-

Posts

99 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by mitbok

-

Hi mikiek, Seems you doing a pretty good job on the sail. If anything, I have a guy who does model sails (making me a set now for sandbagger). He is very good but not cheap.

- 204 replies

-

- trajta

- marisstella

-

(and 1 more)

Tagged with:

-

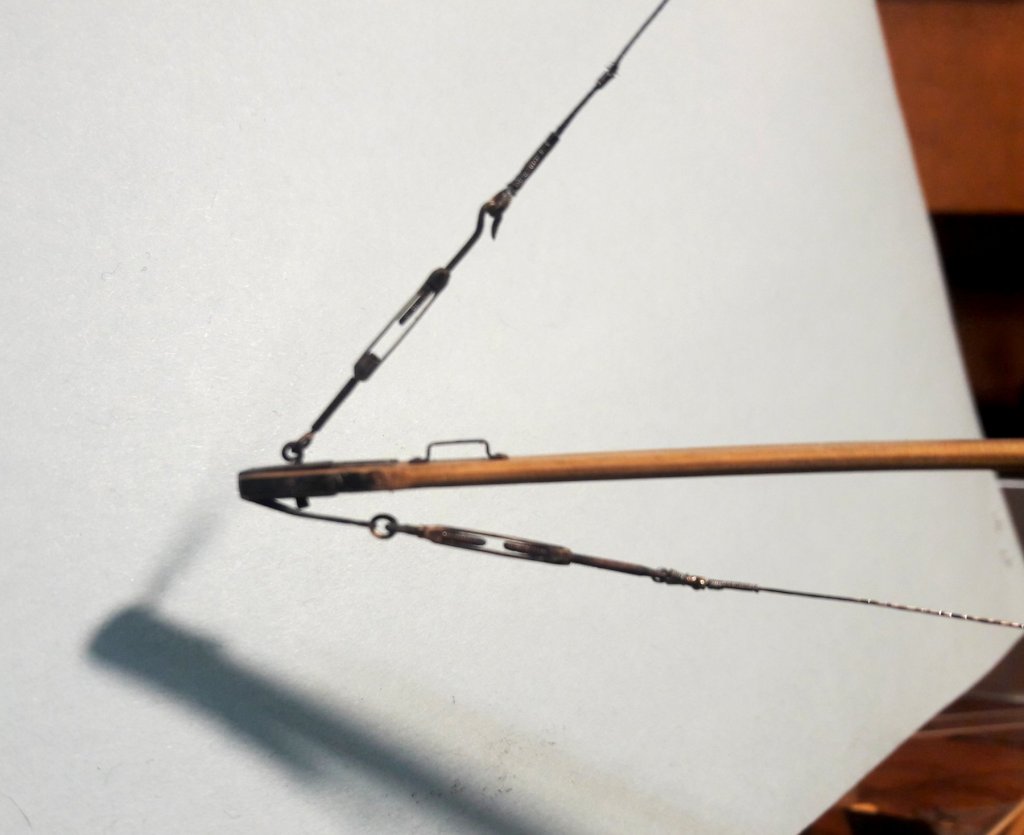

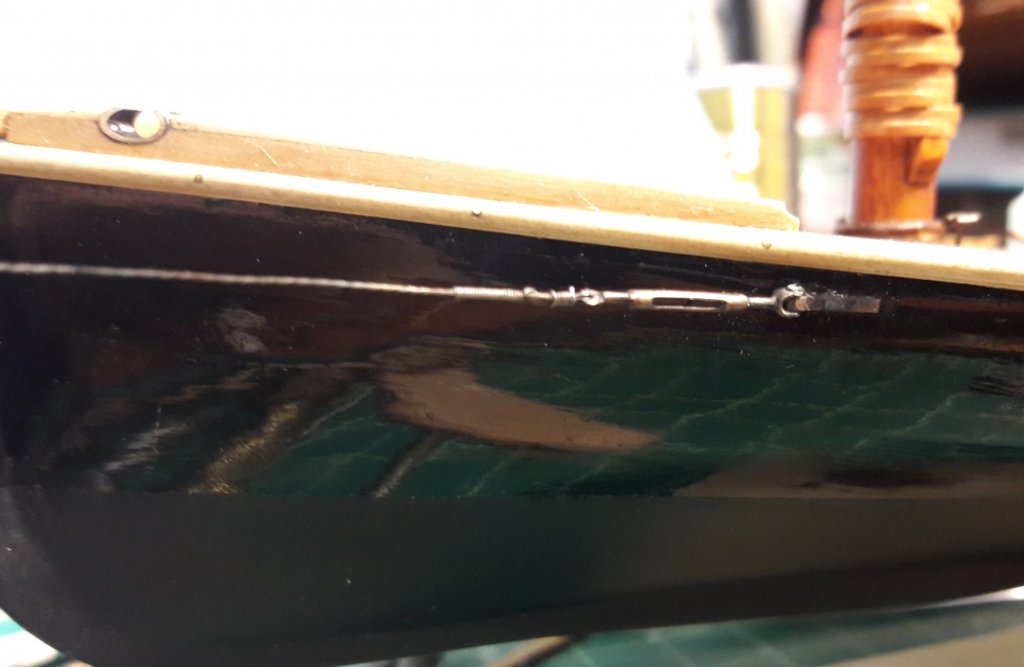

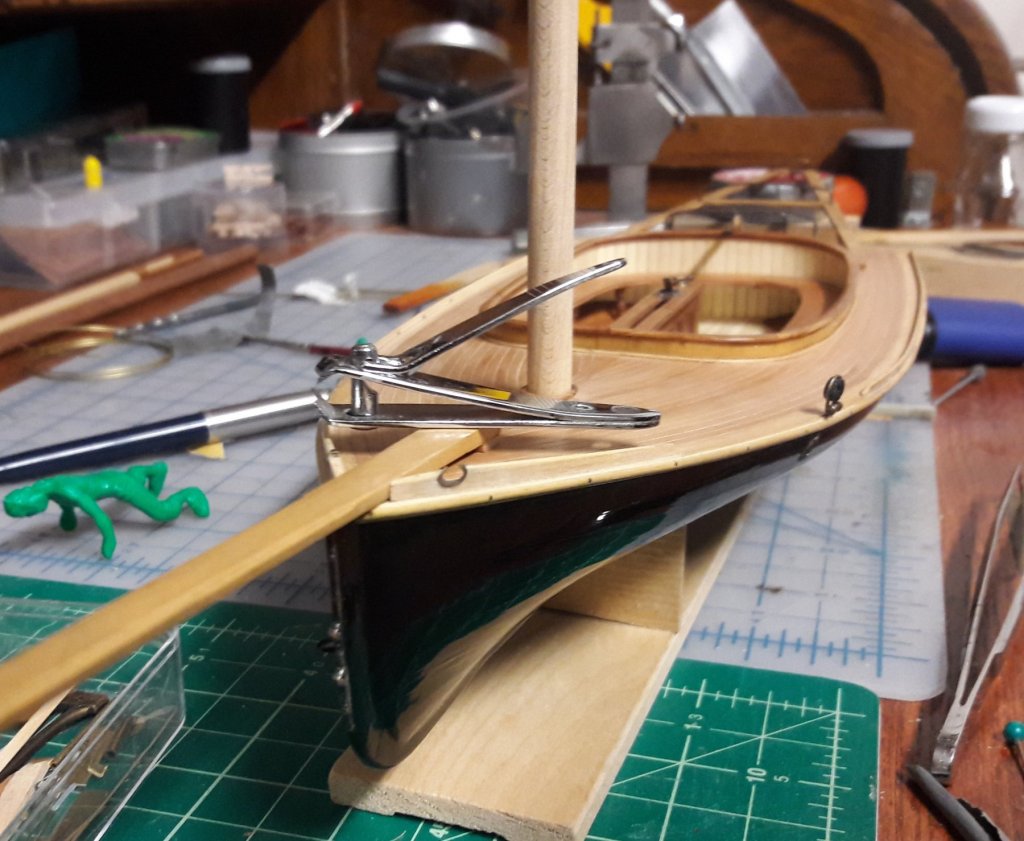

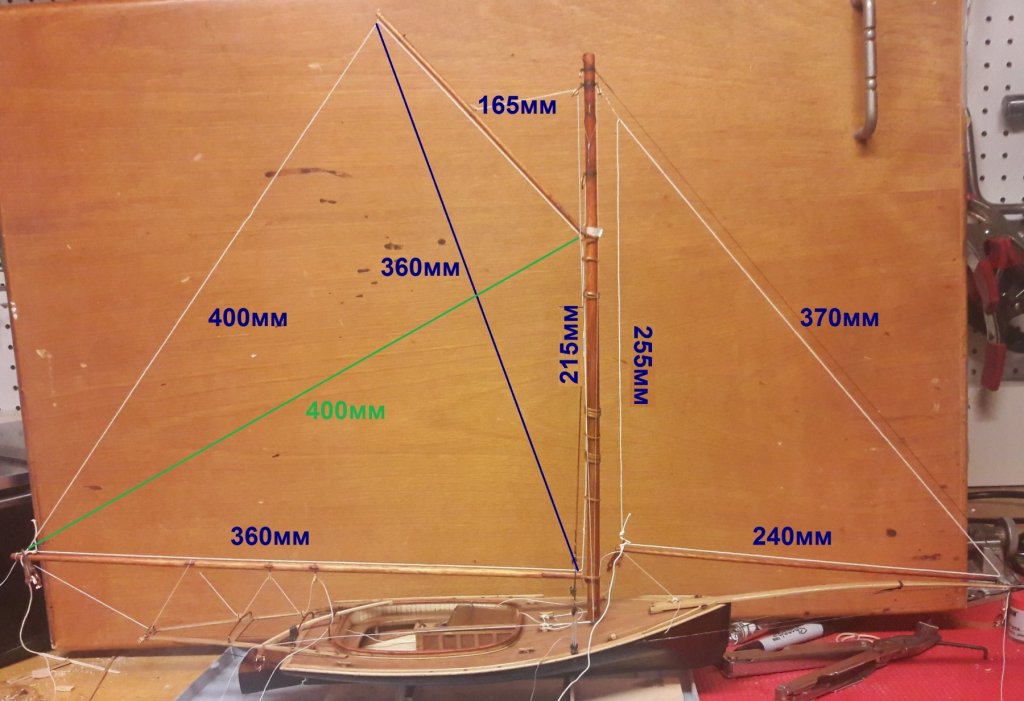

Thank you guys! Dwalker This is just an old Glencoe coast guard rescue boat plastic kit in 1/48 scale. Horrible mold. Yes turnbuckles need left and right tap but I only had one type so they are not working the way they suppose to. I used cheap China made tap set and wasnt sure where to get both right and left in this size besides very expensive watch makers tools. All running rigging is temporary, just to stretch out the spars and run the string as an outline of the sail. This was done to get exact measurements for sails to be made. The are being sewn in Russia and somewhat expensive so did not want to take chances with size.

-

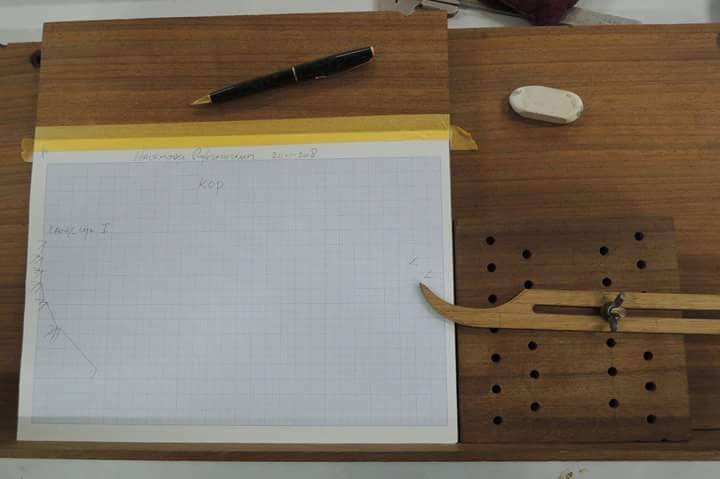

This is an extreme opposite approach of Russians who will get the info or a book and poor it out into a torrent for every one to see and download, regardless of copyright. My question is this - what ever info we get from a museum or a private person who got it from the museum we can not publish or sell but can you use it for a construction of a kit that you going to sell? If you use museum plans to redraw your own to include in the kit is there any legal problems? Well... latest I heart from our Dutch friend that he is willing to share but needs some time to analyze all his findings and measurements, which might not be a bad thing. Chuck, you do have some time before starting the boeier so it should work out. Here is a second measurement session of a half model that took place two weeks ago. This time measurements were taken at the exact location of the eleven frames on the half model (earlier measurements were taken at less number of frames). Waterlines and the buttocks were measured as well. Also frames measured from the inside to get true dimensions of hull without planking.

-

Authentic Shipmodels Amsterdam also had a kit of Green Dragon - a royal Lemsteraak yacht and tjalk type of barge. Those were in bigger scale, POB kits so a bit better than the small series. I have them all but so far only built an Ewer. Looking at the model of Boeier, it seems fairly complicated with all the decor and metal parts. Wander what Chuck's kit will offer and what would be left up to the modeler.

-

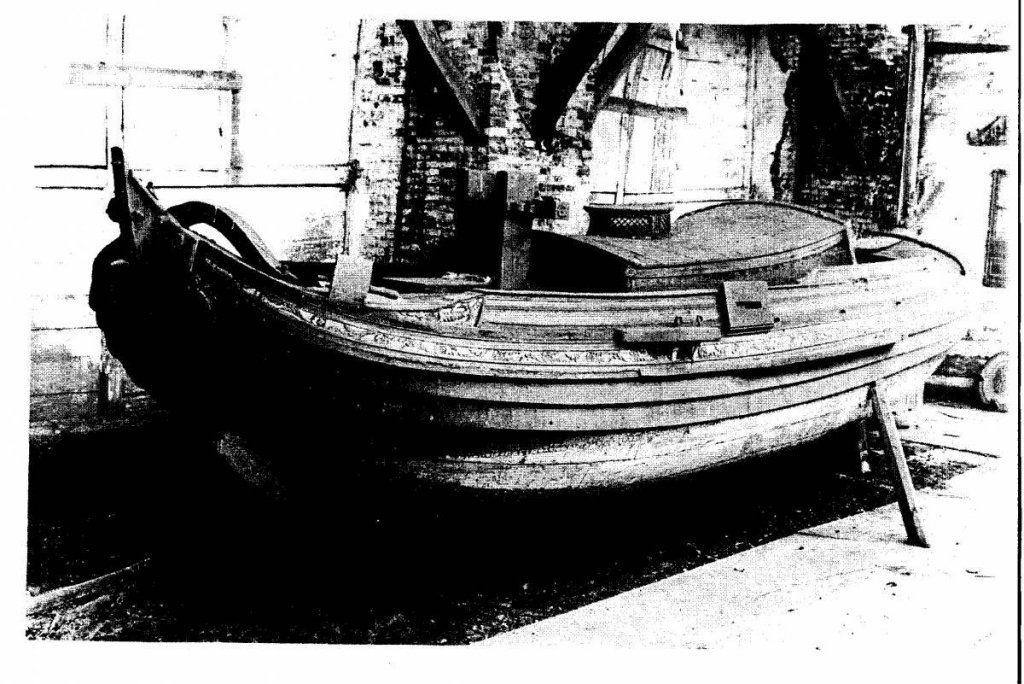

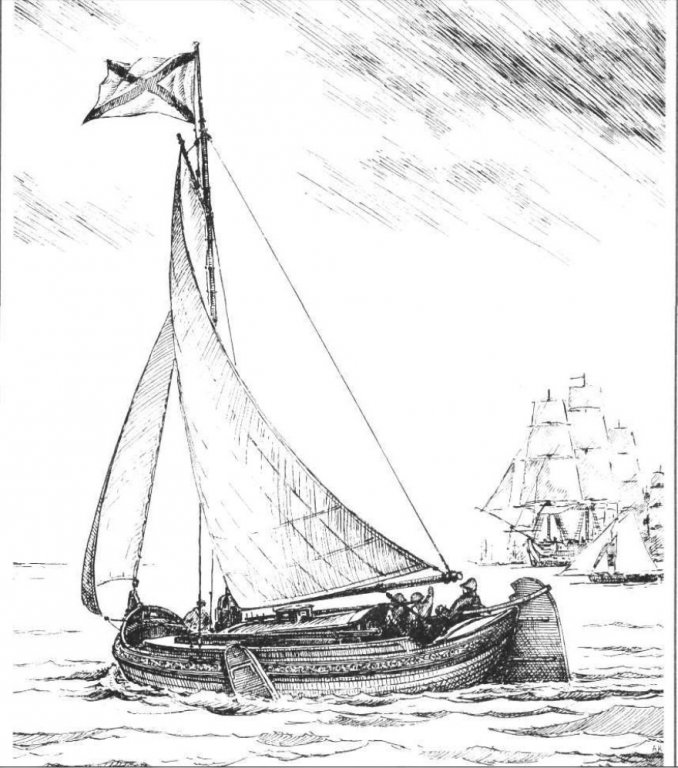

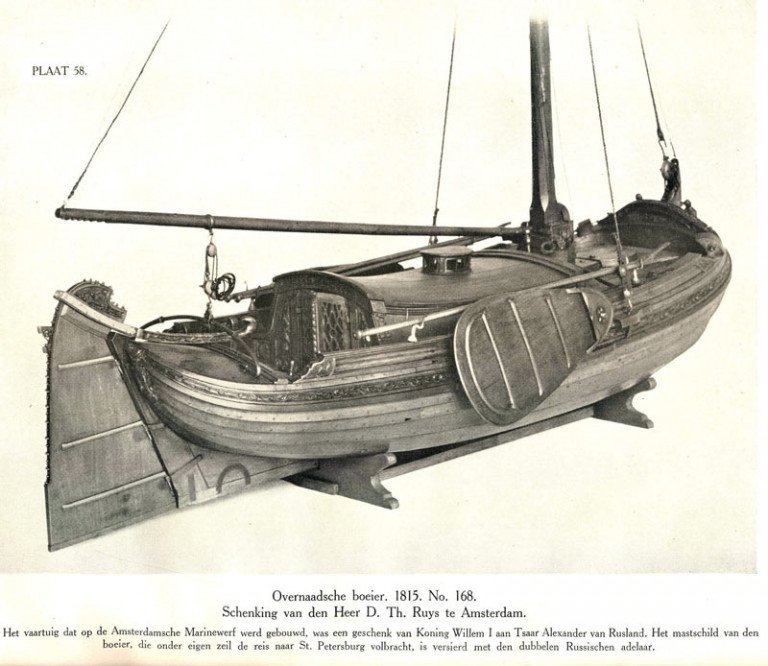

As mentioned, there are several models of this boeijer, one in private collection and two in museums. Seems the model that got the MRI was built by the same guy who built the actual, full size boat, which in turn was sent to Russia. The boat survived the Revolution and war.... to be burned as garbage Not sure when this happened, guess some time after WWII was over, the management of Central Navy Museum in Leningrad (St. Petersburg) rendered the boeijer useless and decided to dispose of it by fire There might be more to this story and some benefit of the doubt should be given but so far that is what I know. Below is the scan of the B&W picture of the full size boat when was still alive.

-

Cross section looks nice and hopefully goes fast as some work is already done. So wanted to ask about the Boeier in anticipation of the kit which hopefully comes after. Chuck, are you going to use the gift to the Russian Zar as the prototype? If so, I may have a useful lead for that particular one. Is there a possibility to make this one is slightly larger scale, along the lines of 1/35 to 1/30 at least? There is so much more potential for detail in that scale vs. 1/48

-

I voted for Boeier. That was on my list for a very long time along with Tjalk and other Dutch and north European boats. I do have a kit of Frize Boeier on the shelf, but its not even close to what Syrens Models can come up with. So that one is a definite must have for me. Scale is a bit surprising though as Boeiers are small boats. 1/24 is a big scale but somewhere along 1/32 would be just right for such boat. Still compact but gives possibilities for better detailing. What ever happened to that Thames rowing skiff that was on NE Conference few years ago?

-

I missed my closet days, everything was a hand reach away, cozy. Now I forget what stored where

-

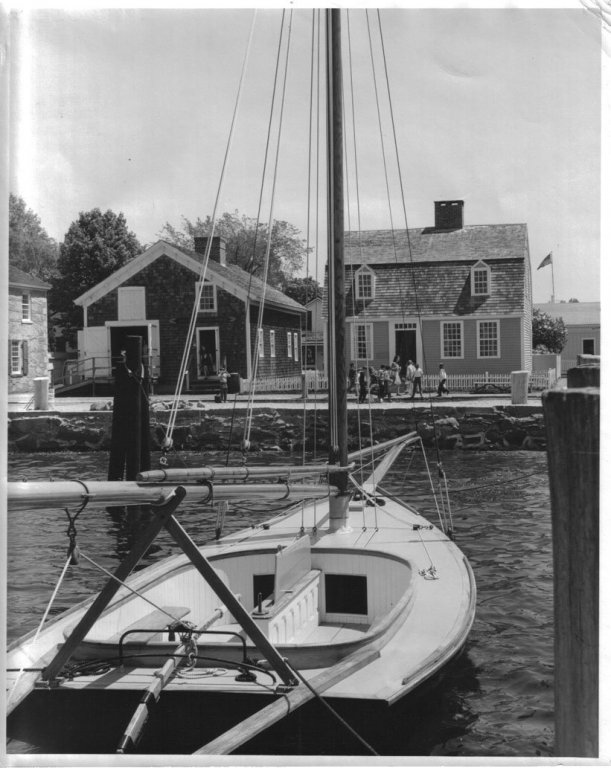

Hi Mark! Yes, if you look at the picture below the one you mentioned, you will see hull being planked with basswood strips. O could have probably just cover it with bondo, sand it and paint it but that would not be true to original construction. Also the outline of the planks is noticeable through paint and oil, just like on the real boat. I have seen Bull and Bear, very nice boats. There are several modern builds that are in private hands as well. http://www.vandamboats.com/modern-sandbagger-sloop-wooden-sailboat But Annie is the only rigged "original" I am aware of and she was rebuilt many times so not much (if any) of her original timbers are there. There are some non sailing hulls in museums too. What I meant is this is a very rear boat to see out on the water comparing to, lets say, catboats that are still sailing around (had one 100 year old moored for a season right next to my boat in Brooklyn)

-

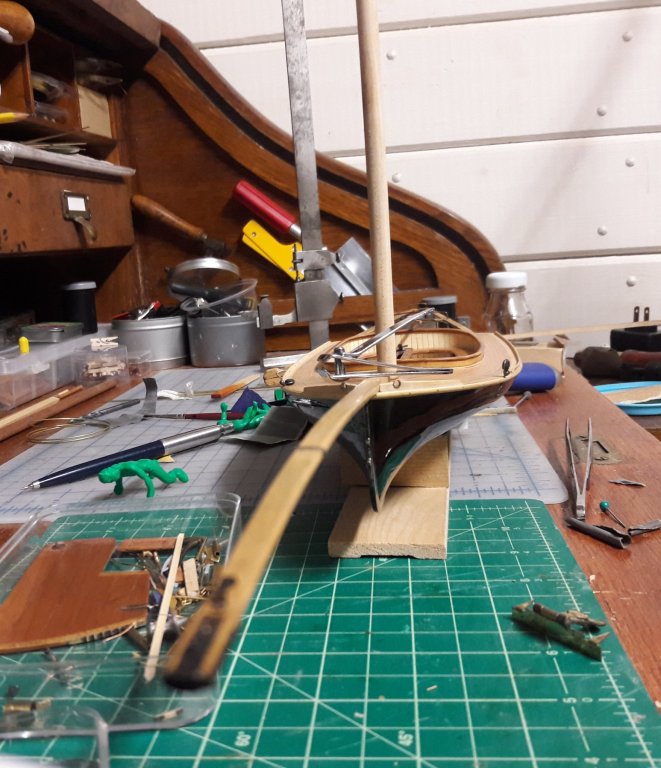

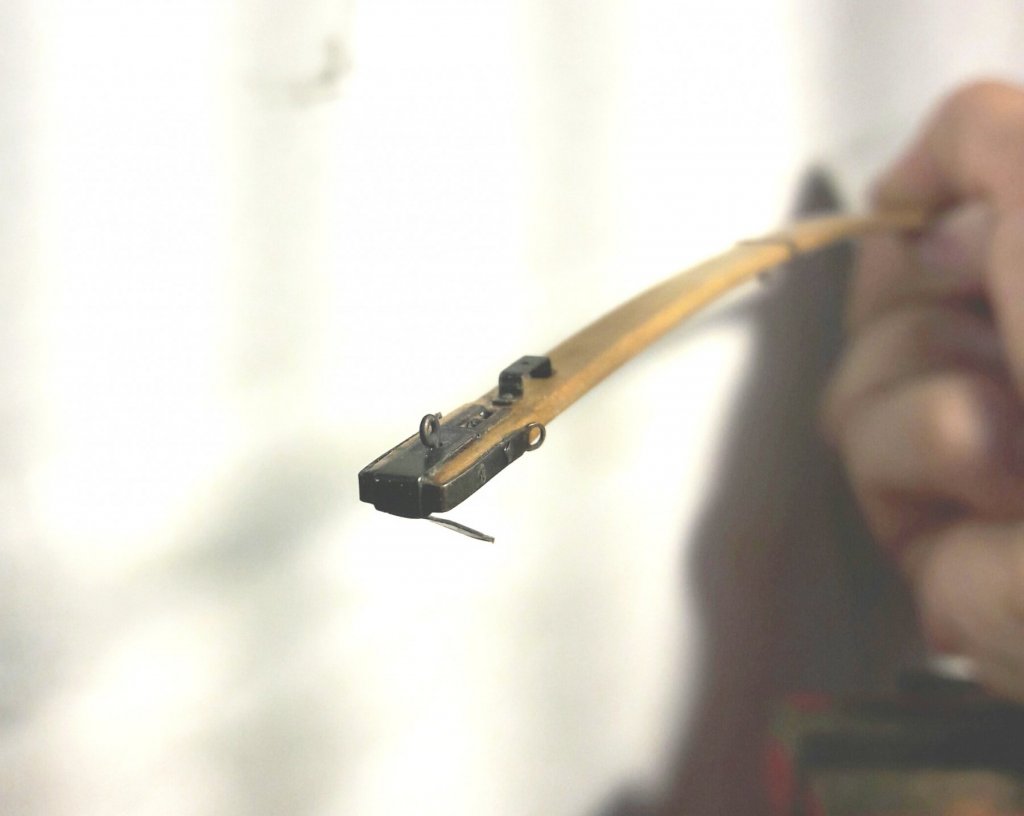

For hoops I cut a strip of pear with cross section approximately 1.2 by 0.8 mm. Dipped it in water and coiled it on my plank bending tool (luckily diameter matched the mast). Than just cut the hoops, filed the edges and glued it together. Afterwards did some final filing/sanding and coated twice with shellac. another set of jaws completed, these were a bit more complicated

-

There are several kits for cat boats and lobster smack/friendship sloops but I think there are more examples of small craft with beautiful lines that sail waters of the North East. Sandbaggers are overlooked as well as South Bay catboats. Would be nice if a line of classic NE sailing boats could be developed in 1/32 (or so) scale. Since these models would not be big, expensive ($60-140 range) or complicated, kits could easily be sold at maritime museum stores. And not to just seasoned modelers, I am sure a father with son tandem would be interested in buying one at Mystic after looking at real boats there.

-

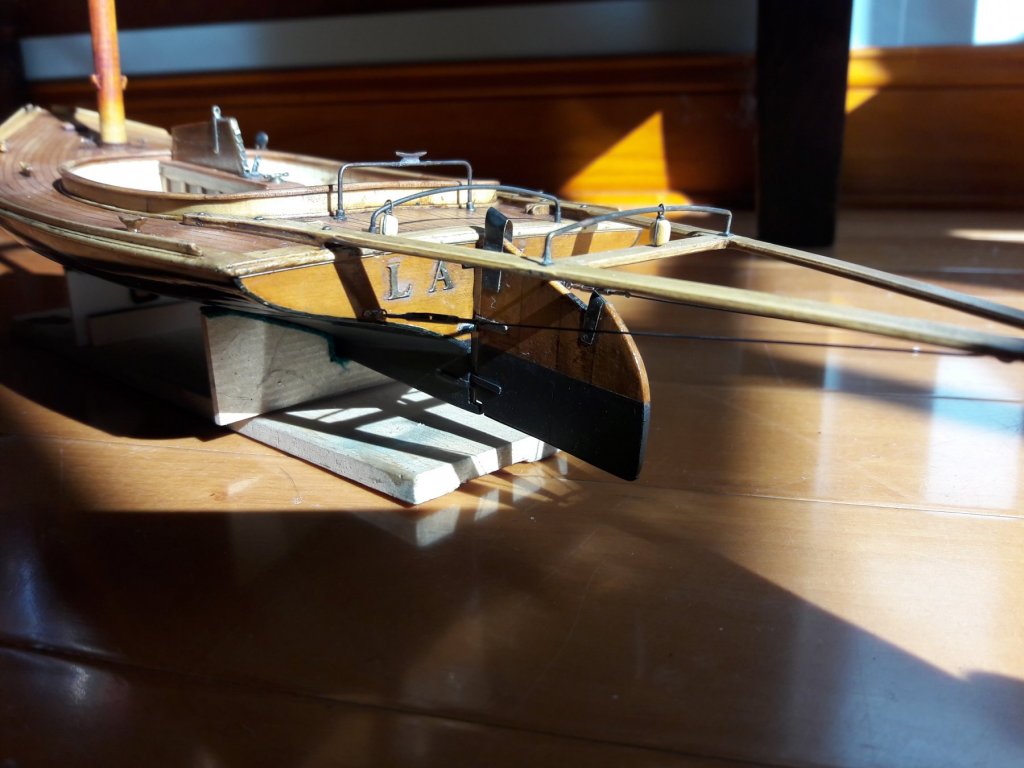

Slowly moving forward. Thy God I am doing a fictional model. My references for Annie are all over the place for many parts of the boat. Seems it was modernized through the years but than her last overhaul took her back, closer to original set up. I did the bowsprit rigging in what seems to be a current set up and plans for it shown in an article in older Ships in Scale magazine are same . Mast in that article is described differently from set up that Annie has now. Older mast had metal gear and now seems all blocks are tied to mast with line through wooden braces which looks like an older way of rigging the mast. I am trying to build a boat how it would look like in 1880-1900's. Wonder if steel wire stays could have been used back than.

-

Here is what I had in my archives. Materials and artifacts were gathered at Home Depot, Ebay, Craigslist and local curbside during garbage collection days. Picture inside porthole was printed on light through film in a printing shop. Lamp and roll top desk required some work but I got them cheap. Design idea taken from Cutty Sark interior. There still some work left on the ceiling and opposite wall were I have a small countertop with a sink and shelves.

-

I used to have a desk at my parents basement, than desk at college dorm, than there was lots of desks until I got my own studio apartment. There a closet was converted into workshop. Upgraded to a house onceI got a family so workshop area is shared with family storage in a small garage. Have two countertops for working with saws, lathes and sanders, storage for large tools, etc. for working on the house as well as models. In the boiler room next to the garage I have my working station were I spent most of the time working on the model (AKA hiding from the family). Used to be a concrete box which I remodeled in style of Victorian officer cabin. If any one interested I have some step by step pictures of the process.

-

Bitumen that Russian are using is not pure bitumen but a patina liquid used in arts for faking antique cracklure. The process is somewhat similar to black wash that plastic modelers do to highlight detail and scribed panels. Patina liquid is put on finished wood surface (oiled or laquered), it fils the cracks and grooves, the excess is wiped off. If this liquid is placed on untreated wood, the effect is off a dark wood stain (as mentioned in posts above). Basically what bitumen patina liquid does is brings out the detail and makes the model look like its few hundred years old. In Europe its made by an Italian company Idea (Idea Liquid Bitumen #741). Judea pitch. Contains white spirit. Gives decorated surfaces an antique appearance. Excellent for darkening cracks and bas-reliefs. Apply with a brush and then wipe with a cotton cloth. Always protect with final varnish. In US I was able to get Bitumen of Judea which is a similar thing. Just Bitumen will not help you! Here is an example of Idea Patina used on a model by a Russian modeller

-

Thank you Jim ! Thank you Jaager ! So #128 I can cut some thin brass (Thought its not recommended to cut anything else but wood on Byrnes saw) and I guess metal itself will stop the blade from flexing/wobbling. I need to take an inventory of blades that came with the saw and post them here to see what they are for. Apparently previous owner had the money to spend and just said give me everything you have and double that (I do have two of each blade)

-

Also want to switch to metric Micrometer stop. Saw has the standard one. Is there a way to avoid buying a whole new stop and just get a metric micrometer for it. Seems like just any micrometer off Ebay will not do the trick as has to be threaded to fit Jim's thread on the stop

-

I got the saw of a guy with almost all bells and whistles and a bunch of blades. As "hobby mills blade selection" advise shined some light on what I have there still a question of this particular blade. It is #128 .010 and it is very thin. Figured would be most economical for slitting planks but feared it will flex which it did. At this point seems useless to me but hopefully someone would hint what it is used for and how to use it. Would Zero-Clearance plate correct flexing?

-

Seems like you have to do some navigation on the site to get to plank bending system so here is the screenshot for it: Wood Bending System 3000 Some thoughts about bending wood The most common task associated with the construction of historical ship models is the bending and forming of wood. Timber used for practically every part of a model hull must be worked to the shape required. More than 30 years ago, when my interest in historical model ship building started, I searched the related literature for everything I could find on how to bend wood. I tried every procedure suggested. But nothing seemed really practical. Some methods suggested "cooking" wood strips as a prelude to bending. Ridiculous! Equally silly - silly, that is, to me - were recommendations to use various mechanical devices to "torture" wood into shape. Crunching wood into shape did not seem to be the answer, I thought. Even raw steam, the popular method, was less than desirable for model building. To bend wood effectively, it's first necessary to understand its composition. It has, of course, a cellular structure. Naturally, each wood type is slightly different, as we would expect. But all woods contain elongated cells and a membrane around each cell that absorbs, retains, or releases moisture. Generally, wood cells absorb water through the membrane at rates about five times greater than the rates at which they release water. Because it's so important to the structure of wood, cell membrane should NEVER be destroyed. When the membrane of a wood cell is destroyed, it's only a matter of time before structural problems arise. Sealing the surfaces of cellular damaged wood with various types of finishes merely delays the outcome of cellular destruction. I use the word "destruction" because that's what happens. When wood cells are cooked, moisture within "explodes," bursting moisture*retaining membrane. Although invisible, serious structural damage does indeed occur. It remains a mystery to me where the idea of boiling wood for model building ever came from. It's certainly not found in the classical ship building literature. Shipwrights of old formed wood for their vessels in a manner quite different from "cooking." Large planks were steamed. Thinner planks were first wetted out. Then, they were weighted to shape. And, finally, a fire was lit under the wood as it was kept wet with mops and brushes until the heat from the fire and the pressure from the weight gradually bent the wood to the desired shape. No cooking. No crunching. Based on my thinking and experimenting, I developed the wood bending system that I now use in my work. The primary component is a 20-30 watt soldering iron in which I mount a forming/bending tip (#3003) for thin timber or, for thicker timber, a plank bender (#3006).The system is extremely simple. It's designed for hour-after-hour of continuous use. Wood to be bent is first soaked in cold water. One to 15 minutes is enough, depending on the type of wood. The wood must be thoroughly wet - but not saturated. It must not, that is, be sopping wet. After removal from the soak dish, after draining or "resting" for a few minutes, the wood is ready for bending or forming. For thin timber, using the forming/bending tip(#3003), heat and pressure are applied with the iron held in one hand while the other hand is used to bend and hold the wood to the exact shape required. The heat and pressure of the iron "set" the wood. Most important of all, the newly acquired shape of the wood will be retained after the heat and pressure are removed. For heavier timber, the plank bender (#3006) is used. The iron iron fitted with the plank bender is held in one hand. The wet plank is inserted into the holder on the bender with the other hand. Then the plank is gently bent down to the desired shape. Again, the heat and pressure "set" the wood to desired shape. And it remains. Using the forming/bending tip (#3003), it's even possible to bend thin wood "the wrong way." (See photo) Handrails, for example, can be formed to the exact shape required. The wood can be bent directly on a tracing of the rail shape. For modelers interested in this technique, I suggest practicing on some scrap wood. Wet and bend wood of all types and dimensions. After just a little experimenting, most model builders are pleasantly surprised at how simple*and useful!*this wood bending technique really is. The wood bending/forming system consists of a soldering iron (#3001), the forming/bending tip, and the plank bending tip.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.thumb.jpg.48f74f482089ba1426741d129134ece9.jpg)