Riotvan88

Members-

Posts

124 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Riotvan88

-

Can anyone identify this model/kit

Riotvan88 replied to Riotvan88's topic in RC Kits & Scratch building

Do you mean the fender? What's wrong with it? I've seen plenty of real yachts with a bow fender like that -

Picked up this RC model sail boat second hand. Seller didn't know anything about it. I really liked the look of it and bought it. Its a fiber glass Hull with wood mast, decks and superstructure etc. The Hull looks exactly like a Revell Inga IV but the superstructure is totally different as well as the rig. It also looks like it either had 2 masts at one point or possibly the kit had the option to fit two masts. Perhaps its a custom design using an Inga Hull or modified Inga. Can anyone identify it?

-

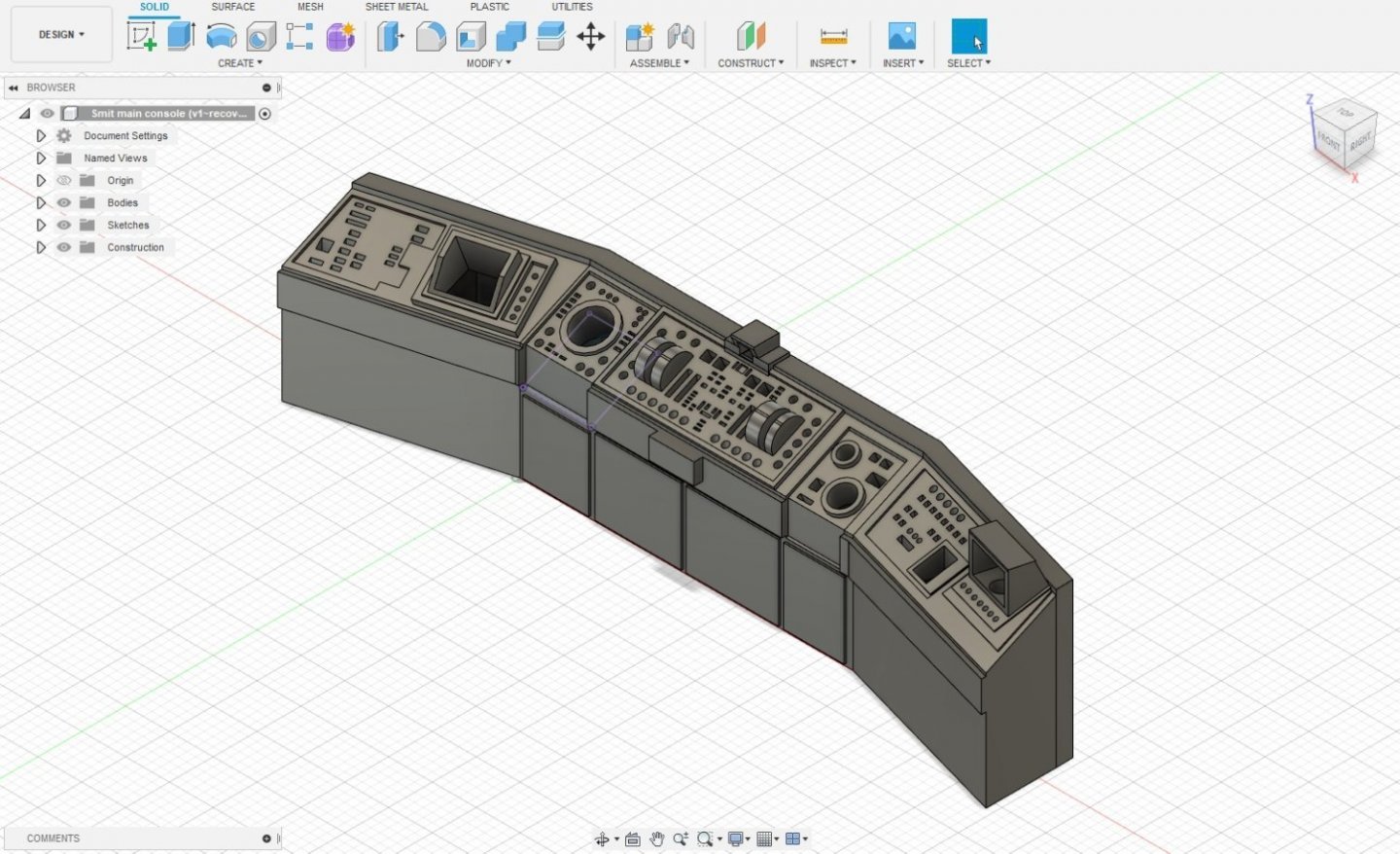

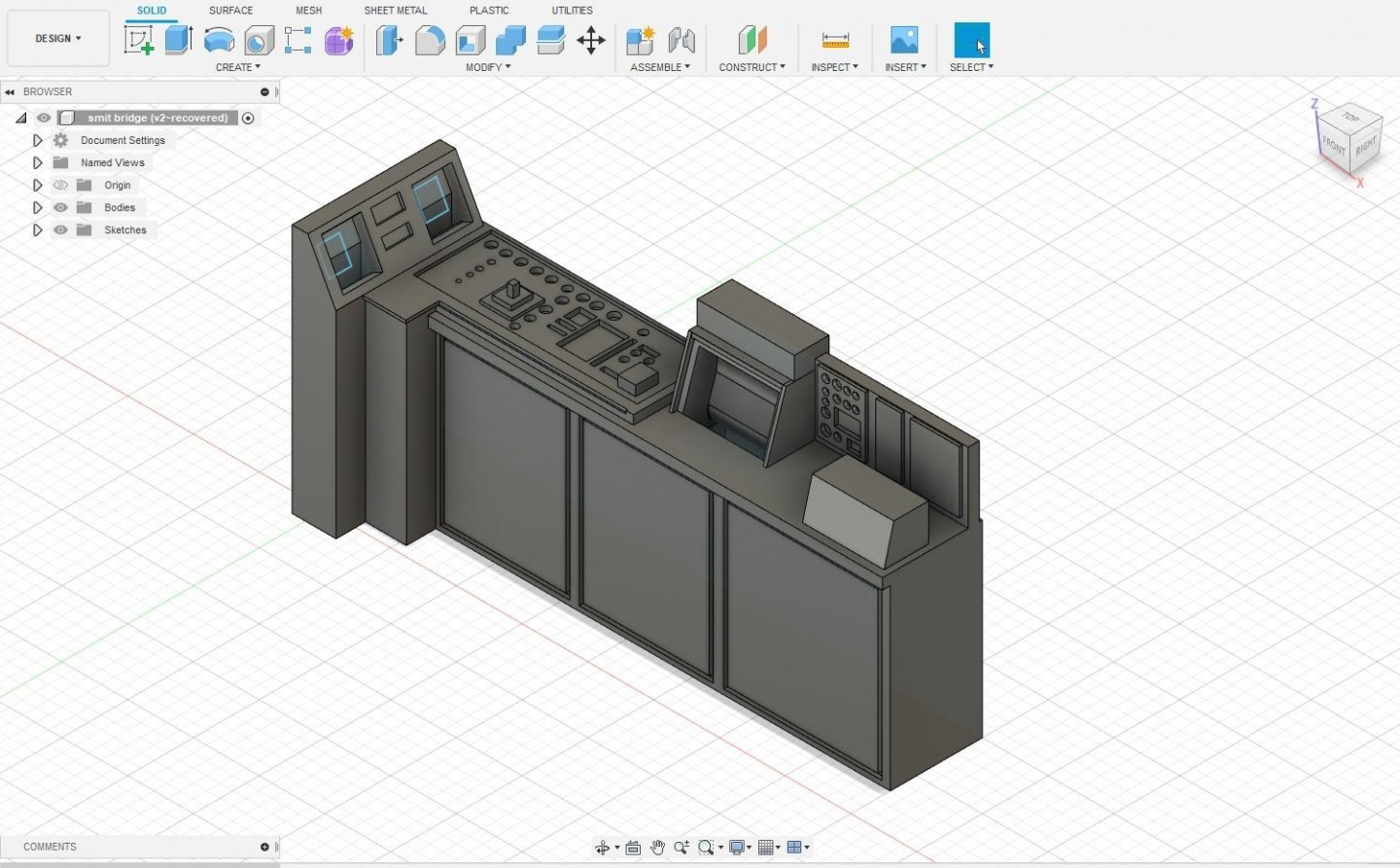

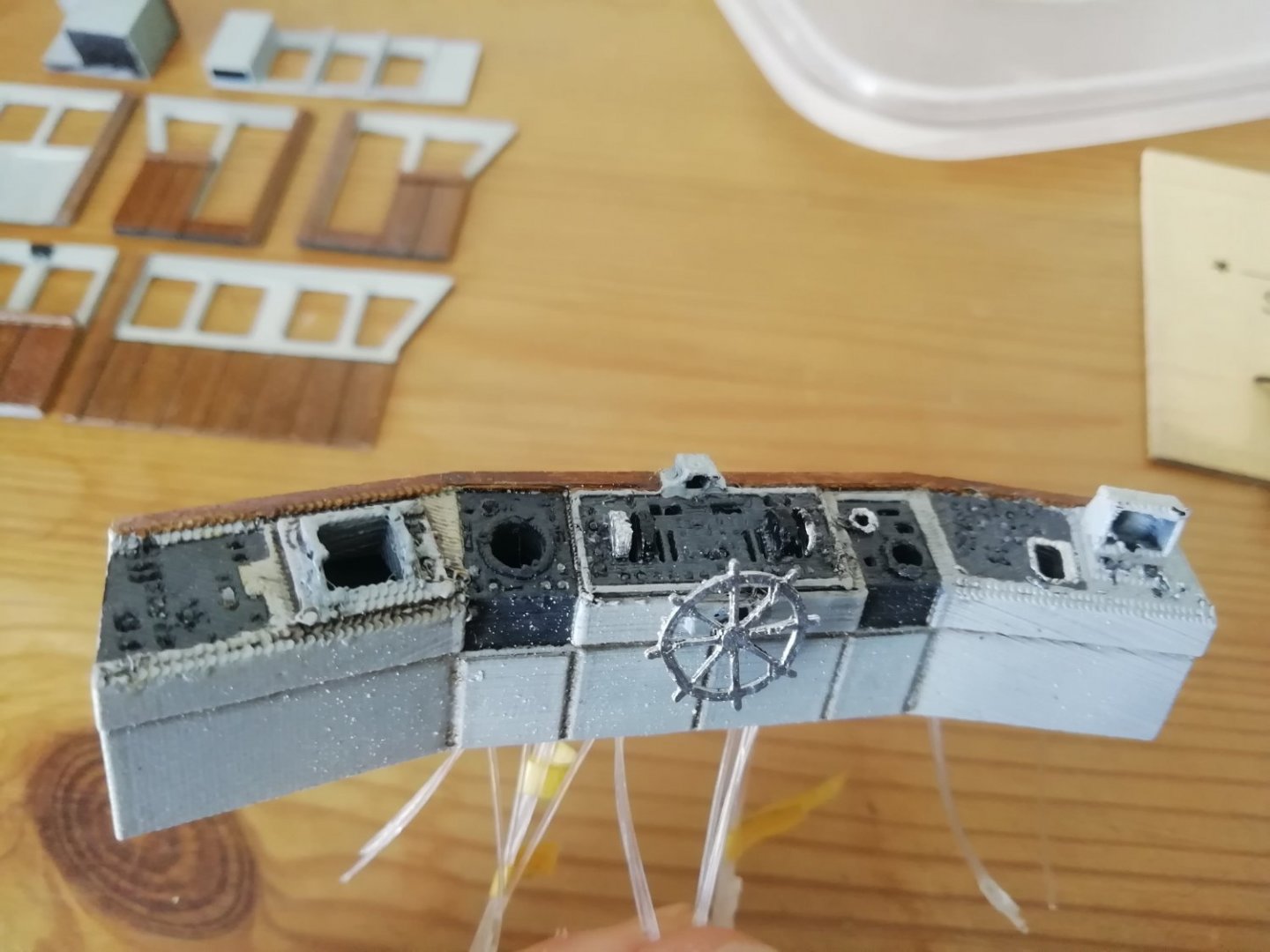

Hi Jan. No this kit is the old version so the interior is very basic. I have made my own interior based on photos I found online. It is made in a CAD program and 3D printed into pannels that I painted and will assemble into the bridge. I've added fiber optic wire to the main consoles as I'm going to light the control panels. I've tested this with everything lose fit and it seems to work quite nicely.

-

Update* Thanks for all the advice in the end I used 3M sandpaper as someone else suggested previously. This sandpaper on a wooden block has knocked back the lumps and high spots in about 2 minutes of sanding. I didn't apply the epoxy thick, I used a credit card to try to squeegee it thinly onto the Hull rather than slather it on with a brush. I intend this to be a radio control model which is why I used epoxy. Now that the 3m paper is sanding it very easily I think the issue is exactly what someone suggested poor abrasive products. The surface is already smooth after a few minutes with 80 grit so I'll keep going with it. Perhaps worth mentioning is the sanding blocks I used previously were infi model sponge pads as pictured (I used 220g not 800g)

-

Thanks for the advice, I'll try to sand this with different abrasives as has been suggested. The epoxy is actually designed to be sanded so I do not believe this is beyond salvage with a better choice of abrasives. This is a kit and a re purchase is simply not an option. The choice of epoxy was actually a recomendation from this site.

-

Hello I've been building a smit rotterdam kit. I've gone and used west systems 650 gflex epoxy with 410 microlight fairing additive to seal the Hull and provide a base for painting. The problem is the epoxy just does not sand at all. I've spent over 12 hours sanding with everything from coarse grit, fine grit, wet sanding, tried everything. The microlight additive was supposed to make this easily sandable and give a smooth finish. It's like sanding solid rock. I mixed the epoxy exactly as instructed. It has fully cured. After 12 hours of sanding I'm now left with a horrible lumpy model and several threadbare sanding pads. Picture is after 12 hours of sanding and multiple pads worn through. Any ideas?

-

Hello Building a smith Rotterdam wood kit with intention to make RC. I've used west systems epoxy to seal the hull. I'm wondering if anyone has suggestions for spray paint? Laquer paint be any good? Enamel? Brand's to buy/avoid. I'm guessing the paint needs to be as water tight as the epoxy so as not to flake or absorb water? Cheers

-

Thanks again for this advice this is the route I've decided to take. I'm now almost ready to do this part now I just have a few questions. How much Gflex will be needed I've seen half liter bottles at force 4 but not seen any larger quantities. And can I mix multiple additives in sucj as the fairing additive and the water barrier in one mix or would these need to be two coats? Lastly would you recommend fitting the korts nozzle before or after the cpes and epoxy coats? Sorry for the questions this is my first build and Thanks again for the help.

-

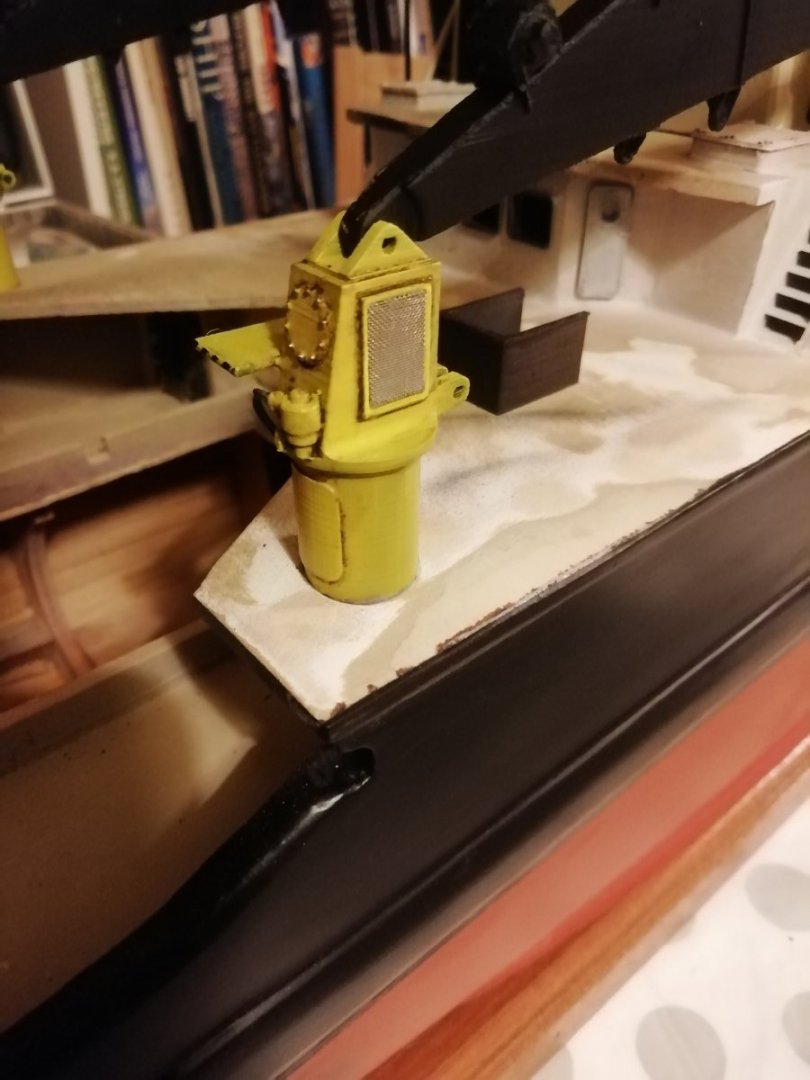

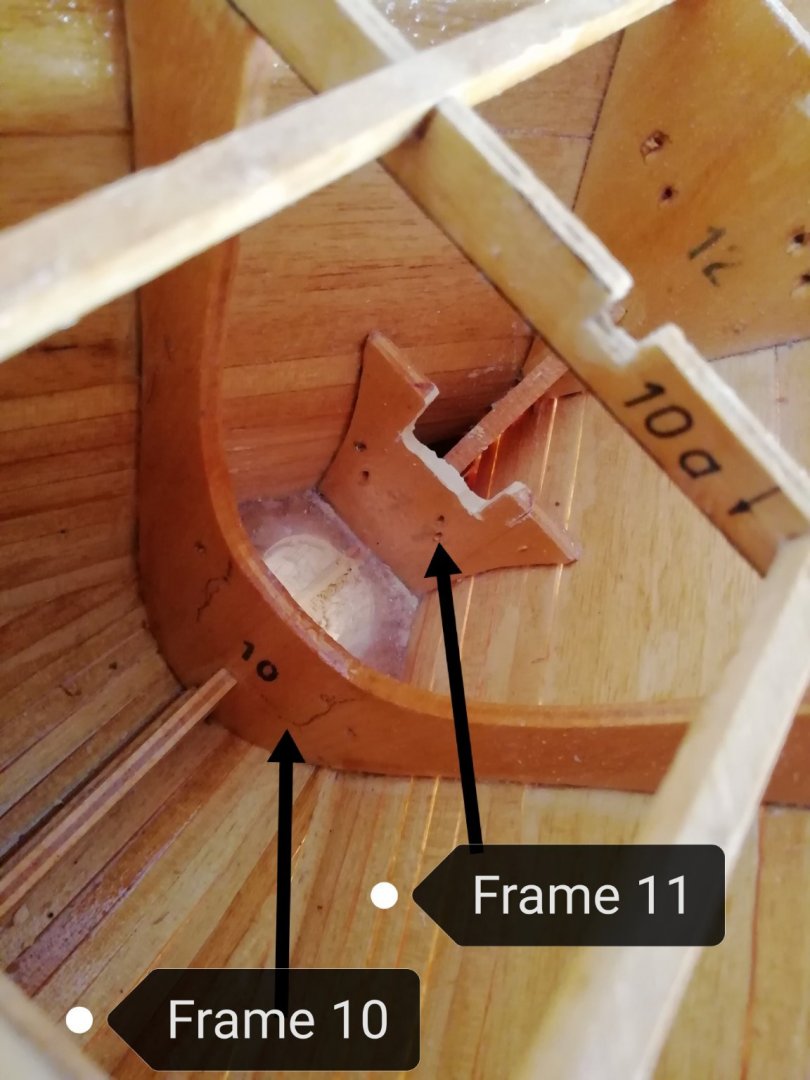

Hello I'm trying to fit a raboesch 108-03 bow thruster on my billings smit rotterdam kit. The problem is that the forward hull frames are in the way and would need some serious cutting to make it fit. As I see it the way would be to cut frame 11. The cut will need to be down to the yellow line and I'm wondering if this may cause problems? Has anyone got any advice for fitting this kit with a bow thruster? Thanks

-

Hello I'm building an old smit rotterdam kit I bought second hand as an unfinished project. I intend to make it RC. So far I've planked the hull and now the next task is to install a bow thruster. I was wondering of anyone has any suggestions as to the size of bow thruster I should look at. I know many people on the site have probably built this same kit so I'd be interested in hearing any recommendations for a suitable bow thruster unit. Thanks

-

I have one more question possibly I have made a big mistake. I drove the planking nails all the way in as I planned to leave them in the hull. Should I remove these? Is it irrelevant? I guess the potential is for them to rust but they should be completely covered by the epoxy and water barrier sealers you recommended. I could still remove them but would be a pain to do.

-

Excellent. Thanks for the information. Although I've made static models this is my first wood RC boat. I think I'll go the epoxy route. What's the kevlar additive you mentioned for the bottom? I may add this to protect from grounding. I always prefer to over build and over engineer for durability and redundancy, anything that adds strength and longevity peaks my interest. Thanks again

-

Thanks for all the info. Can I just varnish the inside? I've already applied varnish to parts that will be inaccessible when planked. Ideally I only wanted to fiberglass the exterior of the Hull. Also in the past I've used PVA mixed with sawdust to create a thick paste and used it as filler. Will this be OK to fiberglass over?

-

Hello I've been building a billings smit rotterdam kit and have almost finished planking the Hull. I plan to fiberglass the exterior but this is the 1st time doing this type of work. I'm not sure in what order the next steps are. My plan was to sand the Hull smooth use wood filler if and where necessary then fiberglass it then prime it and then any last minute sanding/filling before painting the base coat on. Does this sound right? Should I sand and fill and prime the Hull before or after fiberglassing it? Thanks much appreciated

-

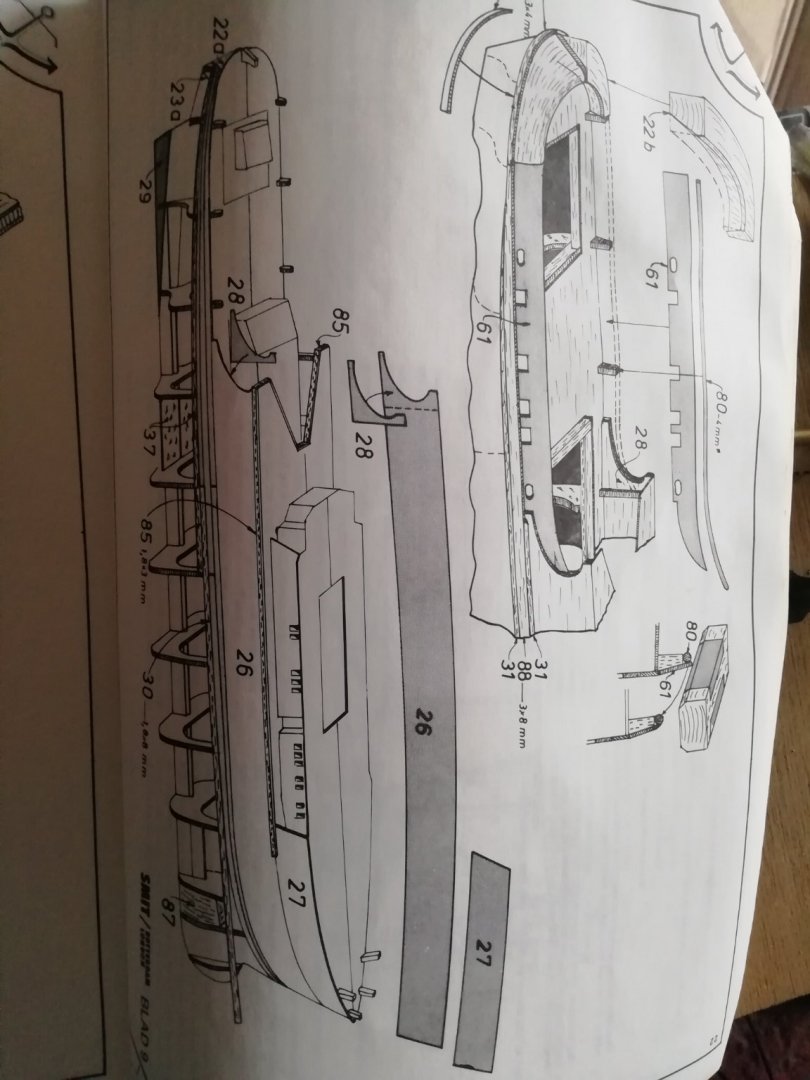

Hi picked up an old second hand rotterdam kit. I'm about to glue the flat sides on part 26 and start planking. The instructions say to glue each side (part 26) on one at a time however I've always planked a POF model with both sides done together to prevent warping. Should I do one side at a time? In my view it seems both of these side pannels should be glued together.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.