-

Posts

1,116 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Valeriy V

-

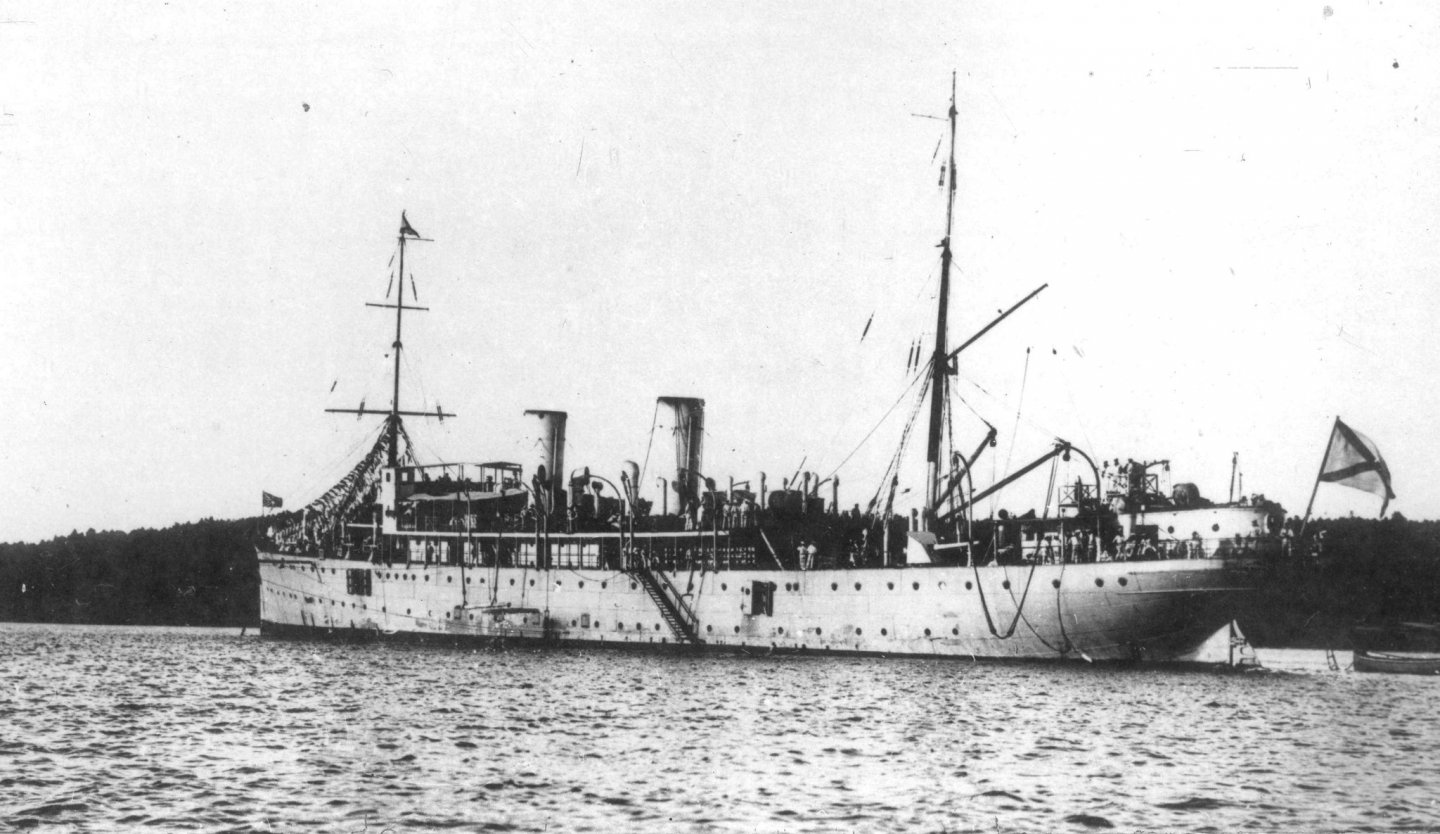

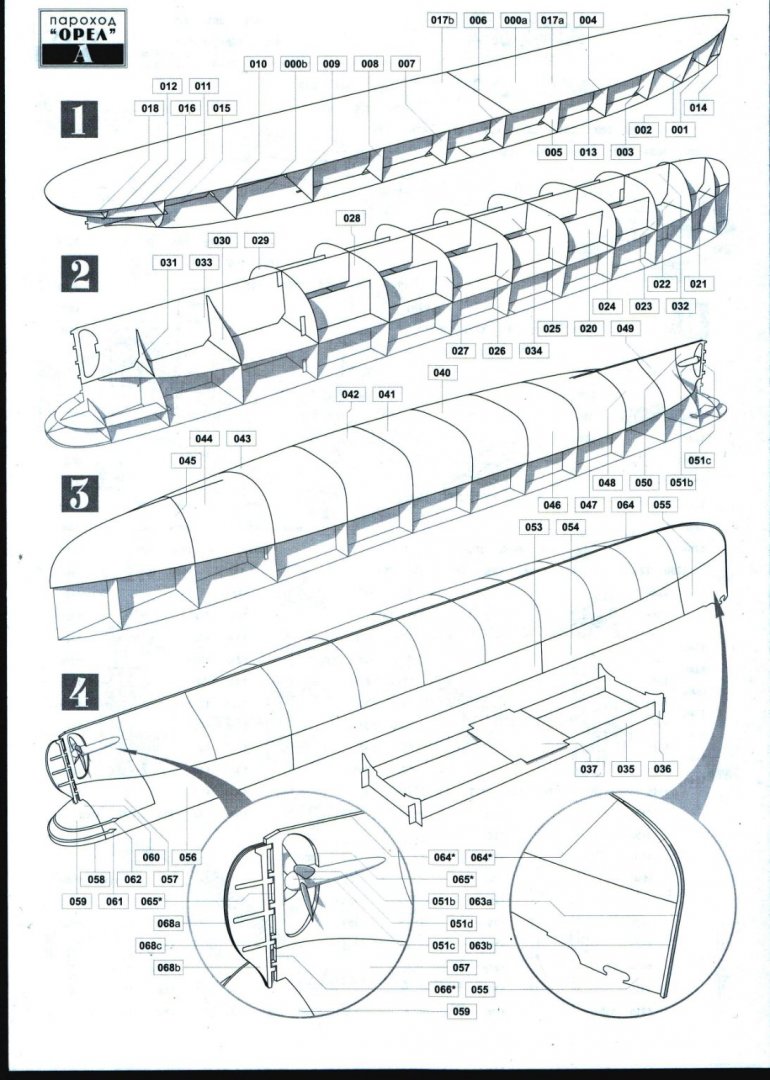

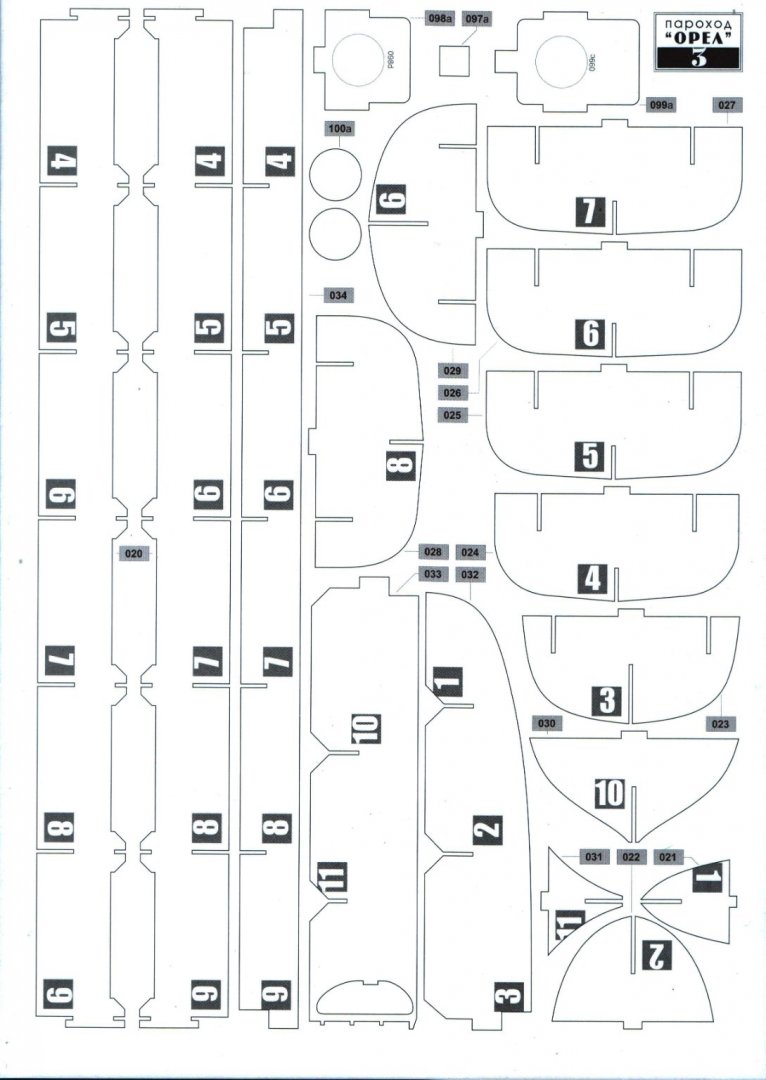

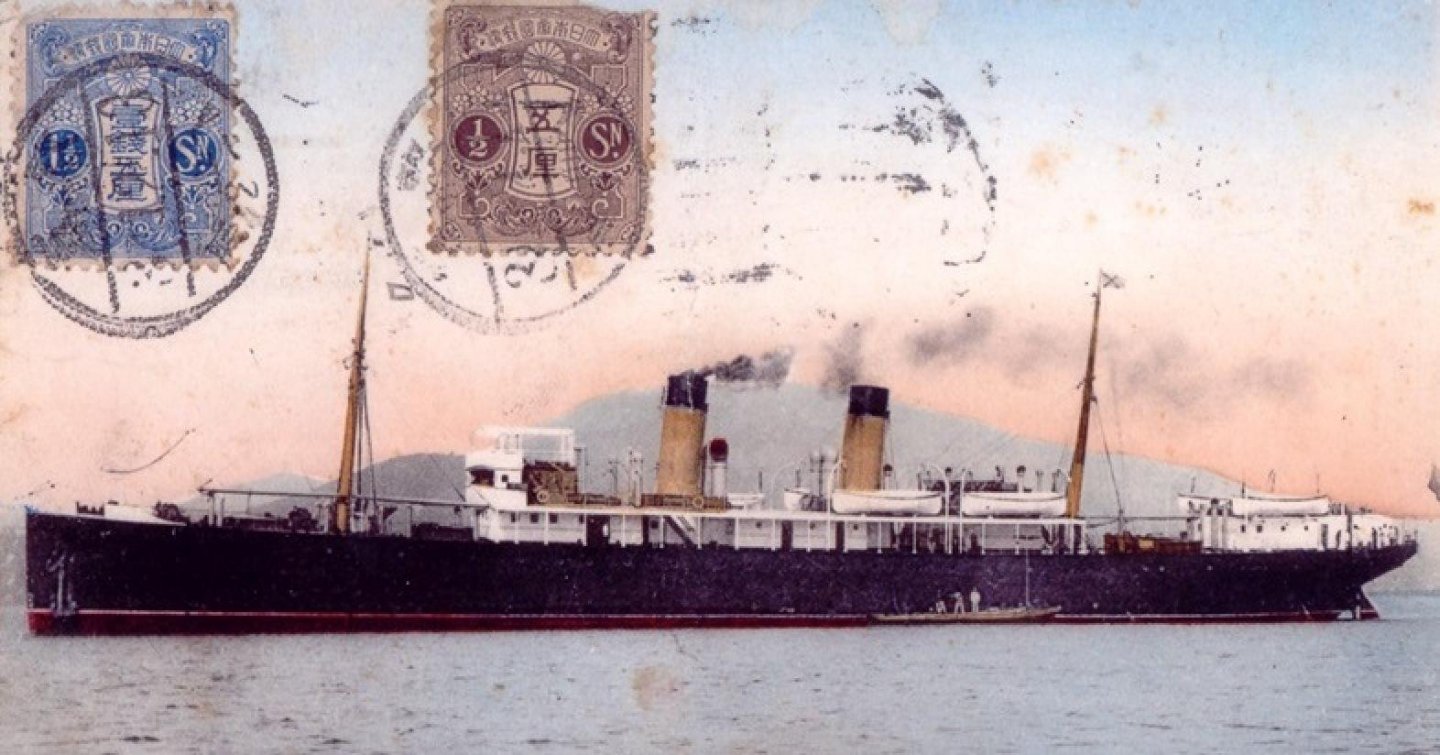

At the shipyards of Germany, 5 steamships were built for the Volunteer Fleet steamship company: - steamships Orel, Poltava and Ryazan had a length of 103 meters and a displacement of 3500 tons - steamships Simbirsk and Penza had a length of 95 meters and a displacement of 2,700 tons. At the beginning of the WW1, the Orel was armed and became an auxiliary cruiser. SS Ryazan was captured by the cruiser SMS Emden. Later it was converted into a raider SMS Cormoran .

-

Model from the Lancaster Maritime Museum.

Valeriy V replied to Valeriy V's topic in Nautical/Naval History

Thank you, Chris! The swift hull of this ship resembles another turbine steamer in the St. Patrick series. Yes, I really like these ships and under some conditions I would gladly take on the construction of one of them. -

Model from the Lancaster Maritime Museum.

Valeriy V replied to Valeriy V's topic in Nautical/Naval History

Colleagues, thank you for your help! -

There is a model of a ship in the museum's exposition, but its name is not in the photographs. Maybe someone knows his name? Maybe someone else has photos of this model?

-

This is a fire hose reel. This is a beautiful car! In general, the design of technology from the 60s has some kind of special appeal, both in cars and ships.

-

Cotrecerf, Keith, Phil , Gary ! Thanks for your comments! In fact, this process of making a chain is not complicated and does not cause any particular difficulties. Soldering the buttresses to the chain is a bit of a tedious task, but it is most suitable for long winter evenings. It took me two evenings to make these two chains. The most difficult part was cutting the buttress to the required length because it is very small. Phil, you've almost got your chain link sizing correctly - actually 4.8mm - 3.2mm.

-

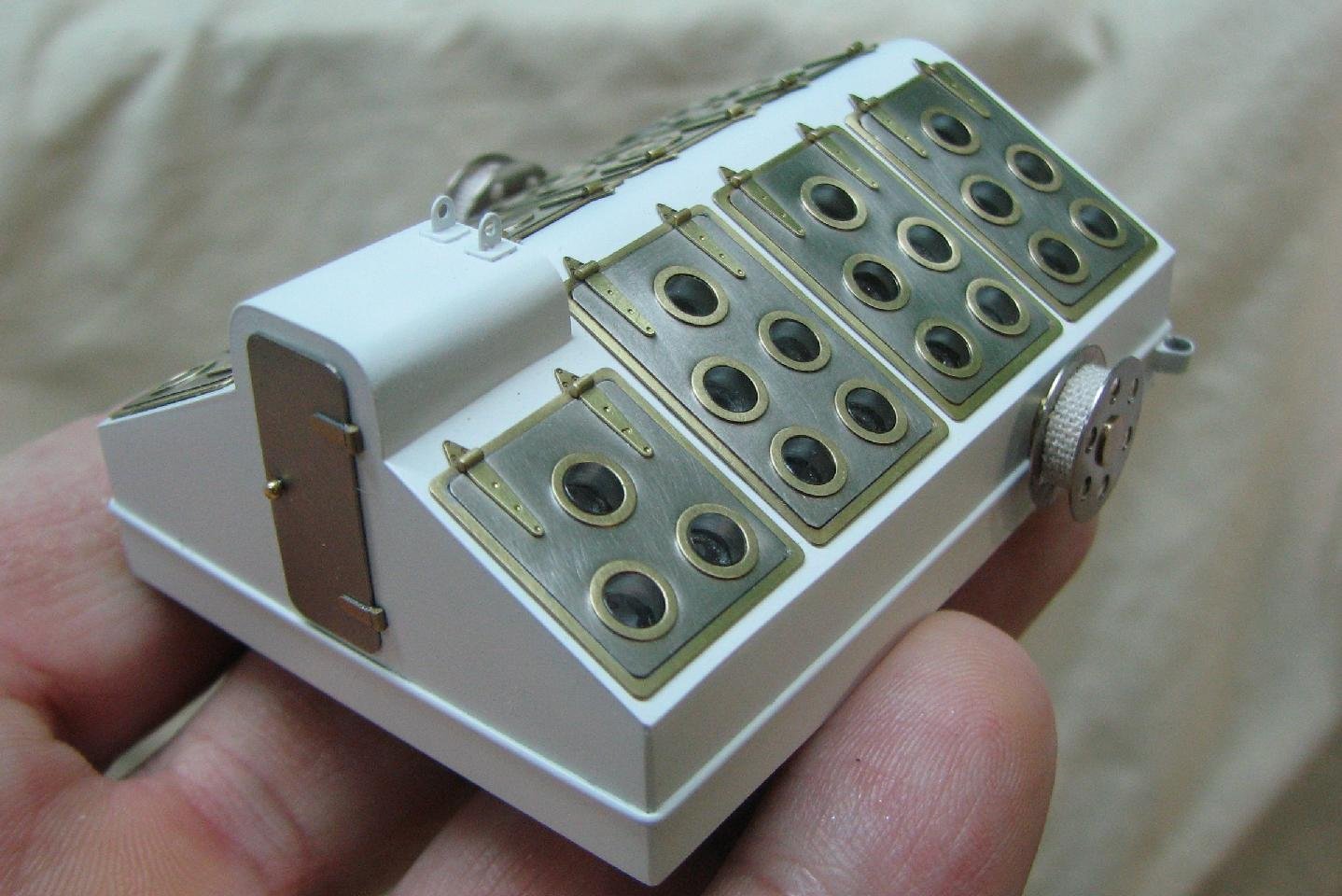

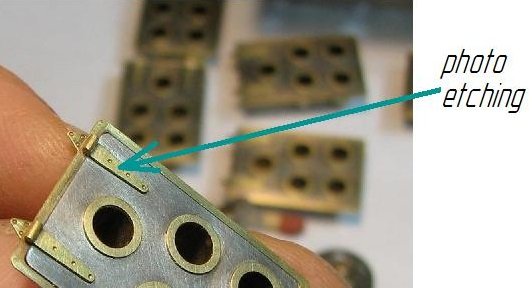

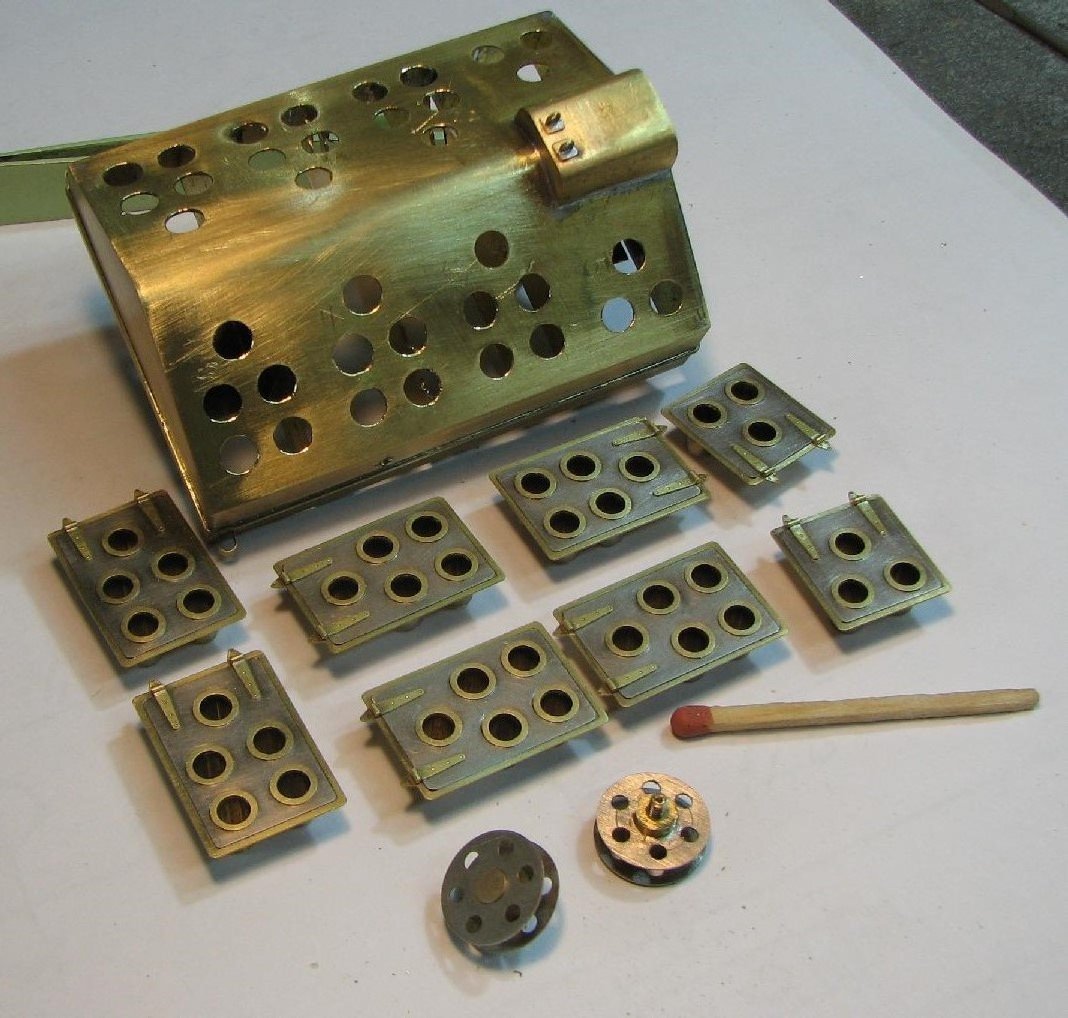

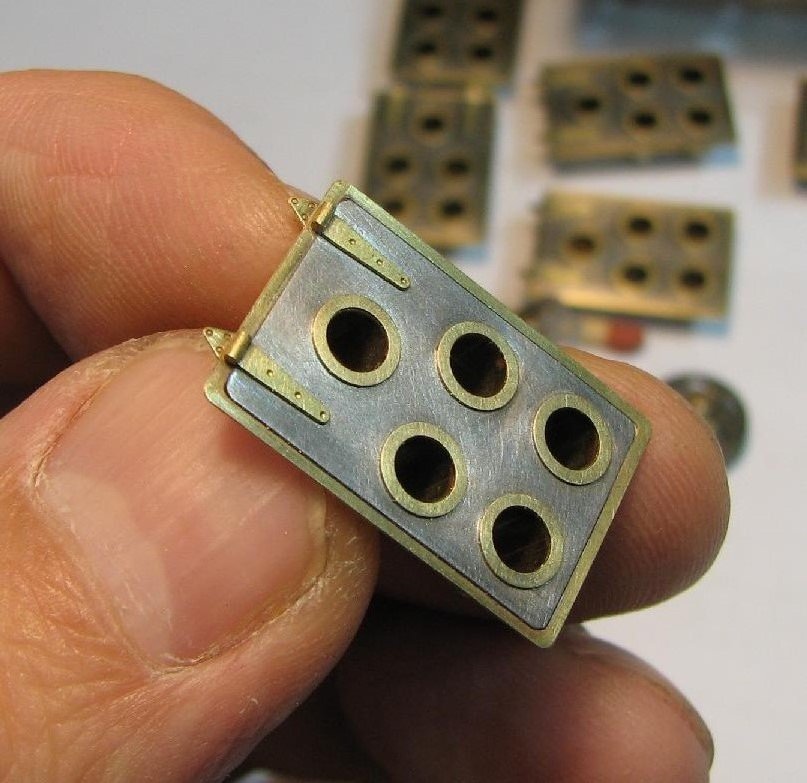

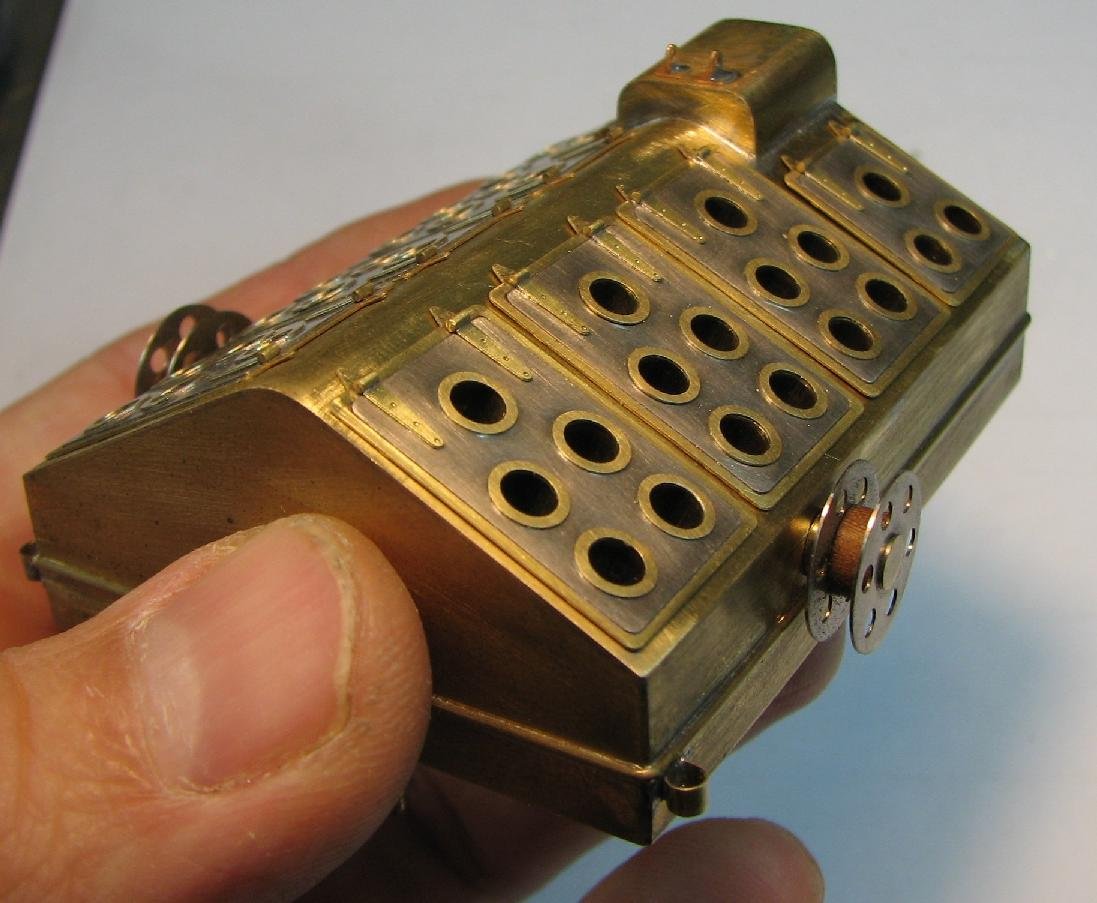

With the help of photo etching, only the hinge for the lid was made. The rest of the details are made by hand.

-

Keith, i also want to congratulate you and all members of the forum on Christmas! Please accept my best wishes for the coming New Year!!

-

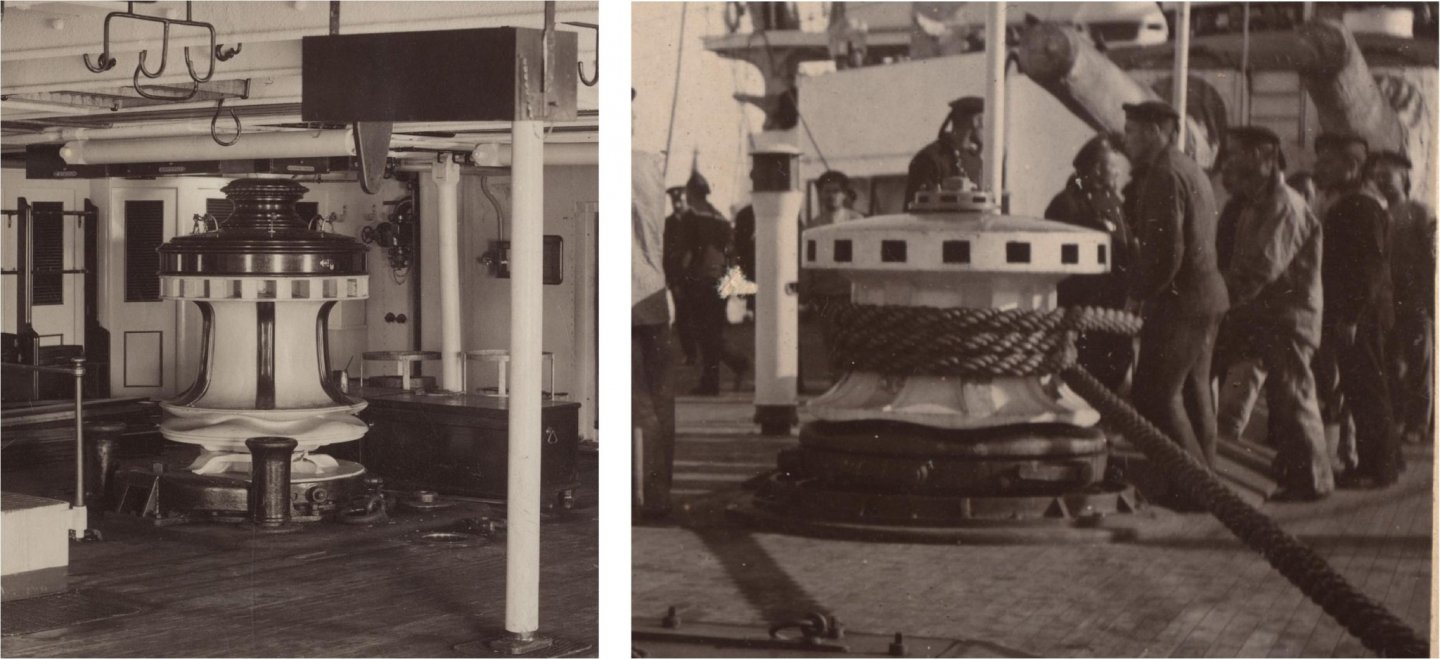

Thanks, Keith! I think that this is a device for winding a wet cable so that it does not slip, or maybe for a temporary stopping of the cable until it is fixed on the bollard or in the stopper.

-

Yes, this is a 1956 Chevrolet Bel Air. It is this specimen that has a special history. Nikita Khrushchev bought this car in Vienna, and then he presented it to Leonid Brezhnev for his collection.

-

Phil, great idea! I'll try to apply it on my next model. Vladimir has almost finished the CLG-5 model, it remains to make boats. You know that it happens that sometimes the modelers are distracted by other work.

-

Lou, of course come to Zaporozhye. We have few museums, but there are some very interesting ones for those who like technology.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.