-

Posts

76 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by SaltyNinja

-

-

7 hours ago, Clueless said:

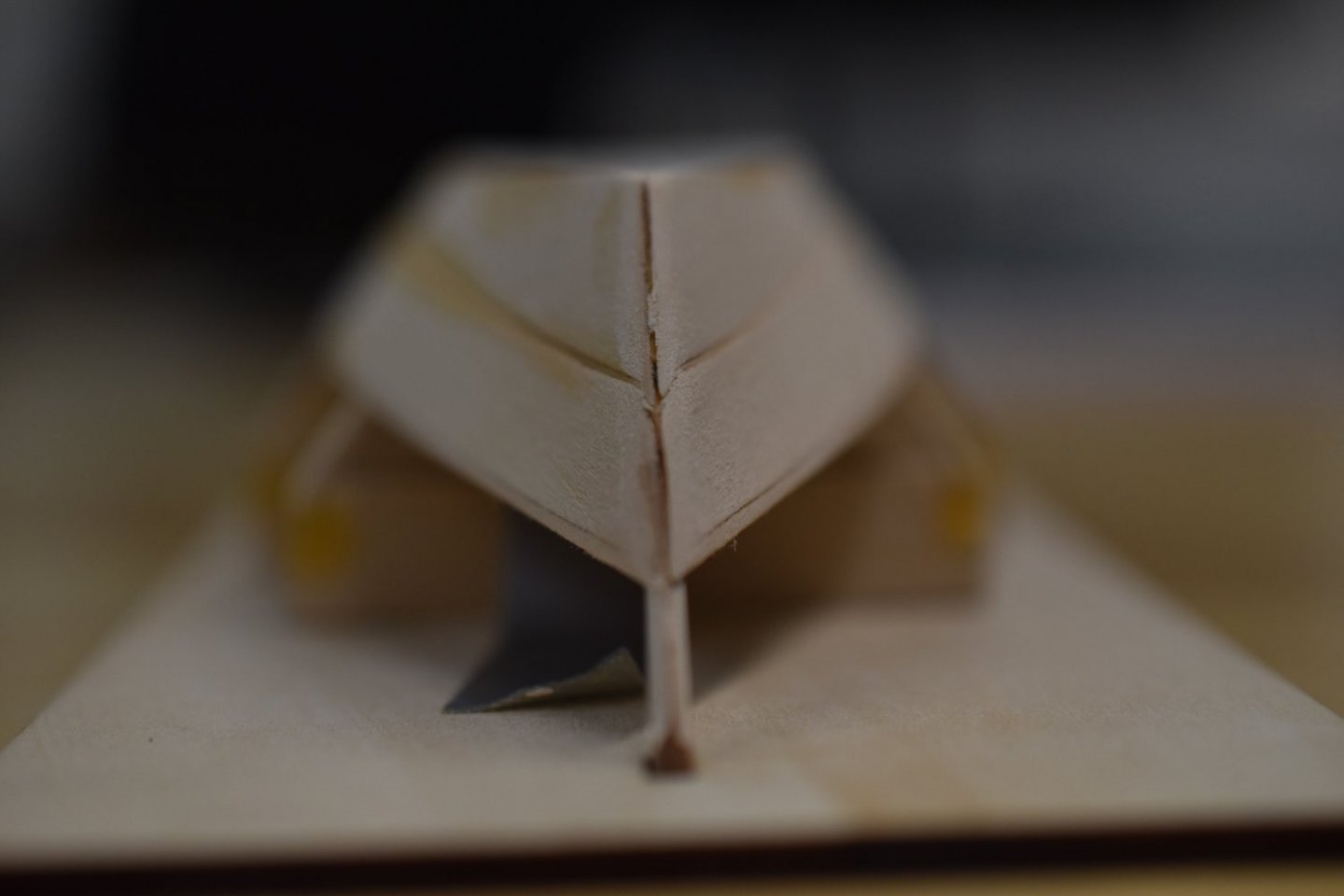

You did a great job repairing those gaps! Isn't there supposed to be a part that goes on the front of the bow yet? I haven't read the instructions for quite some time because I haven't been working on it lately but that seems like a sharp point.

Thanks for the compliment Clueless! It took a bit of time, but I figured repairs are probably part of the process, as I usually need to improve things after screwing them up.

Yeah, the part you are referring to is called the "false stem". It's installed on my boat already, but I forgot to note the installation in the build log. I put it on and sanded it pretty flush with the planking. I did notice today that I need to glue it better because it popped loose in the middle of it's length. I think I'll just use a diluted glue mixture so I don't need to sand any glue after it's dry.

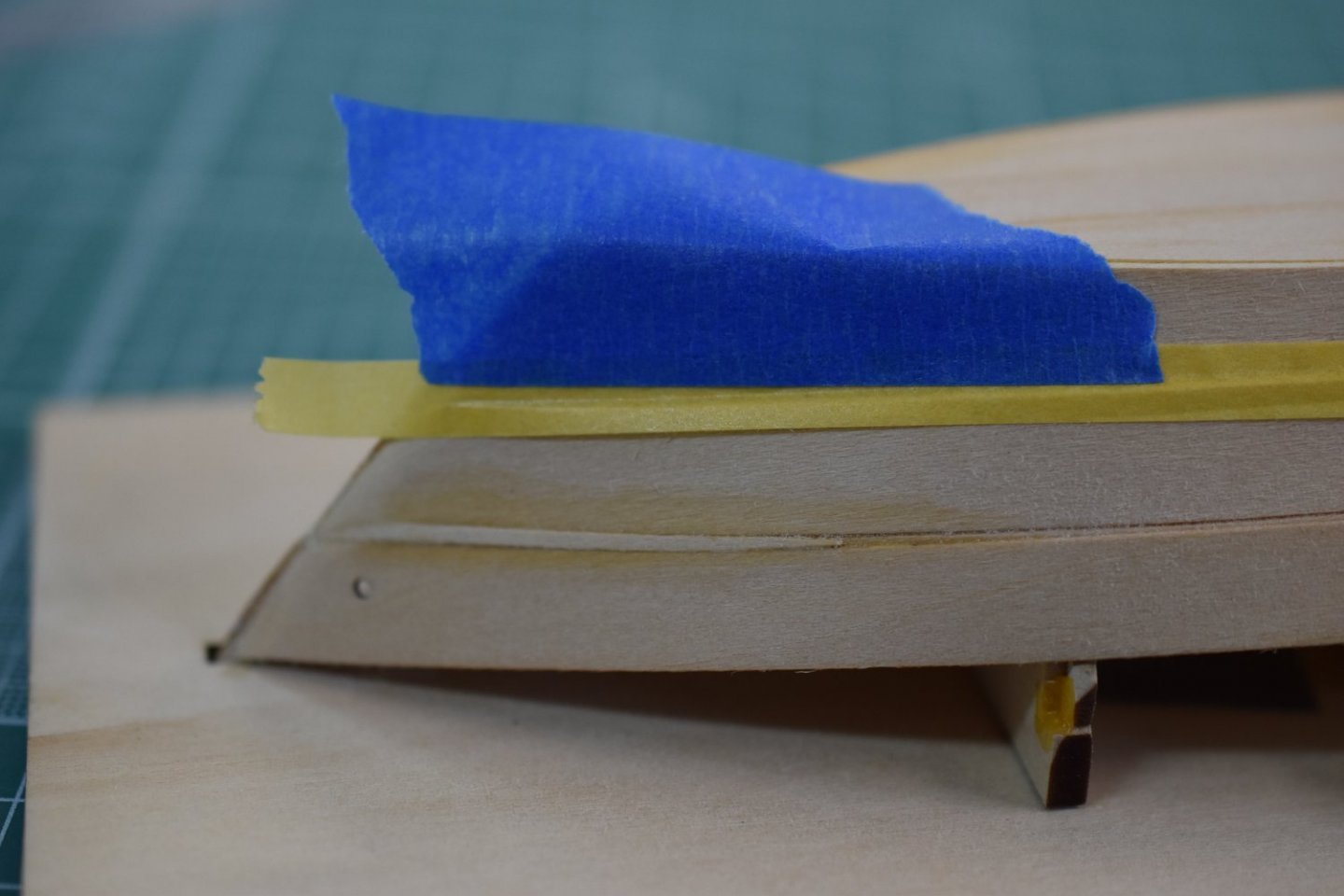

I was also considering trying to correct some warpage in the planking by wetting some areas with water and letting it dry. I think I'm going to experiment with that tonight. I have a few indentations caused by clamps also. I'm going to touch those up with some water as well. The instructions say that some water might pull the grain of the wood back at the spot of indentation.

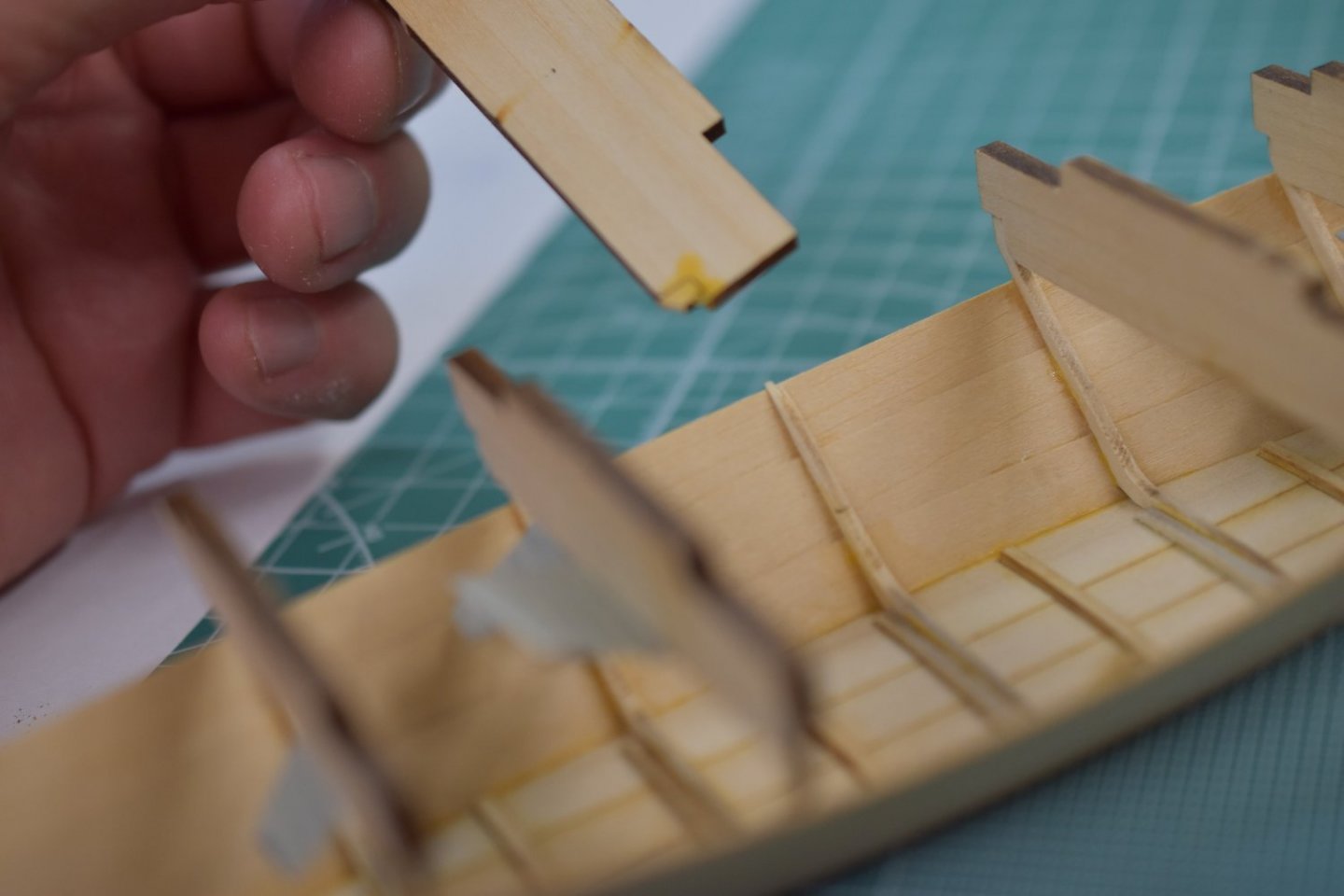

I'll probably put the last cleats in their place on the inside of the hull, attach the "bands" to the exterior top portion on the sheer plank, and glue in the gunwale tonight. I'm going to sand the transom and frames as well. After those steps are complete, I'll probably paint the hull before installing the seat risers and breast hook. I might paint the seat risers the same green as the cap rail just for a bit of contrast and color.

-

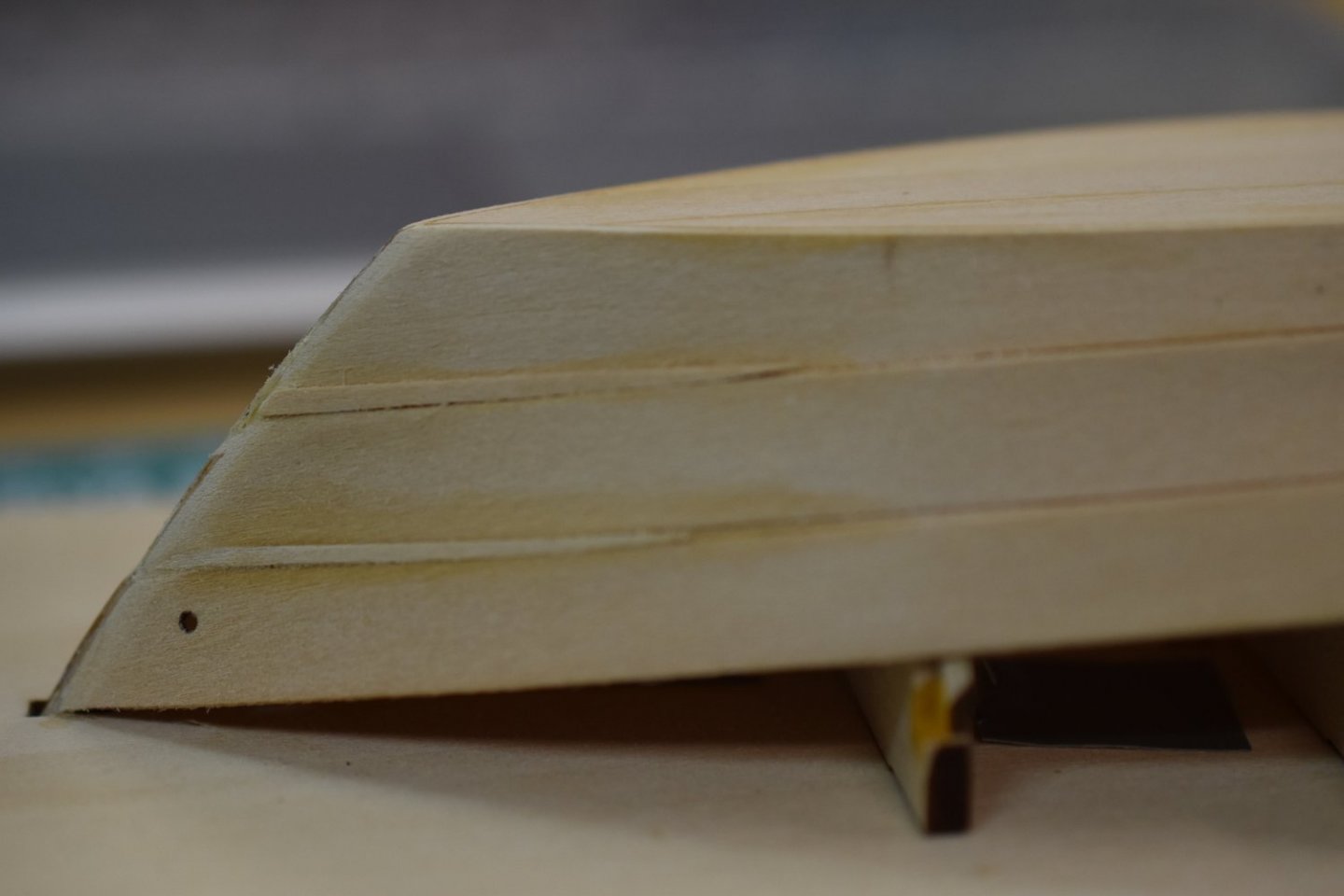

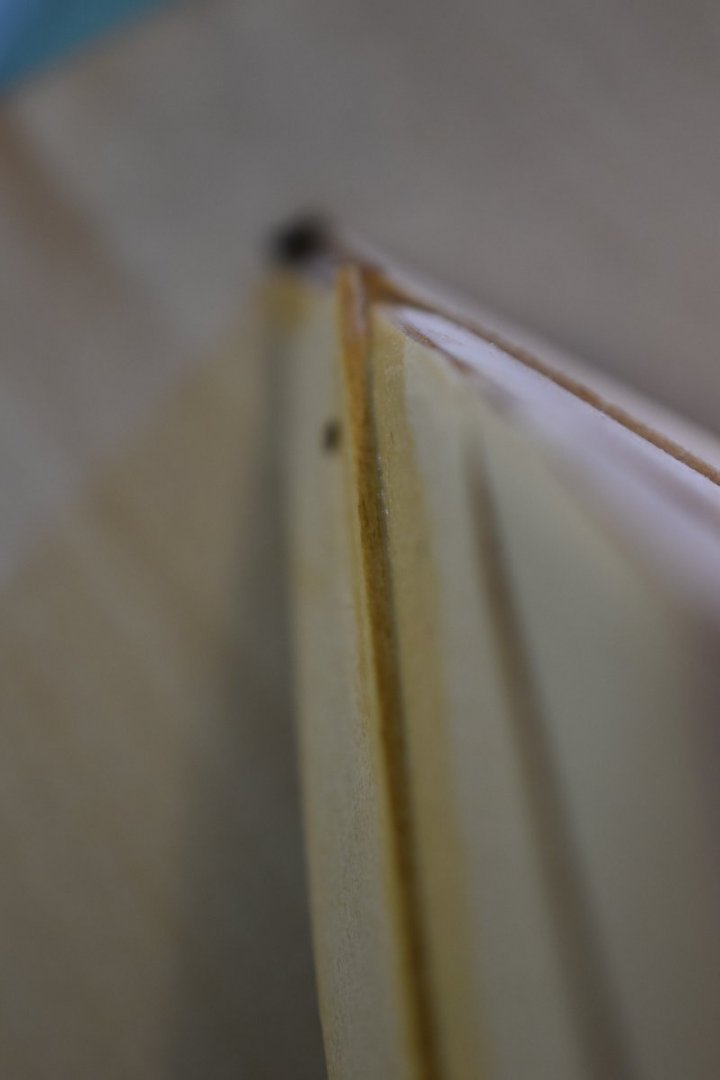

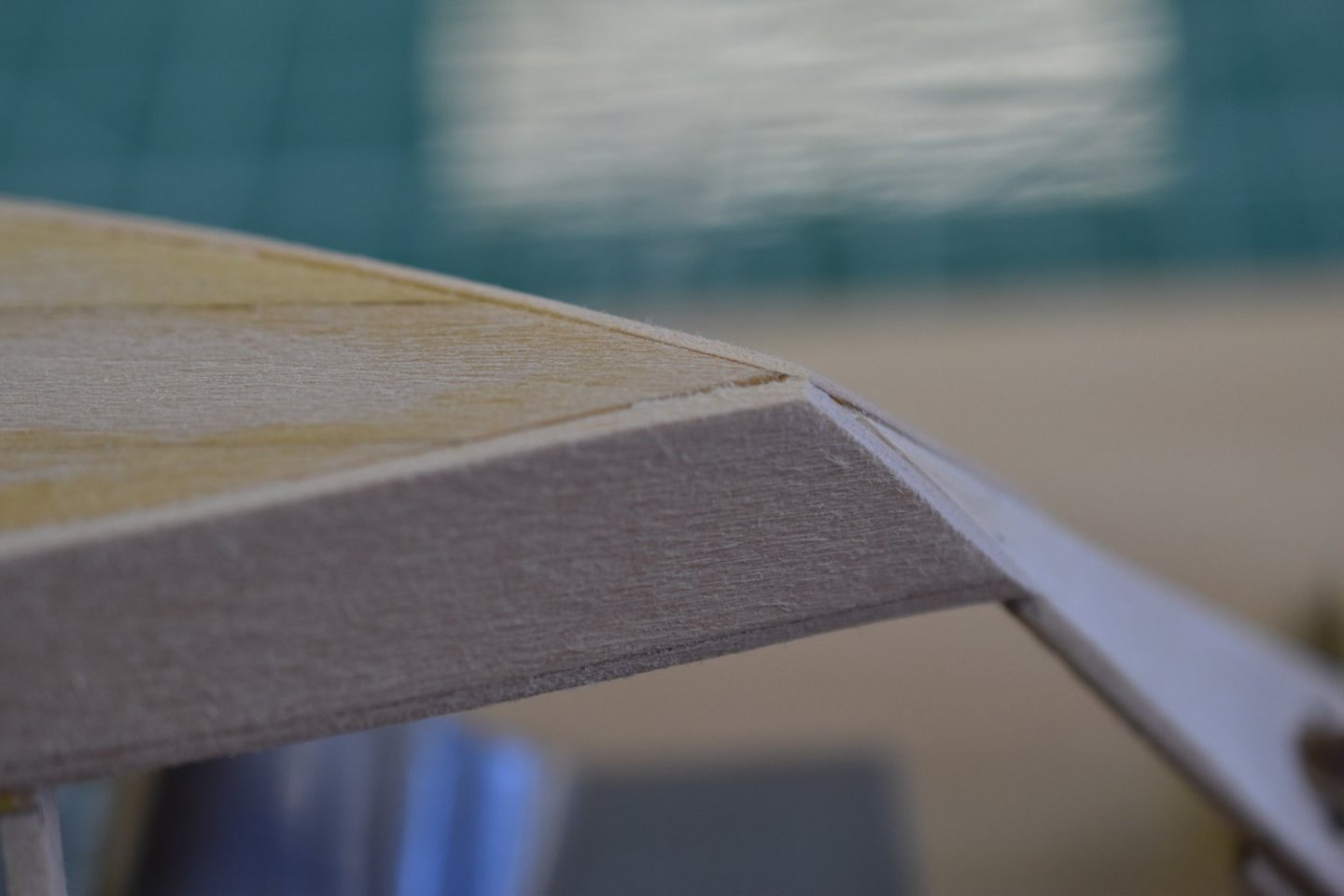

I decided to spend the evening continuing to fair my bow area planking repair. I found that I had previously sanded my repair too much and eliminated the plank ridges too much. I used a couple of files to restore the ridge to the planks a bit and to fair the repair more.

While doing this I ended up breaking off one of the frame molding fixtures. I was supposed to have removed them already, but had been delaying that step for no known reason. Now I will be repairing the frame tops at the gunwale apparently. 🤪

-

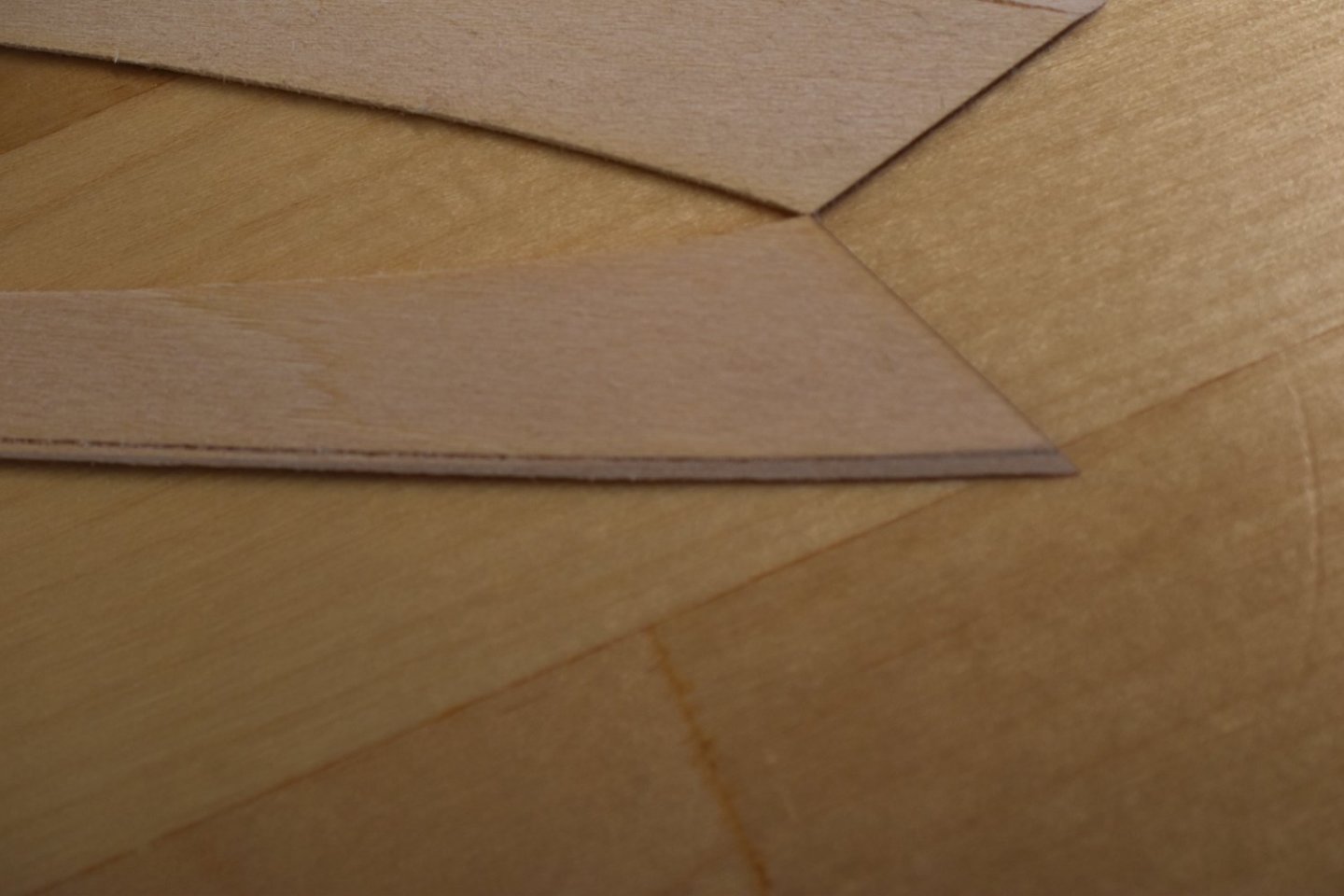

I went ahead and made some small filler pieces to try and fair out my poor craftsmanship. I was a little too lax about lining the planking up with the printed black line. It would have been a lot more fair had I took more care in that aspect of the plank alignment.

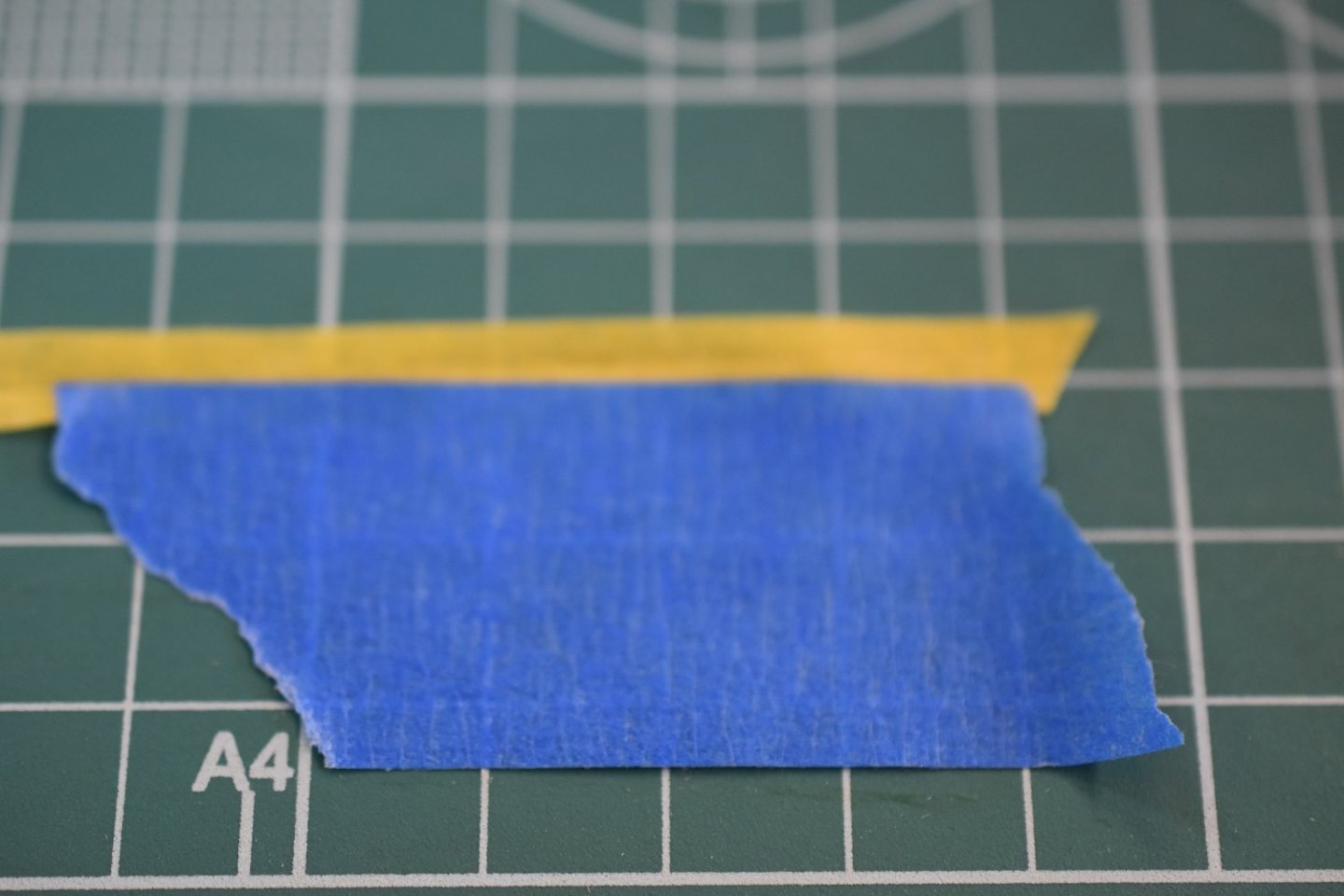

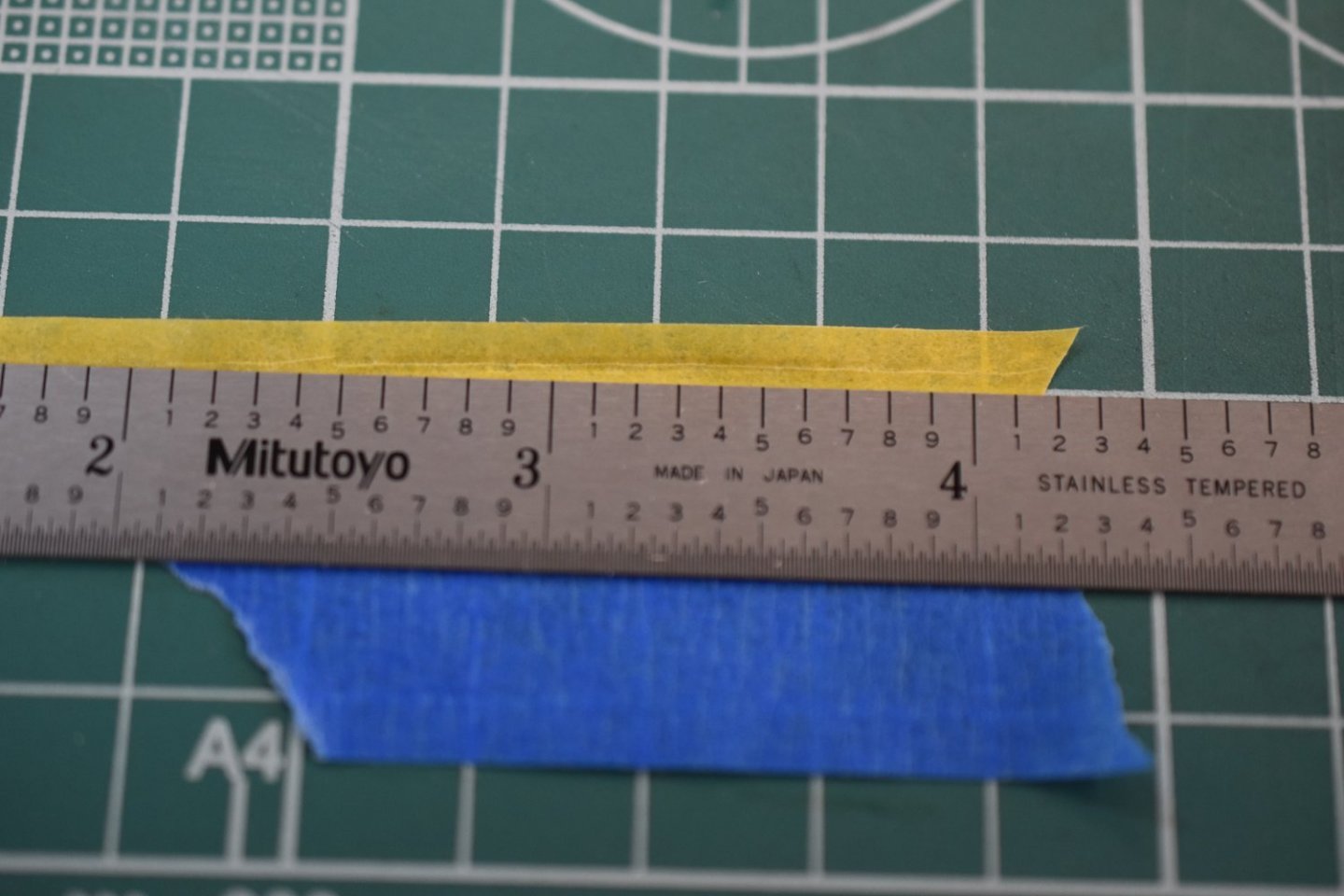

I spent a lot of time making the little filler pieces and tried different methods as I made each one. I tried my hand at the spiling method with a tape pattern, but the needed pieces were pretty small.

In the end I just eye balled it, then sanded to fit and attached. It was much better to sand it very close to a smooth fit before attaching it. that way the planking adjacent to the filler pieces didn't get sanded too much additionally.

I'm hoping a coat of sanding sealer, primer, and then paint will fill the joint transition at the repair to hide it. That may catch me adrift, but we'll see.

- JpR62, Ryland Craze, druxey and 1 other

-

4

4

-

I decided to use that Americana DecoArt multi purpose sealer on the wood before painting the boat. I'm going to try and use an airbrush on the paint job. I will probably use a light primer coat after the sanding sealer stuff. I ordered a couple bottles of Vallejo paints to try out with the air brush. I think I'll be painting the hull pretty soon.

-

The more I work on this clinker boat, the more it turns into a clunker boat!

I attached the sheer planks today. I soaked one side in water to form it up and let it dry. I attached it using AC glue along every glue point on the frames, stem, and transom to attach it. It went alright I guess.

On the second side I decided to not wet the plank and attach it at the transom first with AC glue and let it set. Then I put wood glue on the frames and attached them. I lastly put AC glue on the stem and set it. I had a problem with alignment and popped the sheer plank off the stem while it wasn't completely set. I fixed my alignment and reattached it. I had a problem still, but decided to let it be. I would fix the problem it somehow.

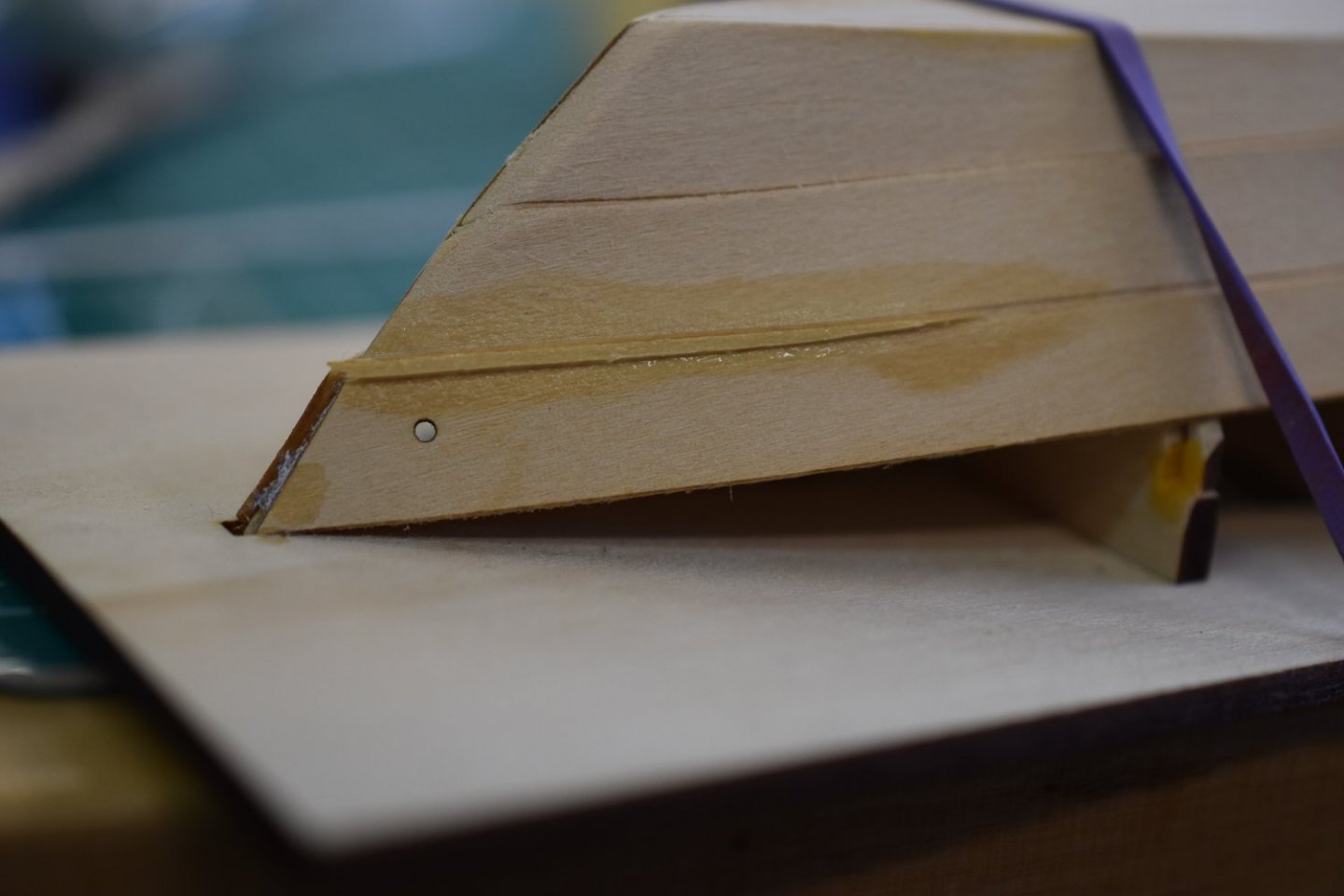

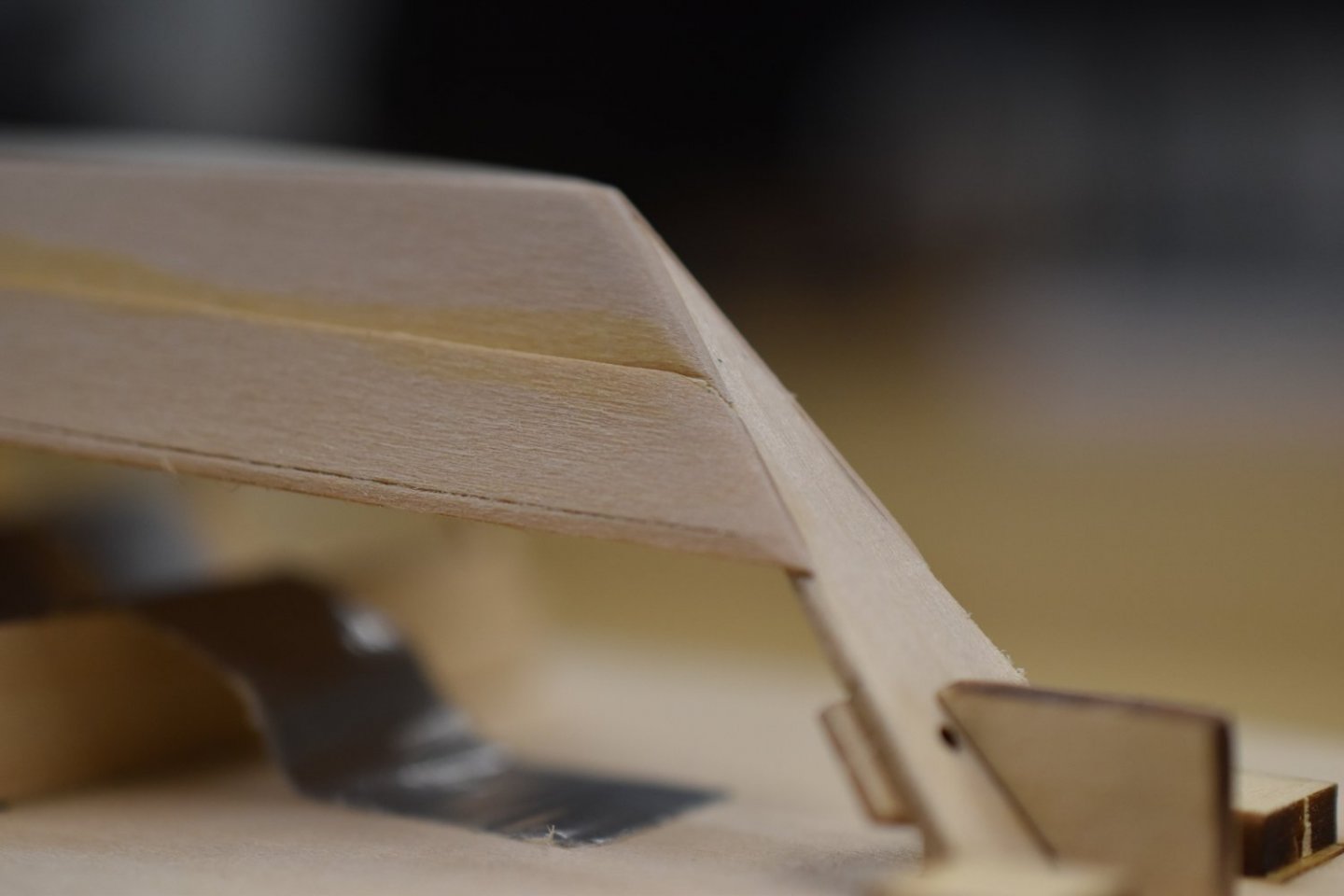

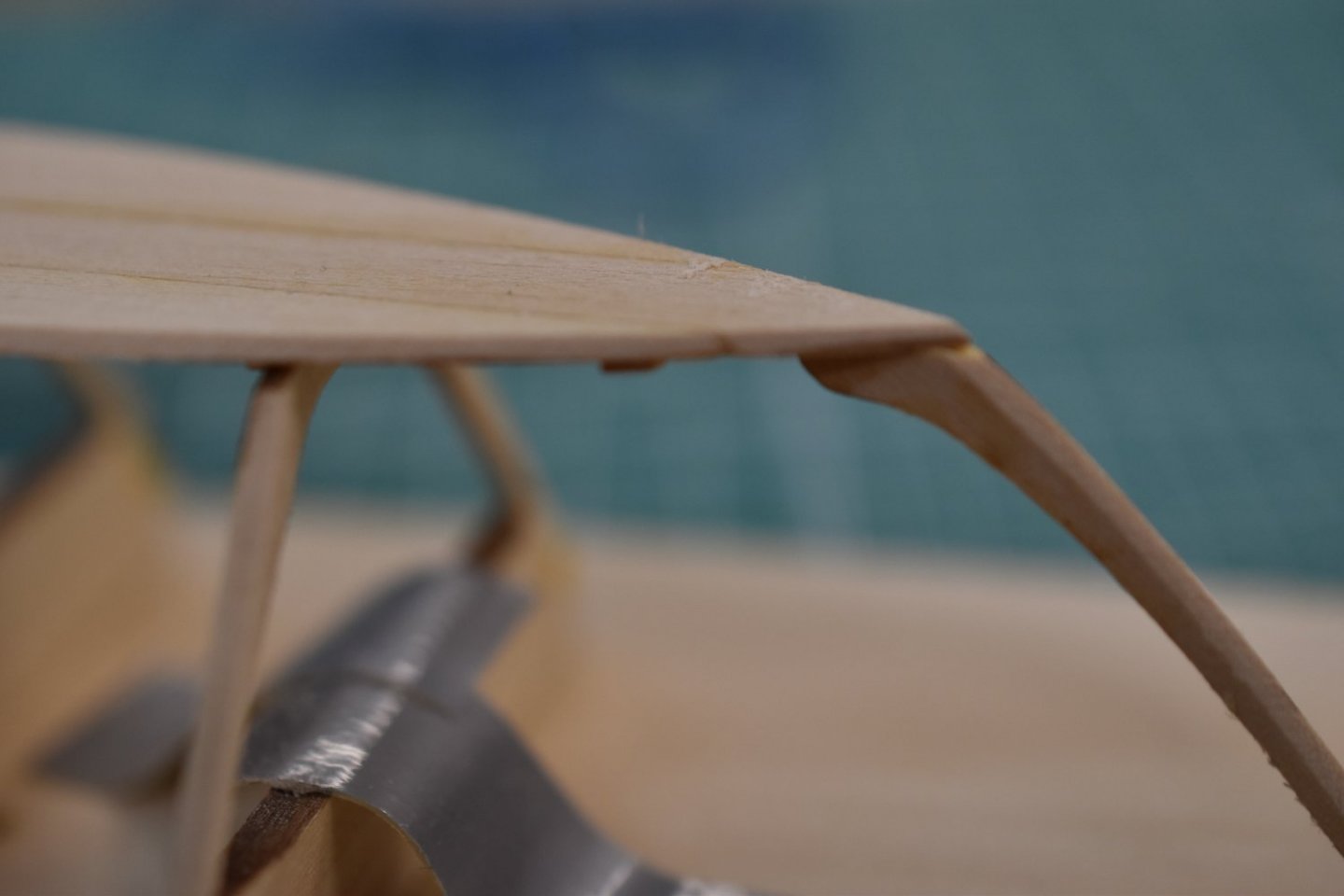

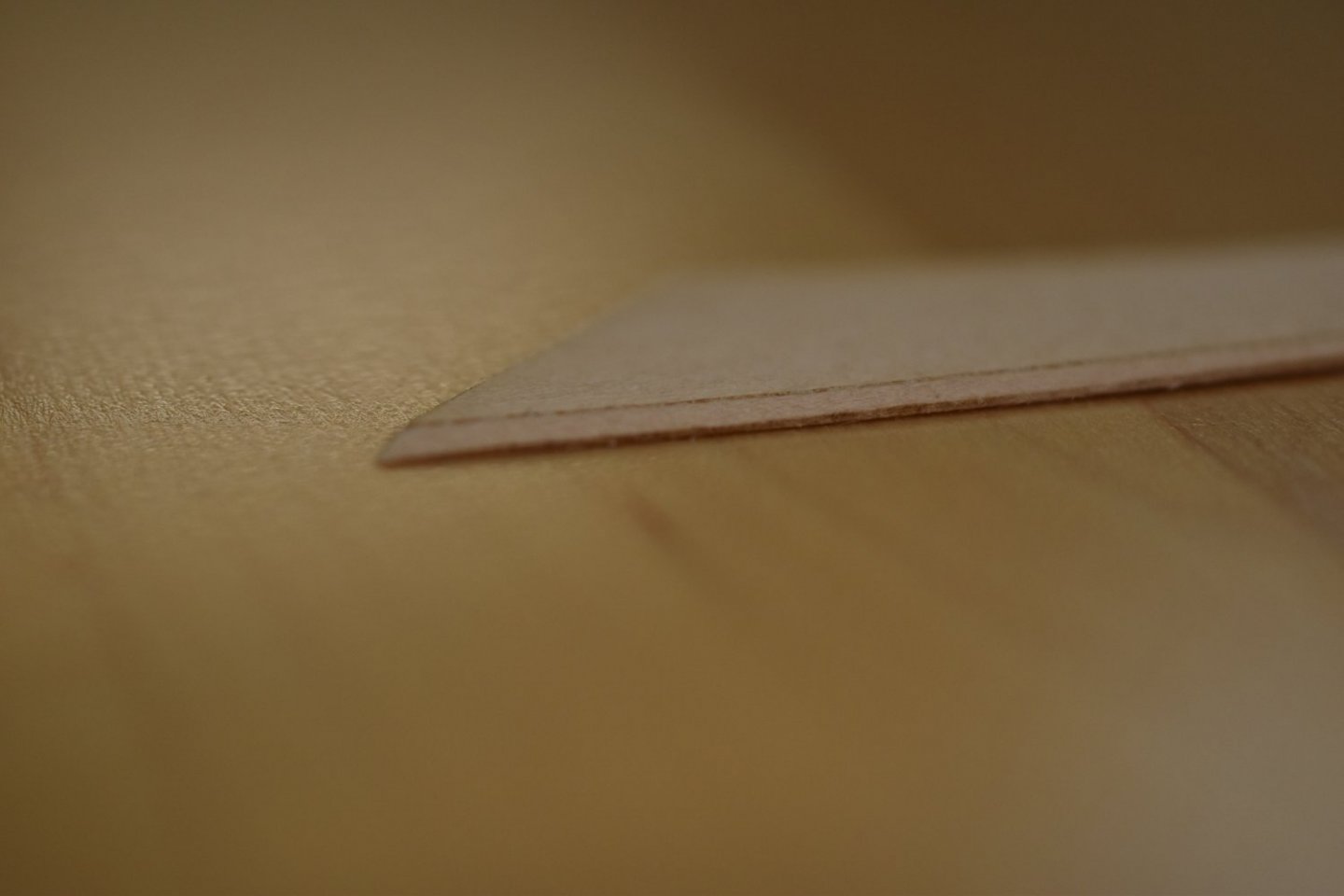

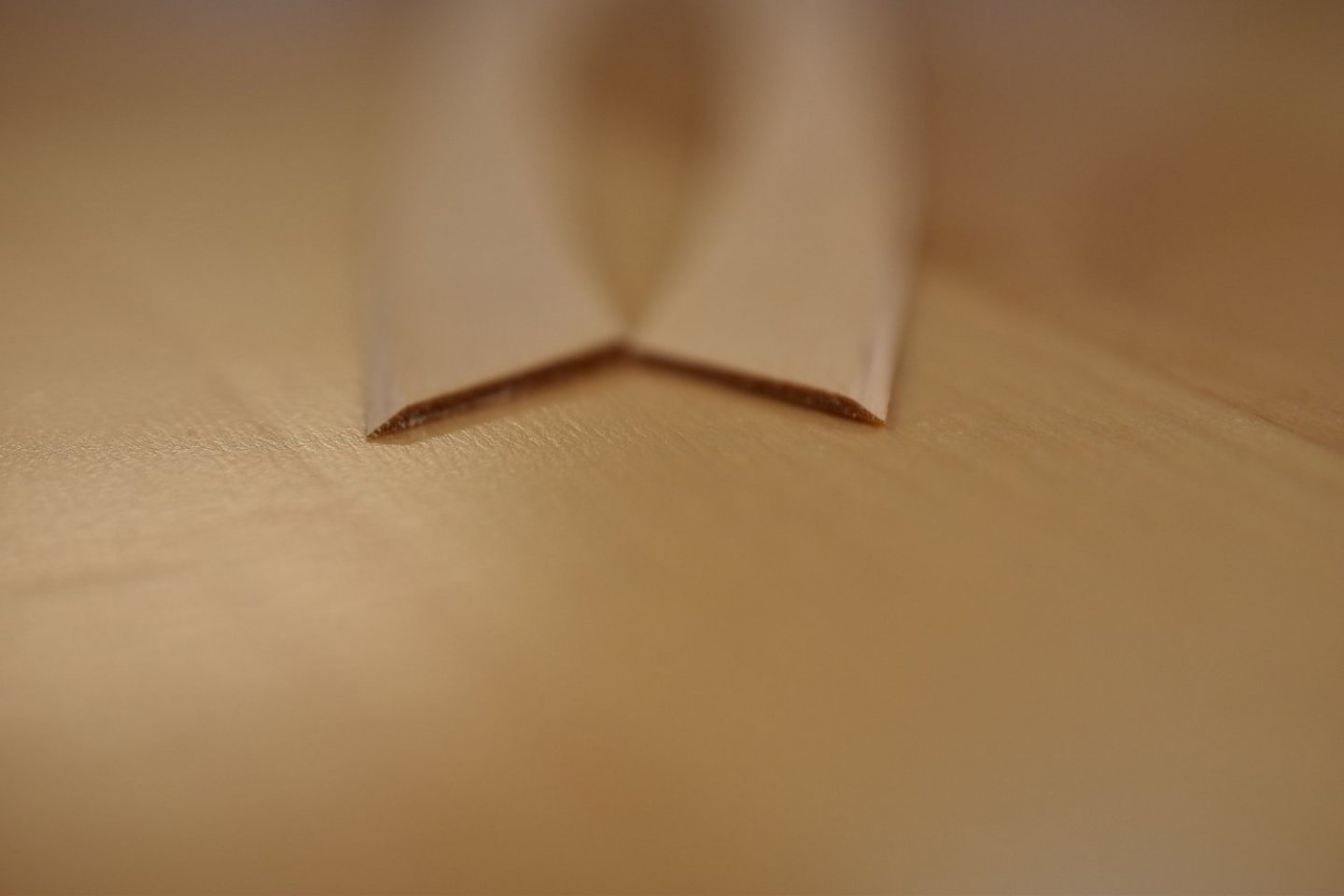

The problem was the alignment being off. The problem resulted in the ridge of the sheer plank to the broad plank was flush. I decided to try and put a very small strip in place and sand it back to reform the ridge. I think it worked pretty well. 👇

I have some issues with the fairness of some planks. I'm considering how to fix it. I need to look at it for a while and think. I might try a scaple knife and trim the offending areas to my liking. Not sure yet. I'm going to let the glue dry for today.

- mark.bukovich, Ryland Craze and JpR62

-

3

3

-

On 3/11/2022 at 12:08 AM, Valkyrja68 said:

Love it! That's my kinda analogy. I am having a hard time navigating this site for sure. There are fathoms of interesting and sidetracking info on here but when I do a direct search it's filled with everything I don't want. Right now I'm attempting to look up making sheets/sails of cloth. I've found some on paper and some on plastic but nothing yet on cloth that helps me...the search continues

I'm from Santa Cruz too, I grew up in Capitola BTW!💪

- mtaylor, Valkyrja68 and Keith Black

-

2

2

-

1

1

-

Hey over there Valkyrja68, I'm new over here too.🎸🤘

It gets foggy sometimes but I'm learning to navigate and learn to use all the tools and instruments for safe passage. I think when the seas get tough and you see mountainous swells rolling your way, the kind that make you get that sinking feeling, this joint can help guide the astute. 👍

- Valkyrja68, Ryland Craze, Keith Black and 1 other

-

2

2

-

2

2

-

You look like you're a highliner already! 😁

I have the half hull planking kit too, so make up a nice build log and I'll tune in to get prepped for mine, and soak up any knowledge you share.

Thanks for joining up here and keep up the great work on your fleet. I hope you can find the support you need to feel better.

- Ryland Craze, mtaylor, Keith Black and 1 other

-

4

4

-

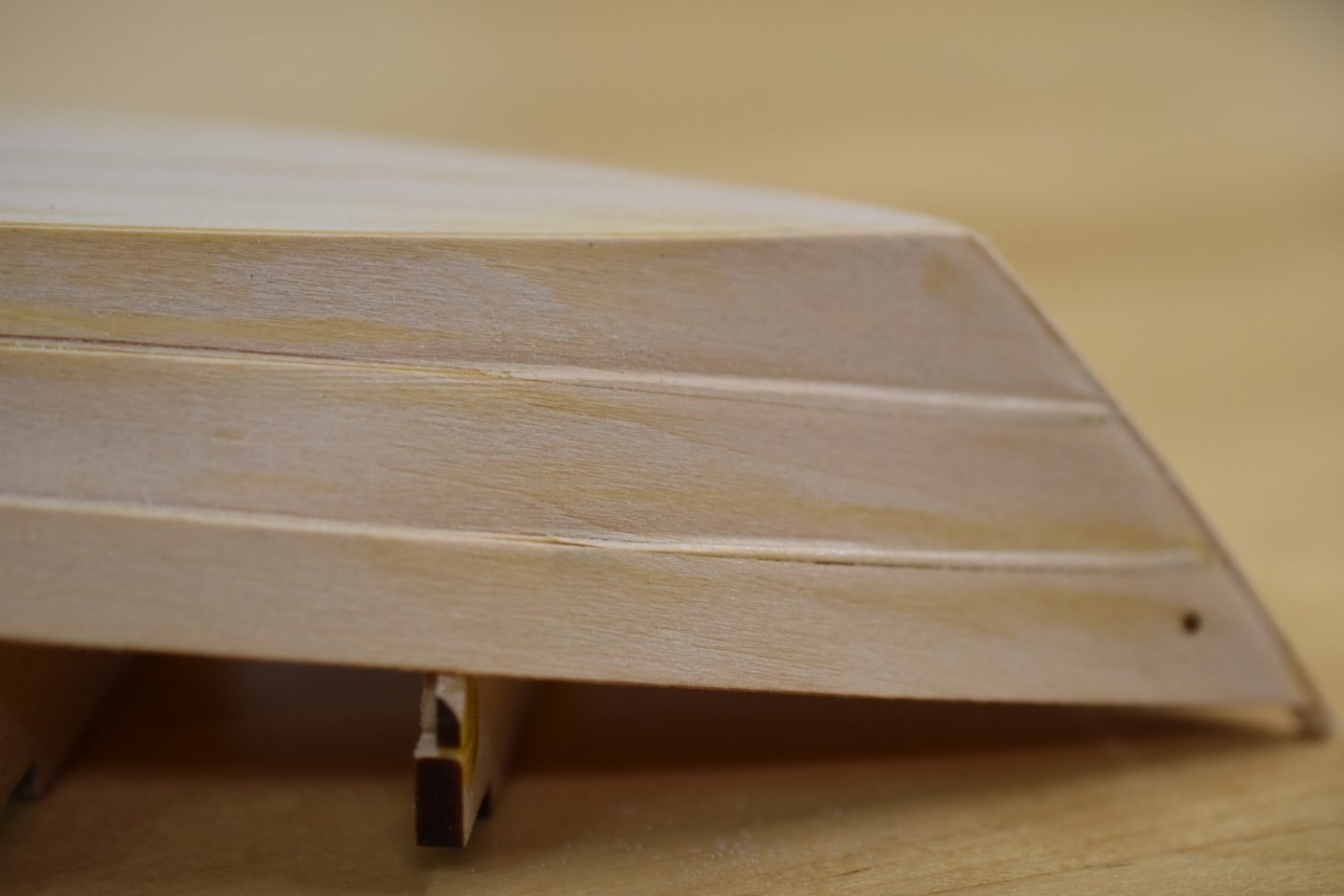

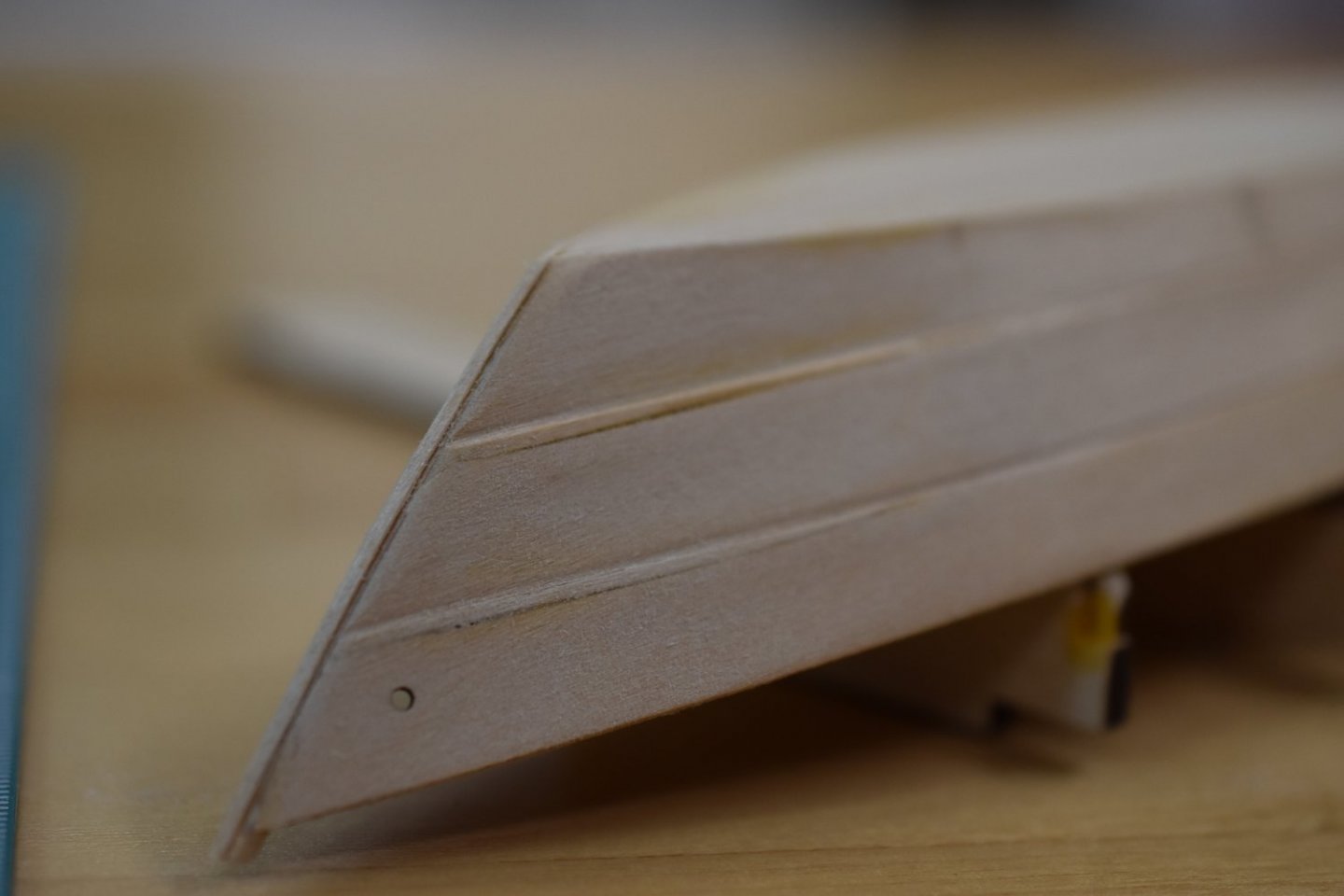

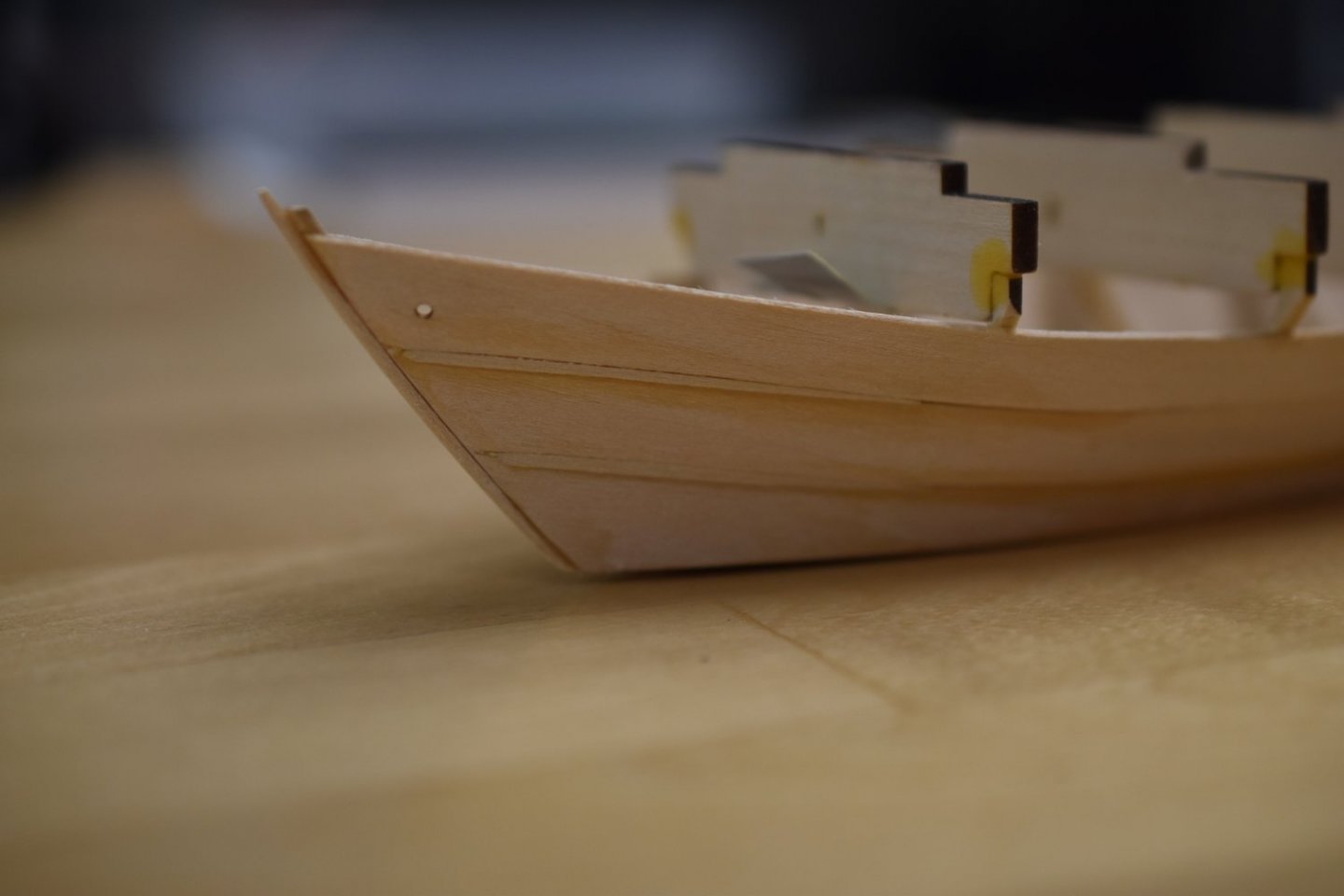

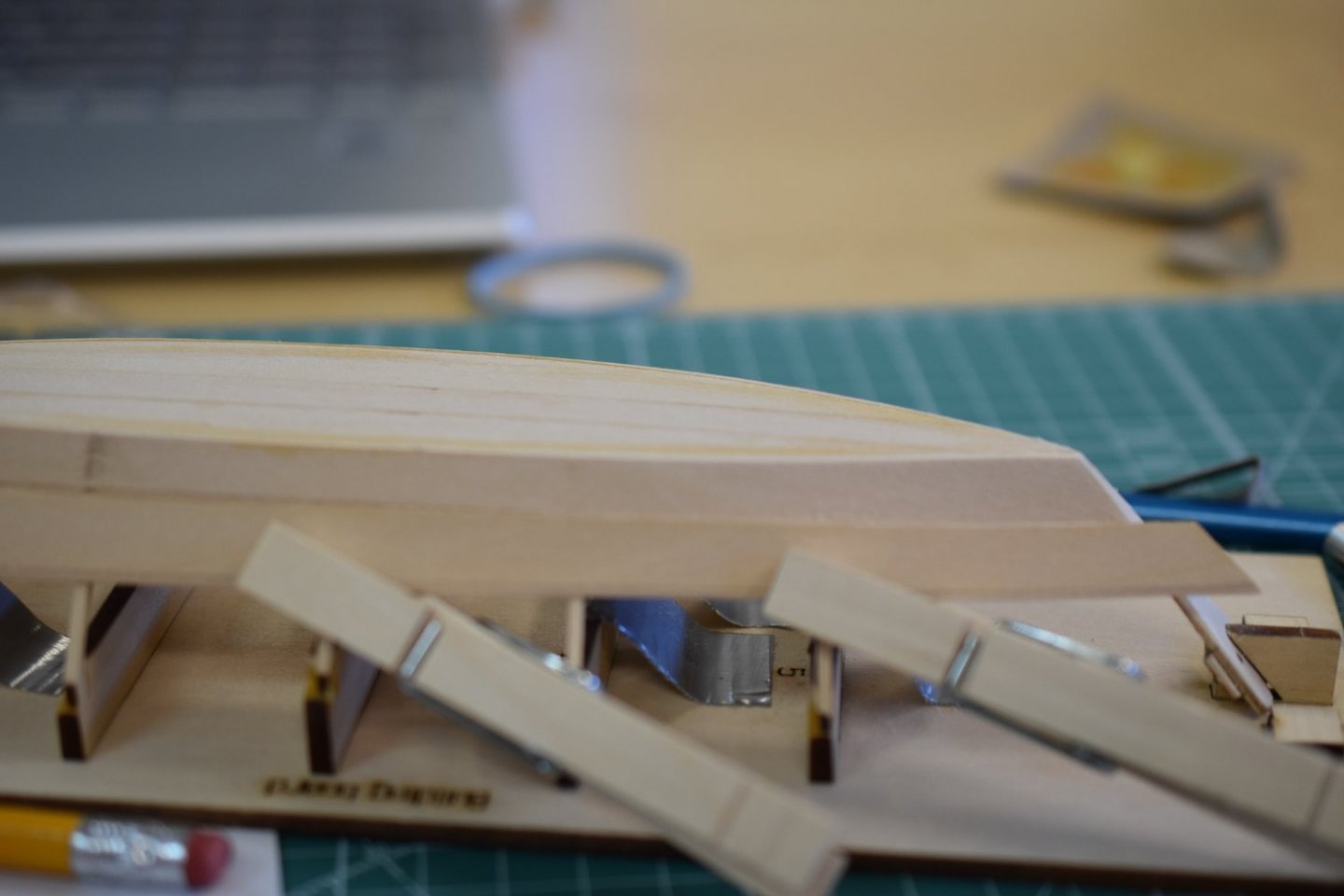

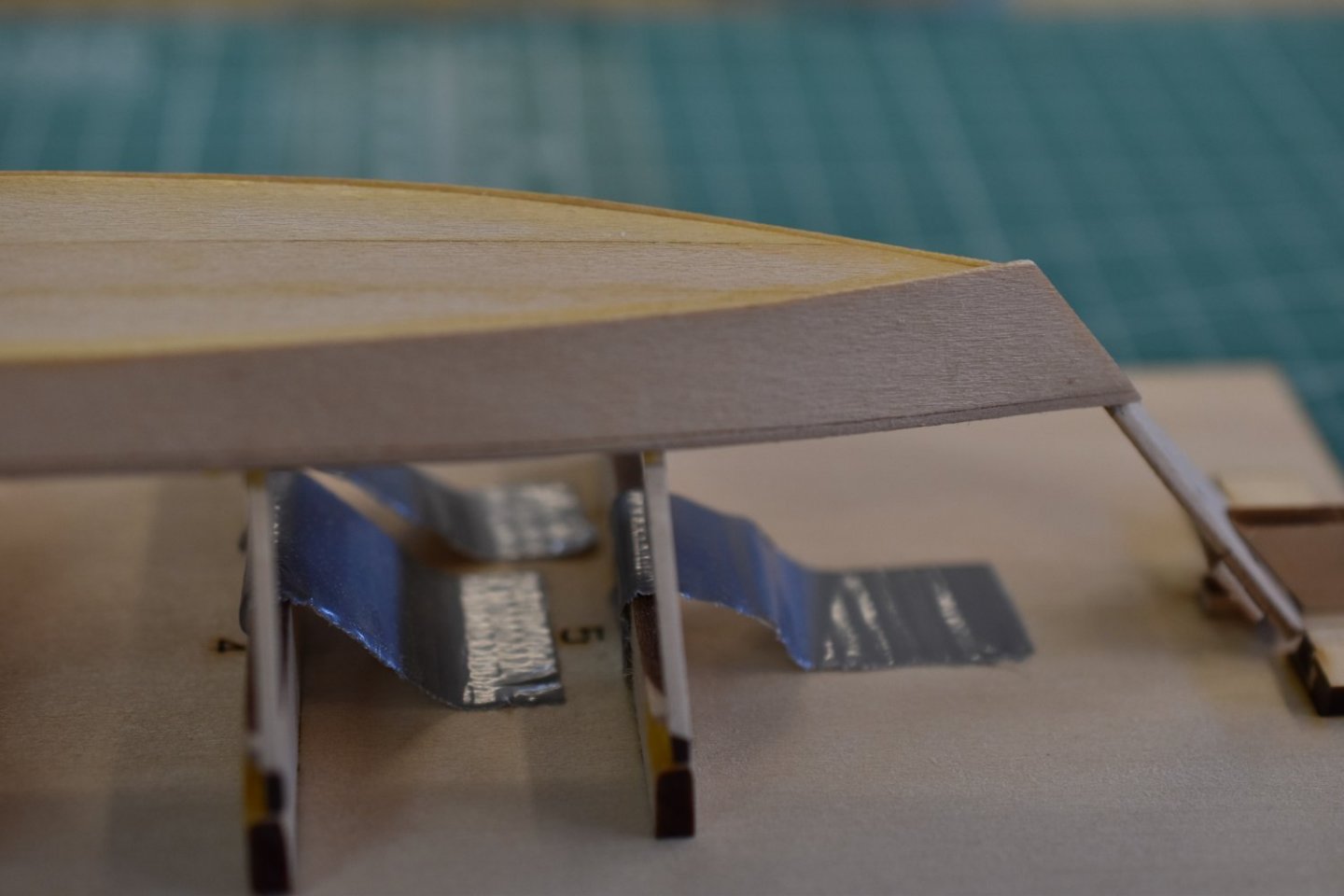

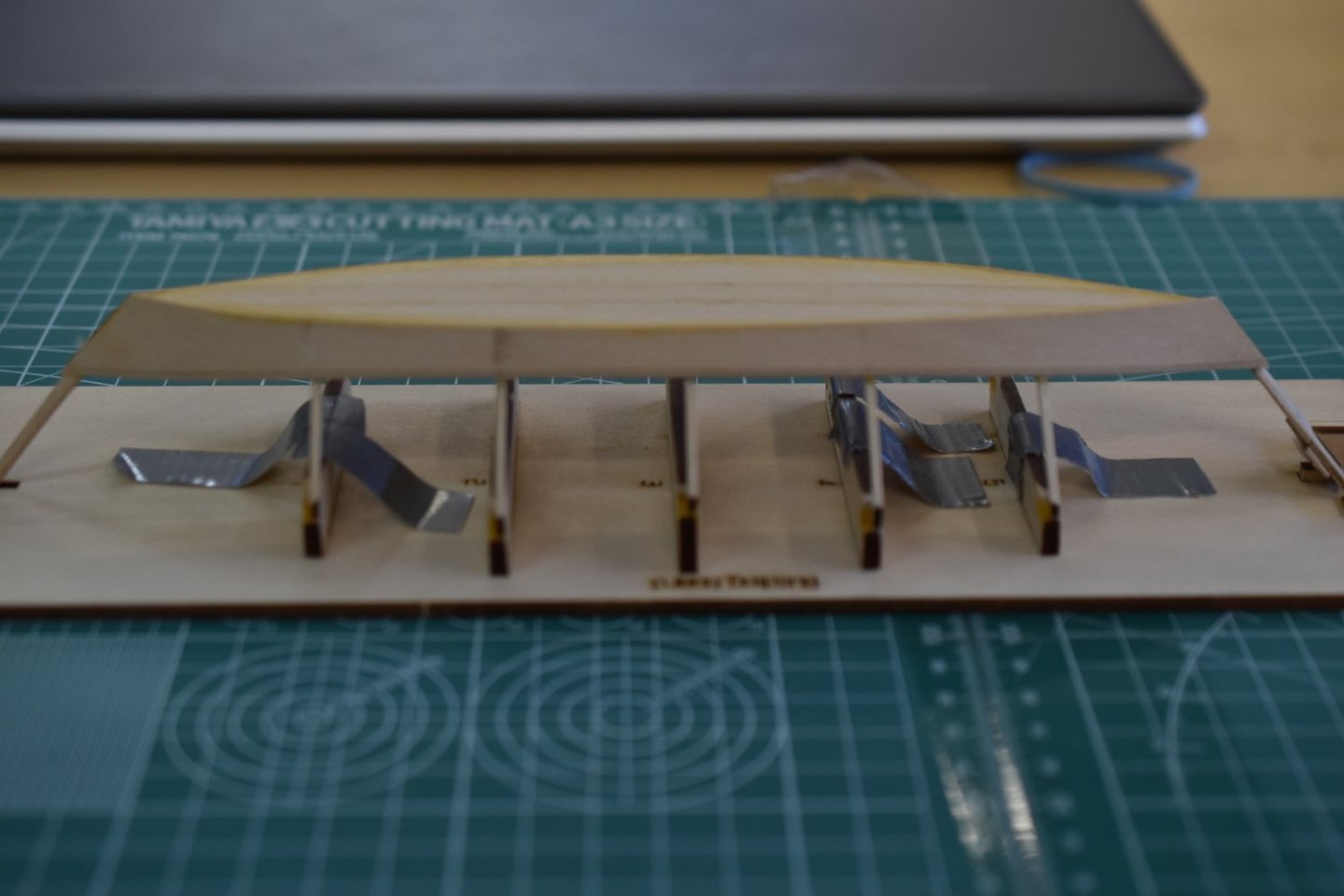

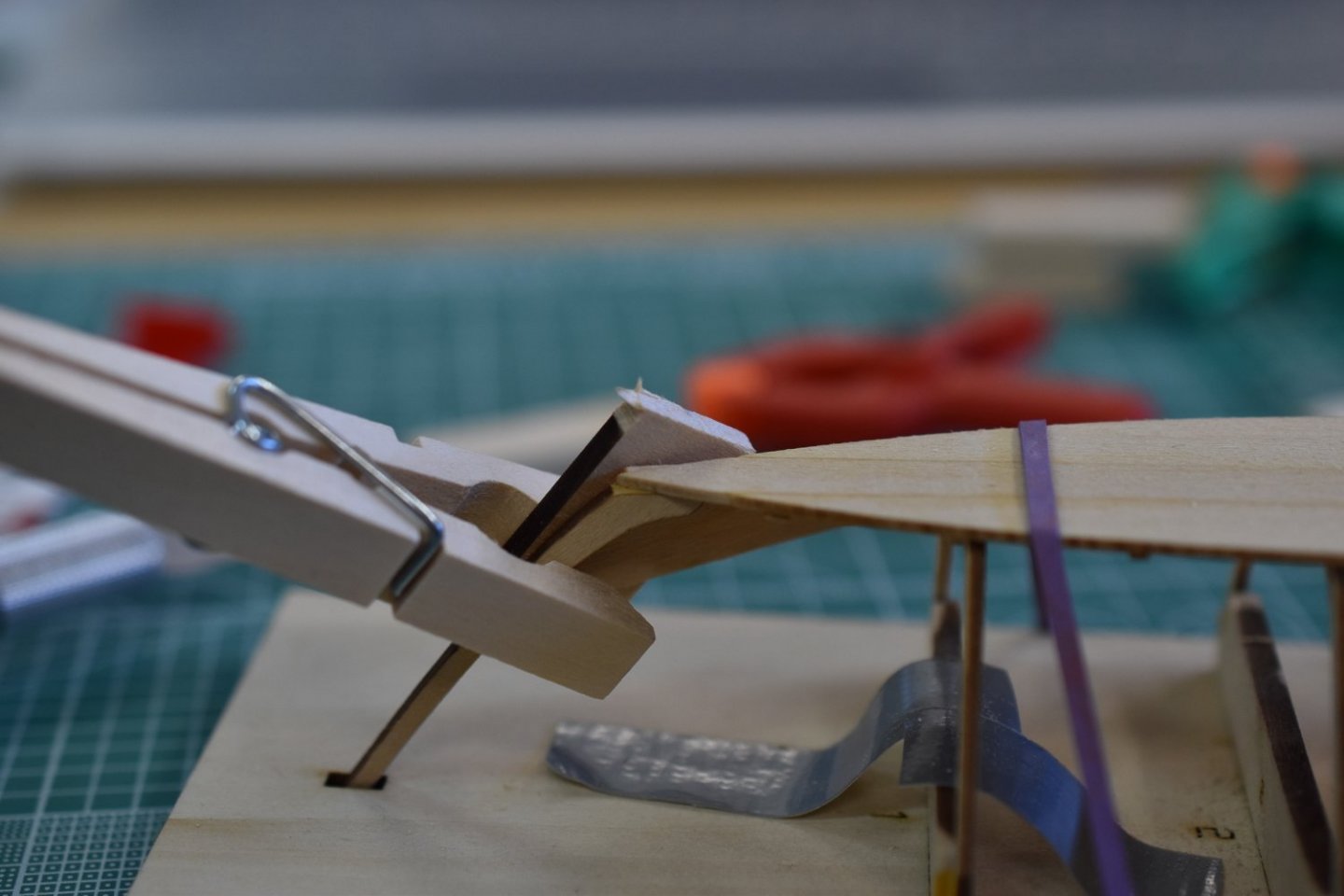

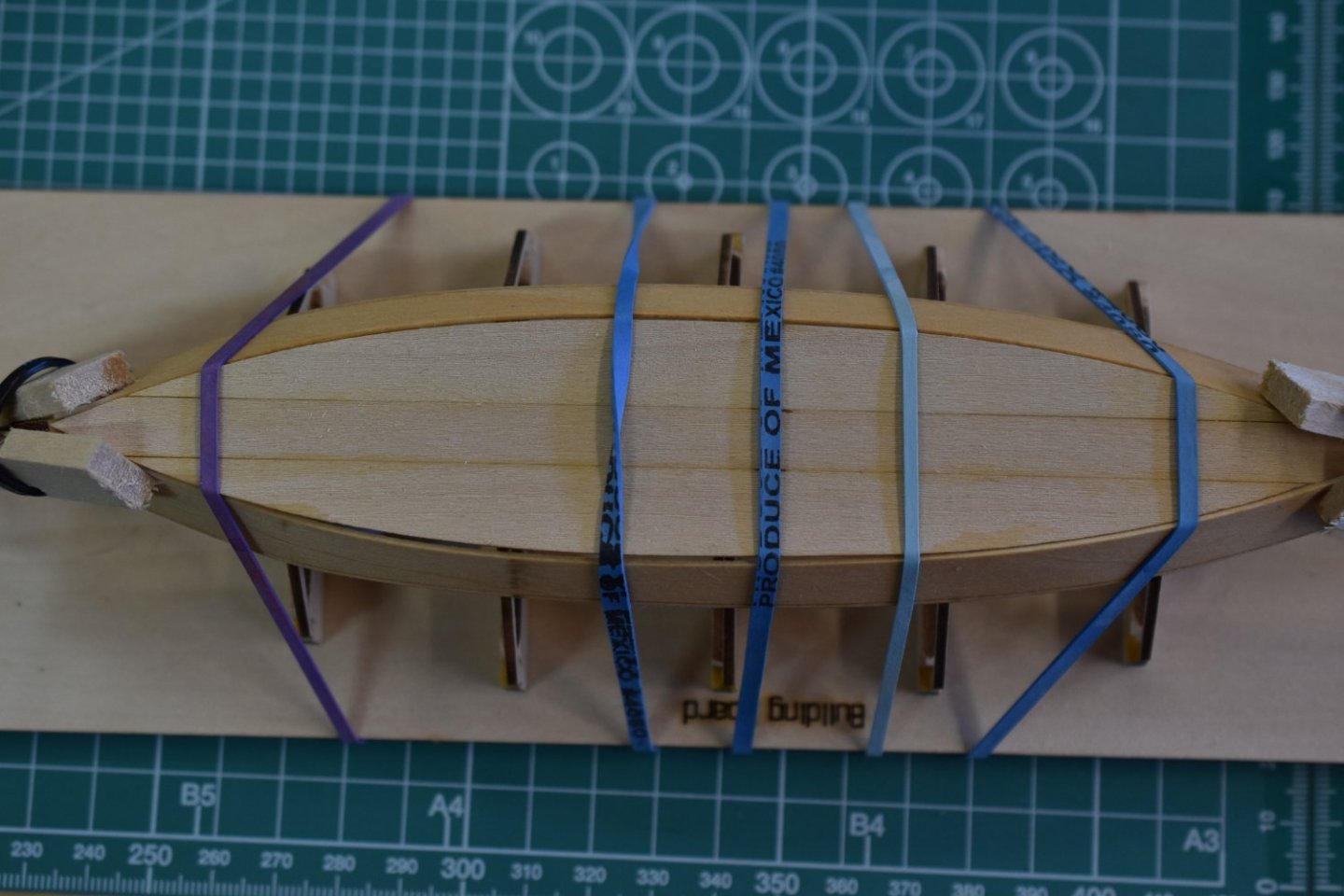

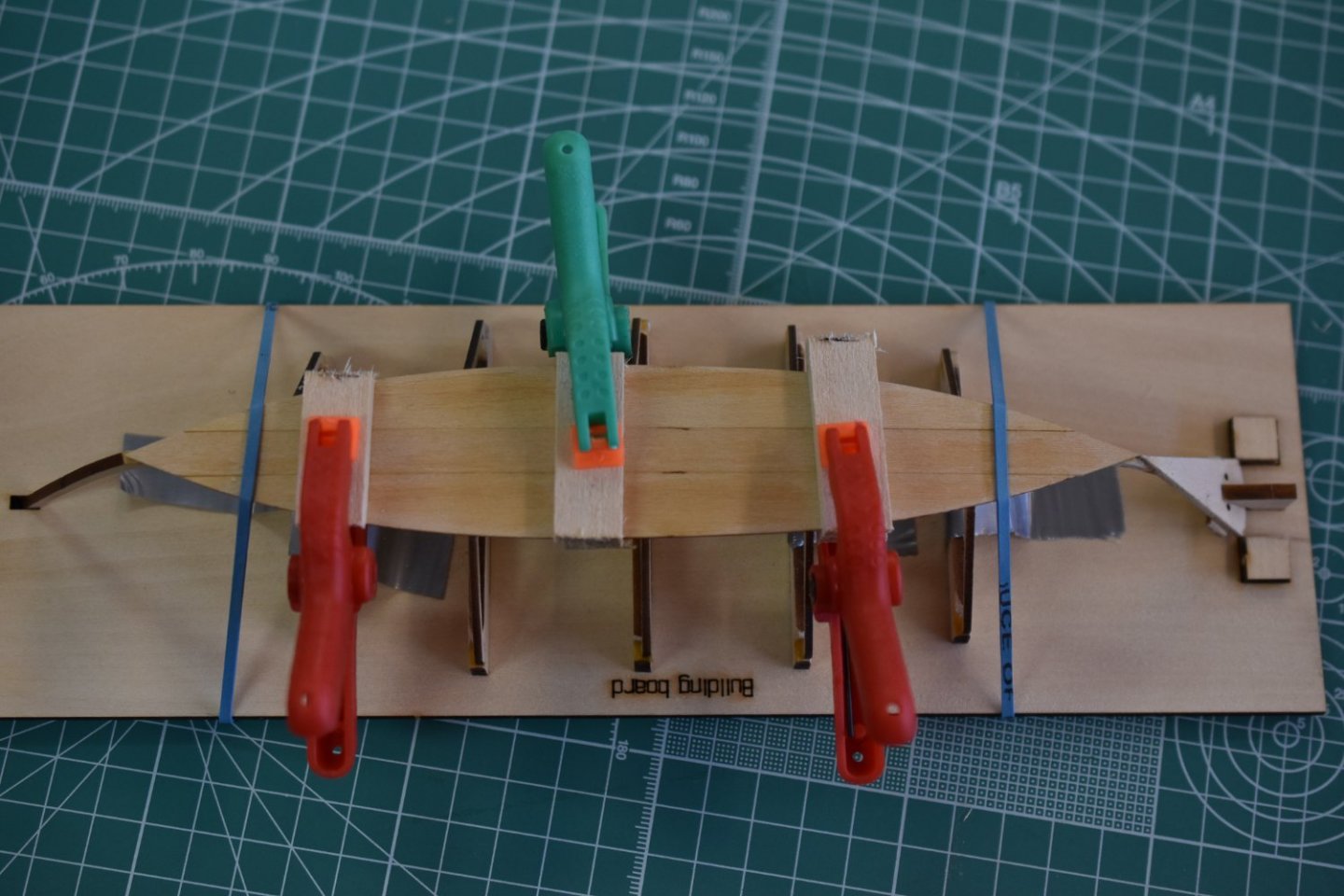

I attached the broad planks yesterday, as noted above. 👆 I got a few pictures after a bit of sanding. The planks look fairly level/even at the top so far after the sanding. I thought one side was going to need a bit of leveling, but it looks alright to my eye so far.

There are a few waves along the run of planks. the worst offending spot was because of the clamp was pushing the plank out and it escaped my attention. another lesson to note >>look closely at your clamps to be sure they're as correct as possible on all sides. They should probably only touch on the actual clamping surface of the clamp and not touch on the sides of the clamp because of a tough angle. It might push on the material you're trying to form and put a ripple in it, like it did to me.

I think I'm going to wet that area of the poor spots on the plank(s) when I glue the sheer plank on and see if the sheer plank can pull it in fair.

I'm going to be spray painting this boat and starting to wonder, I guess I should prime it very lightly to seal the grain, then sand it lightly to knock the grain that raises when it gets wet from the primer? The primer seals it and then the grain won't raise again. I read this somewhere, but I'm not sure where.

- Ryland Craze and JpR62

-

2

2

-

2 hours ago, Clueless said:

The Admiral is doing MUCH better since my near loss of her, so I just might be able to get back to mine this weekend!

Sounds like some great news Clueless! I hope you're able to do that and have a good rest from the stress of ill health. 👍

-

2 hours ago, druxey said:

Have you tried elastic bands?

No druxey, I didn't try elastic bands yet, but these cords are stretchy like elastic and cinch up nicely. I will try them again when necessary.

On the broad planks tonight I tried using super glue. My technique was flawed on the first side, but it went a little better on the second side. I like how it cures fast. I used regular wood glue on the frames and the super glue on the stem and transom. A little more practice with that method should prove worthy.

1 hour ago, DanB said:Hi.

I am still pretty new to all of this, but found that soaking the planks for 5 minutes, then using rubber bands to attach the to them to the boat and allowing them to dry got the shape pretty close, and it did not take a lot of pressure to glue them down . If you want to speed up the drying process, someone on this site gave me the excellent advice to use a hairdryer. That also works well if you need to bend and adjust the plank a bit more. There is a "rolling bevel" on the inner surfaces for the ends of the planks described in manual. I think was not much, just a bit to get them to come together at the bow and stern better. I just glued the planks down a bit at a time using white glue, a bit of finger pressure on the dry bent planks and some spring clamps and rubber bands. I put some paper towel scraps between the clamps and the wood to avoid denting it..

Others have stained the wood, especially the thwarts and the stand. I think you get a better, more even result if you use a pre stain to prepare the wood. . Definitely try it on scraps first. I think the glue could affect the evenness of the stain. There is one of these dory models on this site that was stained and weathered and looked really great- I was happy to just get the paint on with out making too much of a mess.

Dan

Thanks for the intel Dan. I think I'm may only stain the thwarts. I'll be painting the hull and cap rail. I've got glue stains in too many places for a staining job to look alright I think.

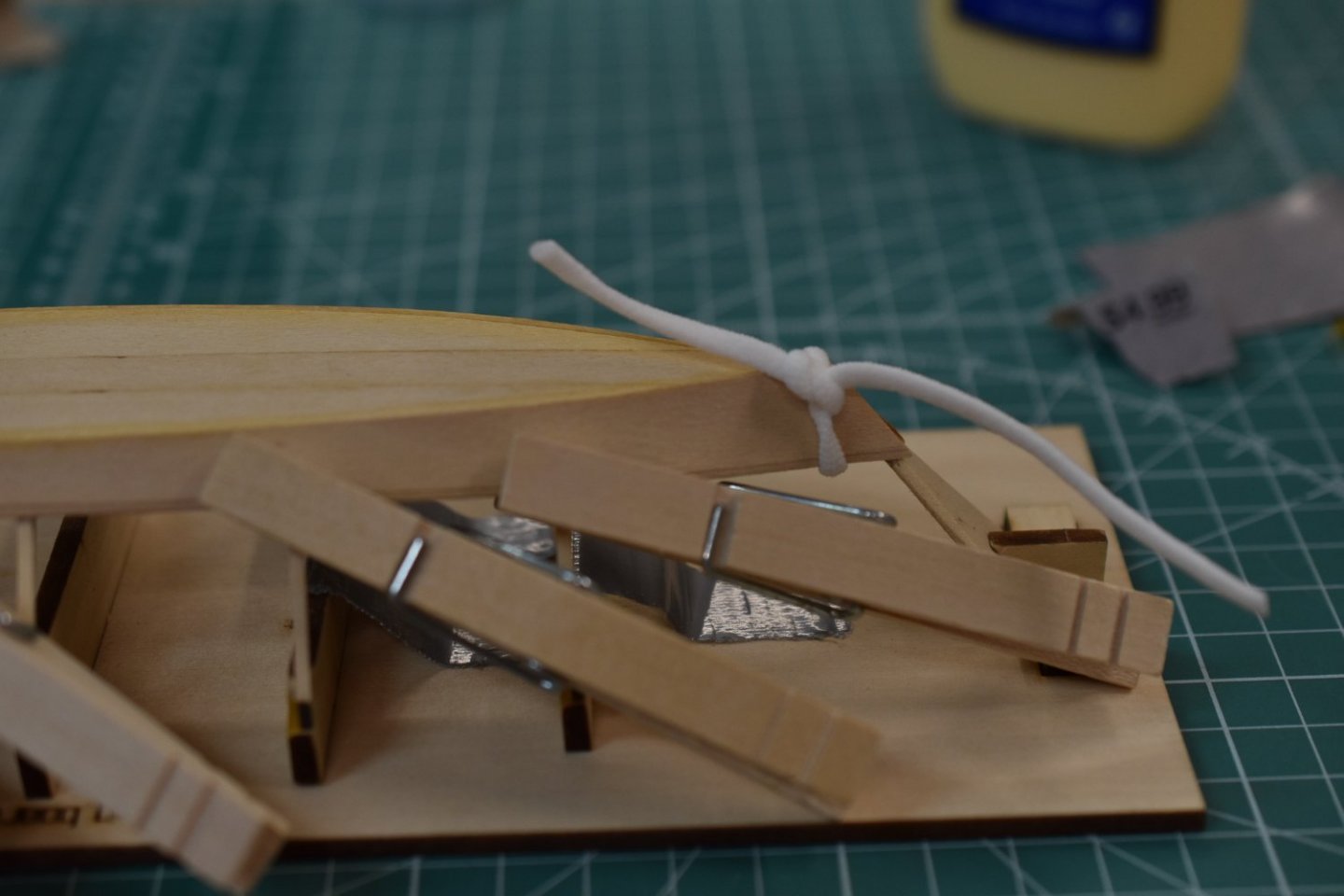

I have tried rubber bands and they worked well for me in the middle portion, but on the ends I'm going to stick with the elastic cord stuff I tried. I'm also going to use super glue. I'm going to start with painting wood glue on the frames along the length of the plank, except for the stem where I will put a dab of super glue at the last second. Then I will attach the plank to the super glue and quickly align the plank across the frames with wood glue already applied. I will hold finger pressure until the super glue dries enough to hold. After making sure the alignment is alright along the plank I'll clamp it or use rubber bands (tonight I clamped the plank to the frames). Then I'll apply super glue to the other end of the plank and hold finger pressure until it grabs solid.

I did this tonight and it worked well enough that I think with more practice it will be a smooth method. I'm going to repeat it a few more times to see if I get comfortable with the super glue on the ends. I think I read somewhere that super glue hasn't been proven over a long period of time yet though?

- druxey, mark.bukovich and Ryland Craze

-

3

3

-

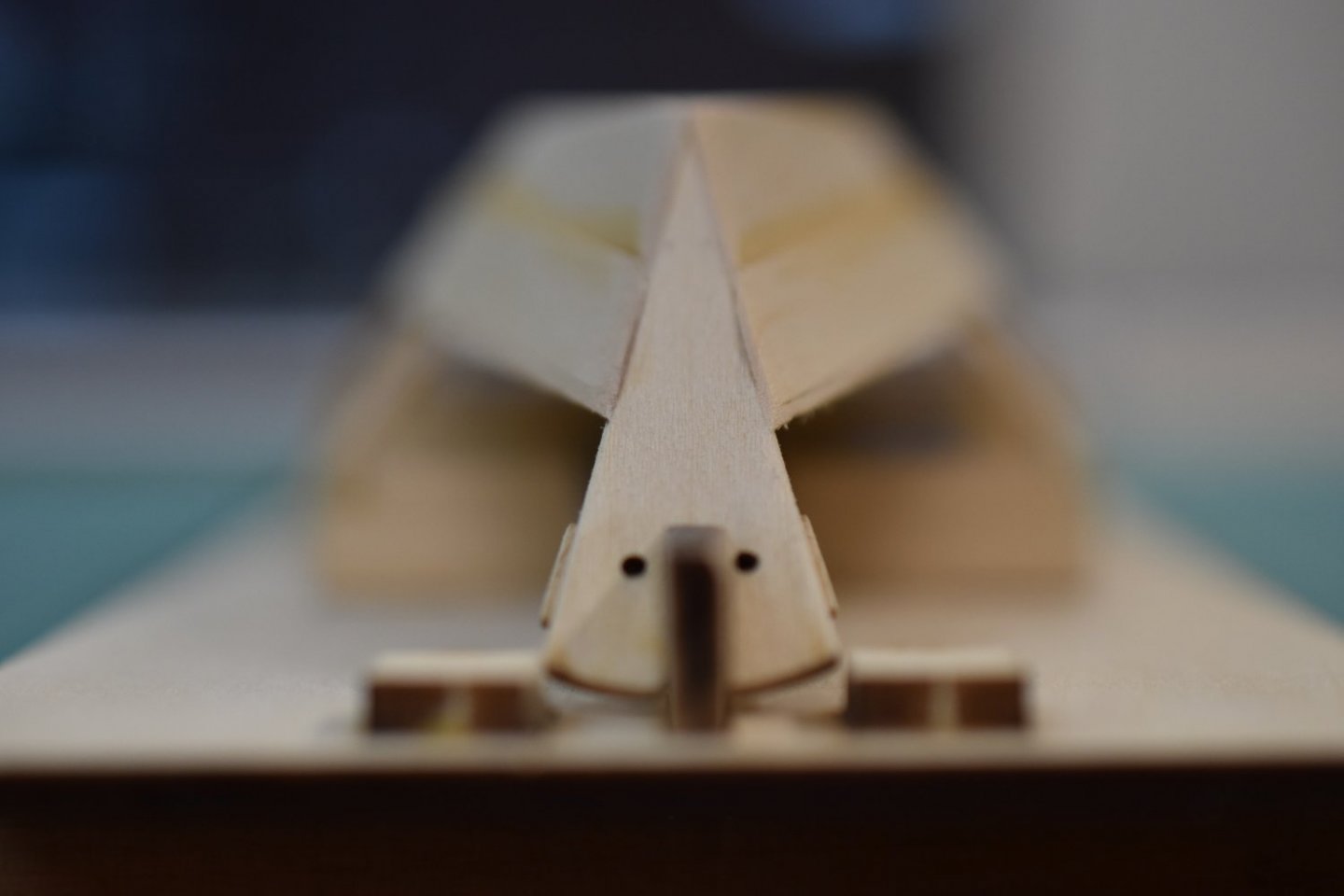

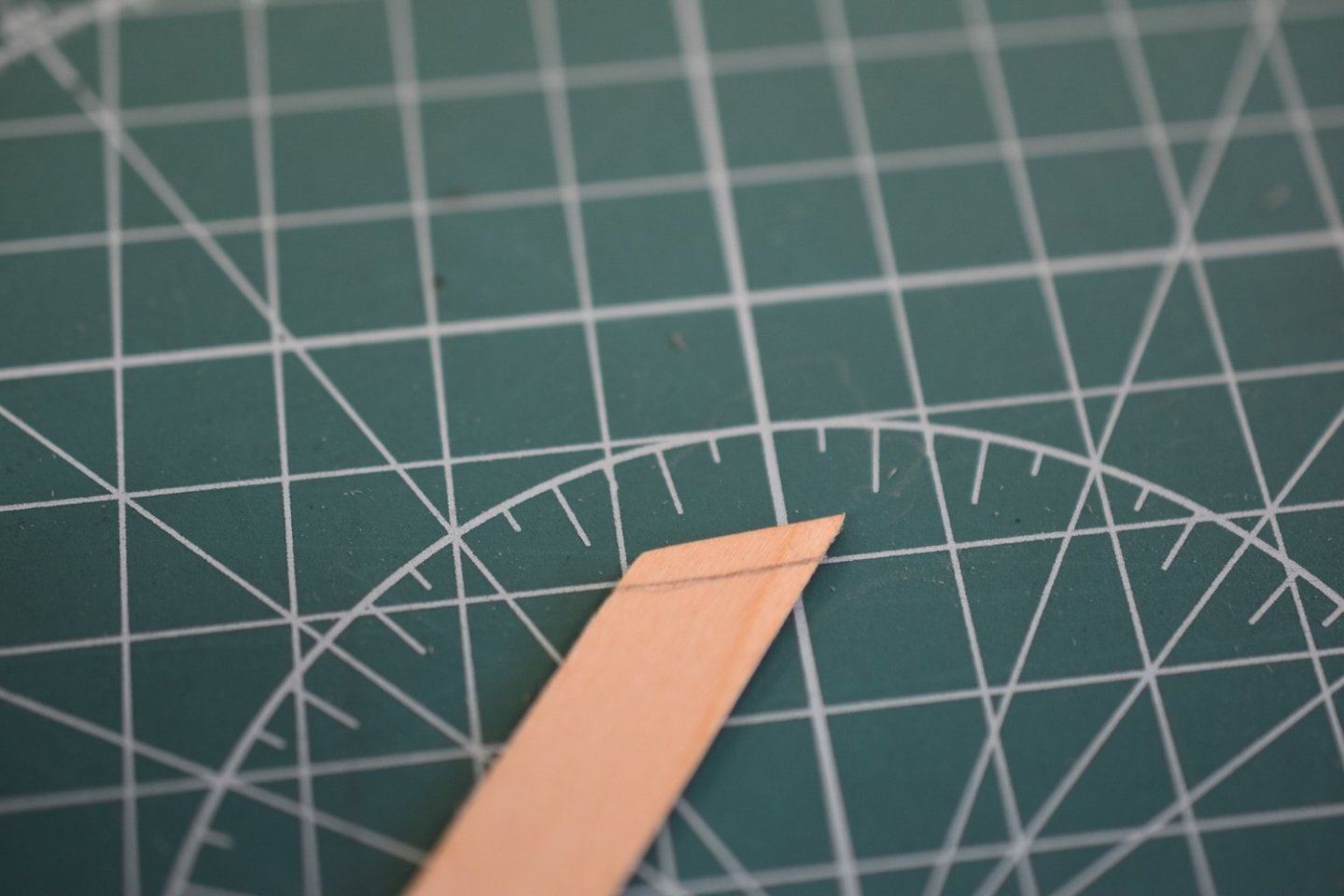

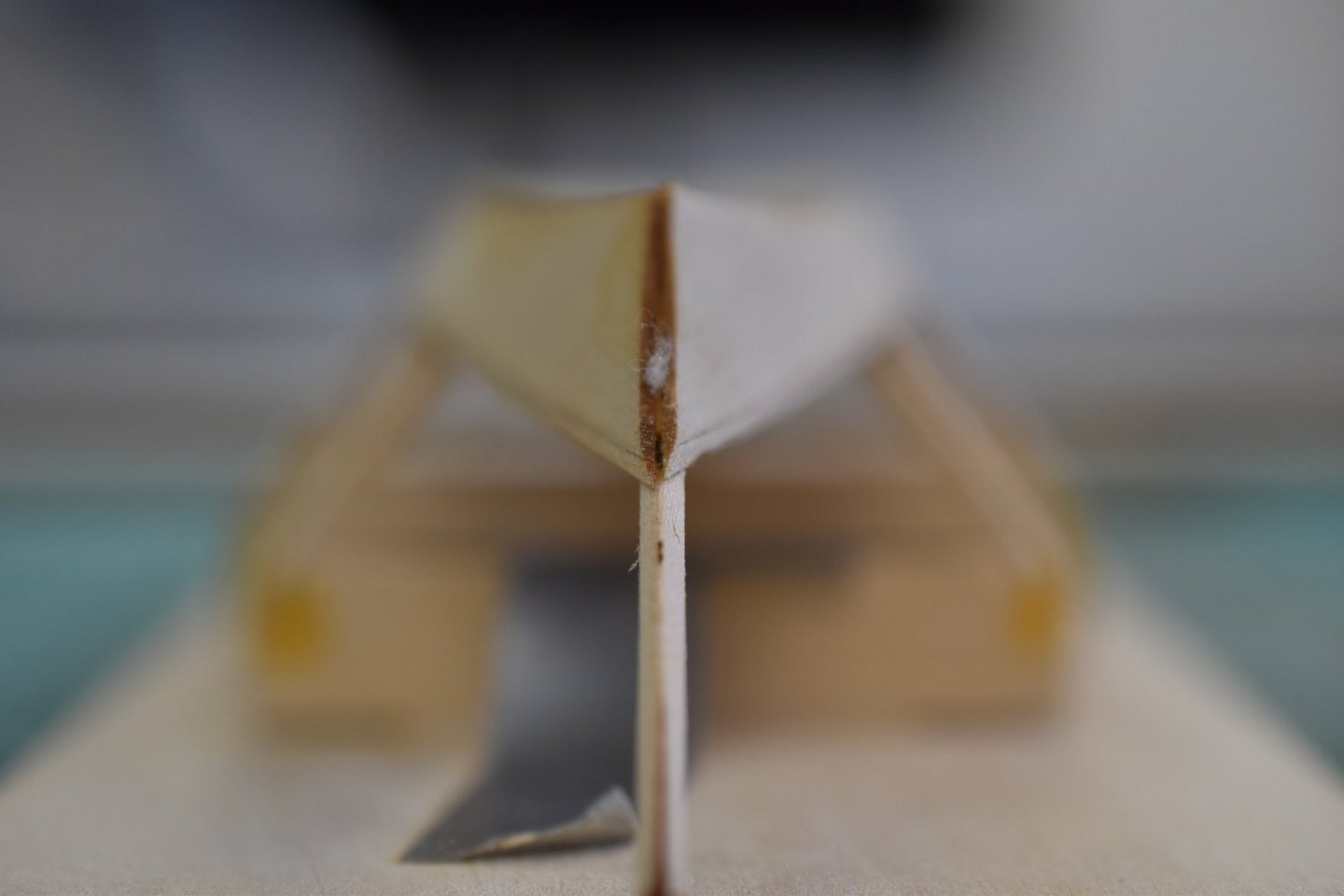

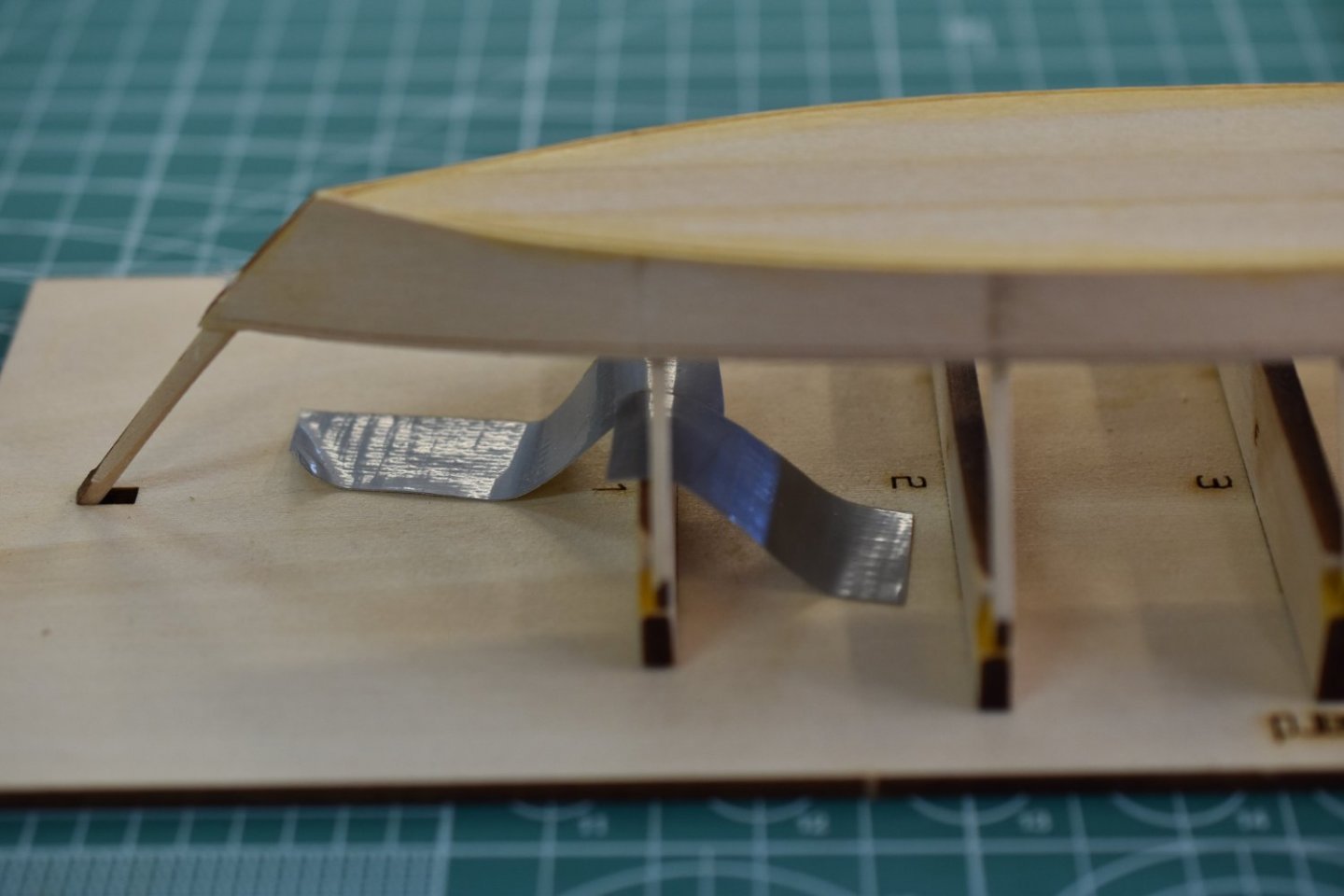

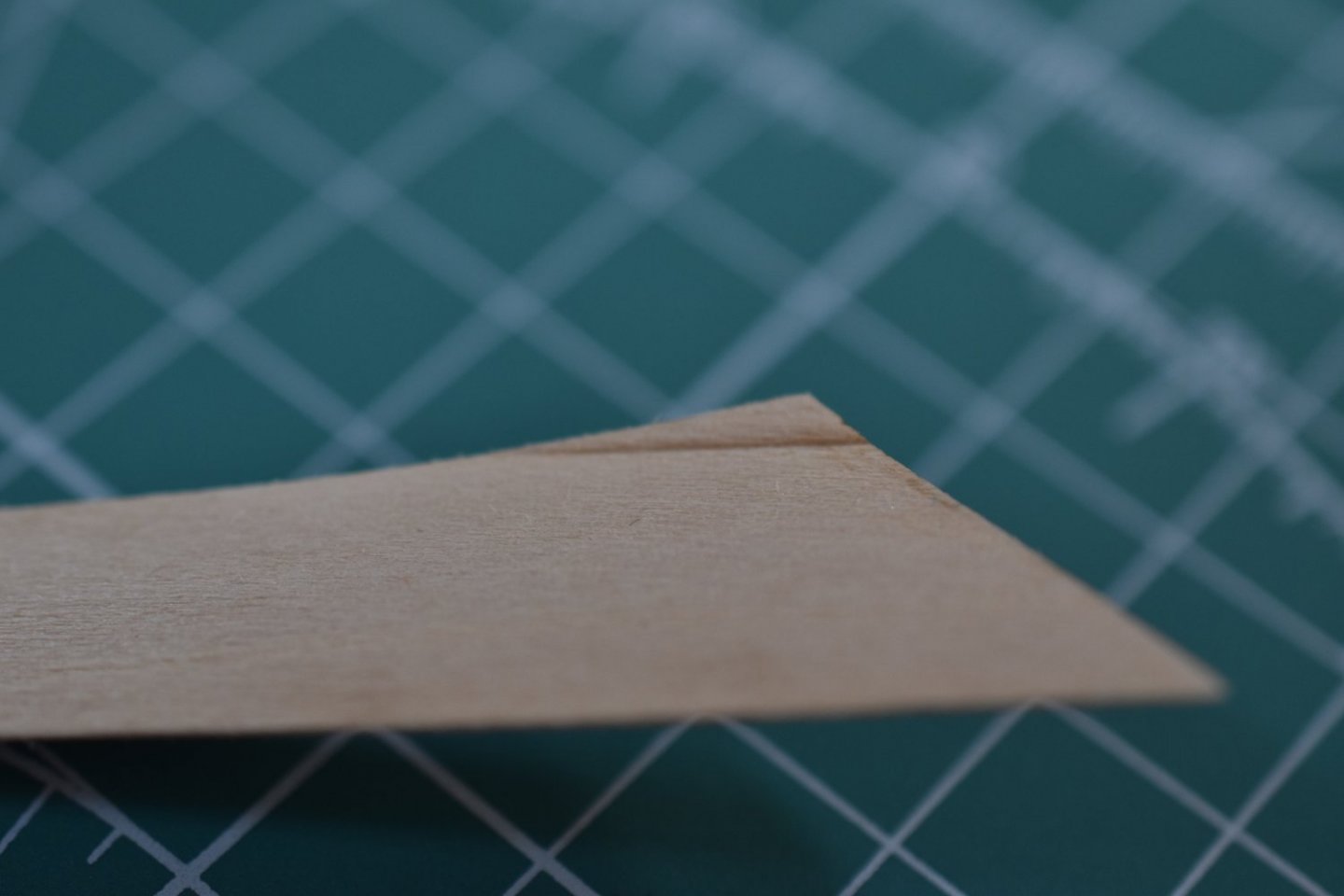

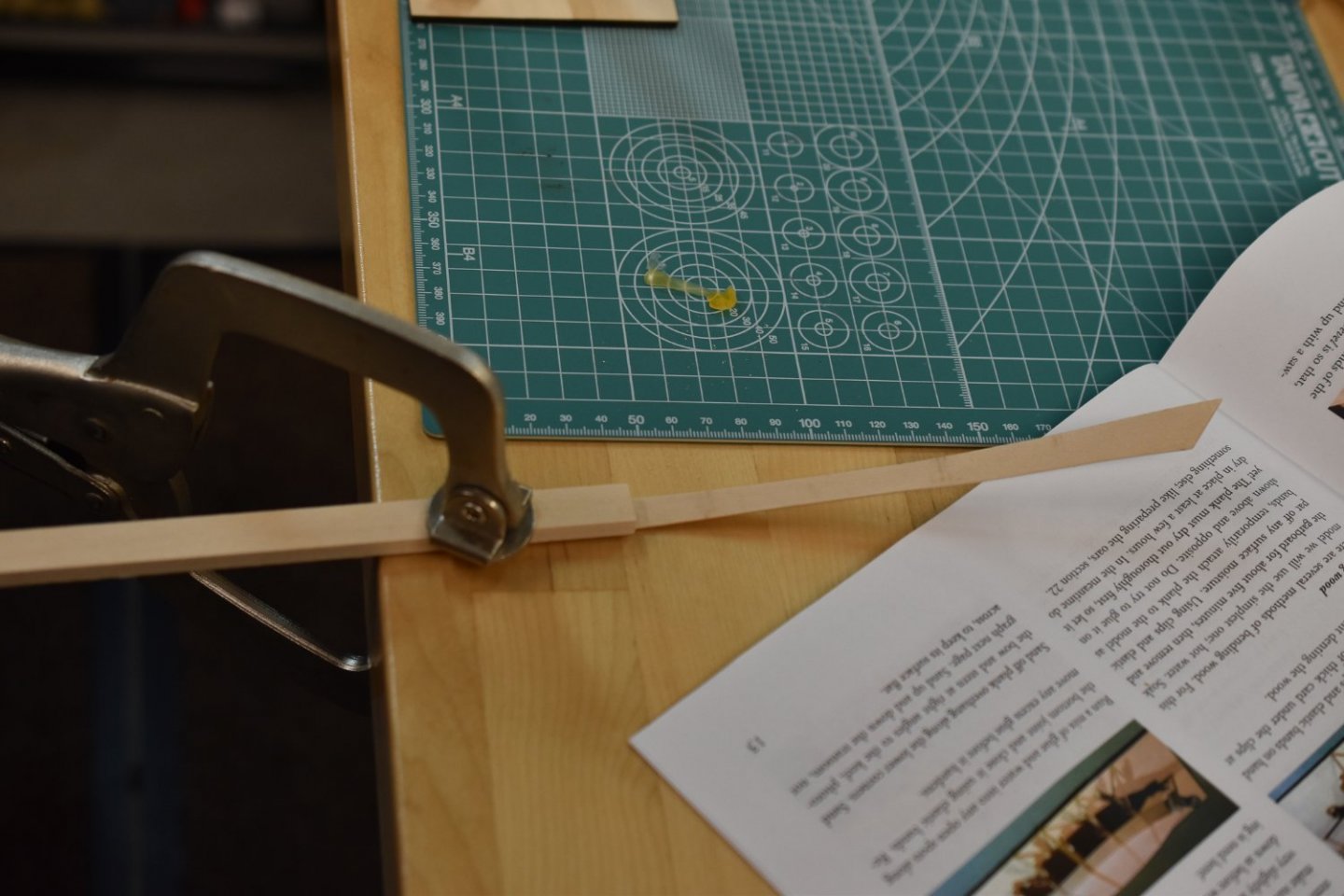

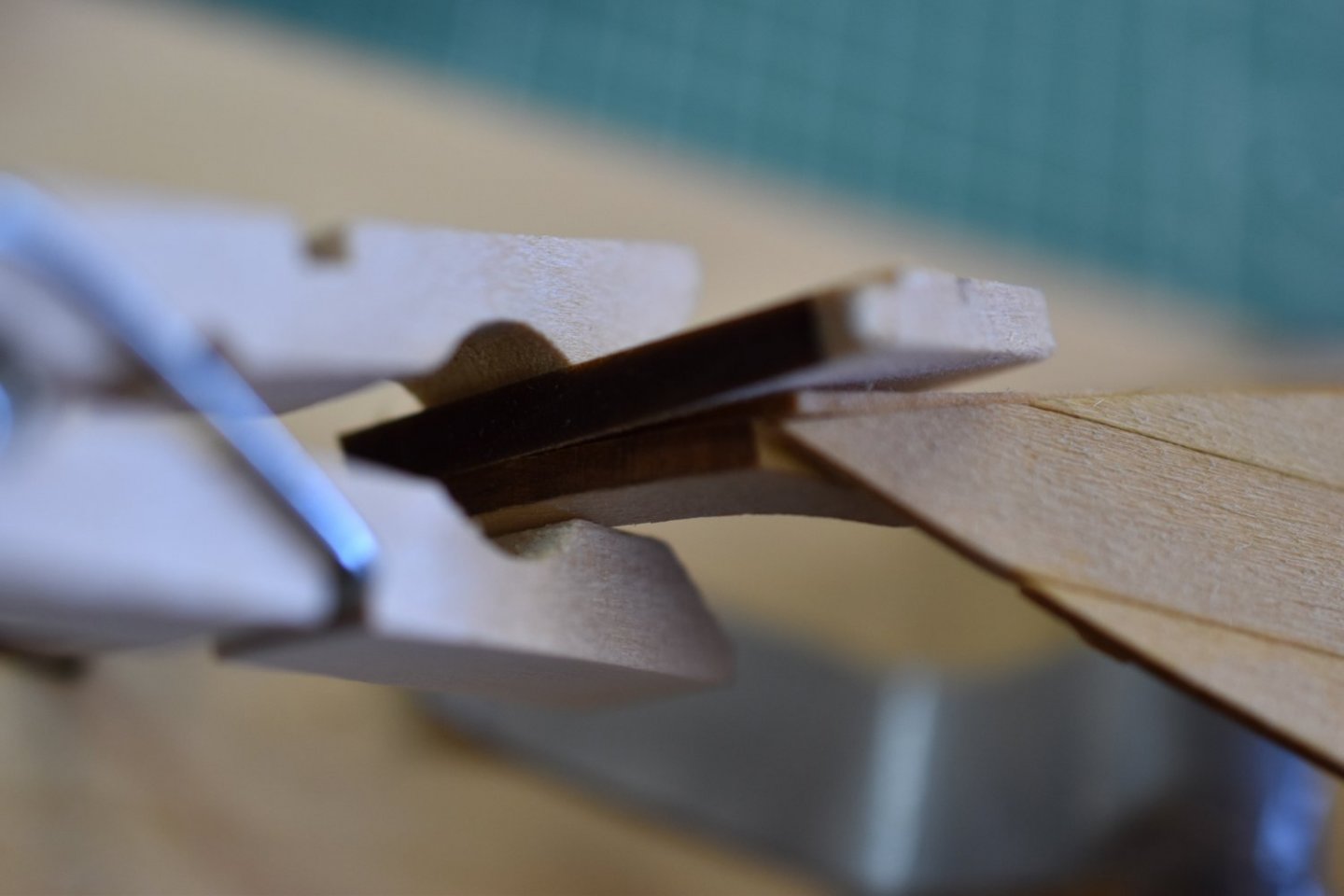

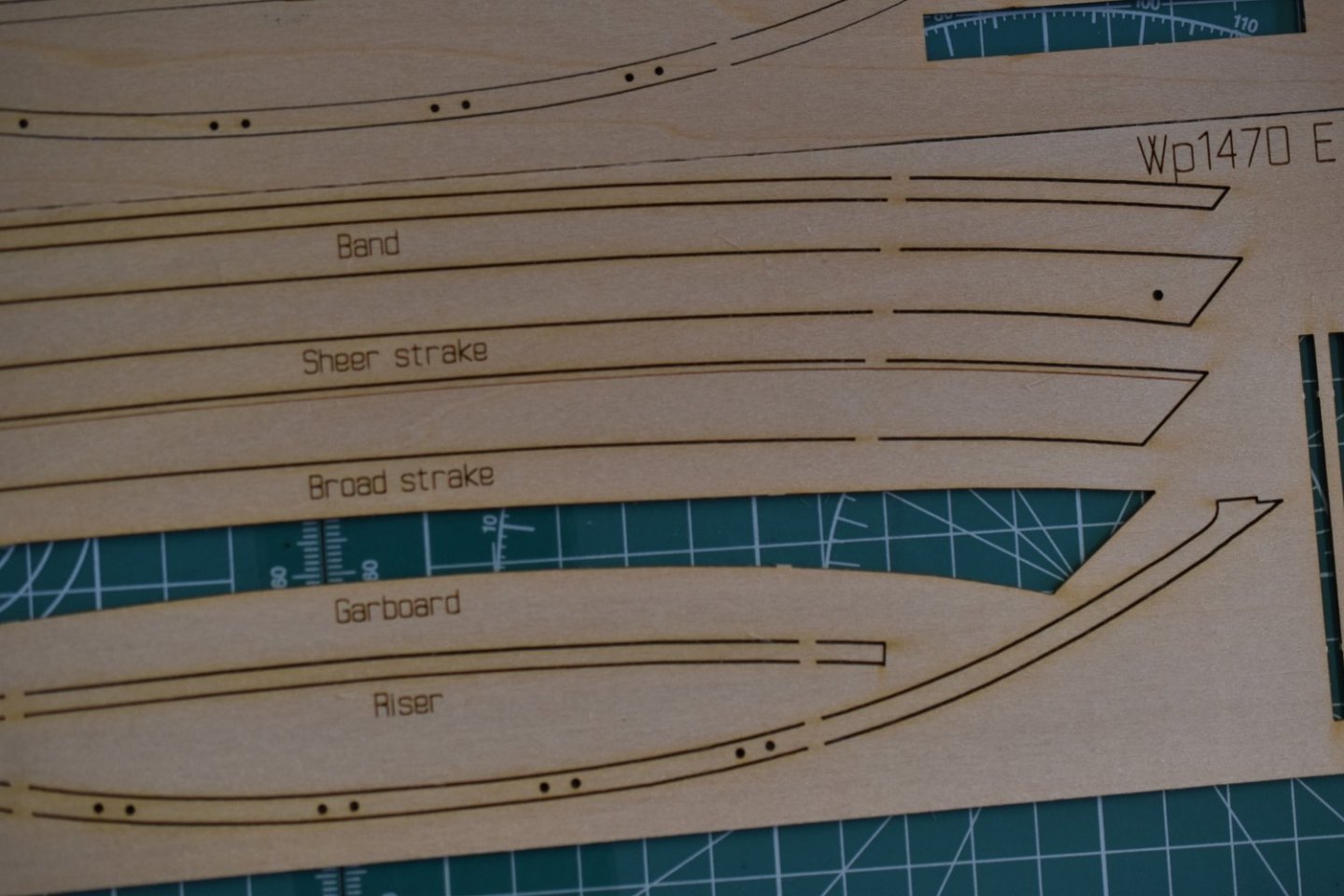

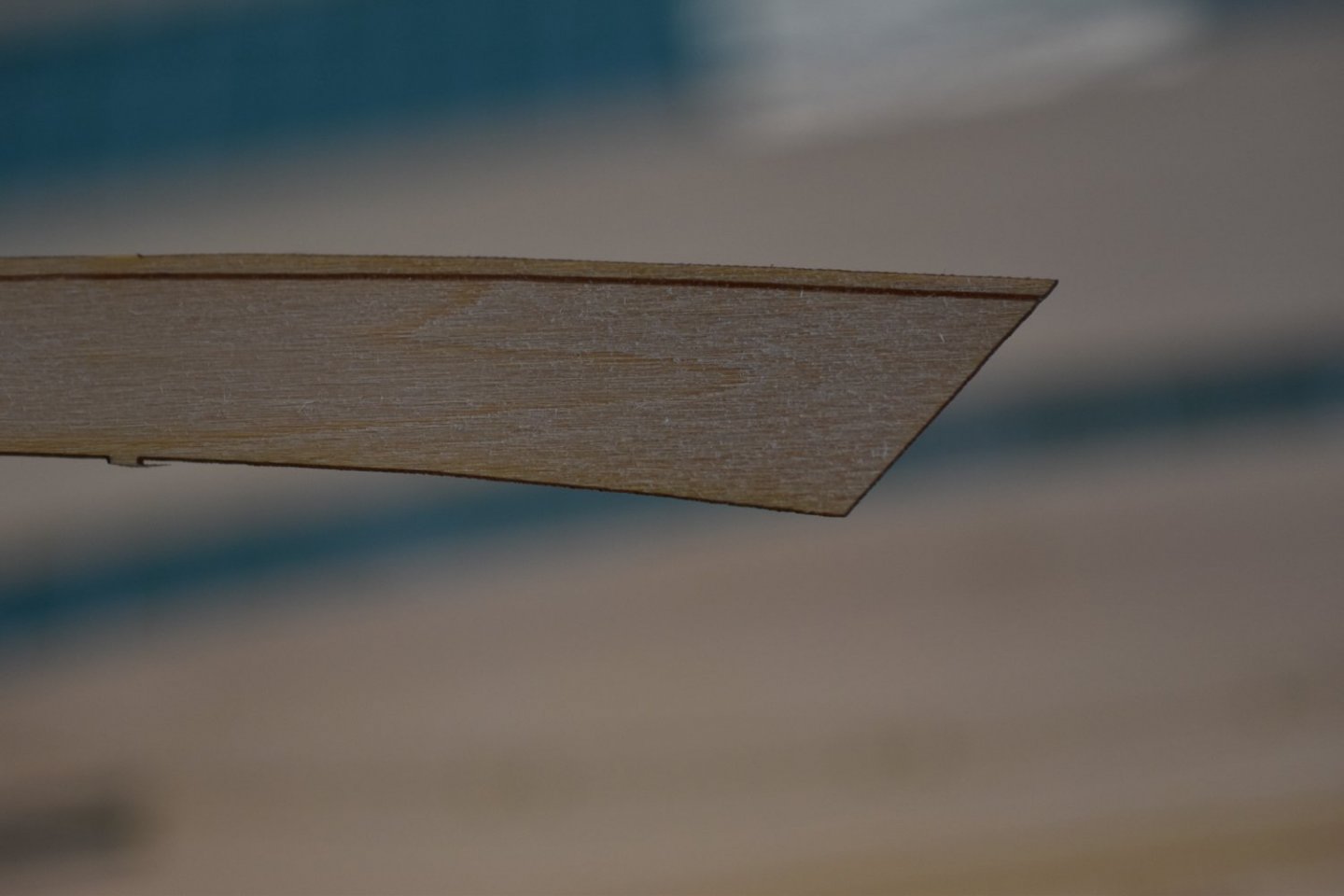

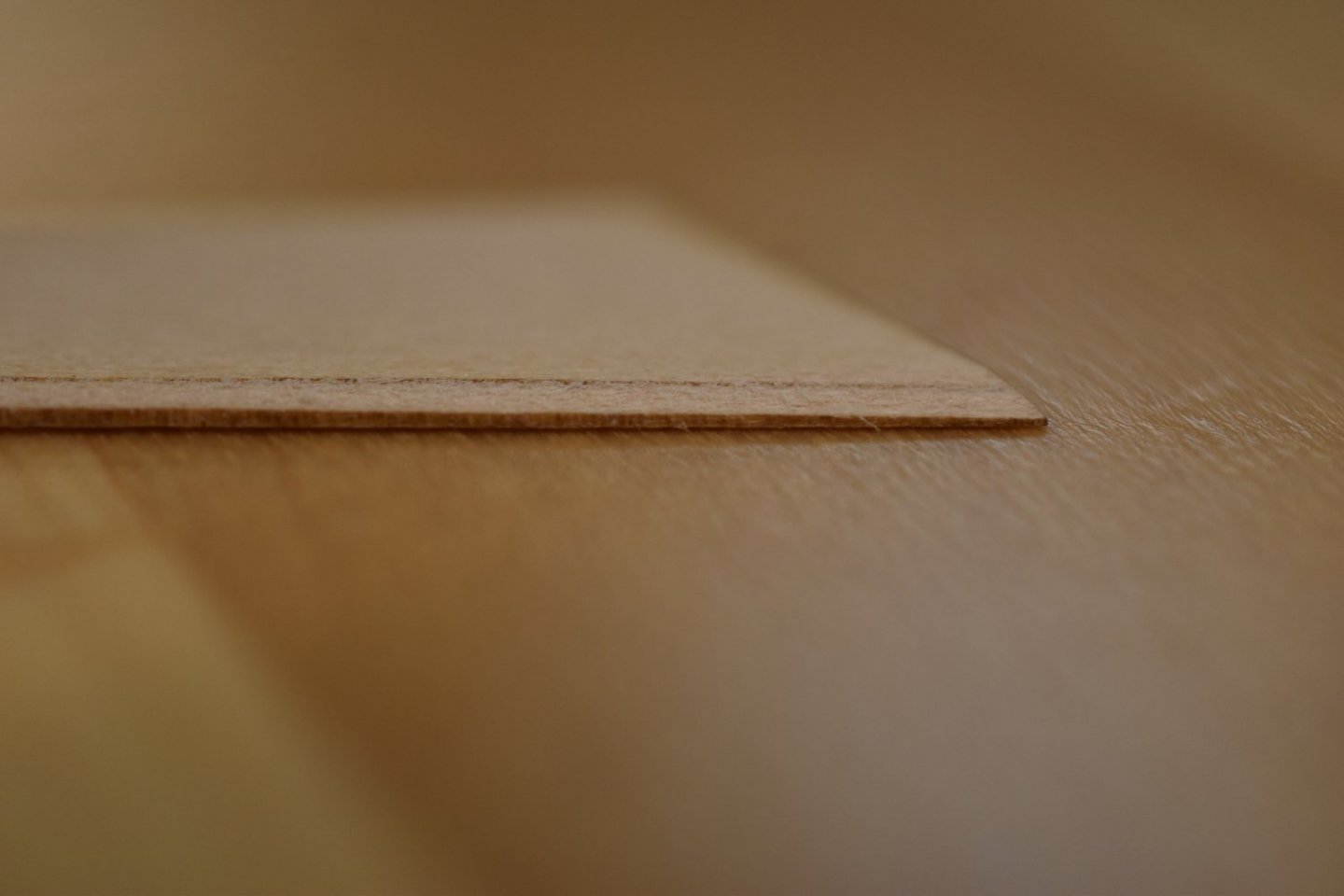

I'm preparing the broad planks. I found the length a bit long, so I trimmed some of the extra after some alignment.

I sanded the bevels on both ends and the length of the upper edge. In the picture in the instructions it looks like there is a bevel on the inside lower edge along the length too, but I'm not sure. I did bevel the inside lower edge length, but didn't on the opposite side broad plank. I'm going to compare the result once they form up and dry.

- mark.bukovich, Ryland Craze, druxey and 1 other

-

4

4

-

Thanks Drux! I'll look at that and take note.

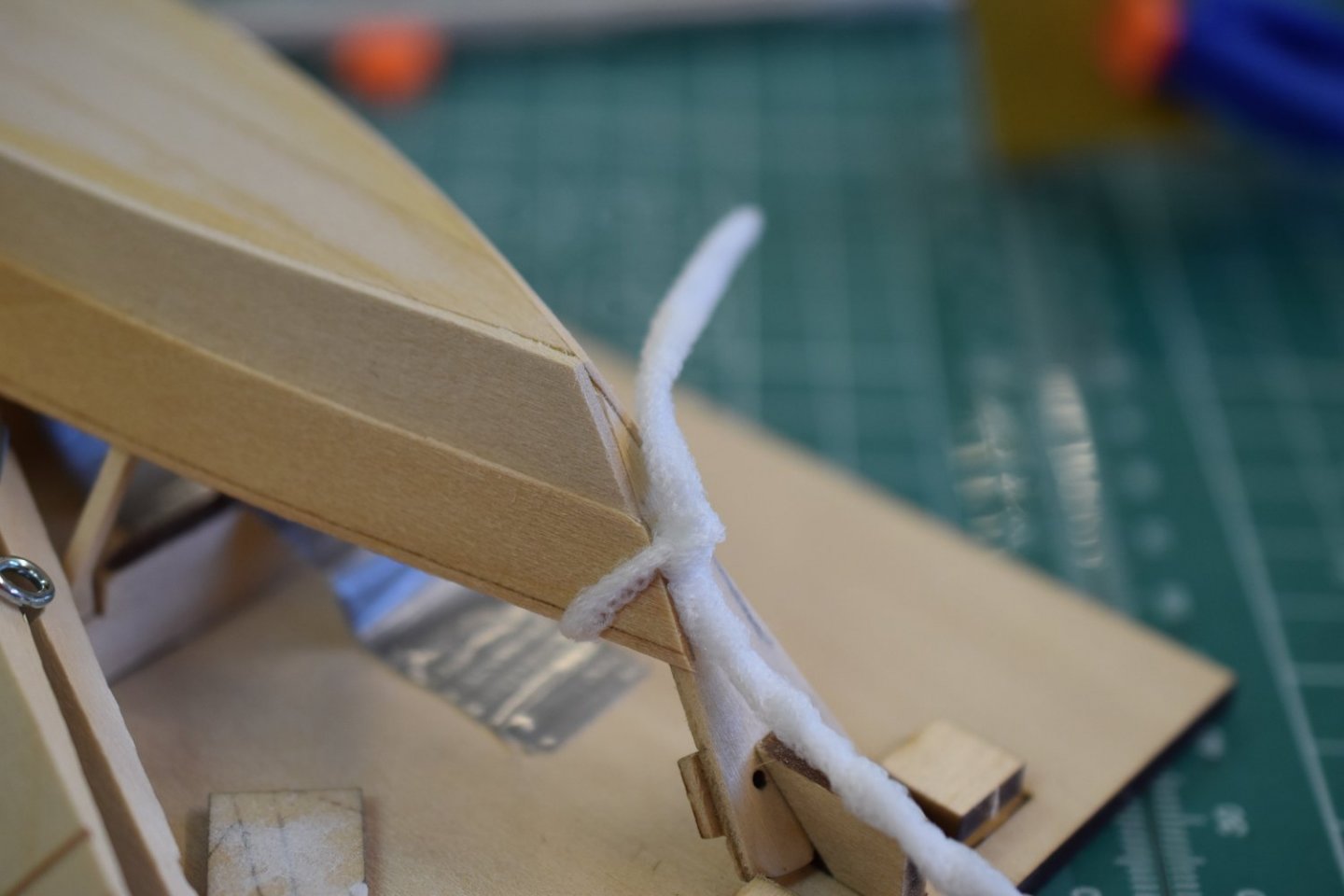

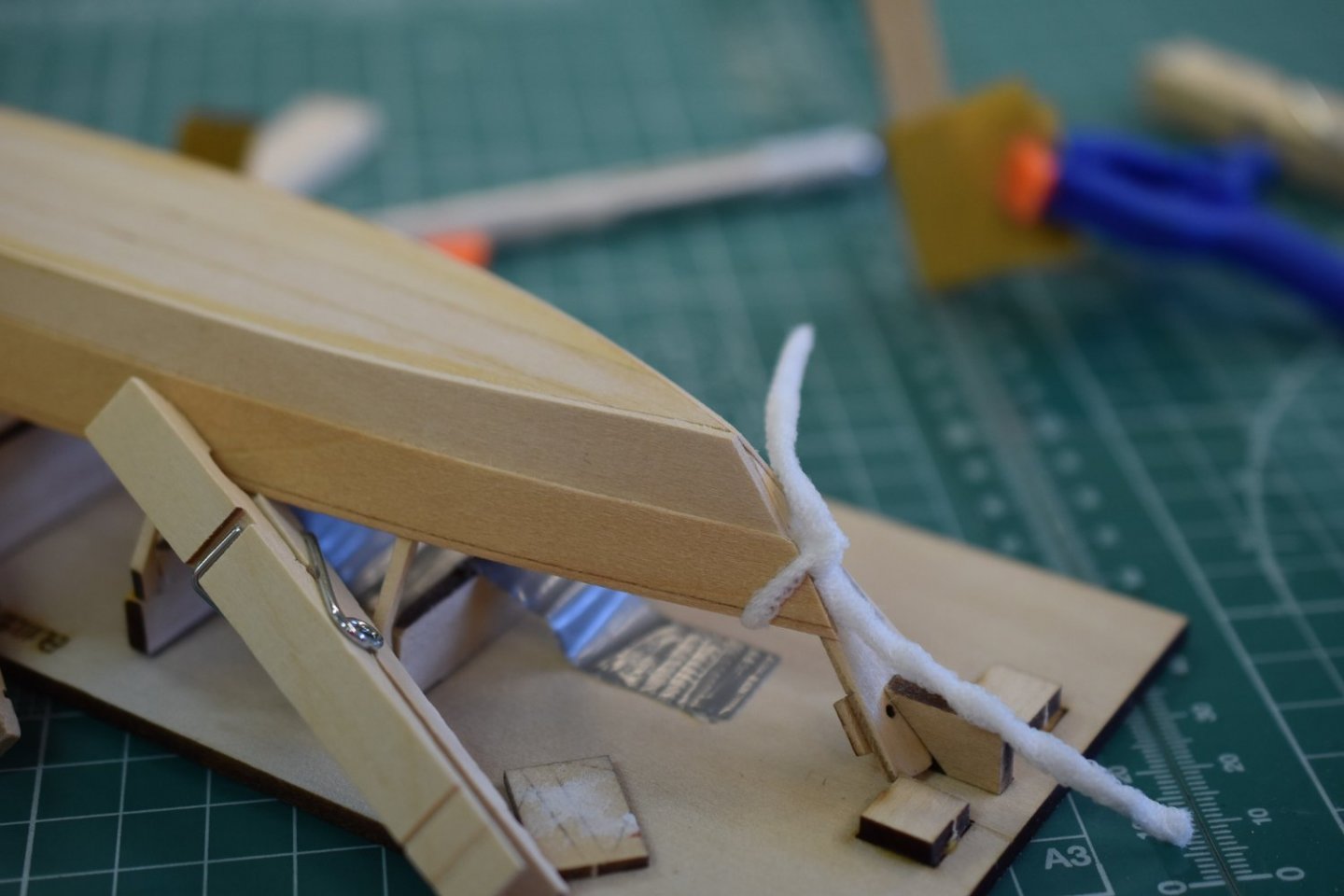

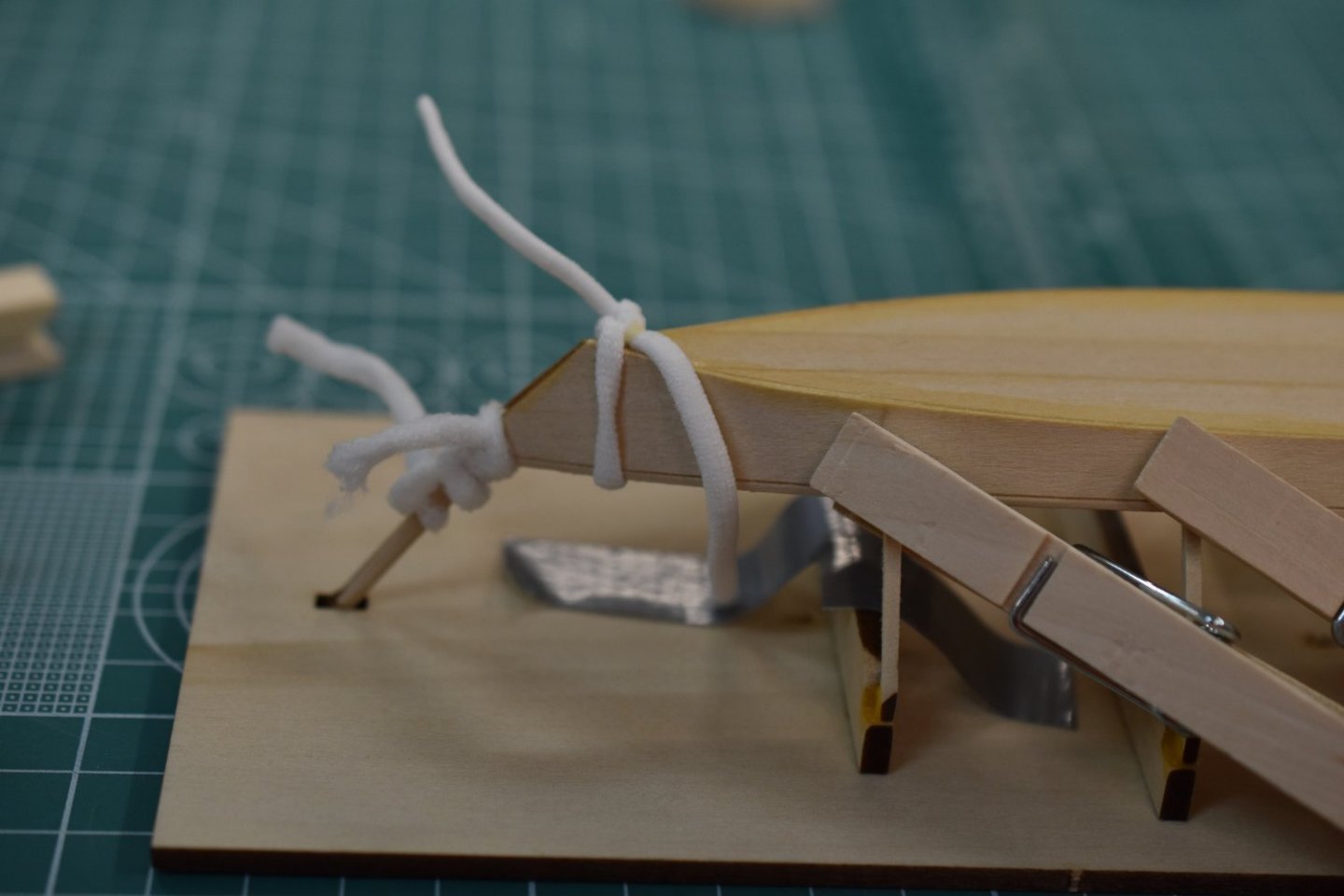

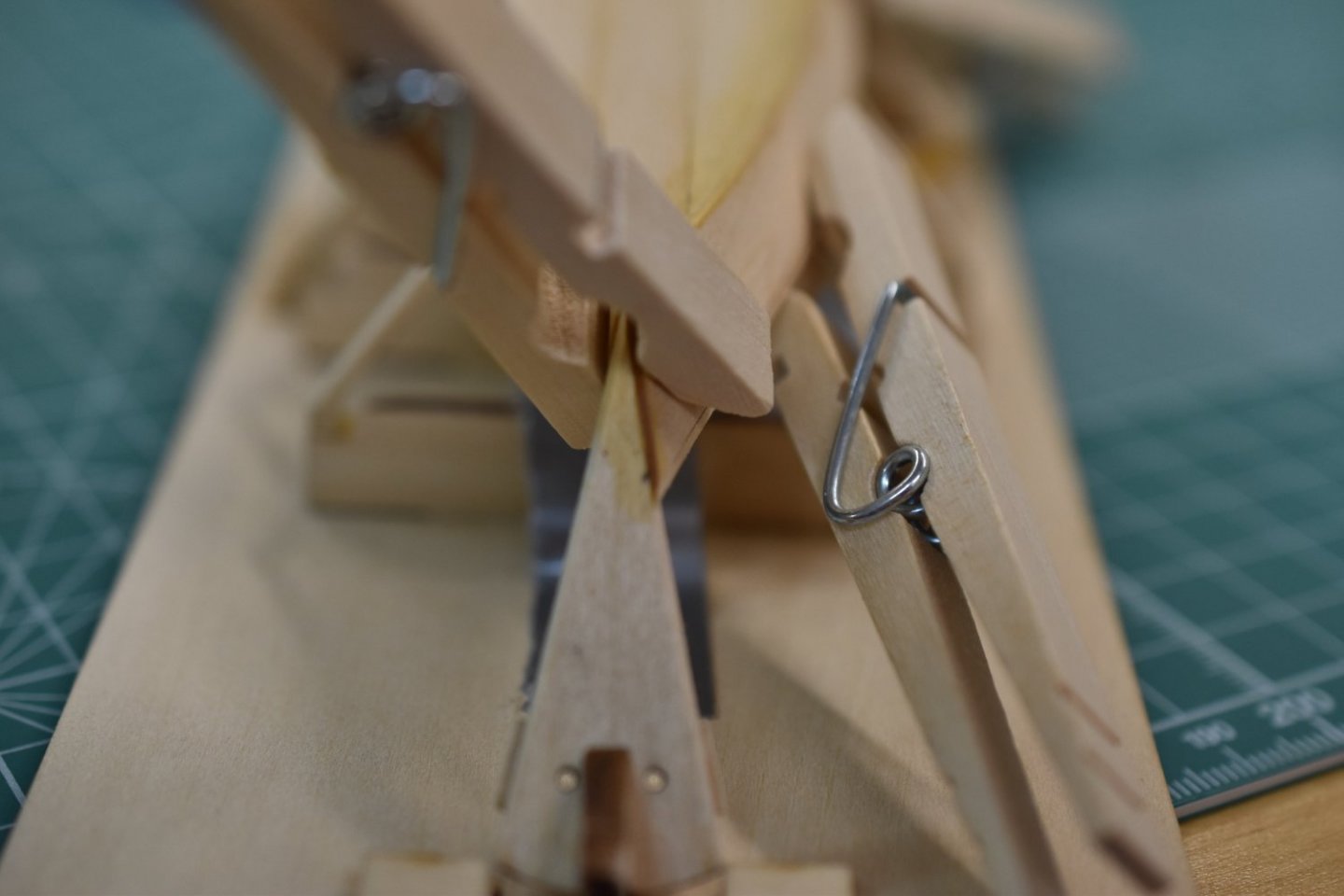

I'm still not smart enough to figure out this clamp issue when trying to glue the second plank on the adjacent side of the boat. So far I resorted to the elastic thick string again as it holds it nicely without slipping frustrations. I guess I'll really look at this over here soon. My clamps aren't on a ball joint pivot, so don't make good purchase on the compound angles, even with sandpaper (which does help a lot). The clothes pins aren't opening wide enough. I'll figure out what works best for me, but I'm really thinking it's going to be yarn as it seems like it wound cinch and hold well, but I'll have to give it a try.

I may resort to pins in a serious planking job. I'm after a snug mating of the joint with no slipping issues. Only practice will determine the method I ultimately use, adapt, or develop. Thanks for listening at my thinking out loud. I often talk to myself and even answer at times. 😁

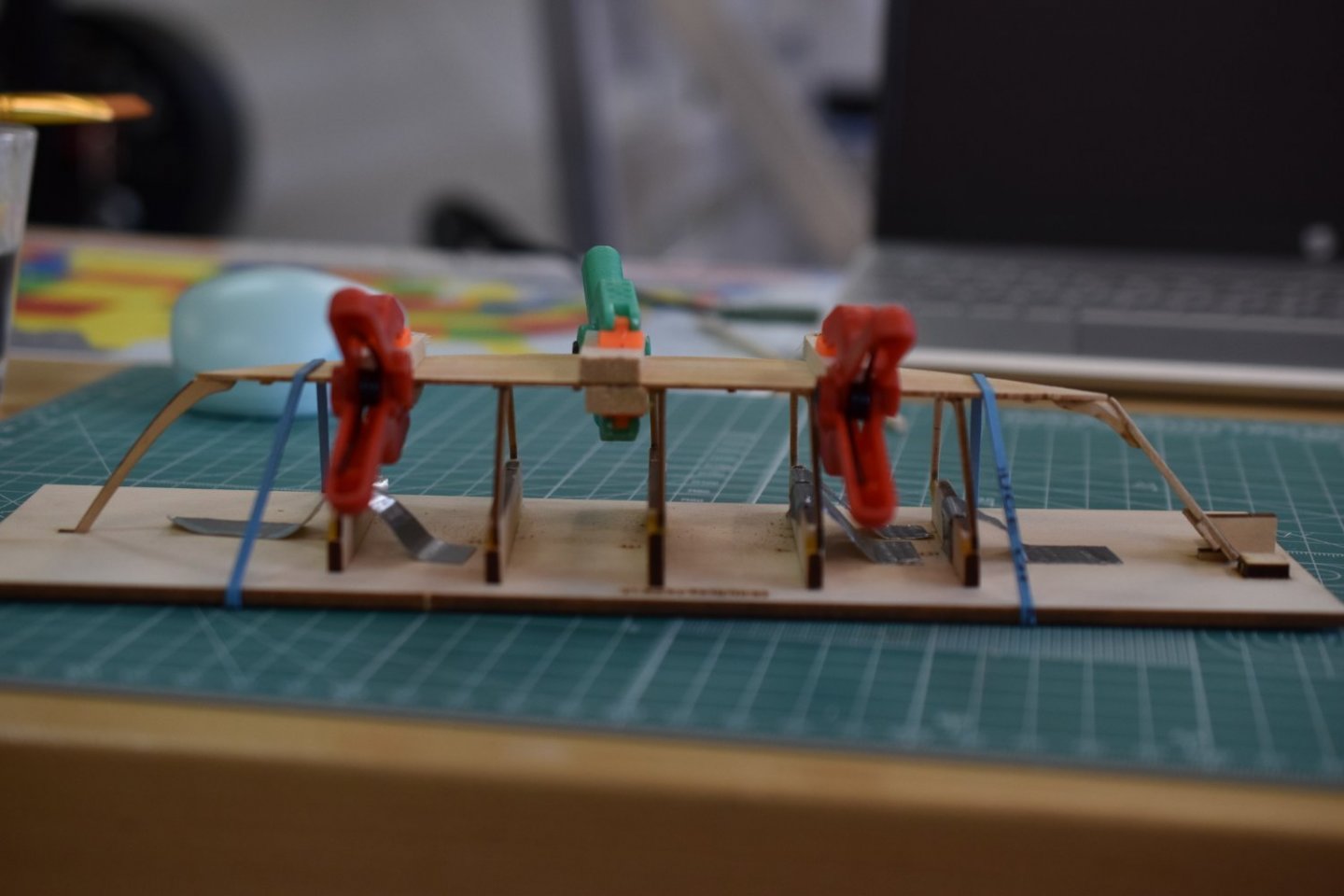

-

I removed the clamps and string then inspected my installation. The bow planks are even at the next board mounting joint, but the rear is a little off. I will see what I can do to compensate when mounting the next planks.

I need to resolve my clamping method and options now with these secure planks in place. I know you can hold the planks at the stem and transom when drying with your fingers, but I'd rather have a system of clamps that works without hassling holding them. I might try the super glue next time too.

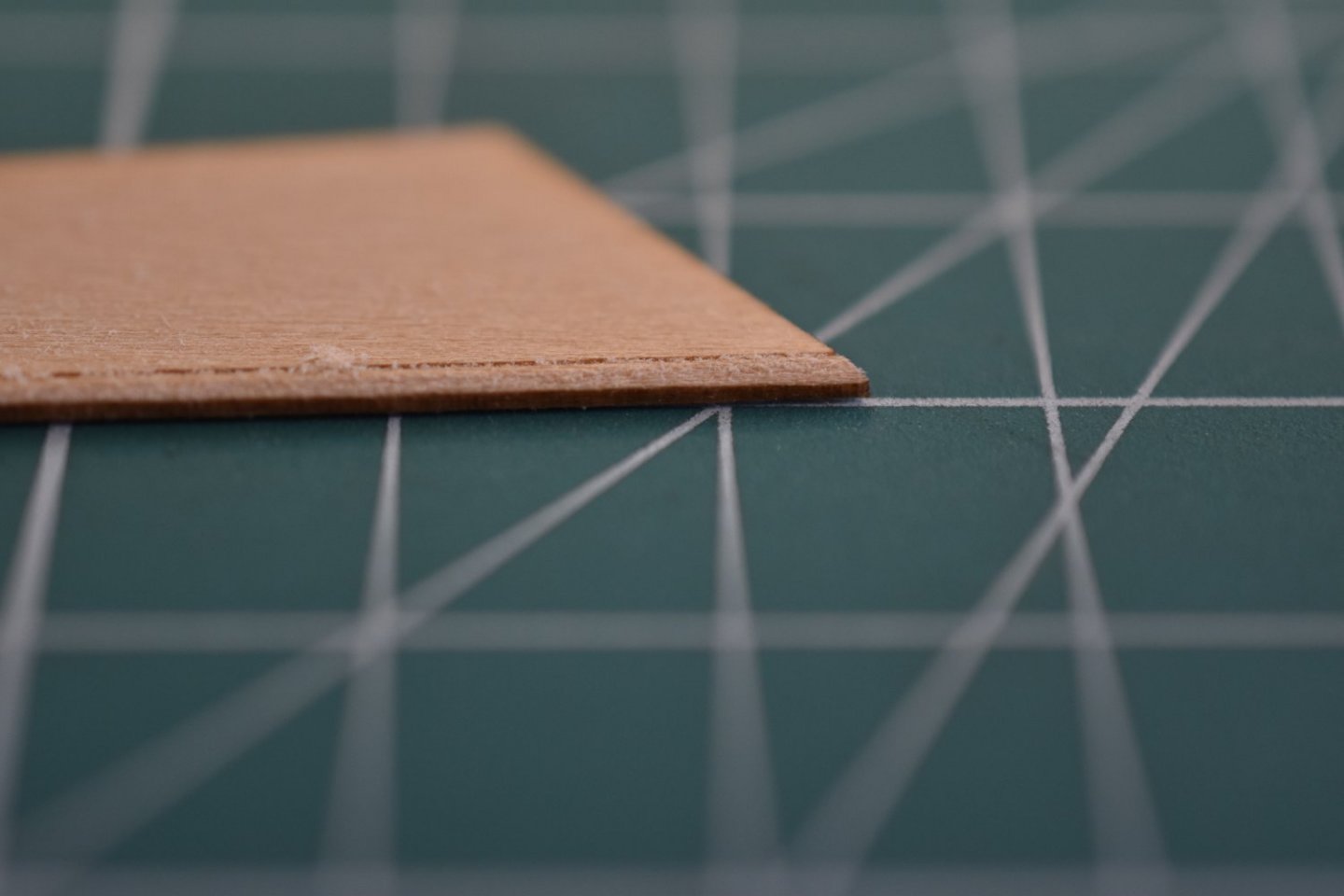

here's the glued planks before sanding. 👇

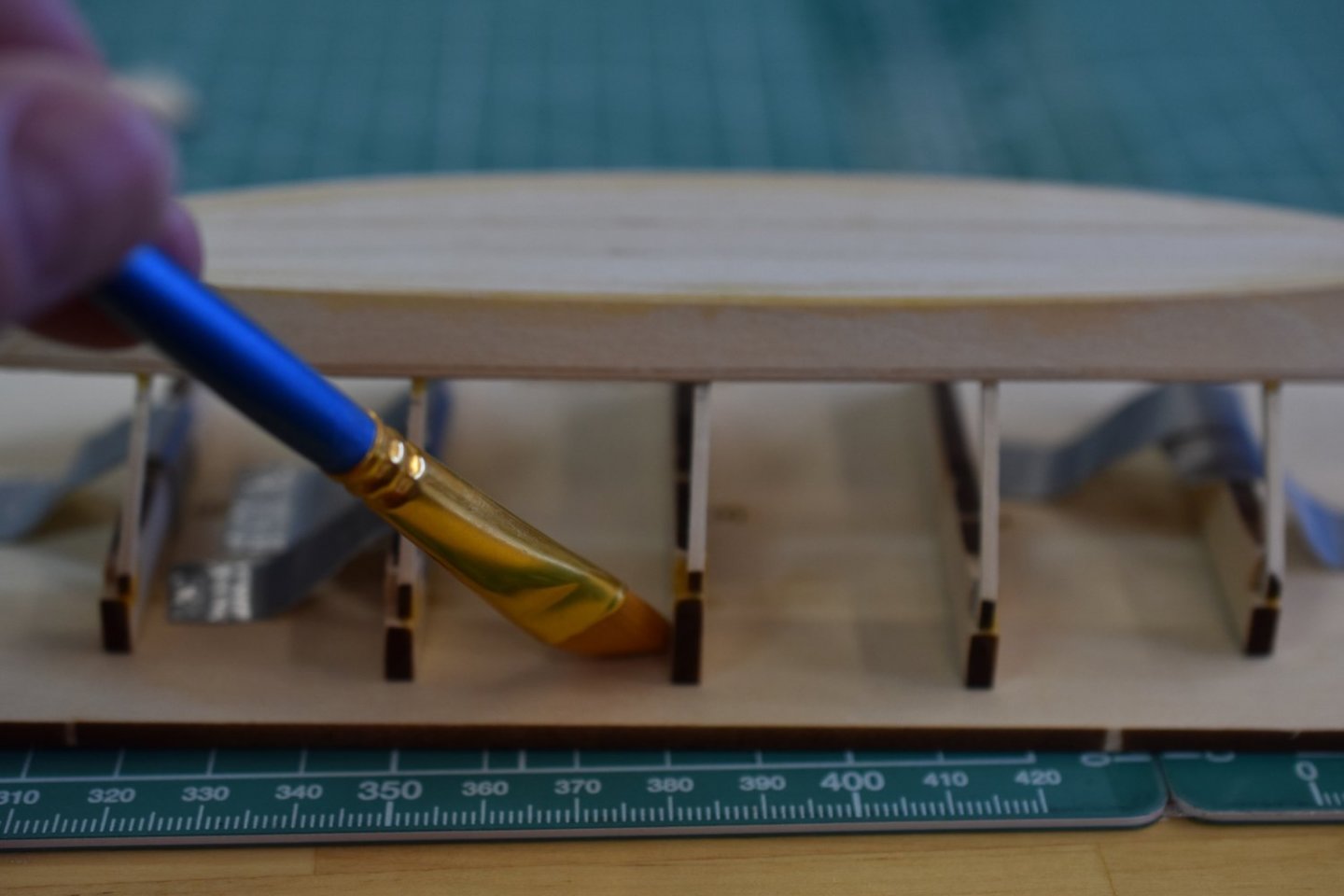

I've started using my surgical mask to prevent breathing the dust too. It seemed like it was only a tiny bit of sanding, but it was enough to disturb my lungs and respiratory tract a little bit.

It's probably obvious to most wood workers, but I started using one of my paint brushes when vacuuming up the sanding dust. 👇

I'm going to paint this boat, but I was wondering if it was to be stained, would the glue wash residue prevent a good finish? I'm looking at you drux! 👀

Here's the sanded result so far.

- Ryland Craze, druxey, mark.bukovich and 1 other

-

4

4

-

I was able to straighten my twisted and bent garboard plank for the starboard side, but I made dent in the wood through careless clamping. I think it'll be fine though, and I mounted it anyway.

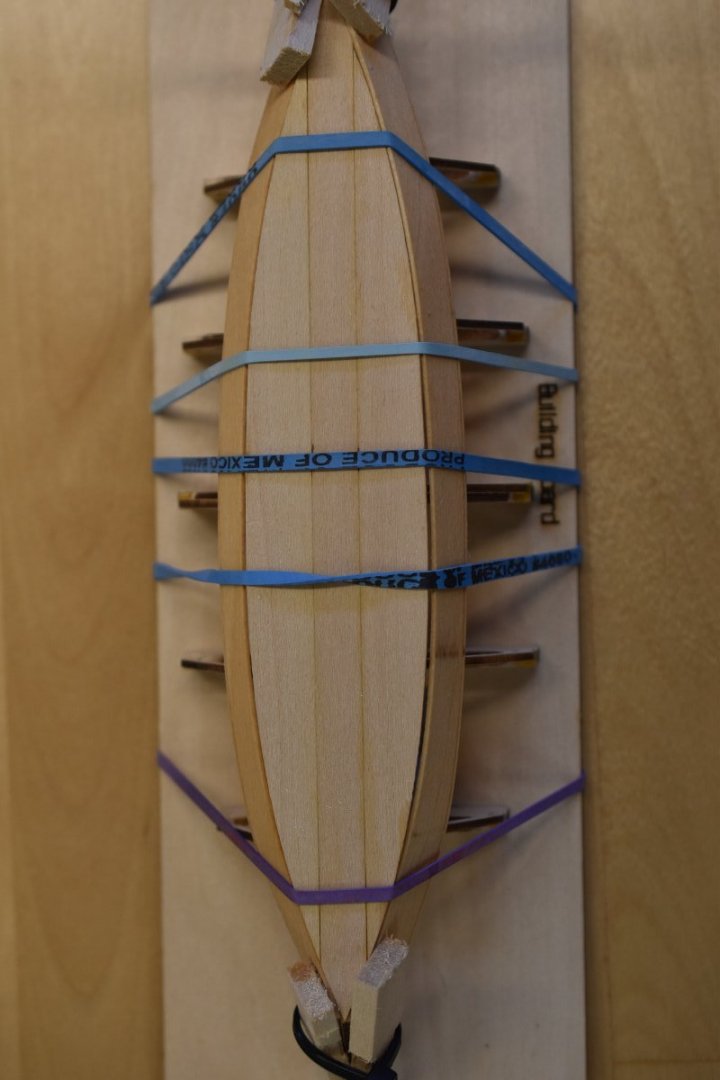

I had a difficult time again with clamping the second plank on when attaching with glue and ran short of skill. I resorted to the string idea and cut some stretchy cord off a couple surgical masks. It worked well enough in an emergency. I'm still a bit upset about my short sided preparedness and lack of plan "B", or even a plan "A" for that matter. I ended up losing a bit of plank height on the starboard side I think. I won't know until tomorrow when I can take a good look.

- mark.bukovich, DanB, JpR62 and 2 others

-

5

5

-

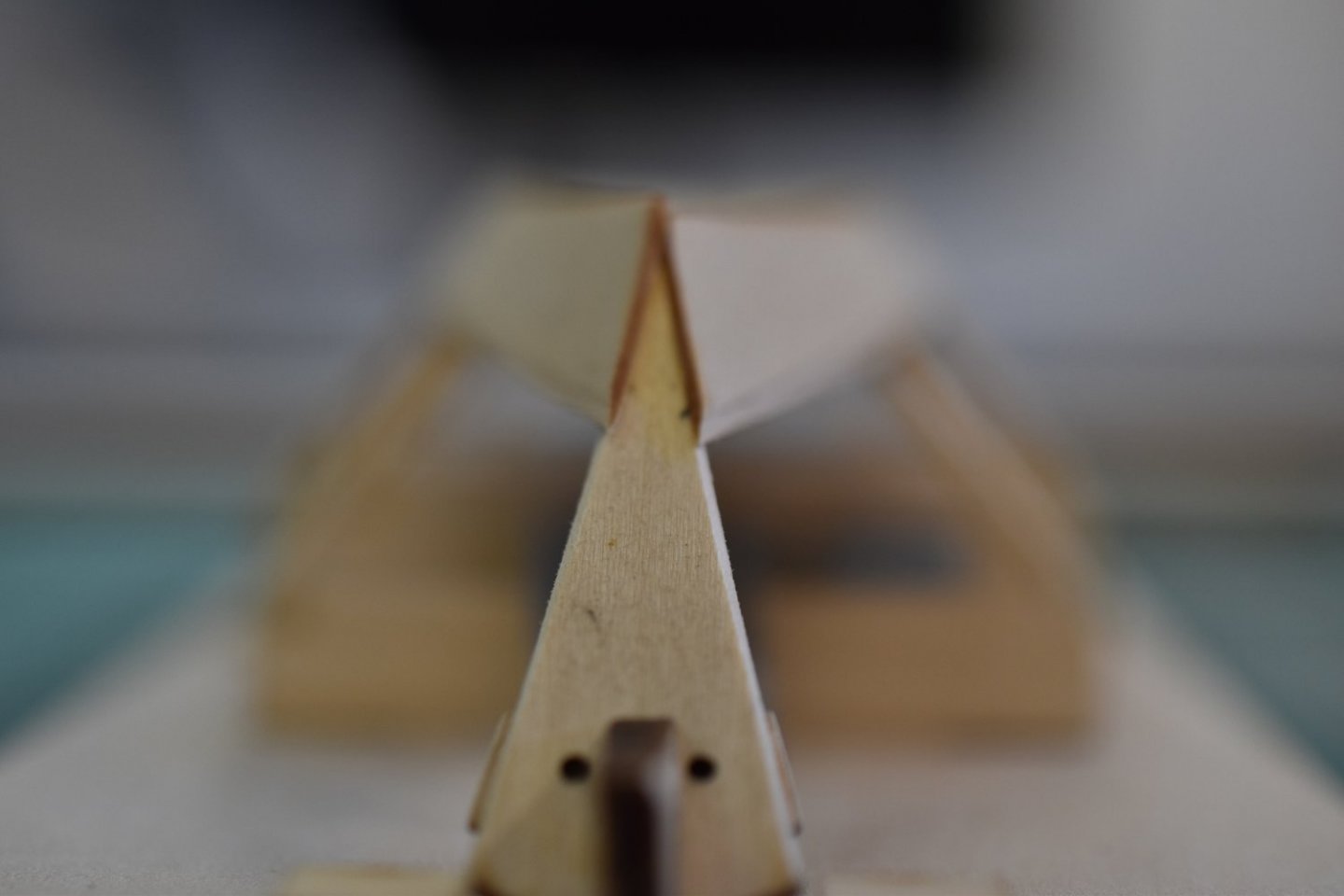

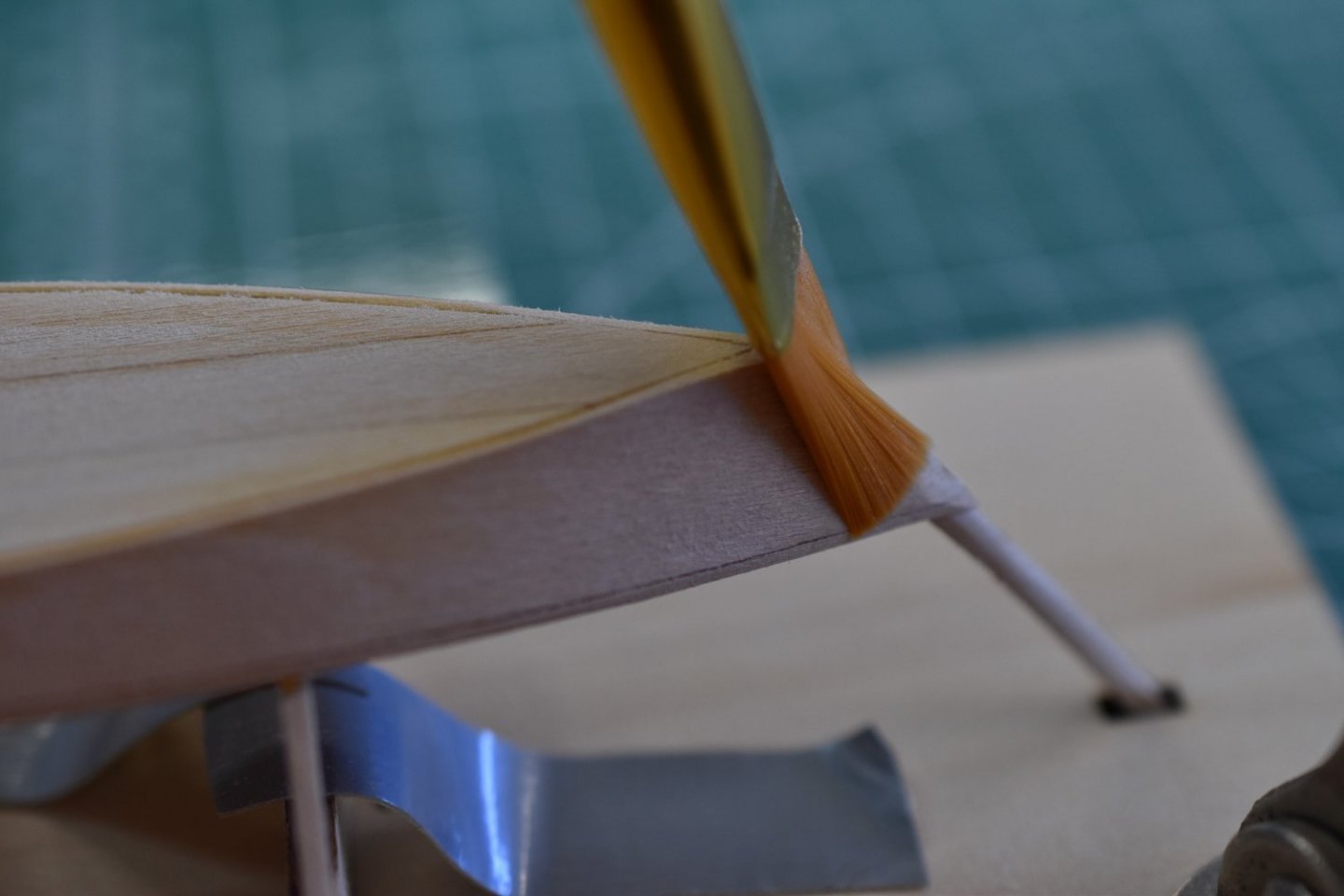

While that other plank is being straightened and drying I sanded the frames, stem, and transom. I tried to bevel everything nicely and smoothly. Some of the frames suffered a bit of too much sanding in the middle section of the side rib. I don't think it's too terrible, but an error none-the-less. When I got the frames, stem, and transom to my satisfaction I checked the plank fit and decided on my plan of attachment.

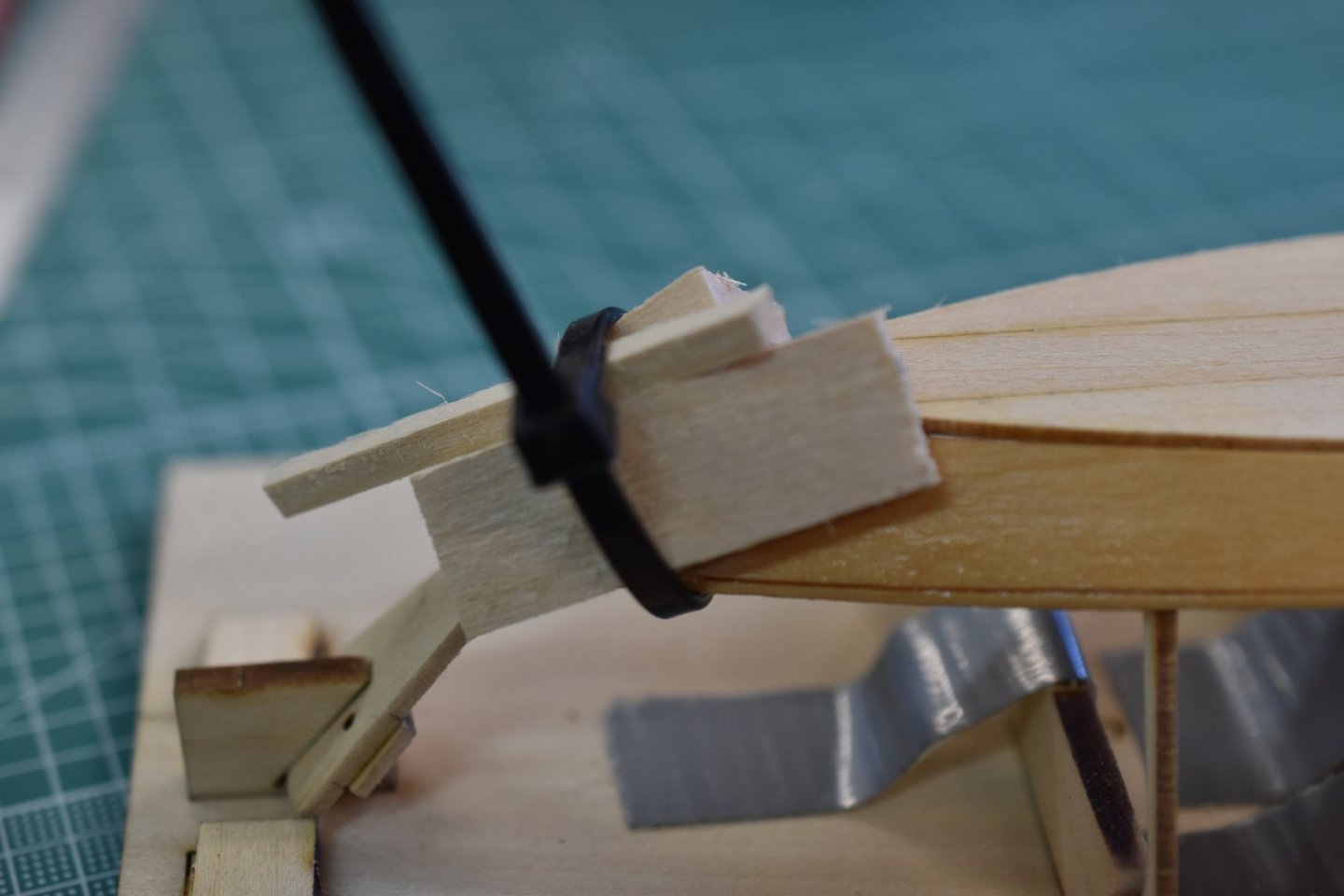

I glued the contact points as instructed in the directions and attached the port side garboard plank. It was much easier to deal with when doing one plank at a time. The clothes pin clamps worked well. The fit seemed pretty tidy and I painted some watery glue on the seems to help ensure a decent bond.

I'll try the other plank tomorrow night if it straightens out well.

- Ryland Craze, druxey, JpR62 and 1 other

-

4

4

-

Tonight I found that my plank bending error of trying to do both planks at the same time compounded my errors. One of the planks got tweaked and twisted by the clamping. That wouldn't have happened if I did one plank at a time. Anyway, I'm going to wet it down and clamp it straight and try to fix it. I'll let it sit over night and see if it's better tomorrow night.

- Ryland Craze and druxey

-

2

2

-

On 3/6/2022 at 6:26 PM, Clueless said:

I've used these in the past. As Tony the Tiger says, "They're great!"

https://modelexpo-online.com/Enkay-44-Plastic-Spring-Clamp_p_1907.html

Thanks Clueless!

I actually have some of those clamps. My basic problem was that I was doing it wrong. 😆 I tried some of those, but they were too strong for my incorrect method. The clothes pins are working well when I do it properly. That would be one plank at a time!

-

Looks like it's coming along nicely! 🎸🤘

-

19 minutes ago, druxey said:

One plank at a time is the best strategy! Line the clamp/clothes peg with scraps of sandpaper as a non-slip option.

What about when gluing? One at a time again I guess? Yeah, it would need to be! Too obvious for me. Well, that should be easier. 🤣🤘

The sand paper on the clip is a great tip! Thanks again.👍

-

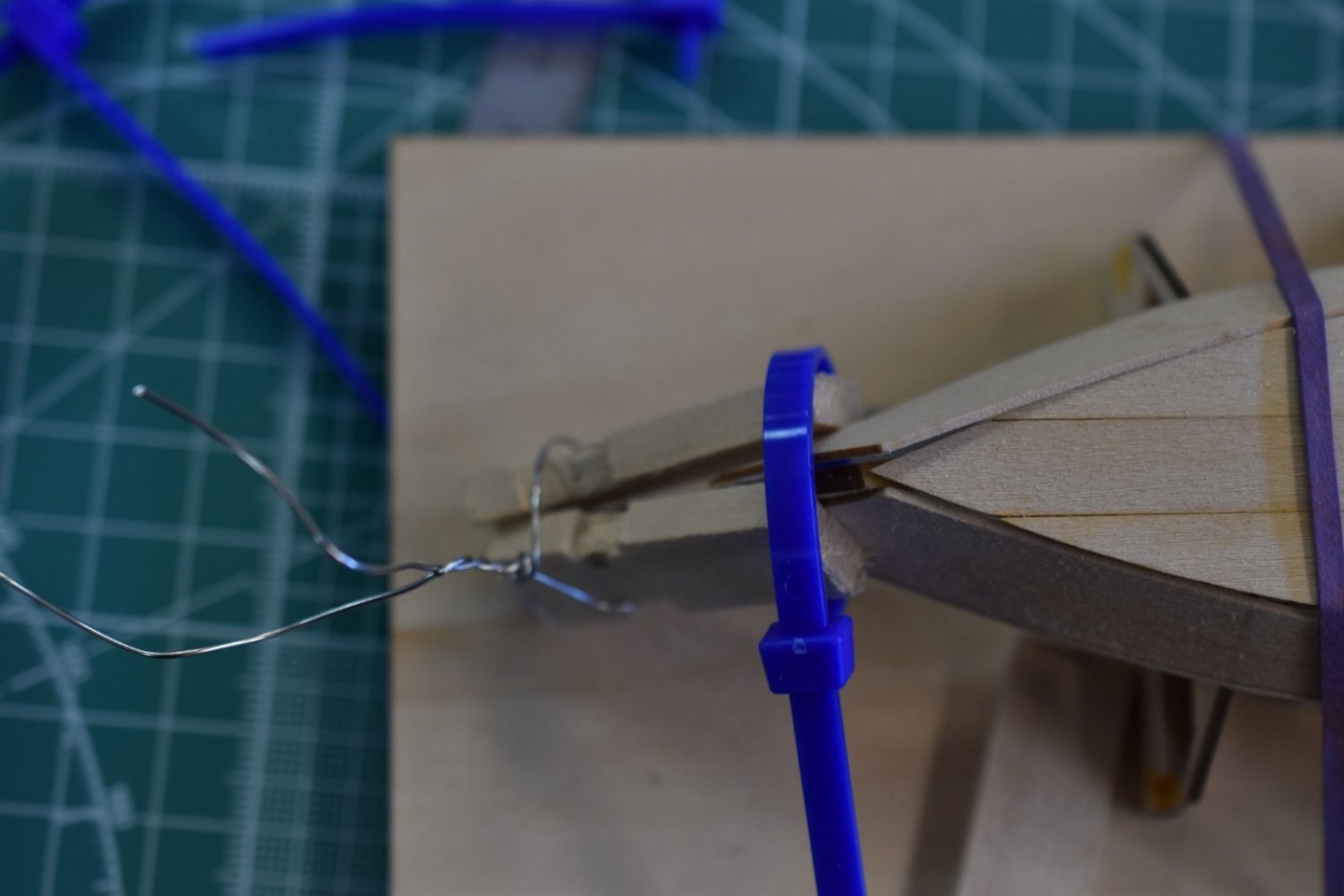

It got pretty foggy and I almost ran aground getting the garboard planks mounted for the bending. I wet them down and tried several different ways to clamp them. My clamps are too strong, don't open enough, and otherwise were useless to stay put!

I resorted to zip ties, but they were too big and slipped off. I tried different angles with different thicknesses of shim wood. Nothing was working. I tried tie wire, but was unprepared to get it snug enough. I was going to tie a rubber band around the ends, but it didn't want to work smoothly either.

The clothes pins would work well with one plank at a time, but wouldn't open enough for two.

The blue zip ties were too big and weren't quite delicate enough. I got one to hold, but it wasn't secure enough to stay put. I then tried to put grooves in my wood shims for the zip ties. It almost worked, but needed more fabrication time to be a good resolution.

The wire would probably be a great method if I had a smaller gage and more sensitive wire tie tools. Something made for jewelry maybe?

I ended up using very small zip ties with the wood shims at a different angle. It'll work for today, but I'm not happy with any of the methods tried.

My blue masking tape probably would've worked, but I didn't try it. I want to try string next time. Maybe yarn made up and ready to cinch to feel?

- Ryland Craze and Valkyrja68

-

1

1

-

1

1

-

I started to prepare my garboard planks for the sides of the boat. I assume that the wider part of the plank is the bow. On the parts sheet it is the same side as the planks with the hole for the rope piece, so the parts all seem to be orientated the same direction.

I had bought a Stanley hobby vice recently from an England Ebay guy. The vice was well liked here on the forum, and I concur; it's a great quality purchase!

Anyway, I thought if I set the vice at an eyeball 45 degrees, then sanding at a vertical angle with the garboard plank might be easier than holding the board at 45 degrees. I think the idea worked pretty well.

I first sanded gently to the line printed on the board, then put an additional compound angle on the last inch or so of the ends of each board. I watched the margin of the board to judge my sanding amount. The margin is supposed to be about half the width of the board in the middle section, and it reduces from half thickness to nothing across the last inch or so. That is my understanding of the directions anyway. The result is in the pictures down there. 👇

- JpR62, Ryland Craze and druxey

-

3

3

-

Nice progress and building log Jason!

I used to fish with a Norwegian Viking named Stanley B. Long. He explained a lot of Norwegians have the surname "Long" and came from the clans that lived in the long valley of Norway. He said that's the origin of the surname, but I'm not sure which long valley?

-

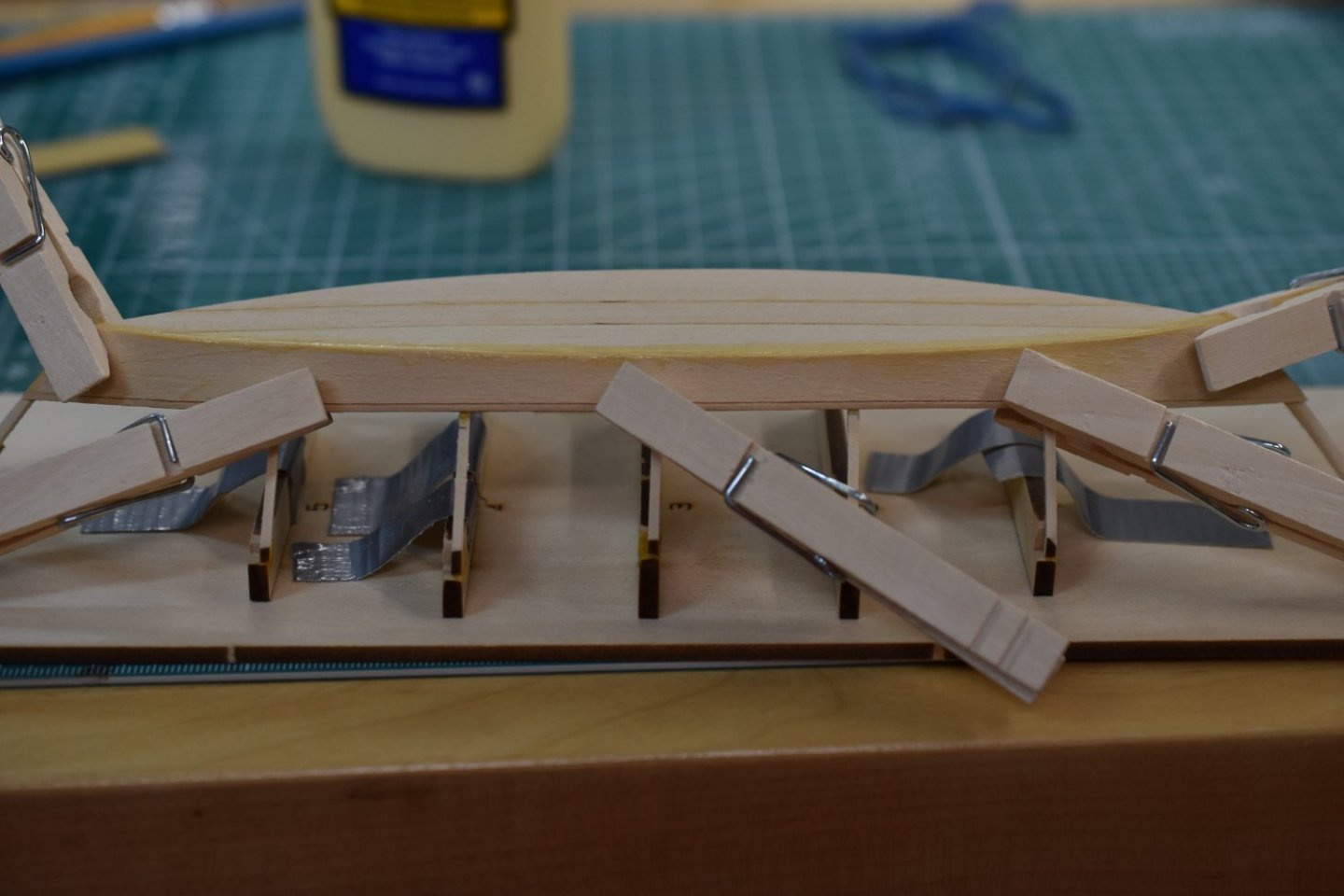

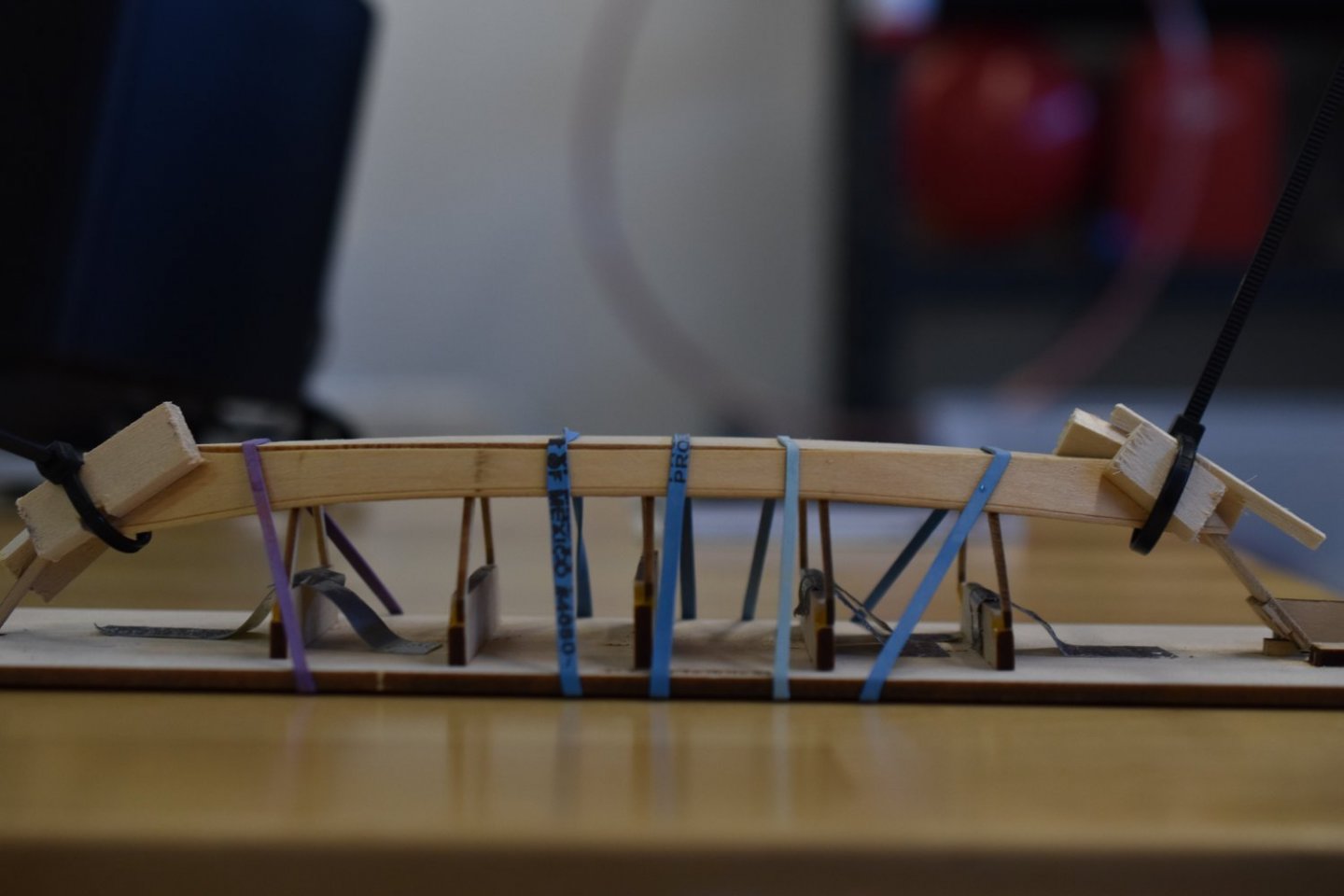

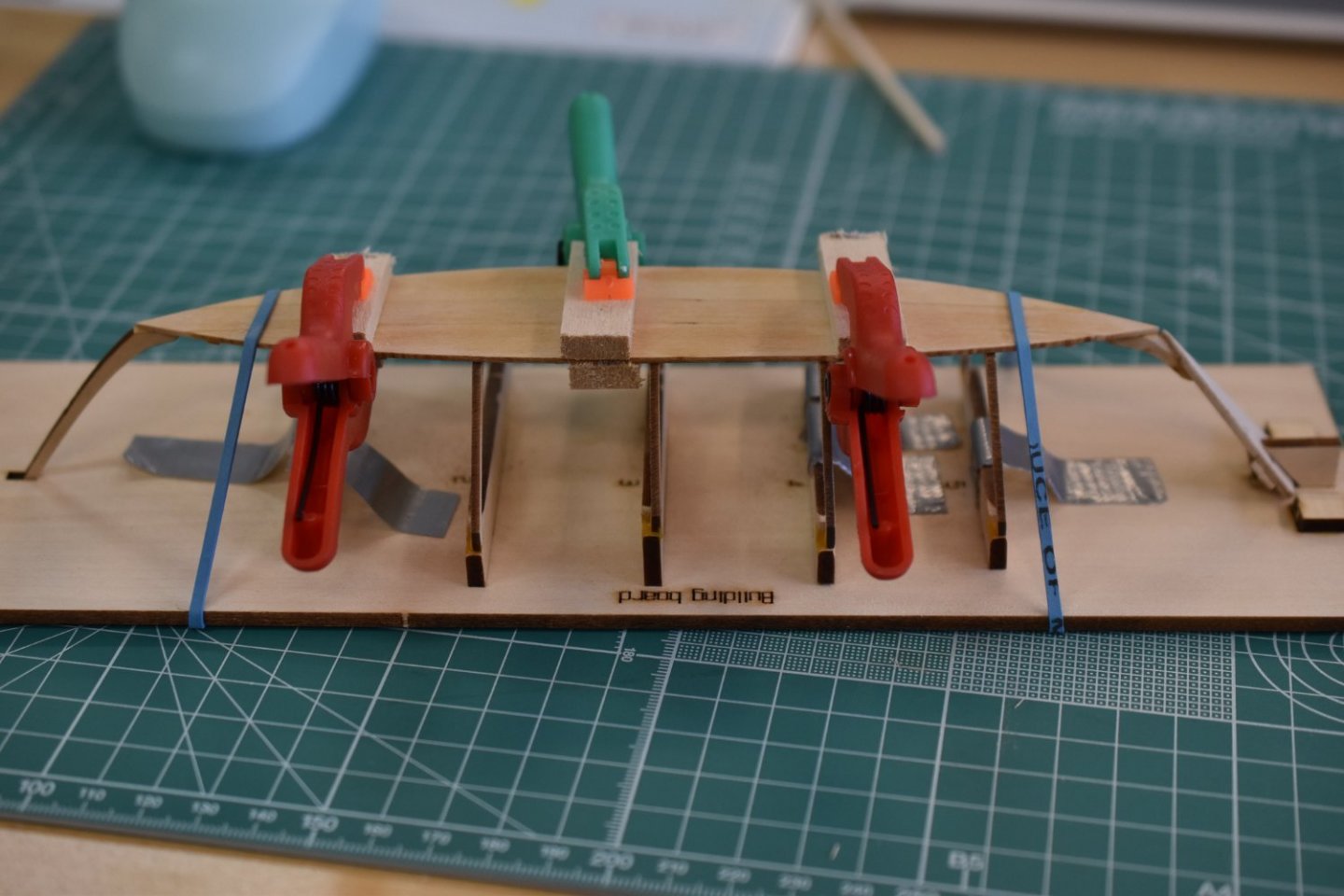

Well I decided to flatten the bottom planks a bit more. I noted the problem back up there 👆 a few posts ago. I got it pretty well fixed previously, but was thinking that maybe I cold get it better now that the bottom plank assembly is glued to the frames. I lightly painted the bottom plank assembly on the bottom side with water and made some flattish boards to clamp across the planks athwartship (my new favorite word😁). I'll let it dry and check the result.

I'm just using the info that is in the instructions and supplied by wylie captains of knowledge, such as my running partner druxey for trying to curve this wood nicely. Thanks again for the helps and intel. I'll see if it improves the bottom planks a bit more, I'm trying to get the very edges at the chine joint area to form up more accurately. I think I can get the sheer curve a tiny bit better too while I'm at it.

We're going to set the fishing gear over here and see if we have any success.

Lowell Grand Banks Dory by Flying Submarine - Model Shipways - 1/24 scale

in - Kit build logs for subjects built from 1851 - 1900

Posted

Looking good! I'm going to make an effort to get back to work on mine. I have been distracted by work for a while now.