-

Posts

1,572 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Garward

-

Carronades

Garward replied to JPett's topic in Discussion for a Ship's Deck Furniture, Guns, boats and other Fittings

Thanks for the link! -

What is the best glue for cast metal parts?

Garward replied to vas1949's topic in Metal Work, Soldering and Metal Fittings

-

What is the best glue for cast metal parts?

Garward replied to vas1949's topic in Metal Work, Soldering and Metal Fittings

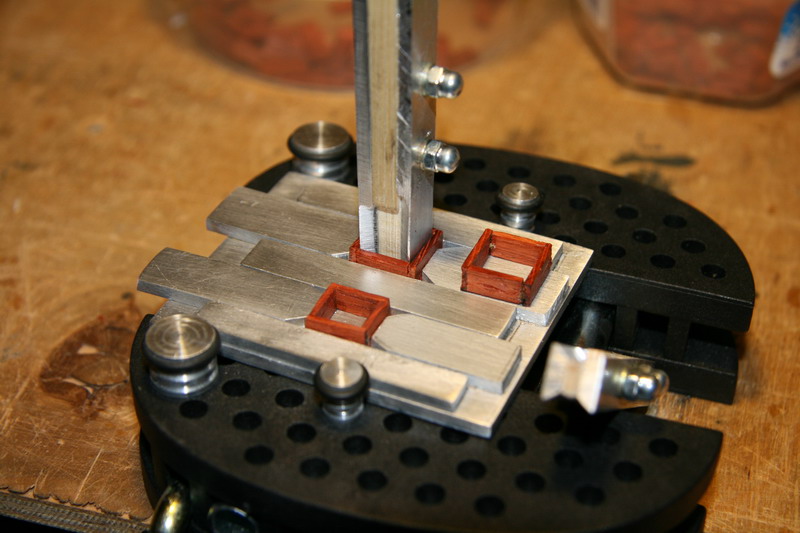

On a photo the template from aluminum for production of a framework of gun ports is shown http://modelshipworld.com/index.php?/topic/82-montanes-by-garward-occre/page-2 Motionless details of a template are stuck together among themselves CA (capacity with CA is visible on a background). The template sustained production of several tens framework and further is suitable for use. -

Really, grinding drums available on sale have too rough sandpaper which should be replaced.

-

Solder brass rod for deadeye

Garward replied to cog's topic in Metal Work, Soldering and Metal Fittings

-

Solder brass rod for deadeye

Garward replied to cog's topic in Metal Work, Soldering and Metal Fittings

-

Solder brass rod for deadeye

Garward replied to cog's topic in Metal Work, Soldering and Metal Fittings

-

Solder brass rod for deadeye

Garward replied to cog's topic in Metal Work, Soldering and Metal Fittings

-

Solder brass rod for deadeye

Garward replied to cog's topic in Metal Work, Soldering and Metal Fittings

-

Solder brass rod for deadeye

Garward replied to cog's topic in Metal Work, Soldering and Metal Fittings

-

Solder brass rod for deadeye

Garward replied to cog's topic in Metal Work, Soldering and Metal Fittings

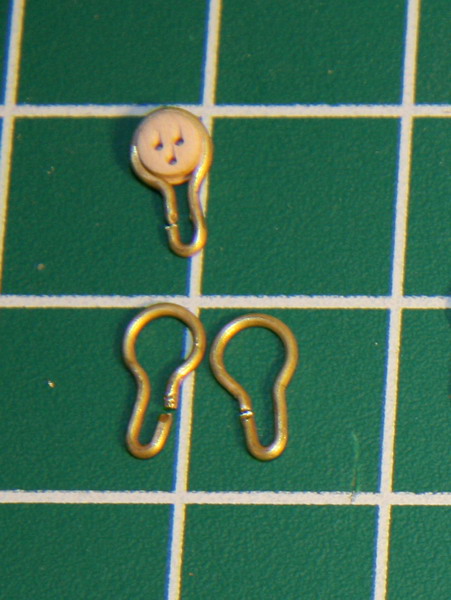

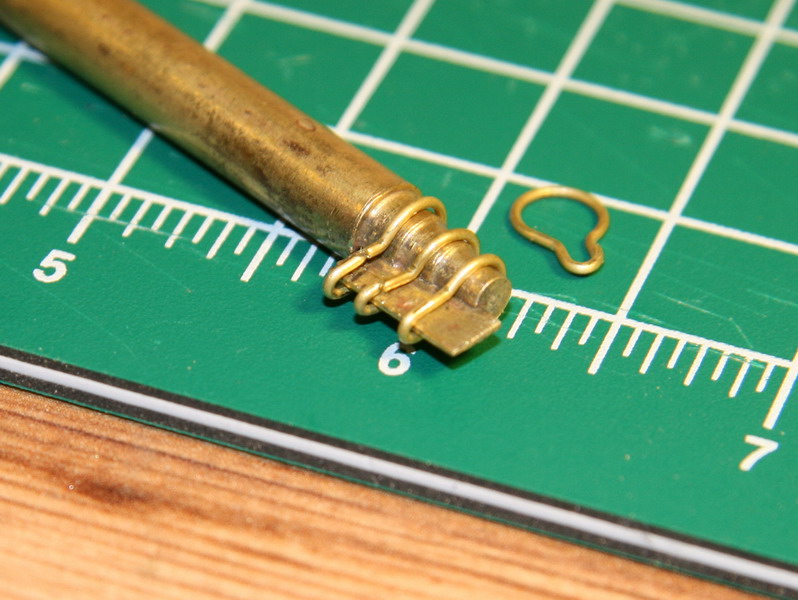

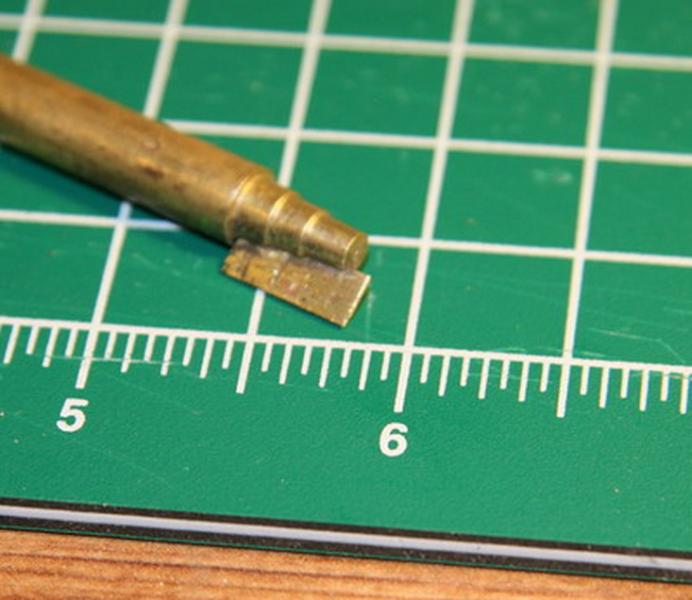

For these dead eye the corresponding chain are made of a brass wire with a diameter of 0,75 and 1,5 mm. The template in the form of the brass cylinder with a diameter of 7 mm pierced under diameters of dead eye is used. The brass hoops which go around the deadeyes are soldered by a gas torch with application of argentiferous solder (40% of silver). In this case application of soft solders on the basis of tin gives insufficiently strong connection which can easily collapse at installation and a tension of shrouds http://modelshipworld.com/index.php?/topic/82-montanes-by-garward-occre/page-12 -

What is the best glue for cast metal parts?

Garward replied to vas1949's topic in Metal Work, Soldering and Metal Fittings

СA is better to glue metal details, but thus surfaces have to be pure, and amount of glue minimum (literally droplets). Surplus of СA when drying gives a white raid. -

In vain you think that the wooden wedge won't hold sandpaper. Such fastening of sandpaper on drums is widely applied in various machines, there is only a difference in a wedge material - a tree, plastic, rubber, metal. On a photo - the Vanda-Lay firm machine with similar fastening of sandpaper.

-

MONTANES by Garward - OcCre

Garward replied to Garward's topic in - Kit build logs for subjects built from 1751 - 1800

Always please, Tylmo, I am glad that this documentation is of interest for you . -

MONTANES by Garward - OcCre

Garward replied to Garward's topic in - Kit build logs for subjects built from 1751 - 1800

In summary I wish to tell that meanwhile jig saw I am satisfied by work, though already there are ideas for its completion. I wish to tell also that all who heard work jig saw and FET (relatives, friends, neighbours), mark essential reduction of noise in comparison with FET (on hearing of time in two). -

MONTANES by Garward - OcCre

Garward replied to Garward's topic in - Kit build logs for subjects built from 1751 - 1800

Thanks for the comment! Finally I managed to construct the tool almost completely corresponding to my initial plans. -

MONTANES by Garward - OcCre

Garward replied to Garward's topic in - Kit build logs for subjects built from 1751 - 1800

On a photo 41 "stuffing" of a network box is shown – a nest of connection of a network cable, the button of management and the magnetic actuator which I have decided to establish starting with enough decent capacity of the engine. -

MONTANES by Garward - OcCre

Garward replied to Garward's topic in - Kit build logs for subjects built from 1751 - 1800

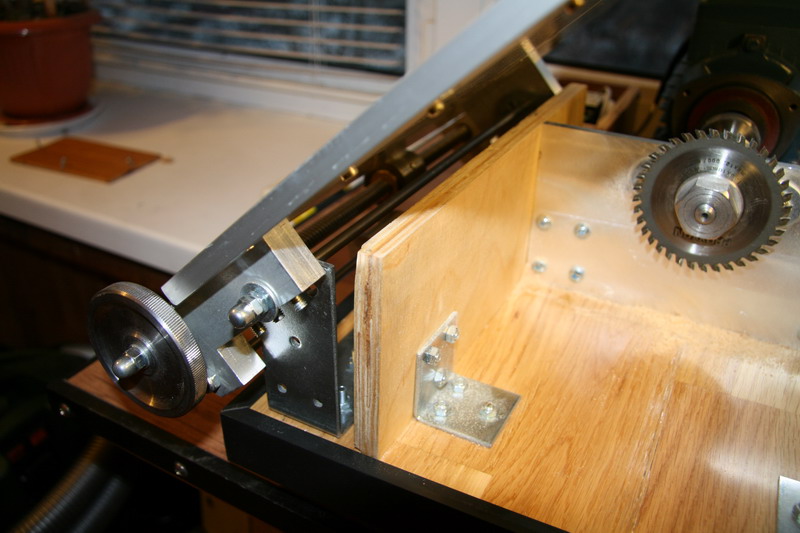

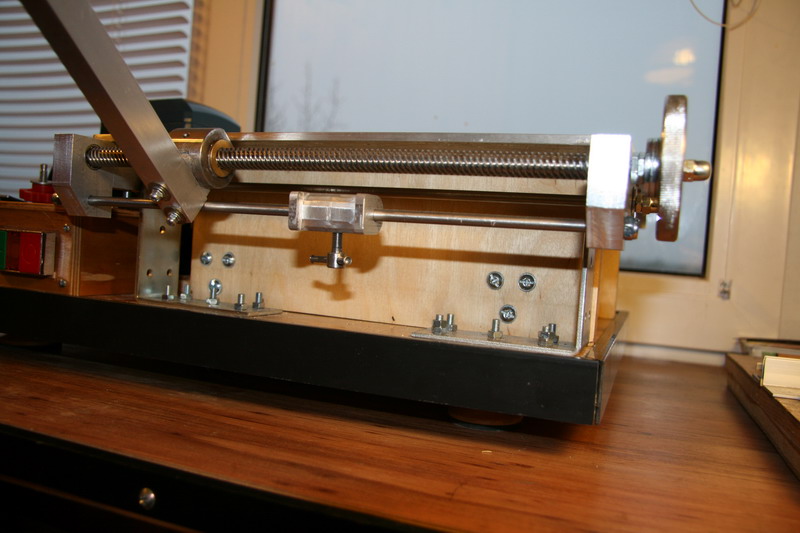

The table rotates on a steel axis in diameter of 6 mm which ends are fixed in vertical steel racks (corners) in the thickness of 3 mm (photo IMG _2109). Turn on 30 degrees of the flywheel shown on the same photo provides moving directing on a table surface on 1 mm, turn on 3 degrees gives according to 0,1 mm. -

MONTANES by Garward - OcCre

Garward replied to Garward's topic in - Kit build logs for subjects built from 1751 - 1800

-

MONTANES by Garward - OcCre

Garward replied to Garward's topic in - Kit build logs for subjects built from 1751 - 1800

-

MONTANES by Garward - OcCre

Garward replied to Garward's topic in - Kit build logs for subjects built from 1751 - 1800

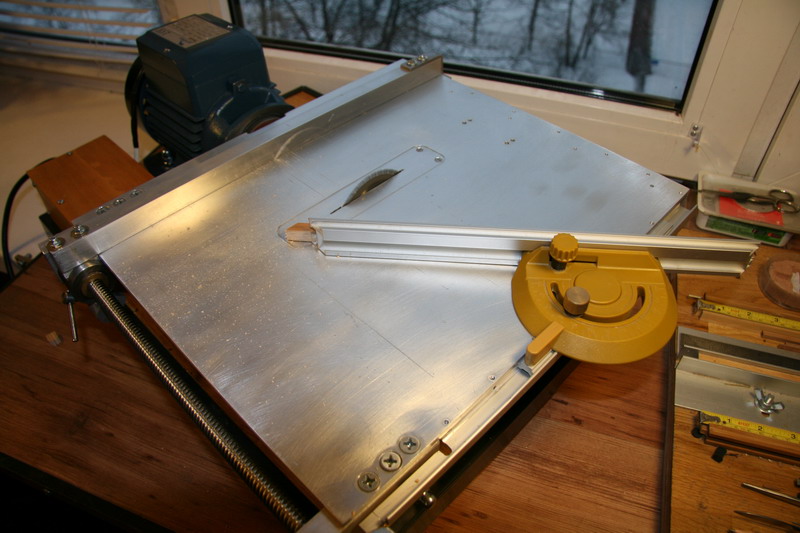

For a cutting of preparations under various corners the device by a protractor from saw FET which moves on directing along a lateral surface of a table (a photo 38 – 40) is used. -

MONTANES by Garward - OcCre

Garward replied to Garward's topic in - Kit build logs for subjects built from 1751 - 1800

-

MONTANES by Garward - OcCre

Garward replied to Garward's topic in - Kit build logs for subjects built from 1751 - 1800

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.