KurtH

Members-

Posts

449 -

Joined

-

Last visited

-

KurtH reacted to a post in a topic:

NRG Capstan Project by JacquesCousteau - 1:32

KurtH reacted to a post in a topic:

NRG Capstan Project by JacquesCousteau - 1:32

-

KurtH reacted to a post in a topic:

HMS Perseus by Thukydides - 1:64 - POB - Sphinx Class 6th Rate

KurtH reacted to a post in a topic:

HMS Perseus by Thukydides - 1:64 - POB - Sphinx Class 6th Rate

-

KurtH reacted to a post in a topic:

NRG Capstan Project by JacquesCousteau - 1:32

KurtH reacted to a post in a topic:

NRG Capstan Project by JacquesCousteau - 1:32

-

KurtH reacted to a post in a topic:

NRG Capstan Project by JacquesCousteau - 1:32

KurtH reacted to a post in a topic:

NRG Capstan Project by JacquesCousteau - 1:32

-

KurtH reacted to a post in a topic:

NRG Capstan Project by JacquesCousteau - 1:32

KurtH reacted to a post in a topic:

NRG Capstan Project by JacquesCousteau - 1:32

-

KurtH reacted to a post in a topic:

Christiania 1774 by TJM – approx. 1:67-1:64 – Danish Light Frigate based on Vanguard Models HMS Sphinx

KurtH reacted to a post in a topic:

Christiania 1774 by TJM – approx. 1:67-1:64 – Danish Light Frigate based on Vanguard Models HMS Sphinx

-

KurtH reacted to a post in a topic:

Muscongus Bay Lobster Smack by JacquesCousteau - Model Shipways - 1:32 - Rescaled and Modified

KurtH reacted to a post in a topic:

Muscongus Bay Lobster Smack by JacquesCousteau - Model Shipways - 1:32 - Rescaled and Modified

-

KurtH reacted to a post in a topic:

Christiania 1774 by TJM – approx. 1:67-1:64 – Danish Light Frigate based on Vanguard Models HMS Sphinx

KurtH reacted to a post in a topic:

Christiania 1774 by TJM – approx. 1:67-1:64 – Danish Light Frigate based on Vanguard Models HMS Sphinx

-

KurtH reacted to a post in a topic:

HMS Sphinx 1775 by Ronald-V - Vanguard Models - 1:64

KurtH reacted to a post in a topic:

HMS Sphinx 1775 by Ronald-V - Vanguard Models - 1:64

-

KurtH reacted to a post in a topic:

Muscongus Bay Lobster Smack by JacquesCousteau - Model Shipways - 1:32 - Rescaled and Modified

KurtH reacted to a post in a topic:

Muscongus Bay Lobster Smack by JacquesCousteau - Model Shipways - 1:32 - Rescaled and Modified

-

TerryPat reacted to a post in a topic:

HMS Sphinx by KurtH - Vanguard Models - 1/64 - First POB Model

TerryPat reacted to a post in a topic:

HMS Sphinx by KurtH - Vanguard Models - 1/64 - First POB Model

-

KARAVOKIRIS reacted to a post in a topic:

HMS Sphinx by KurtH - Vanguard Models - 1/64 - First POB Model

KARAVOKIRIS reacted to a post in a topic:

HMS Sphinx by KurtH - Vanguard Models - 1/64 - First POB Model

-

KARAVOKIRIS reacted to a post in a topic:

HMS Sphinx by KurtH - Vanguard Models - 1/64 - First POB Model

KARAVOKIRIS reacted to a post in a topic:

HMS Sphinx by KurtH - Vanguard Models - 1/64 - First POB Model

-

schooner reacted to a post in a topic:

HMS Sphinx by KurtH - Vanguard Models - 1/64 - First POB Model

schooner reacted to a post in a topic:

HMS Sphinx by KurtH - Vanguard Models - 1/64 - First POB Model

-

Nick 843 reacted to a post in a topic:

HMS Sphinx by KurtH - Vanguard Models - 1/64 - First POB Model

Nick 843 reacted to a post in a topic:

HMS Sphinx by KurtH - Vanguard Models - 1/64 - First POB Model

-

DonSangria reacted to a post in a topic:

HMS Sphinx by KurtH - Vanguard Models - 1/64 - First POB Model

DonSangria reacted to a post in a topic:

HMS Sphinx by KurtH - Vanguard Models - 1/64 - First POB Model

-

TJM reacted to a post in a topic:

HMS Sphinx by KurtH - Vanguard Models - 1/64 - First POB Model

TJM reacted to a post in a topic:

HMS Sphinx by KurtH - Vanguard Models - 1/64 - First POB Model

-

chris watton reacted to a post in a topic:

HMS Sphinx by KurtH - Vanguard Models - 1/64 - First POB Model

chris watton reacted to a post in a topic:

HMS Sphinx by KurtH - Vanguard Models - 1/64 - First POB Model

-

BLACK VIKING reacted to a post in a topic:

HMS Sphinx by KurtH - Vanguard Models - 1/64 - First POB Model

BLACK VIKING reacted to a post in a topic:

HMS Sphinx by KurtH - Vanguard Models - 1/64 - First POB Model

-

Ronald-V reacted to a post in a topic:

HMS Sphinx by KurtH - Vanguard Models - 1/64 - First POB Model

Ronald-V reacted to a post in a topic:

HMS Sphinx by KurtH - Vanguard Models - 1/64 - First POB Model

-

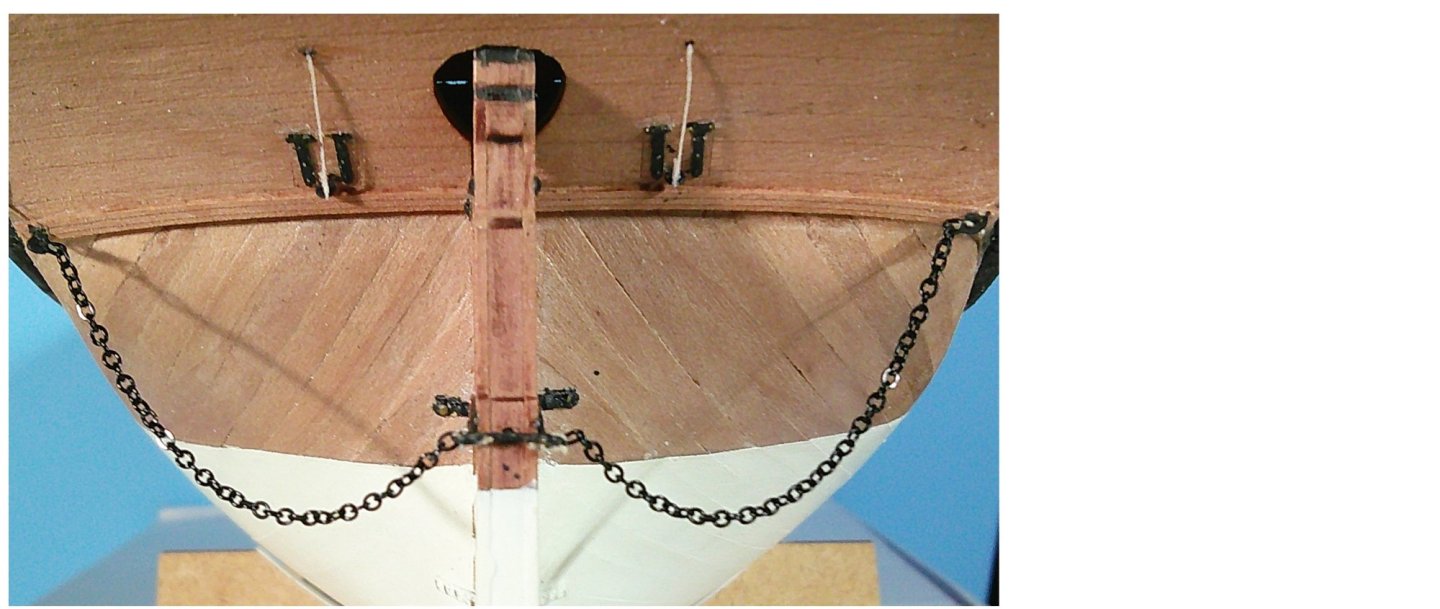

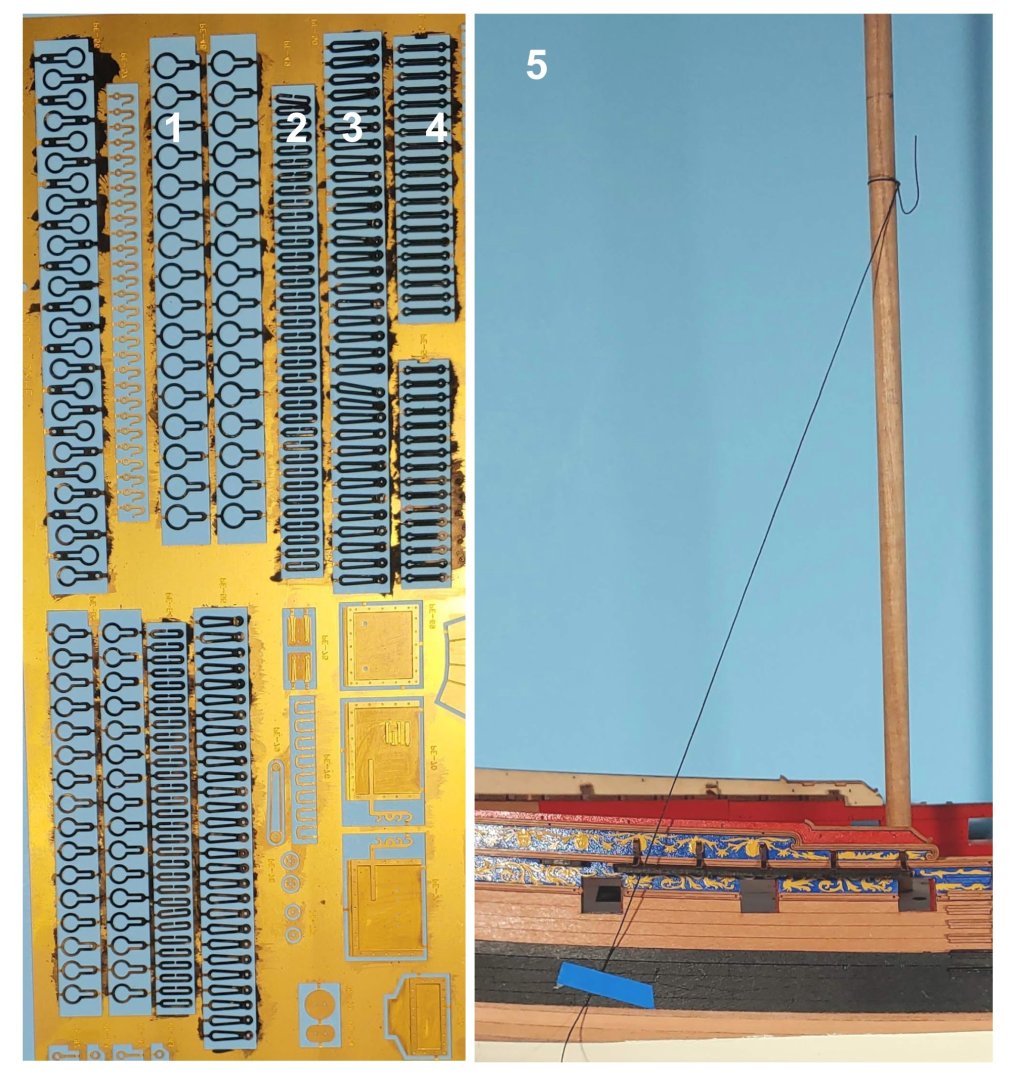

Work on the chains has been completed except for the mizzen backstays. It looks like these will stick up, begging to be broken off or bent, so I will wait until much later to install them. The components of the chains are all on the PE sprue, including some extras of each: 1. Strops 2. Mid Links 3. Toe Links 4. Backing Links (AKA Preventer Links) 5. The method I used to determine the angles of the link assemblies. Here is a photo of the starboard main chains: And here is a shot of the finished chains: Next are the rudder chains. Let's see if I have the time to do that before I have to put this project aside to do video and audio work.

-

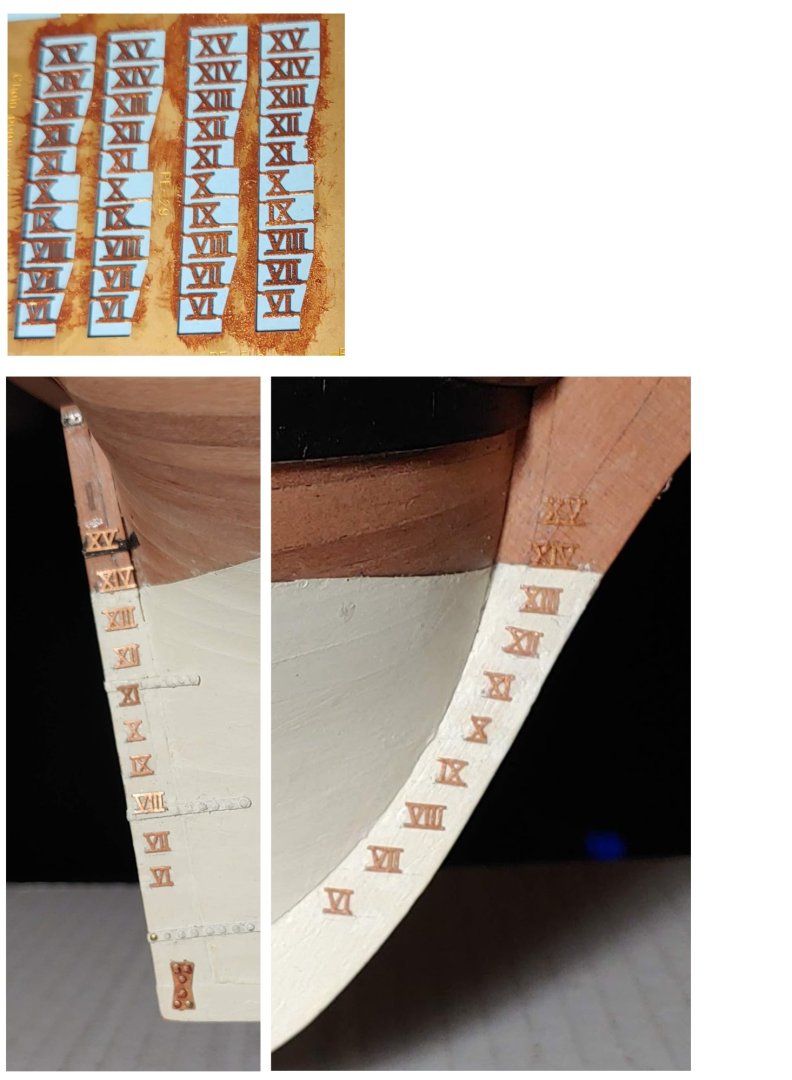

Time to glue on the PE decorations to form the frieze. Here is a sampling of the PE filigree: The numbers you see on the sprue correspond with those on the detailed 1/64 scale drawings provided, assuring accurate placement of these elements on the hull. And here they are all glued into place using Vallejo acrylic matte varnish with occasional touches of CA: I have seen several different versions of this frieze in other builds, and I applaud the skill needed to pull them off, but I am content with the bas relief design, electing only to change the color from gold to yellow ochre.

-

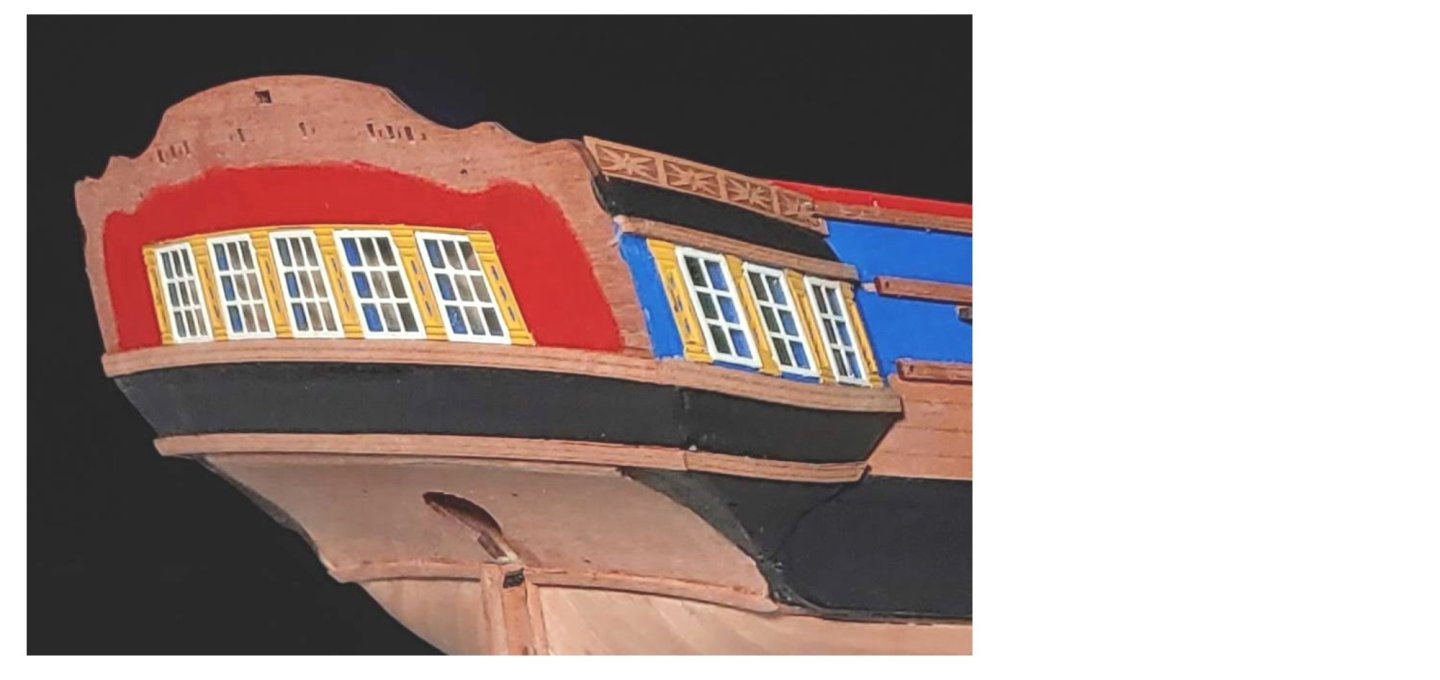

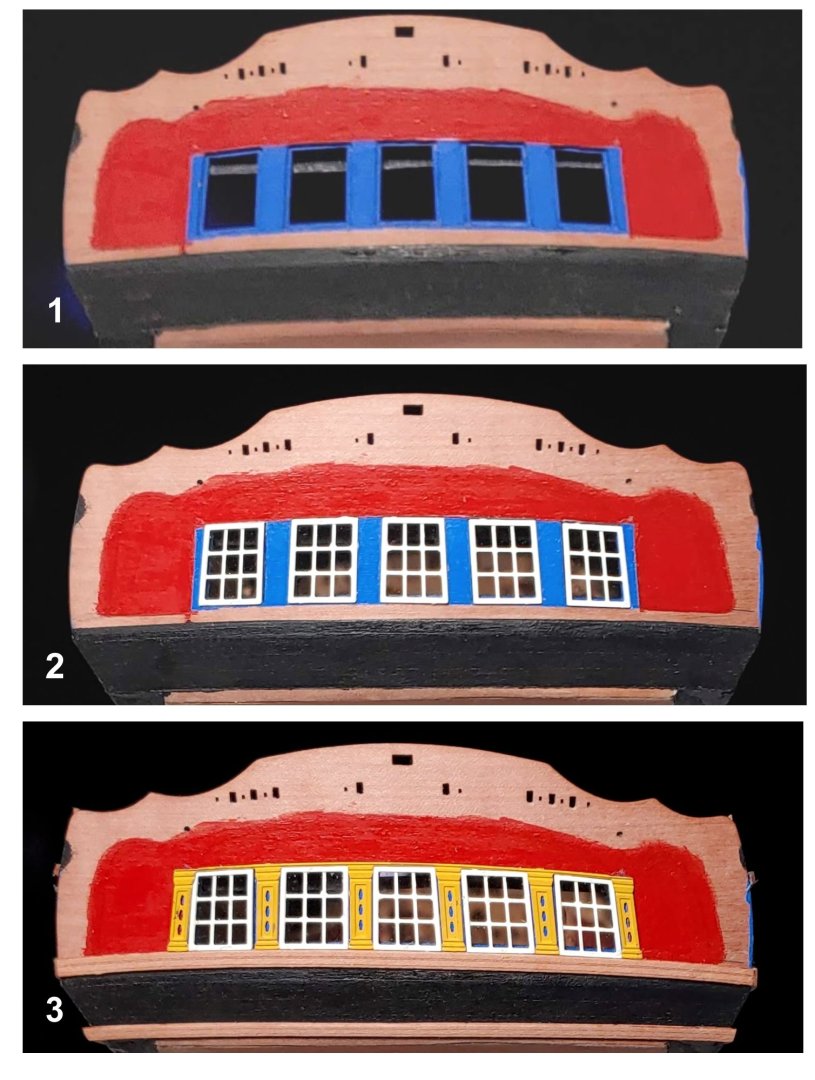

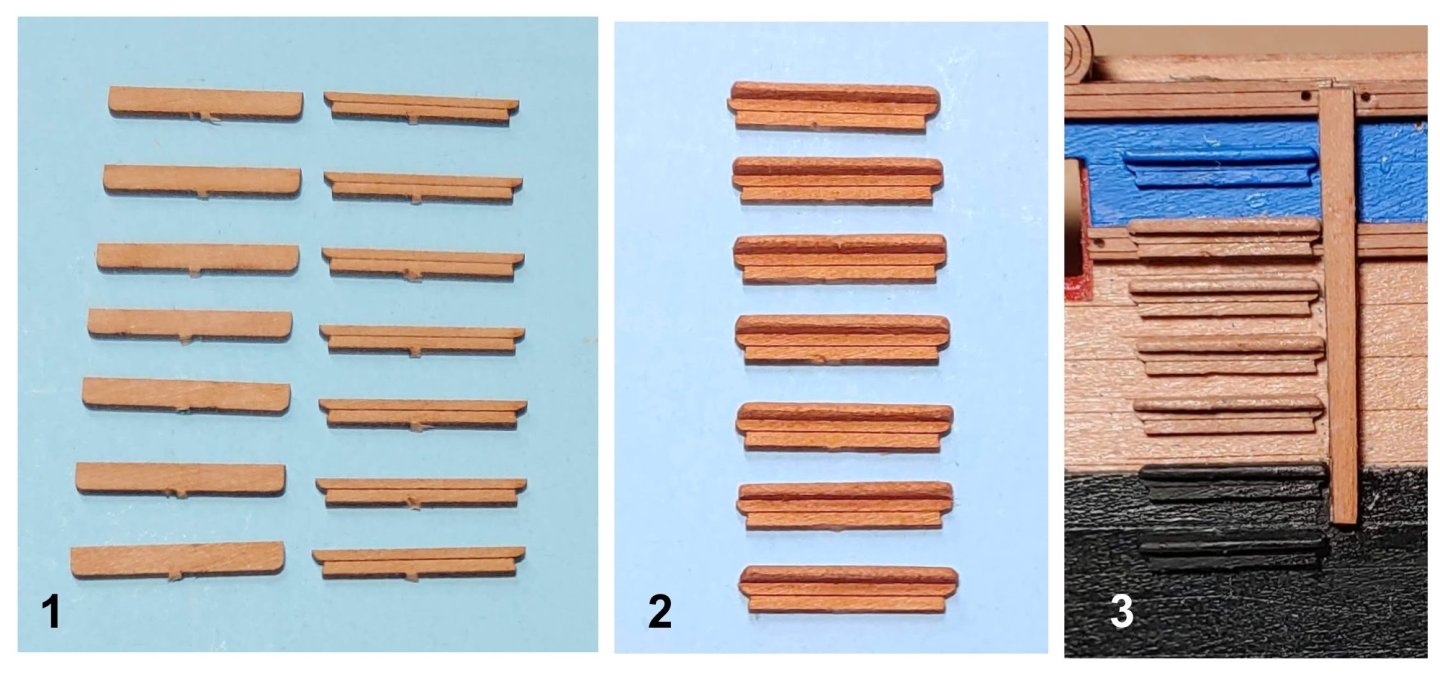

Work is proceeding on the stern: 1. Background painting done. 2. Acetate window panes and frames installed. The same issues I described in my reply to @Ronald-V question are the same here. 3. PE pilasters glued in place using CA. Rails installed. My rendition of the stern is not without its flaws, but at least I managed to have the quarter gallery rails and the transom rails meet neatly at the corners. Next: 1. The superb cast resin taffrail, primed and painted Vallejo Royal Blue. 2. My best effort to paint the detail thereon with yellow ochre. Touchup was done on the pilasters after the photo was taken. Why not before? Well, that's a long story. I began work on the upper counter, but the letter "P" in the name disappeared seemingly right out of my hands. I contacted Chris expecting to buy a new PE sheet, but it turns out that he had some scrap parts of that sheet at hand, and was willing to send me a new "P", no charge. I can add my gratitude to the many compliments I have read concerning Chris's customer support. I will post the results of my efforts at decorating the upper counter when I have finished it. Meanwhile, the next step is the assembly and installation of the gangway steps: 1. These parts sure beat having to make them from scratch 2. Having looked at photos of the gangway steps of HMS Victory, I decided to round the steps. 3. After having exposed the bare wood where the steps will go with the point of a file, I glued the steps in position using PVA. The laser inscribed lines were a big help, especially in view of the fact the steps do not line up with the planks, but with the water line.

-

Thank you Ron. The paint impeded the reaming out of those openings to accommodate the acetate window panes which were larger than I anticipated. After having made a mess of the forward opening on the port side, I ended up filing down the acetate panes to fit. As I could not do the same with the frames which were the same size as the panes, I installed the panes flush with the gallery pattern and then added the frames on top, leaving them proud of the surface of the gallery. This defect became a lot less noticeable once the plasters were installed fortunately.

-

Work is proceeding on the stern. I have not quite finished the transom yet, but I did finish the quarter galleries, so I thought I would post that work now. Here is a shot of some of the PE items which have been primed and painted: As you can see, I elected to paint the decorations yellow ochre rather than gold. I started with Vallejo Yellow Ochre. I thought it was too dark, so I added two drops of Vallejo Ivory, then a squirt of Vallejo Light Yellow which gave me the tone I wanted. I looks very dark here, but the following photos give a better idea of the actual color: 1. I painted the window insert spaces blue. Big mistake!! It caused me no end of problems when the time came to insert the acetate window panes. 2. Acetate windows and their frames glued in place. I used Vallejo matt varnish for this. 3. Rails PE pilasters, and upper fret work installed. I notice that in other builds, there is quite a variety of color schemes used in the fret work and in the bow head rails and bowhead timber fasciae. I thought about doing that, but ended up deciding to leave well enough alone, discretion being the better part of valor. 4. PE decorations added to the quarter gallery berthing patterns and lower finishing stool. I applied a coat of varnish, installed the decoration, then put another coat of varnish over that. The instructions suggest doing that with floor polish, but I found that this method also works. It turned out that there was not enough room for both PE parts on the lower stool, but I am happy with how it looks with just the lower one. 5. Shingles added. One of the PE shingle patterns slipped out of my hand and into the space between spaces, so there are three rows here instead of the four that the instructions call for. I see that several other fine builds also have three rows, so I do not see this as a disaster. There are four rows of shingles on the port side, but as one can only see one gallery at a time, and as I never had any thought of entering my work in a show, I can live with it. You might have noticed that the rudder is absent in these photos. I found it difficult to handle the model while applying decorations without having the rudder come loose, so I removed it. Once all the outer hull details have been completed, I will re-attach it, this time using maximum strength epoxy. I will post my work on the transom when I have finished it.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.