Anguirel

NRG Member-

Posts

45 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Anguirel

-

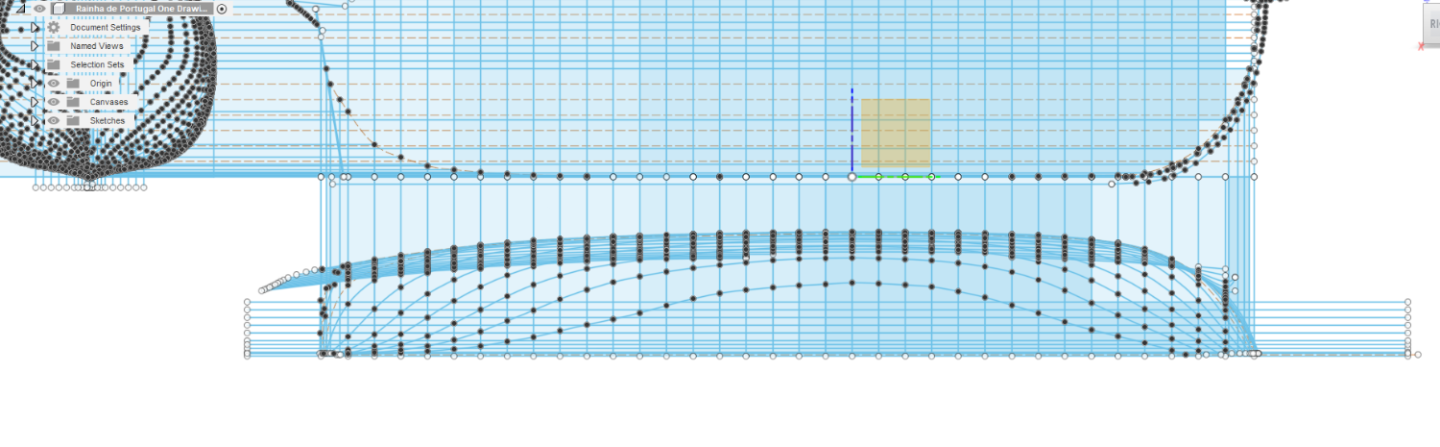

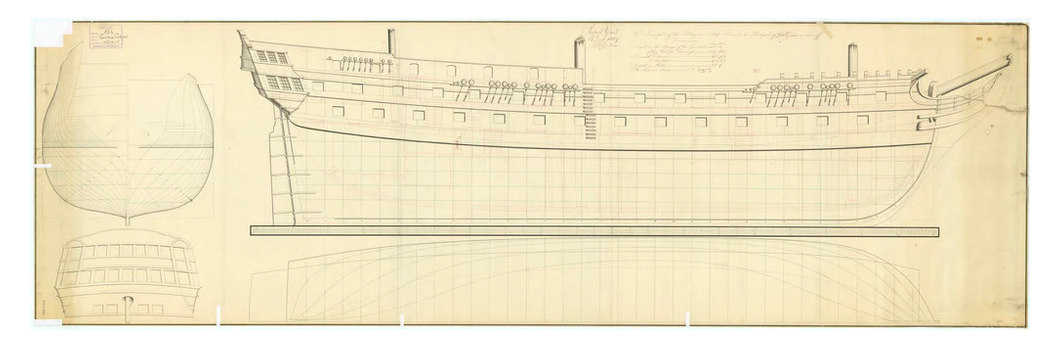

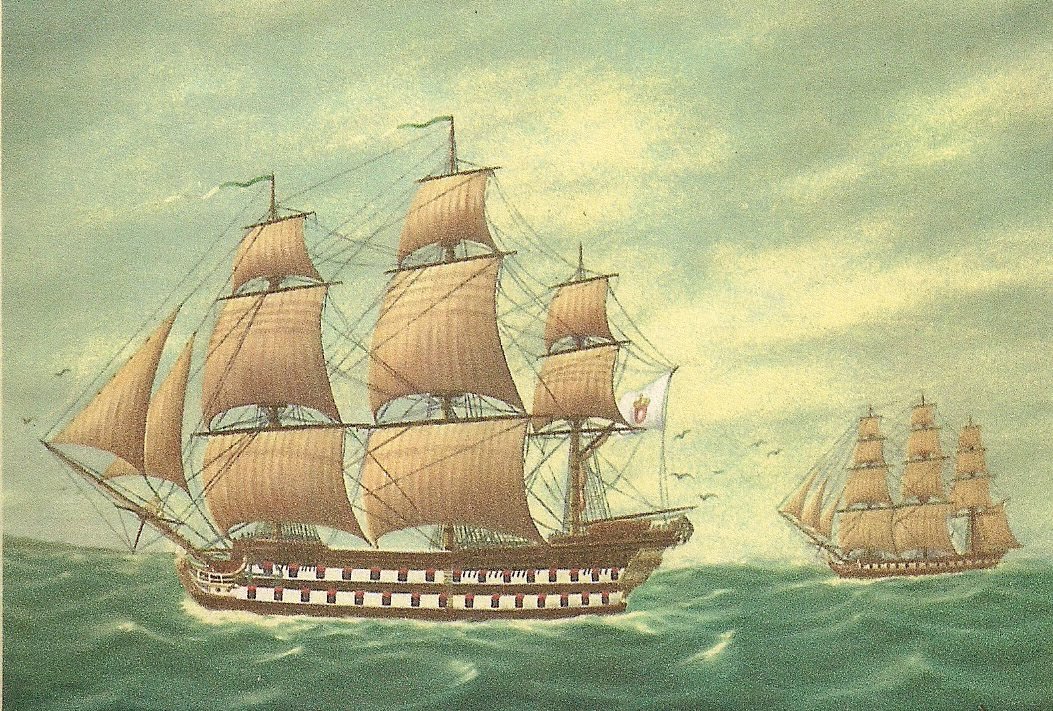

Thanks for your answer Wintergreen, I will try following what you said. Here's a screenshot of the plans: (https://prints.rmg.co.uk/products/rainha-de-portugal-circa-1791-alternative-spelling-rainho-de-portugal-j3203?_pos=1&_sid=ba49b24c4&_ss=r) She was built in Lisbon's dockyards, lunched in 1791. Between 1798 and 1807 she has part of the Squadron of the Strait (Esquadra do Estreito) commanded by the Maqui of Nisa. This squadron supported Admiral John Jervis and Admiral Horatio Nelson in the Mediterranean campaign. The squadron main responsibilities was during the blockade of the Island of Malta. Later in 1807, during the first French invasion of Portugal she helped transport the Portuguese Royal Family to Brazil. She stayed in South America until in 1821, returning to Portugal in that year. In 1833 during the Portuguese Civil War she actively participated in the Battle of Cape S. Vincent on the Absolutists side. She was taken by the Liberals returning to active service during the Cartista Government ending up being dismantled in 1851. She had the reputation of having excellent sailing qualities. Nau Rainha de Portugal in the foreground (https://forum.game-labs.net/gallery/album/98-nau-quotrainha-de-portugalquot/) Nau Rainha de Portugal during the Battle of Cape S. Vincent (1833) being taken by the 46 guns (also) Rainha de Portugal (https://pt.wikipedia.org/wiki/Batalha_do_Cabo_de_São_Vicente_(1833)) Nau Rainha de Portugal returning to Lisbon after the Battle of Cape S. Vincent (1833) under the command of Admiral Charles Napier (he was the commander of the Liberal forces) (https://pt.wikipedia.org/wiki/Rainha_de_Portugal_(nau))

-

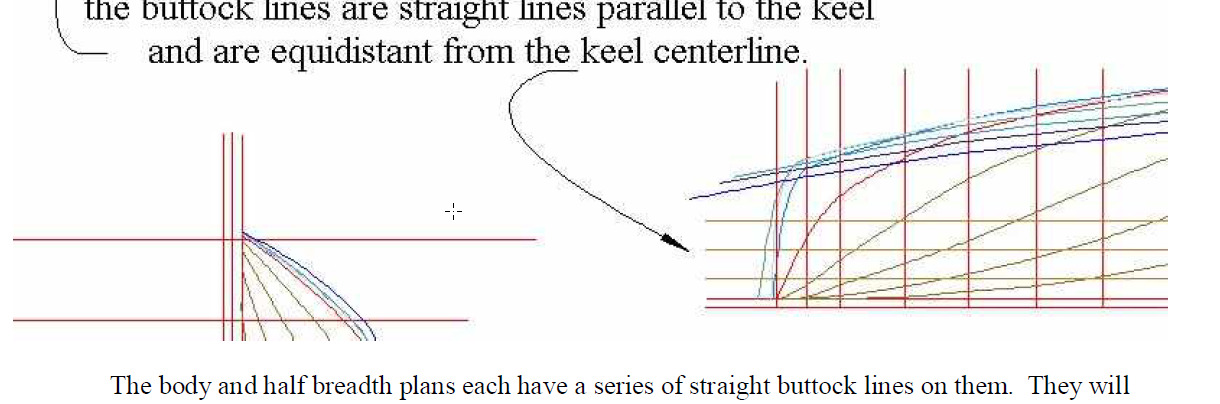

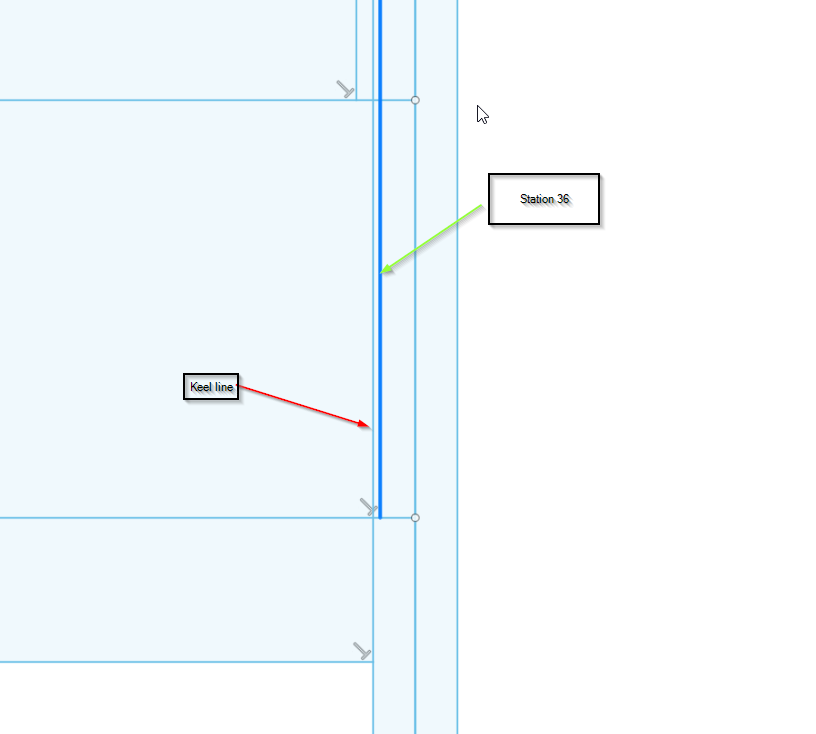

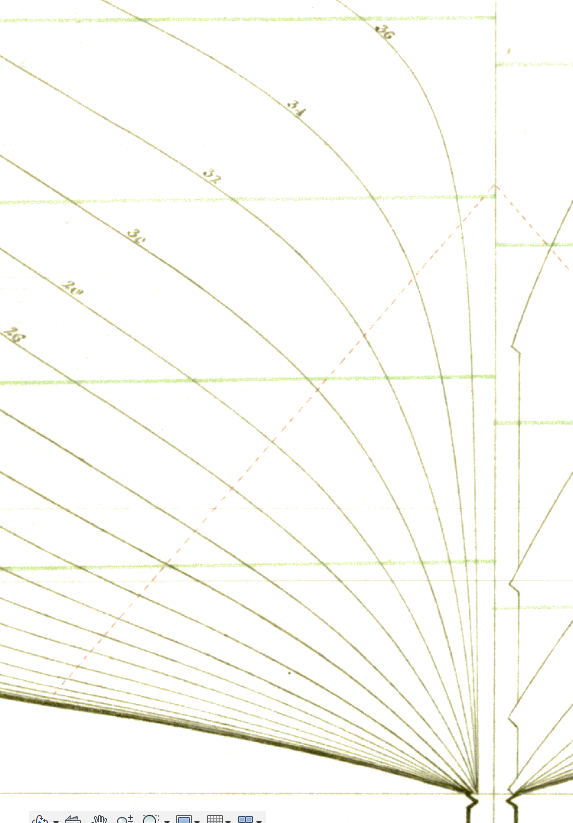

Portugal has a rich maritime history and I always wanted to build a Portuguese ship. The stars kind of aligned when I was reading the Caxton Pictorial Histories series - Nelson against Napoleon. In the chapter about the siege of Malta they talk about the Portuguese squadron that helped in the recapturing of the island. In that chapter there is a drawing of a 74 guns Portuguese ship. That made me think that there has to be some ship plans out there. Apparently not a lot of information survived until today and what is left is not easily available to the general public. It's even more difficult if you are not in country. A few weeks after reaching a dead-end on my research and I was starting to look at other English ships I stumble upon the plans of the Rainha de Portugal at the Greenwich Maritime Museum website. Apparently when she was helping in the Mediterranean campaign she was sent to Portsmouth for refitting. When there, she was surveyed and a plan was made. Armed with the plans and the Drafting Ship Plans in CAD guide by Wayne Kempson I embarked on a drafting journey. I traced the plans in to a CAD software and following Wayne Kempson's guide I'm now drawing the water lines for the half breadth plan. In this section I came across a problem I can't be sure of the answer so I am asking for your help. In Wayne Kempson's guide the ends of the water lines end at the keel: But, on my CAD drawing, at the stern some of the station lines projections are "inside" the keel: Looking at the body plan there are several stations that end "inside" the keel, station 20-36 and a, z, x and u. My question is where should the water lines end? At the edge of the keel or at the deepest point of the rabbet? Thanks in advance, Anguirel

-

How Realistic Can One Make Sails?

Anguirel replied to Julie Mo's topic in Masting, rigging and sails

Hi All, I read this thread with great interest and it answered all my questions except one. In all models I’ve seen the stichs that simulate the seams of the different panels are vertical straight lines. But in all the images of “real" sails this is a zip-zag stitch. Is this true only in modern sail making? Would it be wrong to use a zig-zag stitch on the sails? -

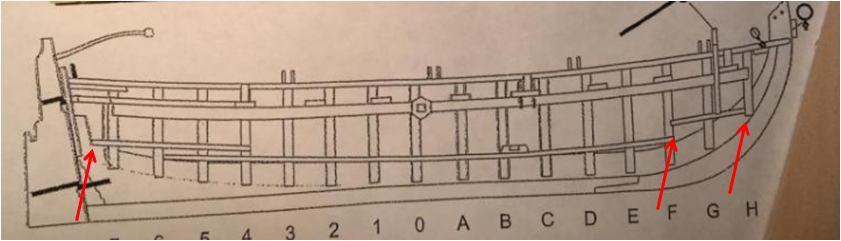

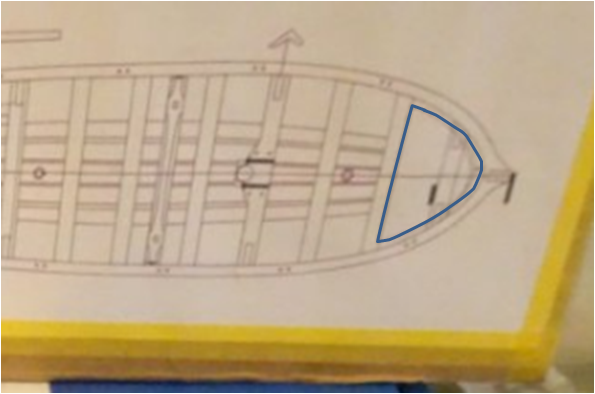

Hi Chuck, Thanks for the reply and if I may another question. I'm installing the floors and found some differences between the instructions and the plans. From the plans the bow floor should start at the base of the H frame so there should be a notch for the keelson (keel?) and it should be round and there is a space of 1/16 between the floor and the footwalings. For the stern floor it should start right next to the sternpost. on your build log the bow floor is round but not notched in the front and it looks like it's too high. On other logs some are notched in the front but are not round and all too high. Also all the logs I've seen the stern floor always starts at the frame number 7, not the sternpost. I'm I reading the planes wrong? Hugo

- 162 replies

-

- 18th century longboat

- model shipways

-

(and 1 more)

Tagged with:

-

Hi Chuck, First off all great kit, I’m having loads of fun... One question, on your log you say you filled the treenail holes. Can you tell me with what? Hugo

- 162 replies

-

- 18th century longboat

- model shipways

-

(and 1 more)

Tagged with:

-

Hi All, I’m on the market for a scroll saw. My inclination was for a Excalibur but they are no longer available. My question to you fine gentlemans is: is the new Jet scroll saw (http://www.jettools.com/us/en/new-products-and-offers/new-products/scroll-saw/) worth the extra $500?in the last toon to the Dewalt (http://www.dewalt.com/products/power-tools/saws/scroll-saws/20-variablespeed-scroll-saw/dw788). Christmas is coming so now is the perfect time to convince the Admiral that I need another machine... Thanks in advance

-

Manage to spend some quality time in the workshop. Planking the inside is done to the level of the lower deck. The guide lines for the treenails is marked, next is drilling the holes and do the treenails. In the meantime I planed to do something different for the deck beams. I did a two timber deck beam with a table and lipped scarph. The one on the right is glued and with the black paper. It came out better then I was expecting for a first try. Now the problem is that the plans are made to use a constant thickness beam which is not the case of this one. Any advice on how to compensate for this? In the case of the lower left and upper right beam arm it must be shorter then on the plans and the other two it must be bigger... I could not find an example of a two timber beam on a model (found several examples of a three timber beams though). As for this one the cuts for the beam arms and carling will "cut" the scarph of the beam. Any advice is welcome... Hugo

-

Hi, i haven't been able to spent as much time on the cross section as I like but I manage to do a bit here and there. Sanding took a lot of time and was the only way I could find to give the hull the right shape. Here how she look now... in some places I didn't manage to get a good fit but still learning I guess... Hugo

-

Hi, today reached a point of no return, the frames are in place... with the help of the jig and the spacers it was easier then I was expecting. Still had to redo some of the frames in order to align them properly (that is where I am now...) I played around with patterns of the treenails to fix the frames against the keel... The pattern on frame B seems better but from what I read it was only adopted after 1811 (Sappings System?, can anyone confirm this) and the one on frame C was the one in practice between 1710-1811. Next is the gunport lintels and sills then sanding, lots of sanding... Hugo

-

Hi, I asked for a quote for boxwood with the thickness you sent but it was more then I was expecting and because it was my plan from the beginning to plank the all cross session and I want to buy a table saw and a lathe I rather save the money for the tools. So my plan now is to make the frames as they are in the plans and later when I have the tools I will make them "properly" and the decks only, with no planking.

-

Hi all, There is a question that's been bugging me for months now. On the ship's frames were the futtocks buts weatherized? With pitch and/or tar? I know that after the frames where assembled the hull was left exposed to the elements (if done properly for years) so the wood would age and mature. But rain water is different from salt water... I could not find anything in the literature I have access to or the internet. A few weeks ago I had the privilege of visiting the HMS Victory in Portsmouth and on the Orloop deck there are some gaps on the inner hull plucking and the frames are visible. I could find one of the frame's buts and as far as I could see there was no pitch or tar. But the fact that there was direct access to the frames, especially in the Orloop deck makes me think that some kind of weatherization should be made. Can anyone confirm or deny if the frames were weatherized like the deck planks? thanks

-

Hi Jan, I had mixed experiences with basswood. For Christmas I made a wood truck for my son in basswood and the edges look pretty good: But the other day I bought basswood by mistake to use on the Triton's frames and this was the result: The wood look chewed mainly in the edges and tops, so I'm assuming different vendors/ brands have different quality. The wood for the truck was bought in Jo-Ann and the other in Hobby Lobby. Anybody with the same experience?

-

Hi, Since I I don't have the appropriate tools and and I don't want to spend the money to buy the milled wood (because I'm saving to buy the a table saw and a lathe) I decided that for now I'm doing the frames as by the plans. Since I was planing to completely plank the cross section it won't make a difference. As soon as I have the tools I will make another with no planking to show the internal construction. So today I brought back the pieces I had already cut, and assembled the two half of frame 0 (having some difficulties adding images using the IPad)

-

Hi, After moving to the new house, unpacking everything and a surprise trip to London a was able to convince the Admiral to double my space Wile in London I managed to take one (very cold) day to go to the Royal Dockyards in Portsmouth. What a wonderful day... I just felt like a kid on Christmas Eve... Now I need to go back and think on how I want to proceed... Thanks

-

Hi, Just an update on my (not) progress... I tried to do the futtocks with different thickness using boxwood from Hobby Lobby, bad idea... the wood is not dense (don't know if that is the correct word to use) enough, it couldn't hold the shape specially the edges. The edges looked like they were chewed. Now I'm in the process of changing houses so my work corner look like this In the mean time I contacted Crown Timberyard to see if they can mill the wood to the thickness I want. If they can't do it I will just have to accepted that I don't have the tool necessary to do it that way.

-

Hi This was waiting for me when I arrived home yesterday, finally I will be able o keep things squared. As for the black paper on the frames, the double frames they are sturdy enough ( if the one I built can be used as an example) the simple ones might be a ploblem. I used the paper because I read somewhere that they used tar or pitch on the frame joints, but now I can't find it, will have to go through the books again...

-

Hi Thanks for the measurements Christian. Just one question, did you switch the floor timber and the 1st futtock? the floor timber should be thicker right? As for the position of the gun ports I'm assuming I can use the plans of the forum for that. Do you have a way to confirm that? Mark I will try the holes thing and next time I'm in Hobby Lobby I will ask if they have the artist pigment... (the only immediate problem I see is the excess glue witch I tend to apply)

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.