-

Posts

253 -

Joined

-

Last visited

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

Vivian Galad reacted to a post in a topic:

HMS Victory by mfrazier - Sergal 782 - 1:78 scale

Vivian Galad reacted to a post in a topic:

HMS Victory by mfrazier - Sergal 782 - 1:78 scale

-

GrandpaPhil reacted to a post in a topic:

Mantua Sovereign of the Seas kit 1:78

GrandpaPhil reacted to a post in a topic:

Mantua Sovereign of the Seas kit 1:78

-

EricWilliamMarshall reacted to a post in a topic:

Golden Hind by mfrazier - OcCre - scale 1:85

EricWilliamMarshall reacted to a post in a topic:

Golden Hind by mfrazier - OcCre - scale 1:85

-

EricWilliamMarshall reacted to a post in a topic:

Golden Hind by mfrazier - OcCre - scale 1:85

EricWilliamMarshall reacted to a post in a topic:

Golden Hind by mfrazier - OcCre - scale 1:85

-

EricWilliamMarshall reacted to a post in a topic:

Golden Hind by mfrazier - OcCre - scale 1:85

EricWilliamMarshall reacted to a post in a topic:

Golden Hind by mfrazier - OcCre - scale 1:85

-

EricWilliamMarshall reacted to a post in a topic:

Golden Hind by mfrazier - OcCre - scale 1:85

EricWilliamMarshall reacted to a post in a topic:

Golden Hind by mfrazier - OcCre - scale 1:85

-

EricWilliamMarshall reacted to a post in a topic:

Golden Hind by mfrazier - OcCre - scale 1:85

EricWilliamMarshall reacted to a post in a topic:

Golden Hind by mfrazier - OcCre - scale 1:85

-

EricWilliamMarshall reacted to a post in a topic:

Golden Hind by mfrazier - OcCre - scale 1:85

EricWilliamMarshall reacted to a post in a topic:

Golden Hind by mfrazier - OcCre - scale 1:85

-

EricWilliamMarshall reacted to a post in a topic:

Golden Hind by mfrazier - OcCre - scale 1:85

EricWilliamMarshall reacted to a post in a topic:

Golden Hind by mfrazier - OcCre - scale 1:85

-

EricWilliamMarshall reacted to a post in a topic:

Golden Hind by mfrazier - OcCre - scale 1:85

EricWilliamMarshall reacted to a post in a topic:

Golden Hind by mfrazier - OcCre - scale 1:85

-

mfrazier started following Old Collingwood

-

mfrazier reacted to a post in a topic:

HMS Victory by mfrazier - Sergal 782 - 1:78 scale

mfrazier reacted to a post in a topic:

HMS Victory by mfrazier - Sergal 782 - 1:78 scale

-

Well ...... I thought things were going OK, but lately, I have been very tired and fatigued. I have been too tired to do anything. It was time to have my pacemaker checked ( I have a machine to do it remotely from home) so I sent a report in to the hospital. Shortly, the nurse called and asked me to send another. I did and then the doctor called and told me to come in because my heart has been in atrial and ventricle fribulation for the last 4 weeks 100 percent of the time. That explains why I get exhausted just getting out of bed. To make a long story short, now I will require heart surgery. On August 10, I will go to have a procedure called a cardioversion done to try and get my heart back in sinus rhythm ( they will put me to sleep and SHOCK my heart to try to correct the rhythm). That same day I will have some tests to determine what needs done to make me stay in rhythm. There are a couple of procedures that may help. I go to Cleveland Clinic in Cleveland, Ohio for my care and they are the number one hospital, in the United States and number two in the world for heart care. Wealthy people from all over the world go there for heart care, so I am confident that if anyone can help, they can.

-

It has been a long haul for me getting better, but I have finally. I have been very busy taking care of my wife. We lost her care giver last year, so I had to take over and that requires about 10 hours a day of my time. It doesn't leave me any time for anything else, but I hope to start back on the victory soon. Mark

-

mfrazier reacted to a post in a topic:

HMS Victory by Daliab - FINISHED - Mantua/Panart

mfrazier reacted to a post in a topic:

HMS Victory by Daliab - FINISHED - Mantua/Panart

-

mfrazier reacted to a post in a topic:

HMS Victory by mfrazier - Sergal 782 - 1:78 scale

mfrazier reacted to a post in a topic:

HMS Victory by mfrazier - Sergal 782 - 1:78 scale

-

Richard, Thank you for the kind words. I have had to put the victory aside for a while as there have been too many of life's little problems getting in the way. I hope to get back to it this winter. At the beginning of the year, my wife and I both had the Covid 19. We were so sick for months, but eventually got better. Yes, the directions are very poor, but I find if I study them long enough, things start to make sense. I too have been and am following several of the other builds on here. This has been a wealth of information and ideas. I am still second planking the hull and ready to cut the cannon port openings. This has been quite a project as I had to move several ports to avoid the bulkheads and still keep everything looking correct. I also found I had to change the height of the upper ports to get the deck height correct for the cannons. I love building this ship, but this kit has been a nightmare. The quality was poor and that was the biggest issue. I am only using the instructions ( term used very loosely) for mostly reference and using John McKay's book for my main references. I also had intended to put LEDs in the gallery mainly. I have the LEDs and the power supply but not sure I will use them yet. I too had a list of parts I wanted to order from Shape ways, but tried my hand a scratch building first and was pleased with my results and have cut my Shape ways wish list more than in half so far. I look forward to getting back to the victory. Good luck to you on your journey with Victory. Mark Frazier

-

mfrazier reacted to a post in a topic:

HMS Victory by mfrazier - Sergal 782 - 1:78 scale

mfrazier reacted to a post in a topic:

HMS Victory by mfrazier - Sergal 782 - 1:78 scale

-

mfrazier reacted to a post in a topic:

HMS Victory by Daliab - FINISHED - Mantua/Panart

mfrazier reacted to a post in a topic:

HMS Victory by Daliab - FINISHED - Mantua/Panart

-

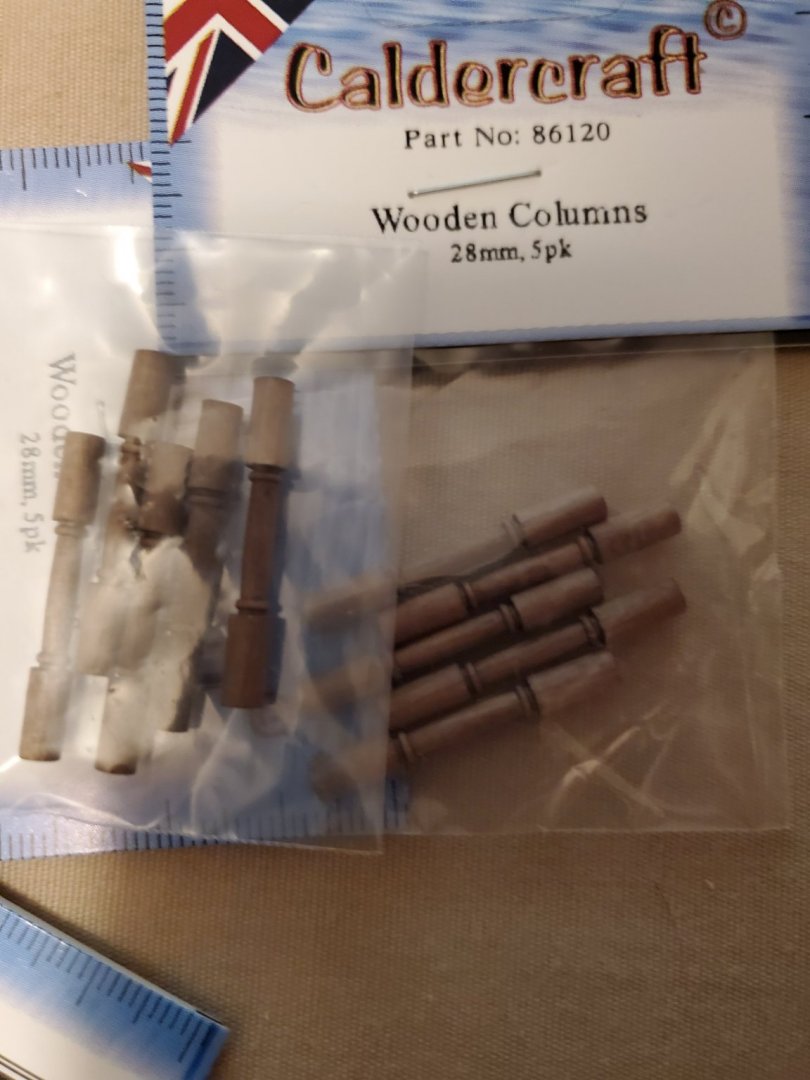

Well ...... I have been unable to work on my Victory for a while as several of life's task had been getting in my way, but I shall be starting back at it again. I am still doing the second planking on the hull. This takes a lot of time. On another note, over two months ago I ordered some parts for the Victory and they finally came yesterday. I ordered a few Caldercraft parts to make this build a little better. I ordered the Caldercraft figure head. The quality is so much better than the "thing" that came in the kit. I ordered the crowns that go on the end of the arms for the anchors (they are really small). And most importantly, the brass fire buckets. These are super nice and proper scale. I will blacken these and apply a handle to hang on the front of the rail on the poop deck edge.The kit came with wooden buckets, which were nice but twice this size. This meant there were fewer and they were too large for this purpose. The kit buckets will be good to place on the deck here and there. I also ordered some nicer columns that support the deck. I was not impressed with the ones in the kit. It will be a while before I get to these as I still have a good bit of planking to do. Mark Frazier

-

mfrazier reacted to a post in a topic:

HMS Victory by Daliab - FINISHED - Mantua/Panart

mfrazier reacted to a post in a topic:

HMS Victory by Daliab - FINISHED - Mantua/Panart

-

Thanks, I was a machinist all my life and was used to working where everything had to be within .0005 inches. This tends to make life almost impossible as I see a tiny gap that most people don't notice as a huge imperfection and problem. This is hard to overcome after 50 years of seeing the world one way. Being a perfectionist makes me super critical of my own work. In my lifetime, I have scrapped many things and started over that most people could not find any problem with. It is hard to change, but I am trying. Sometimes it takes a "normal" person to kind of convince me something is not as bad as I think. Mark Frazier

-

mfrazier reacted to a post in a topic:

HMS Victory by mfrazier - Sergal 782 - 1:78 scale

mfrazier reacted to a post in a topic:

HMS Victory by mfrazier - Sergal 782 - 1:78 scale

-

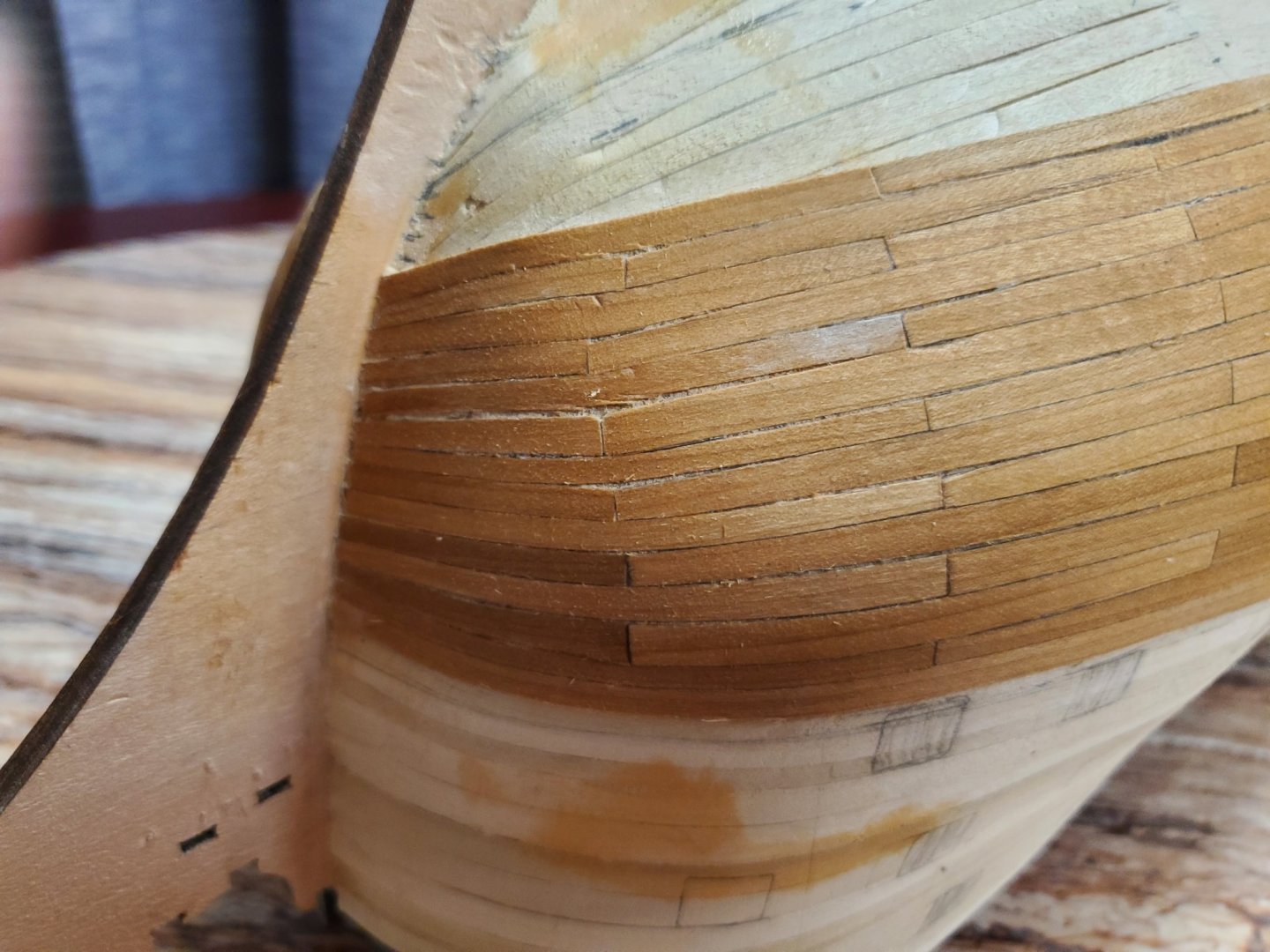

Thanks for the compliments. You are correct OC., things will work out. Everything always works out, one way or another. It is a fact of life. You just have to have some faith and keep trying until it works hopefully in a way you are comfortable with. You are correct, ErnieL. I hadn't and still don't plan to copper the hull. I really don't know why, but I just don't like the look of the copper. The only way I would copper is if I really mess up the planking beyond repair. But then I would know what was under the copper and I could not accept that. Edwardkenway, that is good advice. Thanks. Sanding made a great improvement on how everything looks and I know there will be more sanding when the planking is done. I did a preliminary sanding to see if this crappy wood was even going to look close to good and I think it may. So ....... with that, I shall push on and see how this all works out. The most important thing is that I am enjoying my attempt at building this ship. Mark Frazier

-

mfrazier reacted to a post in a topic:

HMS Victory by mfrazier - Sergal 782 - 1:78 scale

mfrazier reacted to a post in a topic:

HMS Victory by mfrazier - Sergal 782 - 1:78 scale

-

mfrazier reacted to a post in a topic:

HMS Victory by mfrazier - Sergal 782 - 1:78 scale

mfrazier reacted to a post in a topic:

HMS Victory by mfrazier - Sergal 782 - 1:78 scale

-

mfrazier reacted to a post in a topic:

HMS Victory by mfrazier - Sergal 782 - 1:78 scale

mfrazier reacted to a post in a topic:

HMS Victory by mfrazier - Sergal 782 - 1:78 scale

-

My goal was to stain the hull. I have seen a build that stained the bottom of the hull and painted the top half. It looked okay but I was wanting to stain the complete hull. I need to think on this I guess. I really regret not buying new would now. ( the last would I ordered took 2 months to get here.) Mark Frazier

-

I got half of each side planked and did a partial sanding to see how it will look. I am happy with the sides and the stern, but not so happy with the bow. I wiped it with a damp cloth to see how it will finish. There are some small gaps at the bow. I had to do some edge bending and this wood doesn't want to edge bend very well. It may look better if a gel stain is used. The only other option is to strip the bow back and redo it. ( I hate the thought of that). Mark Frazier

-

I am using gel CA glue for the second planking. I used wood glue for the first layer and most other things, but I kind of like the gel CA glue for planking. You just have to be quick because you only have a few seconds to lay it correctly and then it is pretty permanent. If you try to remove it, many times it will pull part of the base up also. It is a little tricky but works well. Mark Frazier

-

Thanks OC., I guess this is the same kind of problems you could have scratch building. There is so much of this kit I am NOT using, it will be more than half scratch built by the time I am done. I know I am going to have a couple "springy" planks as they will be to thin when sanded. I will inject glue into the springy spots with a hypodermic needle to make them solid. I will just do the best I can with what I got. Mark Frazier

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.