-

Posts

257 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by AlexBaranov

-

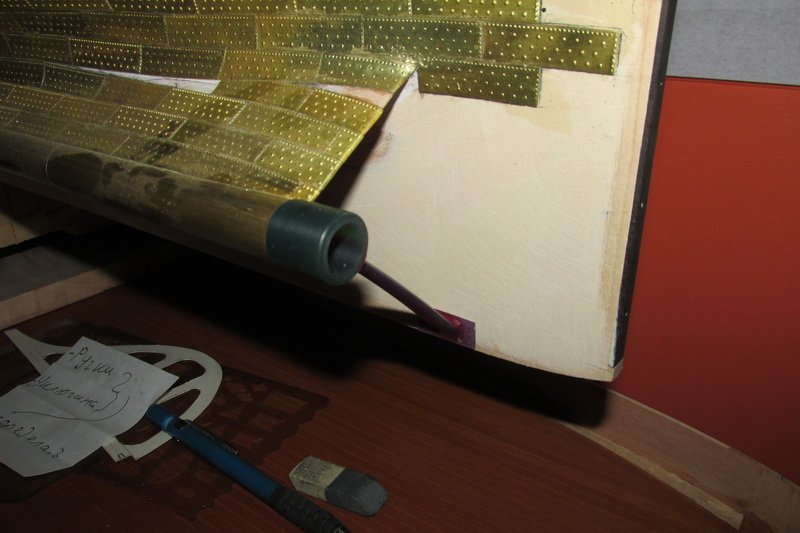

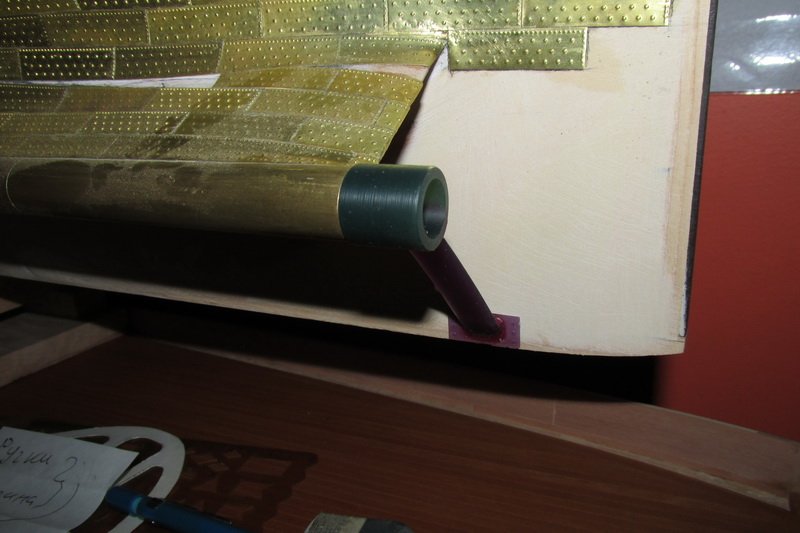

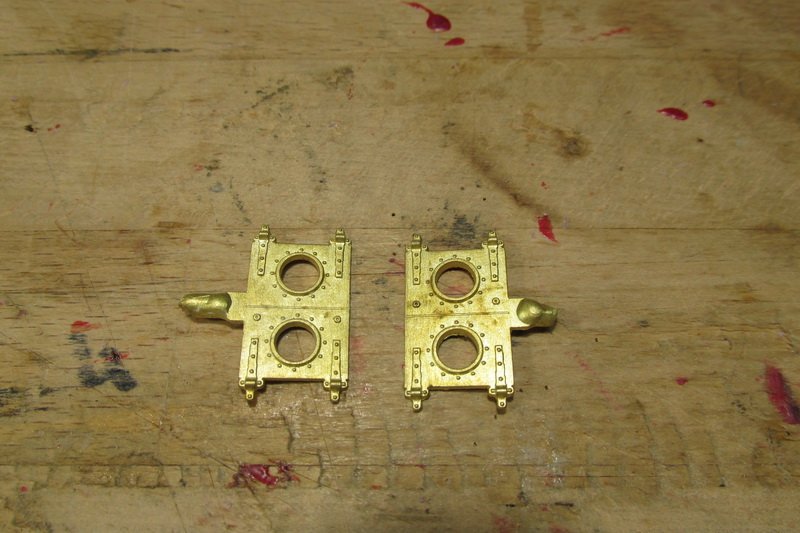

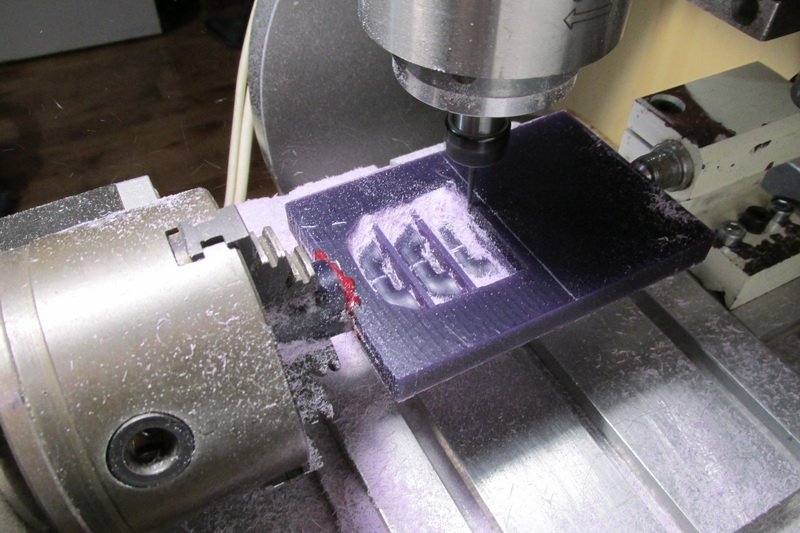

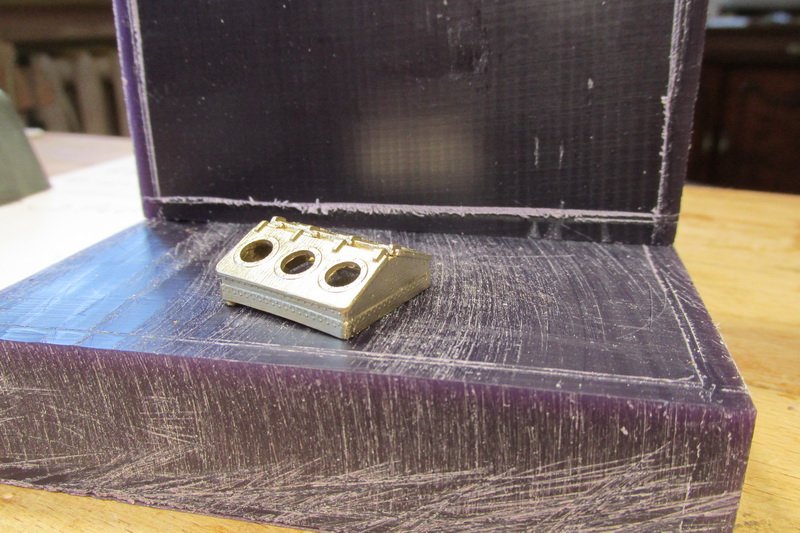

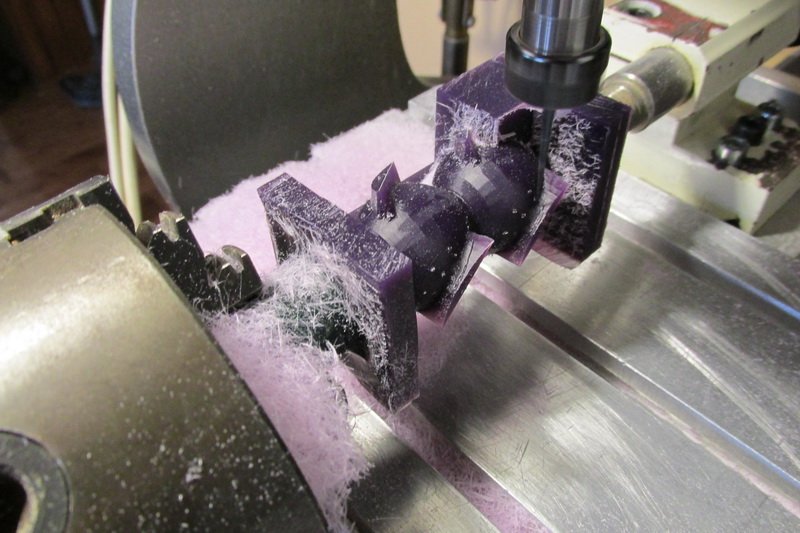

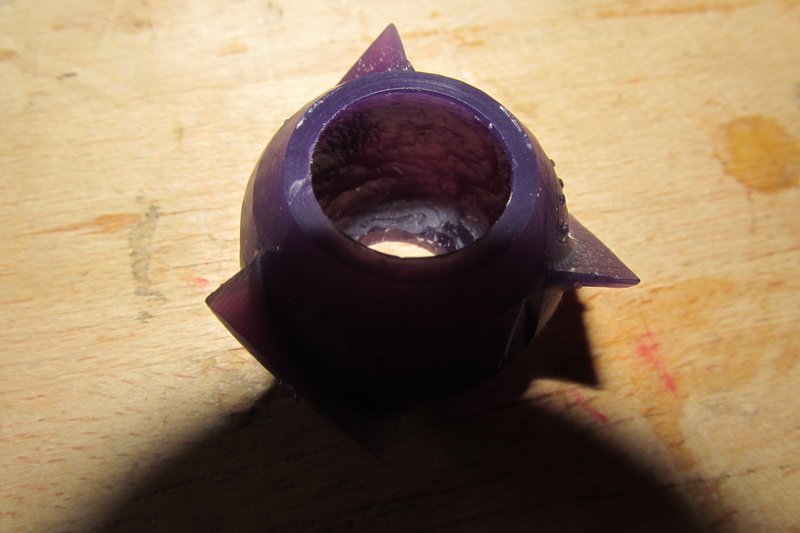

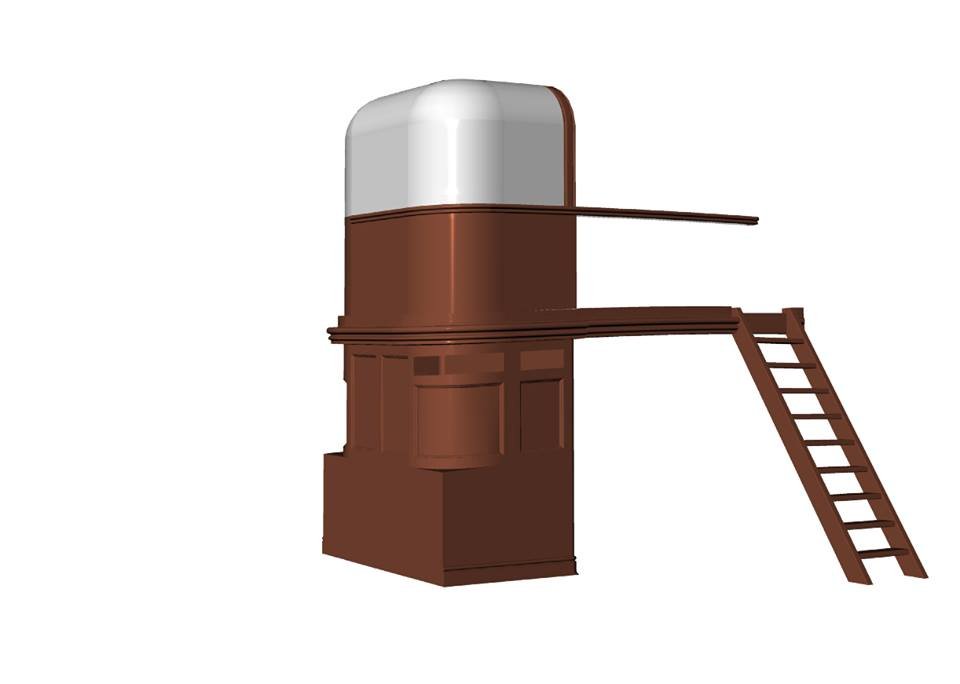

A davit model prepared for baking in a mother tongue (vulcanization process) Forms for the vulcanization of matrices I make on a large milling machine from aluminum alloys (D16T)

-

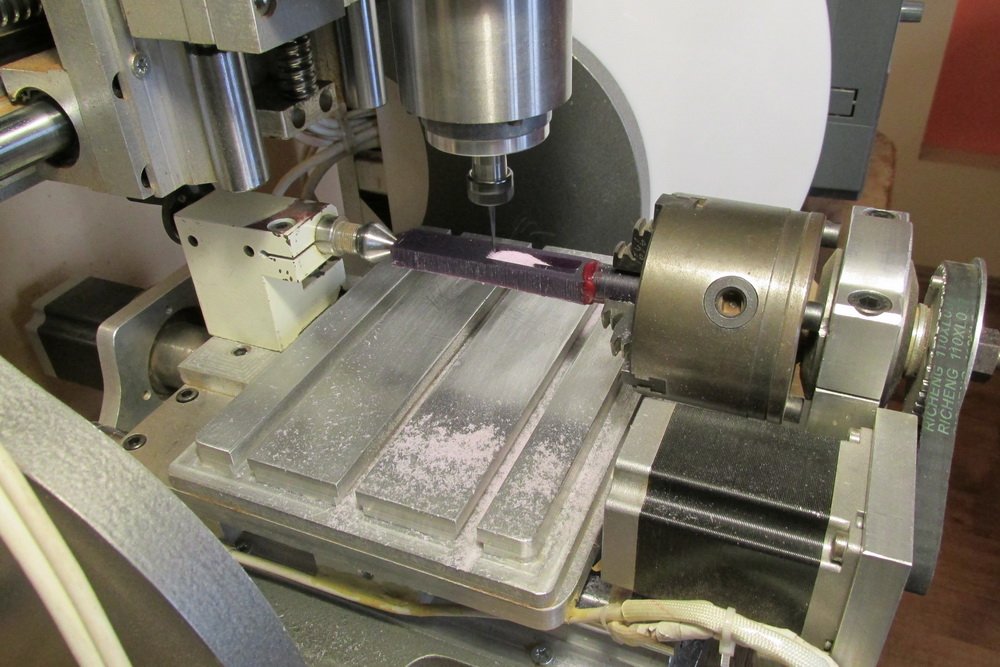

My matrix and my workplace. I began to multiply the mass details. My injector, very old, many times remade and modernized. However, it works very well despite the age ... Мои матрицы и мое рабочее место. Я начал размножать массовые детали. Мой инжектор, очень старый, много раз переделанный и модернизированный. Однако работает весьма исправно не смотря на возраст...

-

If you do not mind, I'll sometimes take notes on the photo ... In my opinion, it's more informative than the general text. This forum is also viewed by my compatriots (Russian-speaking colleagues), so I will make notes in two languages. I met copied photos from this forum in other forums. Let. This will take into account the interests and conveniences of more of our colleagues and adherents of our hobby, art, sports of our way of thinking and living at last.

-

Oh! Yes ! How right you are! The caster is really a godsend. I use the services of two casters. The first caster does the job flawlessly. However, his work costs 1 dollar for 1 gram of casting. This is very expensive, so here I'm only giving away relatively light parts and the master of the model (for further copying (multiplication)). The second caster is not that good, but his prices are cheaper by almost half. Sometimes spoils my wax patterns. However, I managed quite well with the last job. There were large details with very thin (0.9) walls. However, I can tell you about the general misconception about the origin of most languages. This topic (if you are interested) we will discuss in personal correspondence (not in this forum). I am ready to tell you very shocking facts.

-

Hey. I speak and I think in Russian. The Russian language is very expressive and diverse. You certainly will not believe, but all the languages of white people are basically based on Russian sources. On Earth, there are only four main languages (I do not consider two more separate languages (very few people speak these languages)). All other languages are dialects of Russian, Chinese, Swahili and Lakota. The Ukrainian language (I do not use this language (but I know)) is also a dialect of the Russian language. It has all the basic characteristics of the Russian language, and the letters have more than a Latin. I use the GOOGLE translator to avoid making grammatical errors. So, this time the trunks are made correctly. I found a mistake in making the first batch of guns. The whole reason is soft wax. I can not avoid deformation of the workpiece when clamping in the chuck of the machine with subsequent four-sided processing. The breech of the gun is closer to the attachment point, so here the deformations are within one hundredth of a millimeter. However, the end of the trunk deforms much more (1 tenth of a millimeter on each side). The only way to correct the mistake is to change the barrels on a lathe and replace, solder to silver. I continue to remodel (not correct and spoiled wax models) and to make new details. In the near future I will manufacture the matrices based on the previously obtained master models. I will begin to reproduce mass identical parts (the method of lost wax).

-

Artillery is made completely (two sets), a master model is made and it is possible to start making matrices for the grinding of parts (from injected wax).

-

This is an ordinary 3D engraving. I make parts by the method of lost wax. All the details I do myself. Of course, I do not cast myself. For this, there is a caster in a handicraft workshop. I produce part models and this is the most difficult part of the process. Of course, I will process brass parts with several chemical solutions to obtain an elegant and realistic appearance.

-

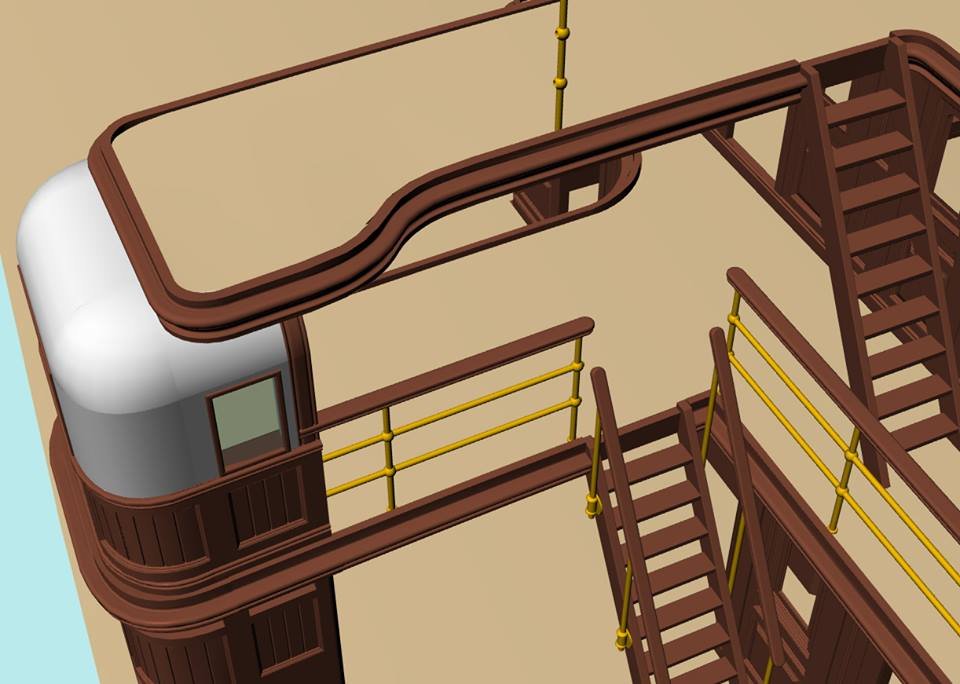

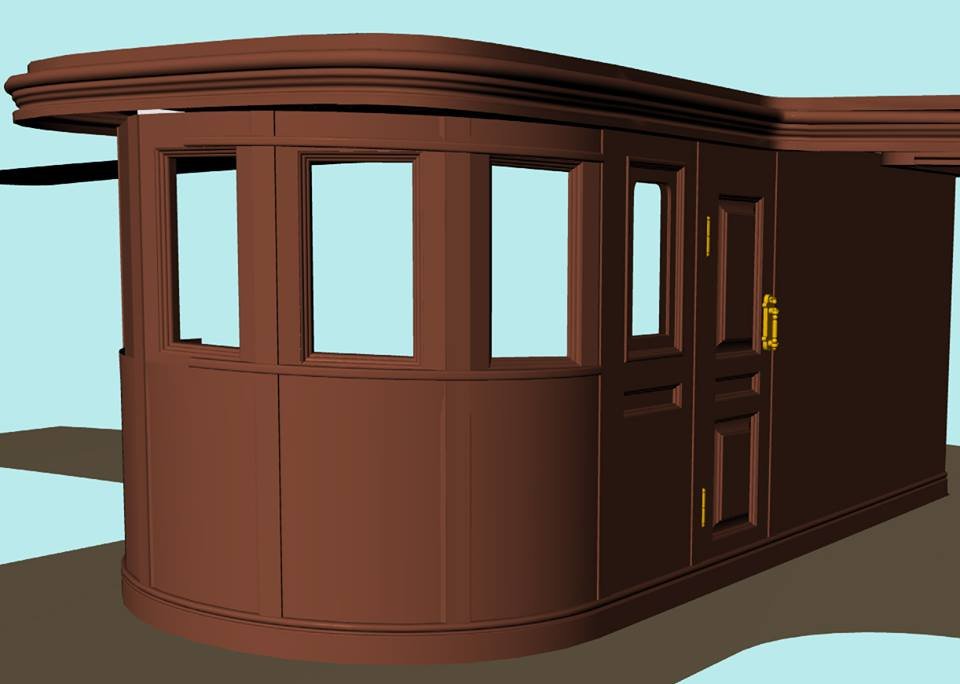

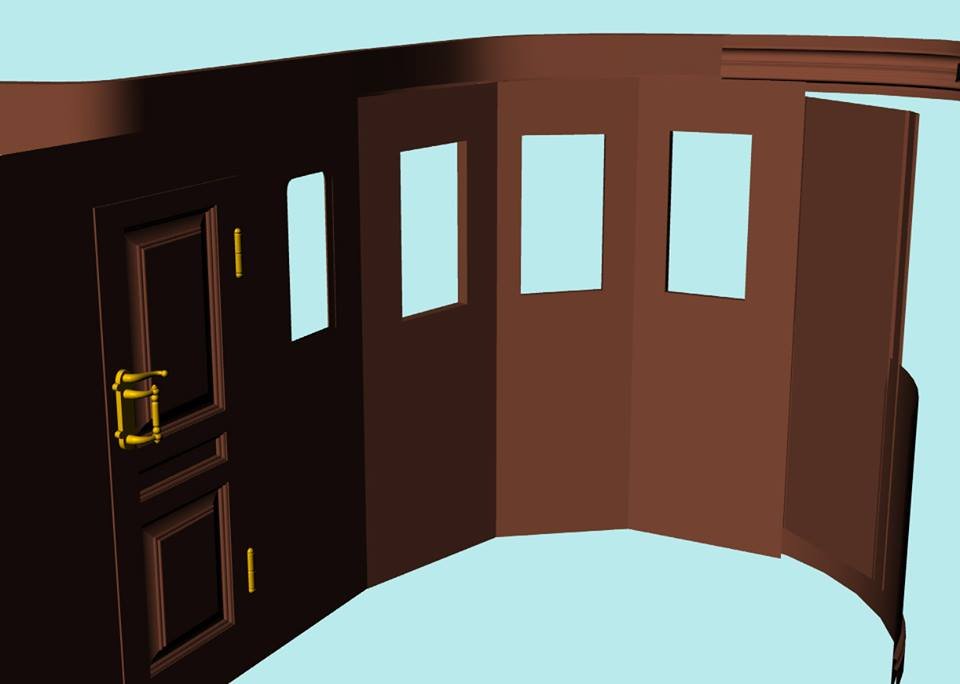

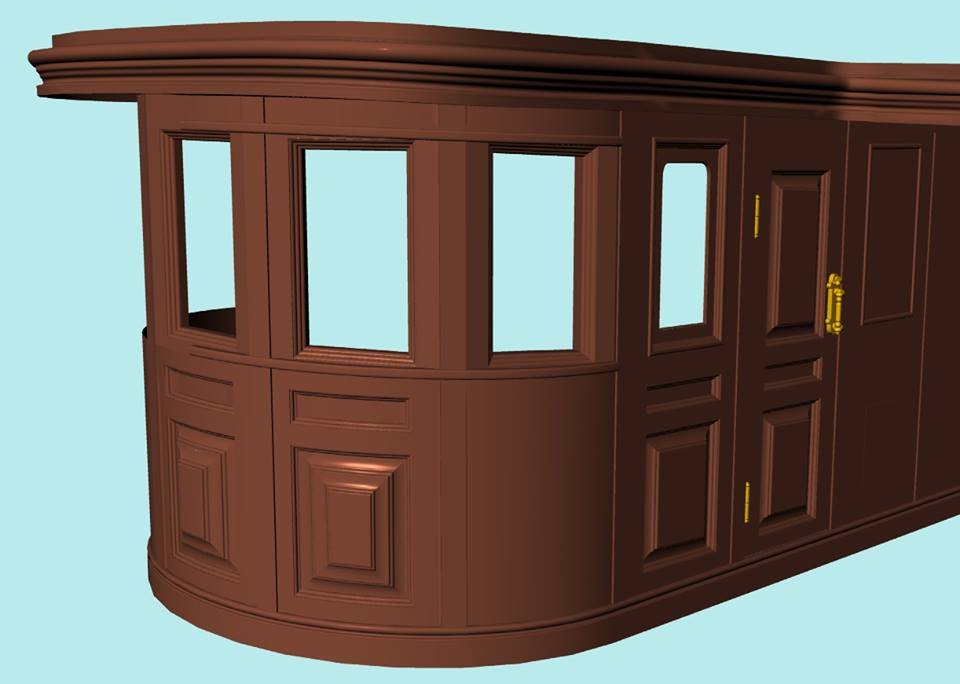

Finish doing 3d model of the bridge. After the completion of the three-dimensional wax patterns, I will begin to make a bridge, an imperial saloon and a galley.

-

Alex welcome! It has turned up, but I can not attach a photo on the avatar for personal settings! Thanks, I'll try to figure out until later look with pleasure! : D Cheers turned to the photo! In the hands of our master BelPul to Novosibirsk - Alexander Nikolayevich it just behind me!

-

Hi Pete I'm sorry, that did not respond in time ... So, this engraving milling machine was built on an individual project for me. It is not produced in firms and factories. Compared with industrial machine tools, my machine has many advantages. Machining accuracy is much higher margin of safety stock has tripled compared with the same industrial machines. However, the component parts (screws, guides, motors), all made in China. The machine has a powerful monolithic structure of metal 20 mm. The machine is heavy and steady.

-

деятельность в области изменения имеют лучший отдых ... Первый розыгрыш, затем фрезерные работы ... и сборка деталей.

-

Of course. Times are changing, changing tools and technologies. It needs more specific knowledge and experience. 3d printor has a much greater capacity than the Range 3D engraving milling machine. However, this is only for wax models (lost-wax casting only)

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.