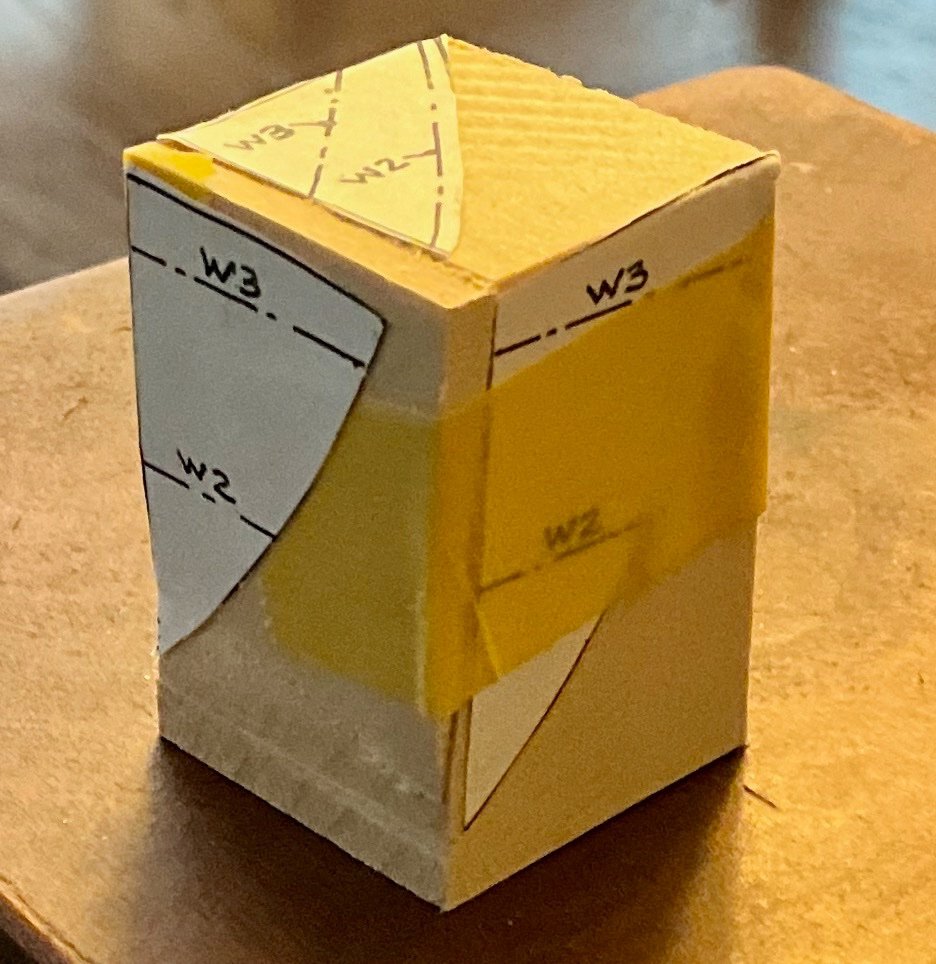

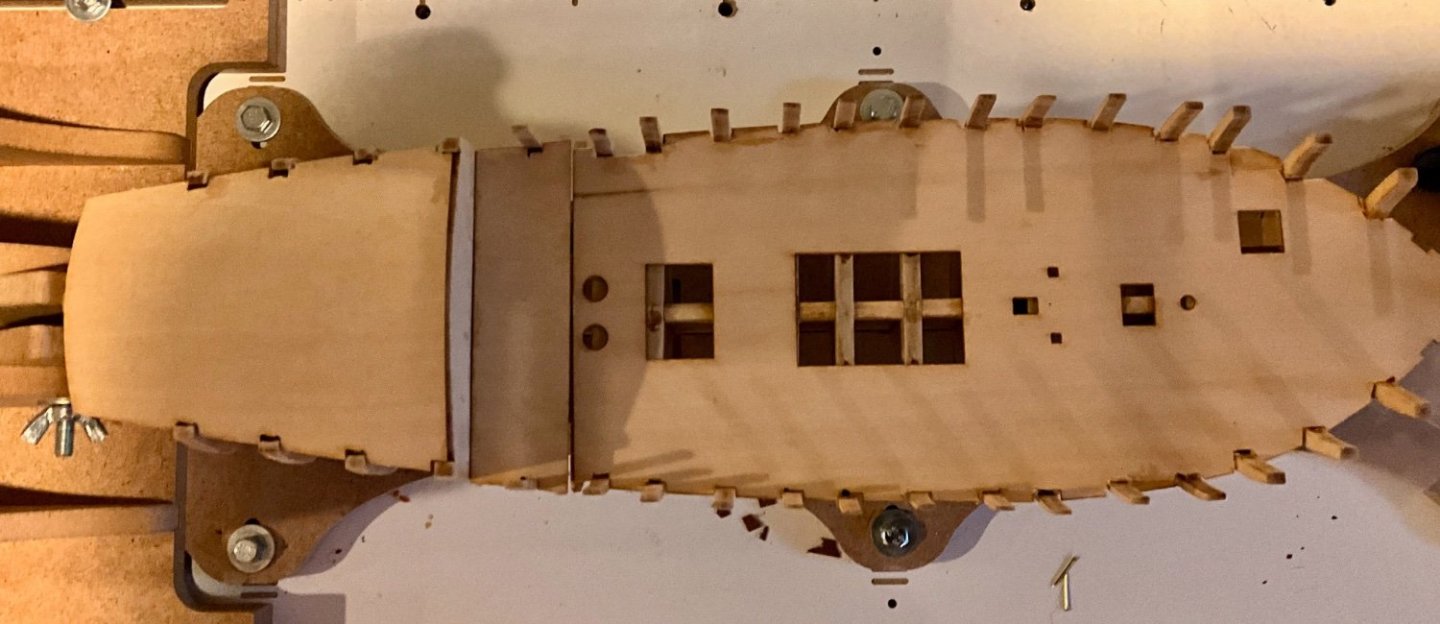

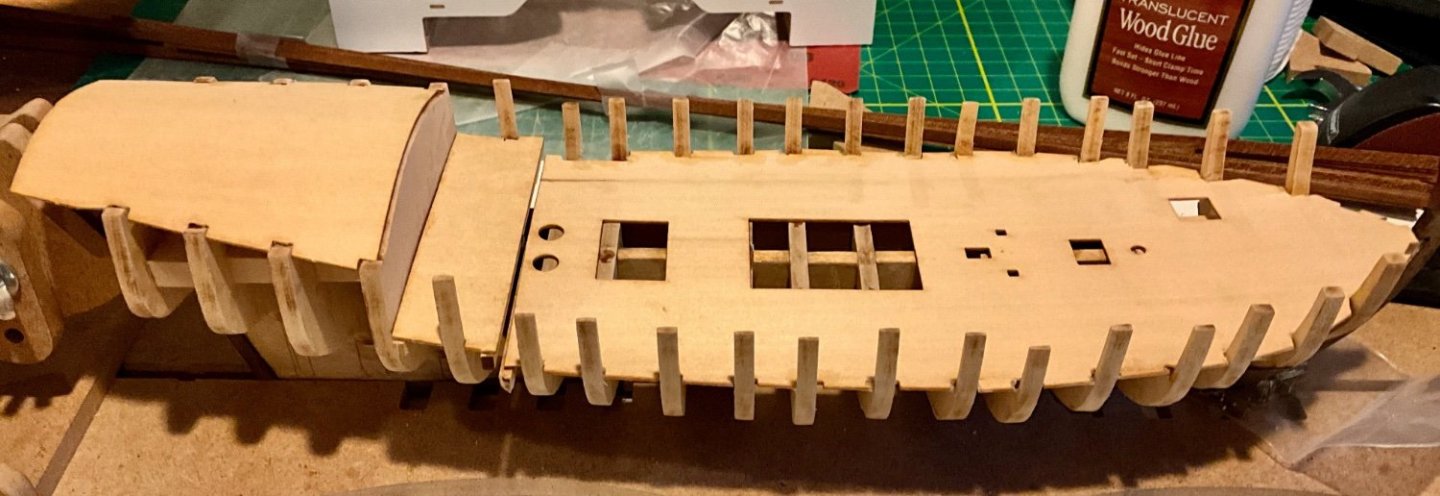

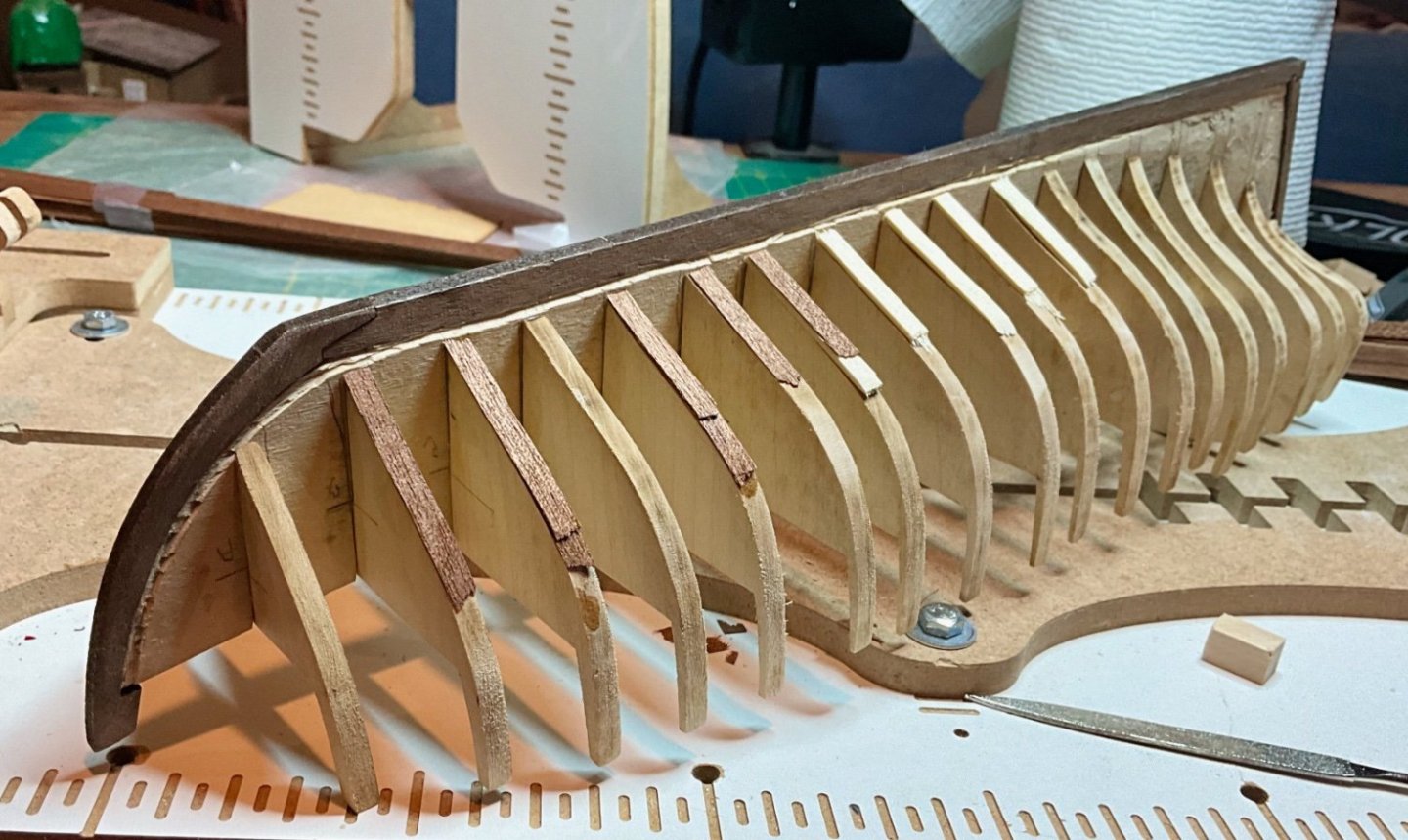

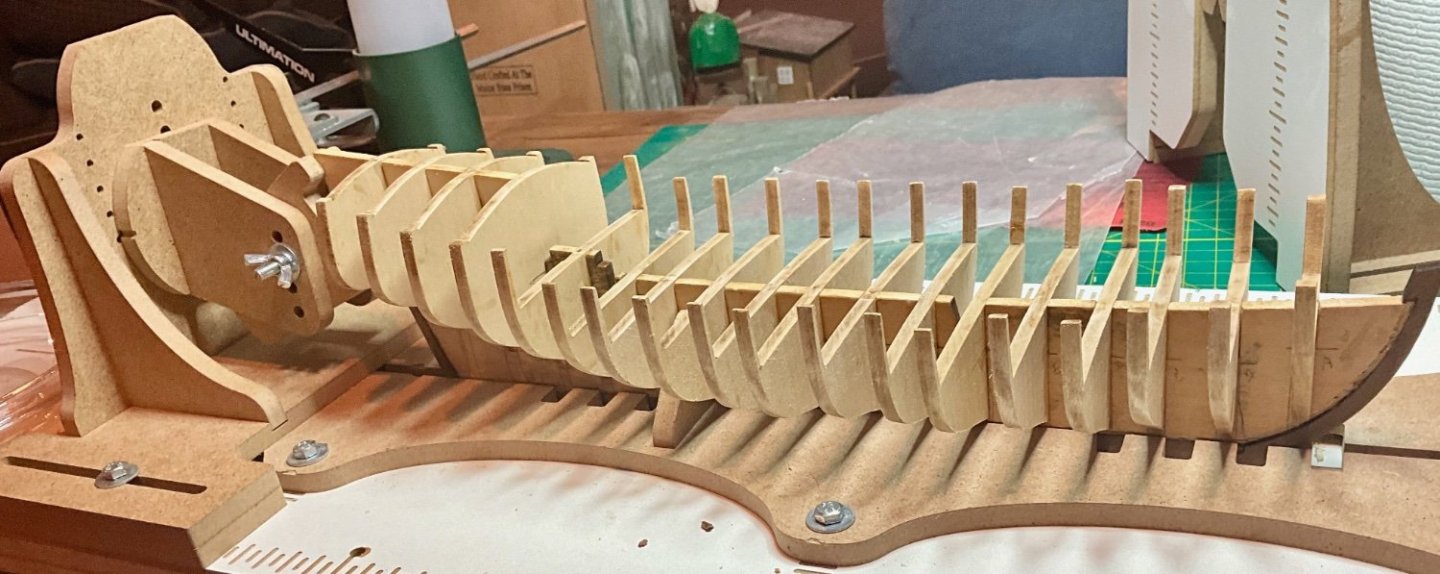

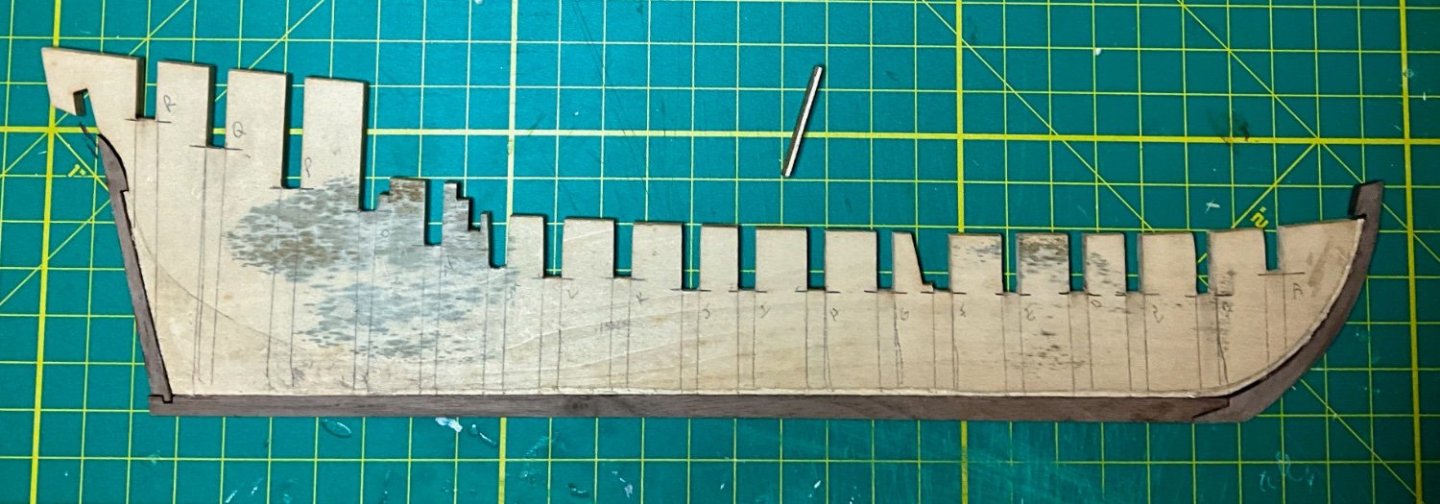

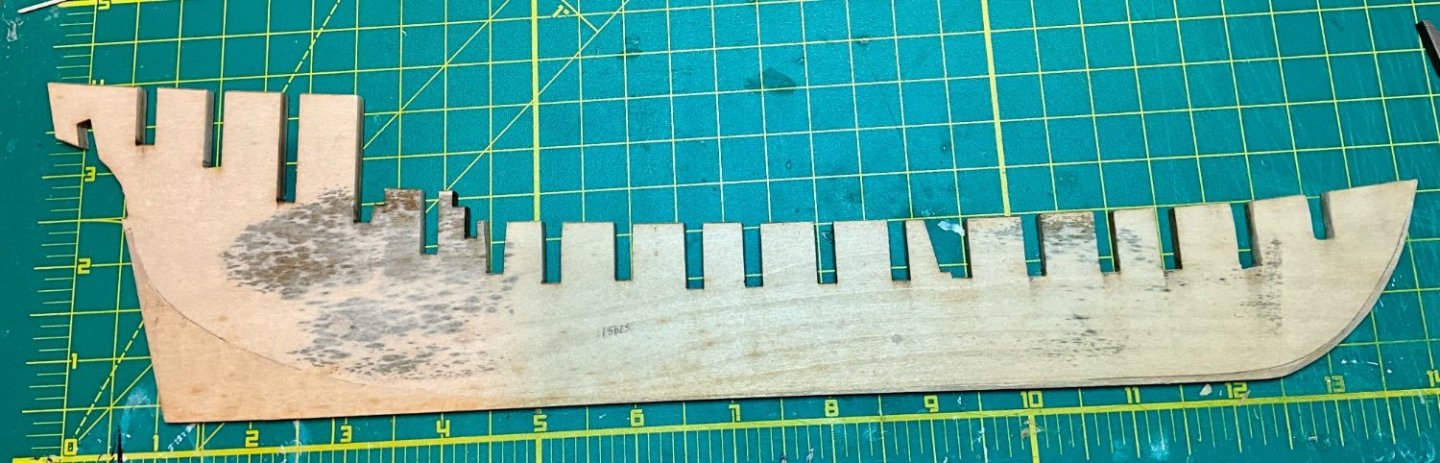

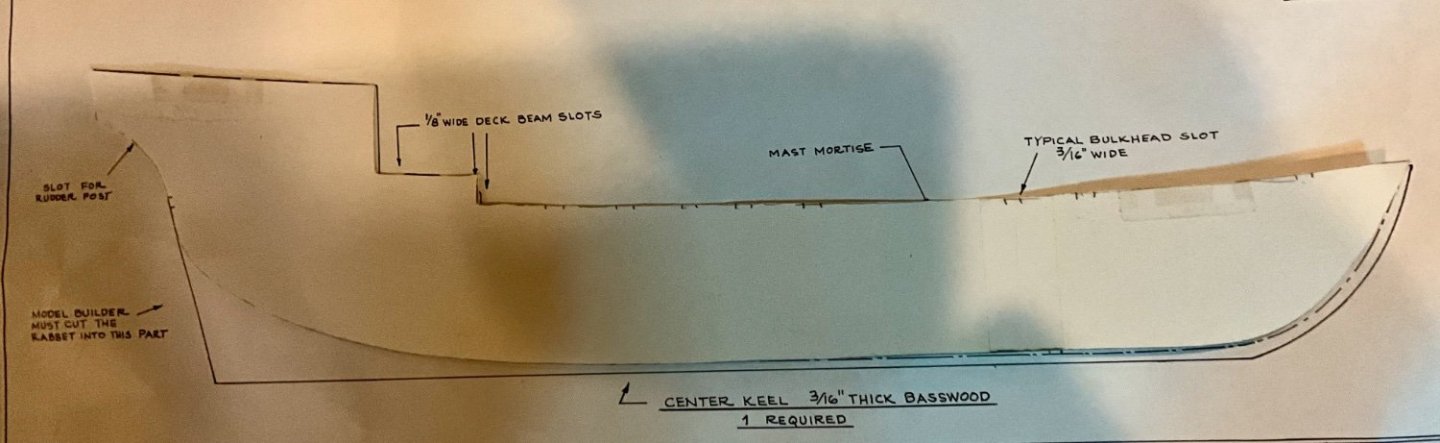

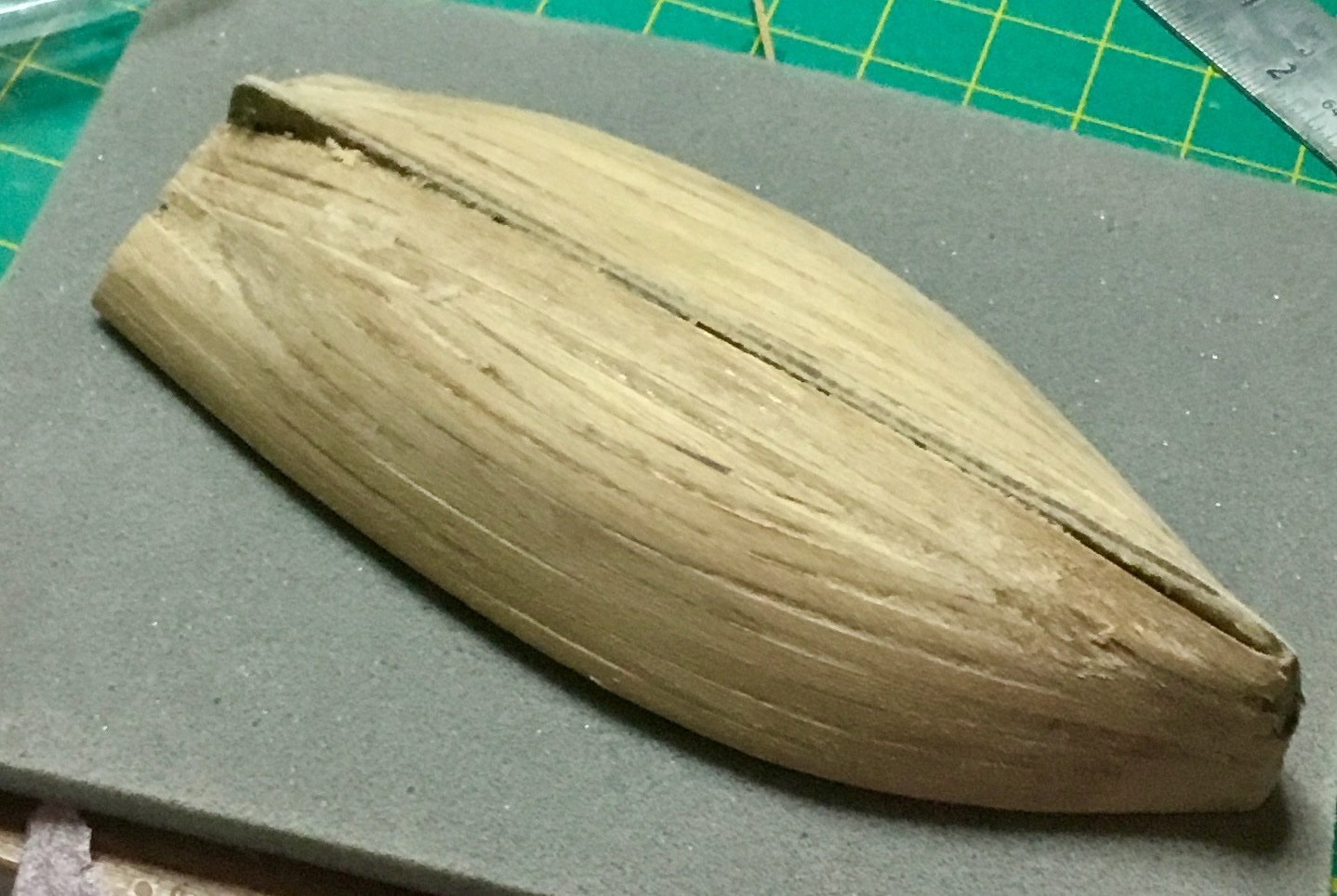

I purchased this kit several years ago but quickly realized it was too advanced for me at the time. Now that I have several completed ships under my belt I have decided to tackle it at this time. I will be basically following Robert Hunt's practicum with some modifications based upon reviews of of other completed builds on this site. I marked out the bearding line on the center keel and then cut the rabbet joint, attached the keel, stem, and sternpost. I then further refined the rabbet joint and began attaching the bulkheads. Since this is a double planked model I created a short test piece combining the planks of the two layers of wood to check the depth and width of rabbet. Some bulkheads fell short of the bearding line so I used some leftover wood from my stash to shim up the bulkheads where needed to meet the bearding line and rabbet. I am adding reinforcement blocks between the bulkheads and at the mast slot.

-

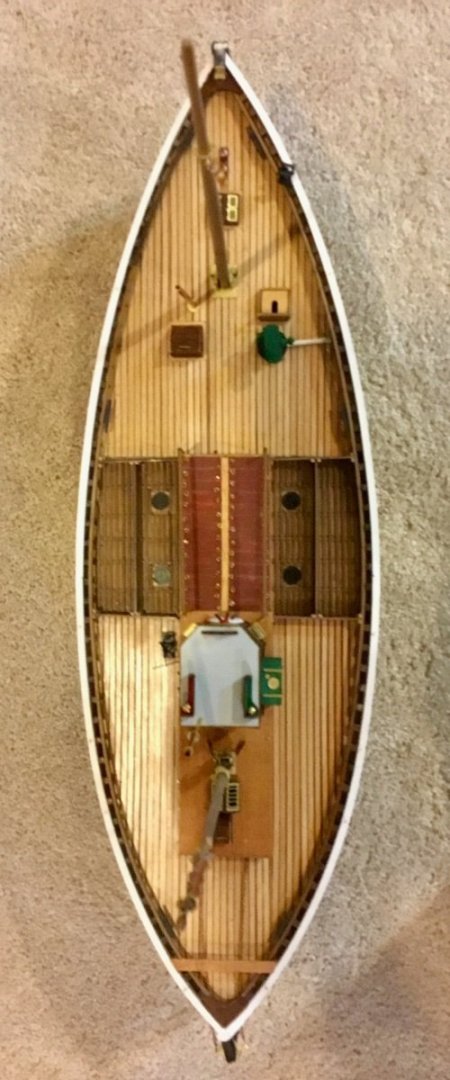

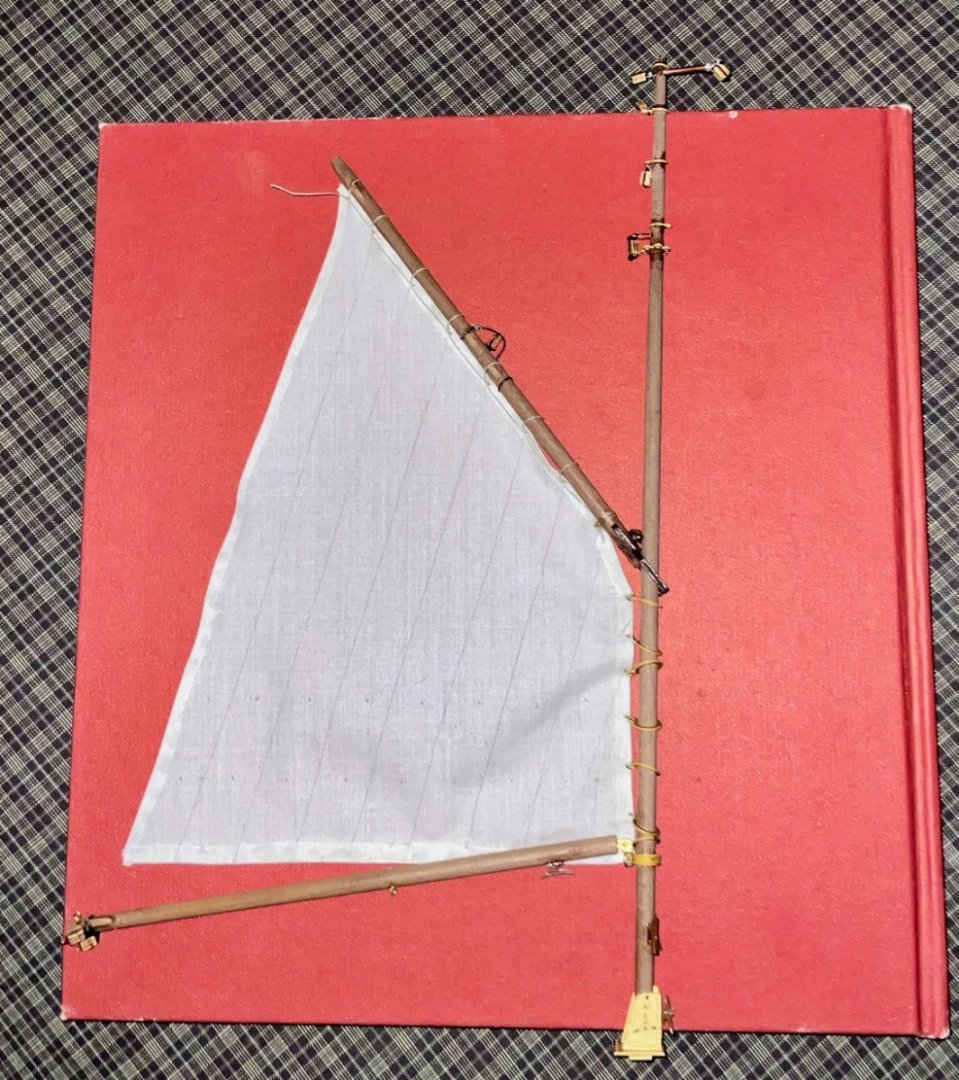

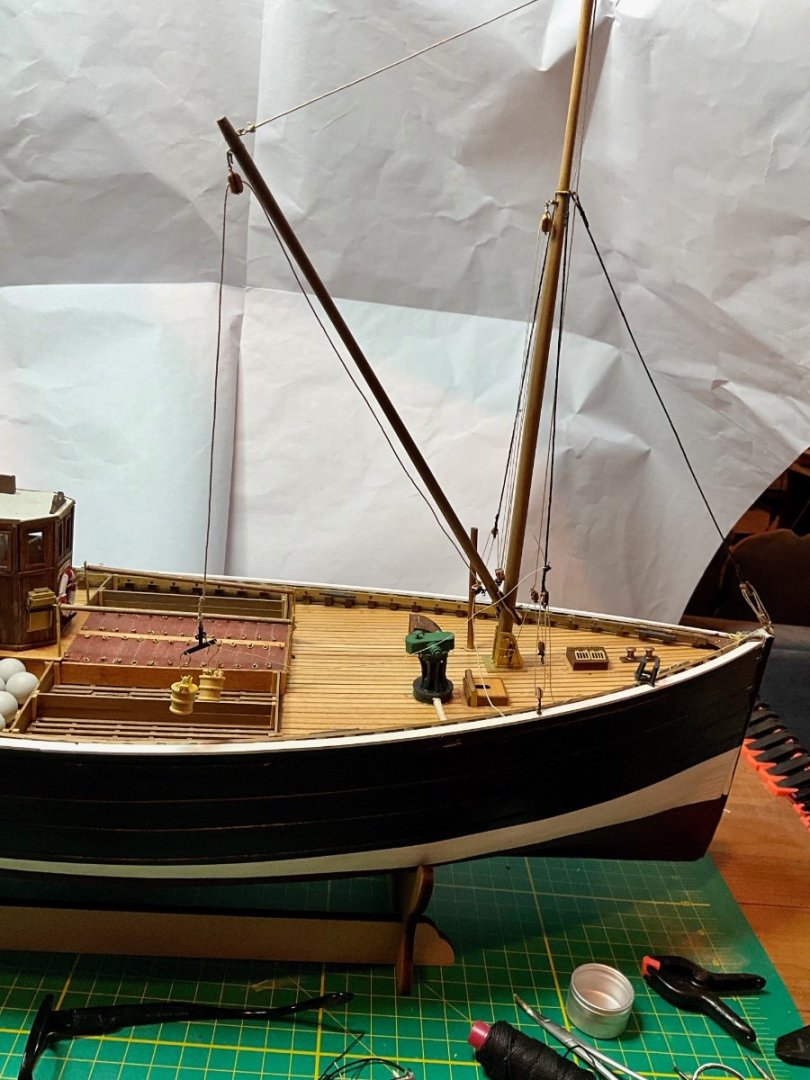

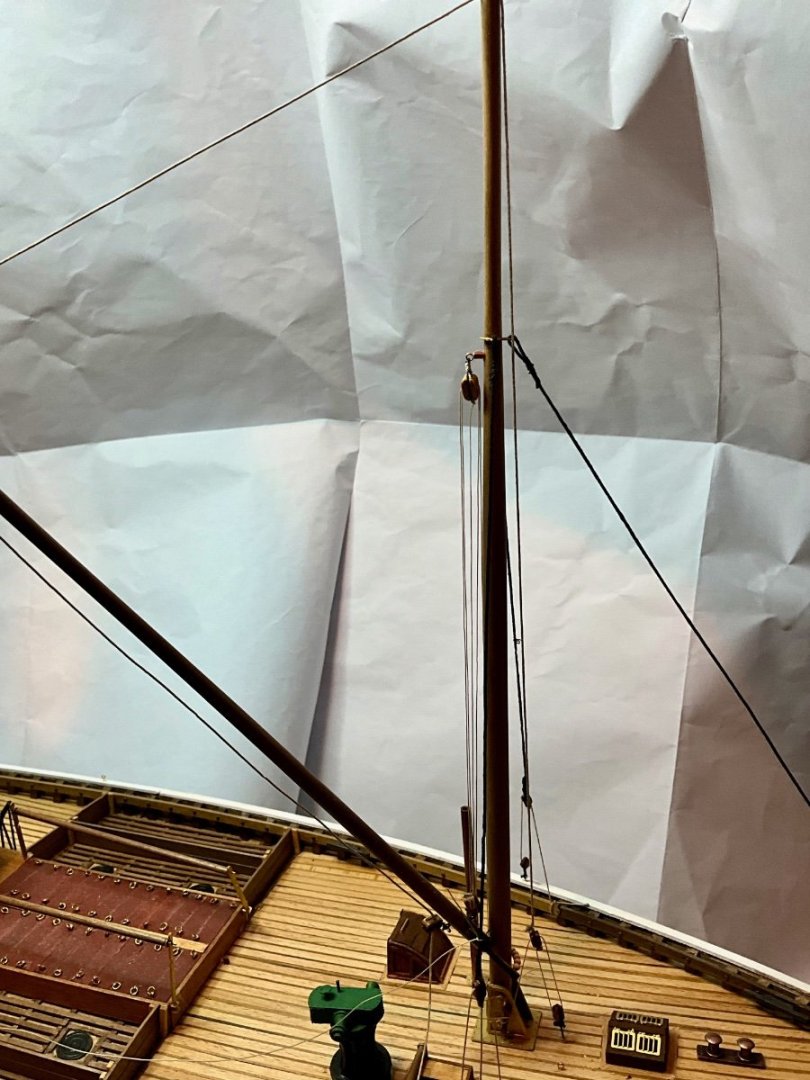

Well I've finally completed this build and the rigging. I had a small problem, I lost one of the small bullseyes for the shrouds but luckily I had a deadeye in my stash the same size and drilled out the center converting the 3 small holes to one large one.

-

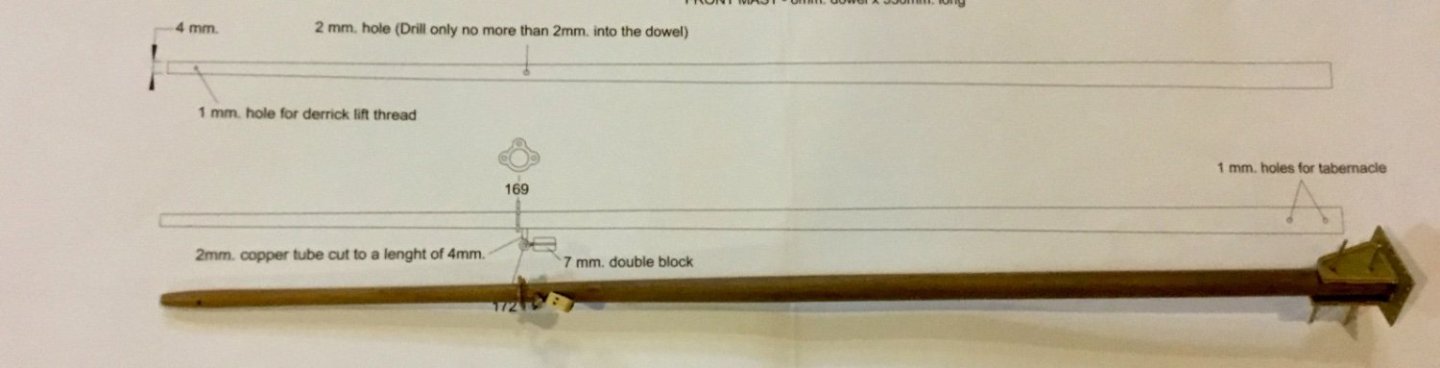

I mounted the derrick. boom to the front mast and completed the front mast rigging. I dismounted the main mast so it would be easier to rig the sail. It took awhile to connect the lower boom to the main mast due to the size of the tiny bolt and hex nut used and my lack of coordination, but eventually I got it installed. Next up is to make the sail and install it on the main mast.

-

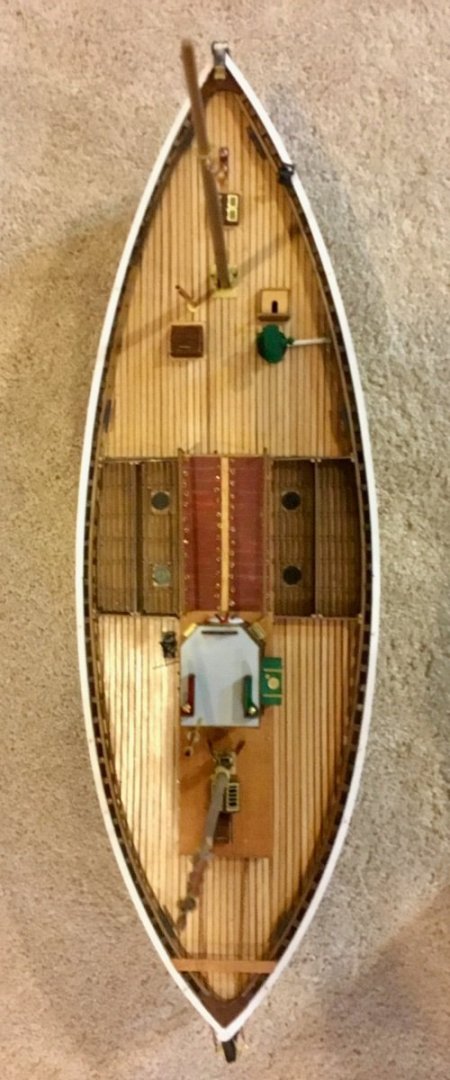

Progress on building the life boat has been very slow. For the last month I've had health related issues caused related to my medications for Parkinson's disease, etc. But at last the life boat is finished. It was equivalent to a mini kit build in itself! Here are the results such as they are: I then added the metal piece to the bow. (You can see the life boat on deck in the background. And currently I am working on the net buoys. All 30 off them.

-

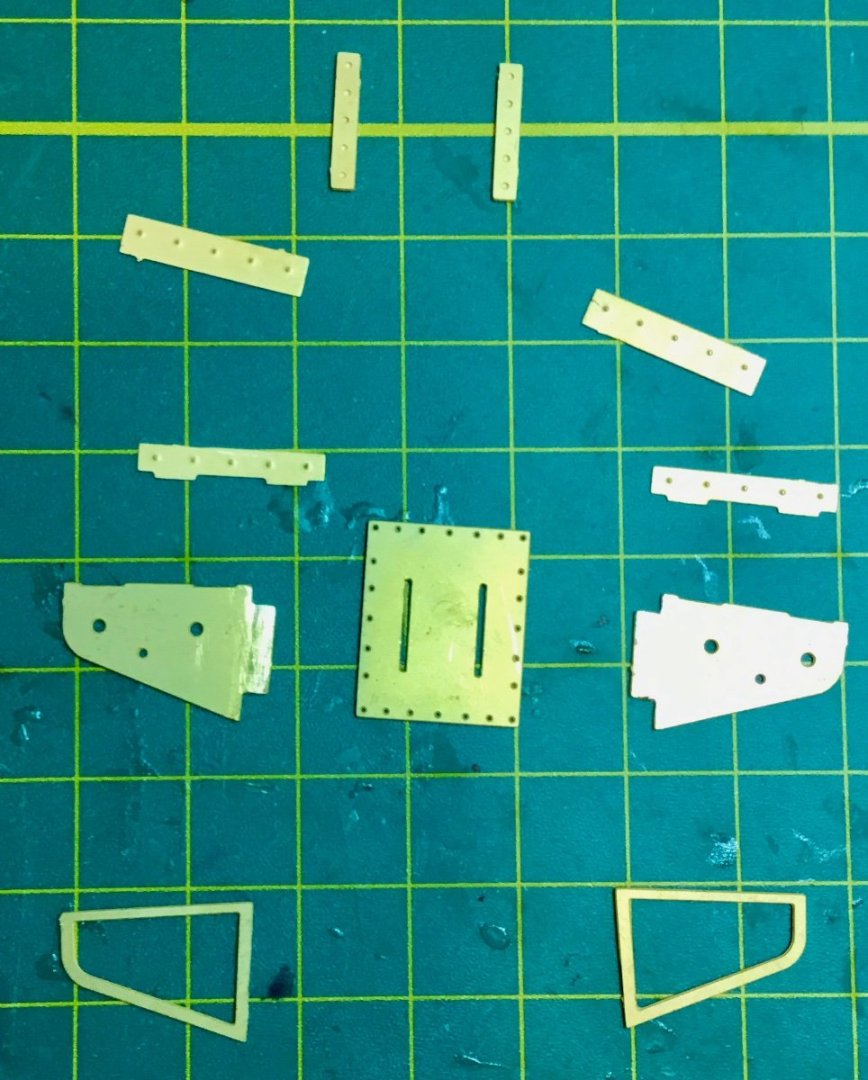

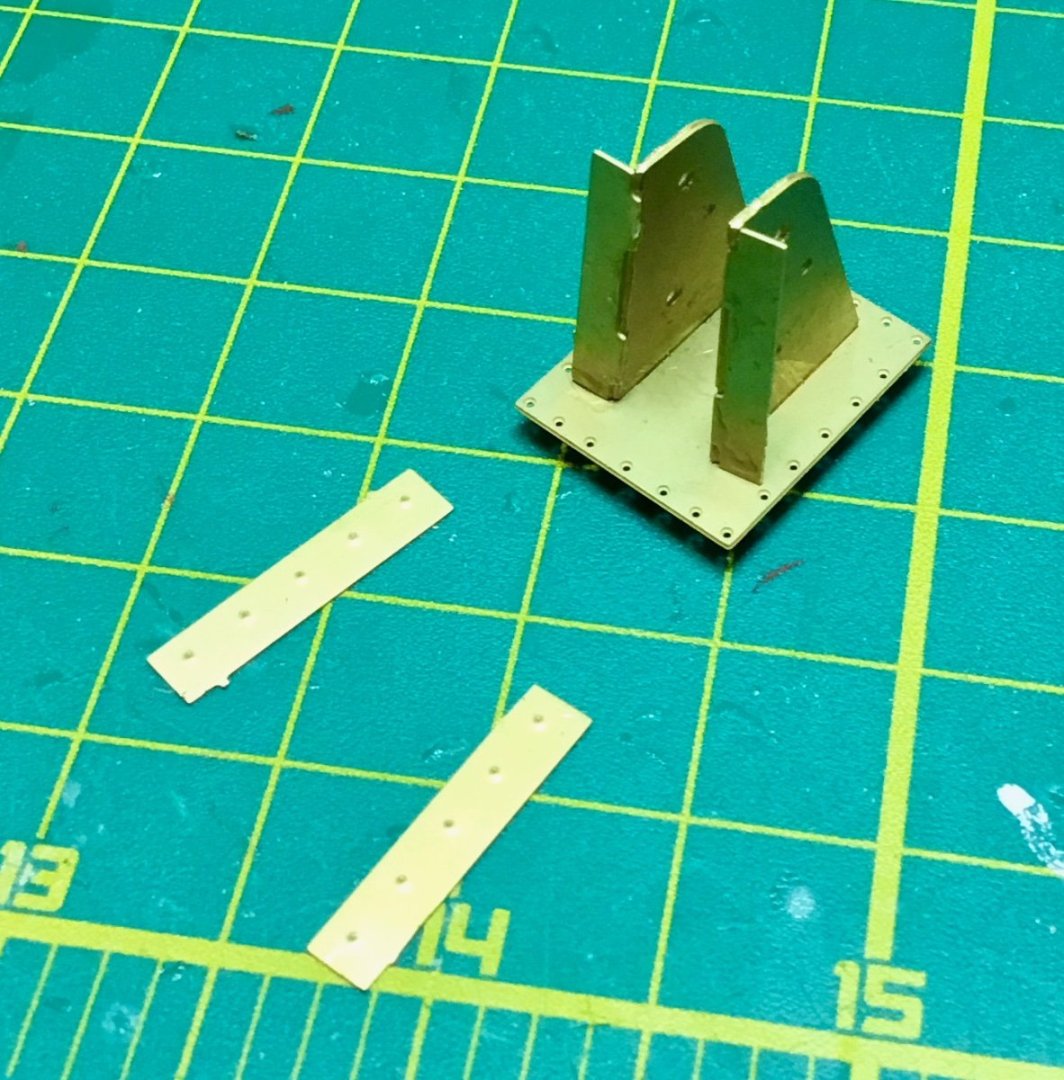

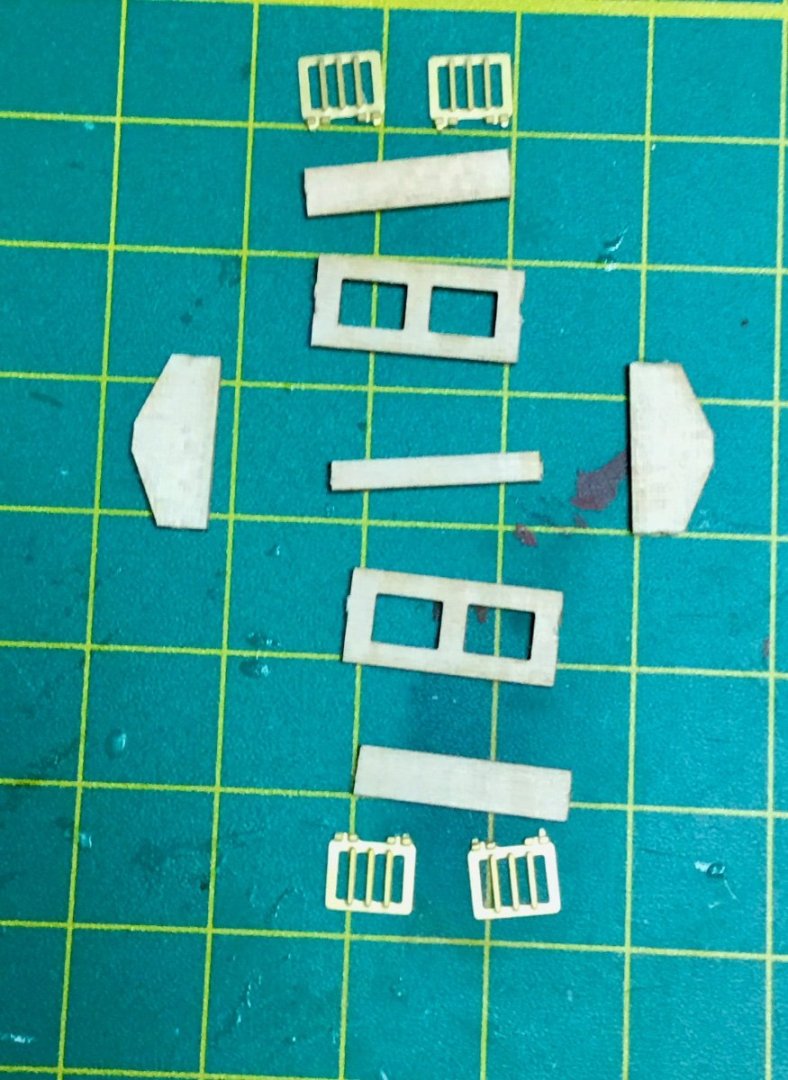

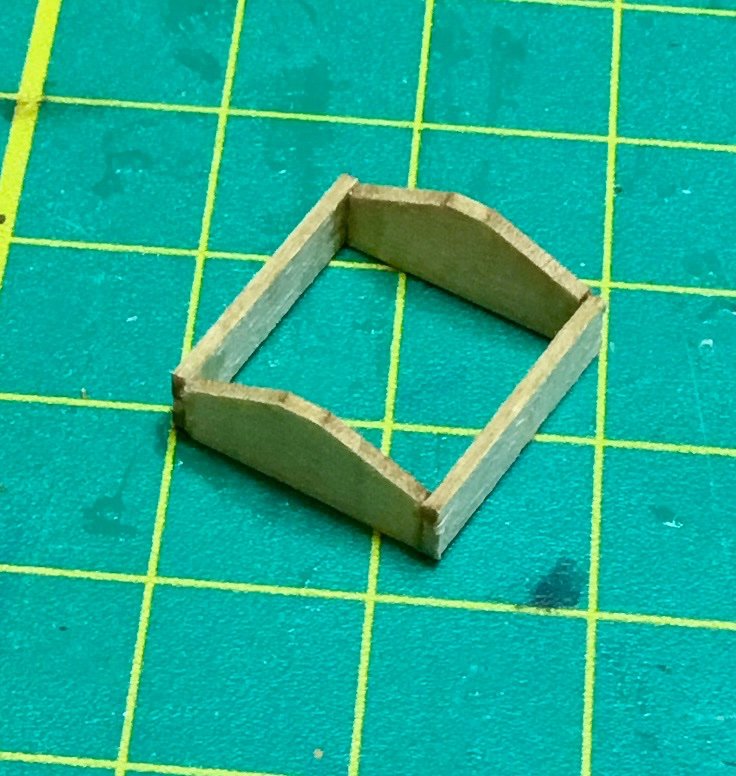

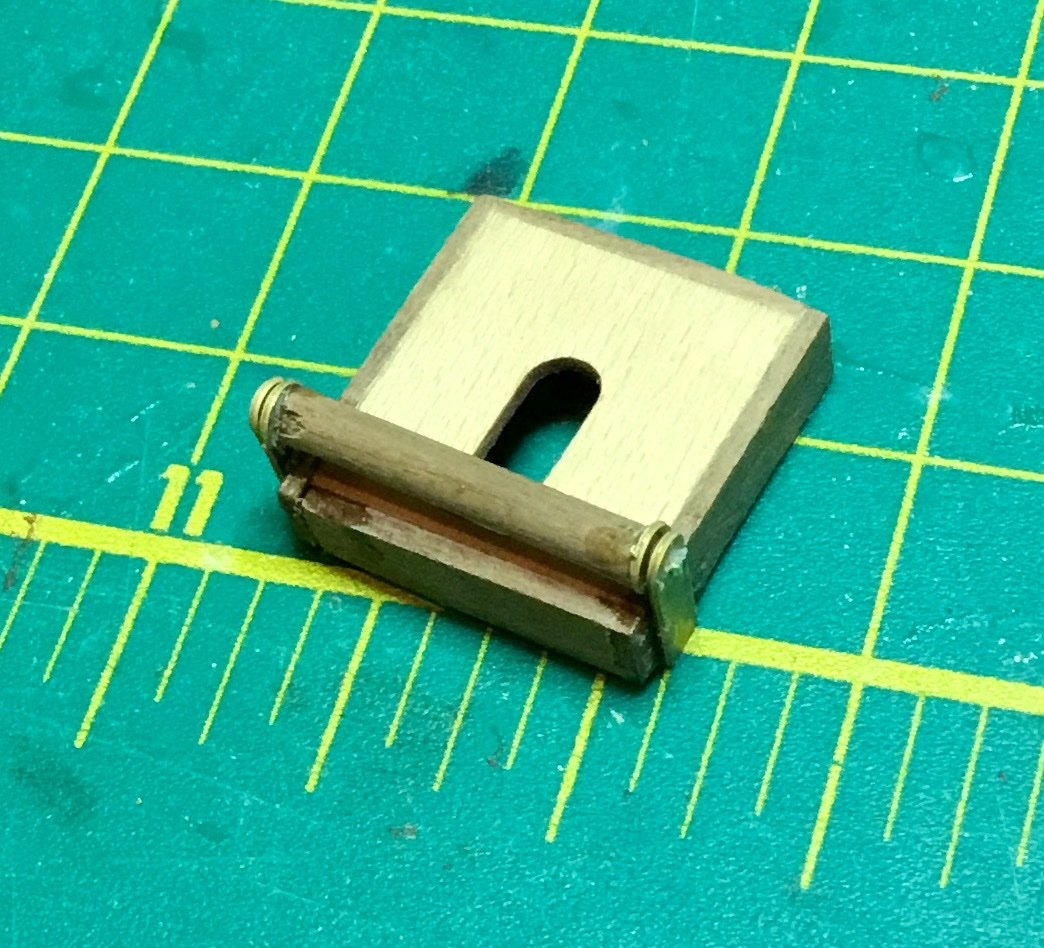

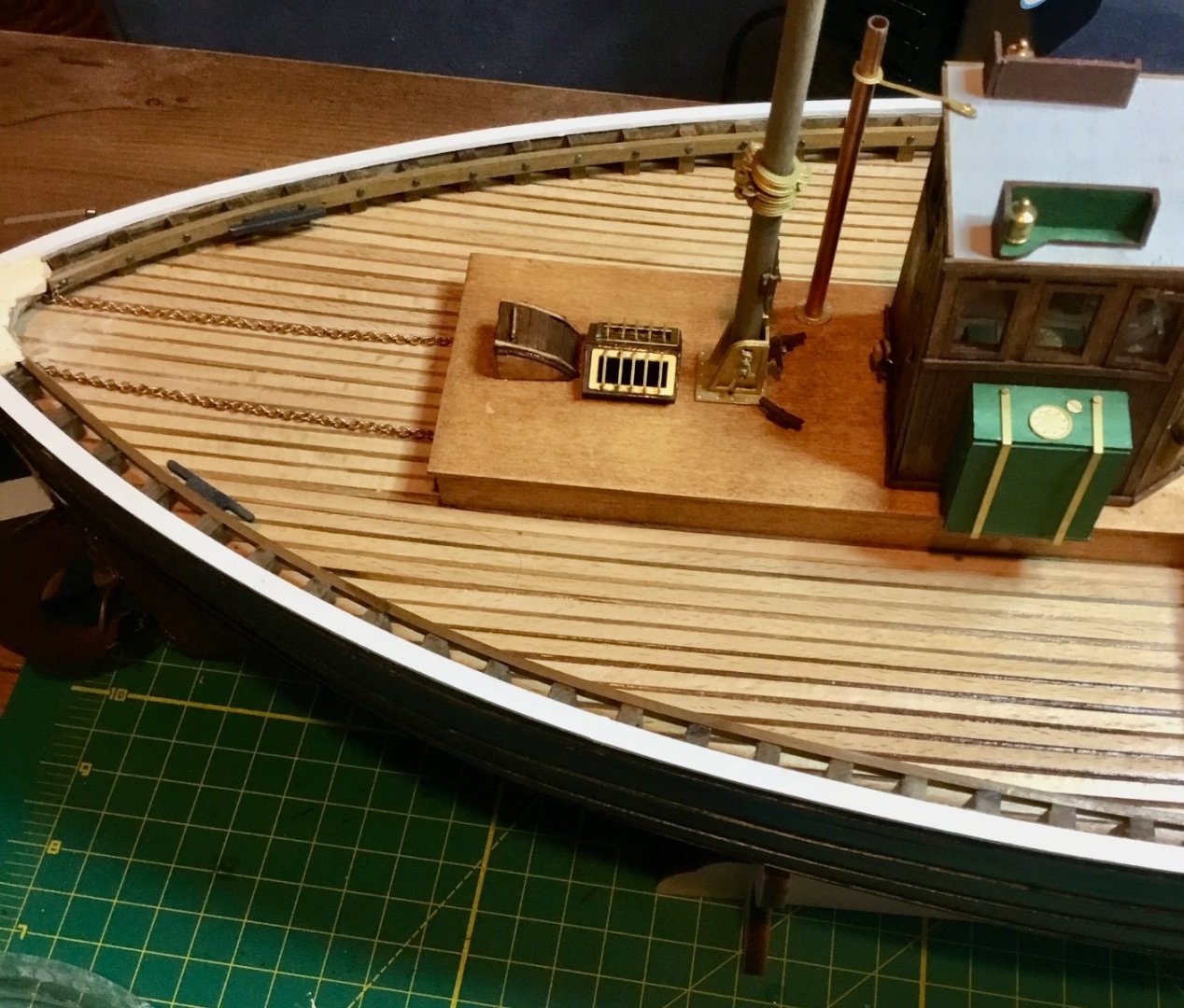

Assembled the front tabernackle (mast base). Tapered main mast, attached to tabernackle, and added mast components. Built the front skylight. And the bus rope hatch (whatever that is). Assembled and installed the bow stay. Then I began adding the various deck furniture, starting with the aft companion way and engine skylight. The front companion way, bus roller hatch, and front skylight. Installed the main mast assembly, chimney, bollards, steam winch, hand pump, stern seat, and various eyelets for mast stays. Next up will be building the life boat.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.thumb.jpeg.baaddaf5ede4612b36cc05d7410a938a.jpeg)

.thumb.jpeg.d71723686f4aace74b4e7a45e2445a63.jpeg)

.thumb.jpeg.edb75e38050af43dea58fbb54dcb13be.jpeg)