-

Posts

257 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by AlexBaranov

-

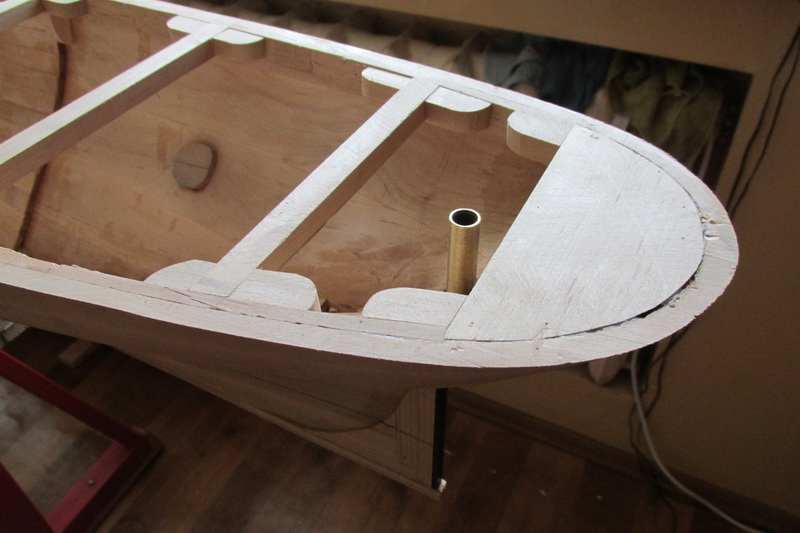

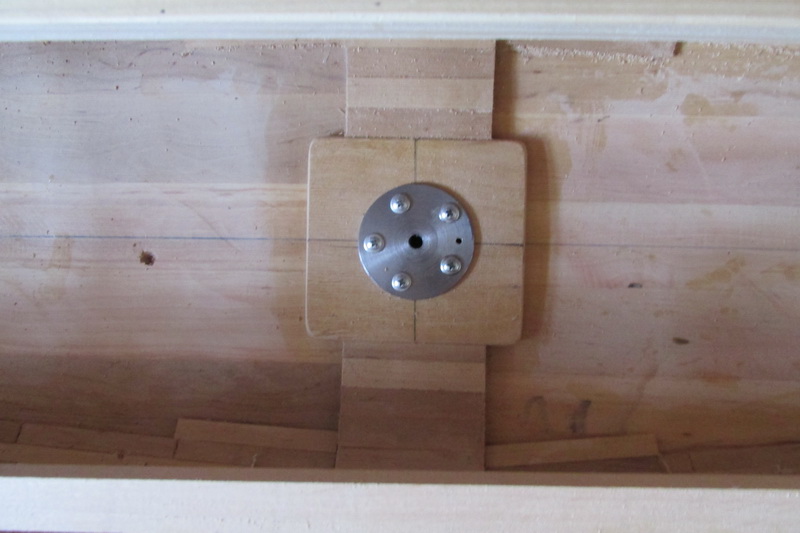

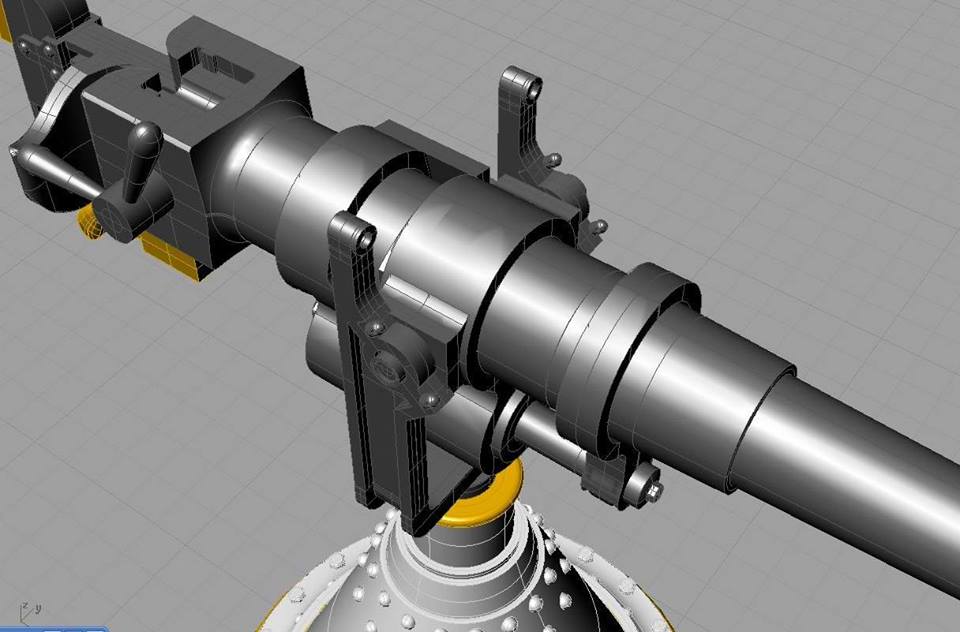

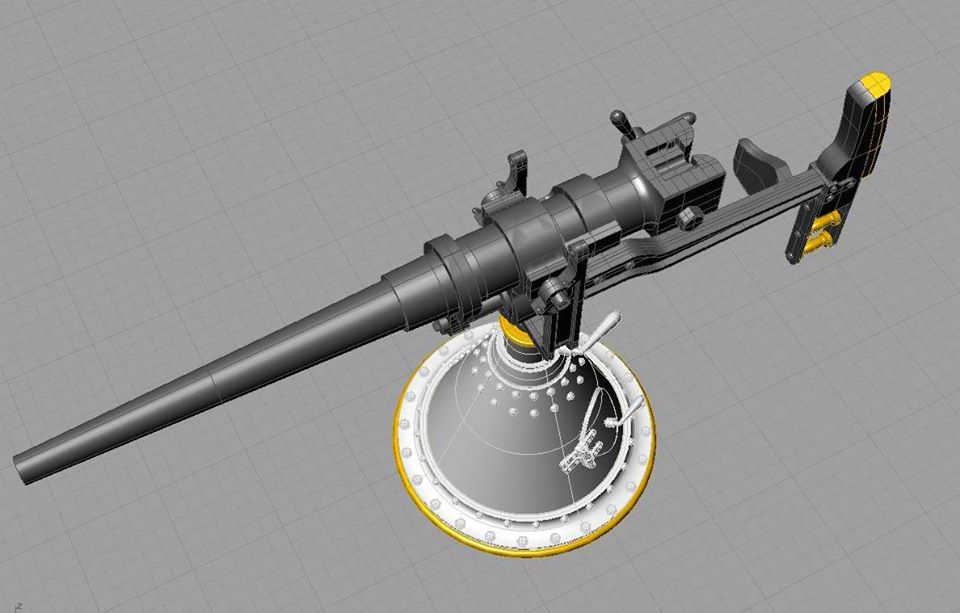

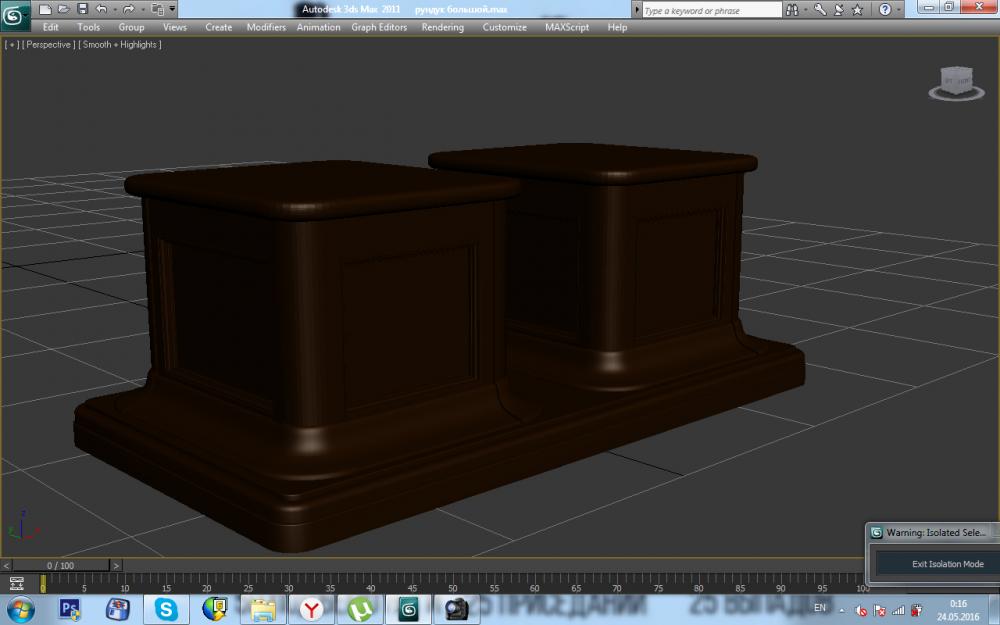

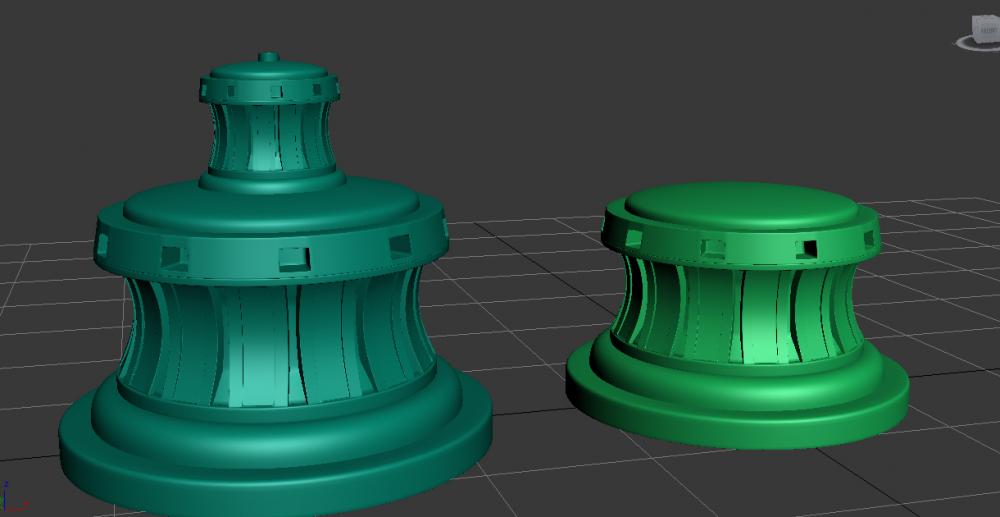

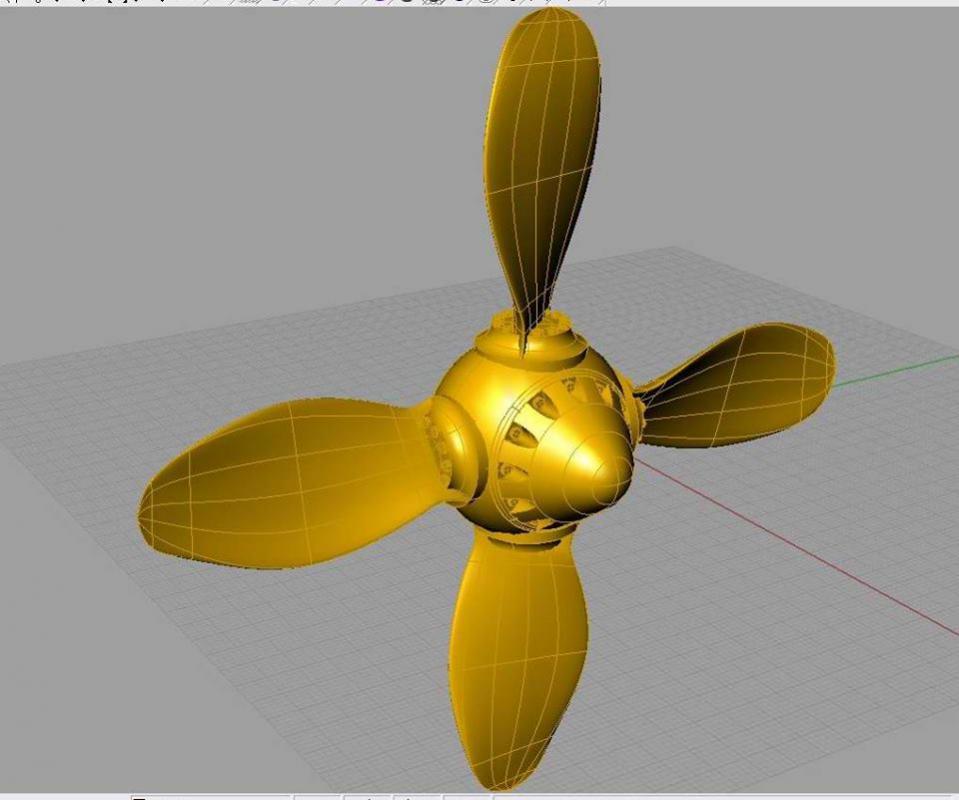

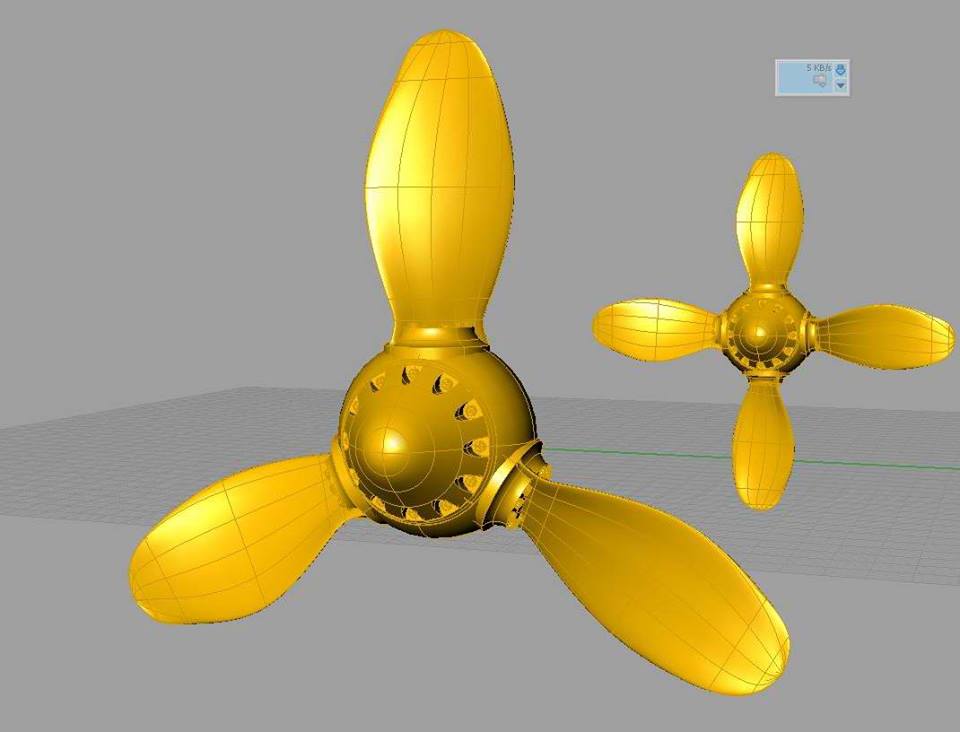

Manufactures fasteners for the model. It must be securely and efficiently. Just do fairleads and propeller shafts.

-

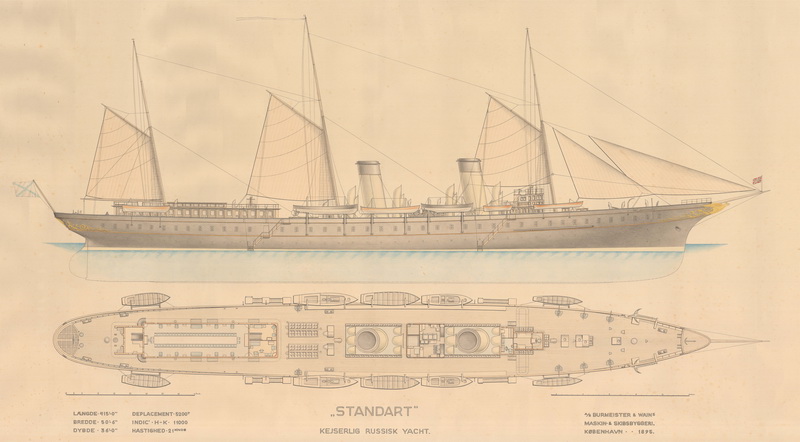

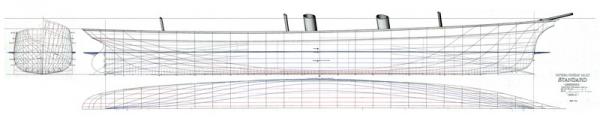

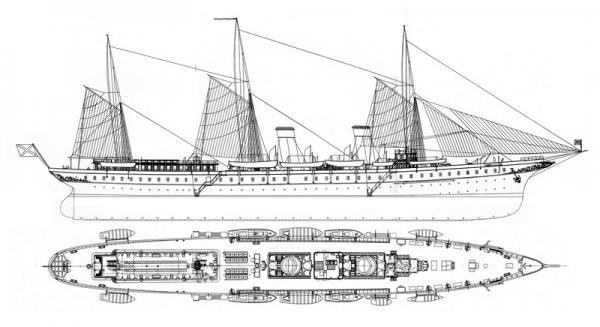

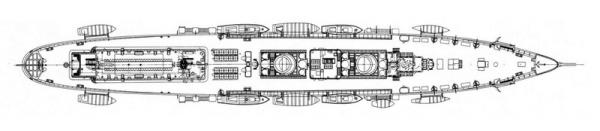

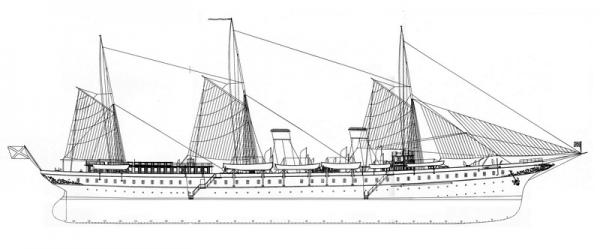

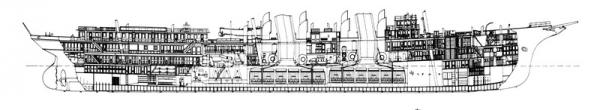

Found drawings of higher quality. In the drawings, the forum in a small file. If anyone should be I can provide large files individually.

-

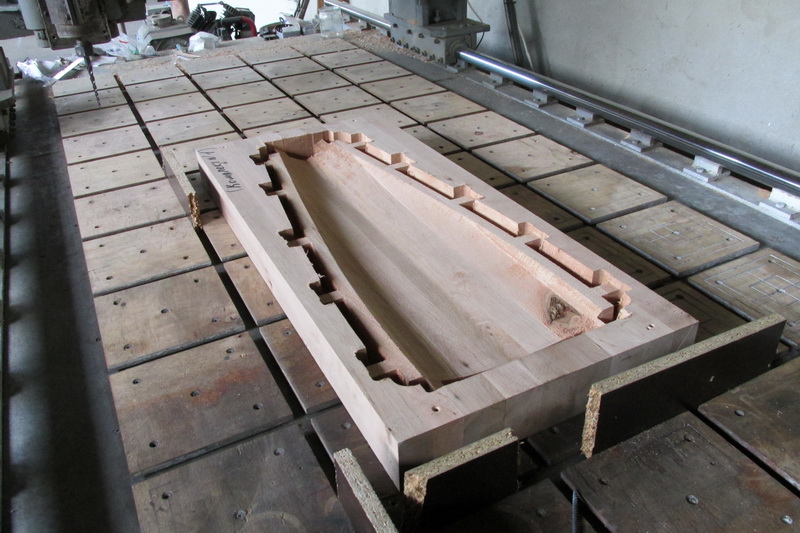

For the two buildings (calculation according to the program) took 64 hours. However, I accelerated the flow. Upon 4 days 16 hours a day. 20 parts processed. The average size of 700Х300Х90 mm

-

Yes, it really looks like ... But on a fantastic result too early to speak. While all invented goes according to plan (no more). Let's hope and try to get an excellent result. I'd like to ...

-

Yes indeed. This is the old Soviet-style radiators. However, it is not flat (in a building). This is my workshop in my villa. The area of the workshop is almost 30 meters. Places will be enough for two ships such as the Standart.

-

Hi Tom. In the past, I built three similar models of the imperial yacht Standart. Includes (1: 100) model for Peterhof Museum. And the two models in the scale 1:75. However, these models are far from perfect. I now have the technology and experience. I pretend to build the best and most detailed model of the ship (as possible). Small scale does not allow us to show the details in detail, moreover, the viewer does not perceive the environment (healthy eyes with good eyesight). Let's not talk about people who have poor eyesight. Scale 1:48 is really quite good. The ship looks not a toy and very solid. However, the larger model would be excessively large. As I mentioned, the quality of the model will try to make perfect. In this topic, I will show the progress of construction and technology in more detail (more than Cumberland).

-

I would like to leave one of the ships for me . However, if a lot of money to seduce me, I'm selling. Yes, you are absolutely right. The second copy is significantly offset the cost of production of the first-born.

-

Selecting a program depends on the file being processed. I use Art Cam also (to create files and control programs).

-

Hi Greg. Yes, of course, professionals (my friends and colleagues) which is not very much, often used method for the simultaneous construction of two ships of the same type. The fact is (and this advanced modelers know) that there is 60% of the work on which the model is not finished. Before you make the item, you need to create tools, tools, software, etc.. To work was justified, it is necessary to do very small wholesale. Very small wholesale, we have two models. However, these two models so you can make a unique (use a different style for the same item). A simple example ... in order to start production of guns (say 100 mm), I diverge a lot of work and money. However, to create one or 100 guns, the amount of labor will be the same.

-

Thank you. However difficult it may be a very strong heat ... Concept model (to complete) designed to trifles. See further. it will be interesting.

-

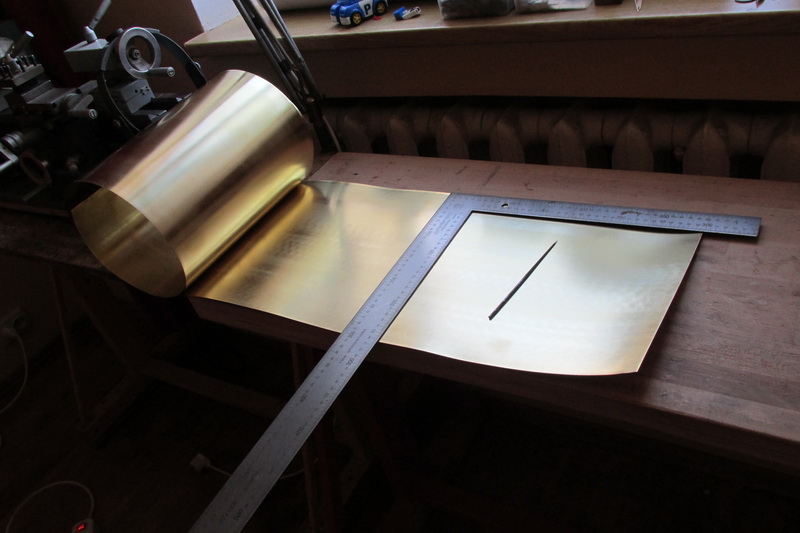

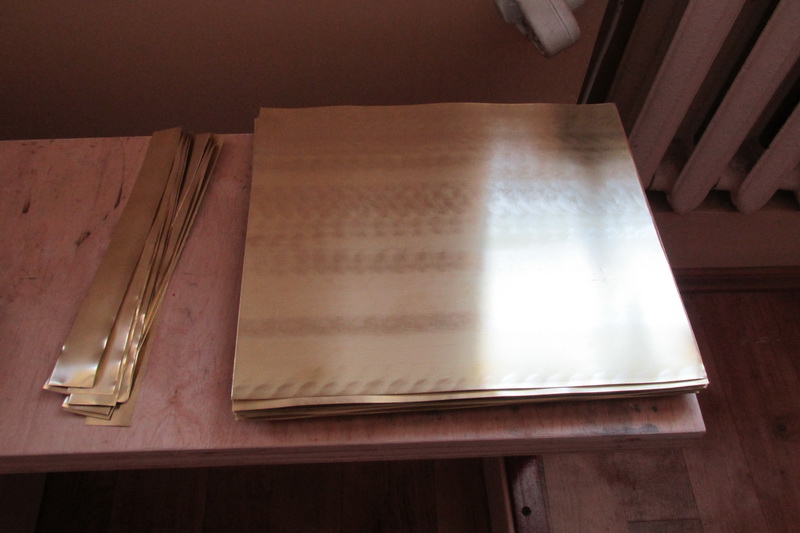

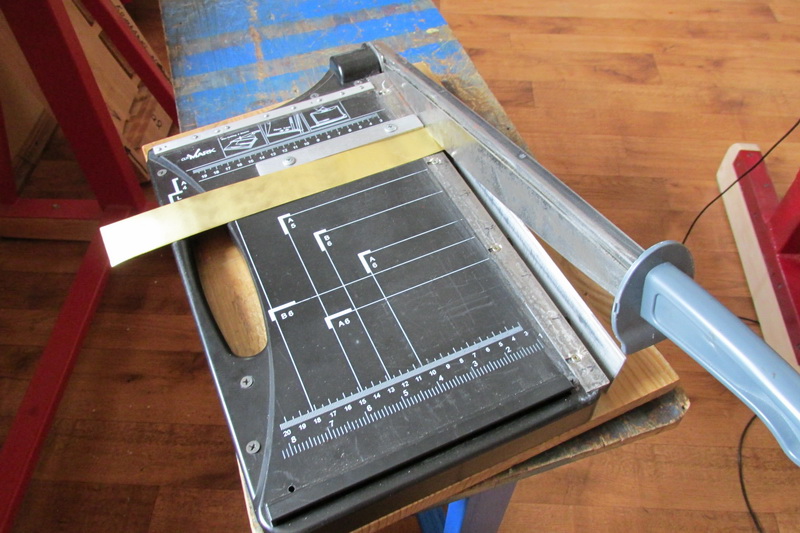

Along with the main work on the body of the device, prepare brass sheets for covering the underwater hull. I bought the usual paper guillotine but replaced the knife and a table on a solid carbon steel. The sheet thickness of 0.3 mm. Guillotine blades with new cutting very precisely and as a hot knife through butter.

-

After making all the details, I processed by grinding them and started to build. I used ordinary PVA glue.

-

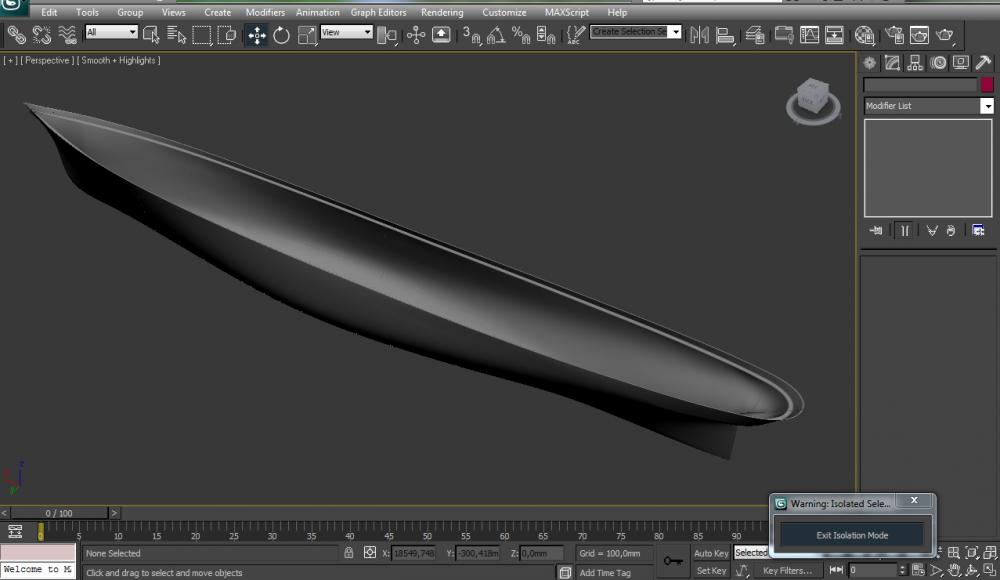

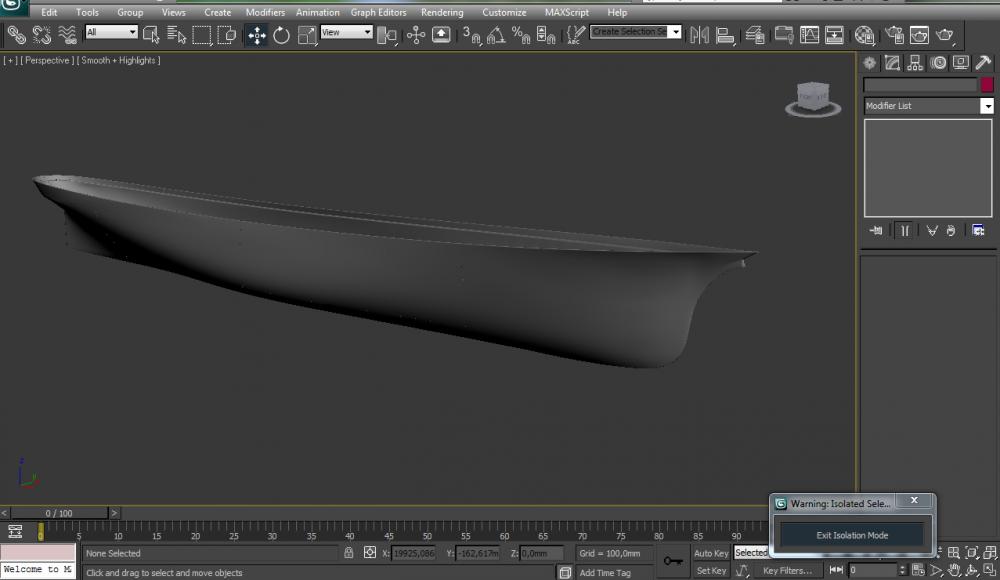

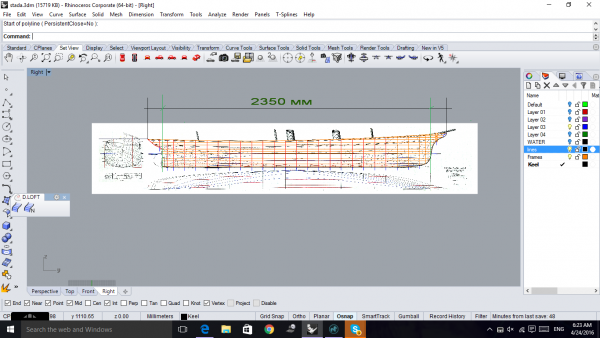

It's time to materialize virtual development. Thus, in the construction of two identical spacecraft to the body size of 2350 mm (between perpendiculars) I ordered the joiner bars for housing, because at home (without equipment) to make this work is not possible. I used alder wood. Total (for two vehicles) 20 parts (with the largest size details 9000H300H900 mm). I rented my friend big CNC milling machine.

-

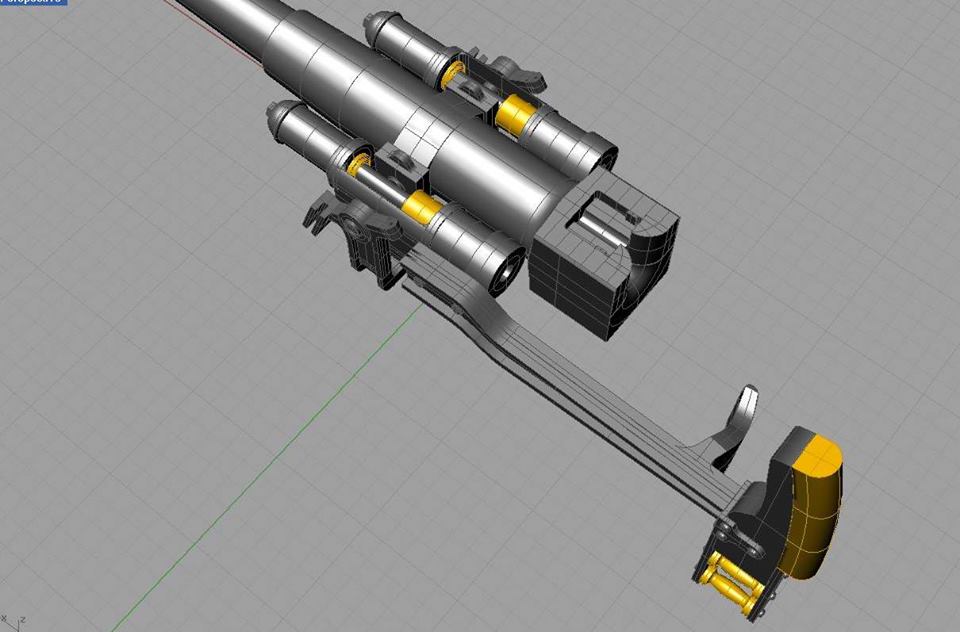

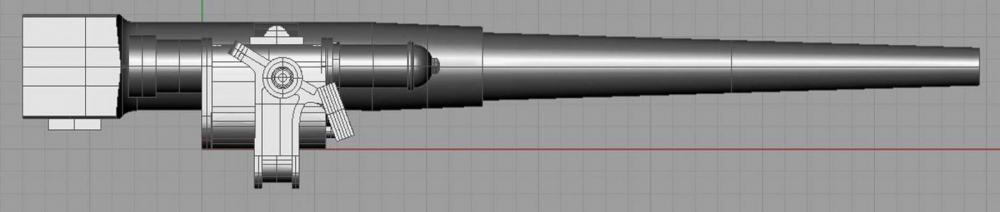

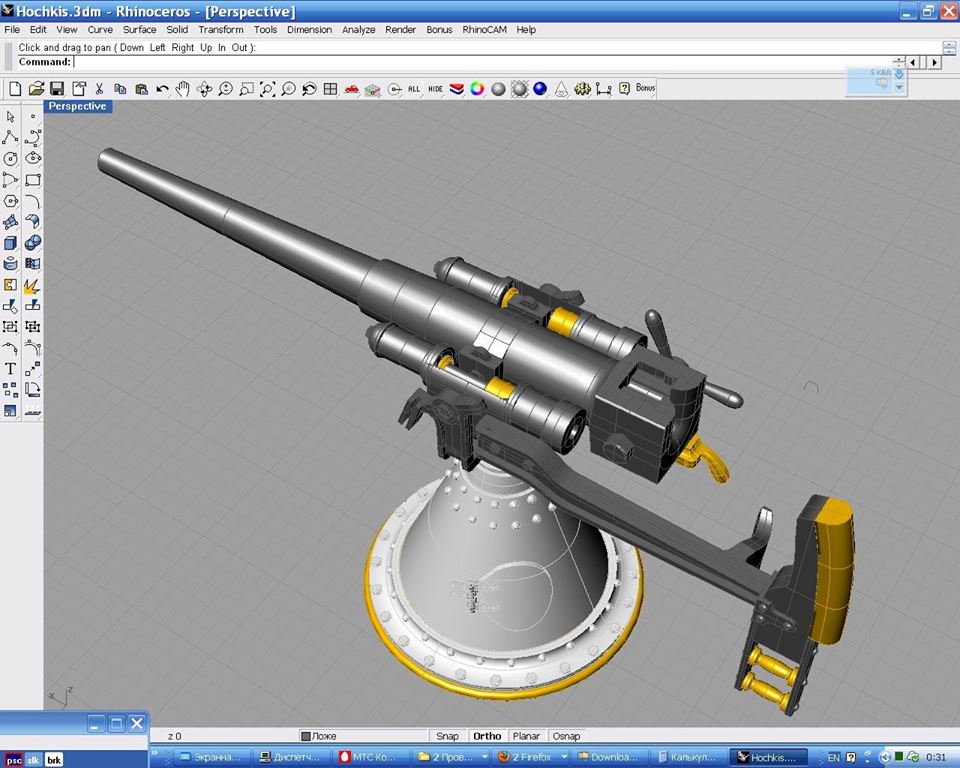

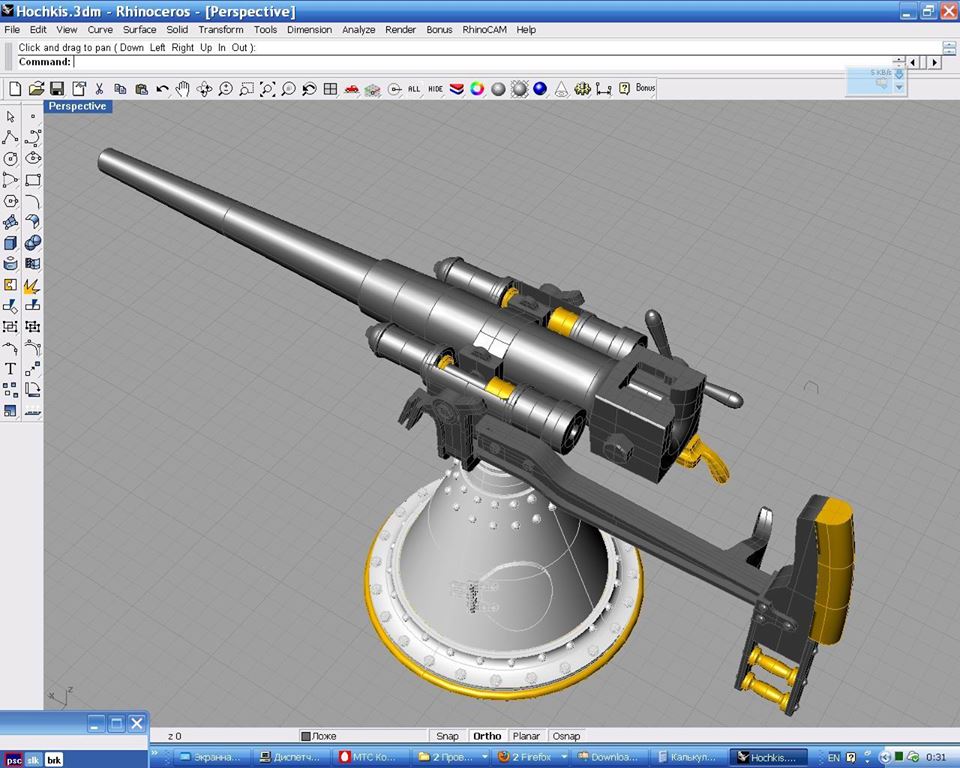

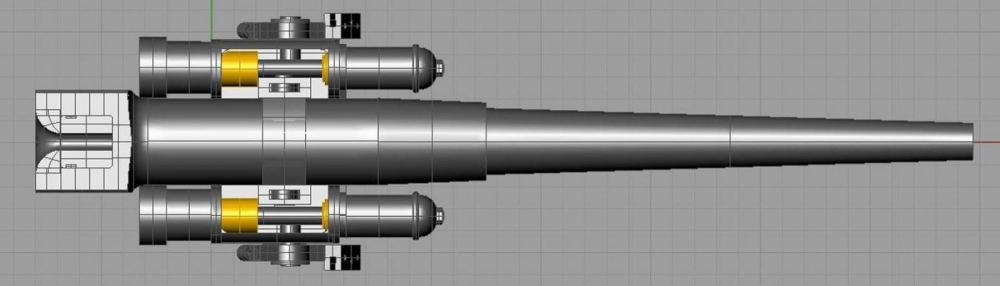

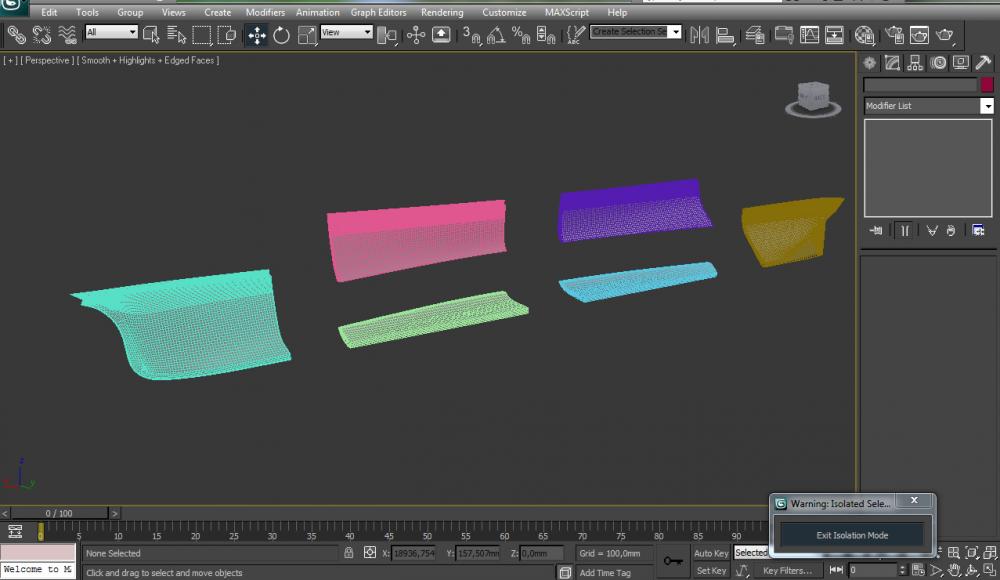

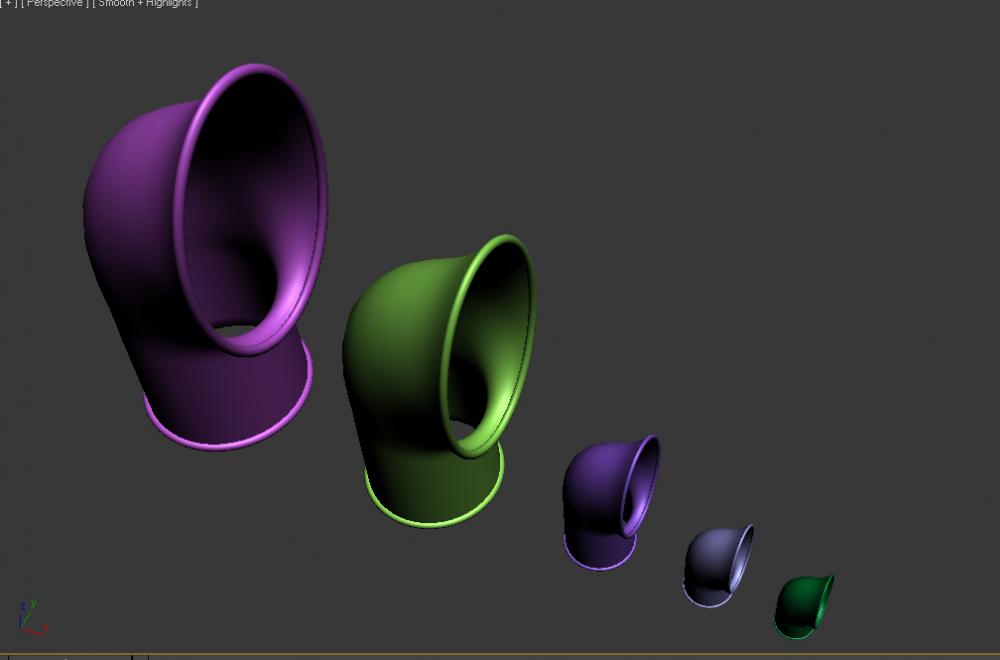

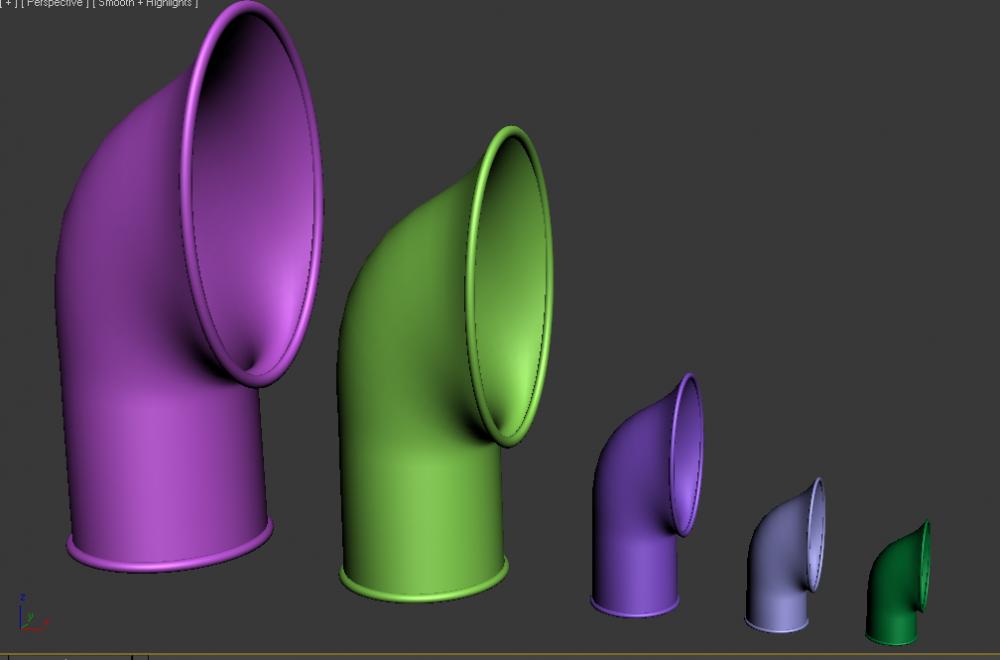

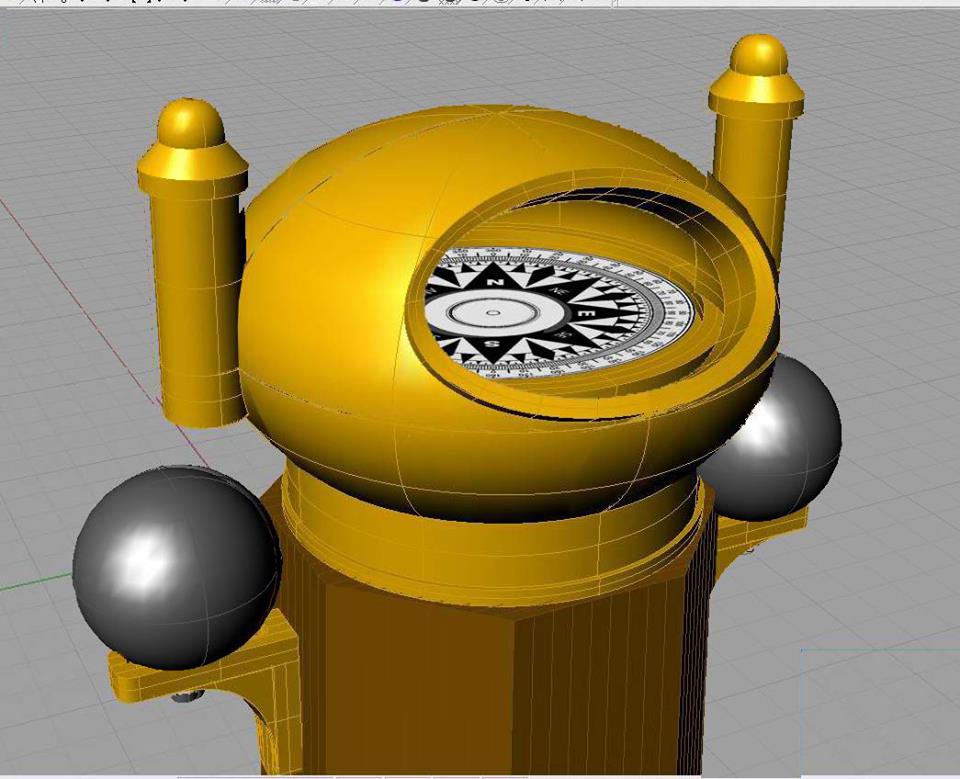

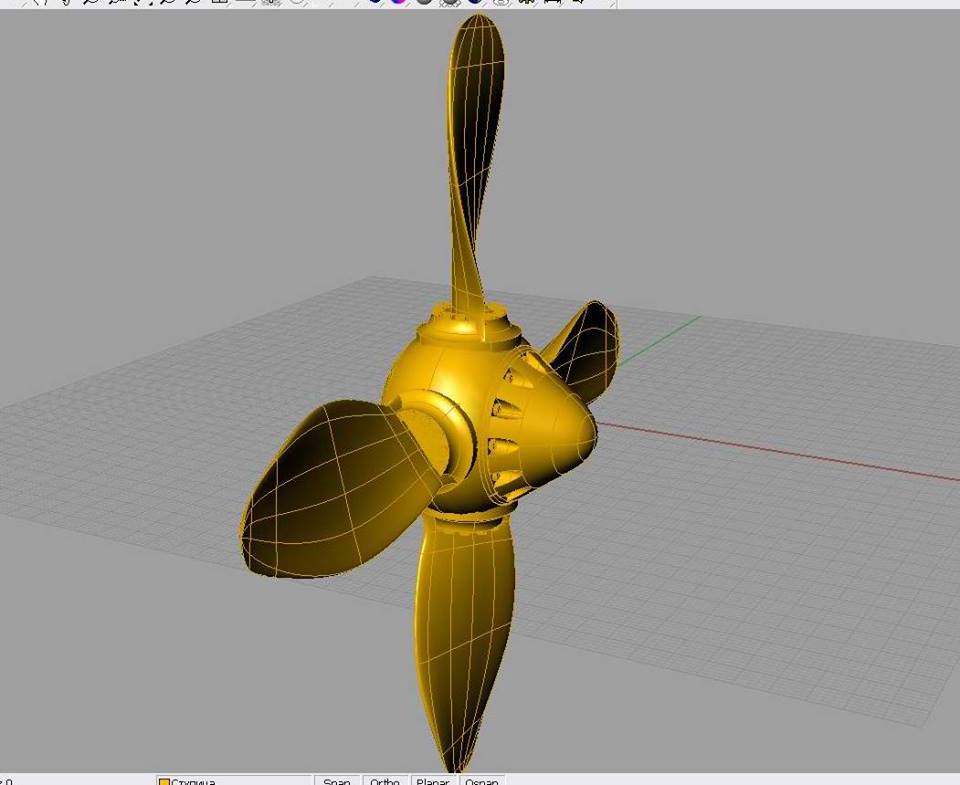

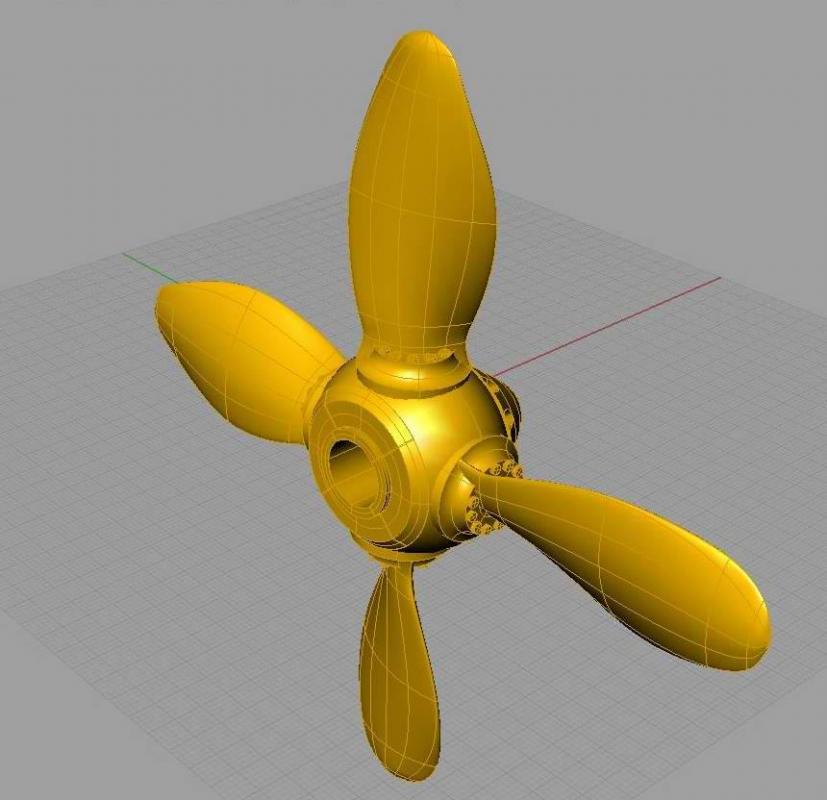

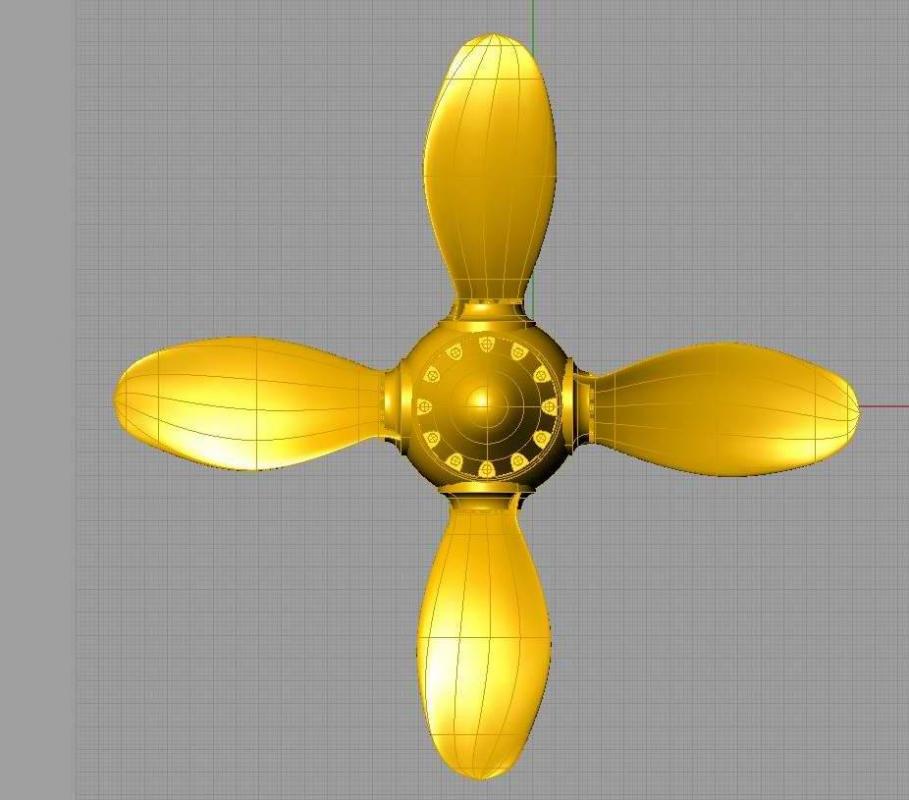

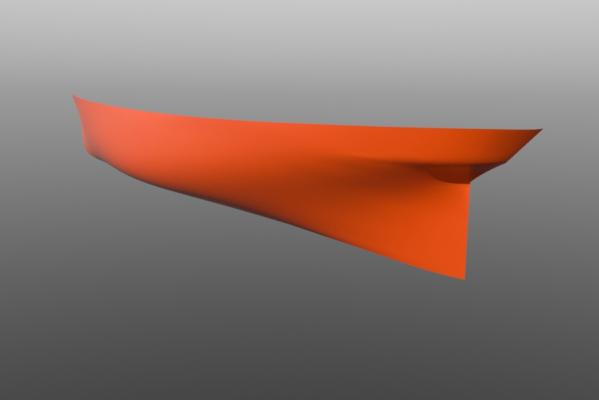

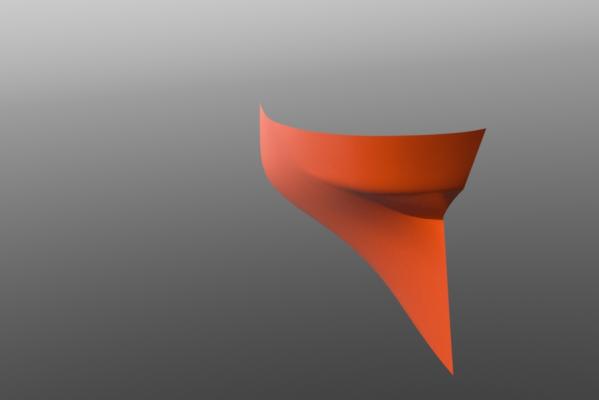

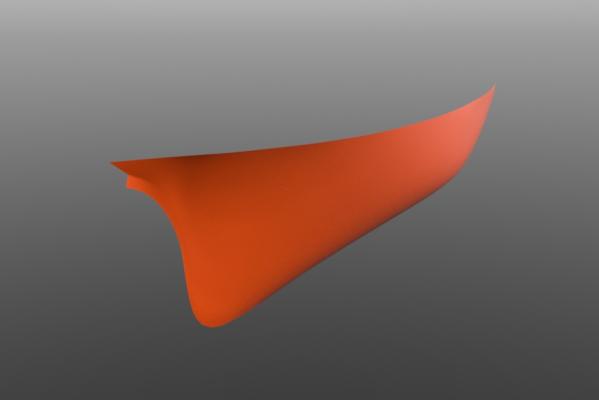

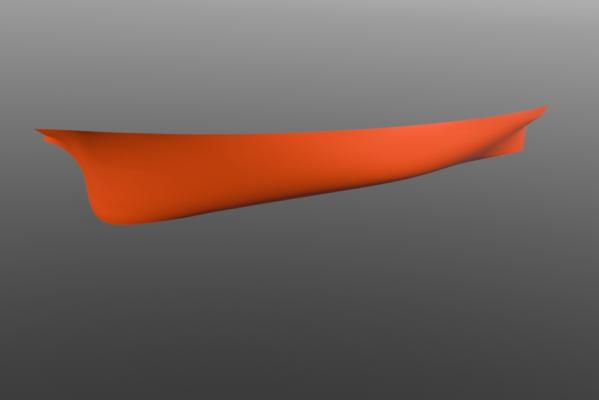

So (as I said), this project is built with a significant use of digital technologies, using highly skilled labor assistants (Carpenter, caster - a jeweler). I usually use a 3D-modeling, which will create parts with high accuracy, the most approximate to the original. Something that is already created. We have created a 3D model of the ship's hull. This model is cut into pieces in order to adapt to the capabilities of CNC machine. The shell is made of two halves, which in turn are divided into pieces. Then, the finished parts are assembled with glue. With age, more and more difficult to work with cases of large size vessels, the use of machines is another advantage in facilitating labor. Slowly but surely create a 3D-model details. Some items will be created with a vacuum molding on wax investment casting (lost-wax) Other (wooden) parts are processed on CNC machines. For the body I use alder. Of the many types of wood is the most suitable properties. Details for additions, interior, flying bridge is made of pink alpine pears.

-

work started a little moving. This ship will be built on non-conventional (non-classical) technology. The lion's share of work is the creation of three-dimensional models, followed by the manufacture of the milling machine tool CNC. Most of the metal parts will be created by casting brass lost wax investment casting. I have not yet thought about whether or not the interior. It makes sense to make the lights and fill the details Imperial Salon (aft) and the suspension bridge.

-

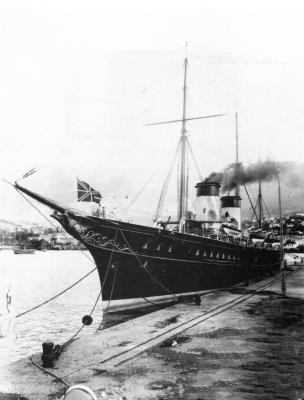

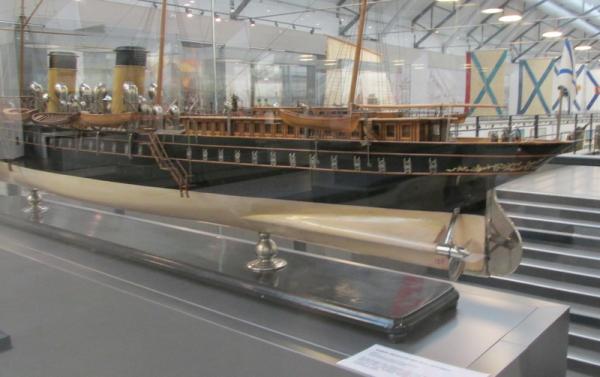

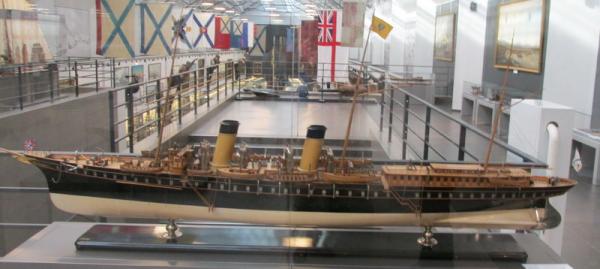

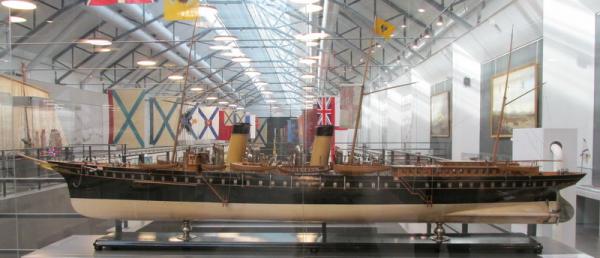

Dear colleagues. Today, April 8, 2016 start construction of another ship model, the imperial yacht Standart. To begin with a brief historical background, drawings, historical photographs.and photos of the model of the Naval Museum in St. Petersburg. It was founded October 1, 1893 at the shipyard Burmeister and Wain in Copenhagen. Launched Aug. 4, 1895. It entered into service in 1896 as the Imperial yacht. Delivered to the port in May 1918. In 1933-1936, it converted into a minelayer. He participated in the productions of mine, the evacuation of the base Hanko garrison, fire support of ground forces. April 3, 1942 awarded the title of Guards. In the 1950's converted into a plavkazarmu, and in 1961 - into a floating target for tests of missile weapons. Scrapped in the early 1960s. Displacement 5480 tons. The dimensions of 112.2 x 15.4 x 6.6 m. Voruzhenie 8 - 47 mm booking Gears 2 steam engines 12000 hp 24 boiler, 2 screws The speed of 22 knots Cruising range 1400 miles at 12 knots. The crew of 16 officers and 357 sailors After conversion into a minelayer Displacement 6189 tons. The dimensions of 122.3 x 15.4 x 7 m. Voruzhenie 4 - 130/55-B 13, 7 - 76 mm 34K, 3 - 45 mm 21K, 3 - 12.7 mm machine gun (2 DSHK and Vickers 1) Booked conning tower - 12 mm Gears 2 steam engines 11426 hp 4 boilers Yarrow 2 screws The speed of 18 knots cruising range of 2260 miles at 12 knots. The crew of 29 officers and 361 sailor

-

Dear Johann. Thanks for your feedback. However, I have seen the construction of your model too. This process excites admiration in me. (Especially working with metals).

- 227 replies

-

- cumberland

- 74 gun

-

(and 1 more)

Tagged with:

-

This is the last edition of the slideshow. Hopefully successful. The following vehicles will certainly be. I very much hope that the next time I will have more time to show the technology works in more detail. Although I note that recently I often use digital technology and precision equipment. This aspect is not very useful for the creation of the classic models of the ships so little use.

- 227 replies

-

- cumberland

- 74 gun

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.