-

Posts

49 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by baribeaujm

-

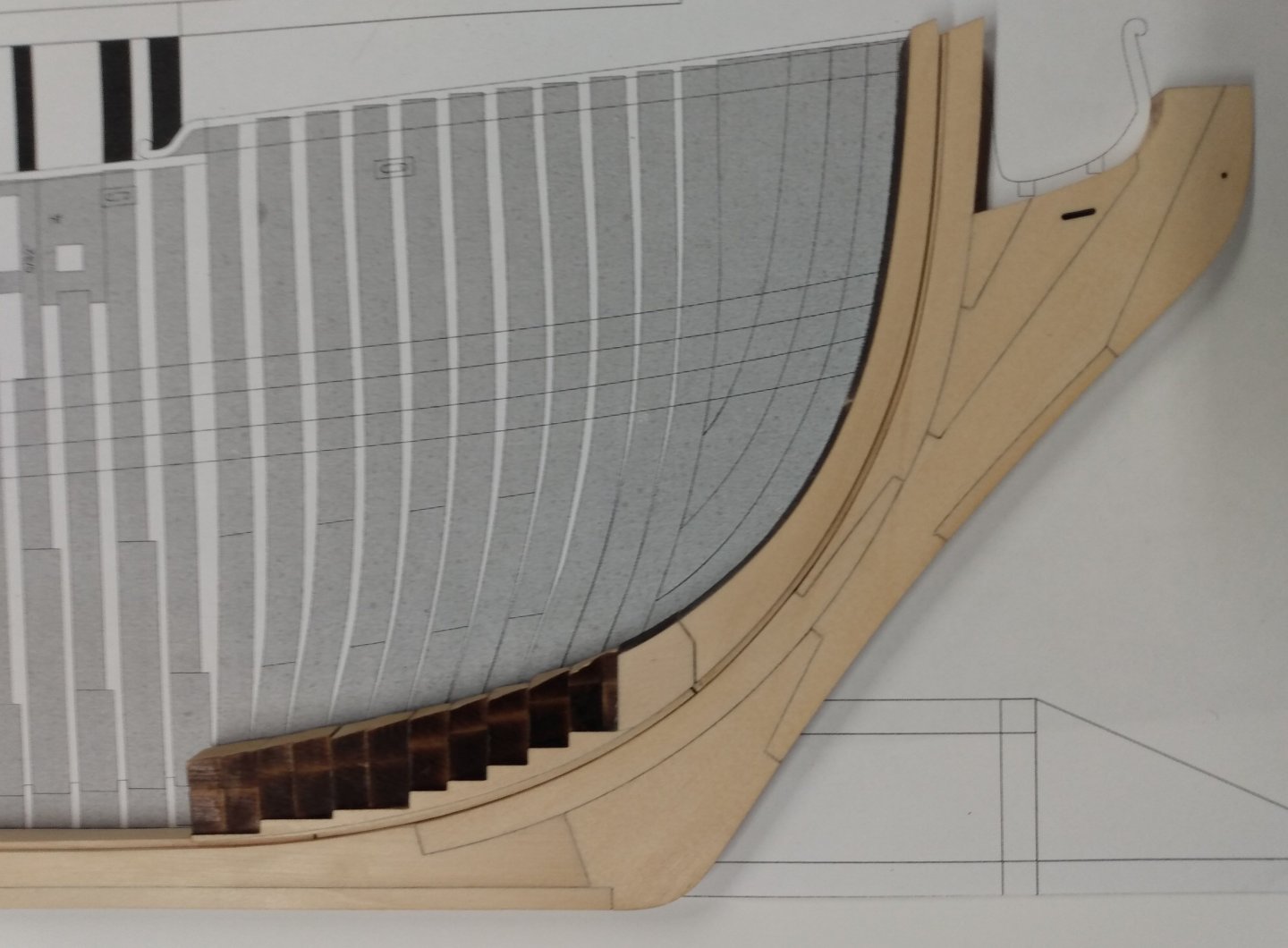

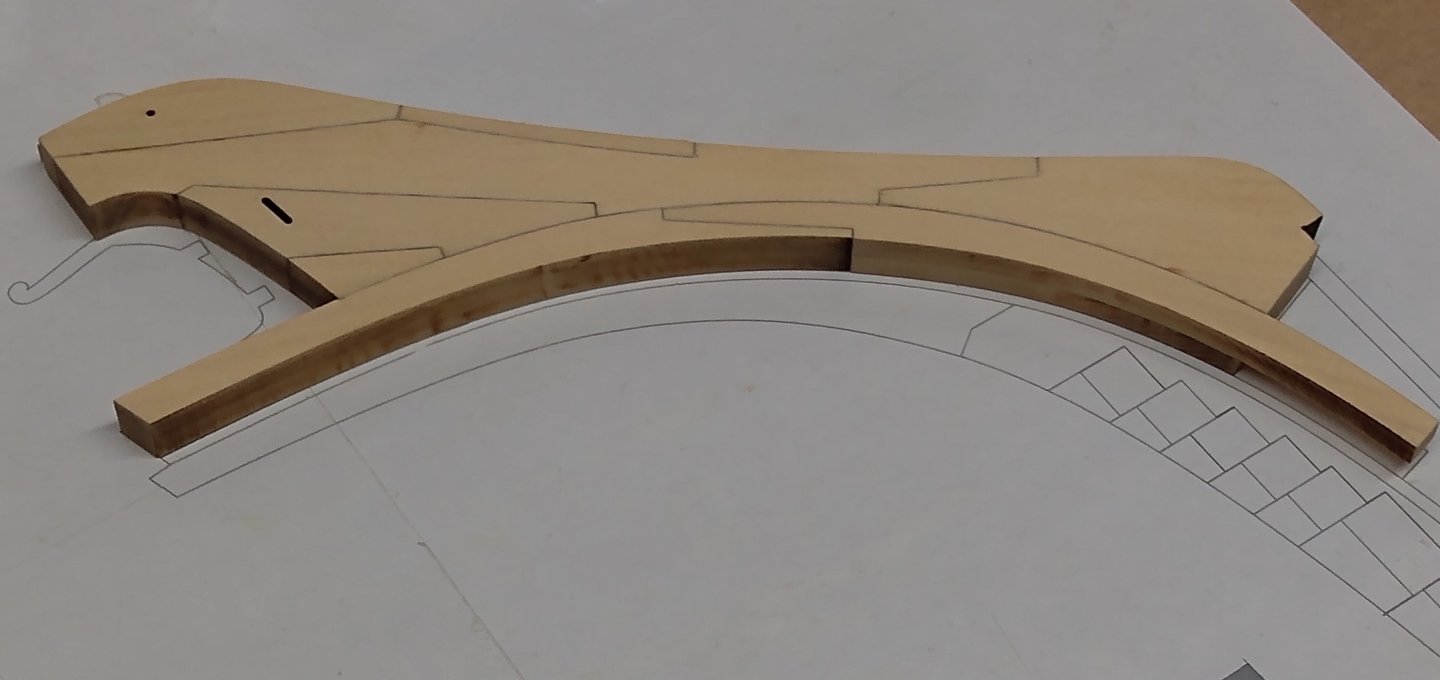

Lower/Upper Apron The pre-cut curved rabbet is a nice feature which avoid the headache of bending and adjusting a straight strip and gluing it to the stem. I had to tweak the curvature at the stem to get a tight fit between the lower and upper apron. I found it tricky to optimize the seam on both sides at once. A lot of back and forth was required here. The final result is shown below. The Rising Wood Before gluing the rising wood sections, I realized that the strip supplied for the rabbet was a touch thicker than the curved section. I fixed this easily using my Varitas mini-plane. The rising wood then went on with no particular issues. Care should be taken to insure that the position of the rising wood is not shifted with respect to the plan. For this I used a plan that I had printed at my local printer. The Deadwood I followed the instructions with no particular issues here. Gluing the angled wedges is easier than at the bow. The completed assembly is shown below.

-

Thanks Greg. I tried magnification loupes and they don't work well with me. I suffer from strong myopia and presbyopia. My myopia is such that my far point (distance at which a far object is in focus) is actually closer than my near point (distance at which a close object is in focus). I found that the best way to work is to not wear any glasses and keep the object I am working on at the far point distance (about 12-15cm). Then the object is in perfect focus. The price to pay is a total lack of depth of field, which becomes a problem when aligning/gluing larger elements.

-

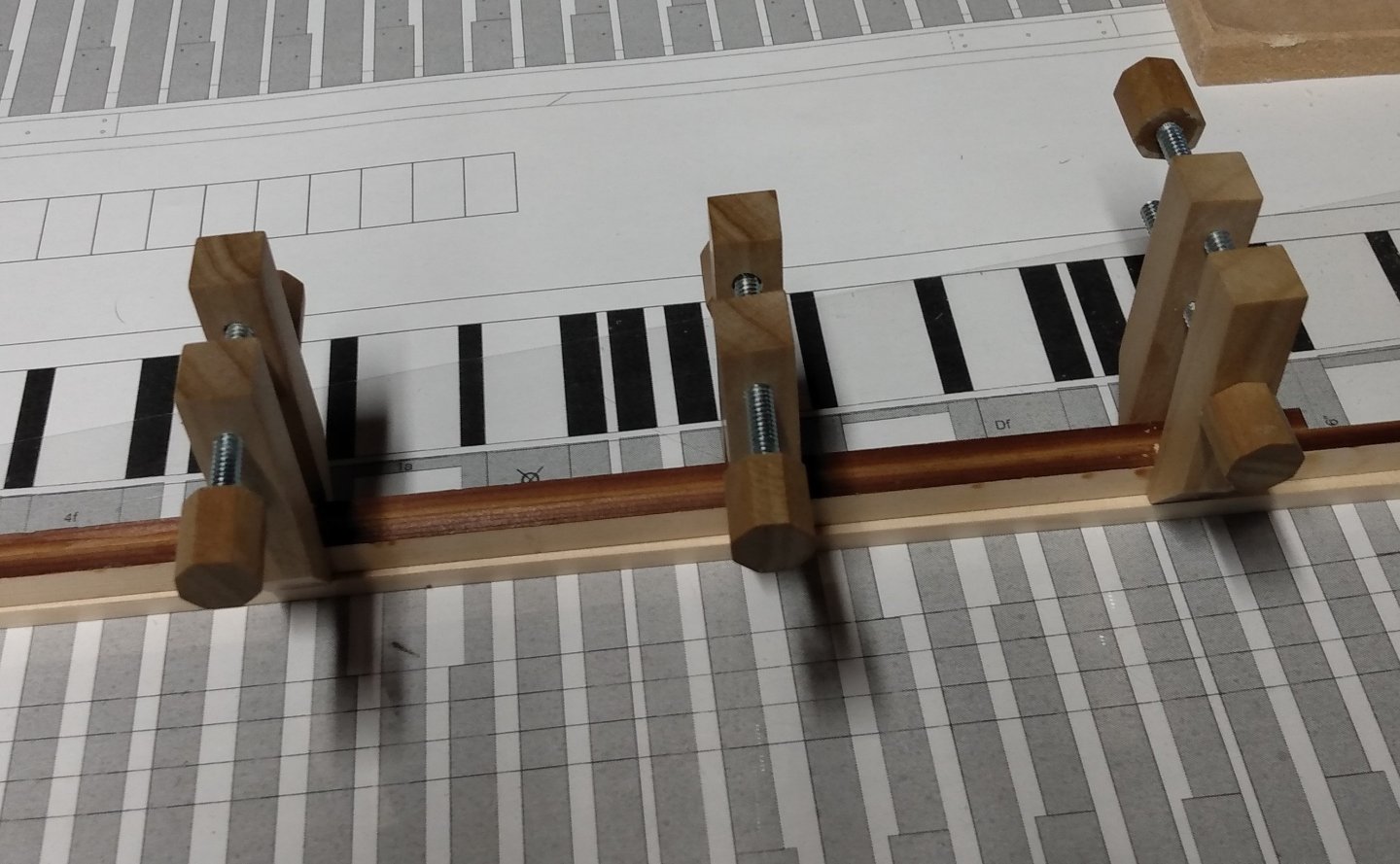

The Keel Assembly The main challenge here is to make a tight fit at the boxing joint between the keel and stem. I had to shorten the curved stem just a touch to get a good fit. The rest of the keel assembly is a matter of gluing the various sections in the right order and on the right side. Very little tweaking of the edges is needed. While I was waiting for my kit, I built a set of simplified "Ed Tosti" clamps. I find these work better than commercial clamps to apply even and adjustable pressure to the parts being glued. They are kind of fun to make too. Lower Apron and Angled Wedges Here I encountered my first difficulty. The stepped lower apron is attached to a sacrificial piece of wood (handle). This makes it easier to glue the wedges one by one. Without the handle, the lower apron would certainly break during this operation. I found that even with the handle, the lower apron remains quite fragile. If you force the wedge in position, you can slightly modify the curvature of the apron or even break it loose from its handle. This happened to me and resulted in a poor fit of the lower apron to the keel assembly as shown below. I was able to correct this by gluing a sliver of wood between the apron and the keel as shown here. This gap may also have been the result of the stem being glued a hair too low (less than 1/32th). Anyway, I am glad that I took the time to correct this.

-

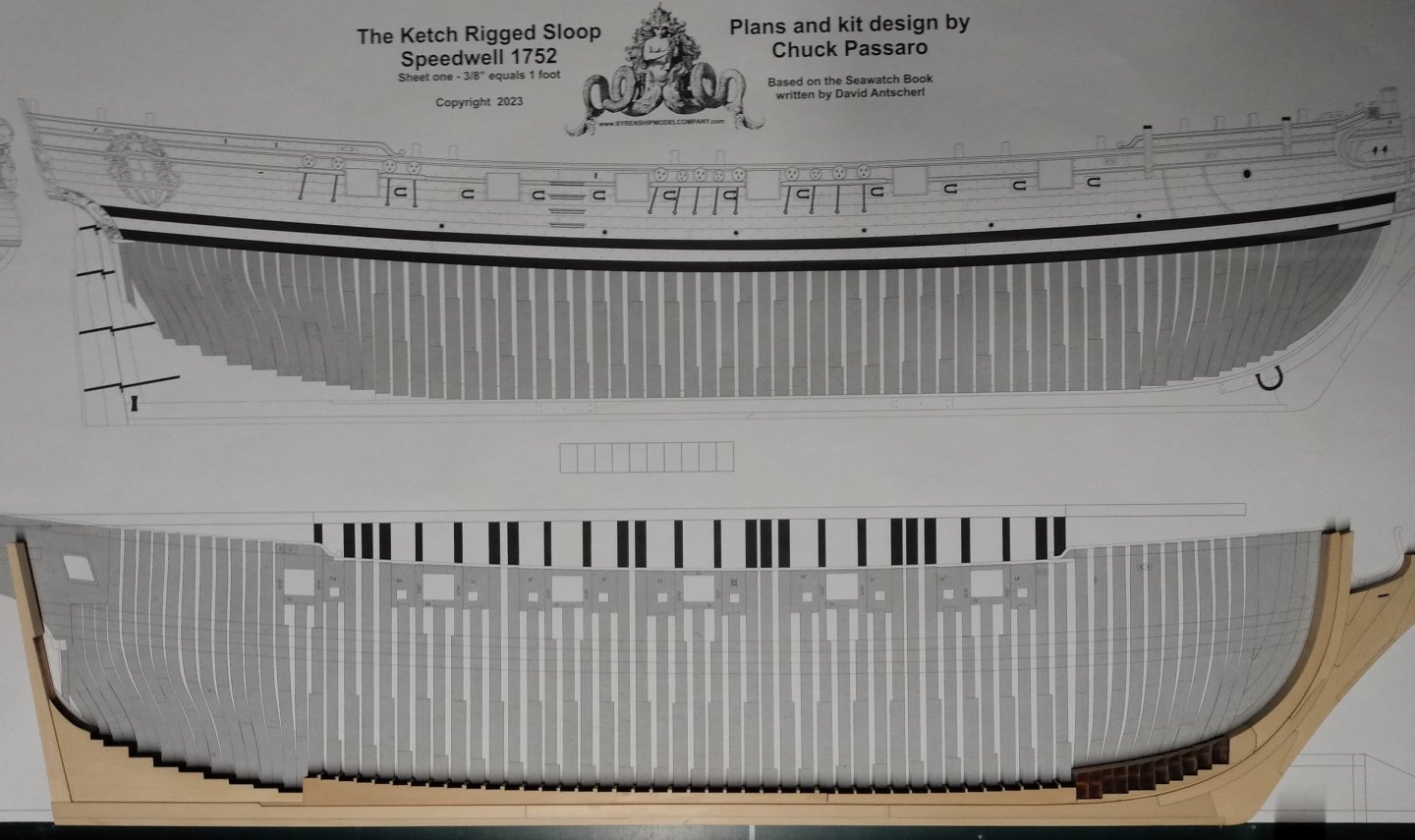

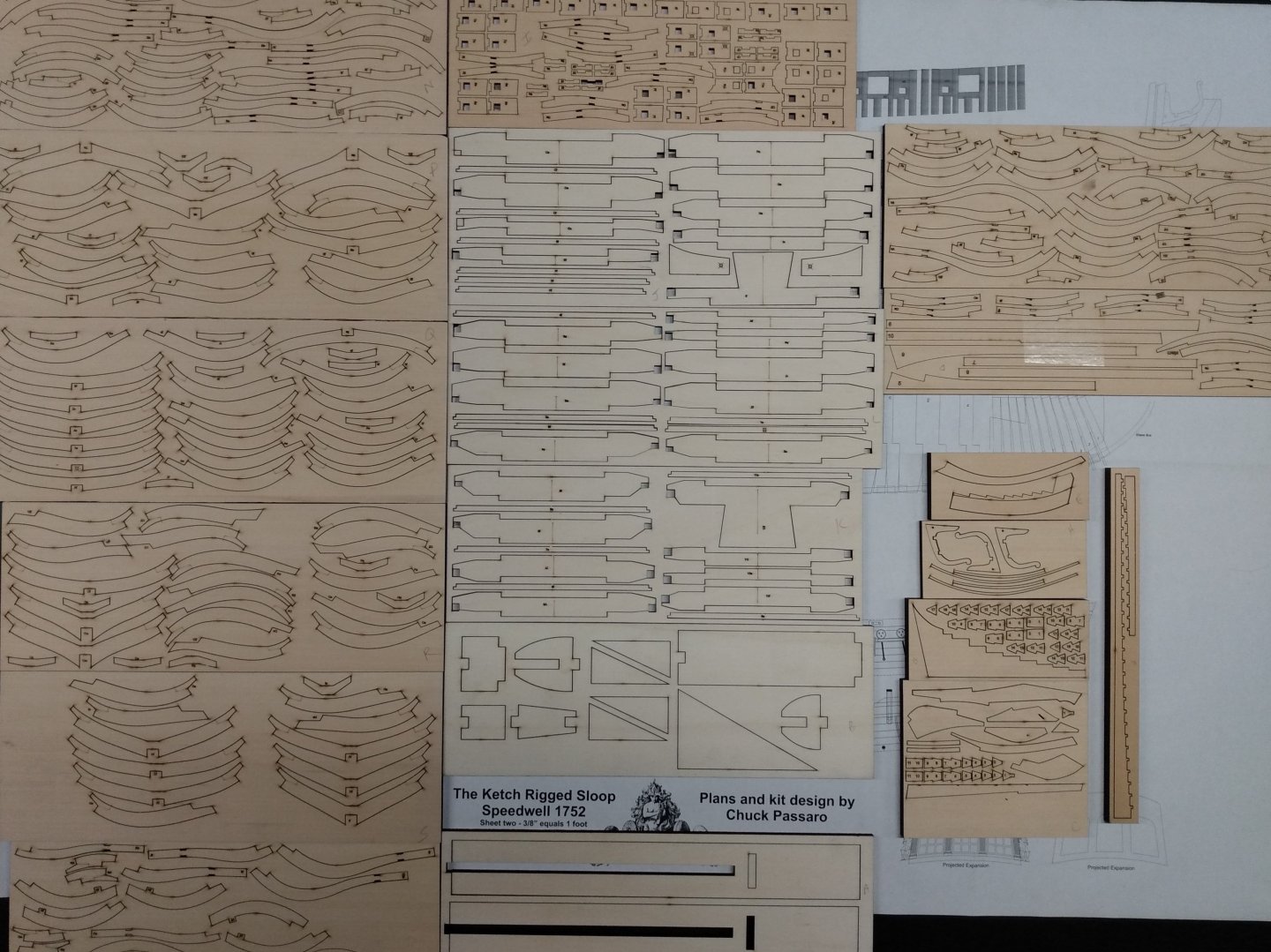

CHAPTER 1 Here we go. I started ship modeling about 15 years ago. I completed all Chuck's projects plus a few others (including Model Shipways Syren). I recently completed the Winchelsea and posted a few pictures on the gallery. Except for Chucks Medway, all my projects had been POBs. I was therefore quite excited when the Speedwell kit was released. This offers me a great opportunity to work for the first time on a POF kit without having to scratch my own frames. Except for ripping planks on my Byrnes saw (yes I am among the lucky ones), I essentially work with hand tools. In this blog I will report on my progress. All the Speedwell builders are well experienced, and I am hoping you guys can provide advices when I have questions or encounter difficulties. Thanks in advance. (This will also free Chuck from answering my numerous emails). On occasion, I hope I can contribute some ideas and tips to those who will undertake this project. Parts for Chapter 1 are shown below. Contrary to others, my kit survived posting very well. Only one small part (5F) in the top center board seems to be missing. It is easy to scratch build, so no big deal. Assembling the stem is straightforward. Tweaking the edges as suggested improves the fit. I had to tweak a few more edges than those indicated to get the tightest fit. Positioning the stem (long curved part to which the rabbet is glued) on the rest of the stem assembly can be tricky. It is important to follow the plan closely to avoid problems when making the boxing joint at the keel and to ensure a tight fit between the apron and the rabbet. I think I glued mine a hair too low and had to make adjustments (to be discussed below). Note that I postponed the gluing of the thinner knee of the head for the time being. To prevent knocking it off, it will be glued on only when the whole stem/keel/stern assembly is completed.

-

Correct Glue

baribeaujm replied to Blacklab's topic in Painting, finishing and weathering products and techniques

To add to the discussion, I have used both PVA and CA in my model building for the last 12 years. I first used PVA for planking, which I found challenging. It could be messy, it requires clamping, especially at the bow and stern. About six years ago, I switch to CA for planking, following Chuck;s method. I find CA a lot easier to use and the resulting plankling a lot more satisfactory. You can get very thight joints with CA without use of clamps. There is no need to apply glue to the edges, minimizing glue stains. It is also a lot more forgiving at the bow and stern. If your plank bending is not perfect. Just hold the plank in the correct position for a few seconds until the glue sets. I first used BSI products but recently switched to Gorilla gel. I really like the latter product and found it performed just as well as BSI. The gel gives you a few seconds to adjust pieces, it alo minimizes splills and stains. The glue dispenser is also very well designed. The spout never clogs, which I found could be a problem with BSI bottles. Jean-Marc -

I join the voice of others congratulating you for completing the project. What a spendid model and how fun it is to build it! Your ability to come up with creative solutions at difficult and critical parts of the build is quite remarkable. I still have many months (years?) in front of me to reach the finish line. Hopefully, in time to embark on a new journey with your forthcoming POF project. Kudos again. Jean-Marc

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Straightening thin brass wire

baribeaujm replied to vossy's topic in Metal Work, Soldering and Metal Fittings

One end of the wire in the vise the other in the mandrel of your hand drill. Give it a quick spin (5-10 turns). The wire will become perfectly straight. This also affects the micro-crystalline structure of the wire making it a lot more rigid. Jean-Marc

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.