-

Posts

52 -

Joined

-

Last visited

About Marsares

- Birthday 05/01/1976

Profile Information

-

Gender

Male

-

Location

England

Recent Profile Visitors

-

Gundorph reacted to a post in a topic:

US Brig Syren by Marsares - Model Shipways - 1:64

Gundorph reacted to a post in a topic:

US Brig Syren by Marsares - Model Shipways - 1:64

-

fatih79 reacted to a post in a topic:

US Brig Syren by Marsares - Model Shipways - 1:64

fatih79 reacted to a post in a topic:

US Brig Syren by Marsares - Model Shipways - 1:64

-

fatih79 reacted to a post in a topic:

US Brig Syren by Marsares - Model Shipways - 1:64

fatih79 reacted to a post in a topic:

US Brig Syren by Marsares - Model Shipways - 1:64

-

fatih79 reacted to a post in a topic:

US Brig Syren by Marsares - Model Shipways - 1:64

fatih79 reacted to a post in a topic:

US Brig Syren by Marsares - Model Shipways - 1:64

-

fatih79 reacted to a post in a topic:

US Brig Syren by Marsares - Model Shipways - 1:64

fatih79 reacted to a post in a topic:

US Brig Syren by Marsares - Model Shipways - 1:64

-

fatih79 reacted to a post in a topic:

US Brig Syren by Marsares - Model Shipways - 1:64

fatih79 reacted to a post in a topic:

US Brig Syren by Marsares - Model Shipways - 1:64

-

Ryland Craze reacted to a post in a topic:

US Brig Syren by Marsares - Model Shipways - 1:64

Ryland Craze reacted to a post in a topic:

US Brig Syren by Marsares - Model Shipways - 1:64

-

Marsares reacted to a post in a topic:

Prins Willem 1650 by Michiel - 1:50 - POB Zeeland ship from own plans

Marsares reacted to a post in a topic:

Prins Willem 1650 by Michiel - 1:50 - POB Zeeland ship from own plans

-

Marsares reacted to a post in a topic:

Prins Willem 1650 by Michiel - 1:50 - POB Zeeland ship from own plans

Marsares reacted to a post in a topic:

Prins Willem 1650 by Michiel - 1:50 - POB Zeeland ship from own plans

-

CaptMorgan reacted to a post in a topic:

US Brig Syren by Marsares - Model Shipways - 1:64

CaptMorgan reacted to a post in a topic:

US Brig Syren by Marsares - Model Shipways - 1:64

-

Marsares reacted to a post in a topic:

Prins Willem 1650 by Michiel - 1:50 - POB Zeeland ship from own plans

Marsares reacted to a post in a topic:

Prins Willem 1650 by Michiel - 1:50 - POB Zeeland ship from own plans

-

Marsares reacted to a post in a topic:

Prins Willem 1650 by Michiel - 1:50 - POB Zeeland ship from own plans

Marsares reacted to a post in a topic:

Prins Willem 1650 by Michiel - 1:50 - POB Zeeland ship from own plans

-

Marsares reacted to a post in a topic:

US Brig Syren by Gahm - Model Shipways

Marsares reacted to a post in a topic:

US Brig Syren by Gahm - Model Shipways

-

Spiderpig reacted to a post in a topic:

US Brig Syren 1803 by Spiderpig - Model Shipways - Scale 1:64

Spiderpig reacted to a post in a topic:

US Brig Syren 1803 by Spiderpig - Model Shipways - Scale 1:64

-

Marsares reacted to a post in a topic:

US Brig Syren by sshadow9648 - Model Shipways - Scale 1:64

Marsares reacted to a post in a topic:

US Brig Syren by sshadow9648 - Model Shipways - Scale 1:64

-

Marsares reacted to a post in a topic:

US Brig Syren 1803 by Spiderpig - Model Shipways - Scale 1:64

Marsares reacted to a post in a topic:

US Brig Syren 1803 by Spiderpig - Model Shipways - Scale 1:64

-

Marsares reacted to a post in a topic:

US Brig Syren by Gahm - Model Shipways

Marsares reacted to a post in a topic:

US Brig Syren by Gahm - Model Shipways

-

Marsares reacted to a post in a topic:

US Brig Syren by danri - Scale 1:64, 1803

Marsares reacted to a post in a topic:

US Brig Syren by danri - Scale 1:64, 1803

-

Marsares reacted to a post in a topic:

Wasan 1628 by Nazgul - FINISHED - Billing Boats Vasa 1:75

Marsares reacted to a post in a topic:

Wasan 1628 by Nazgul - FINISHED - Billing Boats Vasa 1:75

-

Progress has been slow this weekend. Being away from the missus the whole week I dont always feel inclined to disappear too much and work on my ship as I want to spend time with her. Nevertheless, I managed to line up the stern gunports properly so the cannons will fall in the middle of the port, but when I started to chisel away excess wood of the gunport lintels and sills I managed to drive a chisel into my thumb. Nothing major, but felt that perhaps I should take a breather and finish it coming weekend. Started to think about purchasing additional wood for the hull planking as I want to do it in pearwood and ideally buy some sheets so I can try some spiling rather than planking with just straight strips. Found a good supplier in the UK, so doing some calculatiins on how much in need and wilk probably order some, initially for the exterior planking only.

-

alde reacted to a post in a topic:

US Brig Syren by Marsares - Model Shipways - 1:64

alde reacted to a post in a topic:

US Brig Syren by Marsares - Model Shipways - 1:64

-

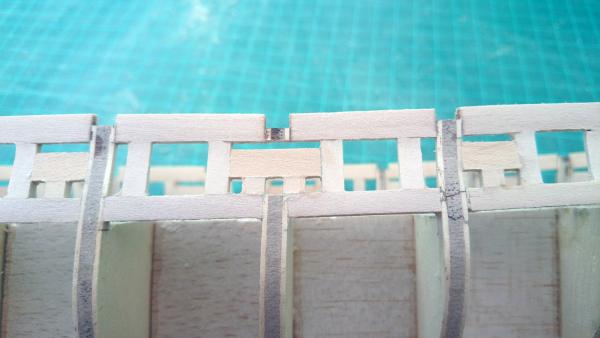

USS Brig Syren Part 7: Stern Framing Step 1: Verticals Taking the stern frames out of the wood was somewhat nerve-wracking. Having broken a fair few bulwarks already, I was only too aware how fragile the basswood is especially for pieces that are so thin. Nevertheless, I managed to cut them out unbroken and started cutting the fillers to length, using the provided template as a guide. Placing the first filler was dead-easy, placing the first vertical less so. I had to ensure that it ended up in the right position in three different planes, with little to go by. I set up a quick and dirty jig using an iron square to at least lock the frame in two different planes, with the third one judging by eye. Adding the next frame gave a further complication as it needed to up exactly like the previous one, whilst maintaining the appropriate distance between them. In order to achieve this, I stuck a temporary piece of width, cut to the appropriate length, between them and held it in place with a piece of plastic band whilst the glue dried up. I used this method throughout and achieved a result that I was happy with, without snapping a single one of the frames. Happy days! Step 2: Horizontals Before I started adding the gunport sills and lintels, I noticed that the tops of the stern frames were not 100% aligned so I clamped a temporary batten in place to completely line them up before I taped the template in place using the laser markings as a guide. Before I started glueing the spacers in place I remembered that a few chapters down the line a cardboard cannon was used to judge the appropriate height of the gun port sills. I think I remembered this as at the point of reading it I didn't quite get why it was done at such a late stage with everything already in place and no ability to make any adjustments. Therefore, I quickly knocked this up and tested the laser-markings for the gunport sills and noticed that they didn't quite sit in the right position. The gun would have some clearance from the sills, but it would be absolutely marginal and ideally the gun would sit in the middle of the gunport. I rechecked my measurements, but the only thing that I think I could have done wrong is that the whole stern is slightly twisted towards the bow, thereby lifting it somewhat up. It approached dinner time anyways, so I left it there and thus giving me some time to mull things over. I am not too worried about it, by dropping the lintels and sills somewhat I should be able to achieve a good clear finish with the cannon in the middle of the gunport. Still, any thoughts are appreciated! Kind regards, Martijn.

-

@Thomas: Thanks! It'll be some time before I can even compare to your fine craftsmanship, but I'll take the compliment nevertheless! ;-) @Tim: I bough them from a UK-based company called Cornwall Model Boats (http://www.cornwallmodelboats.co.uk/acatalog/fl6040.html), but given that you're USA based that may be problematic. Apparently, they're called Modelcraft Sanding Blocks, so perhaps something closer to home has them? Good luck finding them!

-

USS Brig Syren Part 6: Gun Port Lintels and Sweep Ports Step 1: Gun Port Lintels For the gun port lintels I used the same approach as for the sills, as in that I ignored the templates and got a temporary batton in place. I've read on various other blogs that they with their lintels they had them glued in the right place, but then when they checked a while later gravity had taken it's toll and they were no longer in the right location. Therefore, I decided to align the top of the temporary batton with the bottom of the lintels, so the lintels could somewhat rest on the temporary batton. Given that that the natural flow had been established for the sills, it was just a case of replicating this flow for the lintels whilst bearing in mind that a distance of 15/32" should remain between them, as that's the height and width of the gunports. I toyed with making a 15/32" block of wood to get this distance consistent across the whole run of the ship, but instead reverted back to my trusted calipher. I basically used my calipher to quickly mark the appropriate distance by hand, clamped a temporary batton in place and then re-measured with the calipher and adjusted. Once the distance between temporary batton and gun port sill was perfectly 15/32", I double-checked the flow of the batton before I started placing the gun port lintels. Step 2: Sanding With the lintels and sills in place I felt that the bulwarks were now sufficiently supported to take some serious sanding. I was still somewhat apprehensive, given that I had snapped a fair few previously, but it was remarkable how strong the ship now had become. Still, a fair bit of sanding had to take place in order to ensure that the bulkwarks would end up as 3/32" below the railcap and 1/8" thick at the deck level. I tried various tools, including electrical ones but at the end of the day nothing beats some elbow-grease I found. The outside of the ship was rather easy to sand as you had easy access and the curve of the ship helped, the inside turned out to be a completely different kettle of fish. Luckily I had seen this problem coming so I ensured that the lintels and sills were placed as much as possible towards the outside, with as little as possible sticking out on the inside. Eventually I ended up using three tools over and over again. Especially the big sander turned out to be a life-safer on the sanding of the inside given it's many curved angles. Step 3: Sweep Ports After some rigorous sanding, the gunport templates started to line up very well but still I decided to used my own measurements for the sweep-ports and once again used my calipher to ensure that everything was at the right distance of each other. Step 4: More Sanding With the sweep-ports final sanding took place, once again by hand. It's imperative to constantly keep checking with a temporary batton to ensure that you're fairing the hull correctly for planking later on. I've completed the whole hull now and re-took measurements, it's now just a case of fine-tuning here and there. Off to Chapter Four - Stern Framing! Let's see how many of those little buggers I'll manage to snap! :-) Kind regards, Martijn.

-

USS Brig Syren Part 5: Gun Port Sills Well, progress has been virtually non-existent the last month or so. First we had a bit of a heart-attack as at the 12 weeks scan the sonographer dropped a bomb-shell on us: "Well, here's your baby.... and here's your second baby." Apparently my girlfriend was laughing hysterically and I was white as a sheet. Very happy of course once it sunk it, but reading up and shopping takes a lot of time, and the little peanuts aren't even born yet. Drop on top of that a new job in London, so I'm away during the week, and time to work on my beloved Syren suddenly has become a precious commodity. Nevertheless, today is a bank holiday so I've finally managed to complete Chapter Three. Step 1: Gun Port Templates As you would have read in my previous post, I was somwhat flabbergasted as the templates that were provided with the kit really didn't line up with reality, which was rather frustrating as I had spend so much time ensuring that my bulkheads were square to the former. Eventually it dawned on me that the only thing I hadn't done well enough was the fairing of the bulkheads, and that they needed some further sanding. I got on with it and eventually the templates started to fall in line. They still weren't perfect, but given that plenty more sanding will follow in order to line up the gun port sills and lintels, I didn't want to go too far at the first step. Step 2: Gun Port Sill Height Another thing that came apparent from the templates that if I followed the laser-etched markets on the bulkheads, I wouldn't get a natural flow but also that the vertical location of them seemed somewhat out of line. I flicked through the manual and noticed the following build-up from the top of the bulkhead former: - Deck planking: 1/16" - Waterway: 1/16" - Space between top of sill and top of waterway: 1/16" Getting the right vertical location of the gunport sills is critical, as otherwise at a later stage your waterway may be too close or too far from it, which will impact on the look of your finished model. So I quickly knocked up a little piece of wood that gave me the appropriate distance and scribed new marks on the bulkheads, ignoring the original laser-etched ones. Step 3: Gun Port Sill Flow With the new vertical locations marked on each bulkhead, I could tentatively clamp a temporary batton in place. From there on it's just a case of constantly checking it by eye from the sides to ensure that you have a natural flow. Key is that you don't try to force the batton in place, but try to let it run as much as possible how it wants to, bearing in mind that it doesn't stray too far away from your markers. It's a good idea to check the run from every angle possible. I found that once I had established a natural run from one angle, it didn't always feel smooth enough from another one. Once I was satisfied with my gunport run, I added a temporary batton on the port run. This is important as you don't want to start getting the lintel in place on one side, before you mirror it as closely as possible on the other side in case further adjustments are needed. I basically followed the same procedure as for the gunport side, and once I had established a natural flow I checked on the stern and stem to ensure that they ended up in the same position. Luckily, mine did. With some further measurements and minor adjustments and managed to get a identical run on both sides of the ship. Step 4: Gun Port Sill Placement I used a different approach from the manual when I started placing my gunport sills as in that I left my temporary batton clamped in place. After all the careful measurements that I had done to ensure a natural flow, I felt that I wouldn't be able to quite replicate that by marking the bulkheads, so instead used the temporary batton as a guide. This gave the benefit that it was really quick and easy to put the gunport sills in place, whilst it also gave me a great guide to ensure that they were level in the horizontal plane. Once I had left the carpenter's glue to dry overnight I removed the temporary batton and checked the flow of the sills from all angles. After that, it was just a case of replicating the process on the port side. Kind regards, Martijn.

-

Yes, he is and he's keeping a keen eye on every single Syren build log and is always happy to provide advice and guidance. The manual is also very very good. As a first time ship builder it has steered me through the process so far without any issues. There are also a plethora of Syren build logs out there, so there's always somebody at hand to help you. Chuck designed a few other models as well, such as the Confederacy.

-

I'm building the USS Syren from Model Shipways ( so far the kit has been excellent. I wish some basswood pieces were replaced with a bit stronger wood and some of the Britannia castings aren't as clean as I'd like, but I'm a bit of a stickler for detail. Price was reasonable, everything was there upon delivery and in good order, and the manual is outstanding. The seller ModelExpo also give a guarantee that if something is missing or breaks during build, they'll replace it free of charge with no postage costs. I've read in build logs that they even honor this commitment when people make mistakes themselves.

-

Well, in my very very short ship modelling career so far I can't profess to be an expert whatsoever, but for what it's worth these are the lessons I've learned so far (I'm sure you've found these yourself though): - Think and plan ahead - Learn from other's mistakes but also their hints and tips - Measure, measure again and then once more - Always dry-fit before you glue. - Cut/shave/sand little and test often - Take a step back and check what you've done - Don't be afraid to deconstruct and fix any errors - And most of all... do not rush And like my father always taught me: making a mistake doesn't make you stupid, making the same mistake twice makes you stupid. :-) In spite of that, I'm guaranteed to make more mistakes as I go along. Enjoy the journey though, not the destination. In any case, I think your Syren turned out to be a true beauty. Thanks for the tip on the masts by the way, I would indeed more confident to drill a pilot hole now and get the angle right whilst everything you see at the moment will be hidden, rather than working with a drill when the ship is in a pristine condition. Will have to read that chapter again and bring it forward a bit. Good thinking!

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.