-

Posts

48 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by sir francis haddock

-

The next part on the instructions is the belay posts. This was where the 1 to 1 deck plan fell apart a bit. I followed the plan with placing them, then watching the YouTube guide and the pictures in the instructions saw that the foremost post needed to be much further forward.

-

The windows ended up being so small that cutting them out didn’t matter. Unless a strong light is put close they just look black.

-

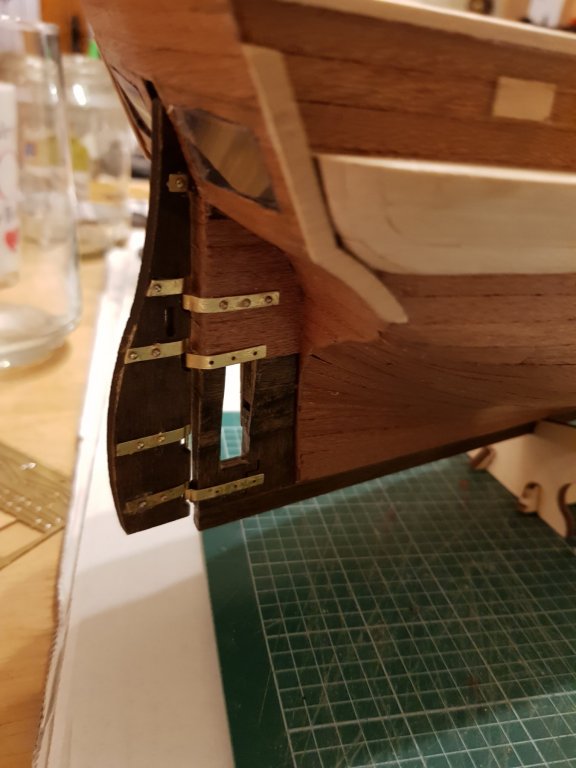

In the instructions the windows are painted on, I didn’t think that looked so good. So I decide to cut out the windows and put plastic to glaze them instead, thinking this would look better. The windows will be covered by a wooden frame so it did not need to be so neat. Next was the rudder. This was a bit of a challenge, getting the cut down pins into the metal strips took some time due them flying out of the tweezers. I lost so many of these.

-

Hi Scott the holes have 3mm brass portholes to cover them and where they are is from the plans. I think they were put where they needed light below deck.

-

Putting large permeant holes into all my hard work with a power tool was a moment I was glad did not go wrong.

-

I traced the deck potholes from the 1 to 1 deck plan, I thought this would be easier than measuring out every position and used a normal electric drill to the pit the holes in.

-

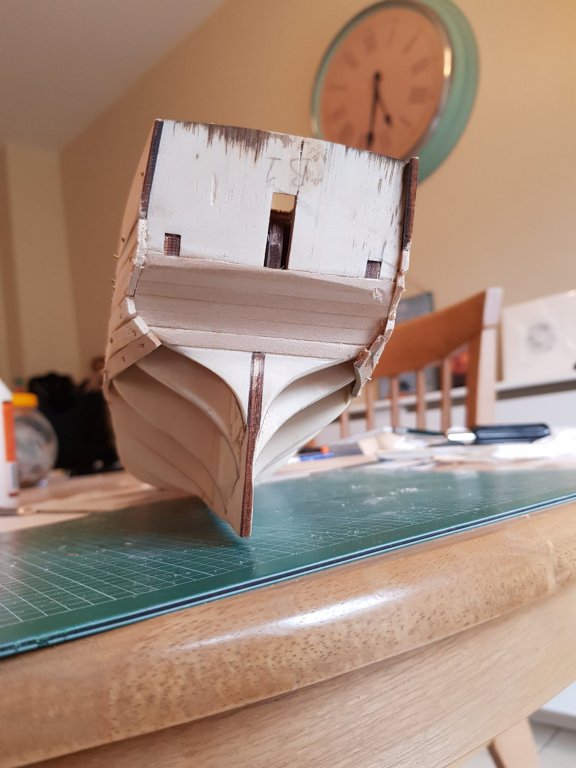

The bumper sanded and finished and the rail on. I painted the back where it had snapped with brown acrylic paint, it looks better but think I will paint the whole piece to match.

-

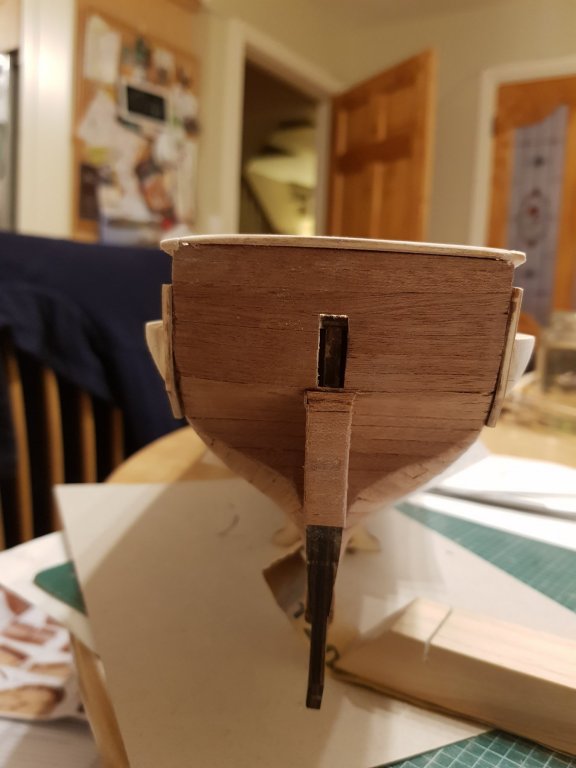

I tried to cut down the 2nd layer where the keel goes in but even with a new sharp knife blade and going slow it splintered. If I can remove this part I have enough left to replace it. The other side looks a lot better.

-

Next is the bumper, doing this used up a full tube of superglue and a lot of sanding to get the angle. I used the front piece of the keel to try to get the gap at the front as close as possible. I think it went ok.

-

The wood for the 2nd layer is very thin and brittle and with the contact glue sticking instantly it was hard to tapper it. There is a limited amount of this wood so I didn’t want to have to pull it off.

-

Thanks Tom, the planking instructions seem a bit abstract at 1st. It wasn't until I was actually doing it that it then made sense, after the mistakes .

-

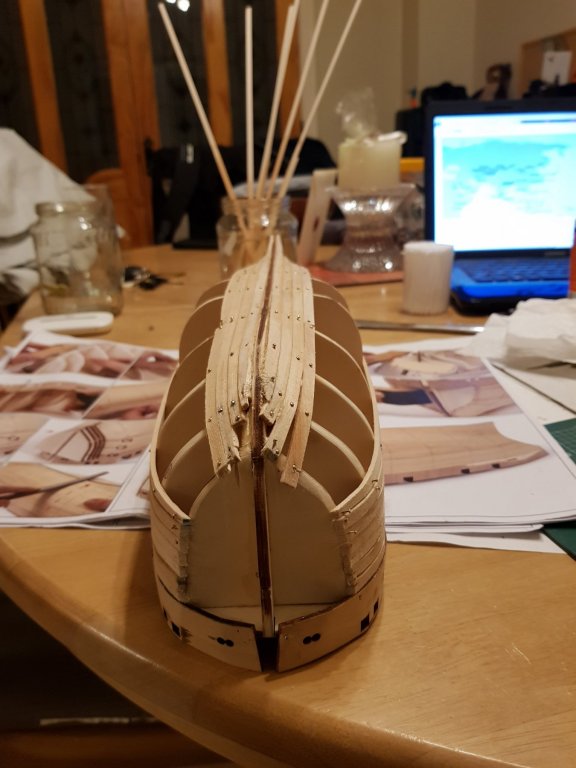

The planking all done, edges tidy, some gaps. Nothing to big that filler cannot fix. Am amazed it all came together and looks like a hull. The instructions and video say to leave the pins in but I thought it would be easier to sand if I took them out. 6 pieces of plywood for the bow reinforcements and lots of sanding. Was braver this time and used a heaver sand paper that really saved a lot of time. I also discovered that sanding filler is something best done outside.

-

The bottom of the hull planking for the prow I felt ended up untidy, but I was able to sort of clean it up. It’s a learning experience and will be covered by the 2nd layer. The YouTube videos skipped over this bit.

-

The planks for the bottom of the hull needs to twist 3 ways and I needed to find a way to soak all the length of the planks in one go. The bath was the only place I have big enough. But the wood floated, had to enlist some extra crew to hold them down.

-

I did both sides at the same time because I read doing one side at a time could warp the hull. Soaking the planks bending getting the pins in the right place were challenging but ok to do with some patience. So far I’m having a great time enjoying it coming tougher.

-

Next is the planking. This and the rigging is what I expect will be the most challenging parts. The information I found was to start at the top work my way down, then go from the bottom up and meet in the middle, pinning and gluing as I go. The stern planking was so easy, short planks with no bends. But trimming the ends with a hobby knife and nothing to rest against is something I think will happen a few times with this project.

-

Sanding the reinforcements took some time to get flush with the false keel. Then the sides to be bent, stained and attached (on the YouTube video it’s called the armour). I live in southern Ireland and there are not many model shops around. Most of the tools I’m using have to be ordered online so I ordered an electric plank bender and small tool kit that had a pin pusher, which were used for the 1st time on the armour. They were easy to use and no problems yet.

-

Contact glue is not the easiest thing to use... But it worked after some trial and setbacks. The deck was easy to clean up, pencil the lines and sand. The mirror (board at the back of the deck, not sure of the names?) I noticed has a slight curve around the deck. So I flexed it to see if it would bend, thinking I might have to soak it. It snapped. After I glued it back and stained it I had a big white line of non-stained glue. Will deal with later.

-

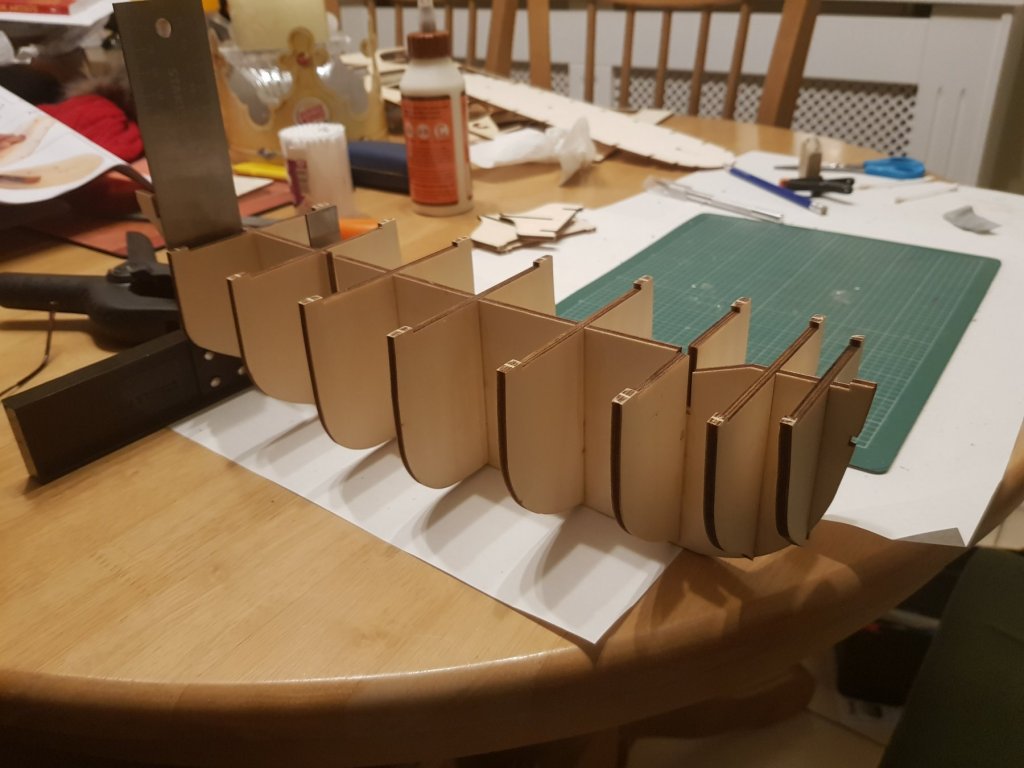

Hello, this is my 1st build. I had only ever made airfix kits in the past (a long time ago) and they always went wrong, with the wings dropping off and the like. I found the Terror kit and thought this would be a good start. I could practise and discover if (1) I could do this, (2) enjoy doing this and get the equipment I need as I am going along. So everything is new to me and I am sure there will be lots of mistakes. But I hope lots of fun. The skeleton went together easily. The instructions are more pictures showing the order to make it with very little actual instruction. Without the YouTube guide I would be totally lost.

-

kit review 1:65 HMS Terror - OcCre

sir francis haddock replied to James H's topic in REVIEWS: Model kits

Hello first time here. Just got the terror, it is my first build. Looking forward to starting it.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.