-

Posts

1,116 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Valeriy V

-

BRAVO! Ras, this steamship turned out much better than the previous models. And it's just great that you didn't paint some parts, this maneuver allowed you to revive your model.

- 128 replies

-

- zulu

- sternwheeler

-

(and 1 more)

Tagged with:

-

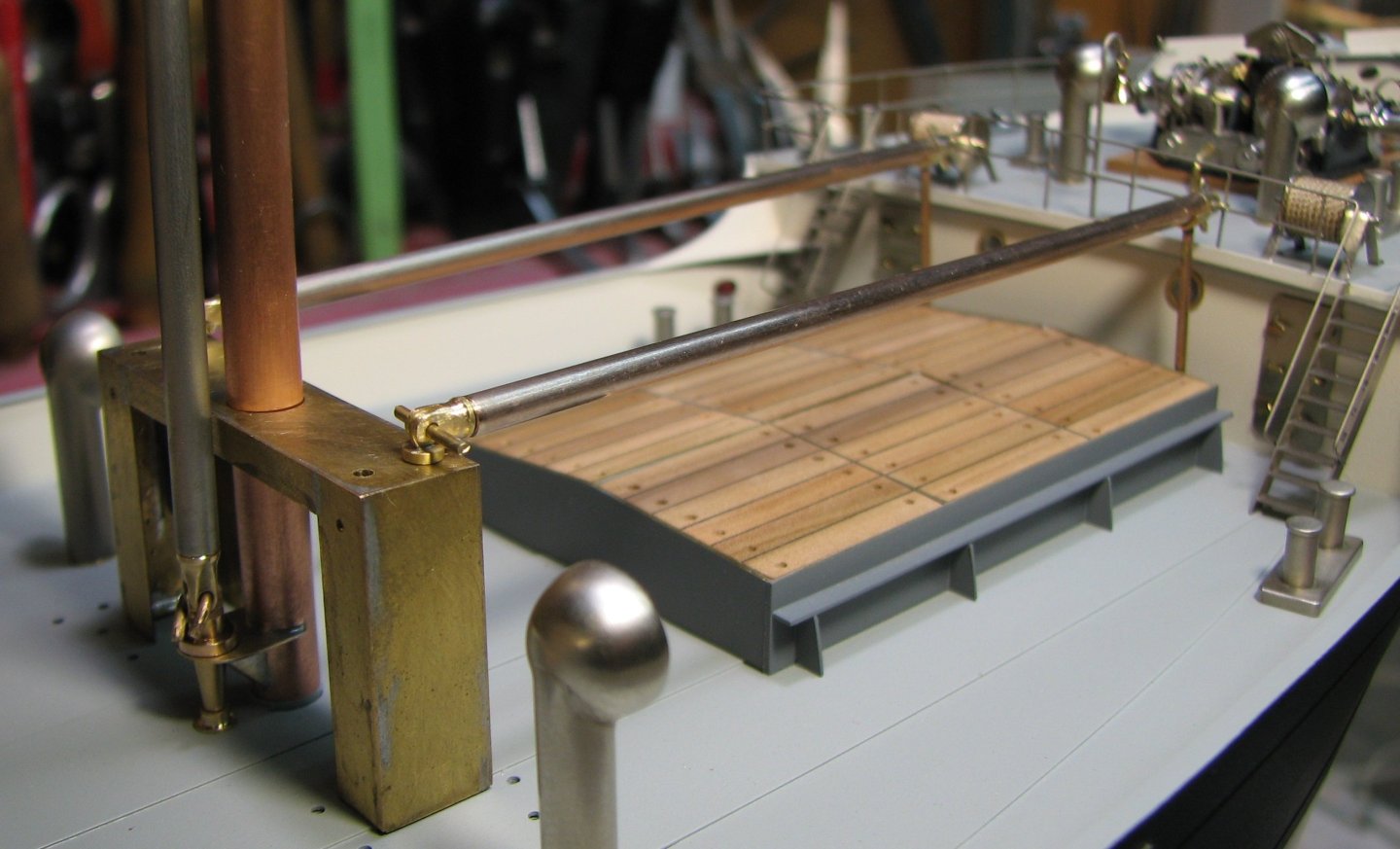

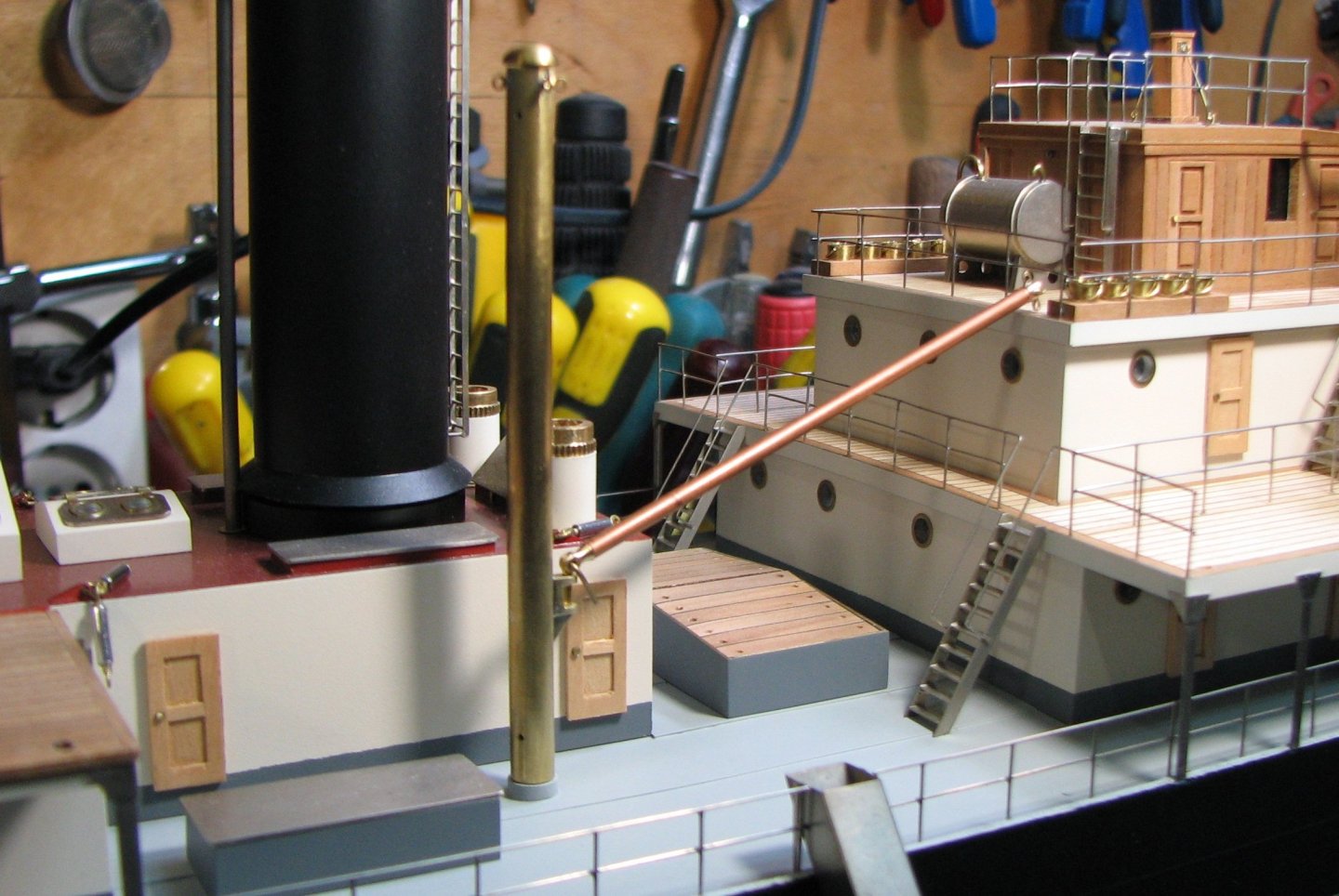

Hi, Dart! It should be explained to the rest of the forum participants that on its first voyage to Spain, the ss Blagoev carried light tanks (T-26) for the Republic on its deck. Therefore, the customer of this model plans to install these tanks on the deck of the model in the future. But it is unlikely that these tanks will be made of metal.

-

Phil, thank you for your amazingly artistic story! 👌👍 Once upon a time I had to get into a severe pitching for the first time on a six-meter plywood sail shell. And it turned out that the Lord had gifted me with the ability to endure pitching without any problems. But what was happening to my crewmates was not a funny sight.

- 482 replies

-

- minesweeper

- Cape

-

(and 1 more)

Tagged with:

-

Phil, very interesting! I'm waiting for the continuation. 👍👌

- 482 replies

-

- minesweeper

- Cape

-

(and 1 more)

Tagged with:

-

Keith, if such people are interested in my work, I am always open to discussing details . But, I repeat, I am completely unfamiliar with this type of book and even more so I do not know how they are published and what is needed for this. I can only photograph the work process and even then not always.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.