-

Posts

181 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Von_Kossa

-

The oar holes of the Oseberg ship had cuts in them so the sailors could attach the oar from the inside without risking falling into the ocean or dropping the oar into the ocean. Byt the way, for others researching this, on some sites it is claimed that the oar holes had shutters to prevent water from leaking in. It is correct but this was found on the Gokstad ship, it had the oar holes much lower than the Oseberg. I have finished this, will post results later, one of the things which i could have done better was the shape of the cuts, mine became triangular because of the tool i used but the cuts are more rektangular.

-

Thank you. I have not even decided if i want the ship light or dark yet. This, Wipe on Poly, what is it? Some sort of plastic cover?

-

Hi! Did you use water based or oil based stain? After the staining process, should you protect it with enamel paint? And finally, what stain did you decide for in the end? I am running out of things to hide behind, soon i must stain the ship. Scary.

-

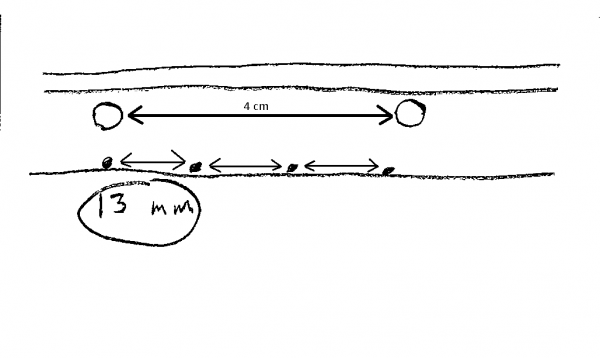

Regarding nails. Looked into the distance between the nails on the oseberg, besides being very chaotic in placement, the type varies between square rivets or nails with rounded heads, i guess they took what they had when it was built. There exists threads and loose information about the scale 1:1 ship has a ~20 cm space between the nails. If it is correct it would make the spacing in the BB kit to 8 mm between the nails assusming you have the correct scale on the nails. I tried to make out the spacing by comparing this picture with the model. In this case it would make the spacing 13 mm. But then i discovered that this only seems to be true with the rail (the two upper plank rows). Study this picture and you can see that the spacing is smaller on the other rows. To conclude this ranting i think i will be doing the following if i decide to join the nail circus: 1. Make the spacing on the two rail rows 12 mm. 2. Make the spacing on the the rest of the ship 10 mm like Jack Panzeca.

-

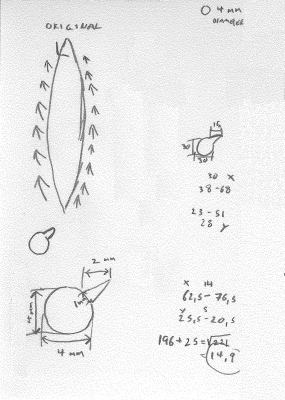

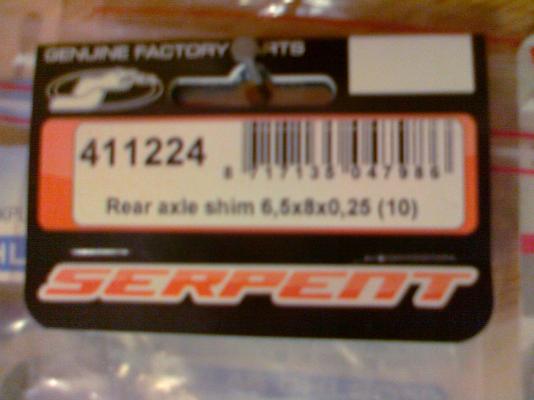

Hi! In my case it is not soon enough, i have a tendency to get stuck. Viking shields had a very distinct look. As you are probably aware by now. A typical shield buckle looked like this: So i ordered this and this, i took the photos this morning with my mobile before going to work, looks like sh*t but it works. As you can see i first bought a furniture nail with a diameter of 6,5 mm, bought here in Sweden in Bauhaus. But the ring around it was still missing. So after some serious digging i finally found my ring in a german hobby webstore. It was very difficult to find a shim that would fit and have the correct scale. But finally i found Manufacturer: Serpent, Article number: 411224, Rear Axle Shim, 6,5x,8,0,25. And the result looked like this: Thanks. Thanks again. I will have to look into this...

-

Making small nails with round head

Von_Kossa replied to Aleksei Domanov's topic in Metal Work, Soldering and Metal Fittings

Brilliant! Thanks so much. -

Up and down as with everything in life. My one action so far is one drilled hole for the rudder, and i did it wrong, so it took over a hour to correct it. I suck at this. Nails for the shield? Amati 4134/57, they had a diameter of 0.8 mm and therefore had horribly large heads, totally unusable. I didn´t know that you could blacken brass, so maybe i will try this nail thing again. How exactly did you do the blackening? I have found four billion different ways on the Internet, rather confusing... You did good by the way. The spacing between the nails you name on the original ship to be 20 cm, were did you find this information? I have a vague memory about it being 40 cm, but i am probably wrong. The head size of your nails, they are usually not printed, do you know it? 1mm or something like that? Lots of questions, i hope i am not pestering you too much.

-

Good day, May I ask, exactly what brand, article number, lenghth, and diameter the nails are? A wild guess, Amati, 4134/10 brass, 10 mm, 0,7 mm in diameter? First time i log in here in 2 months, i can see you have been busy lika a bee. Good work, good progress. I hope everything is well with you. I have not touched the boat since beginning of june, thinking about starting again.

-

That was the tricky part, first i tried to drill down into the plywood from the top, did not work very well. Then i. Took the. Razor and grinded the plywood to pieces.finally i used sandpaper and a funny looking razor which is shaped like the ones you clean windows with but much thinner. The. Vikings? The floor tiles are loose on the real ship, propably used the space for storage, but it should also be easy to scope out the water if you have access to the lower compartment.

-

Yes, but not for me... That is, if not Jack does something about this, then i will have to reconsider.

-

Regarding the scroll work i found a little detail on the real ship i had not noticed before, on the front scroll work it is a dragon snakes head like on our model, but on the rear scroll work it is only the dragon snakes tail, but on our model we instead have to dragon heads. it is to hard to change the rear head into a tail so i will let it be, but it is an interesting detail.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.