-

Posts

99 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by mitbok

-

I bought a bender and plank forming tip from here: http://info.gk-modellbau.de/usa/index.htm There is some guidance on the use of these tools which is applicable for Ralt RA 5 if you open the link above. Bender is similar to Ralt RA 5 but I seem to use the forming tip 3003 most of the time.

-

Any decal film should be ok, but of course leave it to the individual modeler to decide if they want to go that route and keep the cost of the kit down. I think friezes can also be done that way (if there is white color present, than back ground has to be painted white or decal printed on white decal paper) I did not think of sealing the ink... good point! I used ready made decals and as Jack said, they can be applied even on cloth if set with special solution

- 269 replies

-

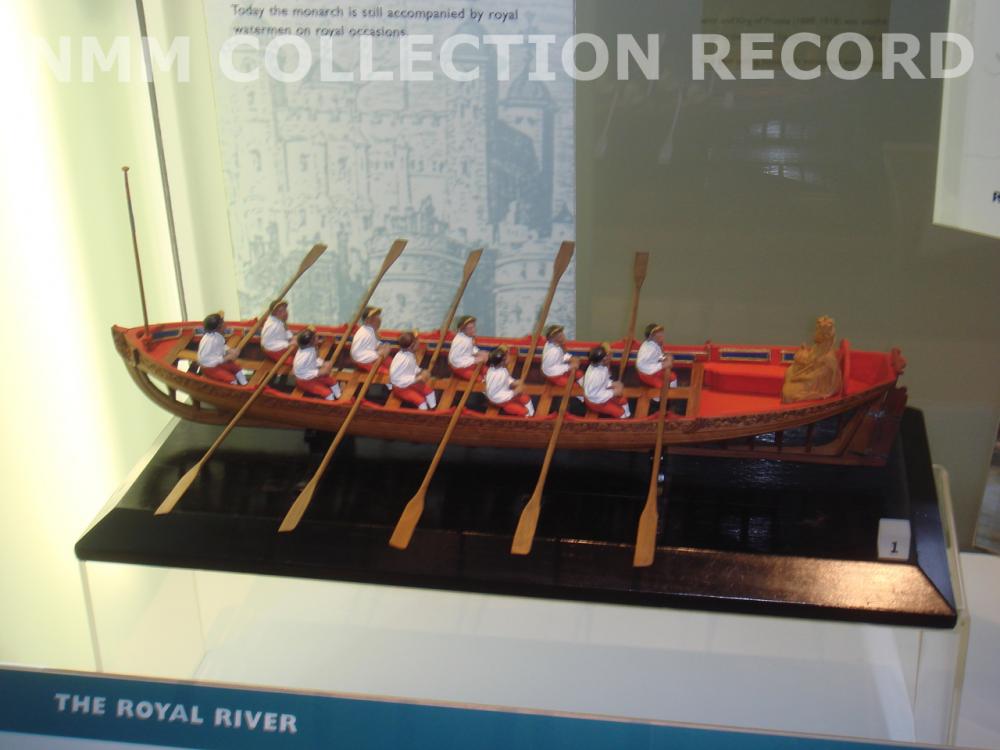

- Queen Anne Barge

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Hi Chuck! I don't remember if I ever mentioned this but there could be a better way to transfer any decorations on wood - decals. if you can provide the image for those who wish to go that way than it can be printed on clear decal paper using ink jet printer. Than just follow instructions for decal transfer. I set decals with Solvoset which dissolves decal film, leaving an appearance of image painted on wood.

- 269 replies

-

- Queen Anne Barge

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

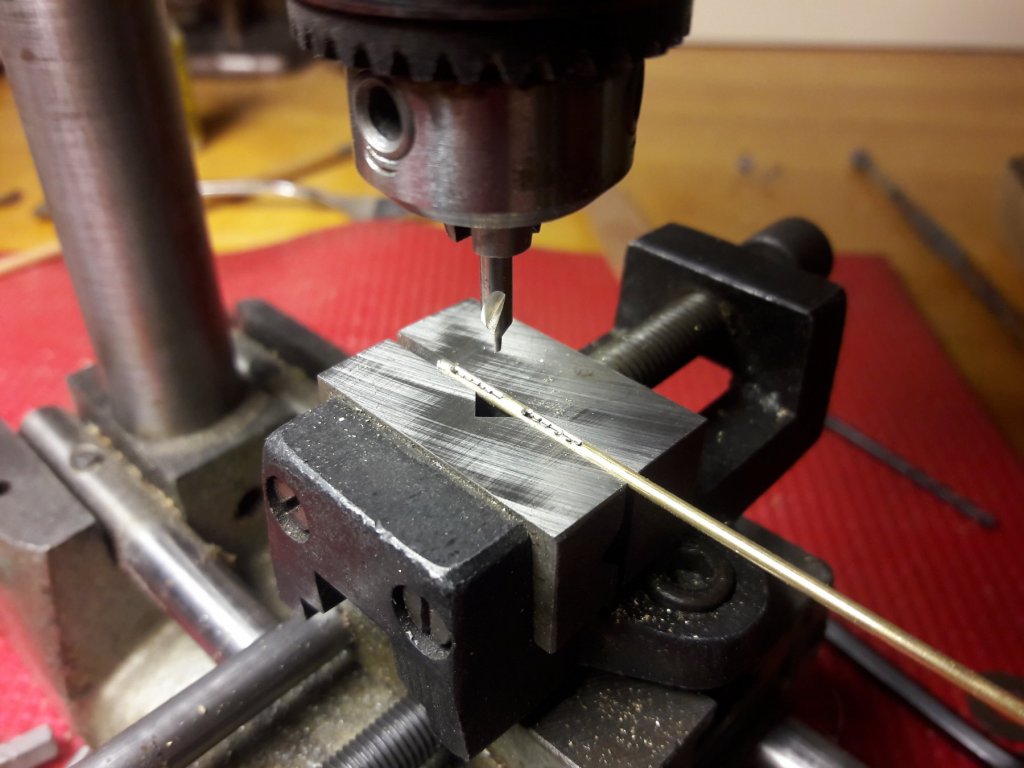

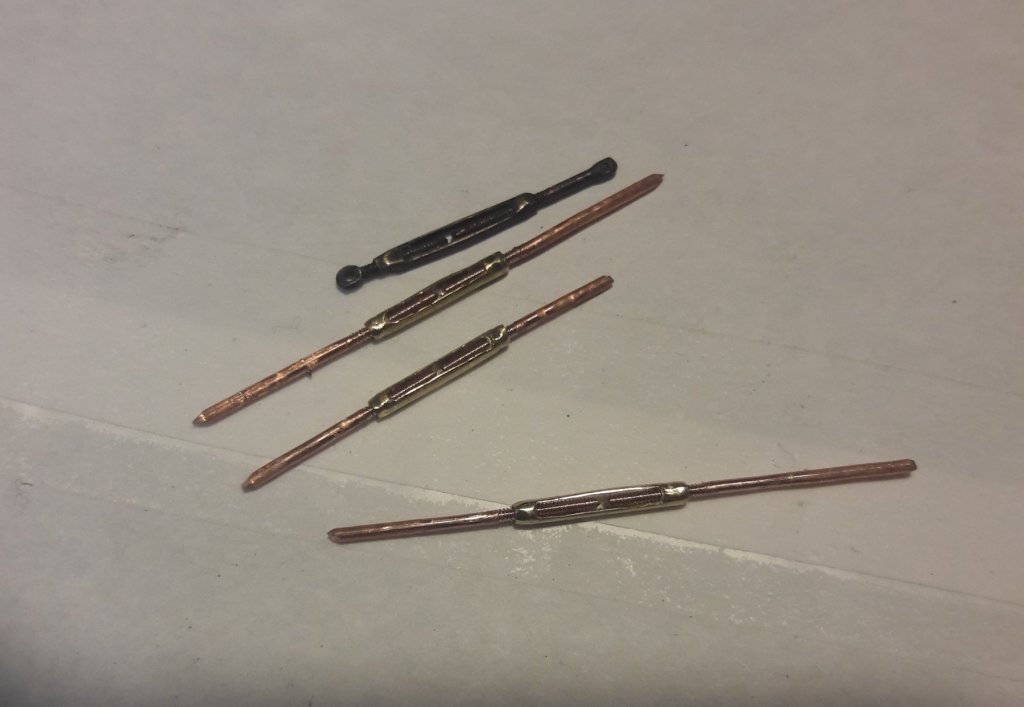

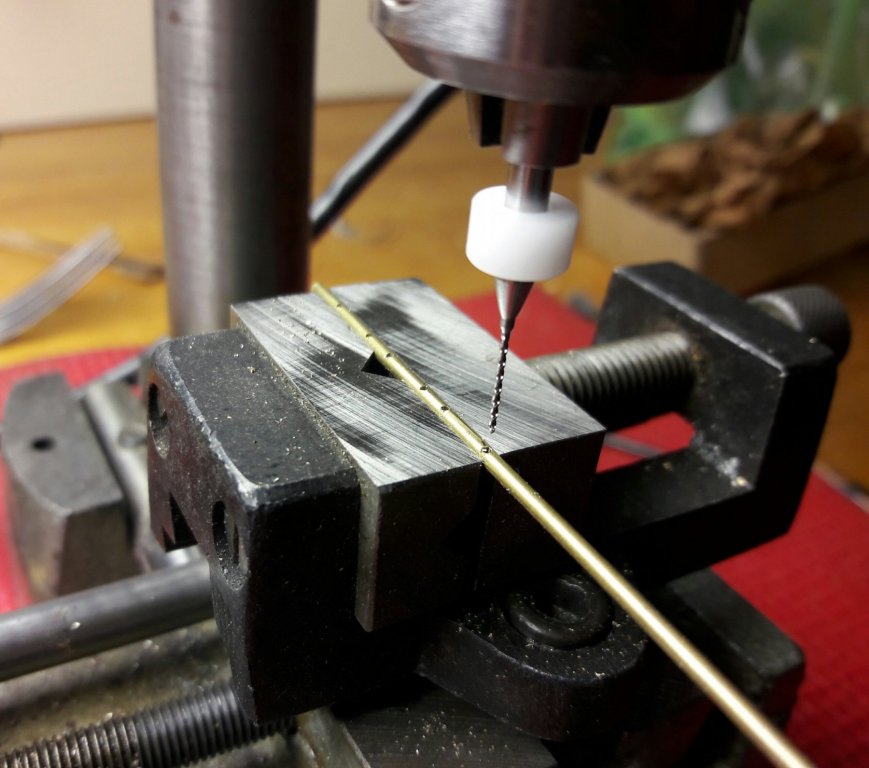

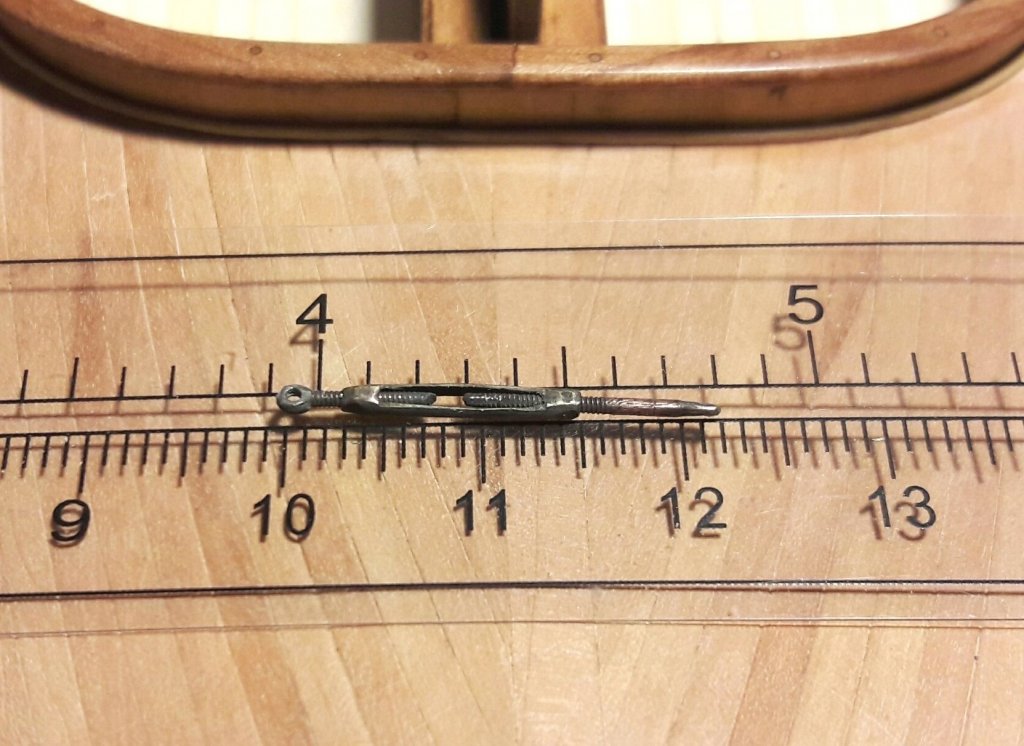

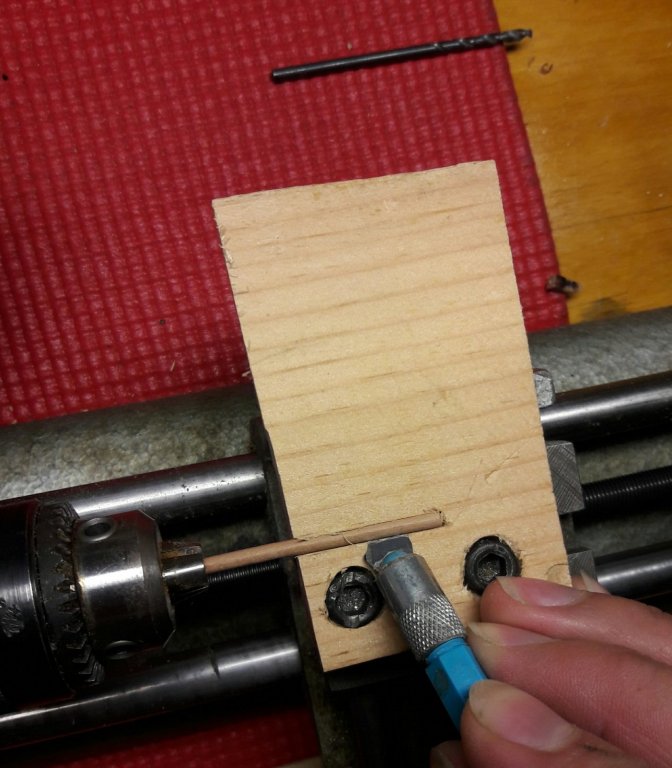

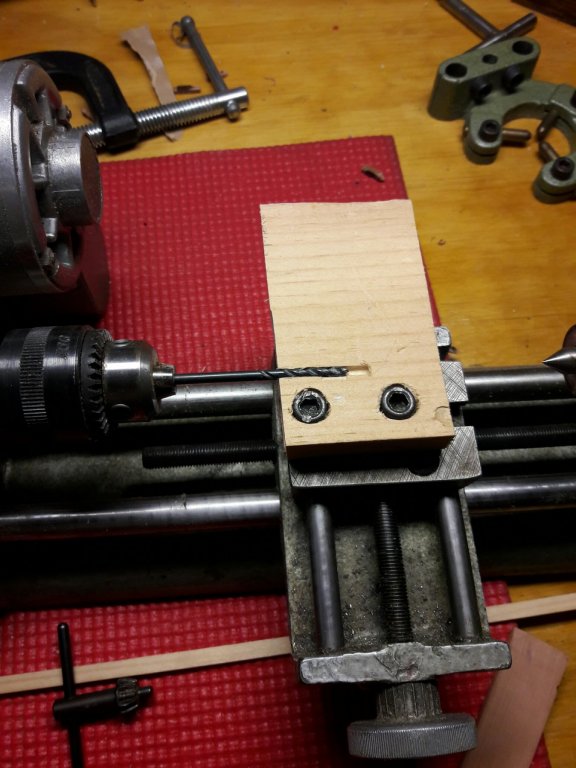

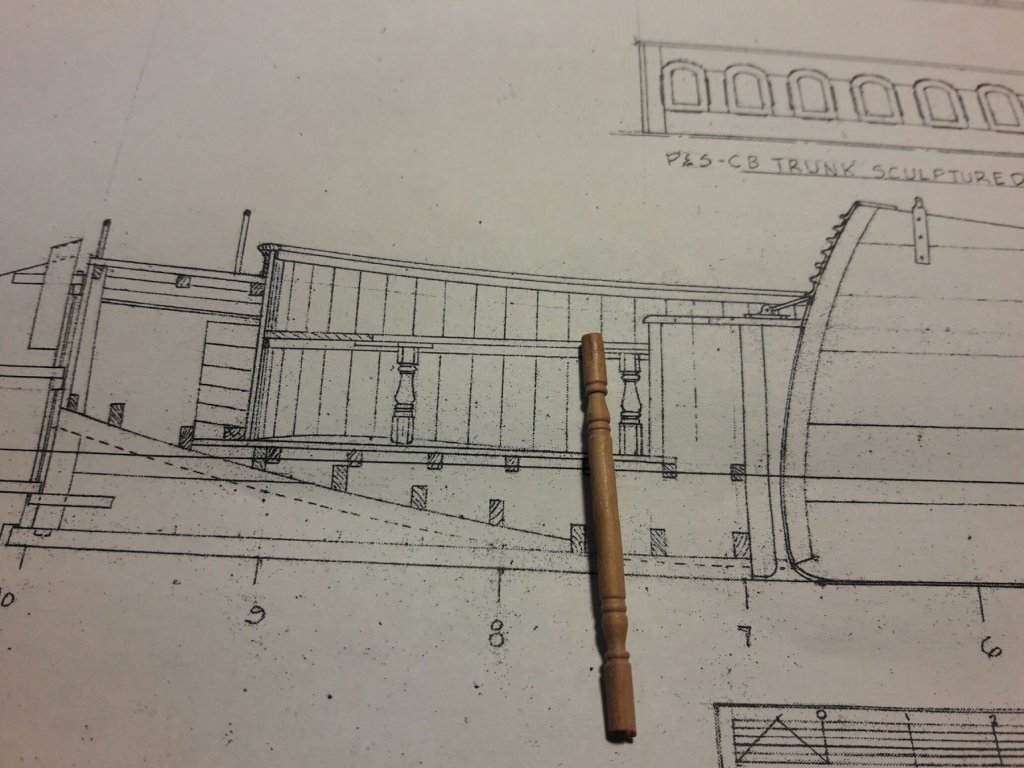

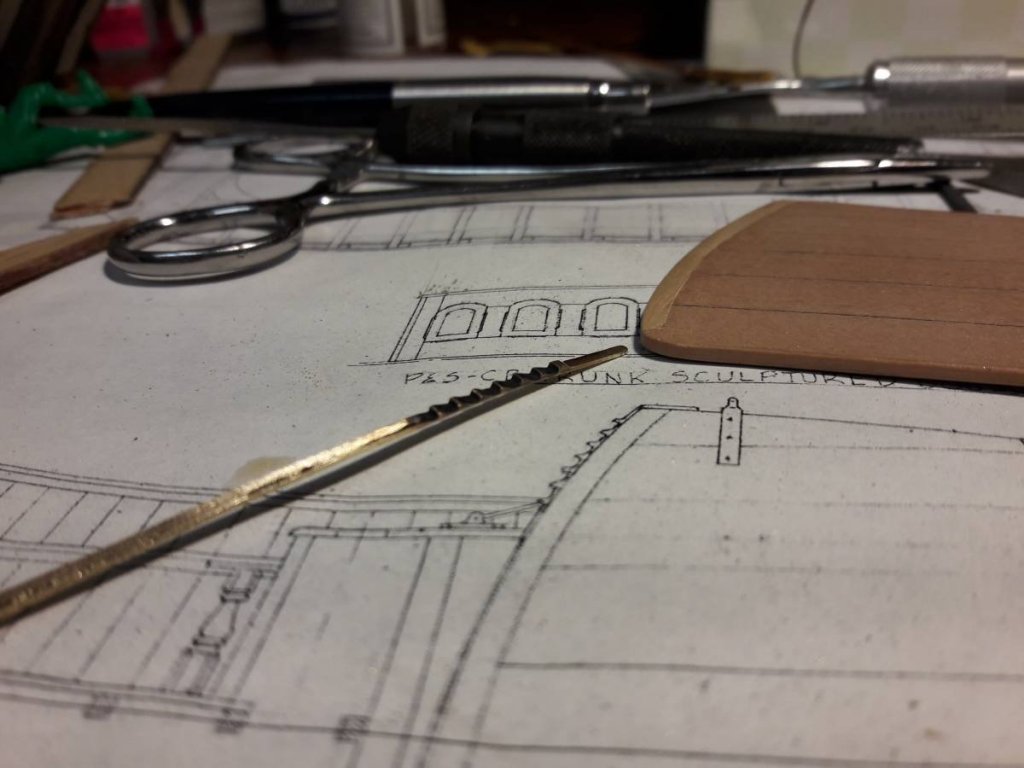

Was trying to come up with a uniform method of producing the turnbuckles but it didn't work out too well. Also a problem is that left and right handed thread has to be made on opposite sides but i don't have the tap and die set for that. Will have to tighten them by spinning the cable itself. Here are some pictures of me making them but there was a great deal of shaping with small files as well

-

I will try to take pictures when making more of them. Basically shaped it out of brass tube and wire. Matched inner diameter of the tube and diameter of the wire (puled wire through draw plate) Tube sides were slitted with cutting disc/Dremel and shaped with files Thread was done by cheap jewelers tap and die set (0.7mm to 2.0mm) I got from ebay

-

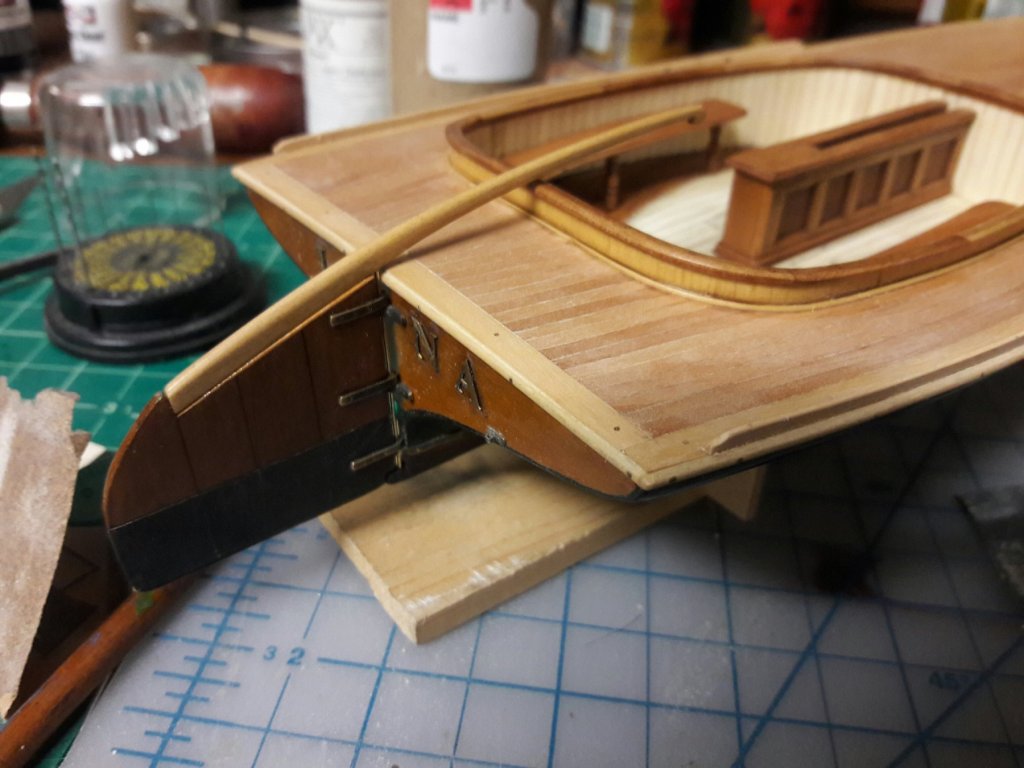

Rudder is now attachable, although tiller is yet to be attached. Can't figure out how the rode that secures gudgeons (no pintles on this one!) was inserted or removed. Seems that tiller had to be removed first, something that will not be possible on the model. Also working on some brass hardware for attaching rigging. Cockpit floor that I made originally was to low and curviture of the hull protruded into the cockpit way more than on Annie. So now I am reworking it by overlaying the old floor with thin ply and new decking on top. All that without removing seats! Ugh...

-

Thank you guys! There is a reason why only a few of those are sailing now days. Despite the fine lines and specious cockpit sailing those things was far from leisurely. Compared to cars they would be something of a bolide racers - fast but demanding and not easy to handle. They required an experienced crew which actually cost money back than. Movable ballast consisting of sand bags had to be moved on each tack. Capsizing did happen, apparently often enough. By the 1880's a cutter type boats where proving themselves as fast but much user friendlier craft. Sandbagger type racing slowly transfered itself in dinghy racing that is still very well alive.

-

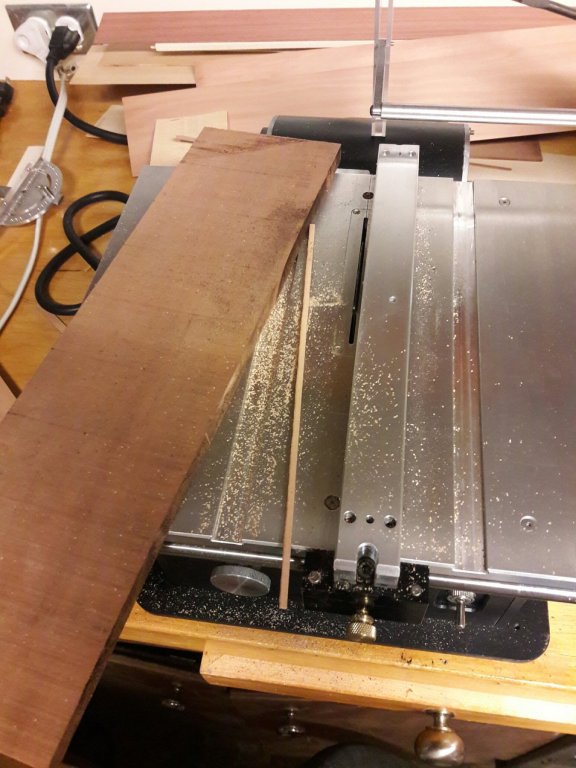

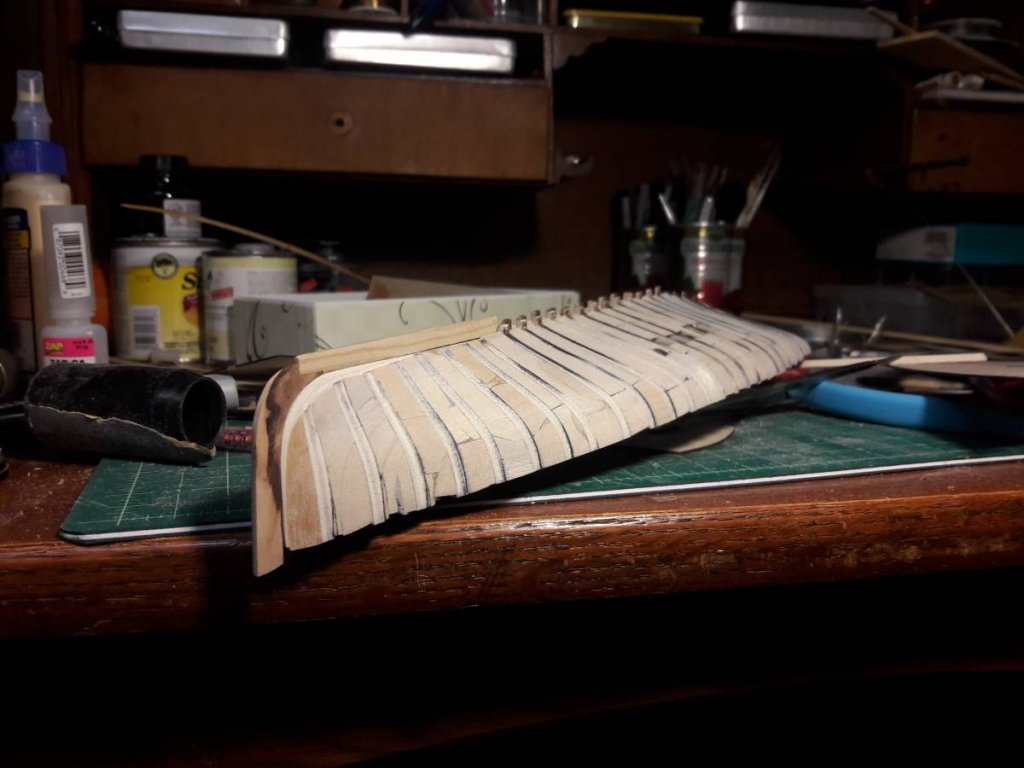

Thank you guys! I like both options and some sandbaggers had two mast holes so rig could be changed. I am thinking sloop rig although it will double models foot print. Now working on planking the cockpit. Sidewall is made from boxwood veneer that was run through thickness sander to get it paper thin. Planks are white holly.

-

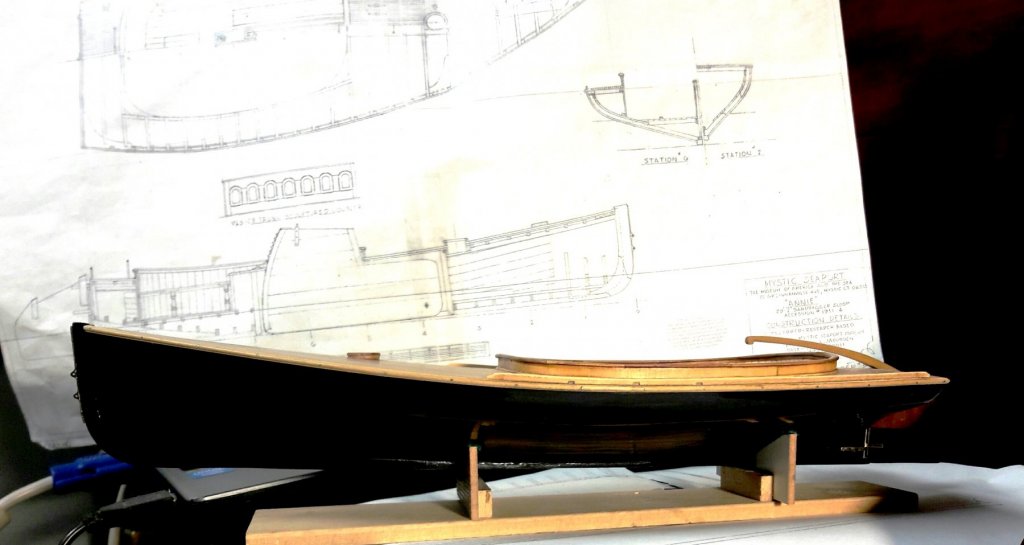

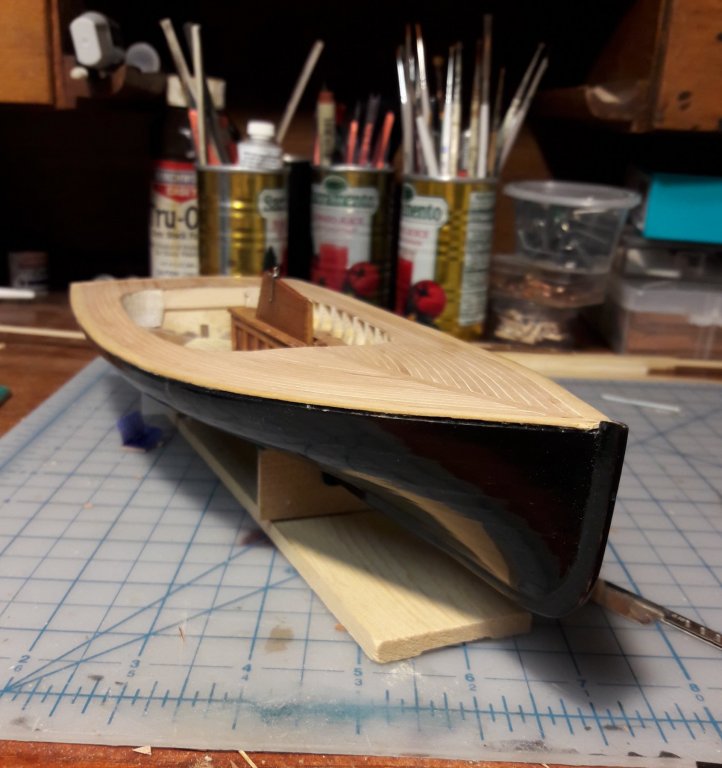

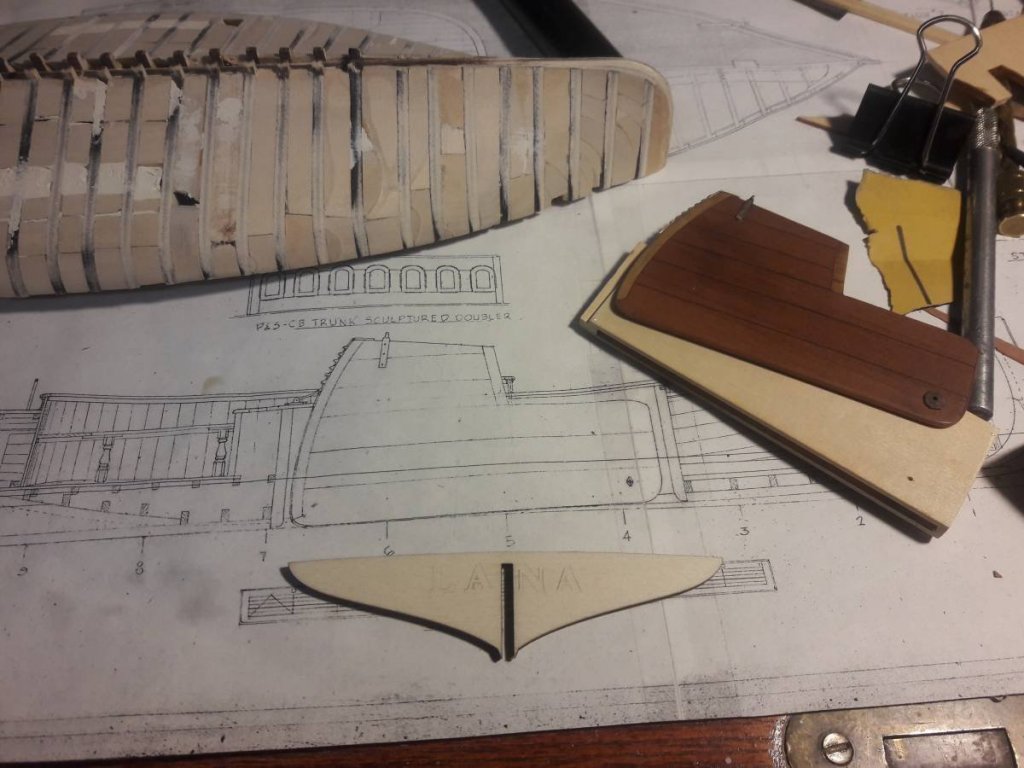

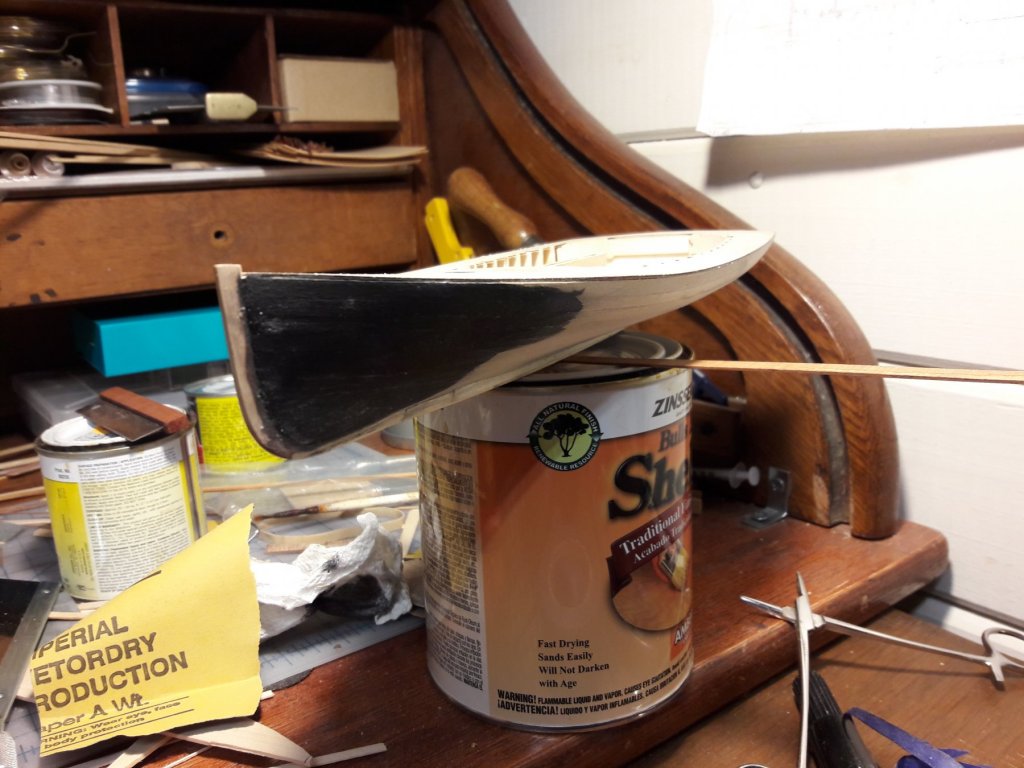

Keel and frames were laser cut by Chuck Passaro from plywood (not sure if that would throw this build into kits category). Got them from Chuck way faster than I was ready to start. Decided to paint the hull and leave the rest in bare wood so hull planking is bass wood for ease of working with. Rest of the boat will be done with boxwood, pear (swiss and my neighbors) and white holly. Some of the wood I got from Wood Project Source, got really great service for such small order.

-

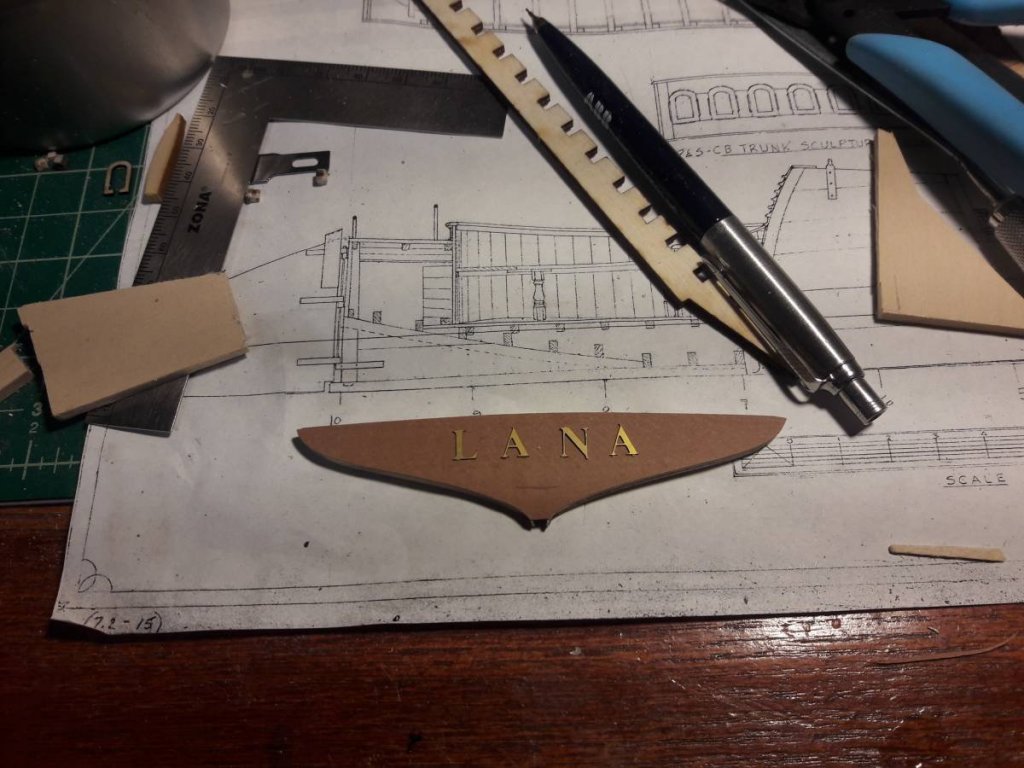

I have fallen in love with the hull shape of these boats before knowing any story behind them. There was a hull model in NYYC model room where I first came across it. Later found out what it was but since I build kits only and there isn’t any of the sandbaggers, building one was sort of a dream. Than several years later, a member of MSW, altalena18 started building one here and was kind enough to share the info and some of his work with me. Finally I started my own build. When it comes to small boat models I tend to drift away from plans of a particular boat, let some imagination in as if I was building a real boat for myself. I also give them names after women in my family (so far grandma and daughter are already on the stern and name plate). This one will be named after my wife (for all she cares)

-

- 641 replies

-

- greenwich hospital

- barge

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.