-

Posts

1,116 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Valeriy V

-

Hi, Phil! I continue to admire your work. 👍👌 I'd like to say a few words about painting brass. The problem isn't that paint doesn't adhere well to brass, but that brass needs to be degreased before applying primer. Solvents like acetone don't degrease. They only dissolve the grease, but they don't completely remove it from the surface. Even if you dip the part in acetone, the grease dissolves, and when you remove the part and let the acetone dry, the grease reappears. It doesn't change its chemical composition. Completely degreasing brass is done in a caustic soda solution (NaOH). As a result of the chemical reaction, all the grease on the brass surface turns into soap flakes and precipitates. After this, I rinse the part with running water, dry it with a hair dryer, and apply primer.

- 490 replies

-

- minesweeper

- Cape

-

(and 1 more)

Tagged with:

-

Thank you all for your feedback, likes and congratulations! I made the decking boards from rowan, and the side boards (watersides) from pear. Besides rowan, I also typically use maple and birch for decking. In my opinion, these woods best reflect the color of the decking after exposure to sun and saltwater. I use pear for the watersides because I like the contrast, which visually highlights the fine details. To simulate the seams between the boards, I use black paper.

-

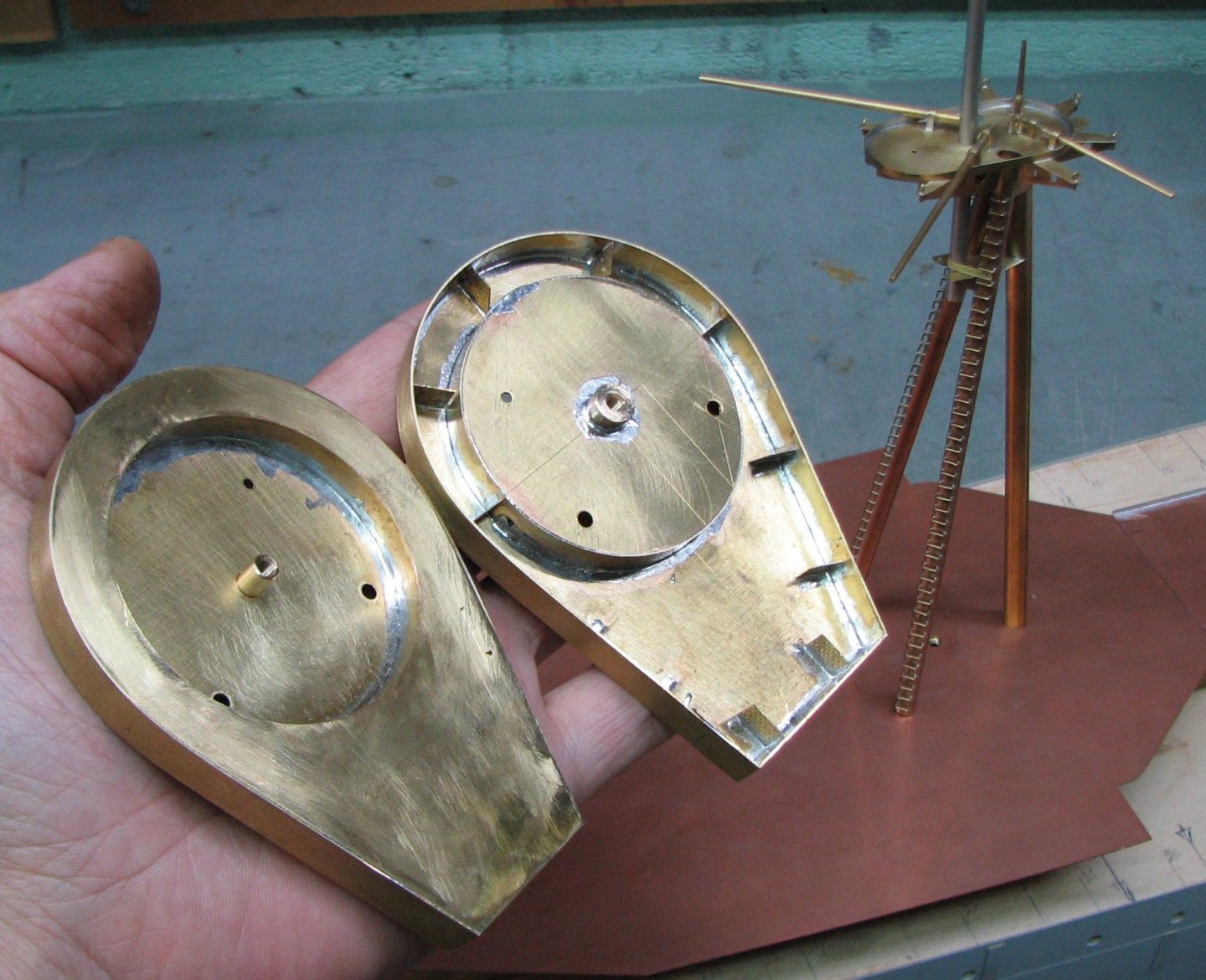

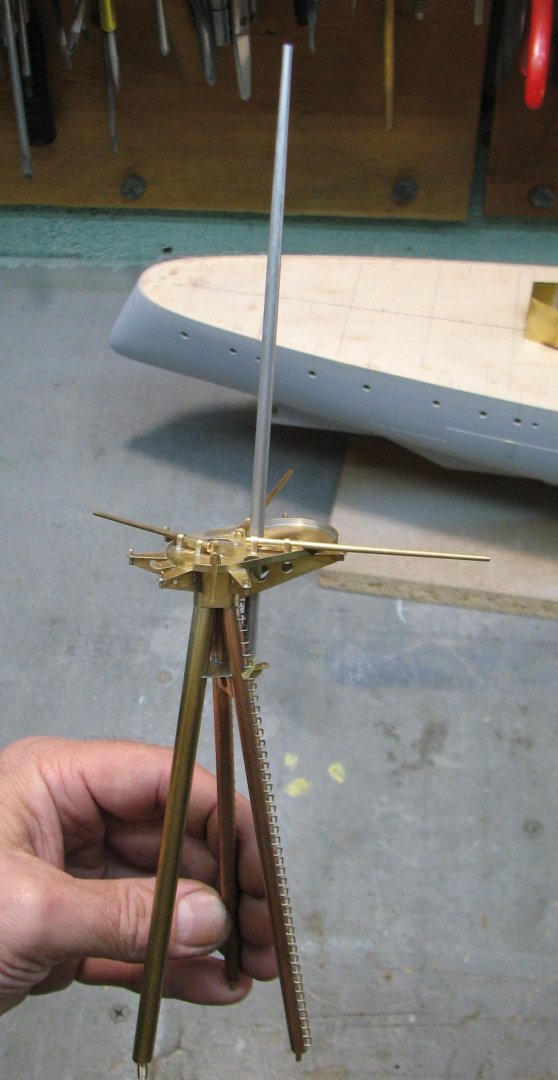

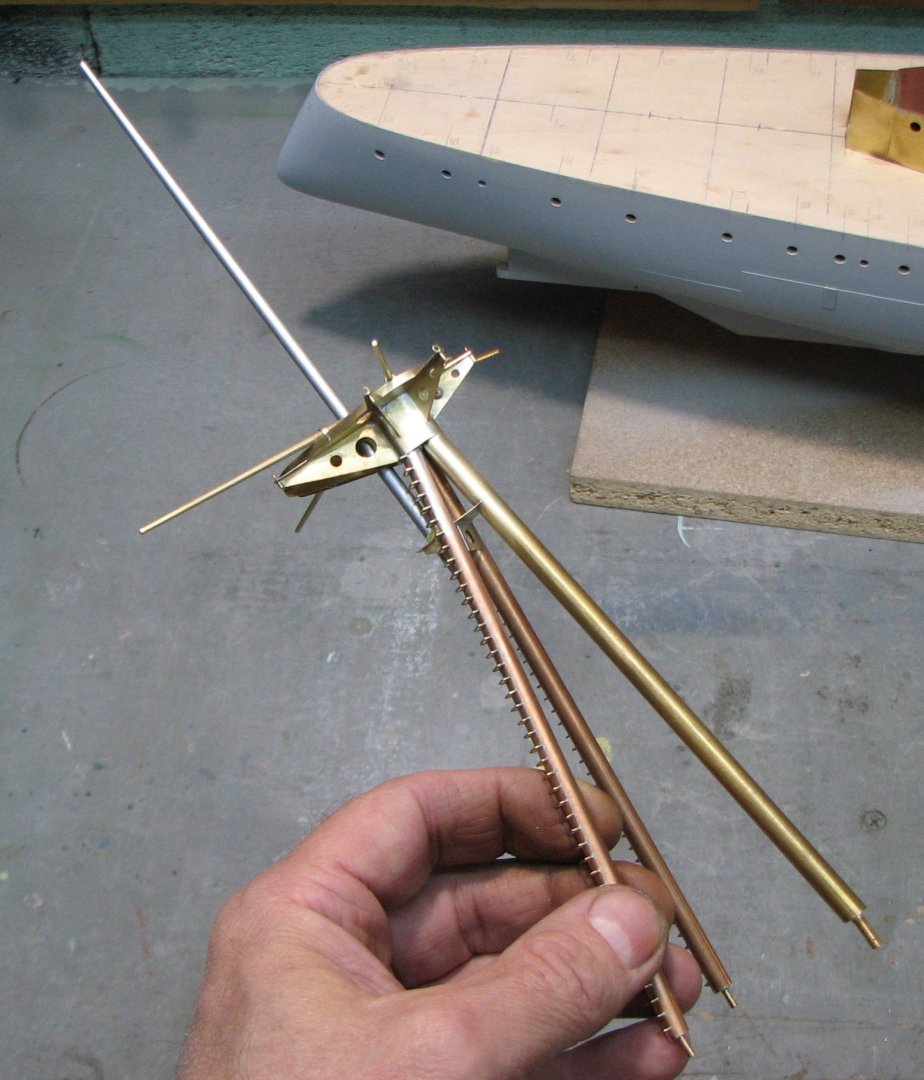

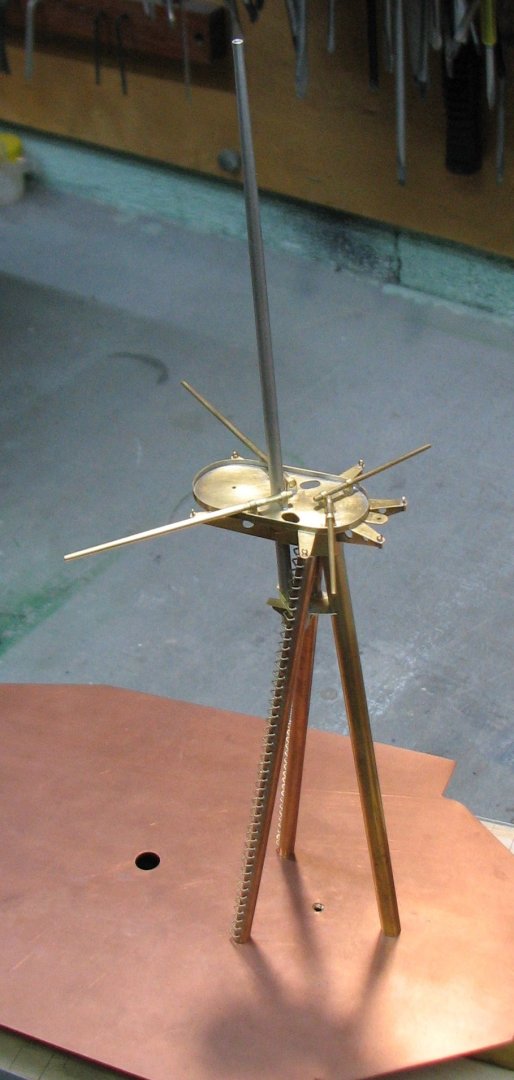

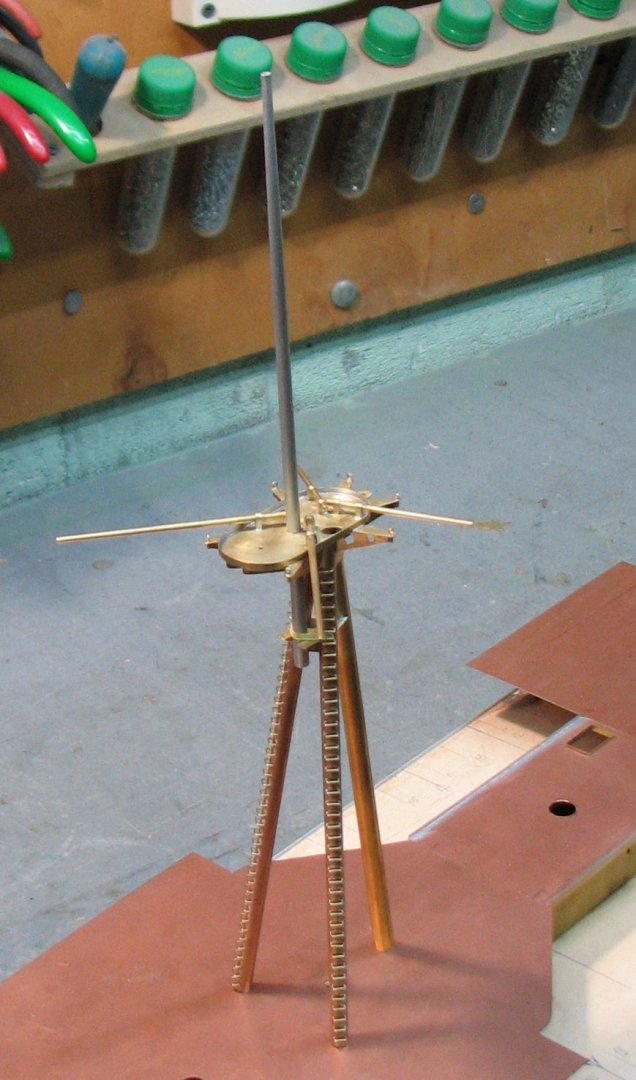

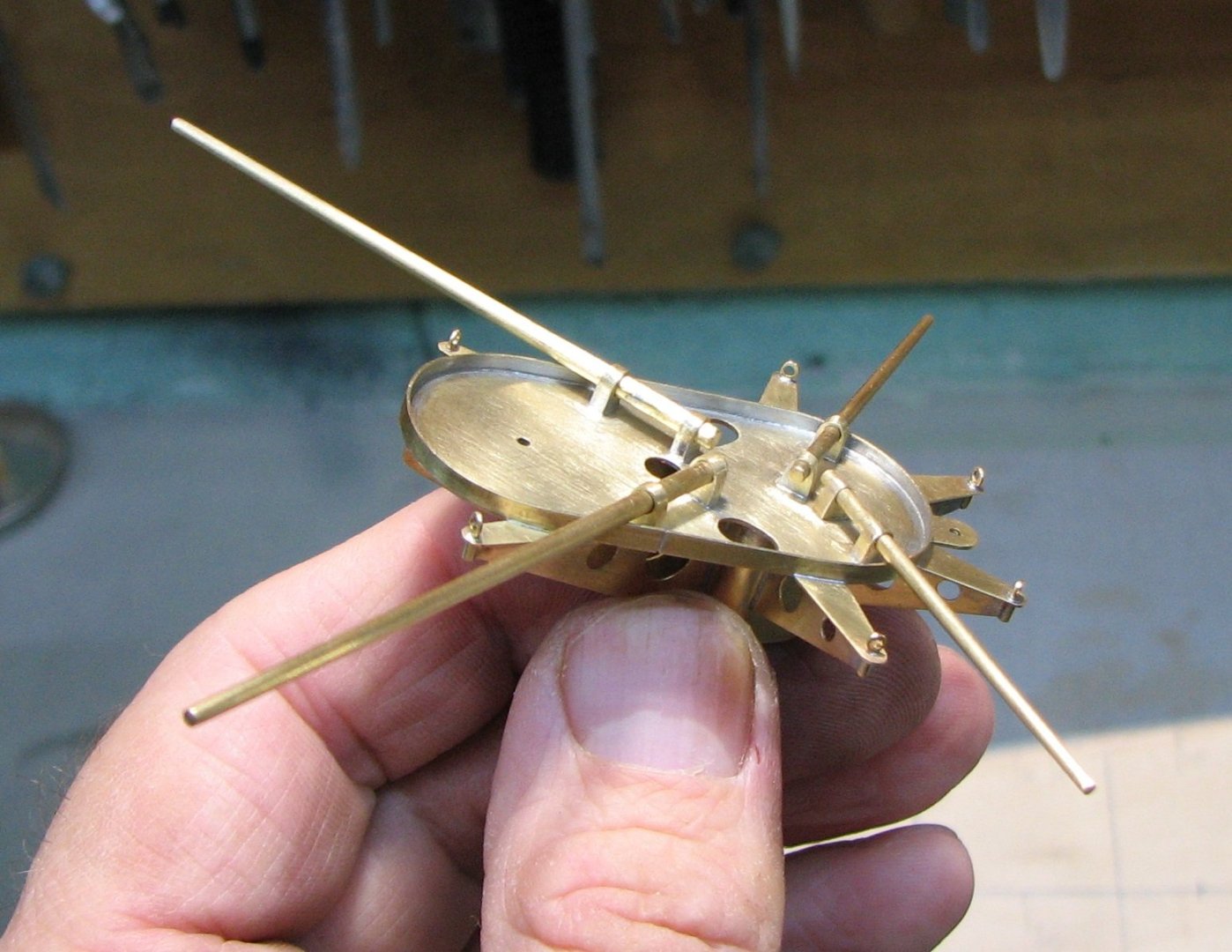

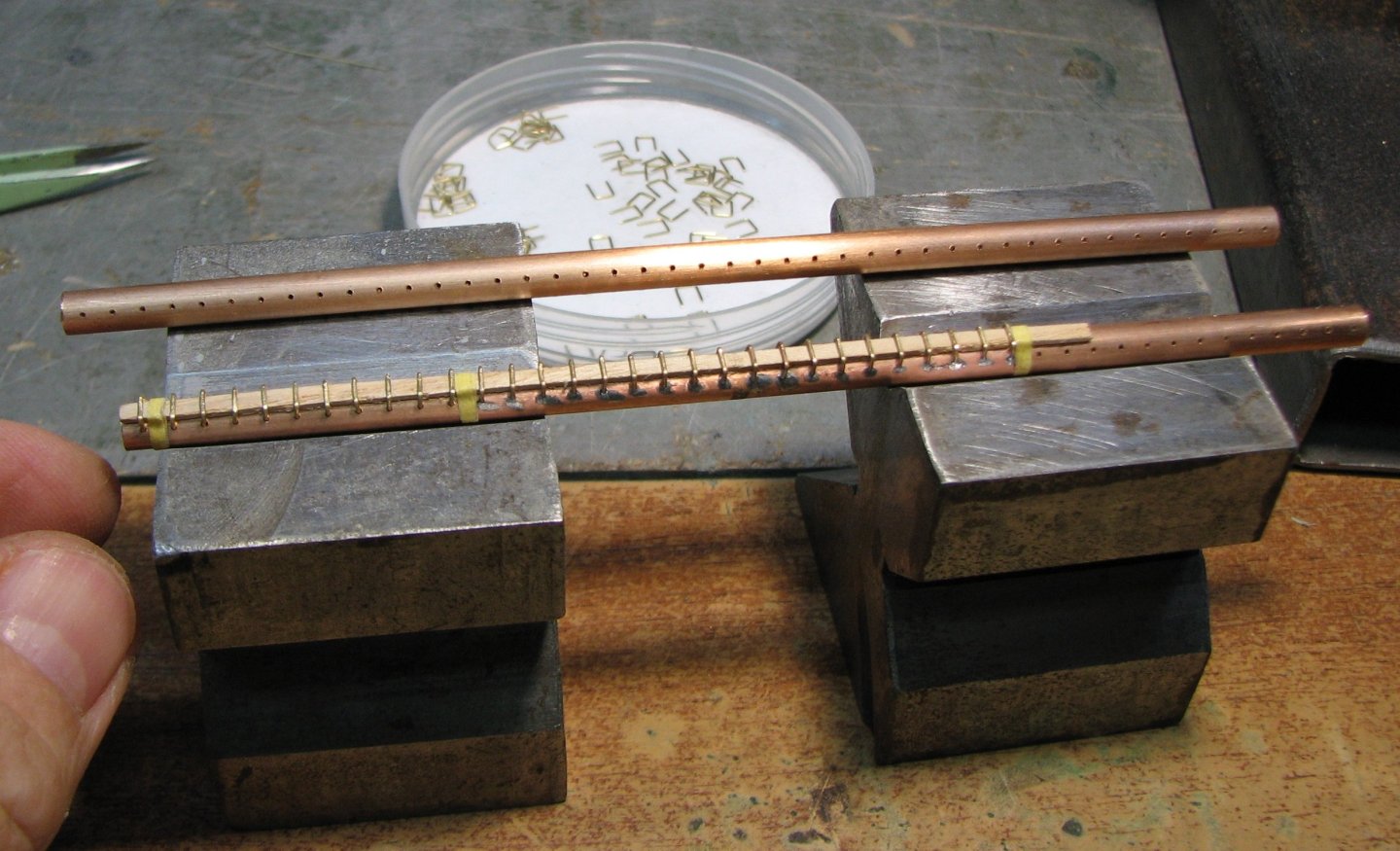

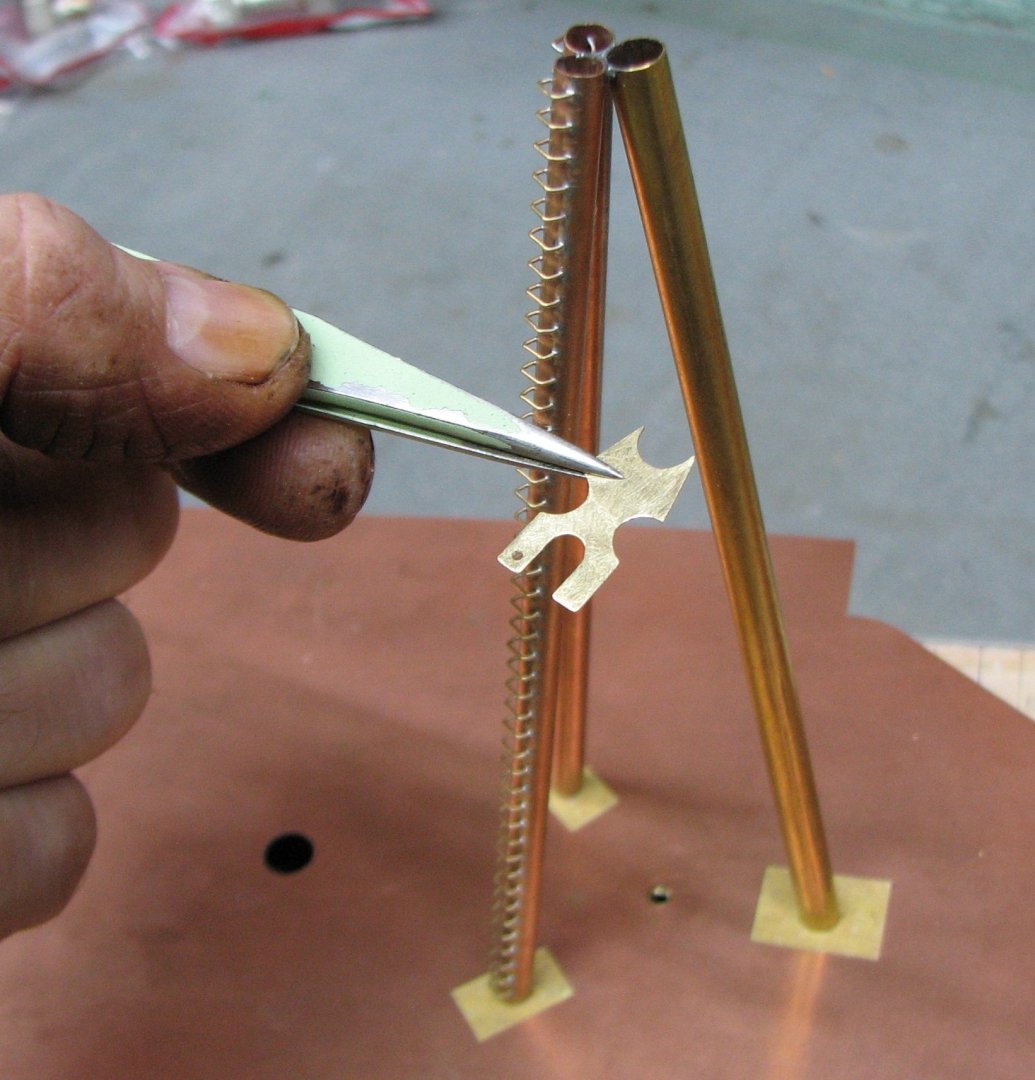

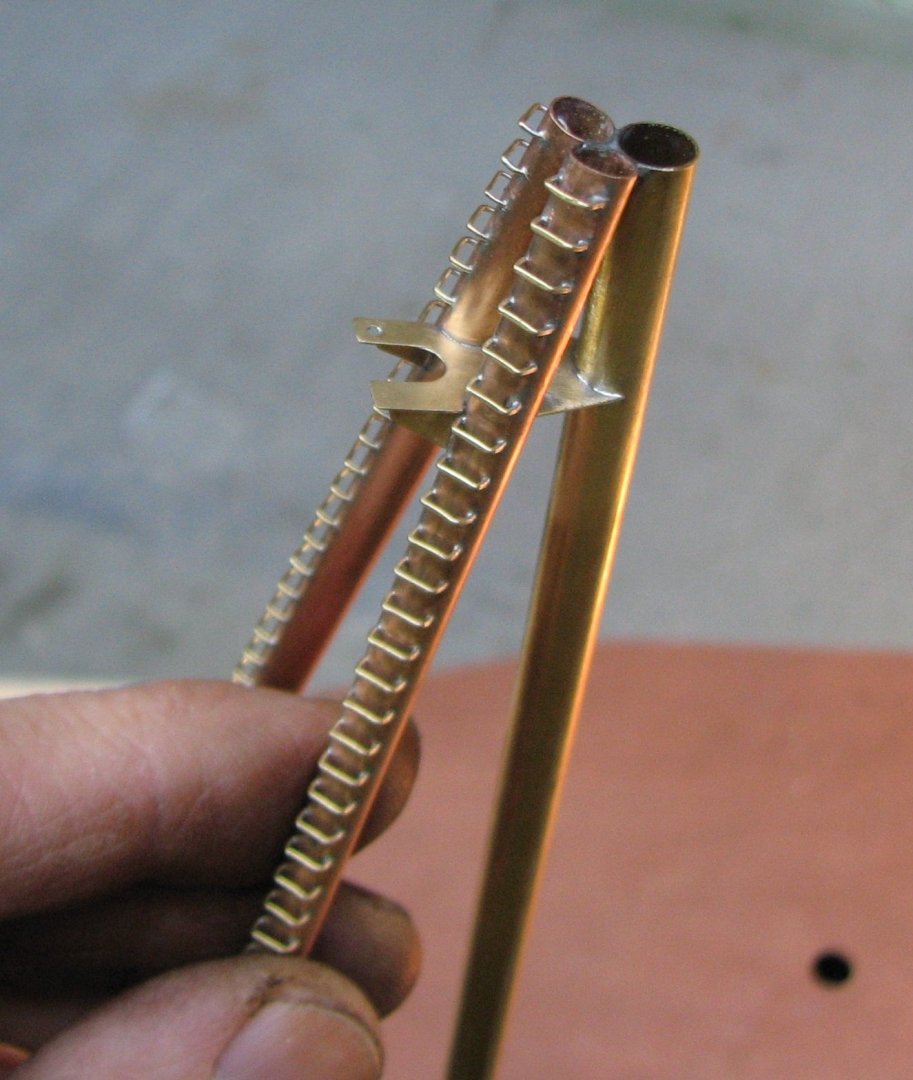

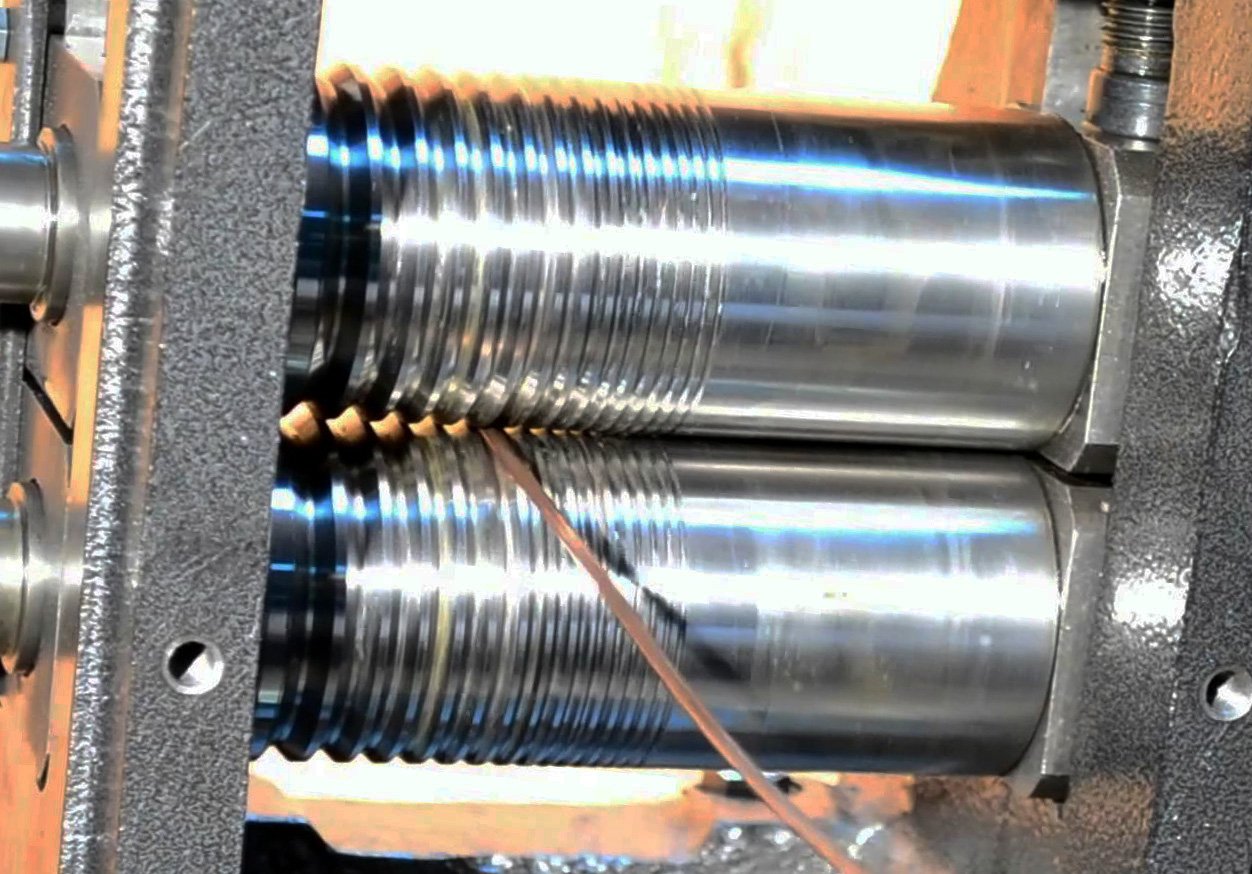

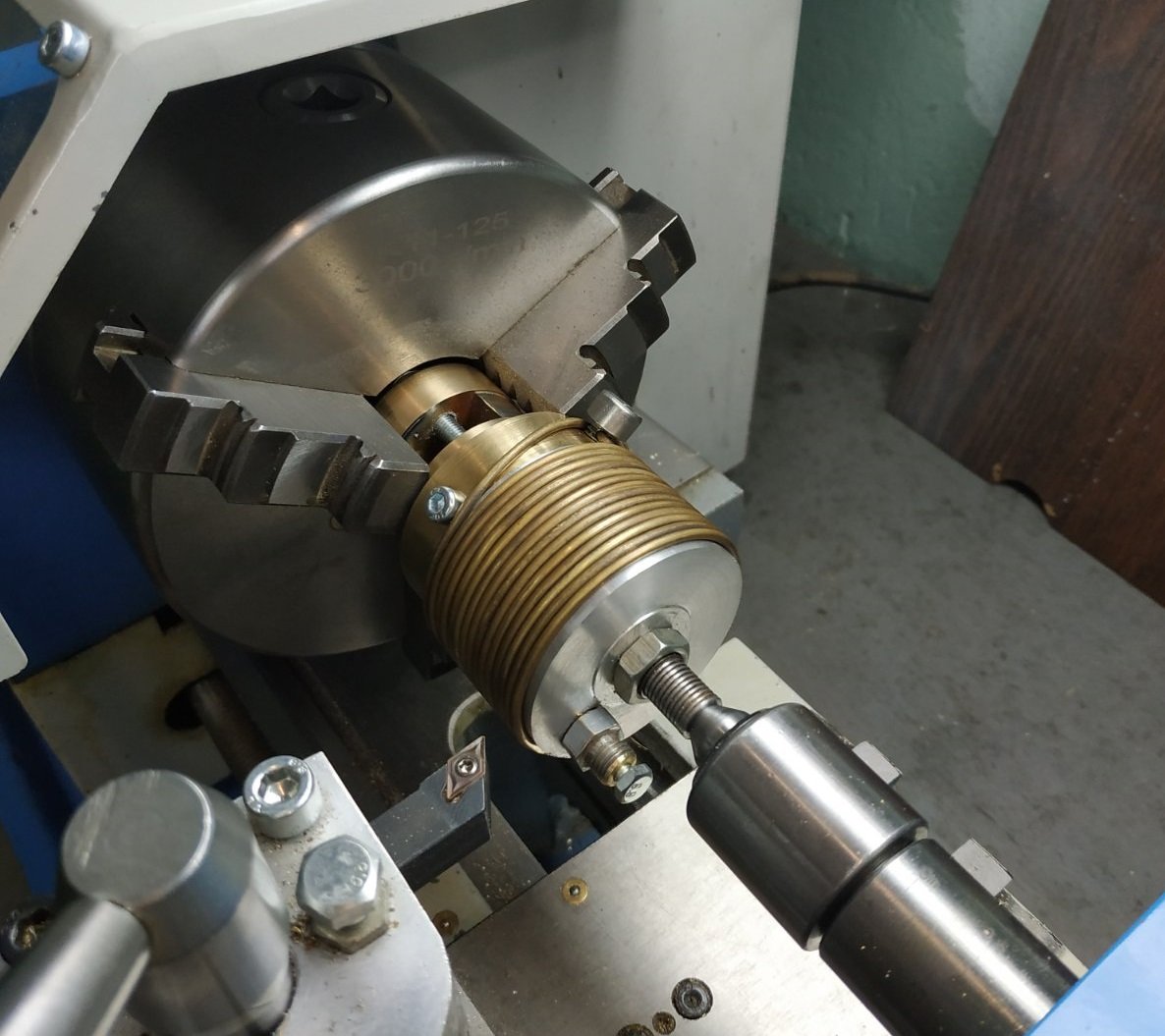

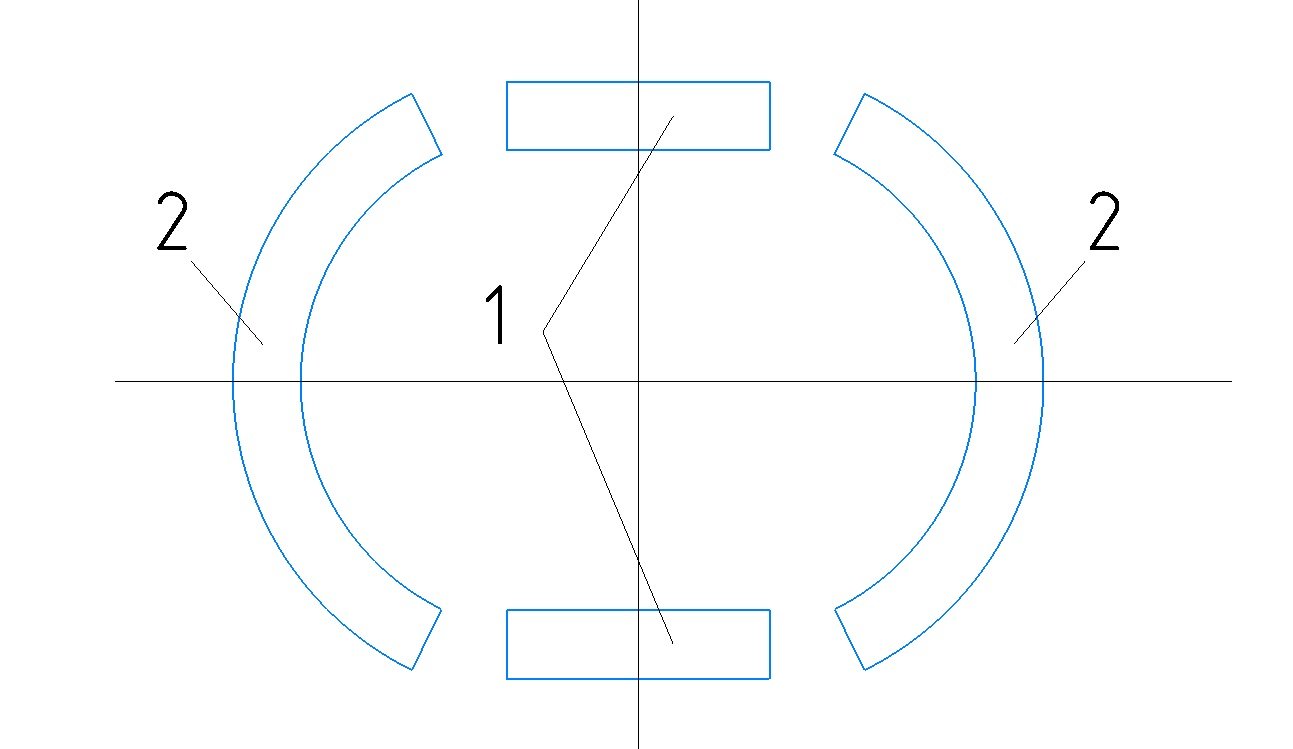

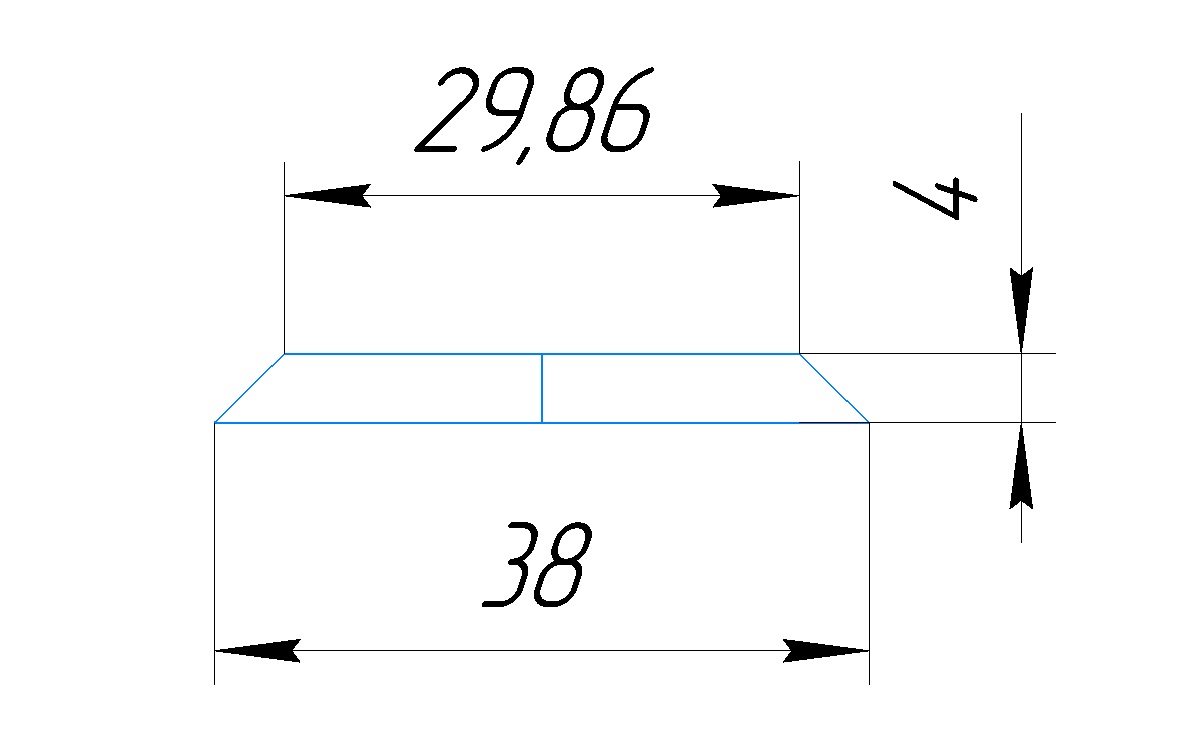

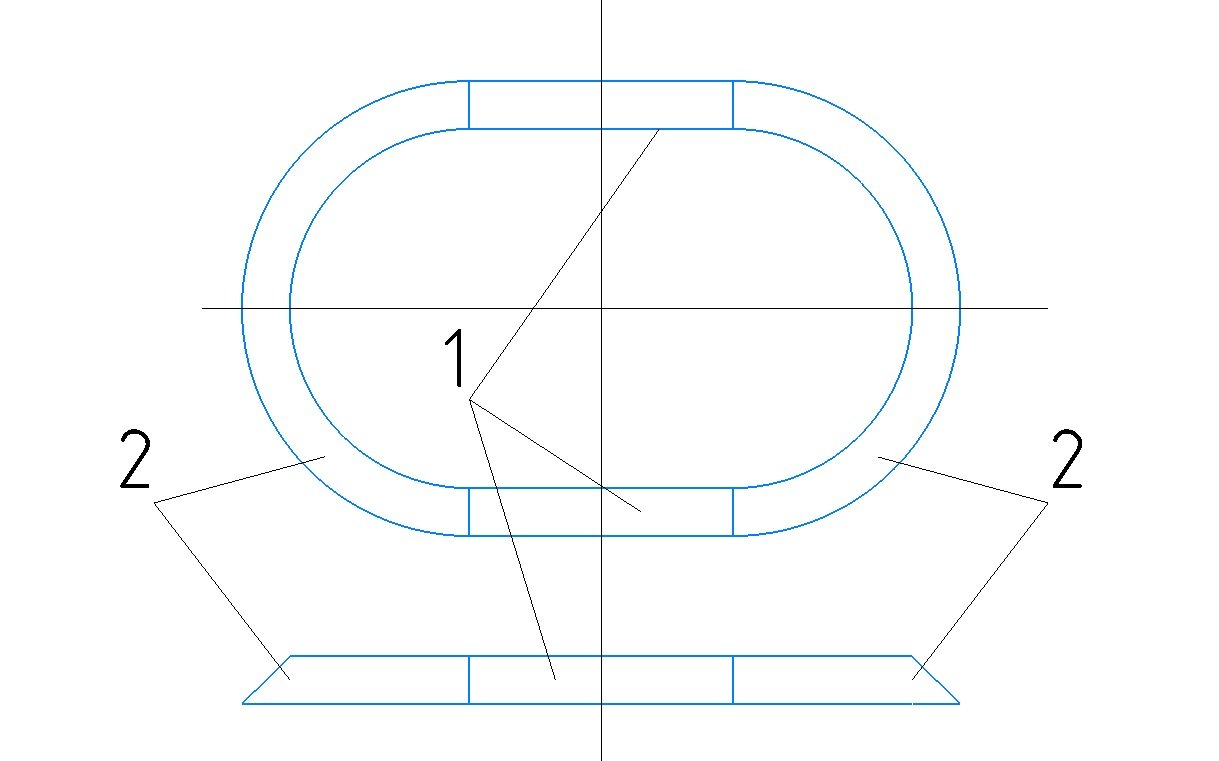

Hello everyone! Today I'll share a method for making a semicircular brass profile. Perhaps this will be useful for someone building models. The simplest way to create a semicircle is with a jewelry die. However, when the wire diameter increases beyond 1.5 mm, significant physical force or a special drawing mechanism is required. I decided to make my life a little easier and made this drum.

-

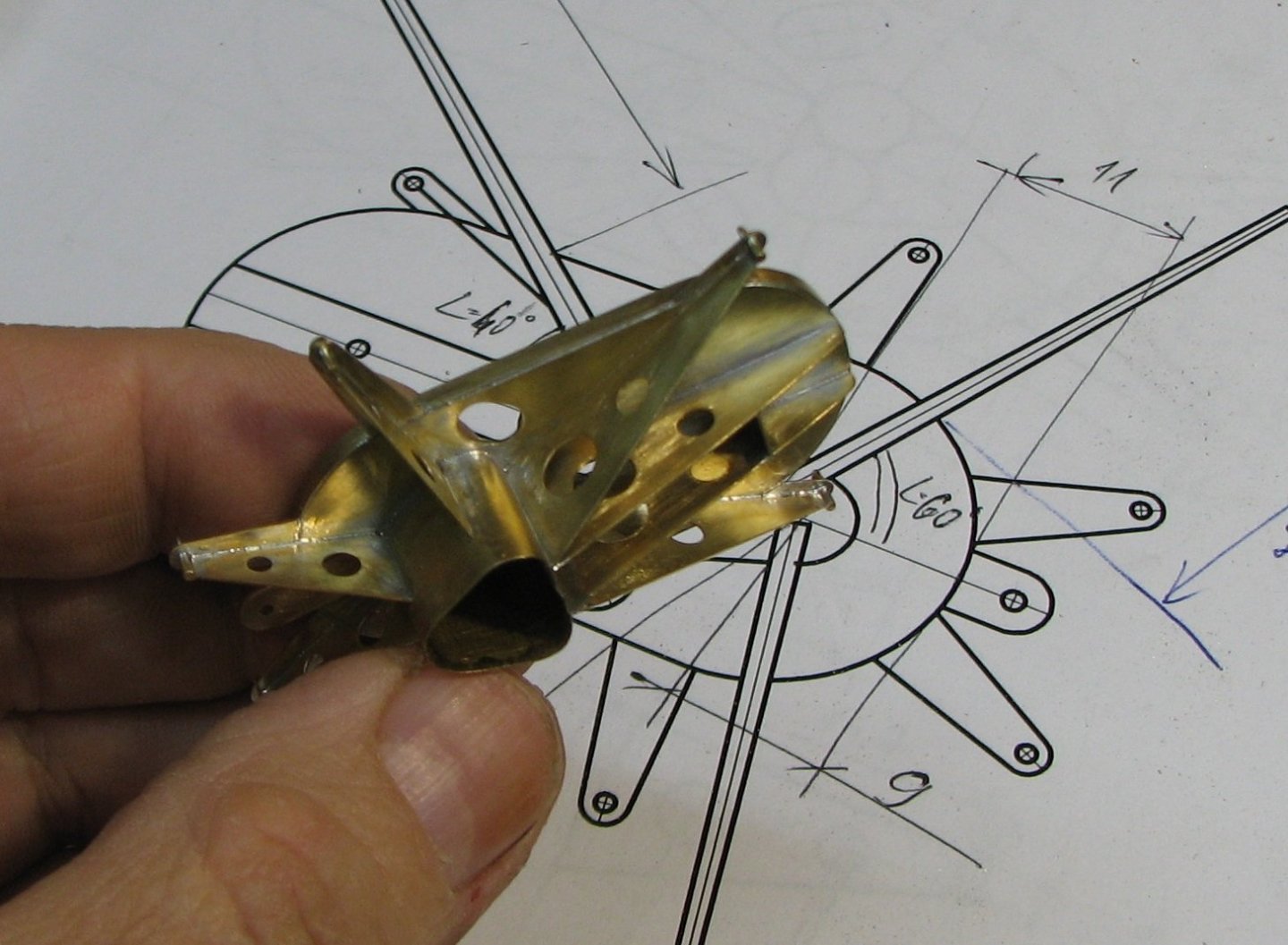

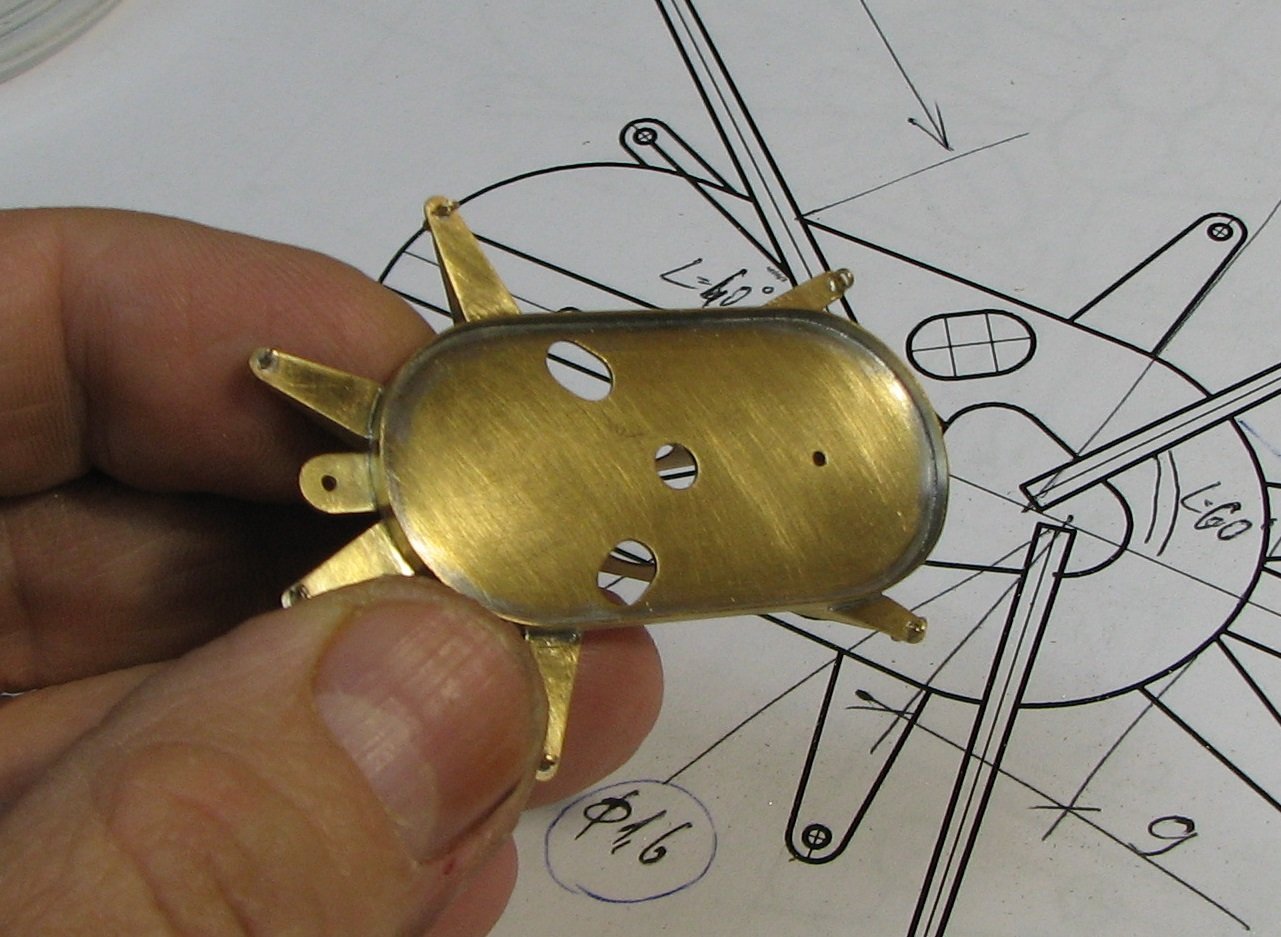

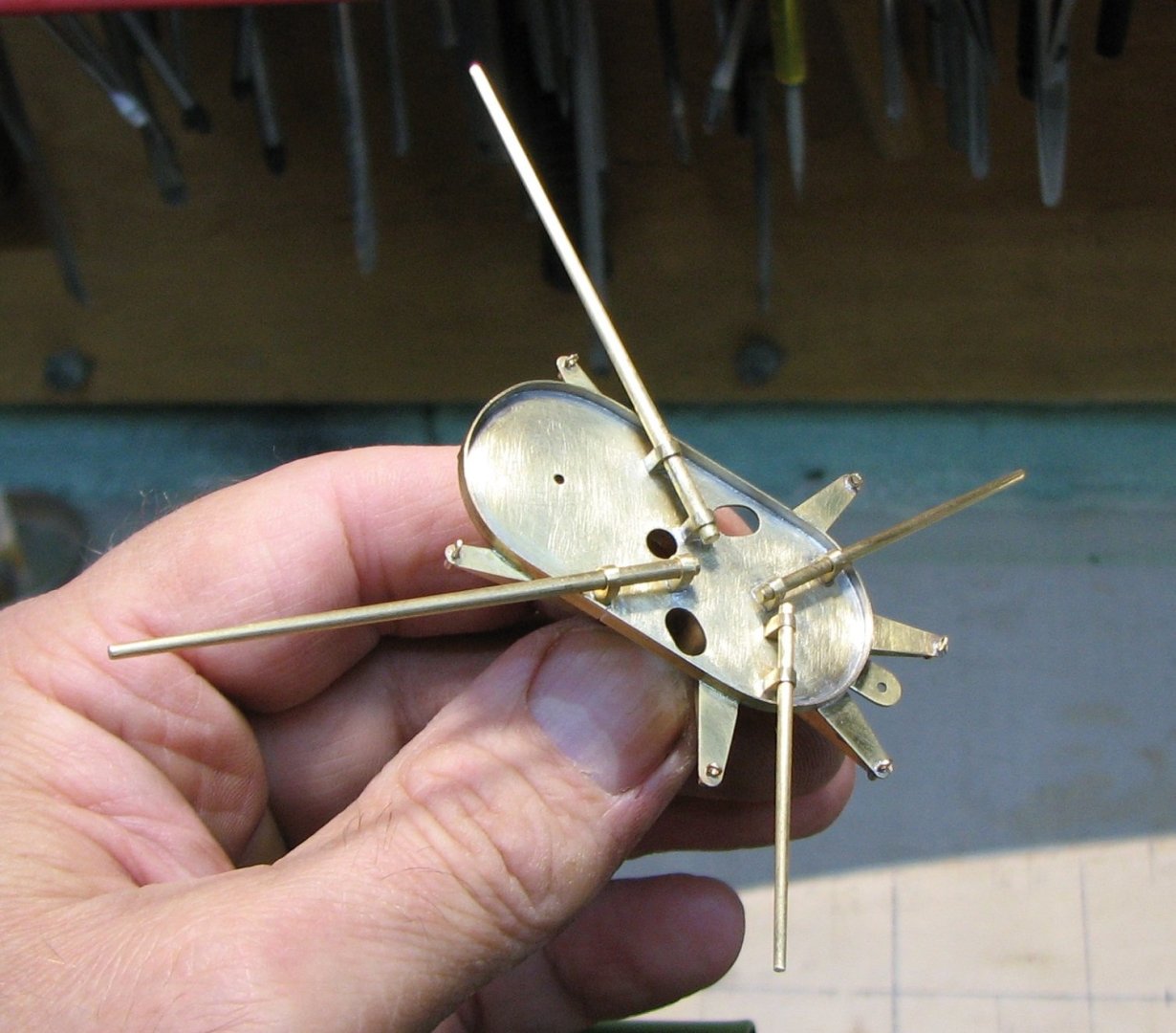

Phil, thank you for your kind words, I am flattered! In this situation with the manufacture of a sloping visor, everything is also quite simple. If the part is of a rather complex configuration, then I try to apply the following principle: - divide the complex part into several very simple ones in configuration - concentrate your efforts not on the manufacture of one very complex part, but on the assembly of several simple ones into one single and complex part.

-

Jan, thank you for your feedback! And I will allow myself to comment on it a little. What you called "gifted" I still put in third place in importance. Experience and skills definitely claim second place. But in first place should be the necessary high-quality machines and tools, because without them the necessary experience cannot appear and no gifted can help with this.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.