-

Posts

168 -

Joined

-

Last visited

About KennyH78

- Birthday 07/06/1978

Profile Information

-

Gender

Male

-

Location

Perry, Georgia

-

Interests

Cooking, woodworking, building models

Recent Profile Visitors

-

GrandpaPhil reacted to a post in a topic:

Raleigh 1777 by KennyH78 - Scale 1:96 - Continental Frigate - Hahn Plans

GrandpaPhil reacted to a post in a topic:

Raleigh 1777 by KennyH78 - Scale 1:96 - Continental Frigate - Hahn Plans

-

GrandpaPhil reacted to a post in a topic:

Raleigh 1777 by KennyH78 - Scale 1:96 - Continental Frigate - Hahn Plans

GrandpaPhil reacted to a post in a topic:

Raleigh 1777 by KennyH78 - Scale 1:96 - Continental Frigate - Hahn Plans

-

GrandpaPhil reacted to a post in a topic:

Raleigh 1777 by KennyH78 - Scale 1:96 - Continental Frigate - Hahn Plans

GrandpaPhil reacted to a post in a topic:

Raleigh 1777 by KennyH78 - Scale 1:96 - Continental Frigate - Hahn Plans

-

GrandpaPhil reacted to a post in a topic:

Raleigh 1777 by KennyH78 - Scale 1:96 - Continental Frigate - Hahn Plans

GrandpaPhil reacted to a post in a topic:

Raleigh 1777 by KennyH78 - Scale 1:96 - Continental Frigate - Hahn Plans

-

GrandpaPhil reacted to a post in a topic:

Raleigh 1777 by KennyH78 - Scale 1:96 - Continental Frigate - Hahn Plans

GrandpaPhil reacted to a post in a topic:

Raleigh 1777 by KennyH78 - Scale 1:96 - Continental Frigate - Hahn Plans

-

GrandpaPhil reacted to a post in a topic:

Raleigh 1777 by KennyH78 - Scale 1:96 - Continental Frigate - Hahn Plans

GrandpaPhil reacted to a post in a topic:

Raleigh 1777 by KennyH78 - Scale 1:96 - Continental Frigate - Hahn Plans

-

GrandpaPhil reacted to a post in a topic:

Raleigh 1777 by KennyH78 - Scale 1:96 - Continental Frigate - Hahn Plans

GrandpaPhil reacted to a post in a topic:

Raleigh 1777 by KennyH78 - Scale 1:96 - Continental Frigate - Hahn Plans

-

GrandpaPhil reacted to a post in a topic:

Raleigh 1777 by KennyH78 - Scale 1:96 - Continental Frigate - Hahn Plans

GrandpaPhil reacted to a post in a topic:

Raleigh 1777 by KennyH78 - Scale 1:96 - Continental Frigate - Hahn Plans

-

CiscoH reacted to a post in a topic:

HMS Winchelsea 1764 by KennyH78 - 1/48

CiscoH reacted to a post in a topic:

HMS Winchelsea 1764 by KennyH78 - 1/48

-

Matt D reacted to a post in a topic:

HMS Winchelsea 1764 by KennyH78 - 1/48

Matt D reacted to a post in a topic:

HMS Winchelsea 1764 by KennyH78 - 1/48

-

KennyH78 reacted to a post in a topic:

HMS Winchelsea 1764 by glbarlow - FINISHED - 1:48

KennyH78 reacted to a post in a topic:

HMS Winchelsea 1764 by glbarlow - FINISHED - 1:48

-

KennyH78 reacted to a post in a topic:

Sloop Speedwell 1752 by Chuck - Ketch Rigged Sloop - POF - prototype build

KennyH78 reacted to a post in a topic:

Sloop Speedwell 1752 by Chuck - Ketch Rigged Sloop - POF - prototype build

-

KennyH78 reacted to a post in a topic:

Endurance by Tomculb - OcCre - 1:70

KennyH78 reacted to a post in a topic:

Endurance by Tomculb - OcCre - 1:70

-

Glenn, the boarding ladder came out beautifully. And no one would have know about the slight mishap when turning her over if you hadn't mentioned it. A testament to your work and attention to detail!

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

KennyH78 reacted to a post in a topic:

HMS Winchelsea 1764 by glbarlow - FINISHED - 1:48

KennyH78 reacted to a post in a topic:

HMS Winchelsea 1764 by glbarlow - FINISHED - 1:48

-

KennyH78 reacted to a post in a topic:

HMS Winchelsea 1764 by glbarlow - FINISHED - 1:48

KennyH78 reacted to a post in a topic:

HMS Winchelsea 1764 by glbarlow - FINISHED - 1:48

-

KennyH78 reacted to a post in a topic:

Sloop Speedwell 1752 by Chuck - Ketch Rigged Sloop - POF - prototype build

KennyH78 reacted to a post in a topic:

Sloop Speedwell 1752 by Chuck - Ketch Rigged Sloop - POF - prototype build

-

KennyH78 reacted to a post in a topic:

Sloop Speedwell 1752 by Chuck - Ketch Rigged Sloop - POF - prototype build

KennyH78 reacted to a post in a topic:

Sloop Speedwell 1752 by Chuck - Ketch Rigged Sloop - POF - prototype build

-

KennyH78 reacted to a post in a topic:

Sloop Speedwell 1752 by Chuck - Ketch Rigged Sloop - POF - prototype build

KennyH78 reacted to a post in a topic:

Sloop Speedwell 1752 by Chuck - Ketch Rigged Sloop - POF - prototype build

-

KennyH78 reacted to a post in a topic:

Endurance by Tomculb - OcCre - 1:70

KennyH78 reacted to a post in a topic:

Endurance by Tomculb - OcCre - 1:70

-

KennyH78 reacted to a post in a topic:

HMS Winchelsea 1764 by glbarlow - FINISHED - 1:48

KennyH78 reacted to a post in a topic:

HMS Winchelsea 1764 by glbarlow - FINISHED - 1:48

-

She is looking quite exquisite! Beautifully done!

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

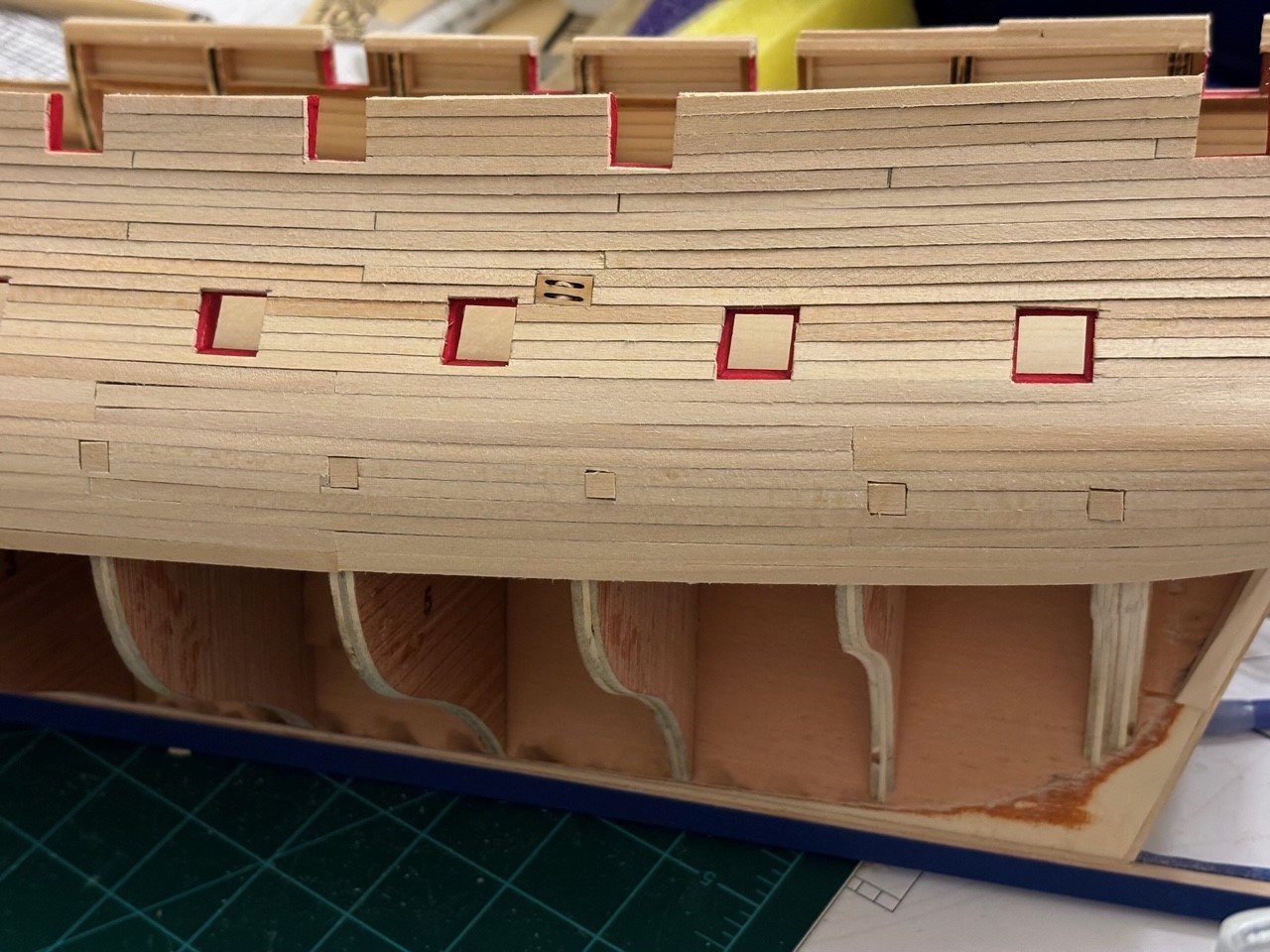

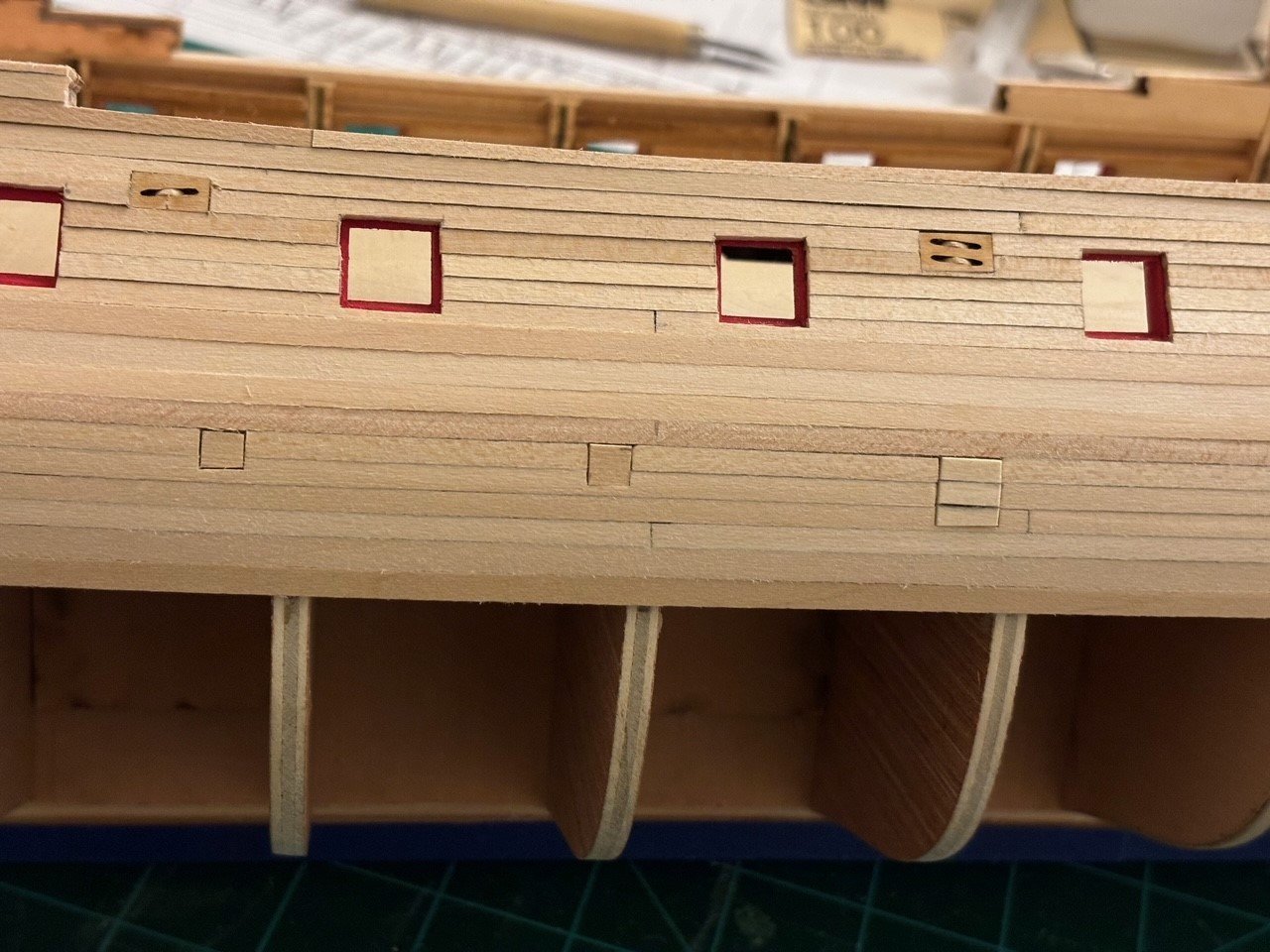

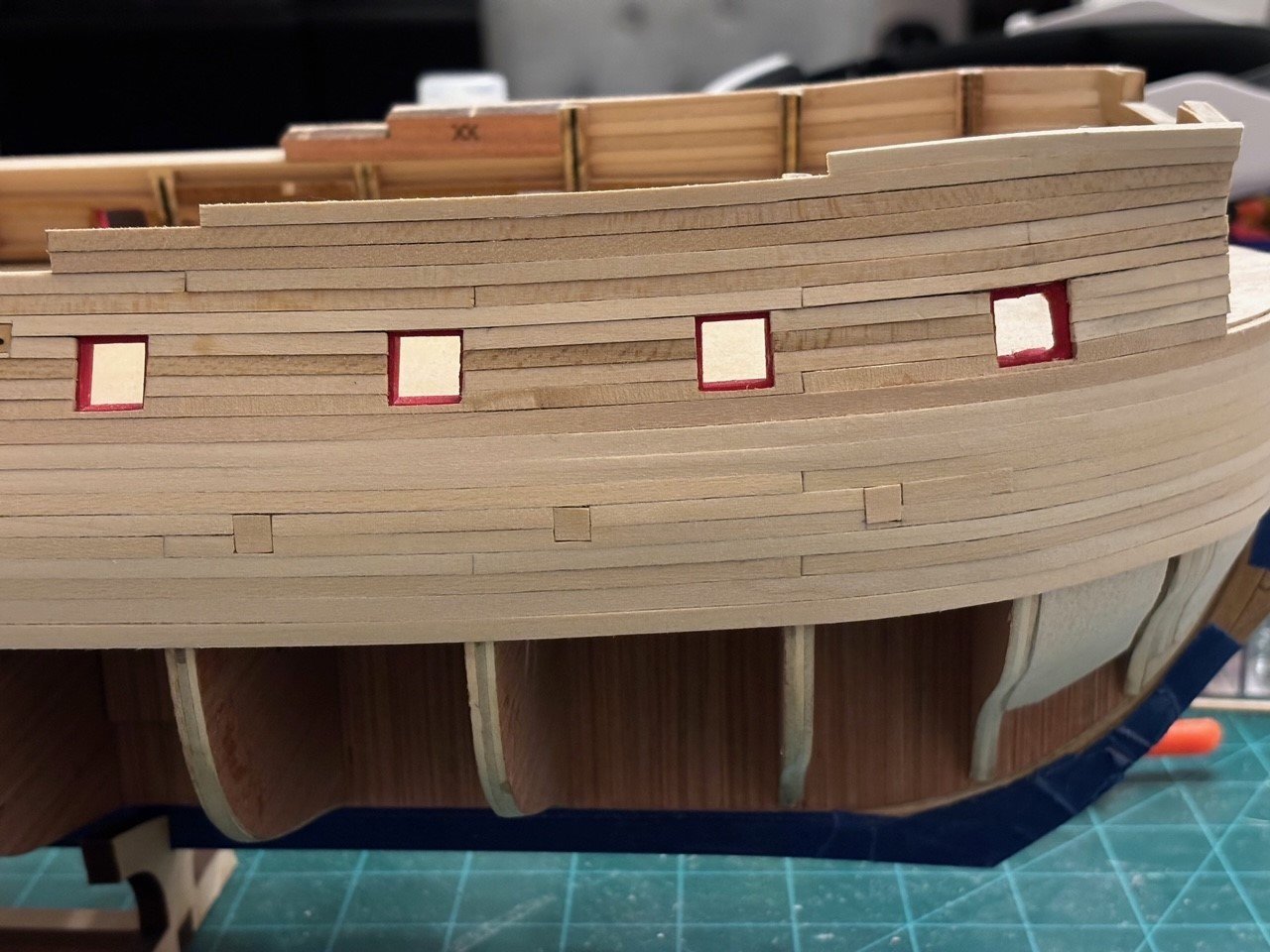

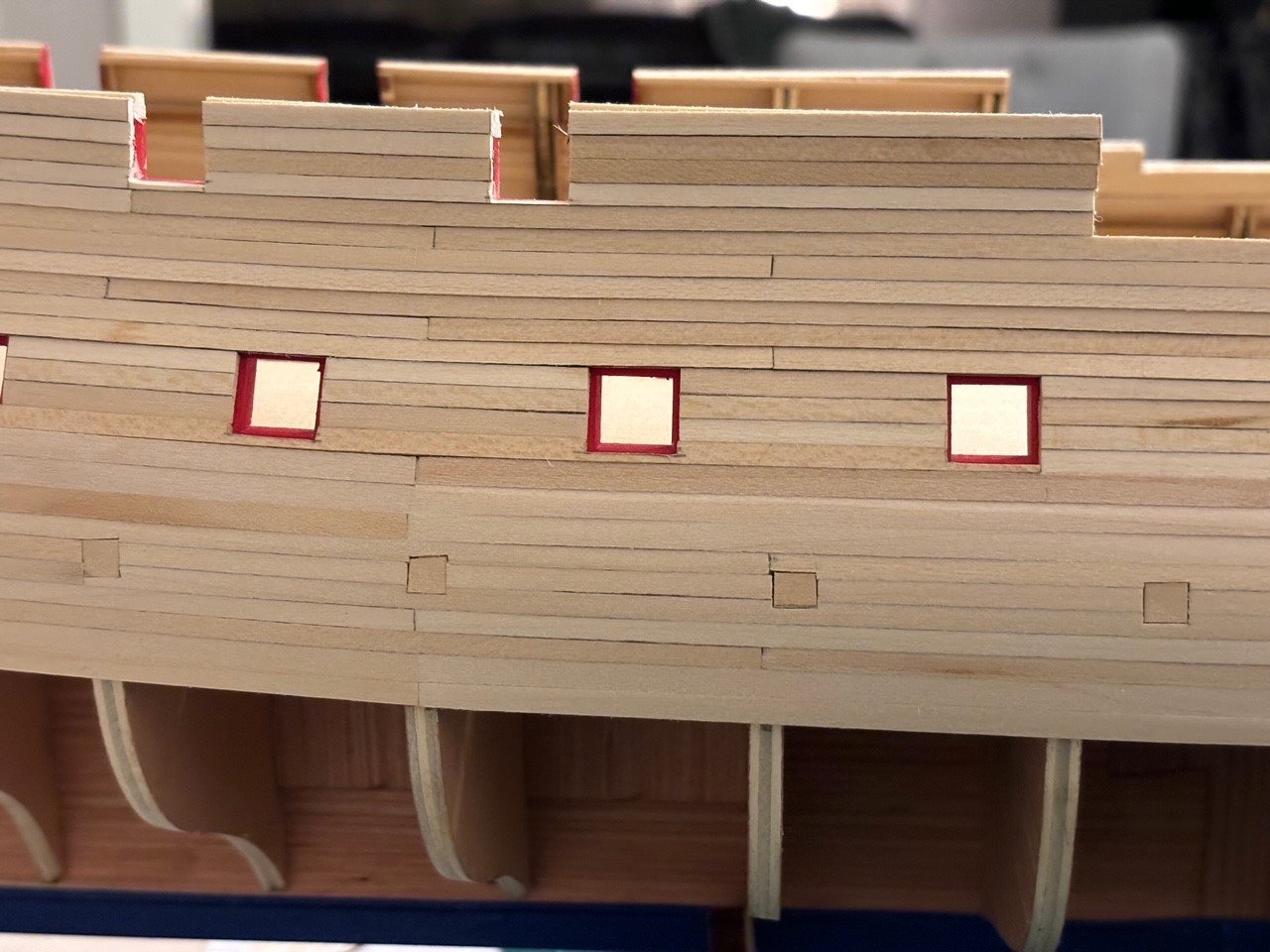

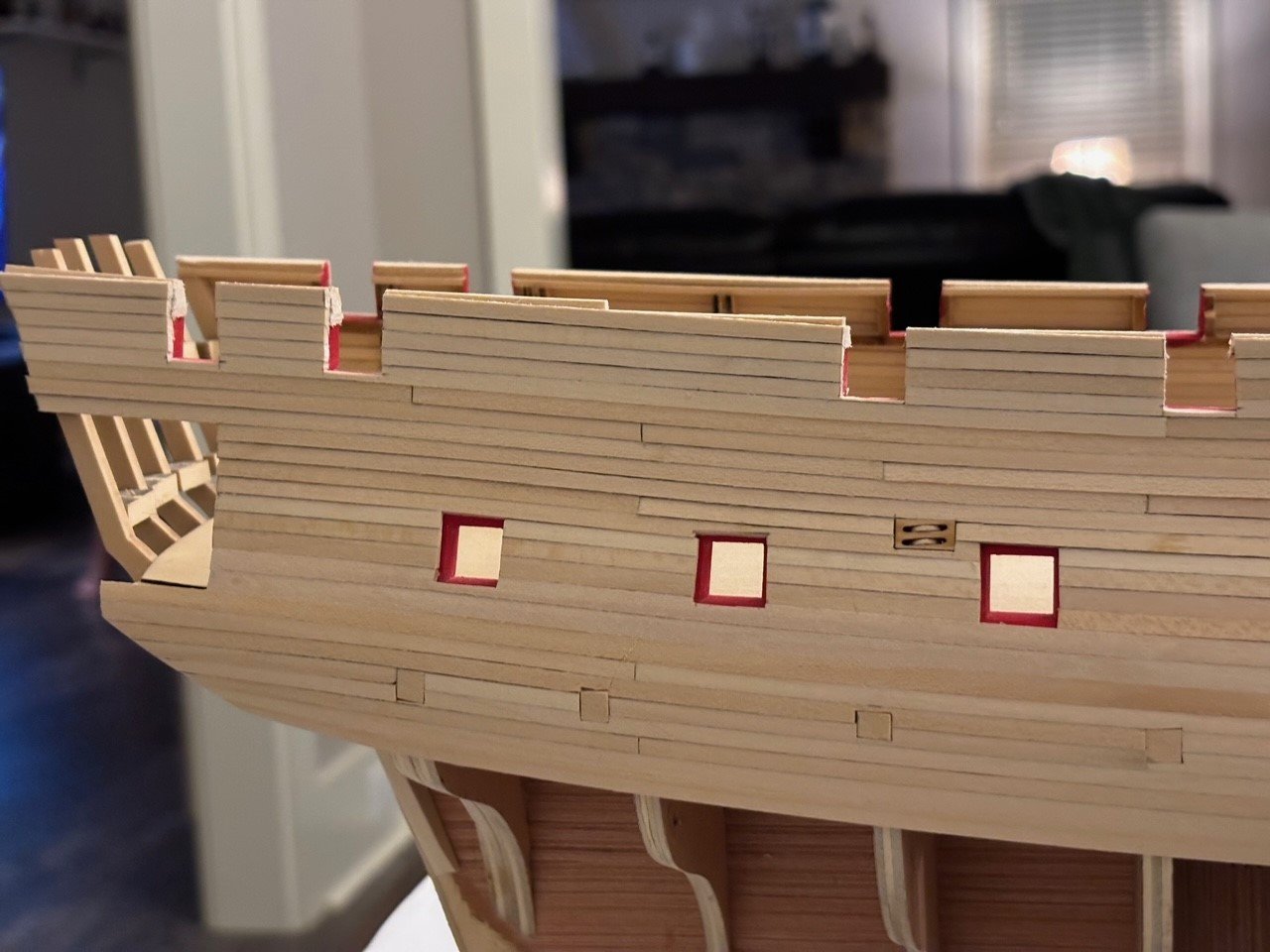

Starboard side is now planked up the sheer. The port sweep and ballast port lids have also been installed. The port side sweep ports and ballast port lids have also been installed. Next task is to do a rough sanding on the planks, install the remaining 3 blanks for the main wales on both side and then install the second layer on the main wales, channel wales and black strake.

-

JJ, coming along nicely and I must second the comment by Allan on the attention to detail. Your model will look stunning next to your Winnie. That really sucks, I hope that you are able to get your timber back. Seems like you just can't trust anyone anymore these days. That is why I have cameras set up all over the exterior of my house.

-

Looking really good. Glenn. She is shaping up to be a very superb model.

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

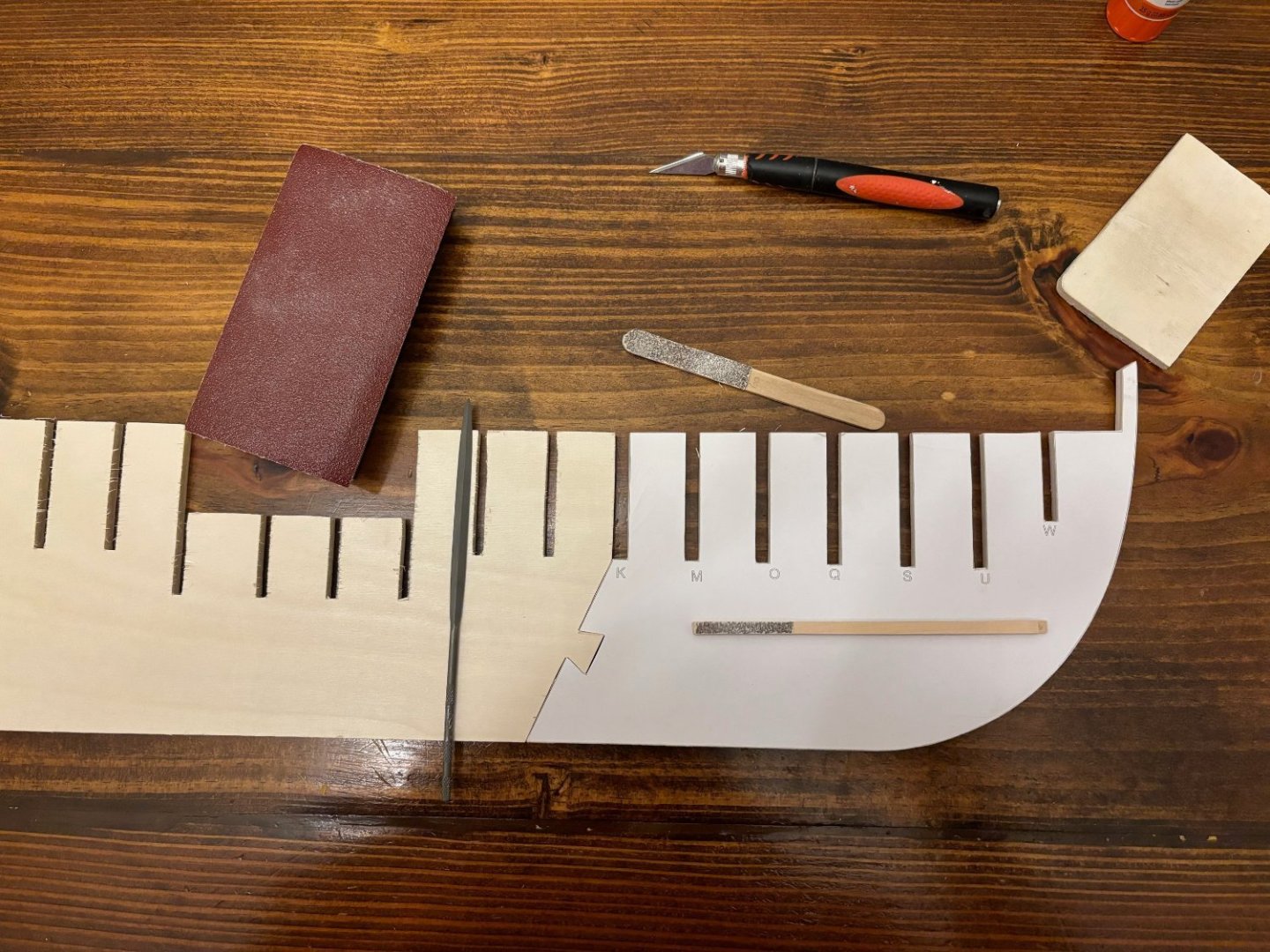

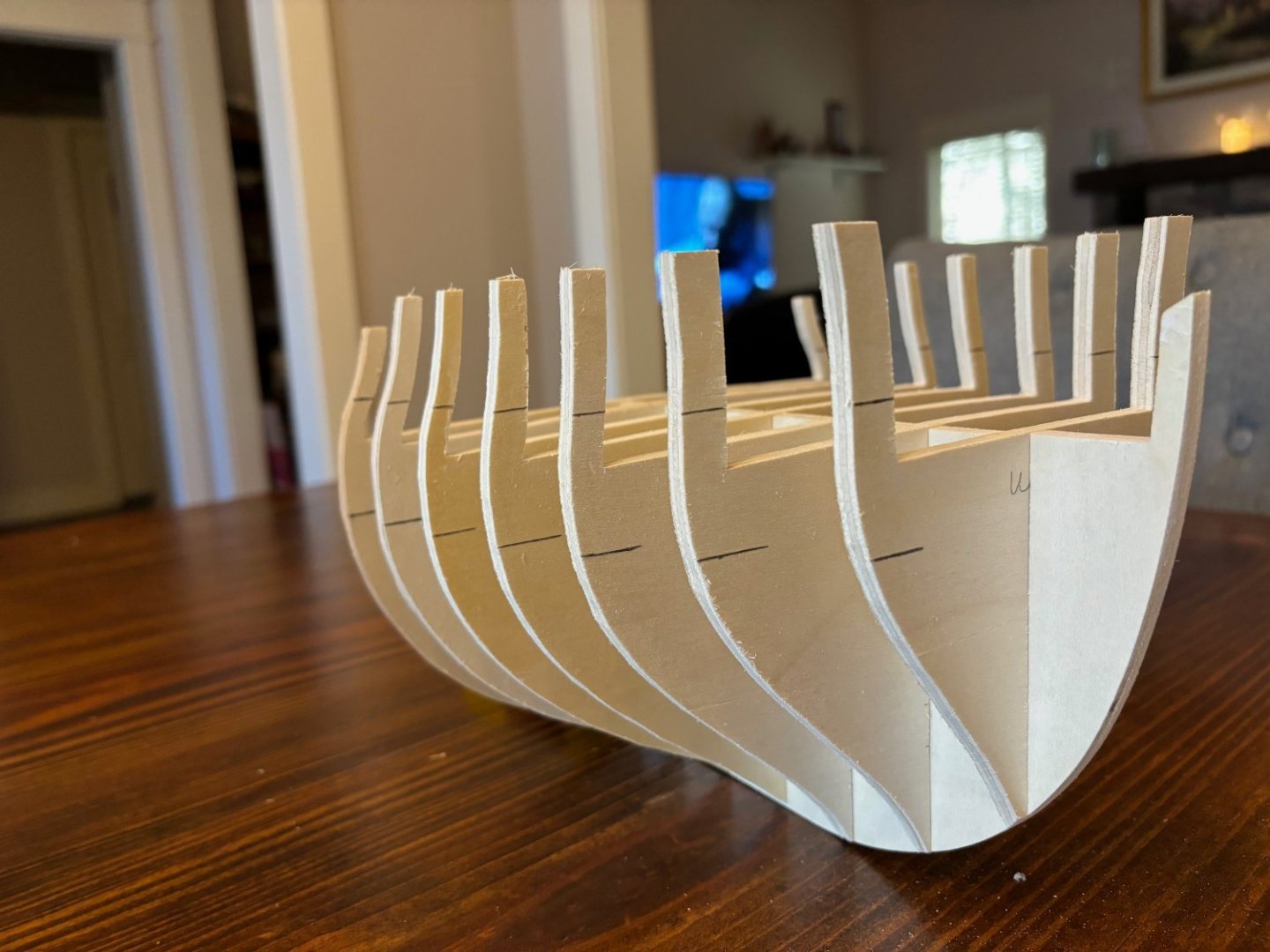

The ply that I used is 1/4” basswood ply that I bought off of Amazon. I got 6 sheets of 12x24 for $36. So far I have had zero issues with it. https://www.amazon.com/Basswood-Unfinished-Plywood-Rectangular-Architectural/dp/B0CG4JHZKR/ref=sr_1_1?crid=3MB3KVILE9HBK&keywords=6%2BPack%2B12%2Bx%2B24%2Bx%2B1%2F4%2BInch-6mm%2BThick%2BBasswood%2BSheets%2Bfor%2BCrafts%2BUnfinished%2BPlywood%2BSheets%2BRectangular%2BWood%2BPanel%2BBoards%2Bfor%2BDIY%2BLaser%2BProject%2C%2BWood%2BBurning%2C%2BEngraving%2C%2BArchitectural%2BModels%2C%2BStaining&qid=1707695587&sprefix=6%2Bpack%2B12%2Bx%2B24%2Bx%2B1%2F4%2Binch-6mm%2Bthick%2Bbasswood%2Bsheets%2Bfor%2Bcrafts%2Bunfinished%2Bplywood%2Bsheets%2Brectangular%2Bwood%2Bpanel%2Bboards%2Bfor%2Bdiy%2Blaser%2Bproject%2C%2Bwood%2Bburning%2C%2Bengraving%2C%2Barchitectural%2Bmodels%2C%2Bstaining%2Caps%2C110&sr=8-1&th=1

-

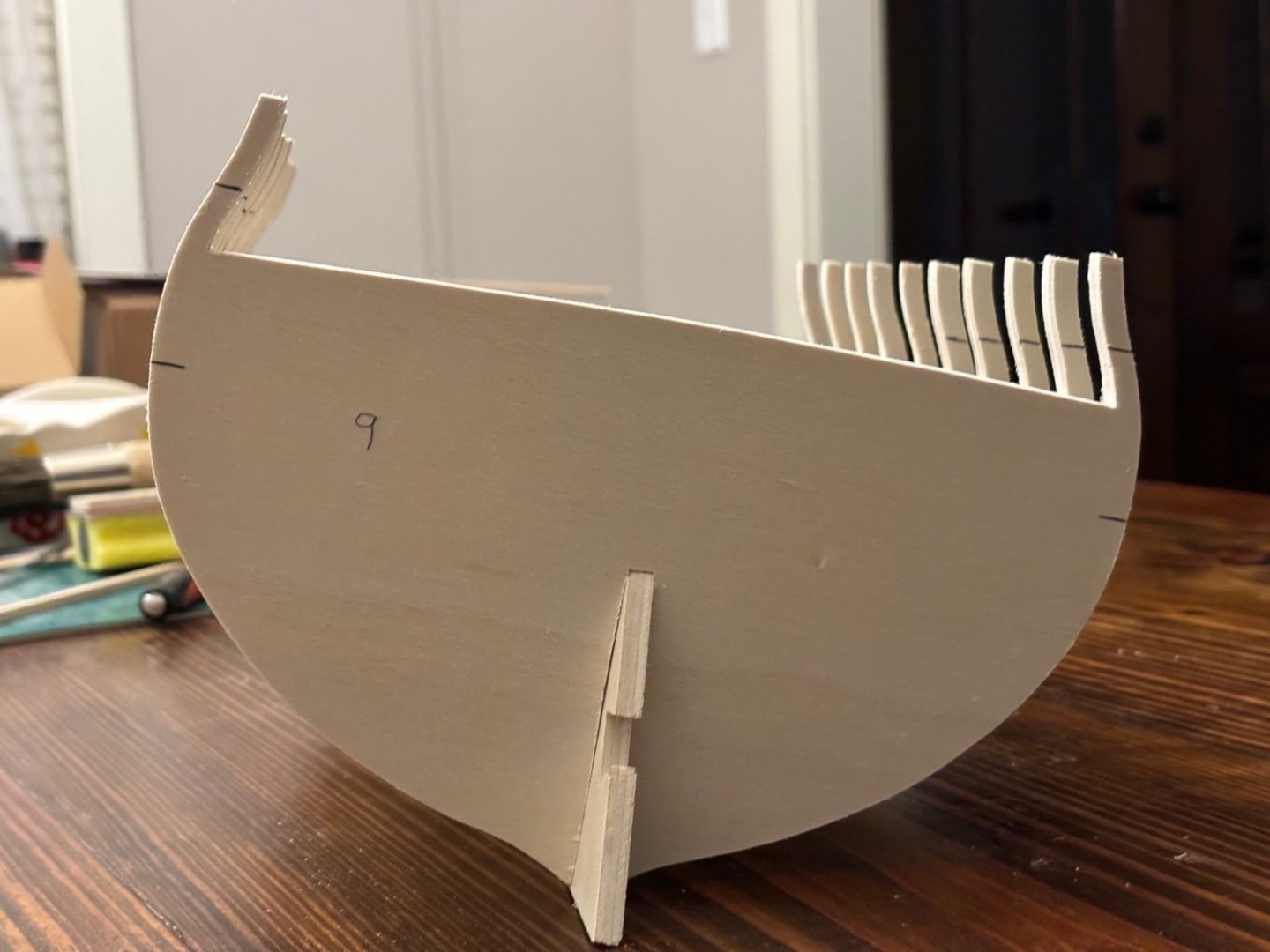

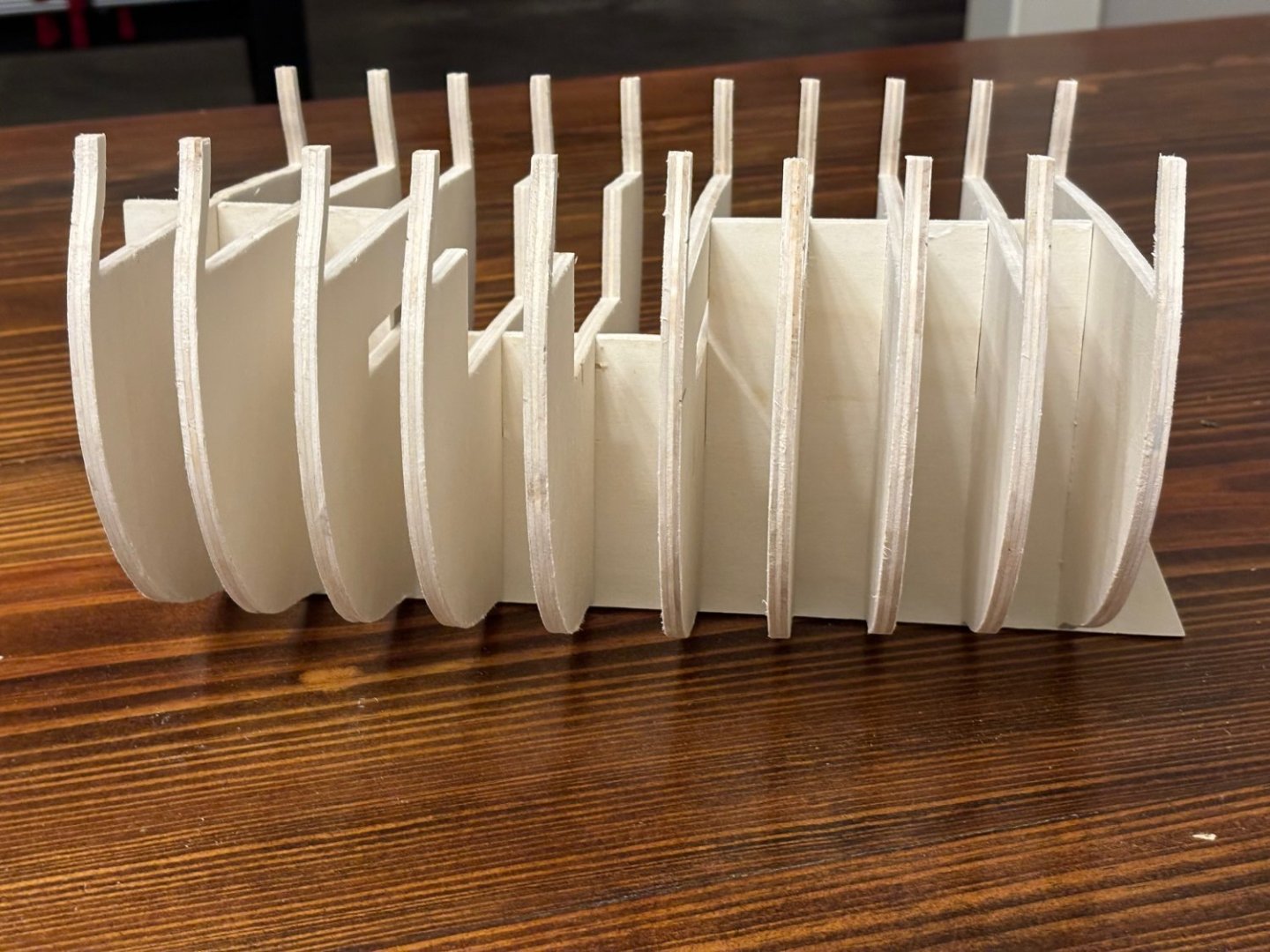

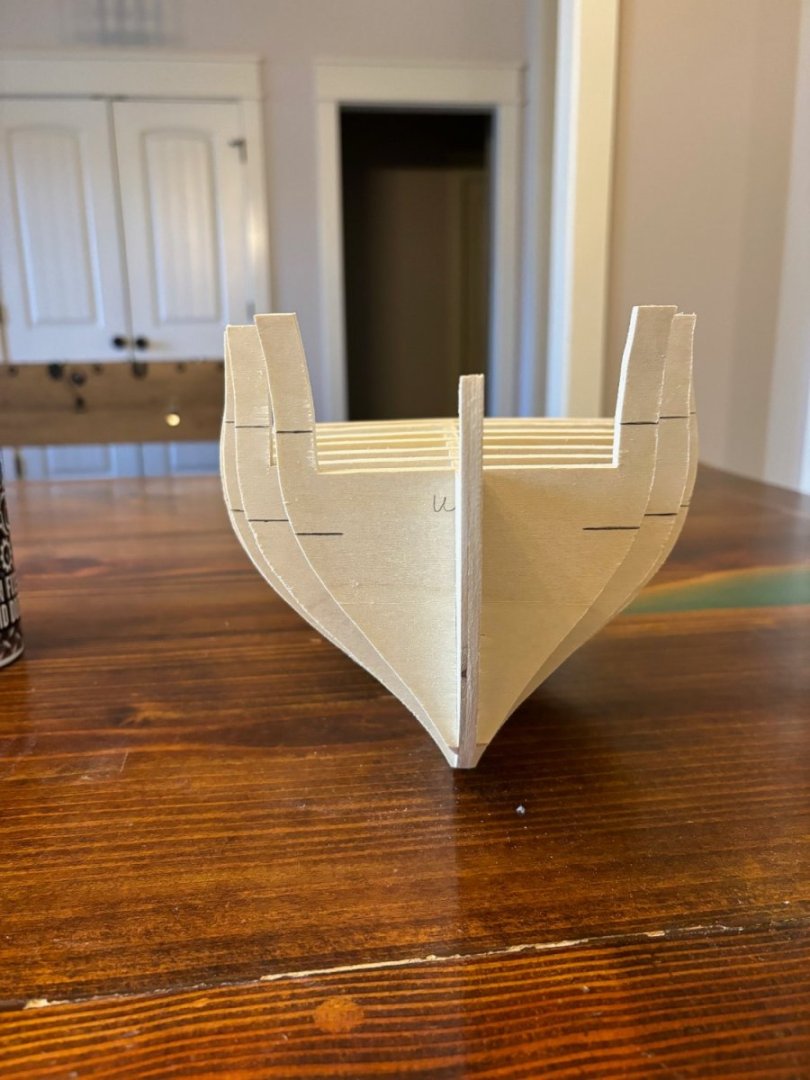

Thank you for all of the likes. Progress is moving along, even if it is at a snail's pace. I got bulkheads K-W fitted to the forward former. The forward former piece is also fitted to the middle former piece. The bulkheads are only dry fitted right now. Working on the middle former piece now along with bulkheads I through 9. I also cut out the pieces for the skeleton hold up clamps on my X-Carve. So far I have 2 of them assembled; only 4 more to go. Once I get these all assembled and the bulkhead former completed, I will make the build board for the model. As always, thanks for looking in on my log; any and all comments are welcomed.

-

Why am I always late to the party? Simply amazing with the design and build so far, I will be following along intently with my bucket of popcorn and chair.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.