-

Posts

1,572 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Garward

-

MONTANES by Garward - OcCre

Garward replied to Garward's topic in - Kit build logs for subjects built from 1751 - 1800

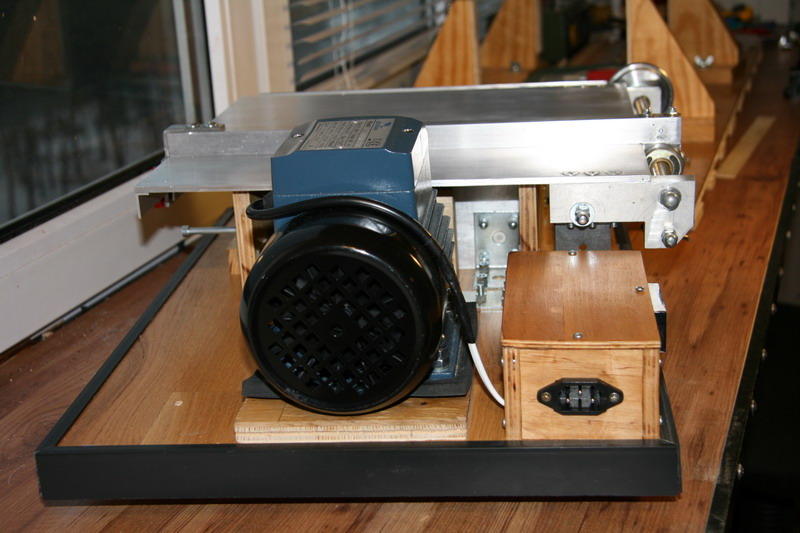

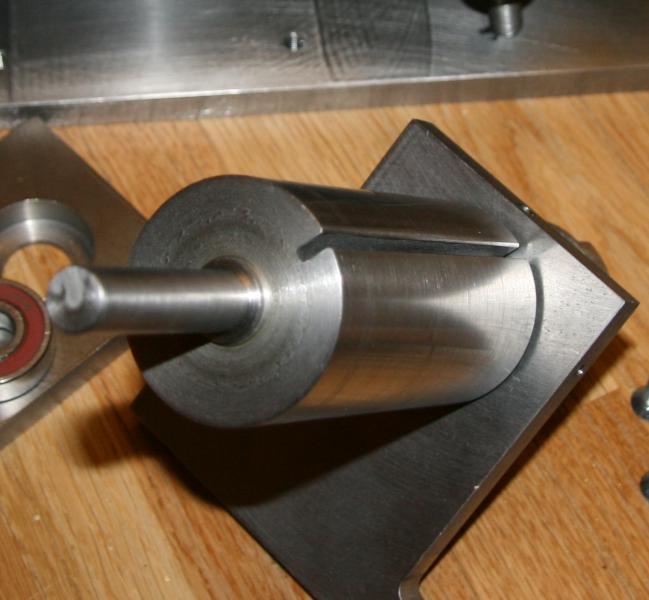

A motor is used by power 370 watts (descriptions on a photo 12) ot an aquatic pump. The details of drive are shown on a photo 13 – 14. On the photo of 13А is a form from hardening on air plasticine, in which from silicon a cross-piece was made for semimuffs. -

MONTANES by Garward - OcCre

Garward replied to Garward's topic in - Kit build logs for subjects built from 1751 - 1800

-

MONTANES by Garward - OcCre

Garward replied to Garward's topic in - Kit build logs for subjects built from 1751 - 1800

-

MONTANES by Garward - OcCre

Garward replied to Garward's topic in - Kit build logs for subjects built from 1751 - 1800

-

MONTANES by Garward - OcCre

Garward replied to Garward's topic in - Kit build logs for subjects built from 1751 - 1800

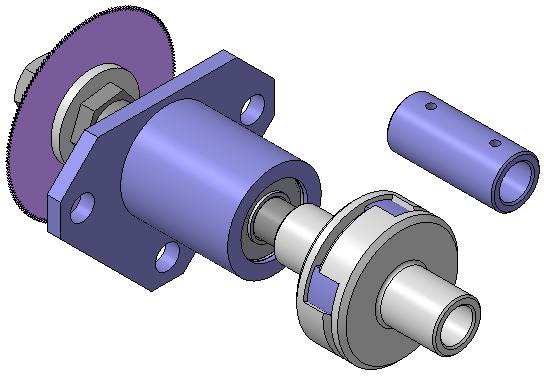

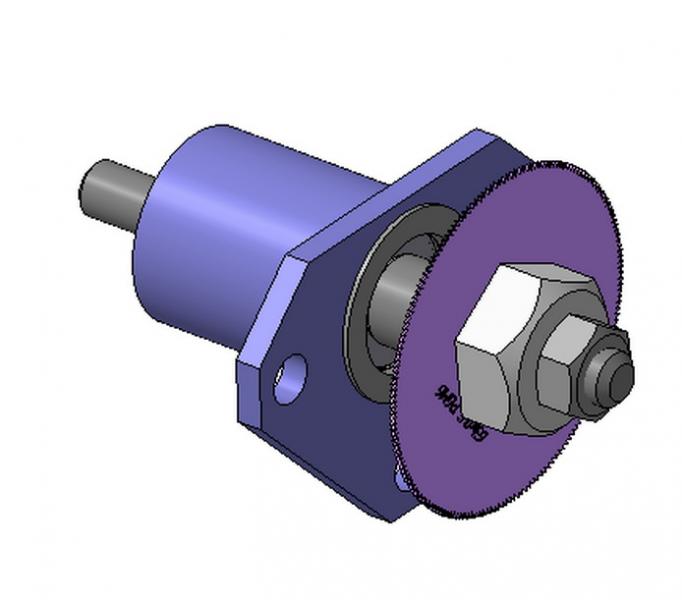

The knot of drive is made on description (photo 8 – 11) and drafts, by developed Boris B. This construction, to my mind, combines in itself dignities of direct drive and strap transmission, simplifies assembling and regulation of knot, and also does not make noise practically. Description of Boris B: http://www.shipmodeling.ru/phpbb/viewtopic.php?f=10&t=1421&start=465 Drafts of Boris B: http://narod.ru/disk/9861644000/%D0%A6%D0%B8%D1%80%D0%BA%D1%83%D0%BB%D1%8F%D1%80%D0%BA%D0%B0.rar.html As compared to initial drafts the diameter of semimuffs is diminished on 6 mm, that they did not come forward for the sizes of holder. -

MONTANES by Garward - OcCre

Garward replied to Garward's topic in - Kit build logs for subjects built from 1751 - 1800

-

MONTANES by Garward - OcCre

Garward replied to Garward's topic in - Kit build logs for subjects built from 1751 - 1800

-

MONTANES by Garward - OcCre

Garward replied to Garward's topic in - Kit build logs for subjects built from 1751 - 1800

-

MONTANES by Garward - OcCre

Garward replied to Garward's topic in - Kit build logs for subjects built from 1751 - 1800

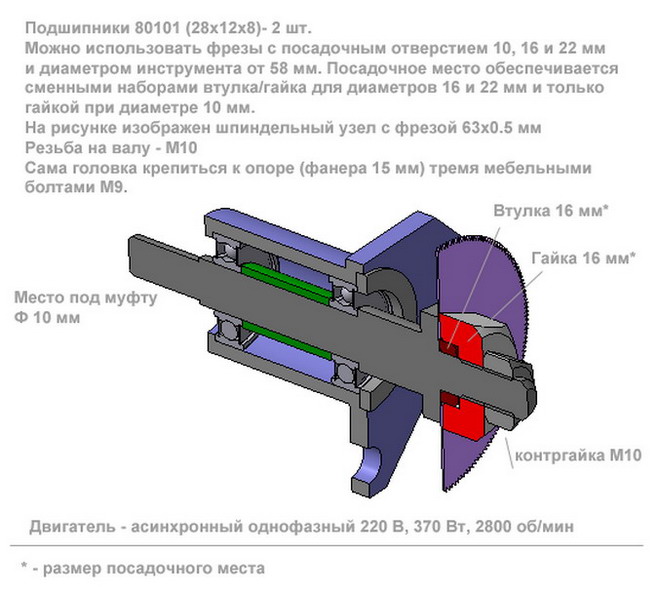

15. THE TOOL MADE FOR CONSTRUCTION OF MONTANES 15.1. JIG SAW In the course of Montanes construction for production of details I used available for me jig saw (self-made "minifactory" for thin laths and an interline interval, FET PROXXON for thickness to 20 mm and MJ10200J Feida for thickness to 40 mm). I have come to a conclusion about necessity of construction jig saw, deprived, whenever possible, lacks of the listed units (the design features sometimes essentially complicating operation; time and the efforts spent for maintenance of accuracy of a cutting; the big noise etc.). In particular, at FET saw a disk – tightening the screw constantly so gets jammed the extremely unsuccessful knot of fastening that I already two times had to cut off its head, differently a disk was not to remove (the same lack marked also others modellers). Initial ideas of construction were: - The basic range of a cutting – wood in the thickness from 0,5 to 20 mm; - Accuracy of a cutting 0,1мм; - A cutting under various corners; - Table adjustment on height; - Reliable knot of fastening a cutting disk and simplicity of its replacement; - The stock of capacity excluding (reducing) overheat of the engine at long work; - Noise reduction. As a result of viewing and the analysis of a considerable quantity of descriptions industrial and self-made jig saw at me the design shown on a photo 1 - 7 has turned out. -

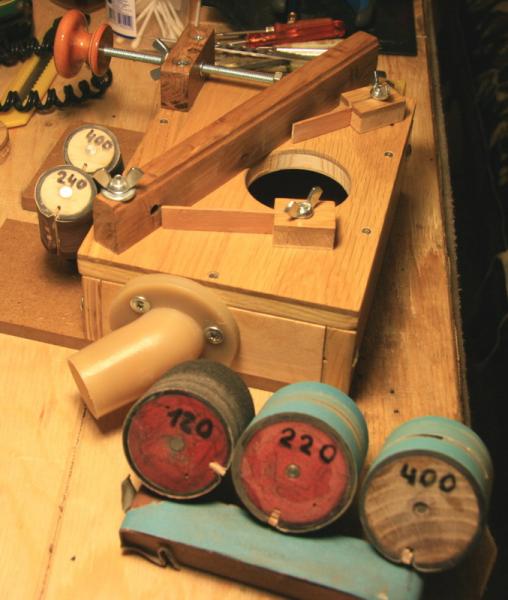

Thanks for the comment! The sandpaper on the drums fastens by jamming of the ends of paper in a rectangular groove on a wooden drum. On a photo the similar groove on a metal drum is shown. For jamming the wooden rectangular level of suitable thickness is used.

-

MONTANES by Garward - OcCre

Garward replied to Garward's topic in - Kit build logs for subjects built from 1751 - 1800

Hello, Keith! Many thanks for warm words in my address and a work appreciation, it is very pleasant to me. Decor on the transom I coated Revell Gold, it is gilding imitation, the real gold would cost too expensive . -

MONTANES by Garward - OcCre

Garward replied to Garward's topic in - Kit build logs for subjects built from 1751 - 1800

Hello (привет), Anja, many thanks for attention to my model and job evaluation! While it still restoration earlier made, I try to finish this process somewhat quicker. -

-

-

-

-

-

-

-

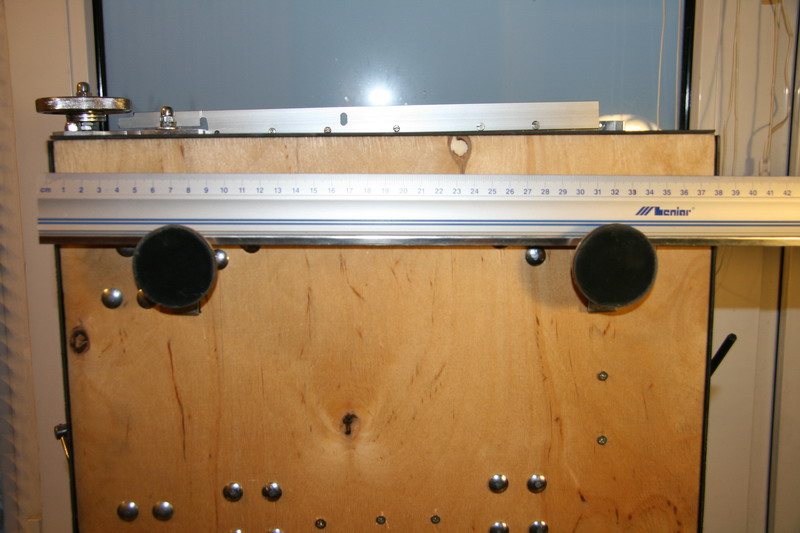

The adaptation to boring machine PROXXON ТВМ 220 is constructed for polishing and calibration of direct laths and various curvilinear surfaces of details. The ideas obtained with various shipmodels sites, and also struggle are put in a design basis for ecology (vacuum cleaner connection - in this case Metabo ASA 1202). The box is made of the laminated parquet board in the thickness of 14 mm, grinding drums factory, and also self-made in diameter 30 and 50мм (the wooden cylinder covered with a layer of firm rubber and насаженный on a steel axis in diameter of 6 mm). I result some photo of this adaptation more low.

-

MONTANES by Garward - OcCre

Garward replied to Garward's topic in - Kit build logs for subjects built from 1751 - 1800

-

MONTANES by Garward - OcCre

Garward replied to Garward's topic in - Kit build logs for subjects built from 1751 - 1800

-

MONTANES by Garward - OcCre

Garward replied to Garward's topic in - Kit build logs for subjects built from 1751 - 1800

-

MONTANES by Garward - OcCre

Garward replied to Garward's topic in - Kit build logs for subjects built from 1751 - 1800

Thanks for an assessment, Carl!

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.