-

Posts

79 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Richard Bradfield

-

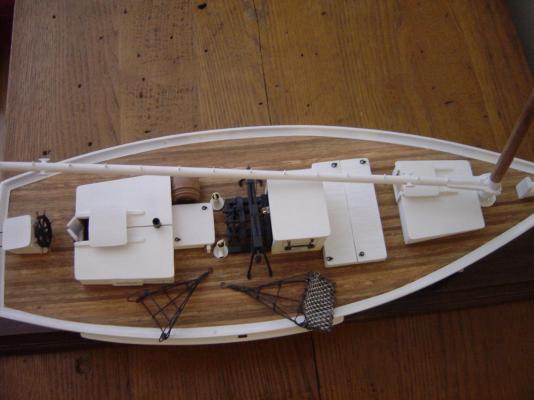

I finished all the major painting, touchups and constructed the display stand today. Next step is the cap rail, install rudder linkage, and more ironwork (when my supply of brass gets here). Here are a few pic of the where I am at the end of today. Nothing is glued down yet. Gonna take a break for a few days and get back on it Monday.

- 135 replies

-

- willie l bennett

- model shipways

-

(and 1 more)

Tagged with:

-

Adam, I have Min Wax polycrylic clear satin, Min Wax polyurethane semi gloss and Rust-oleum polyurethane matte but none of them say its ok to use on painted surfaces. Just talk about stained surfaces. What do you suggest?

- 135 replies

-

- willie l bennett

- model shipways

-

(and 1 more)

Tagged with:

-

Adam, Tim and Bob, thanks for checking in. The bottom paint turned out a whole lot better than expected. I'm quite happy with it. I'm using the Model Expo water based paints and generally am not all that happy with them. They definately need to be thinned as they dry almost as fast as I can put it on. The paint also seems very fragile and scratches very easily. I'm wondering if I should put a protective finish over it. Any suggestions anyone?

- 135 replies

-

- willie l bennett

- model shipways

-

(and 1 more)

Tagged with:

-

Tim, I am enjoying your build of this boat. I have always loved these PT boats. After looking in on your log last night, I spent the next few hours on YouTube viewing videos of PTs in action and current restored ones. Keep up the great work!

-

Russ, I agree - no pin stripe. I don't want to chance messing it up. Davidb, I used a brush on everything. I thinned the paint quite a bit and lightly sanded between coats. Paint was applied over a two day period. Thanks for having a look guys!

- 135 replies

-

- willie l bennett

- model shipways

-

(and 1 more)

Tagged with:

-

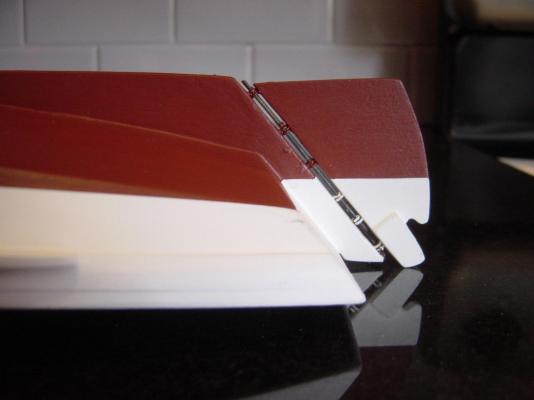

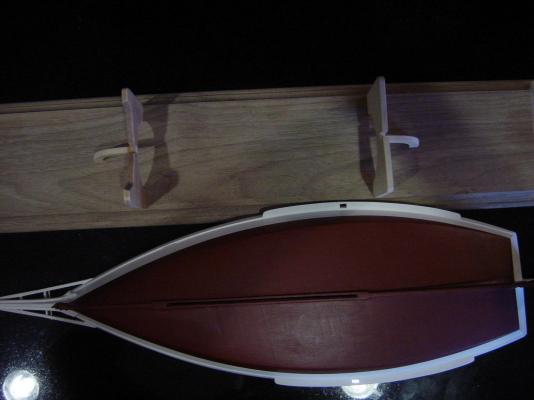

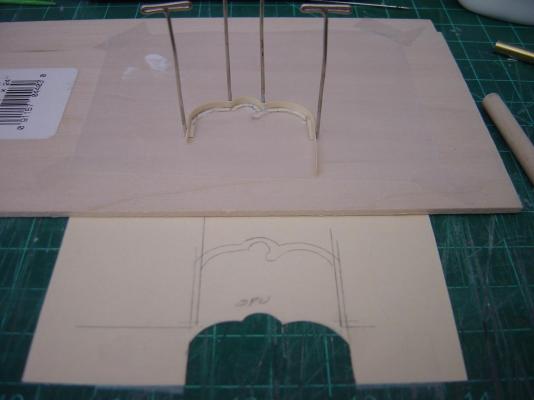

Tim, Russ, bob and Davidb, thanks for checking in on my build and for the gracious comments. They are appreciated! Danb, I think perseverance is the word to describe my improved soldering skills. I'm not really sure what is going on with my ability there, it is just so hit or miss. Anyway thanks for the comment as it did turn out pretty well. I painted the bottom of my boat over the last few days and really like the results. That Tamiya masking tape is great. Really got a clean waterline and I only need to touch up the white color where I screwed up the taping. I was expecting to have to paint a green pinstripe between the white and red, but I have such a crisp line I'm not sure I want to anymore. I also made the cradle for the boat and have only to paint and position them on the display board, but I need to let the paint dry for a day or so. Pics to follow. This is the first coat. Second coat. Third coat. Fourth coat. Removing the tape and exposing the waterline. Wow, I'm so happy with the result, here is another picture! And another. Here are a couple pics of the cradles I made for displaying the boat. Still need to fine tune them to the hull, mount, and finish. I'll do that tomorrow when the bottom is good and dry.

- 135 replies

-

- willie l bennett

- model shipways

-

(and 1 more)

Tagged with:

-

Bob. Thanks for the comment. I really appreciate the positive comments you and the other seasoned model shipwrights provide. Being new to the hobby its nice to know I seem to be on the right track. At least I haven't gotten a "Whoa there, what are you doing" comment. I ran out of brass strips and couldn't work on some of the ironwork I had intended. I ordered a "boat load" of brass strips and tubing, C and I beams so I should not run out again, ever! So I decided to piddle a little bit and wanted to check out the waterline I marked on my boat. I put it in the bathtub and it floated true for a few seconds, then started taking on water. Took me a minute to figure out that the centerboard case was not water proof! Oh well, I have a nice clean bilge now, and I need to redo my waterline markings. I then decided to move on to putting the safety guards on the dredge winder. After some thought I decided to try using card stock in lieu of metal. It actually was much easier and should work just fine. The following pictures show my process. It took me about 6 hours to do two of them. They look better than the the pictures show them to be. I'm happy with the result.

- 135 replies

-

- willie l bennett

- model shipways

-

(and 1 more)

Tagged with:

-

Russ and Hamilton, thanks for your comments.

- 135 replies

-

- willie l bennett

- model shipways

-

(and 1 more)

Tagged with:

-

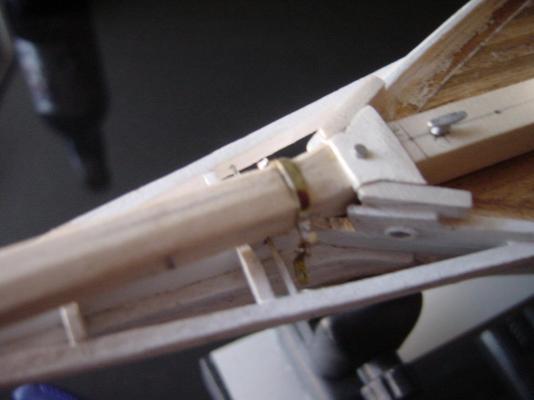

So over the last several days, I've been working on more metal work. This time its the A-Frame for the dredges. This was quite a challenge since I suck at soldering, but after several disasters I got er done! The cable pulleys were almost fun to make. I made the actual pulley by forcing some wood dowel into a 3/32 copper tube, then I scribed a line on the tube with my scroll saw for the groove, then hand filed it further. I still need to paint them. After I finished them, it dawned on me that I could have just filled the piece of tubing with solder and had a stronger piece. Maybe next time. I also worked a bit on my bilge pumps by cutting them down to a lower profile, then painted them, you guessed it, White! Pics follow. Here it is positioned on the boat for a look. I had thought about leaving the pumps in brass, but I like the white just as well. Its more correct anyway since they were actually made from galvanized tin. I need to work on them a bit to get a flusher fit on the deck Next, I will work on the dredge rollers. Thanks for looking!

- 135 replies

-

- willie l bennett

- model shipways

-

(and 1 more)

Tagged with:

-

Russ, Josh, Adam, and "mischief", thanks for checking in and for the comments. Josh, I've been waiting to see an update on your build! Come on man, post it! Mischief, I will check out the hair net, thanks for the tip. It just dawned on me the other day while in the shower that I have a great source of net material right under my nose. I have one of those fluffy body scrubbing thingies that may be perfect. Its white, small openings and wrinkly.

- 135 replies

-

- willie l bennett

- model shipways

-

(and 1 more)

Tagged with:

-

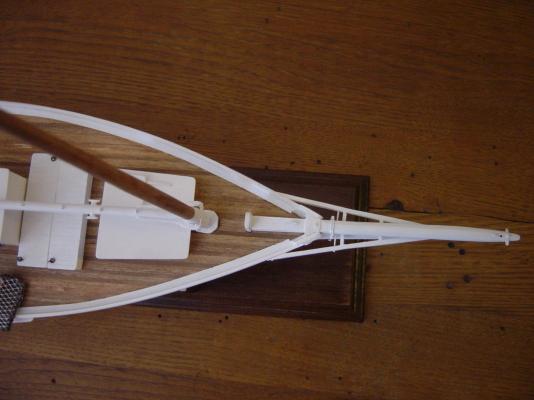

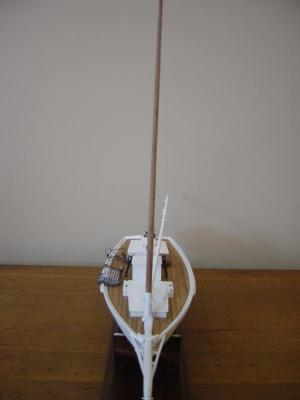

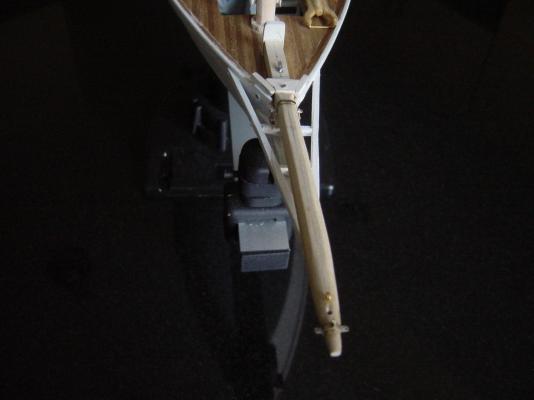

Here is a pic of the mast boom and bow sprit painted and positioned on the boat. Nothing is permanently attached.

- 135 replies

-

- willie l bennett

- model shipways

-

(and 1 more)

Tagged with:

-

Bob, Mario, Tim and Russ, thanks for checking in on my build and thanks for the comments. Russ, that is exactly the red I intend to use. Looks just like the antifouling paint I've seen used on the real thing.

- 135 replies

-

- willie l bennett

- model shipways

-

(and 1 more)

Tagged with:

-

Hey Gerty, thanks for checking in on my log. I have since painted everything and am ready to move on. I think my next task will be to paint the bottom some shade of red. I'm not sure if I want to paint it with a brush or use a spray can. I also need to prepare a base to mount it on as once the bottom is painted I can use the work vise. I think I'll go with a cradle mount in lieu of pedestals. When are we going to get to see more of your build? Its been a little lonely being the only Bennett builder posting here lately. I need to see how bad I've screwed mine up, so come on and post some progress pictures!

- 135 replies

-

- willie l bennett

- model shipways

-

(and 1 more)

Tagged with:

-

Tim, thanks for checking in. The last few days I've been working on the iron works for the rigging. First pic is the bobstay plates, a pretty simple job. Next was working on the bowsprit iron. I must admit that for me these little pieces are quite a challenge at this scale (large by the standards on this forum). I give unlimited kudos to all the model builders that do a far superior job on a much smaller scale. I guess practice does make perfect. I next moved on to the boom. That is a very busy stick of wood, with the boom iron, cheek blocks, cleats, fairleads, boom jaws and eyelets for the sail lacing. Next ,I moved onto the mast with the mast head band, cleats and boom rest and fake mast wedges at deck level. I also readied the mast hoops by washing them in CA glue to strengthen them, then sanding the excess glue to ready for paint. Finally I worked on the rudder. I made the steering horns, but have not yet attached them. These things are pretty small and I can't see how the heck I could put three nails in each and also solder a fillet onto them, so I cheated a bit. Only one nail hole and no fillet! All this iron work will be painted white as will the boom the bowsprit and a bit of the mast. Made some good progress but still have a long way to go. I want to get this build finished so I can start my Victory Tug!

- 135 replies

-

- willie l bennett

- model shipways

-

(and 1 more)

Tagged with:

-

Russ, Wayne, Bob and Buck, thanks for checking in on my build log and thanks for the comments.

- 135 replies

-

- willie l bennett

- model shipways

-

(and 1 more)

Tagged with:

-

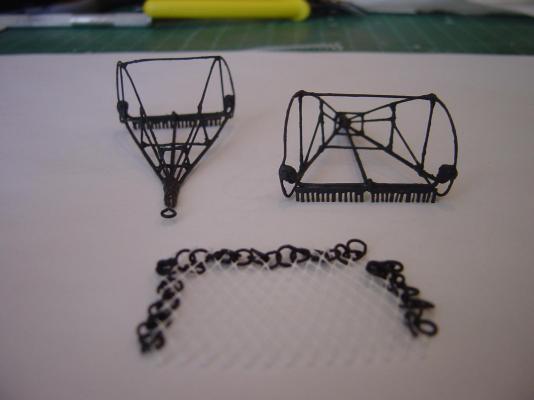

Made some progress on my boat over the last few weeks. I finished one of two oyster dredges and man what a challenge. It took about 20 hours just to put the netting and chainmail on the frame. I even cheated a bit by buying some 2.3mm necklace chain from the local craft store. It turned out ok, but I may try some other type of material like cheesecloth for the netting on the next one. I also made the mast, bowsprit and boom. Getting the transition from square to octagon to round and putting the curve in the bowsprit was also a bit of a challenge but all the pieces look good. I stained the deck instead of painting it white even though the wood has such a variety of color, it looks ok, I think. I even hired some additional workers. These little guys were actually Jamestown settlers that I modified to make look more like 19th century watermen. They are very close to correct scale, but I did some major surgery on each as they originally scaled out to be about 6' 6" tall. Once I finish the boat, I may need to do more surgery to position the arms as appropriate. Made of resin, they were easy to modify. Hope to start working the rigging hardware this weekend.

- 135 replies

-

- willie l bennett

- model shipways

-

(and 1 more)

Tagged with:

-

Slagoon, I recently ordered the Ranger and Phanton kits from them. I received the Ranger and a notice that the Phantom was back ordered. No estimated delivery date was provided. The paint and tools were part of the kit I purchased for about $90.

-

Lami, Wow! What an exciting build! I am really looking forward to seeing the completed project and videos of its operation.

-

Homemade Rudder Hinges

Richard Bradfield replied to lamarvalley's topic in Metal Work, Soldering and Metal Fittings

They look great Randy. Good job! -

Thanks again Russ. I've been experimenting a bit with the heat setting and think I was using to high a setting, also maybe the parts weren't clean enough. I thing I'll make another one and be very through about the parts prep and maybe make a very precise jig.

- 135 replies

-

- willie l bennett

- model shipways

-

(and 1 more)

Tagged with:

-

Thanks Russ. I'm using. 015 diameter silver-bearing solder and a Bernzomatic micro torch. The torch has 4 levels of flame, I've been using it on level 3. Maybe that's to hot? Could that also be why the paste solder didn't work well?

- 135 replies

-

- willie l bennett

- model shipways

-

(and 1 more)

Tagged with:

-

Well I spent the last two full days building these oyster dredges and man what a challenge! They turned out ok, I guess, but I wish I was better at soldering. Actually I assembled one with about 20 percent solder and 80 percent CA glue and one with 90 percent solder and 10 percent CA glue. The glued one looks better to me. I had a real problem with previously soldered joints melting when working on a near by joint. The paste solder didn't work very well. I couldn't see when the solder melted because there was so much slag generated by the stuff. I used and open flame and a tip but still had problems with both. I guess practice makes perfect. I probably should have spray painted them, but I used a brush and there is some clumping of the paint. Oh well they look good from about 18 inches away so I will live with them. ( Duh, I have "Blackin It" but just thought of it now) I started making the nets using 1/8" split rings but I'm thinking they are too big. They scale out to 4" when they are supposed to be 2 1/4". The smaller rings are 3/32", which scale to 2" but they are so small I know it will be very tough to assemble. What do you all think?

- 135 replies

-

- willie l bennett

- model shipways

-

(and 1 more)

Tagged with:

-

Dan, yeah the cheesecloth may be a better choice. I'll compare the two to see. Thanks for the tip.

- 135 replies

-

- willie l bennett

- model shipways

-

(and 1 more)

Tagged with:

-

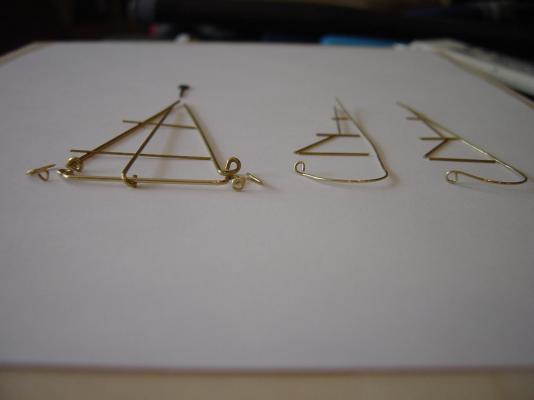

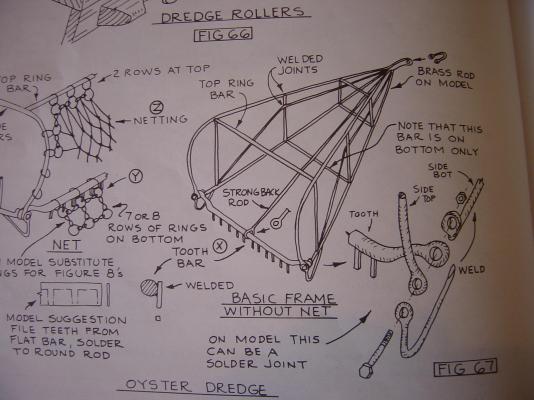

Well I finished the second bilge pump and it turned out as good as the first. I started building the oyster dredges yesterday and quit in order to come up with a better more organised method. So I went and bought a nice piece of poplar to serve as a build board for the dredges, made a copy of the dredge plans and taped it to the board. Then I spent the next two and a half hours cutting and shaping the pieces for the frame for one of the two dredges. Oh yeah, I also went to the local craft store and bought a pair of 4mm X 2mm Bale Making pliers and a pair of Round Nose Pliers from the jewelry department which helped a bunch. Went to the local supermarket and bought a bag of White Pearl Onions just for the bag, as it will work very well for the netting on the dredges ( I need to find a recipe to use the onions!) Now I need to come up with a plan or jig to hold these parts so I can assemble them. I intend to bolt the pieces I made eyelets for together and solder the rest of the joints. I think I will make it in sections, the two sides and the bottom then assemble and finish soldering the connecting braces and joints. I may staple the individual pieces in place to the build board then use FloTemp paste solder to join them. Hopefully I will be successful. I will post my results. Here are a couple pics of the 23 pieces needed to to construct the dredge frame. I still need to cut and shape the pieces for the second dredge and make a rake for each one. Hopefully it will look like this when finished.

- 135 replies

-

- willie l bennett

- model shipways

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.