Jim in KC

-

Posts

33 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Jim in KC

-

-

I did indeed cut a new keel. Next question, what's the best way to attach a flat deck to frames that are curved on top? I've read other build logs for the same model and others have had this question. I'm thinking of soaking the deck, then pinning it, then gluing it. Any advice would be appreciated.

-

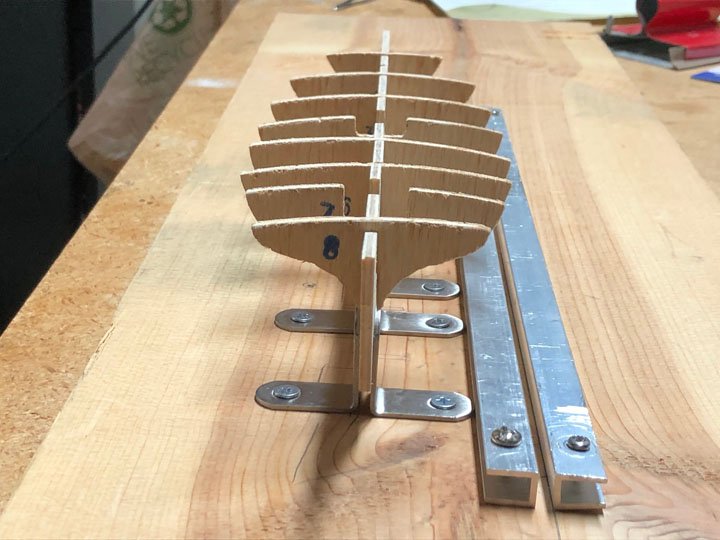

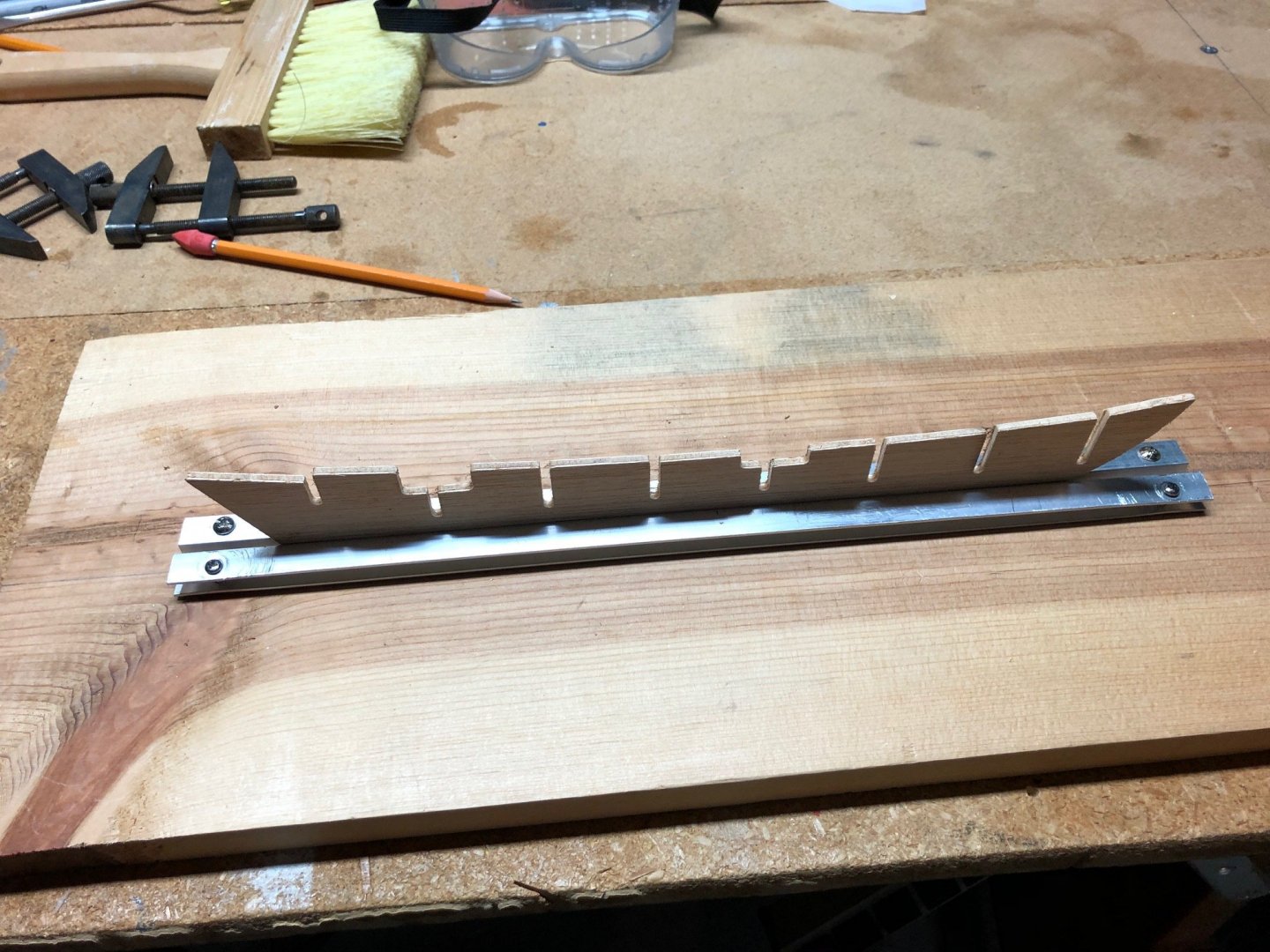

Thanks for the input. I made a building jig using l clamps, as suggested. It holds the false keel firmly. I cut out the bulkheads and fitted them on the false keel, but haven't glued them as yet. I glued balsa shims in the keel notch on few and then filed them to make the fit tighter.

I also cut out the false deck. As to cutting things out, when I built wood aircraft models years ago everything was balsa. Then I used Xacto knives to cut pieces out and I assumed I would do the same now. However, I don't know what kind of wood these sheets are but they're much tougher to cut through then balsa. I ended up using an electric coping saw. I've read the other Swift building logs, and most people don't indicate how they cut the pieces out. Grimber indicated he used xacto knives, and now I'm worried that using a coping saw could have been a mistake because of the thickness of the cutting line. This is probably a really boot question but I would appreciate any feedback.

Looking ahead, it's clear that the fitting the flat deck to the rounded frames will be a challenge. Different builders have used different techniques. Grinder used rubber bands, others glued the deck along the top of the frame with CA. Some suggested soaking the deck ahead of time to get more flexibility. I'm not sure what I'll do yet, and again I would appreciate suggestions. Besides, I have yet to glue the support blocks in place between the frames or to glue the bow and stern blocks in place, all of which comes before attaching the deck.

-

The Swift is my first wooden boat build, so I’m a newbie. I appreciate any suggestions, advice or input from you more experienced builders.

I used to build plastic and wood aircraft models as a kid, but that was more than 50 years ago. Now that I’m retired, I have really been looking forward to building models again, particularly ship models. I’m hoping I can maintain my enthusiasm through the trials and tribulations ahead.

When I first opened the box I noticed that the false keel was warped. I know for my reading (the kit directions, “Ship Modeling Simplified,” by Frank Mastini, and various articles in this forum) that it is essential to get the false keel and bulkheads perfectly aligned. So I posted questions on the Building, Framing and Planking forum about this issue, and got some good advice.

Mtaylor suggested just cutting a new false keel, and both he and michael101 talked about inserting spacers between the bulkheads and clamping them to straighten out the keel. The more I looked at the false keel, the more I realized that the most obvious warps were right on the bulkhead cut lines. See attached pictures. So in the end I ordered some plywood of the same thickness and I have now cut the new false keel. It’s quite straight and I’m quite happy with it. I have begun fitting (but not gluing) the bulkheads.

Obviously I’m just getting started. I really appreciate the availability of these forums because I’m convinced I’m going to need lots of advice.

-

Hi Russ - when do you attach the actual keel to the false keel. I have the same kit and I'm just starting to build. I've been over the instructions multiple times I don't see it anywhere. It looks like you haven't done that yet which, I guess, is why you used angled metal strips for your build board. The false keel is nor deep and the frames slide down too far to use parallel wood or strips to support the keel. Anyway I would appreciate your input. Jim in KC

-

Thanks to all who responded. To mtaylor, cutting a new keel seems like a good idea if I can find plywood that thin - see pictures. I like the idea as well of using spacers attached to the keel between bulkheads. I get what michael101 is saying = the spacers should not push on the bulkheads but just straighten the keel. To michael101, the warp is in the middle - see pictures.

I will start a build log.

-

I'm just getting ready to start on a kit-build of a Virginia pilot boat, a sloop. I noticed that the keel piece is a little warped. It's a thin plywood precut piece. I tried steaming it for about 15 minutes, then clamping it flat against a 2x4. That didn't work. I'm afraid of soaking it in hot water - might that make the plywood separate? I would appreciate any suggestions from you pros out there. Thanks.

-

Hi, I'm Jim from Kansas City. I am just starting a model, the Virginia pilot boat, Swift. I'm paying heed to the warnings for newbies - the kit from Artesania Latina includes just one deck and the rigging doesn't look too complicated. The manufacturer is not on the forbidden list - I certainly agree with that policy. I used to build plastic and balsa models growing up, and now that I'm retired, I want to try ships.

I'm also new to forums of any kind. I tried to post earlier but I don't see a response so I assume I messed it up somehow.

By the way, I'm a former tin can sailor, so my fascination with ships and the sea go way back.

- GrandpaPhil, ccoyle, JeffT and 1 other

-

4

4

Newbie Keel Problem

in Building, Framing, Planking and plating a ships hull and deck

Posted

Thanks for your input, ASAT. The reason I'm concerned is a previous builds of the same model reported difficulty getting the false deck to bend to the rather severe curvature of the upper frames. See for example: Swift by PopJack - FINISHED - Artesania Latina - Virginia Pilot Boat 1805 Older version

By PopJack, April 15, 2013 in Build Logs for SHIP MODEL KITS

One previous build reported the deck split.

I have had this model probably 10 -15 years and haven't had time to work on it until now (I recently retired). So the deck is dry and not very flexible though it is only 1/16" thick. What do you think about soaking it?