Search the Community

Showing results for tags 'photoetch'.

-

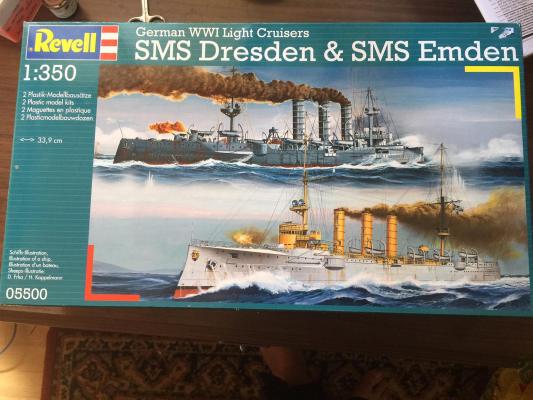

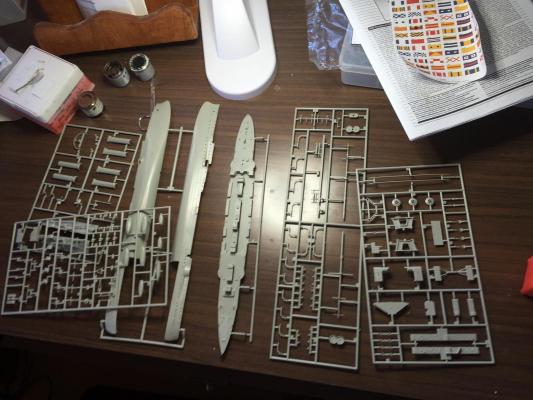

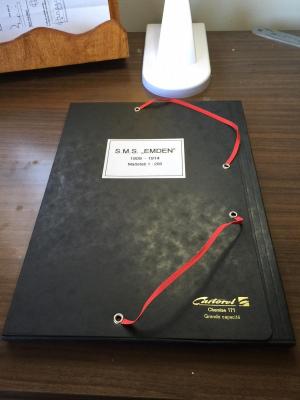

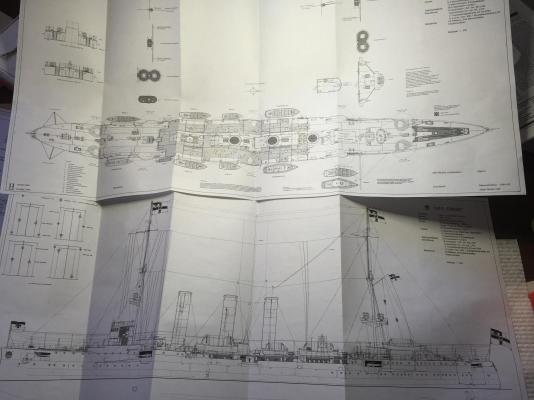

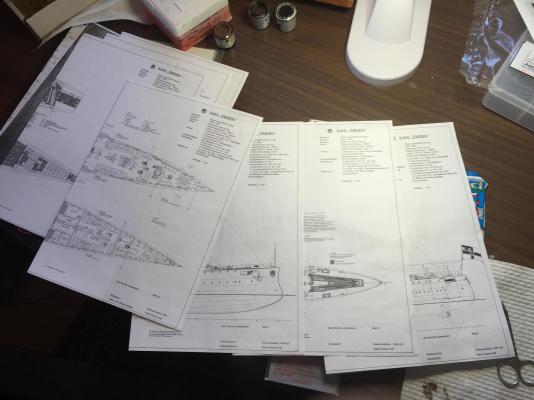

My third build will be the SMS Emden. It has a history for us Aussies I suppose. I won't go into the history as there is the whole of the internet for that. Revell brought out a twin kit recently which will be good if I stuff up something, as I don't intend on building both it and the Dresden. There are a lot of open source builds on the net for this kit, most of which seem to be strait out of the box. I managed to purchase the last set of draughts in 1/200 on the internet for Peter Huff's 1995 publication. I had a look at the Kagero book and yet again, their research leaves a bit to be desired, as the even the photos don't match. The kit will need a LOT of bashing. Thus more internet shopping for bits and pieces. Heaps of work, but that's the joy of it. I got the Eduard Emden photo etch set for a start. A lot of the sprues look like they have been put in an oven as they just look blurry with very little detail. There will be very little of the original kit used but the hull is nice. I'm thinking six or more months, given my Varyag has a lot more detail but also a lot more commercially available extras. This era is not well represented for after market.

-

I got this for over half price from a model club member, so it justified getting the photoetch from Eastern Europe.

-

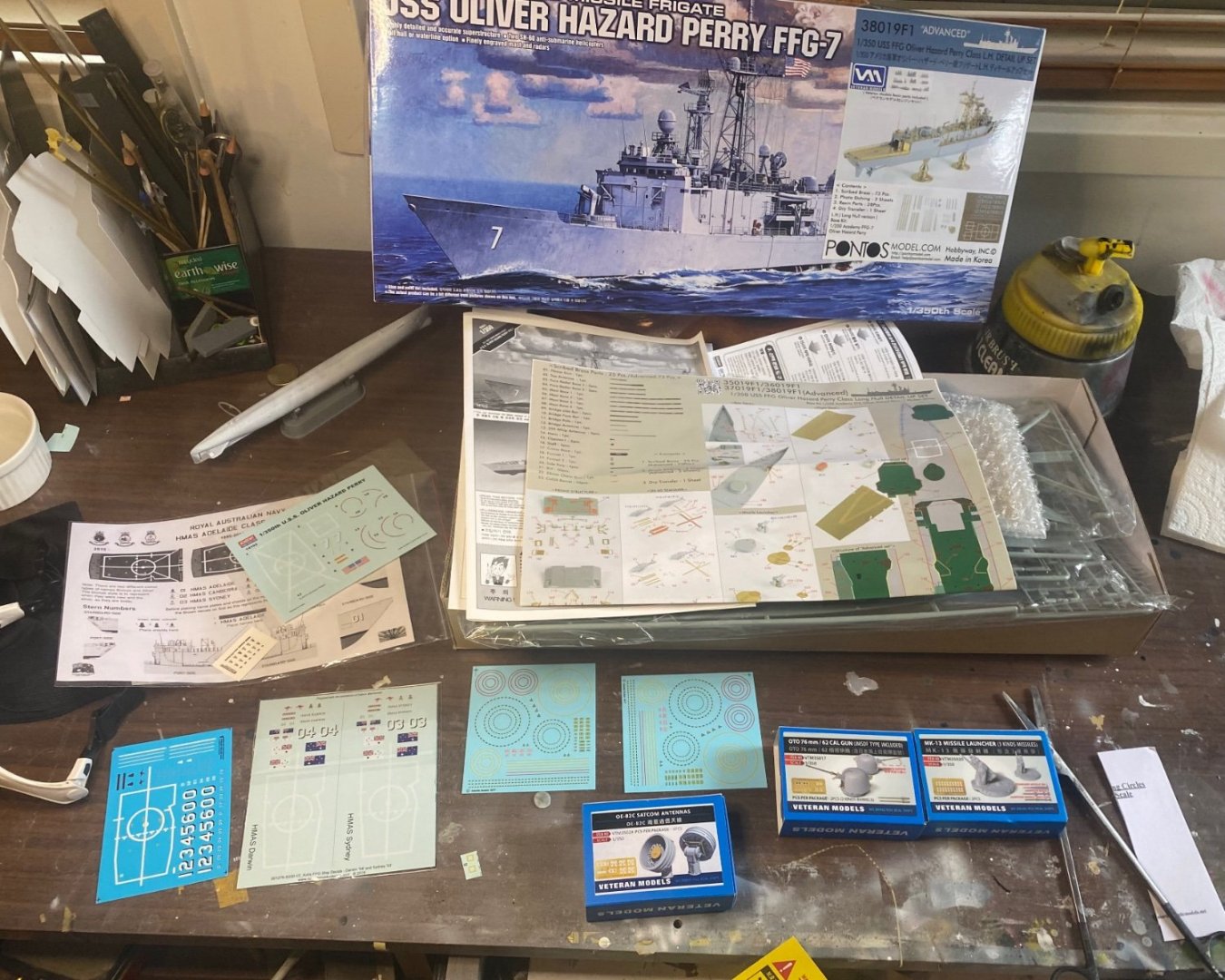

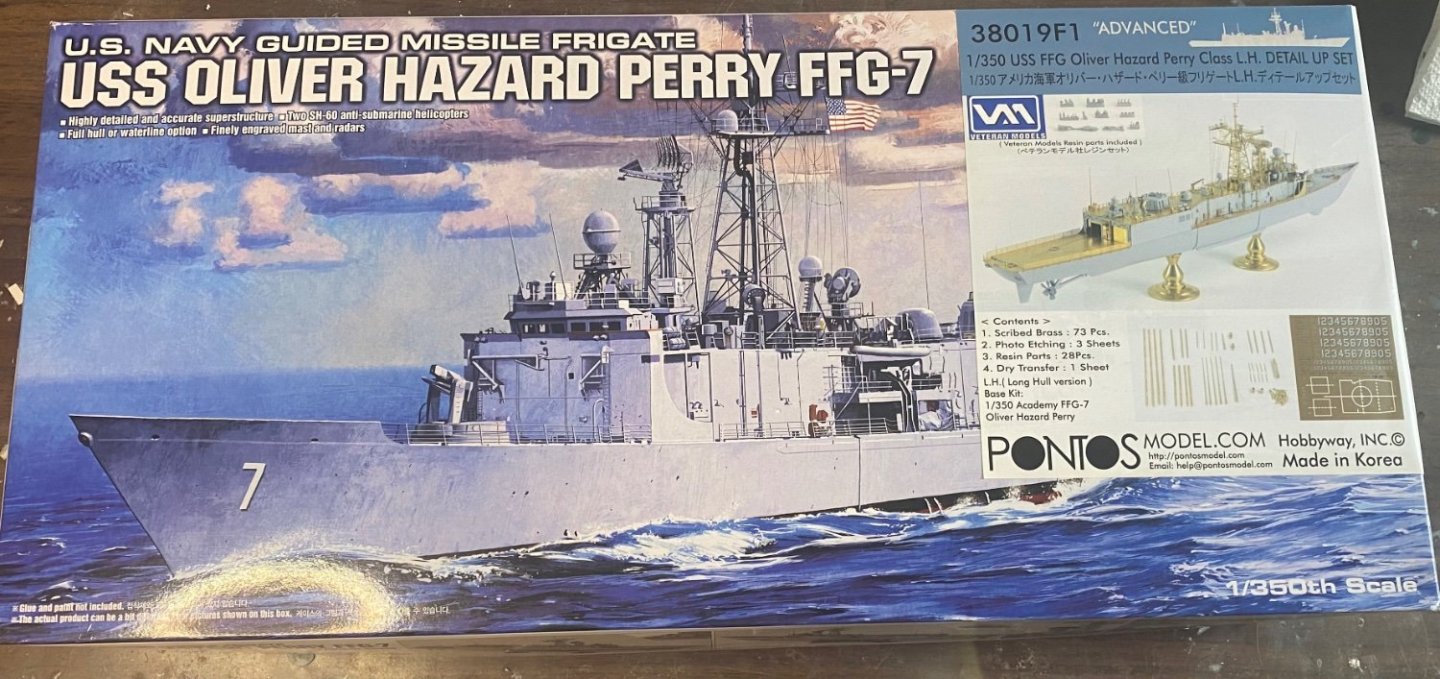

I’ve got about 4 builds planned this year, and this set is a really reasonable price as it comes with an excellent PE Set from Pontos. I have some other extras from Veteran models and aftermarket decals. there are a HEAP photos of a Sydney and this class of ship on Facebook as well as those who have served on her.

-

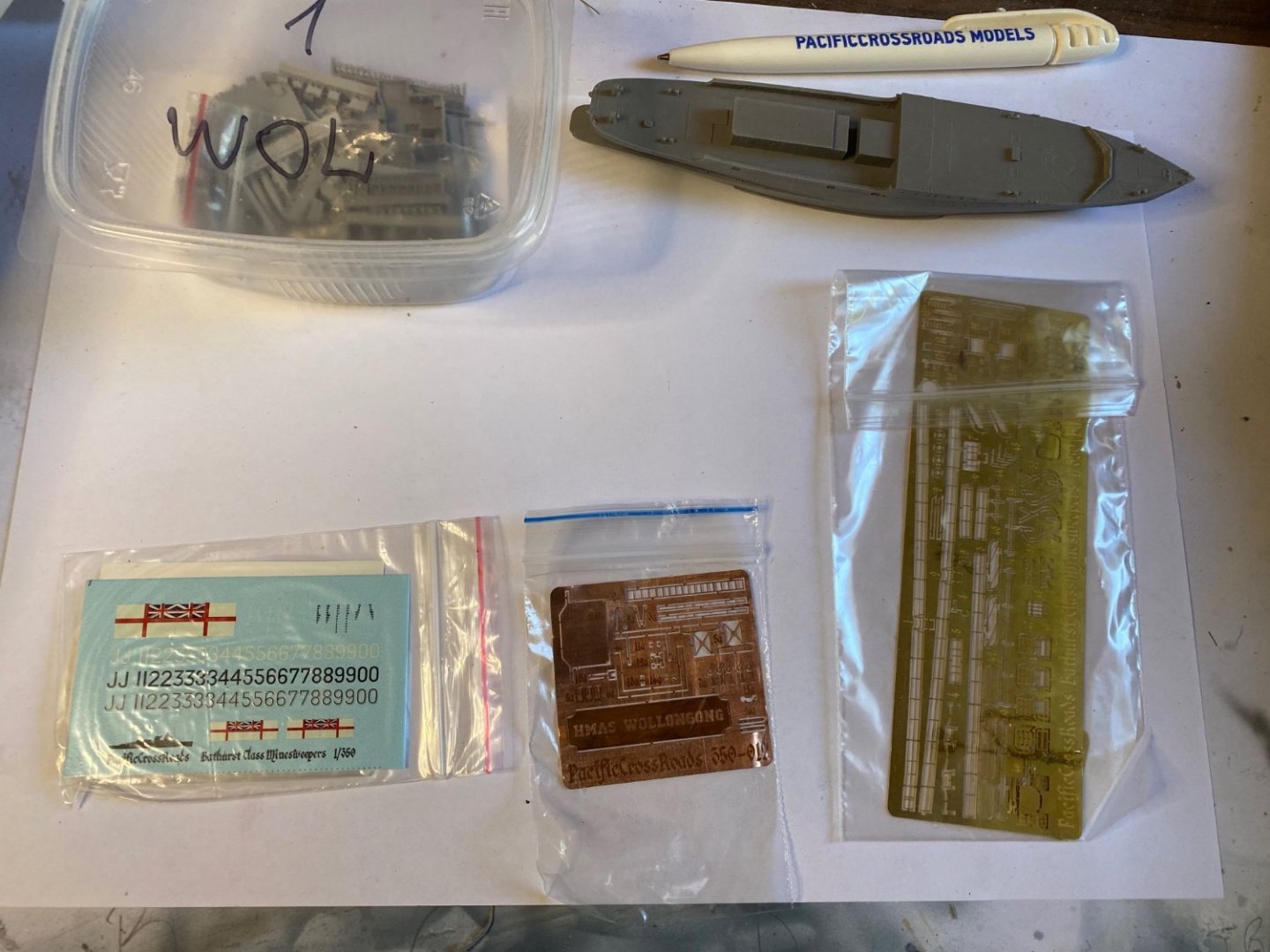

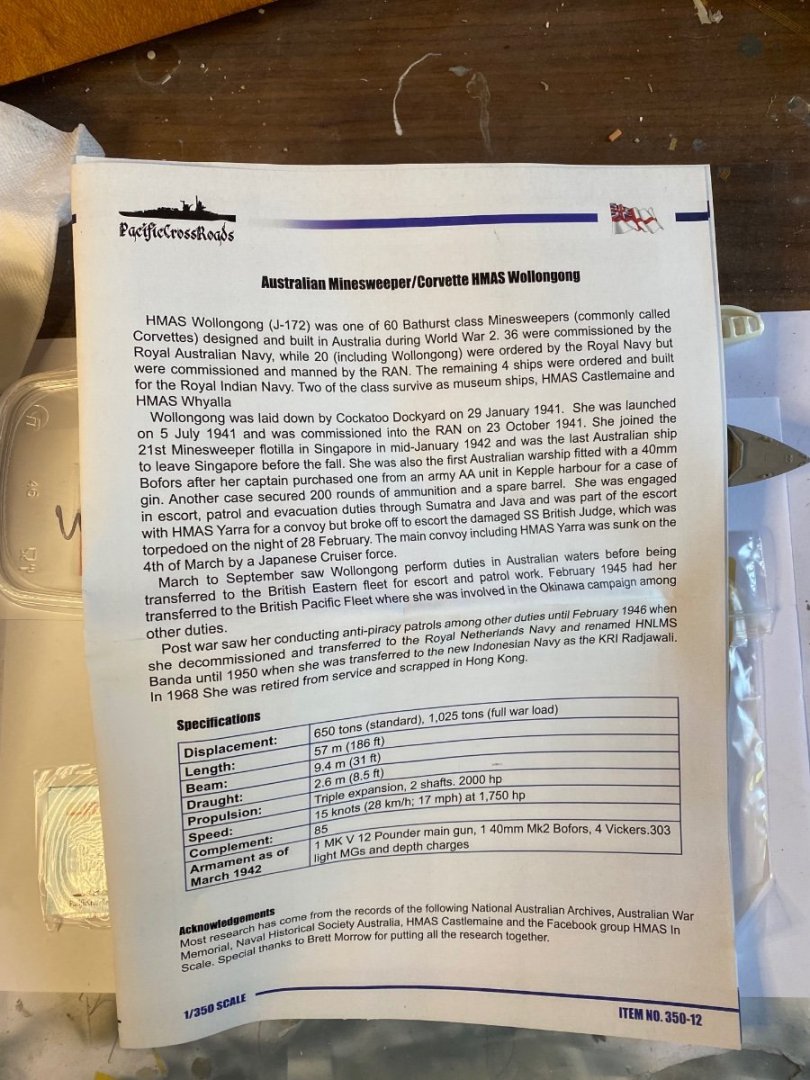

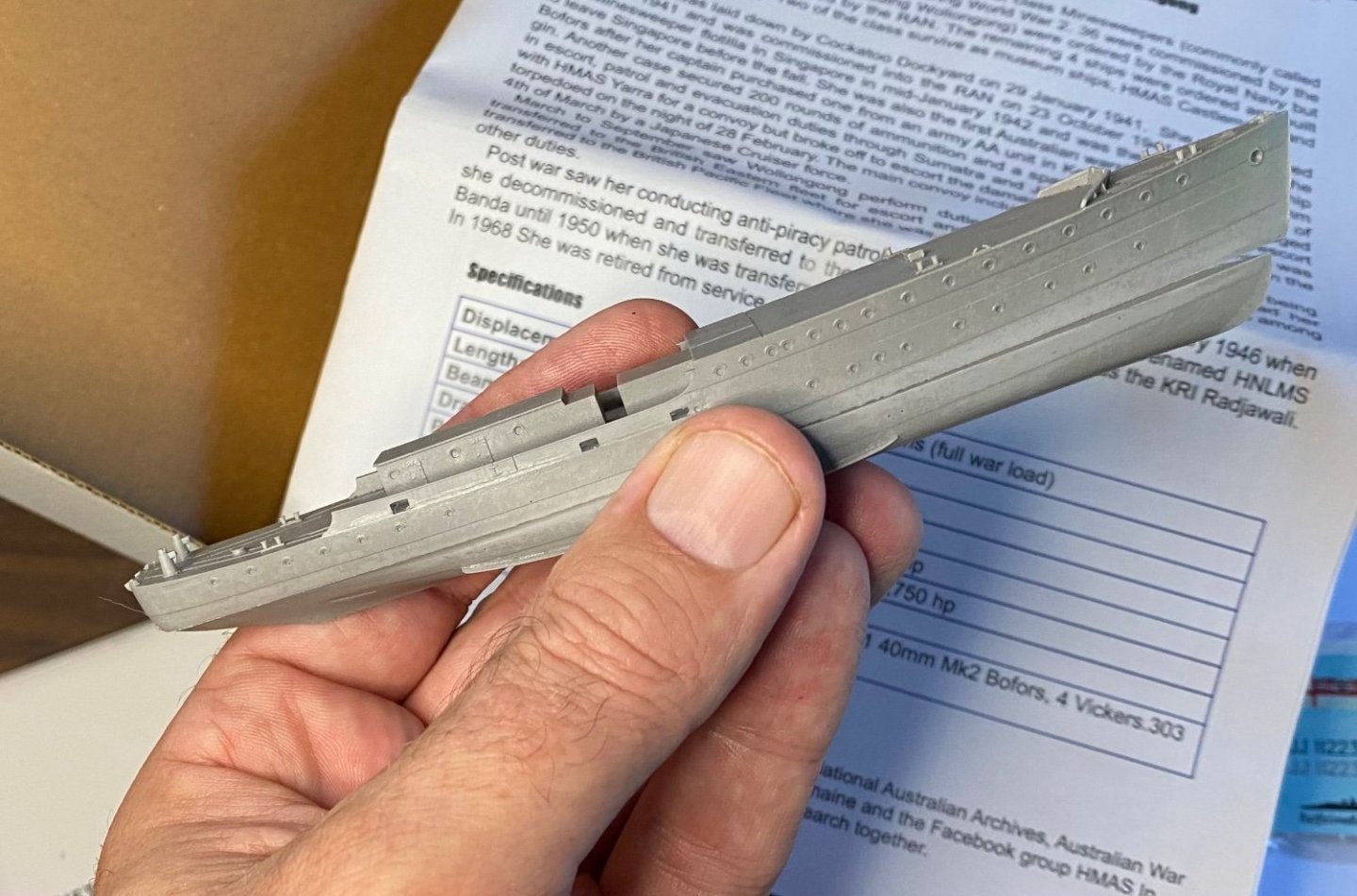

Next should be a quick build of a resin 1/350 Bathurst class minesweeper by Pacific Crossroads. Nice PE, resin and this will be a OOB build.

- 35 replies

-

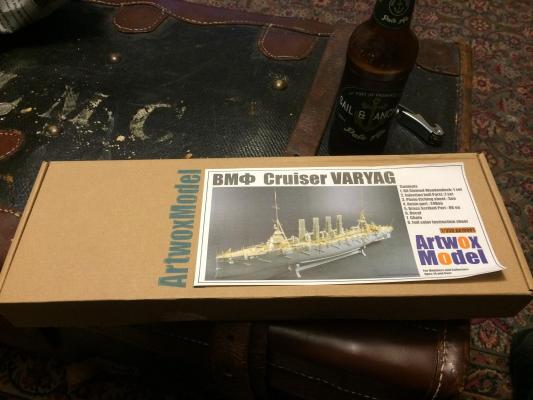

I needed a change of scenery after a 10 year build on my Endeavour. I couldn't face another long term challange. Months ago I found the Artwox Varyag on the net on an overseas site and liked it a lot, but shipping to Oz is usually a nightmare. I found the kit at BNA Models at a reasonable price and thought that itn would be a nice change as I have not done a plastic model this century. I suppose the advantage of a late 1800's early 1900's kit has the advantage of real photos. Also the aftermarket range of goodies for plastic kits is great, as plastic is a lot more unforgiving than wood. The Artwox kit only has the original Zvesda hull, with their own false deck, wooden deck, resin, photoetch and barrels. The instructions are fairly good but without other references I would be lost. After having done a tall ship model, I now know how important the rigging plans are (the kit has none) and I have orderd the Kagero book. There are some things missing from the Artwox photoetch fret which are included in the Eduard kit and vice versa, so I also got that.

-

Hello all, I did a search and did not come up with any results, so I thought I would start a thread. Has anybody here tried making custom parts using photo-etch? I know that dafi has, so perhaps he would like to chip in. I have done some googling to find out if it is possible to make parts for a ship I would like to build. The fittings that come with the kit are rather chunky and I have been thinking about how I would replace them. I think PE is the solution. It is possible to do photo-etching at home, as per these links: http://www.steelnavy.com/etching.htm http://www.starshipmodeler.com/tech/fh_pe.htm ... and you can buy your own PE kit here: http://www.micromark.com/micro-mark-pro-etch-photo-etch-system,8346.html HOWEVER, it requires an investment in machinery (if you do not already have these): laser printer, fluorescent lamp, heat source, laminator. It also requires consumables, including some toxic chemicals, a glass plate, and so on. In the end, the investment sounds pretty substantial for making a small run of parts. My next thought was to look at businesses that can do it for you. So far I have found a few: http://www.ppdltd.com/web_site_3/page_1_intro.html http://www.photo-etch.co.uk/page1/page6/page6.html http://www.photofab.co.uk/ http://saemann-aetztechnik.de/ http://www.orbel.com/photo-etched-precision-metal-parts I have not looked in detail to see if any of these companies would be happy to do a one-off project. It appears that as a minimum, you need to supply your artwork in vector form, either AutoCAD format or CorelDRAW format. A pixel manipulator (like Photoshop) will not work. Does anybody know of any free CAD programs or vector drawing programs that can output to AutoCAD format or CorelDRAW format?

- 12 replies

-

- photoetch

- photo-etch

-

(and 1 more)

Tagged with:

-

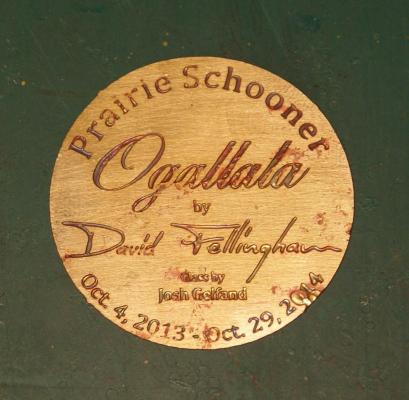

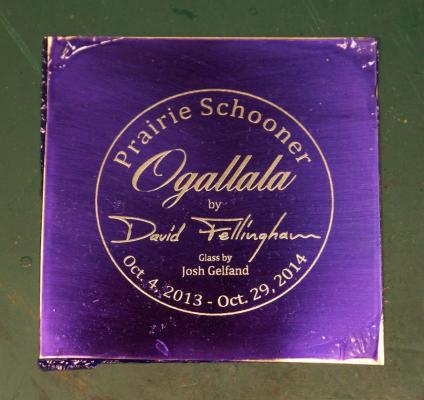

I received the Micro-Mark Pro-Etch Kit and set out on the learning curve - which is rather steep to successfully make usable photo-etch parts on the first try. It took me three. After ordering and waiting for delivery, I set about drawing in my drawing program the etched letters I wanted on two brass discs - one as a seal for the bottle and one on the display base. Keeping it simple, I planned to remove lettering on one side of the discs that I would later fill with paint, black letters on the brass discs. When the kit arrived I read the instruction book multiple times and identified all the tools and materials in the kit. Following the instructions, I made the masks for both sides of a disc and printed them on the backside of the mask transparency film. Follow the instructions carefully. The black areas of the mask are the areas that need to be removed from the metal and this mask will be printed backwards (flipped horizontally) so that the print is on the backside of the film. After the ink is dry the two masks are perfectly aligned, print side to print side and taped together. The print side of the mask transparency. The face side of the disc with reversed lettering and the back side with interruptions in the circle so that the disc will stay partially attached to the square of base metal. The black is what will be removed, half-way through from both sides with most of the edge all the way through. With directions in hand I cut two 2.5 inch / 64 mm squares of .005 inch /0.13 mm thick brass sheet. Before I opened the package of photo-resist film I set up a darkened work area lit by a single yellow "bug" bulb, then opened it, removed the resist and cut two squares, put them in an envelope lined with black paper, and returned the photo-resist film to its package and sealed it shut. This film hardens in UV light. I prepared a brass square by wet sanding each side of the square with a provided 3200 grit sanding pad until very shiny and so that the water sheeted across the square. I pulled one piece of the resist from the envelope, peeled off the inside cover film and, like applying a decal, attempted to lay the resist film on the wetted square, get it aligned to the edges of the square and adhered to the square without bubbles of air or water between the film and the brass. This turned out to be rather difficult and I had problems with it. On my second through fourth tries I submerged the brass square in just enough water to cover and applied the resist film through the water. (An old school decal application trick.) I did the same to the back side. While doing this I had the Pro-Etch laminater plugged in and warmed up. I cut two squares of carrier sheet (card stock with one side treated so that it is glossy and smooth) slightly larger than the brass squares. I made a sandwich of the photo-resist covered brass square with the two squares of carrier, glossy side to the photo-resist and ran it through the laminater twice, flipped over and turned 90 degrees for the second pass and let it cool in a black envelope. Next the cooled, laminated brass square (carrier sheets set aside) is slipped between the two masks and centered, then placed in the center of one of the Plexiglas squares provided, the other Plexiglas square placed on top and clamps applied at the four sides. All of this has been done with minimal exposure to UV light, just the yellow "bug" bulb - a suggestion in the directions. Again per the instructions I exposed each side of this sandwich to full sun at local noon for 20 seconds. The UV light hardened and turned the photo-resist in the areas not masked a deep blue from its original light blue. I disassembled the sandwich and returned the brass square to a black envelope while I set up for the next step and put away what I wouldn't need right away. I prepared a solution of sodium hydroxide and water per the instructions, removed the outer protective layer of the photo-resist film from both sides and submerged the brass square in this solution. This chemical reacts with the masked and un-hardened photo-resist film, softening it so that it will brush away. This is the most important part of the process, if the film is not completely removed from the areas to be chemically etched it won't etch properly. This is where I messed up in my first two tries; for the third and fourth tries I used my 2.75X Opti-Visor and inspected and brushed with the solution and inspected and rinsed and brushed some more until I was certain that every bit of resist was removed from the areas that needed to be etched. I made use of a hand held magnifying glass with the Opti-Visor to make sure every bit of un-exposed resist film was gone. The second brass disc with blue photo-resist and bright brass showing through the areas that will be etched. I thought this was good enough but it was not. Many areas did not etch properly, especially from the backside, due to my lack of diligence. Paying close attention to the instructions, I set up the equipment for the actual photo-etching. I had to supply a rinse bucket and a smaller rinse bowl, both filled with water. I warmed the bottle of ferric chloride in hot water running from the tap before filling the etching tank. I plugged in the aerator (to circulate the etching solution) and submerged the brass square. I set a 5 minute timer. Etching in process. There's a clamp on the hose to prevent the etching solution from flowing back into the pump plus the pump is placed on two pieces of foam packaging to raise it above the solution level. After five minutes, I removed the brass square from the etching tank (turned off the aerator and pinched shut the hose clamp - the fumes must be assumed to be nasty) rinsed and re-rinsed to inspect the progress. Most of the double side etching at the edge of the disc was cut through, so I turned the brass square 180 degrees in the clamp, returned it to the solution (turned on the aerator and released the clamp) and waited three minutes. Upon inspection, it was done and I rinsed it in hot tap water before setting it aside and cleaning up. Now, to see the results. I poured out just enough of the sodium hydroxide (undiluted this time) into one of the trays provided to cover the brass square. Full strength this chemical removes the photo-resist from the brass with a little help with a brush. When cleaned of the resist the brass was rinsed in hot water from the tap and set aside. Here's my first try with some practice with black enamel to fill in the letters. There are several places where the photo-resist did not adhere and laminate properly as a result of my difficulty with getting the resist in place as directed and etching solution got into them from an edge exposed to etching solution. I had no more problem with this using the submerged technique of applying the photo-resist film. Many places in the lettering have incomplete depth because I didn't get all the masked film removed the way I should have. Micro-Mark was right when they said this was the most important step. Third and fourth tries, both appear perfect. The lettering has not been filled with enamel yet, just the result of better photographic technique learned since the photo of the first disc. I didn't even bother stripping the second attempt since I could see that I had not removed all the masked and un-hardened photo-resist film. The discs are 1.73 inch / 44 mm in diameter. I am very pleased with the Micro-Mark Pro-Etch Kit. It has everything needed except for a yellow "bug" bulb and the two rinse buckets I provided. I bought a better pair of rubber gloves than the single use, throw away gloves supplied in the kit for my second session when I made the last two discs. I also added a small in-line on/off switch to the aerator electric cord so I would not have to crawl under my work bench to unplug it when I needed to turn it off. The process does have a steep learning curve, a mistake made anywhere in the process will affect the results. READ AND STUDY THE INSTRUCTIONS and MAKE SURE YOU UNDERSTAND EACH STEP. I hope my experience helps others learn from my mistakes. Dave

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.