-

Posts

61 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Stubby

-

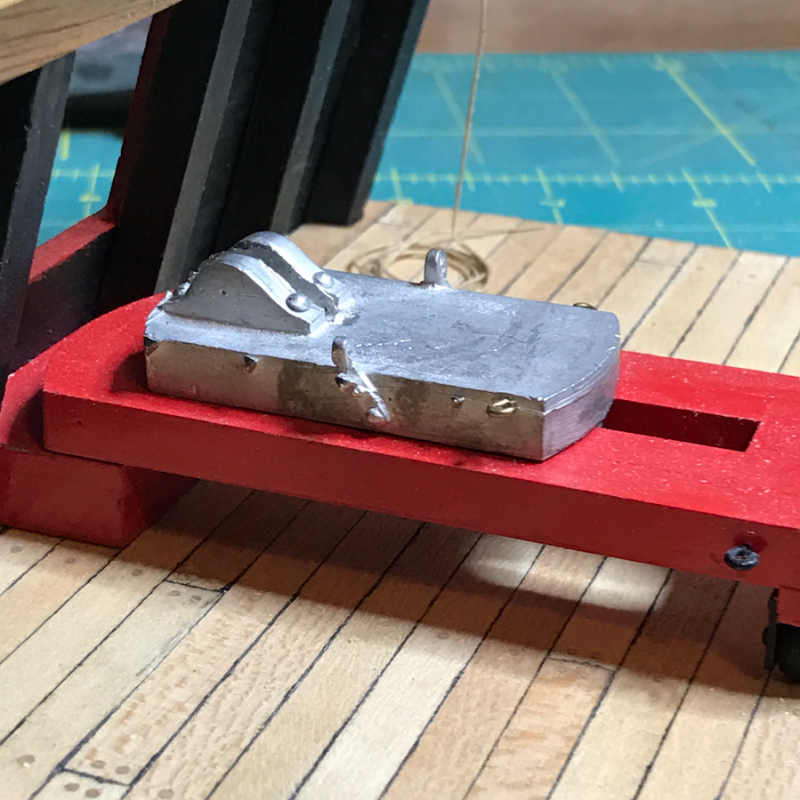

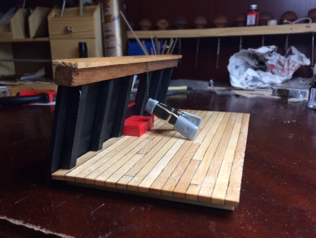

I did do a little work on the model too. I had to manufacture the block and tackle brackets for the sled and the cradle to mount the carronade itself. I tried shaping solder to make the brackets, but while i could get the right shape, it was really to soft. I then tried regular wire, which I soldered to make it a solid piece. The wire I used was not very conducive to solder - I'll have to get something that will work better for the future. Still - I deemed it "good enough." I then shaped the cradle pieces from wood, painted and attached all. The photo shows the carronade installed - the center of gravity is off because the barrel is not hollow. I'm counterbalancing with a clamp in the picture, but I'm hoping that glueing everything will overcome this problem. There! SOMETHING was done. I'm hoping to do some block and tackle this weekend.... we'll see how it goes.

-

Wow, five months since I posted on this project! It's been a crazy summer. Among other things, I built a new workbench over the summer. I'm going to build overhead cabinets too, but I'm going to wait a bit before taking on that project. The room is a bit messy, but here is the workspace as it is....

-

JesseLee, I know just how you feel. I'll be driving my daughter to her new home 1,100 miles away tomorrow to start graduate school. She already went off to college, but that was only a couple hours away..... twenty hours is going to hit a lot harder! Hang in there buddy! Stubby

- 1,306 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

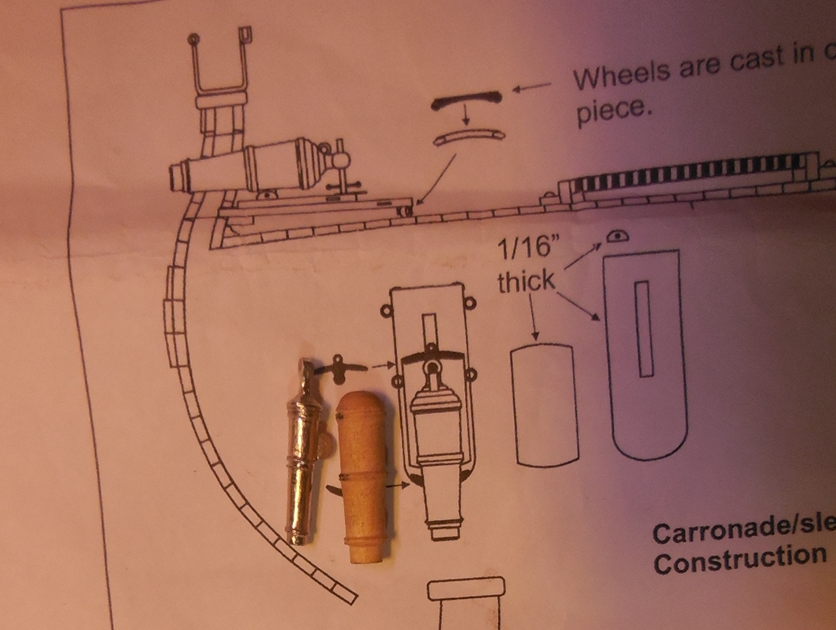

Jesse, Looking back at some of your previous entries I found this pic - I thought it was weird that the plans called for a larger cannonade than the kit provided, but when the proper size was installed the positioning was off. I read that you experimented with the thickness of the sled; it's hard to tell scale in a photograph... are your sleds really 1/16th of an inch thick as described in the plans in the photo? That seems really thin... I think it may be an academic discussion.... I agree with everyone else's comments. It all looks great as is! Stubby

- 1,306 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

You're right about where I am on the same build.... of course, I started the build eighteen years ago.... so your month doesn't sound so bad!

- 38 replies

-

- benjamin w latham

- model shipways

-

(and 1 more)

Tagged with:

-

I'm not sure if I'm inspired or intimidated Jesse! You do some awesome work! I can't wait to get to this project myself.

- 1,306 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

I bought a Benjamin W. Latham kit almost 20 years ago and never finished it. It was the second kit I purchased - the first being the Phantom. In the course of moving from Virginia, to Iceland, to Hawaii, and then to Florida, I'm not sure i even have all of the pieces anymore. I made a lot of mistakes in construction, as resources like this were less available back then, but I've learned a lot looking though these build logs, and i plan on picking it up again and finishing as much as can be done before moving on to the other kits I have in waiting. I'll be very interested in following your progress! Stubby

-

Jud - That may be beyond the level of effort and experience that I currently have, but I will certainly keep that in mind for future projects. I found a link describing the molding process with silicone, but I think I will start with the Bondo Spot putty for this one! https://www.smooth-on.com/tutorials/moldmaking-tutorial-resin-metal-cold-casting/

-

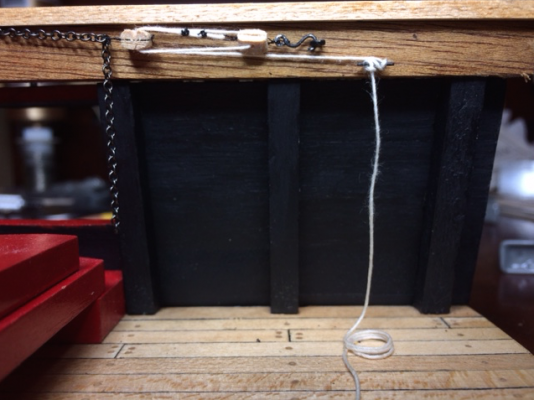

All right; I looked through some logs on this site and found some great ideas for block and tackle. I'm not quite up to the quality of some, but I think it is a marked improvement. I also moved the eye and the cleat over a bit because I had them too close to the port. I wasn't too happy about that because it left holes in the clamp beam where they were previously, but the one hole is covered by the single block, and the other by the rope so it's not too noticeable. You can see the former hole for the cleat in the larger picture right beneath the eye.

-

I have a Syren in the box for a future build - I'm definitely learning a lot from your log and enjoying your mods and ingenuity! - Stubby

- 1,306 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

Attached the gunport tackle today. The blocks that came with the kit were too brittle, so I made new ones. I'm not completely happy with the hook - which I fashioned out of wire, and the eyes - which I made out of black thread which was really too thin for the task. I haven't cut the chain yet just in case I want to redo it. I doesn't look bad; I think I'll sleep on it.

-

So, I haven't been very chatty about my progress, but have been progressing none the less. I installed the hull planking, cap piece and rail cap, and am pretty happy with it. I decided not to use tunnels on the hull planking - mostly because I was being lazy, but also because I wasn't sure if they would show up under the black paint. Looking at it now, I think they probably would - but I can live with it. I also put together and attached the gunport lid. I made a few minor mistakes as I went through, but I don't think they are too noticeable. The next step is to install the block system that raises the gunport lid. I also need to start prepping the actual carronade. I've been putting that off because it came so rough. The last picture shows the carronade base. Not yet installed - just sitting there so I can pretend I'm farther along....

-

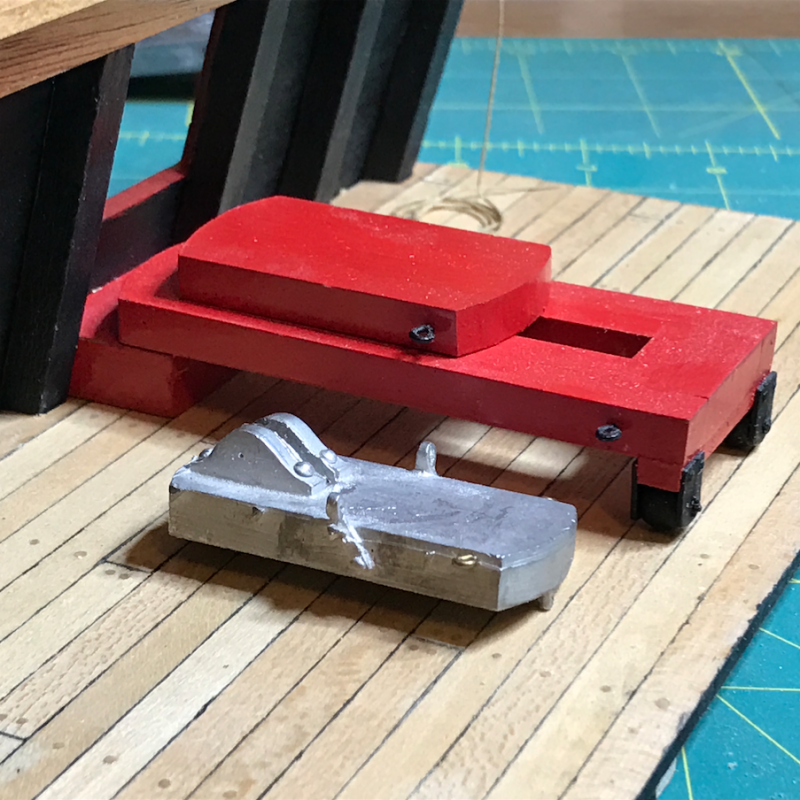

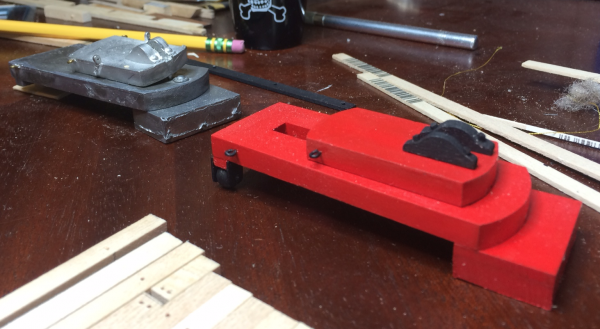

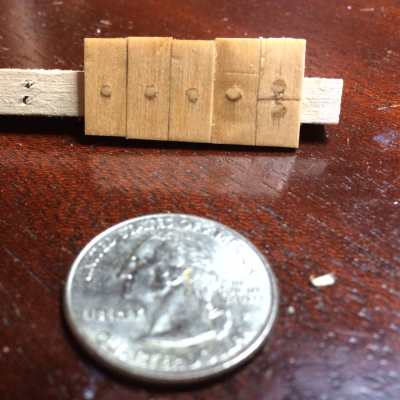

So it's been quite a while since I last posted an update - been a crazy busy couple of months. I have however, don a little work on this model. I measured out the deck planks and drilled the holes for the tree nails. I am painting the edges of the planks to simulate caulking. I tried the pencil trick with my other model, and while a generally liked the result, it was kind of messy. So... giving the paint approach a try.... The photos show the progress. None of the planks are glued in place yet. I plan to paint the caulking on all of the planks and then glue them in place. Then I will make and install all of the tree nails and sand and stain the entire deck. I'd welcome any constructive advice along this lines, as I have never attempted it before. I also recreated the carronade platform out of wood, because I thought it would look better. Not done yet, and not perfect, but I am generally happy with the results.

-

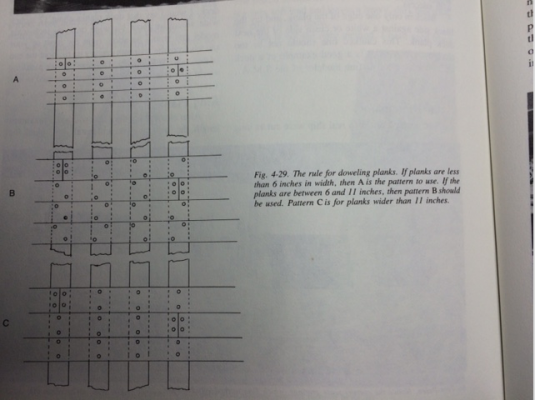

One thing I didn't like about the older model kit was that there is no planking; the deck is a block, and the directions call for "scoring" to mimic the deck plates. So for that reason I decided to build the platform (at least) from scratch. So instead of a solid base, I went and bought some wood for beams and planks. The kit included 1/4" x 1/4" pieces for the timber heads, so I made the beams match. The directions called for "scoring" to be every 1/4", so I got 1/4" planks. I cut the beams and timber heads yesterday and fussed with them for a while. The pivot block in the kit is cast metal, but in the modern kit it is wood. I liked the wood version better - and think it's more accurate - so I reproduced it from some scrap wood. The pivot block is 5/8" x 1 1/4", the latter being the spacing between the timber heads (and consequently the beams). I also constructed a waterway, which isn't mentioned in the kit. Based on the scale, the deck planking would be 6" wide on the deck, so I looked up the proper pattern for dowling/tree nailing the deck. Here is where I could use some advice: I've not seen the pattern shown in my book before. I think it might look good, but certainly a departure. Also, looking at the pattern in the modern kit, the planks don't seem to line up with the beam. I hadn't planned on being too detailed with the cross-deck beams, as the model will be resting on them and they won't be terribly visible. Do the cross-deck beams account for the fact that the planking doesn't seem to line up with the deck beams? I'm trying to decide whether to ignore the pattern in the new kit and go with the one in the book lined up with the deck planks, or if I should do some kind of hybrid between the two..... or maybe I'm overthinking it and should just keep it simple.... - Stubby

-

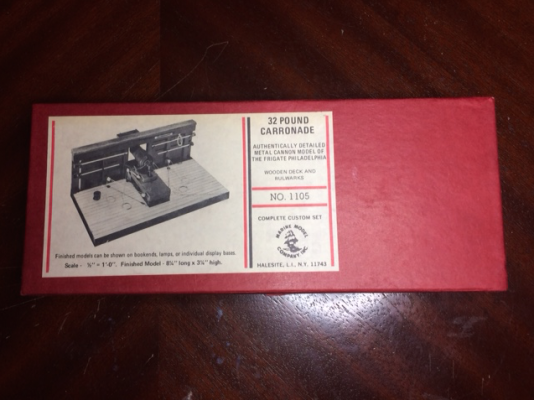

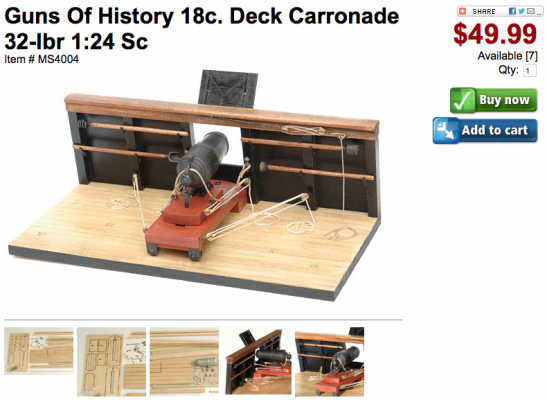

So my dad found this cool model at a garage sale. The model kit was sold by a company called Marine Model Company Inc. - which is a precursor to Model Shipways. In fact, Model Shipways still makes this kit, but it is a little different than the older form. It is pretty interesting to see the differences between the model and the older kit. Obviously, Model Shipways is pretty well known for its laser engraved pieces, but this isn't the case with the older kit. Also, the older kit has more metal pieces than the new kit, and they are wrapped in tissue paper to keep them safe. I do have a couple of other projects going at the moment, but this looked like a fun diversion that I could finish relatively quickly, and the large scale would allow me to try some cool techniques I've learned on this site. So... here goes.... - Stubby

-

So I have finished planking the lower deck. I built the frame separate from the hull so that I could remove it for planking, and even now have not glued it in place. The inner hull planking too is not all glued in place; above the lower deck only the top inner hull plank is glued in place - the others are wedged in between the deck and that plank. I did this so I could remove the deck to drill the mast hole later - and perhaps other holes if I decide to extend the pumps to the bilge. I also used pencil to mark up the sides of the deck planking to simulate calking. I like the effect, but have some clean up. There are some stray pencil marks, but I think they will come off with a light sanding. I will take care of that after I drill the holes, so that i only need to sand once. I am thinking I would like to pain the bottom of the deck white (as the ceiling of the hold), and do the same for the bulkhead and endorsed of the deck above. There are so many great ideas from others who have built this model that I'm not sure what I'd like to do. - Stubby

- 11 replies

-

- constitution

- mamoli

-

(and 1 more)

Tagged with:

-

Okay, so I figured out (remembered) how to post pictures. I think I need to relearn this lesson every time I post! So I continued on by planking the interior of the orlop deck and framing out the deck above. I didn’t stagger the planking on the interior, but I will stagger the planking on the birth, gun, and spar decks. The picture shows the beams of the birthing deck in place and framed out. They are held in place with planks so as to square it with the hull, but not fixed in place so the frame can be removed for planking. I’m actually pretty happy with how it is turning out. The directions call for placing the runners (upon which the deck beams rest) before planking. I found however, that planking to the point of the runner and then installing the runner makes it much easier to level the deck. I will continue this process from the bottom up. Looking at some of the great ideas incorporated by others who have built this model, I am greatly inspired by ways to improve upon it. I’m trying to restrain myself a bit so that I don’t distract myself from completion – but I will certainly have to try some of those great ideas! Stubby

- 11 replies

-

- constitution

- mamoli

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.