-

Posts

41 -

Joined

Content Type

Profiles

Forums

Gallery

Events

Everything posted by TurkSailor

-

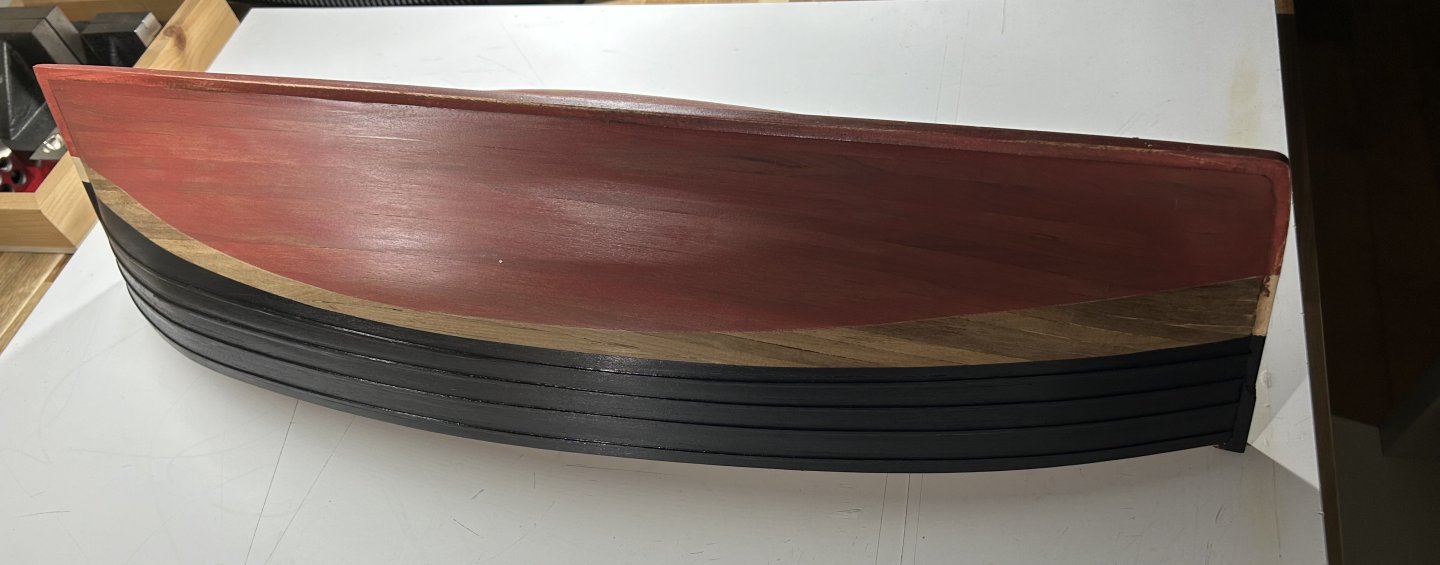

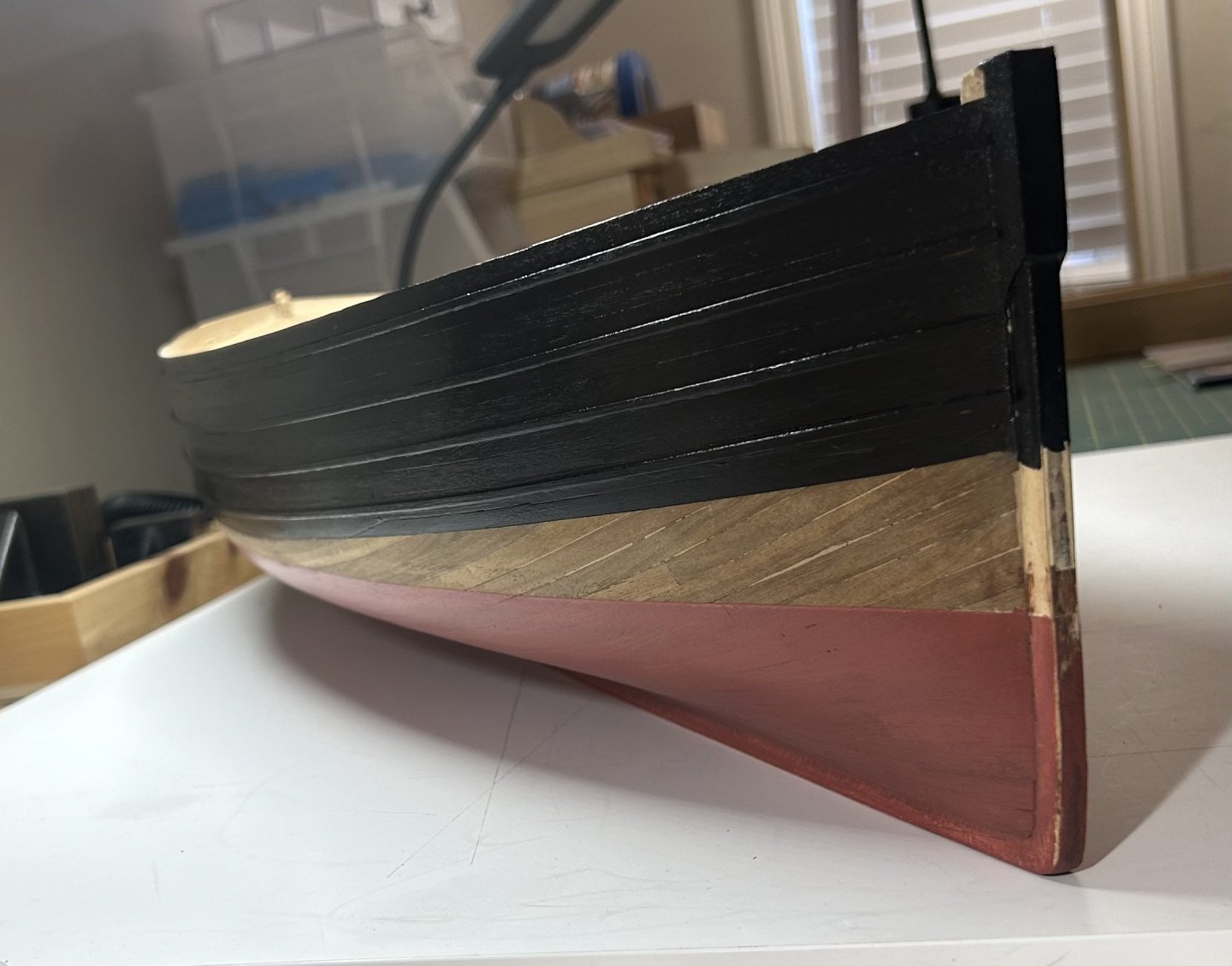

I used a “semi transparent” stain for the upper hull. I’d argue it’s actually opaque. Still, I think it turned out well enough. I’m allowing this to dry a bit before I paint the white. Folks, I’m not an airbrush user, well not yet. I’m going to use some sanding sealer, apply a Vallejo primer with a foam brush, then matte white with a brush. Any advice here would be appreciated. I’m knee deep in the paints section here on MSW, hopefully this method will work for me. Another option was to use a gesso base, then brush on an oil based titanium white. Though I’m concerned it’ll be too thick. I’m going to try and setup some space to take better pictures, but currently I’m doing some major home renovations so it’ll have to wait till after. Thanks for stopping by my log!

-

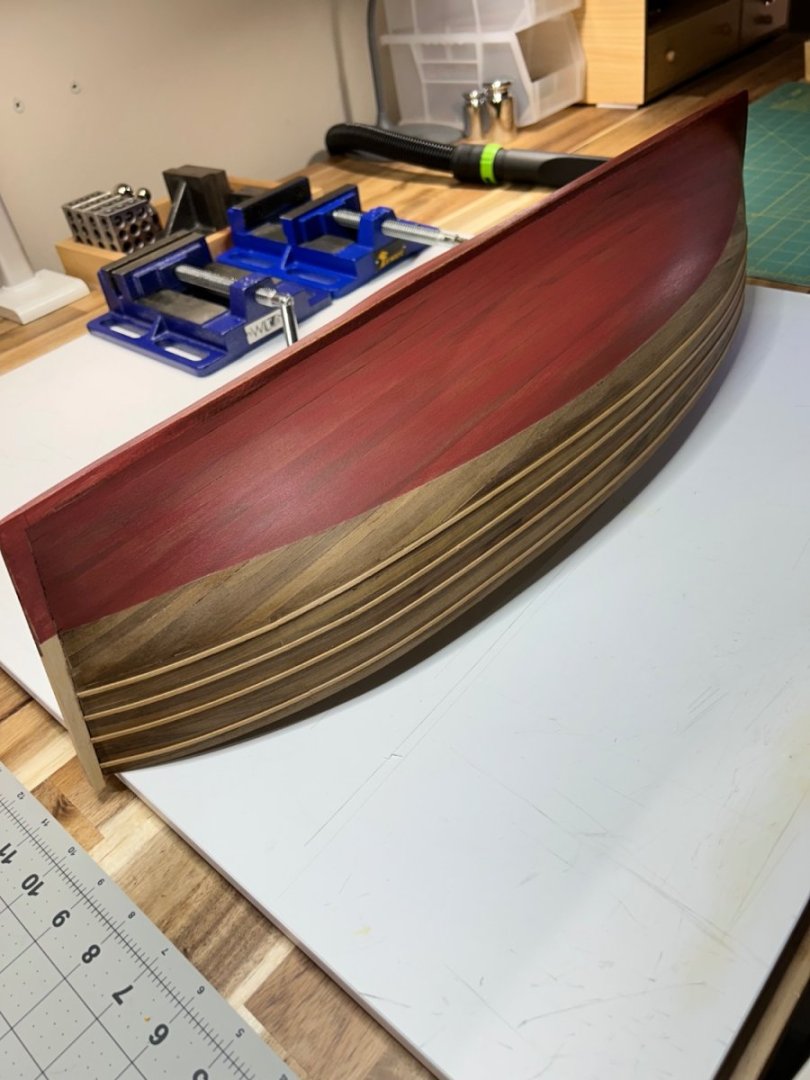

Disaster averted! I was anxious about how to finish hull for good reason. I’ve never succeeded in staining anything. Initially I chose a stain that I thought would look good. So I brushed it on naively without pre stain conditioner. I was very disheartened by the result. So I slapped on another layer hoping it’d cover more and perhaps hide the blotchy bits. Unfortunately this just made it look worse. I waited till the stain fully cured and sanded as much of it down as I could. This was surprisingly easy as it hadn’t actually penetrated the wood. In my second attempt I used a water based stain conditioner, then applied an opaque “barn red” stain. After 2 layers I felt satisfied with the results.

-

Moving merrily along. Did yet more sanding, and along with that noticed more flaws in my second planking, never mind the accuracy. Almost done with the rubbing strakes. I used a compass and the plans to get these on as accurately as I could. Still ruminating on the finish. I’m thinking to emulate a color motif that I saw here using a dark red stain, an oil based white, and an ebony stain.

-

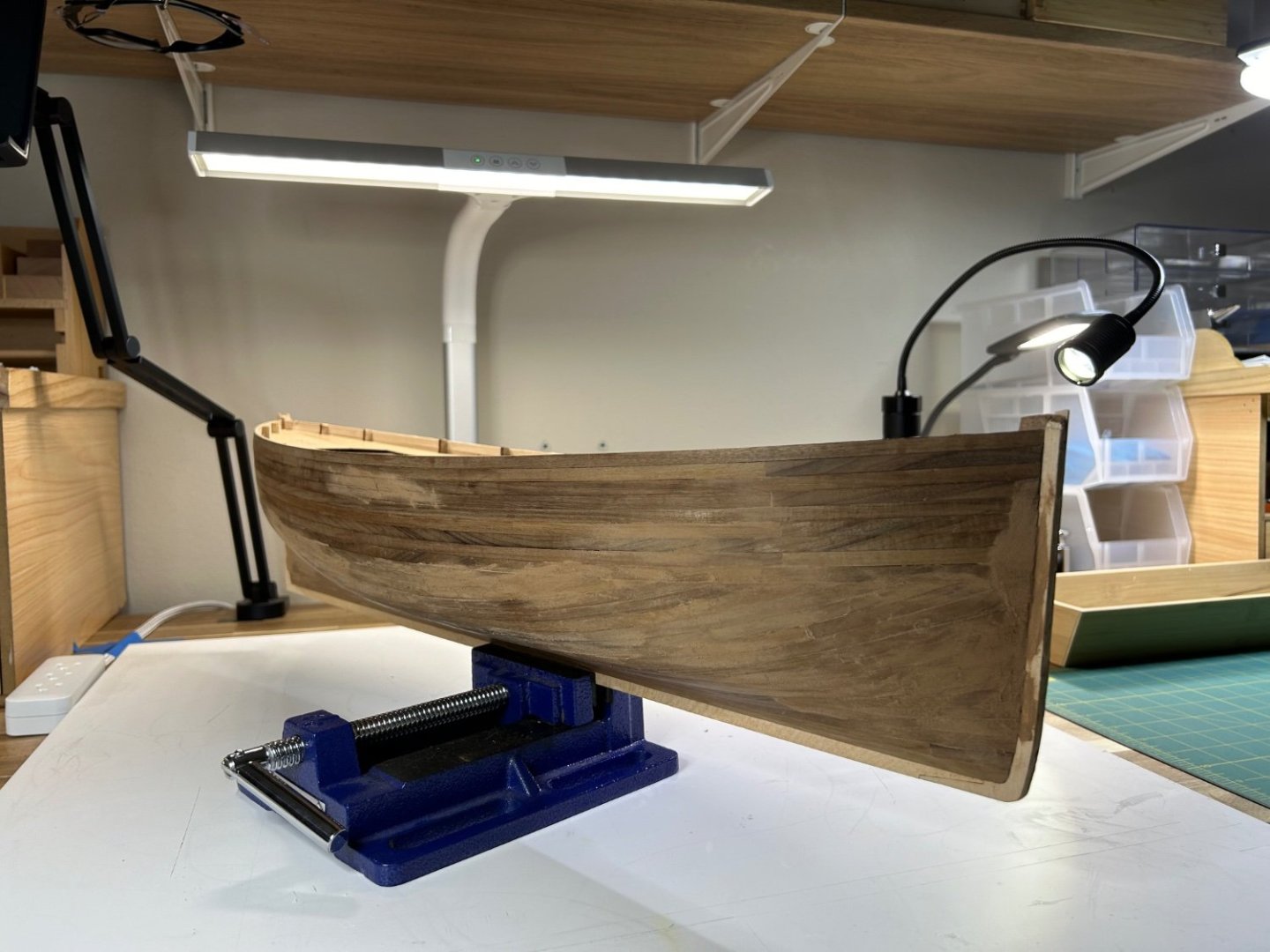

Moving steadily onward. Certainly gaps have been an issue. As well as less than perfect cuts. But as my first go, I reckon it looks well enough. I’ll be using a little bit of walnut plastic wood to fill in the gaps before sanding. In the meanwhile I’ve been reading more on planking, and studying builds here on MSW. It’s obvious that I’m hardly doing this correctly, however, I’m not going to just get up and quit. I’d love to emulate how they made ships properly one day. That’d have to be a scratch build. Perhaps in 20 years? 😅

-

So far so good…quite chuffed with my progress. For the next vessel, I’ll try my hand at measuring things out. Before I started my Fifie I had found a very small Woody Joe kit in my cupboards. The Catalonia. This was really fun to put together albeit at a size that I struggled with. Here are some pictures. I just couldn’t manage the sails at this size so opted to roll them up. Cheers!

-

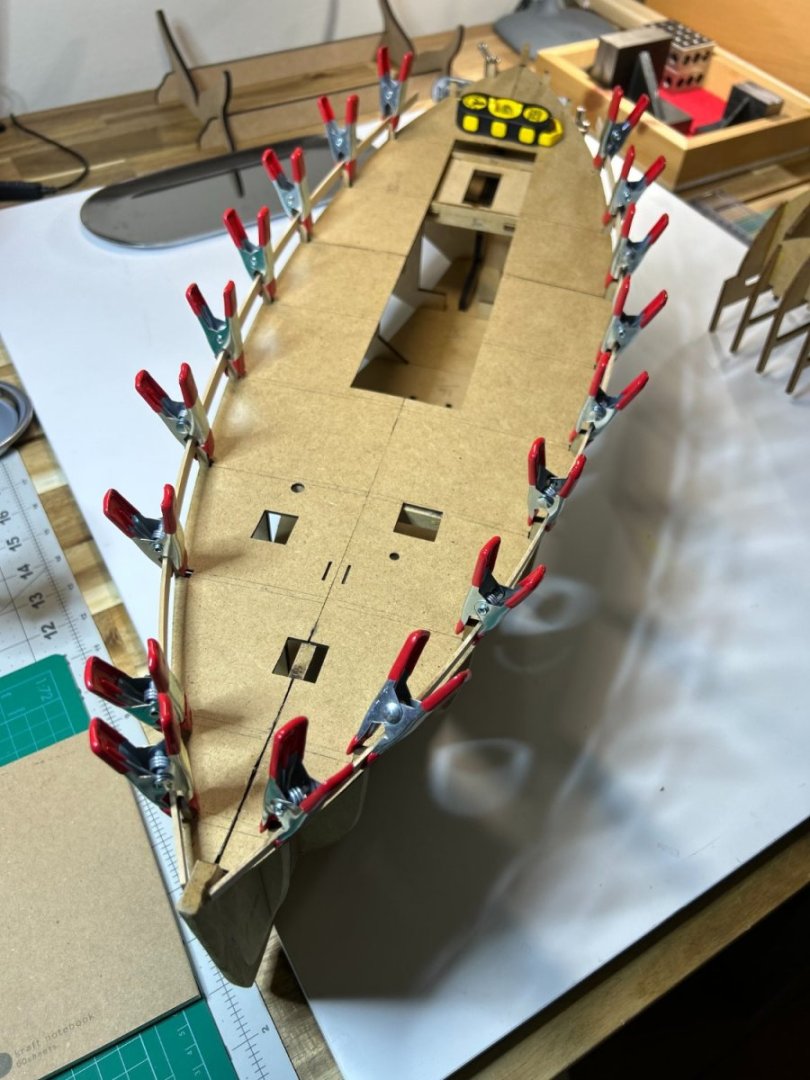

Some progress with the second planking. I’m giving myself a break considering it’s my first time doing this. I am a perfectionist in my trade but learn best through doing and just wanted to jump in. I really enjoy edge bending and I’m really surprised by how much easier it is to fit the planks. So far everything has just been by eye. As a result the Fifie has a few imperfections and scorches. Notice also a little wobble. I’ve used a rasp to sort that for the planks that come after. Hopefully it’ll turn out ok. I was quite worried about the second planking but I’m pleased with how it is turning out so far. Opting not to make it harder for myself and cutting the planks into small bits is a trade off I’m willing to live with for this model. So far I’ve been using Titebond white glue, but may switch to the quicker and thicker variant as I approach the belly of the hull (forgive my terminology).

-

USS Constitution by mtbediz - 1:76

TurkSailor replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

Bravo! Hızlı ve bu kadar detaylı çalışıyorsun! -

Hi Loracs, You’ve done a wondrous job thus far. I can only dream of being this good! I must ask, and apologize if it has been asked of you before. Can you share the details of that absolutely incredible building slip you use? I MUST have one! It looks invaluable. I find myself using drill press vices and various other things, but nothing compares to what you have. Thank you,

-

Very inspired by your work. I’m well behind on my Fifie and certainly didn’t take as much care with the first planking as you did. I’m very nervous to tackle my second layer.. however I’m glad it wasn’t just me. The curves on this boat call for so much twisting. But I’ll admit, I adore the shape!

-

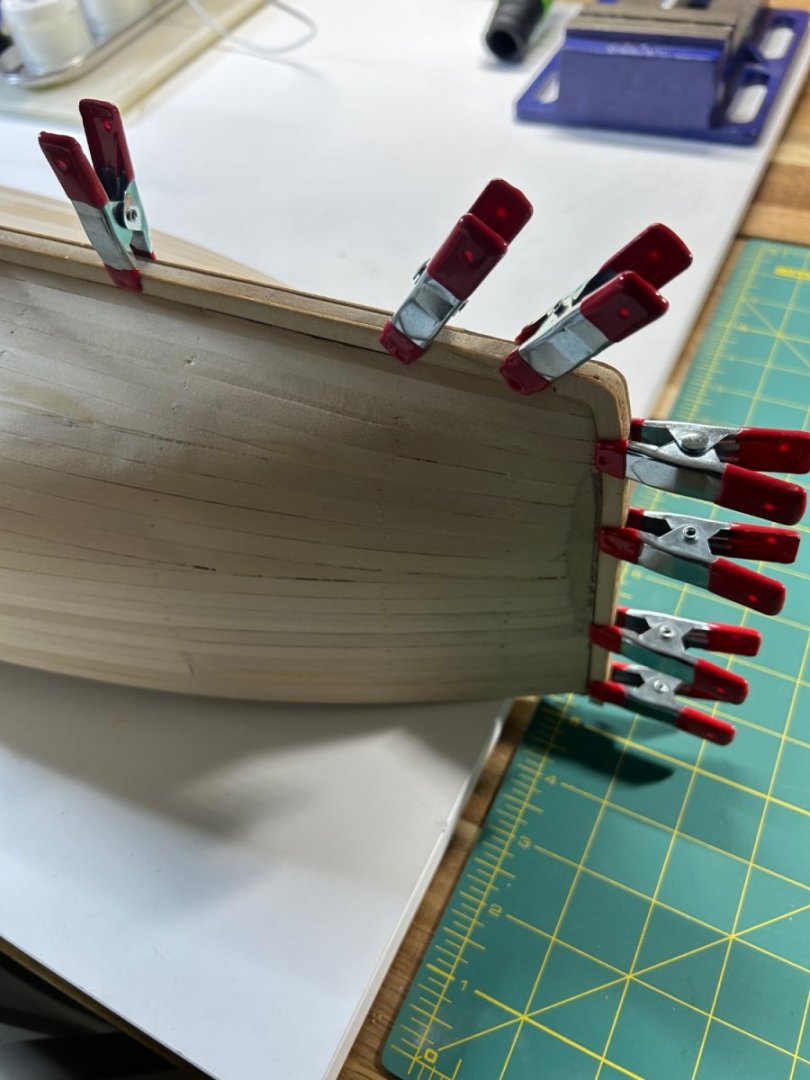

Did another round of sanding. Focusing mainly on stern and bow areas. Bringing in the first layer as tight as I could. So much so I might have made the planks paper thin. The goal is to try and emulate a rabbet? When sticking on these bits I want to have a little space to slot in my second layer. I’m fairly nervous about this next layer. I cannot use CA glue and will be using white wood glue. I’ll be using the method Chuck employs for his incredible vessels. I’ll instead be attempting to clamp on my planks once bent. I used the garbage clamps again.. last time.

-

I stepped into the backyard with my Fifie and a detail sander. I came back in with what I felt was a decent looking first layer of planking. I'll likely get more wood filler on and sand a few more times then tidy up the edges in order to stick on the keel bits. Cheers to everyone who stopped by my build log!

-

I continued on with planking, nailing in the planks. Trying hard to keep them against the bulkheads. I resisted the urge to taper as I knew I'd mess that up. So I soaked the planks for an excessive amount of time and simply bent them as much as possible. I figured I could get away with this for my first planking. Unfortunately it did not last. I was forced to cut some planks. I held my breath and gave it a valiant effort. It was around this time that I started reading about planking. Holy crap! Talk about a rabbit hole! So much to learn and study on the topic. I've purchased a few tools to assist me in the 2nd planking and hope to do a much better job at it.

-

Moving on. Here I use some lousy Amazon bought clamps to get the first planks on. Side note: I was very disappointed that the little steel clamps were so weak. I compared them to older clamps I had bought a few of from a local hardware shop and noticed the springs in the Amazon ones were significantly thinner. I'll pass these on to the kids to use for paper craft. It was after the first couple planks that I quickly realized I'd be better off using longer planks to avoid the splicing. Quite lazy of me I know. Here you'll notice the less than perfect sanding job on the bulkheads, as I did.

-

Assembling the components was very straight forward. The kit quality is fantastic and the directions clear. Here you can see my "fairing" which was to be desired as I'll discover later when planking. There was quite a lot of MDF to sand down on both bow and stern. I used a homemade sanding stick which made the process take much longer. If I were to do this again I'd use a rasp, or even a rotary sander to get the bulk of it down. It wasn't till much later did I notice I had sanded away much of the keel. Next time I will be sure to mask my keels. Lastly I recall some fantastic advice on using thread to gauge progress, that was recalled much much later unfortunately.

-

Ahoy all! It has been a number of years since I have posted here, and for good reason. We've a new addition to the family, and both he and my eldest have been the focus of my attention and energy. In our last home reorganizing I was able to secure myself a large dining table in our second living room to use as my "miniatures workshop". Finally, onto the build, with one final preface: I am a novice, but keen to improve. I'd appreciate any and all feedback. I'm as far as the first planking but have photos of prior steps. I will upload a group of pictures and explain as best as I can.

-

USS Constitution by mtbediz - 1:76

TurkSailor replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

İkinci çocuğum doğduktan sonra yeniden başlıyorum... I have a Fifie by Amati currently in progress. I will start a log on here at some point. I'd love to scratch build like you do one day. Next time I am in Istanbul I will see if I can find some plans of Osmanlı ships. I'd like my first scratch built ship to be special. This hobby is so fulfilling, and so demanding of skill in order to achieve a truly masterful model. -

USS Constitution by mtbediz - 1:76

TurkSailor replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

Süper! Türkiye'de birini görmek çok güzel. Very detailed build, I stumbled across your Santa Maria build with the extra details and just had to see what you were currently working on.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.