-

Posts

322 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by igorcap

-

Very nice work , Alex ! I just thought about it, and you've already made. This will be a new revolution in modeling!

-

Try like this http://forum.modelsworld.ru/topic1392start160.html

- 969 replies

-

- hahn

- oliver cromwell

-

(and 1 more)

Tagged with:

-

- 20 replies

-

- swedish privater

- frigate

-

(and 1 more)

Tagged with:

-

Unfortunately I did not take photos during long period. Next picture: over external planking and gun deck

- 20 replies

-

- swedish privater

- frigate

-

(and 1 more)

Tagged with:

-

Precision work. Too bad it will not be seen.

- 969 replies

-

- hahn

- oliver cromwell

-

(and 1 more)

Tagged with:

-

HMS Naiad 1797 by albert - FINISHED - 1/48

igorcap replied to albert's topic in - Build logs for subjects built 1751 - 1800

Very neat work. Excellent! -

- 20 replies

-

- swedish privater

- frigate

-

(and 1 more)

Tagged with:

-

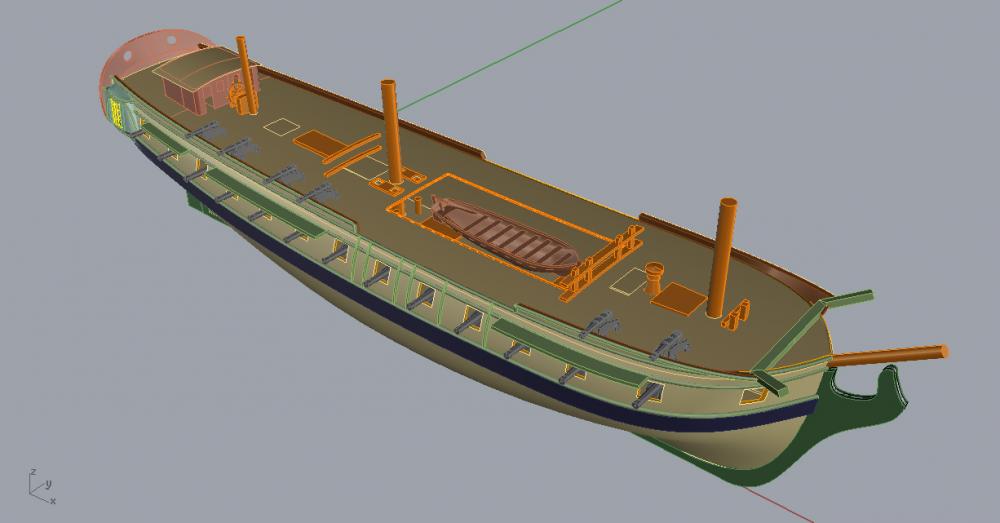

Hello Wacko ! I use Rhinoceros as 3D editor , Rhino CAM ( CAM plugin for Rhino ) , LinuxCNC as controller. In Rino I work on for 14 years.

- 20 replies

-

- swedish privater

- frigate

-

(and 1 more)

Tagged with:

-

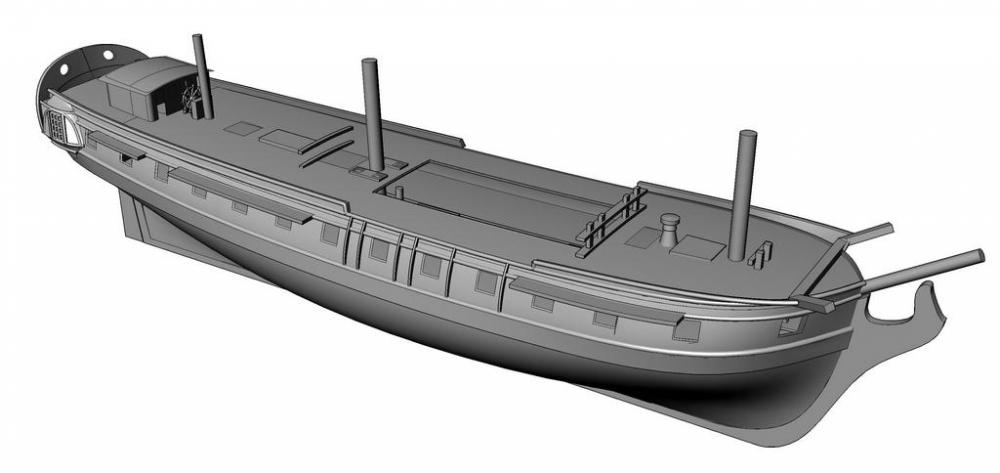

Yes, I did it myself. First I made a 3D model, then CNC milling and final manual processing.

- 20 replies

-

- swedish privater

- frigate

-

(and 1 more)

Tagged with:

-

At this point I interrupted work, because I received an order to build a model of Flemish galleon. Then I came back periodically to build of model but did not take a photo. A little bit about some detail .Decorative elements to the stern.

- 20 replies

-

- swedish privater

- frigate

-

(and 1 more)

Tagged with:

-

- 20 replies

-

- swedish privater

- frigate

-

(and 1 more)

Tagged with:

-

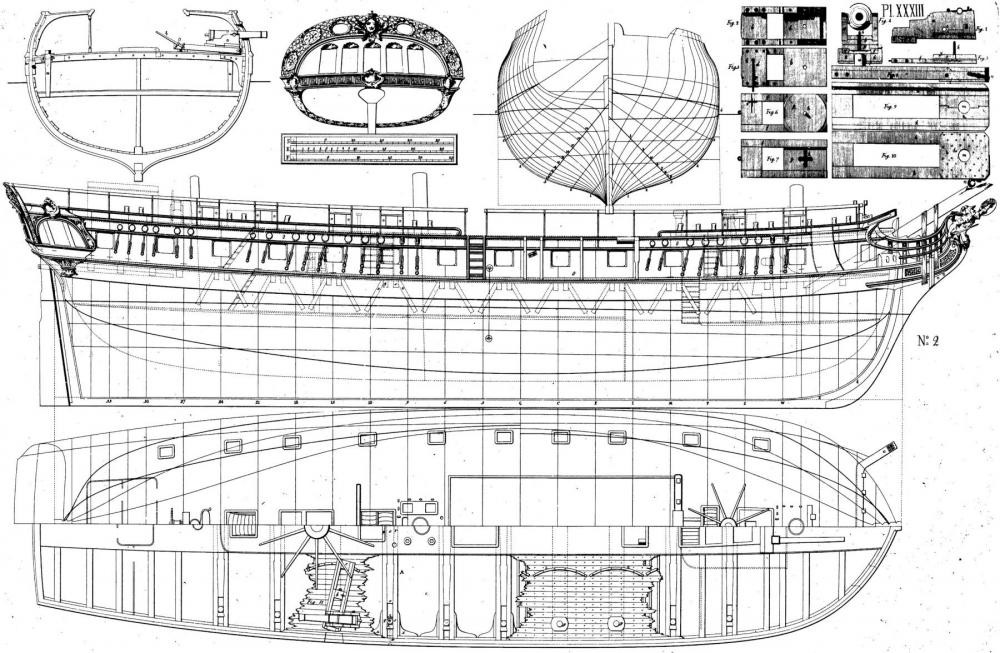

A bit on the prototype and model. In reality, such a ship was not built ever. This is one of concepts that developed F.Chapman on request the Swedish Government in 1765. He was given task to create an inexpensive heavy frigate, which would battle with the ship line, if necessary. Frigate had to meet the following specifications: Dimensions Length 145' 6'' (imperial) Breadth 38' Draught Aft 17' Height of middle gunport above the water 6' 4'' L/B ratio 3.83 Armament 26*18-pounders, 12*6-pounders At least a decade ahead of it?s time when Chapman made the plans for this ship (the first french and british 18-pounder frigates were launched in the late 1770s). The guns are mounted on sliding carriages to reduce the number of men needed to operate them. In future, based on this concept F.Chapman built a series of heavy frigates type Bellona The model is built on the scale of 1/48 . Style of model should simulate naturally aged model of 18th century

- 20 replies

-

- swedish privater

- frigate

-

(and 1 more)

Tagged with:

-

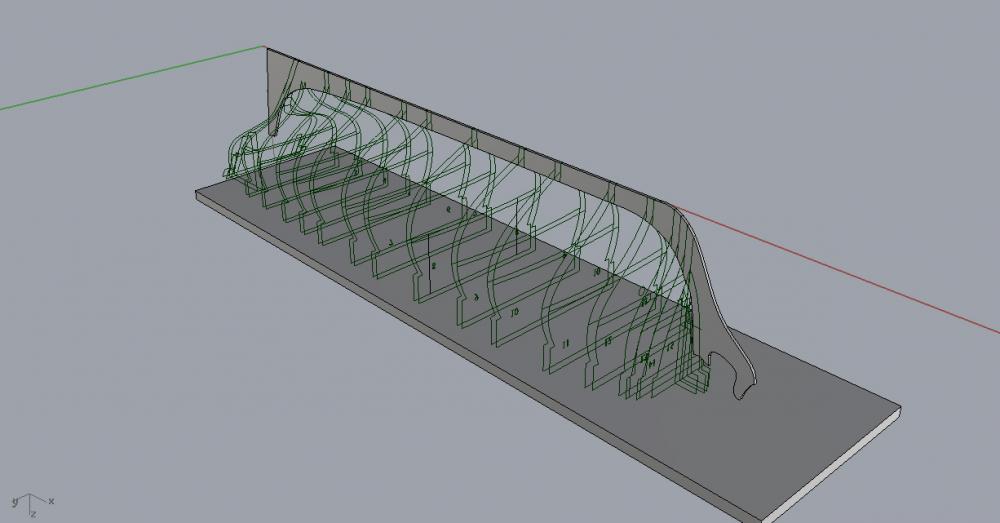

Next, I need to remove fragments of technological frames. I took a short video that showcases simplicity of this process http://sailmodel.ho.ua/present/09098288.MP4.mp4

- 20 replies

-

- swedish privater

- frigate

-

(and 1 more)

Tagged with:

-

Then I begin to create base hull. Pine strips are glued to frames using a stapler. Total of two layers. First layer must be dried at least one day. After drying, staples are removed and surface is processing with plane .

- 20 replies

-

- swedish privater

- frigate

-

(and 1 more)

Tagged with:

-

- 20 replies

-

- swedish privater

- frigate

-

(and 1 more)

Tagged with:

-

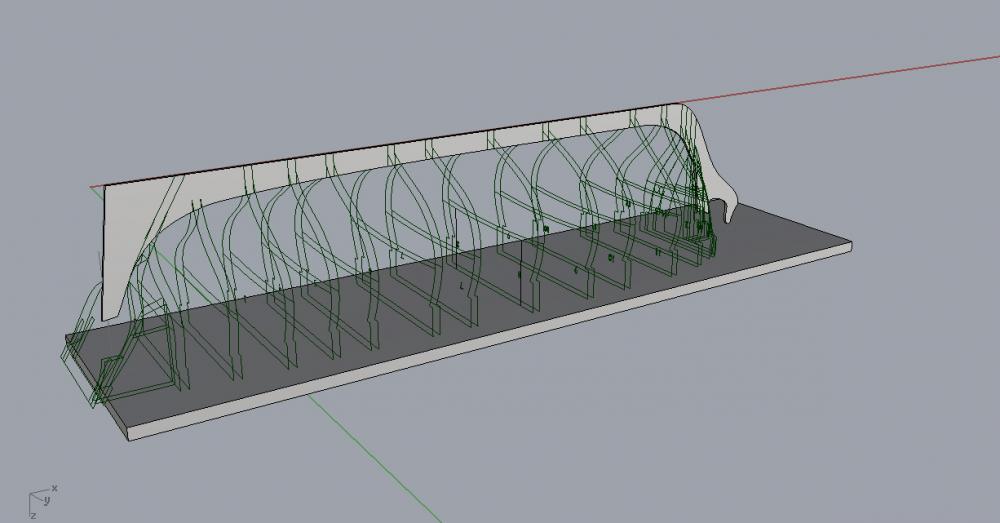

Then I get shape of "thick" frames from 3D for the manufacture base hull. A detailed description of my technology manufacturing basic ship hulls can be seen here http://sailmodel.ho.ua/present/pres_e.htm

- 20 replies

-

- swedish privater

- frigate

-

(and 1 more)

Tagged with:

-

Thank you Mateusz ! Yes , I'm friends with Mirek

- 20 replies

-

- swedish privater

- frigate

-

(and 1 more)

Tagged with:

-

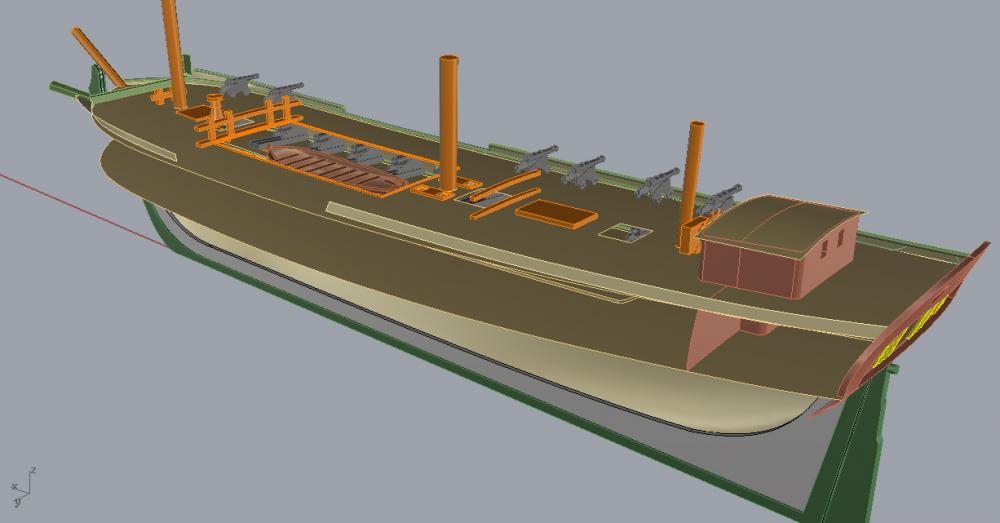

I use extensively in their work 3d-modeling and CNC, so I started by creating a 3D model of frigate. Using this model I check all structural elements and can get shape of frames and other parts

- 20 replies

-

- swedish privater

- frigate

-

(and 1 more)

Tagged with:

-

Hello everybody ! My favorite theme in modeling is Swedish shipbuilder F.Chapman and his ships. Previously, I have built a model of the Swedish privateer on Chapman's drawings from album «Architectura navalis mercatoria» (can see in the Gallery http://modelshipworld.com/index.php/gallery/album/208-swedish-privateer/) In 2011 I started to build another model of this album - a frigate (sheet XXXIII). This project was repeatedly interrupted, but I went back to building of model. I will show gradually all steps of building model. Baseline - Chapman's drawing. Analysis design of frigate has shown that this is an earlier and smaller version of the well-known series such as frigates Bellona (1782). Swedish Maritime Museum have excellent model Bellona 1/16. Photos of this model give additional information about the hull detailing and rigging.

- 20 replies

-

- swedish privater

- frigate

-

(and 1 more)

Tagged with:

-

It looks great. I look forward to continuation ....

- 969 replies

-

- hahn

- oliver cromwell

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.