DanB

NRG Member-

Posts

163 -

Joined

-

Last visited

About DanB

- Birthday 09/01/1956

Profile Information

-

Gender

Male

-

Location

Lafayette, California

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

DanB reacted to a post in a topic:

PHOENIX 1787 by ccoyle - Master Korabel - 1/72 - Russian brigantine of the Black Sea Fleet

DanB reacted to a post in a topic:

PHOENIX 1787 by ccoyle - Master Korabel - 1/72 - Russian brigantine of the Black Sea Fleet

-

DanB reacted to a post in a topic:

Mary Day by jdbondy - 1:64 scale (3/16" to 1 foot) - Schooner

DanB reacted to a post in a topic:

Mary Day by jdbondy - 1:64 scale (3/16" to 1 foot) - Schooner

-

DanB reacted to a post in a topic:

HM Cutter Cheerful 1806 by Erik W - 1:48 scale

DanB reacted to a post in a topic:

HM Cutter Cheerful 1806 by Erik W - 1:48 scale

-

DanB reacted to a post in a topic:

Endeavour 1934 by SaltyScot - FINISHED - Amati - 1:80

DanB reacted to a post in a topic:

Endeavour 1934 by SaltyScot - FINISHED - Amati - 1:80

-

DanB reacted to a post in a topic:

Lowell Grand Banks Dory by Galkar - FINISHED - Model Shipways - 1:24

DanB reacted to a post in a topic:

Lowell Grand Banks Dory by Galkar - FINISHED - Model Shipways - 1:24

-

DanB reacted to a post in a topic:

Viking longboat by toms10 - FINISHED - scale 1:64 - late 9th century

DanB reacted to a post in a topic:

Viking longboat by toms10 - FINISHED - scale 1:64 - late 9th century

-

DanB reacted to a post in a topic:

Endeavour 1934 by SaltyScot - FINISHED - Amati - 1:80

DanB reacted to a post in a topic:

Endeavour 1934 by SaltyScot - FINISHED - Amati - 1:80

-

DanB reacted to a post in a topic:

Emma C Berry by Kenneth Powell - Model Shipways - 1:32 - as a yacht

DanB reacted to a post in a topic:

Emma C Berry by Kenneth Powell - Model Shipways - 1:32 - as a yacht

-

DanB reacted to a post in a topic:

Chaperon by John Gummersall - FINISHED - Model Shipways - Scale 1:48

DanB reacted to a post in a topic:

Chaperon by John Gummersall - FINISHED - Model Shipways - Scale 1:48

-

Kirby reacted to a post in a topic:

Sultana by DanB - Model Shipways - 1:64

Kirby reacted to a post in a topic:

Sultana by DanB - Model Shipways - 1:64

-

yvesvidal reacted to a post in a topic:

Sultana by DanB - Model Shipways - 1:64

yvesvidal reacted to a post in a topic:

Sultana by DanB - Model Shipways - 1:64

-

SiriusVoyager reacted to a post in a topic:

Sultana by DanB - Model Shipways - 1:64

SiriusVoyager reacted to a post in a topic:

Sultana by DanB - Model Shipways - 1:64

-

ccoyle reacted to a post in a topic:

Sultana by DanB - Model Shipways - 1:64

ccoyle reacted to a post in a topic:

Sultana by DanB - Model Shipways - 1:64

-

JacquesCousteau reacted to a post in a topic:

Sultana by DanB - Model Shipways - 1:64

JacquesCousteau reacted to a post in a topic:

Sultana by DanB - Model Shipways - 1:64

-

CiscoH reacted to a post in a topic:

Sultana by DanB - Model Shipways - 1:64

CiscoH reacted to a post in a topic:

Sultana by DanB - Model Shipways - 1:64

-

Sultana by DanB - Model Shipways - 1:64

DanB replied to DanB's topic in - Kit build logs for subjects built from 1751 - 1800

It has been a long time since I posed, but i have been working on the Sultana occasionally and have added more of the deck details, catheads and timber heads. I got stumped by the cheeks and head rails decided to come back to the project later, after messing it up a few times. Currently starting work on channels. -

yvesvidal reacted to a post in a topic:

Sultana by DanB - Model Shipways - 1:64

yvesvidal reacted to a post in a topic:

Sultana by DanB - Model Shipways - 1:64

-

Roger Pellett reacted to a post in a topic:

Sultana by DanB - Model Shipways - 1:64

Roger Pellett reacted to a post in a topic:

Sultana by DanB - Model Shipways - 1:64

-

Kirby reacted to a post in a topic:

Sultana by DanB - Model Shipways - 1:64

Kirby reacted to a post in a topic:

Sultana by DanB - Model Shipways - 1:64

-

ccoyle reacted to a post in a topic:

Sultana by DanB - Model Shipways - 1:64

ccoyle reacted to a post in a topic:

Sultana by DanB - Model Shipways - 1:64

-

Sultana by DanB - Model Shipways - 1:64

DanB replied to DanB's topic in - Kit build logs for subjects built from 1751 - 1800

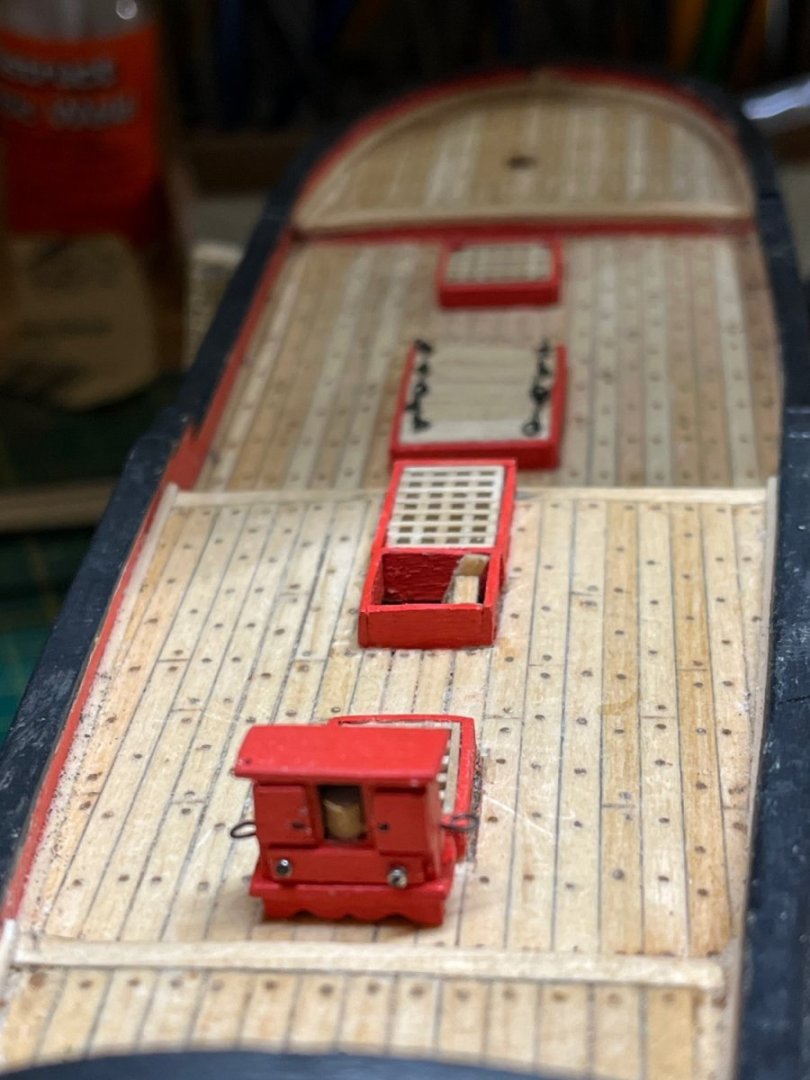

Pumps and windlass. Scratch built pumps using Chucks instructions. I was stumped by the windlass. I could not get the hexagonal shape right. I gave up after 3 attempts. I painted the kit supplied castings for the windlass and galley stack. -

Sultana by DanB - Model Shipways - 1:64

DanB replied to DanB's topic in - Kit build logs for subjects built from 1751 - 1800

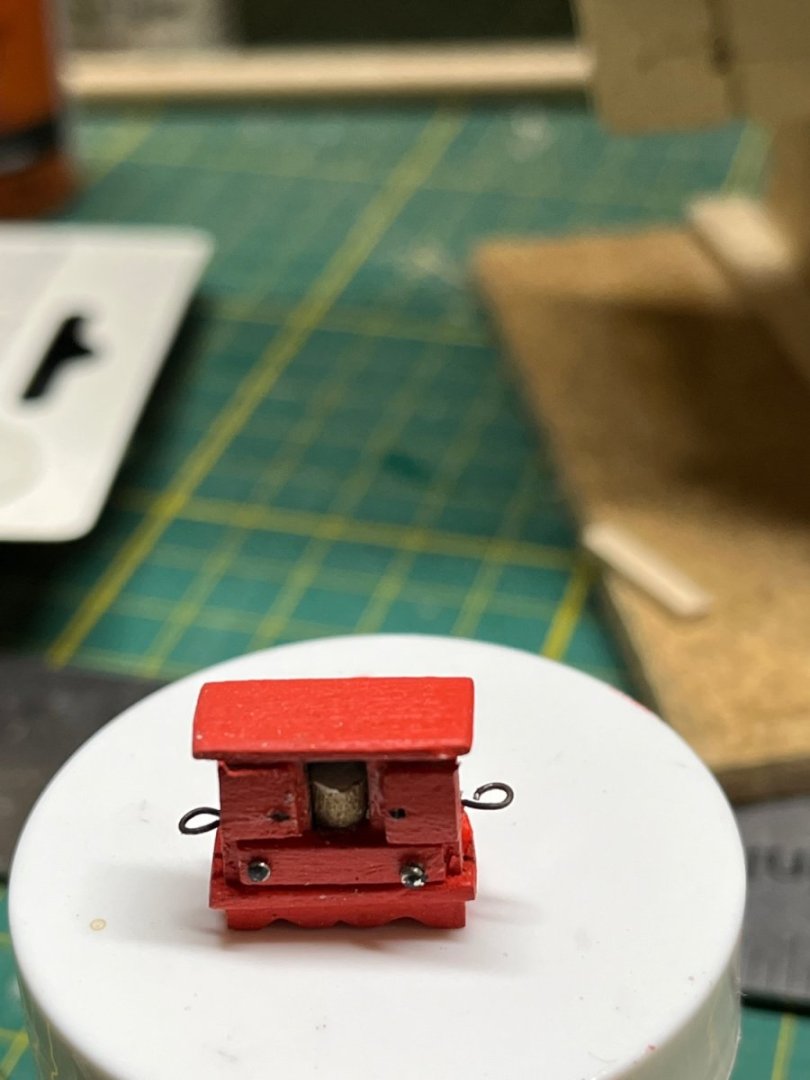

Thanks Bill. I also like them both. I did not feel I was able to be as accurate using the templates to shape the solid hull on my first try here , but I think I need more practice and would definitely try another solid hull in the future. I have been woking on the binnacle. Chuck’s shop notes have great step by step instructions how to scratch build one that looks like the one on the plans and has more detail than the casting supplied with the ship. This was mostly great fun. Chuck suggests using heads of brass nails for drawer handles. They looked to big so I tried using heads of pins, Slippery things that flew all over the place never to be seen again! I got 2 of them in and gave up on the upper 2 and decided a couple of little black dots would be good enough. Next is to figure out how it gets lashed to the deck. -

Sultana by DanB - Model Shipways - 1:64

DanB replied to DanB's topic in - Kit build logs for subjects built from 1751 - 1800

Yes. Model Shipways stopped producing solid hull models. Maybe they could bring it back as plank on bulkhead at a larger scale. -

Sultana by DanB - Model Shipways - 1:64

DanB replied to DanB's topic in - Kit build logs for subjects built from 1751 - 1800

Traveler rod and bock On the ship now, an I did not knock the transom off or drill a hole clear through it! Getting the hook on the block was difficult. This site was very helpful in understanding the process, but I still had to look at the pictures a bunch of times. It took several tries. The third hand tool, CA glue and a lot of patience were essential. http://modelboatyard.com/stropping.html -

Sultana by DanB - Model Shipways - 1:64

DanB replied to DanB's topic in - Kit build logs for subjects built from 1751 - 1800

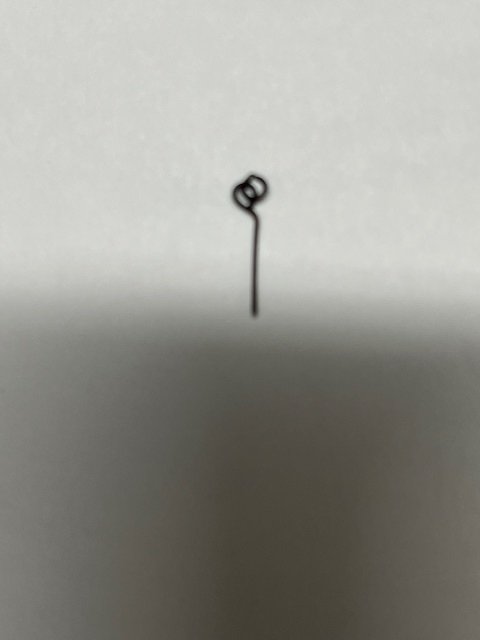

Ship instructions have a nice drawing of the block set up for the traveler rod and . Kit has pins that worked well for the extended pin. Made the loop and sister hook with 28 gage steel wire. Will paint pins and traveler rod and figure out how to attach hook to the block and get the rod on the ship next. -

Sultana by DanB - Model Shipways - 1:64

DanB replied to DanB's topic in - Kit build logs for subjects built from 1751 - 1800

Added the coaming for the space that goes below deck (left it off by mistake) and built a ladder to go down there. Ladder took several tries using Chuck’s template. It’s still a bit rough, but most of it really is not visible. Next is to build a traveler rod for the boom and install it on the in on the not very thick and not very sturdy transom. The kit instructions say it’s supposed to have a double sheave bock connected to the rod with sister hooks .I was able to find pictures of what those look like. I am not really sure how I could make them and attach them to the block. The bock is also supposed to have a rod on each side of it. Chuck says he used two small nails for that part. This will be an adventure. I hope the transom survives it! -

Sultana by DanB - Model Shipways - 1:64

DanB replied to DanB's topic in - Kit build logs for subjects built from 1751 - 1800

More Hatches Chuck’s instructions say to make eye bolts and split rings for the boards that cover the next hatch by bending 28 gauge black steel wire. I got an excellent refresher on how to do that from this thread. I took a bunch of tries and looking at the pictures in the thread a few times, but then it was not too difficult to get close : The last 2 hatches continued to need a lot of fiddling, but they are on the ship. Next is to make a ladder to go below decks. -

Sultana by DanB - Model Shipways - 1:64

DanB replied to DanB's topic in - Kit build logs for subjects built from 1751 - 1800

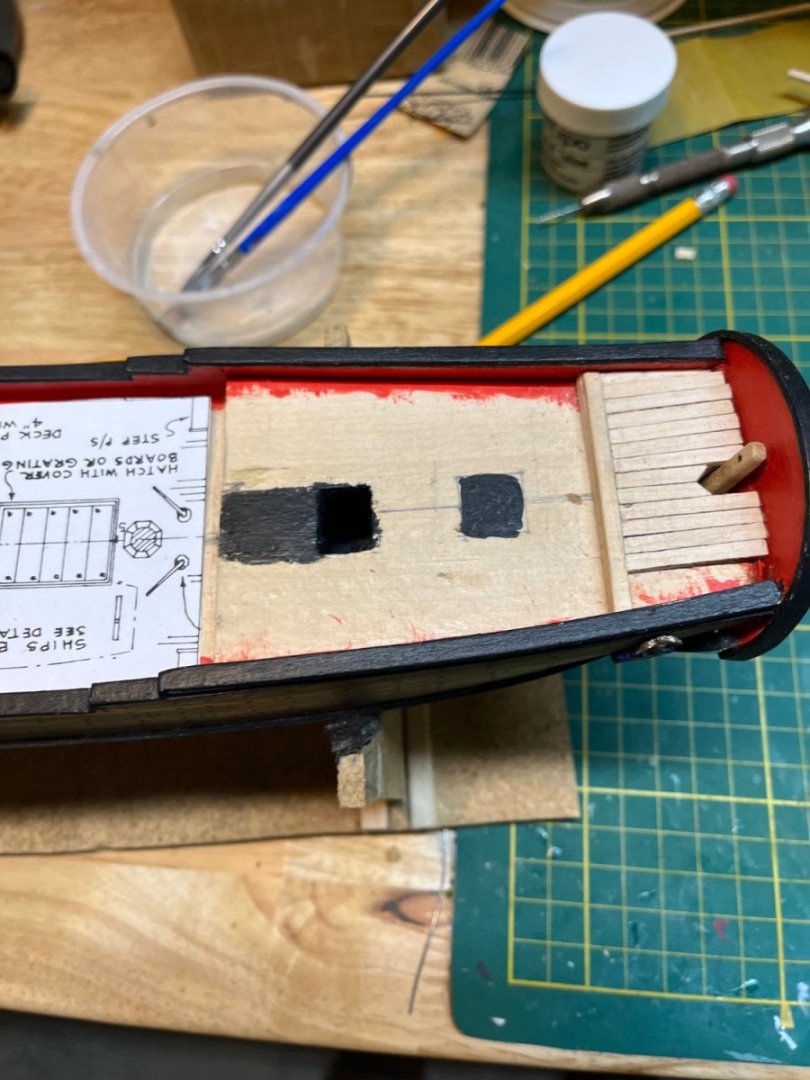

Working on hatch coamings and gratings. I marked out the holes based on the plans and planked around them. The problem was the gratings wound up being a bit larger to make the gratings fit well. so I had to make the spaces on deck bigger. It was difficult to enlarge the spaces in the planks and keep them aligned and square. I think should have made the hatch covers first and used them to mark out the spaces and then planked around those spaces. It’s a slow journey, this ship. I am learning how to do it better the next time though! Two more hatches to go. -

Sultana by DanB - Model Shipways - 1:64

DanB replied to DanB's topic in - Kit build logs for subjects built from 1751 - 1800

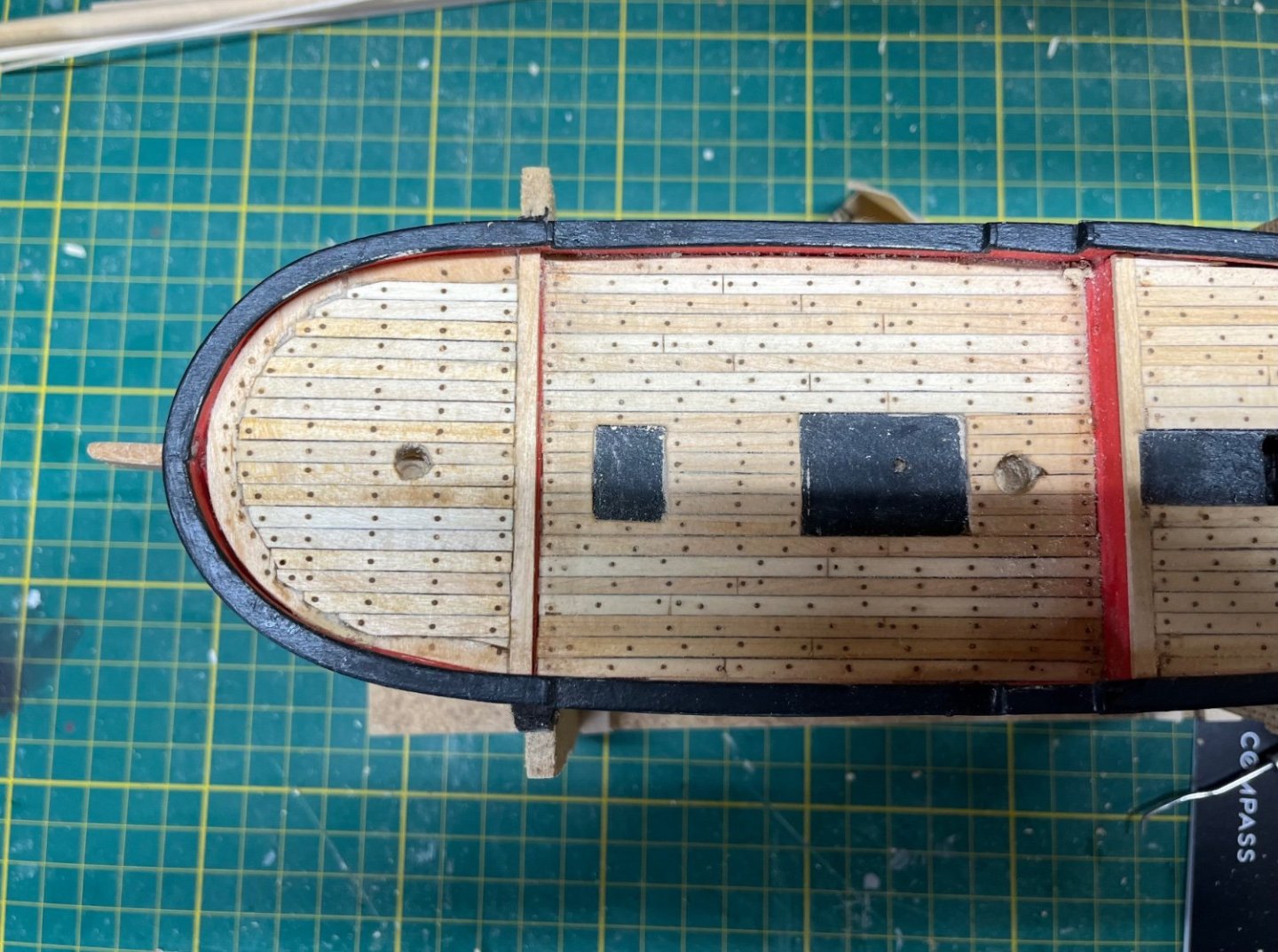

I finished the deck planking! I Looked at Chuck's shop notes and drawings in Historic Ship Models a bunch of times to try to understand joggling the planks into the margin plank. It did not come out so well. There was not much margin plank near the edges, and it split as I tried to fit the planks in. It was surprisingly difficult to get rid of the pencil lines I made to mark the cuts in the margin plank. Lessons for next time.! The next task is to install the waterway Chuck says to slice a 1/32 square basswood strip. diagonally so it has a triangular cross section. I am not sure I can do that, certainly not accurately, and I do have a fondness for my fingers!. Sanding the strip did not seem to work well, but it's safer! The wedge shaped piece then is supposed to get a concave shape by using a ball shaped sculpting tool to crush the triangular shape after it is glued down. This bit may be beyond me. I may just put in the strip ,smash it a bit with the ball thing and call it good! -

I think when I built the Pram I held the wire with a pair of fine nose pliers and used a small hammer to tap the end of it a bit. At some point the instructions tell you to get one of those flat metal plates that jewelry makers use. I may have used that to press against. You do not need the wire to expand to much, just enough to keep the “rivet” in the hole in the tiller. A lot of folks in different building longs had difficulty with the tiller on the Pram. I think it’s pretty thin and splits easily, you need to be gentle with the pin vise when you drill the hole. Search for the Pram and look at a few build logs. Good luck on your Pram Dan

-

Sultana by DanB - Model Shipways - 1:64

DanB replied to DanB's topic in - Kit build logs for subjects built from 1751 - 1800

Continuing to plank the deck. I am following Chuck’s suggestion to do one deck at a time to spread out the drilling, filling and sanding tasks. I am working on the margin plank to joggle the planks on the fore deck. -

Sultana by DanB - Model Shipways - 1:64

DanB replied to DanB's topic in - Kit build logs for subjects built from 1751 - 1800

More deck planking, I used a rotary tool to drill all the holes. Much faster than the pin vise I was using! -

Sultana by DanB - Model Shipways - 1:64

DanB replied to DanB's topic in - Kit build logs for subjects built from 1751 - 1800

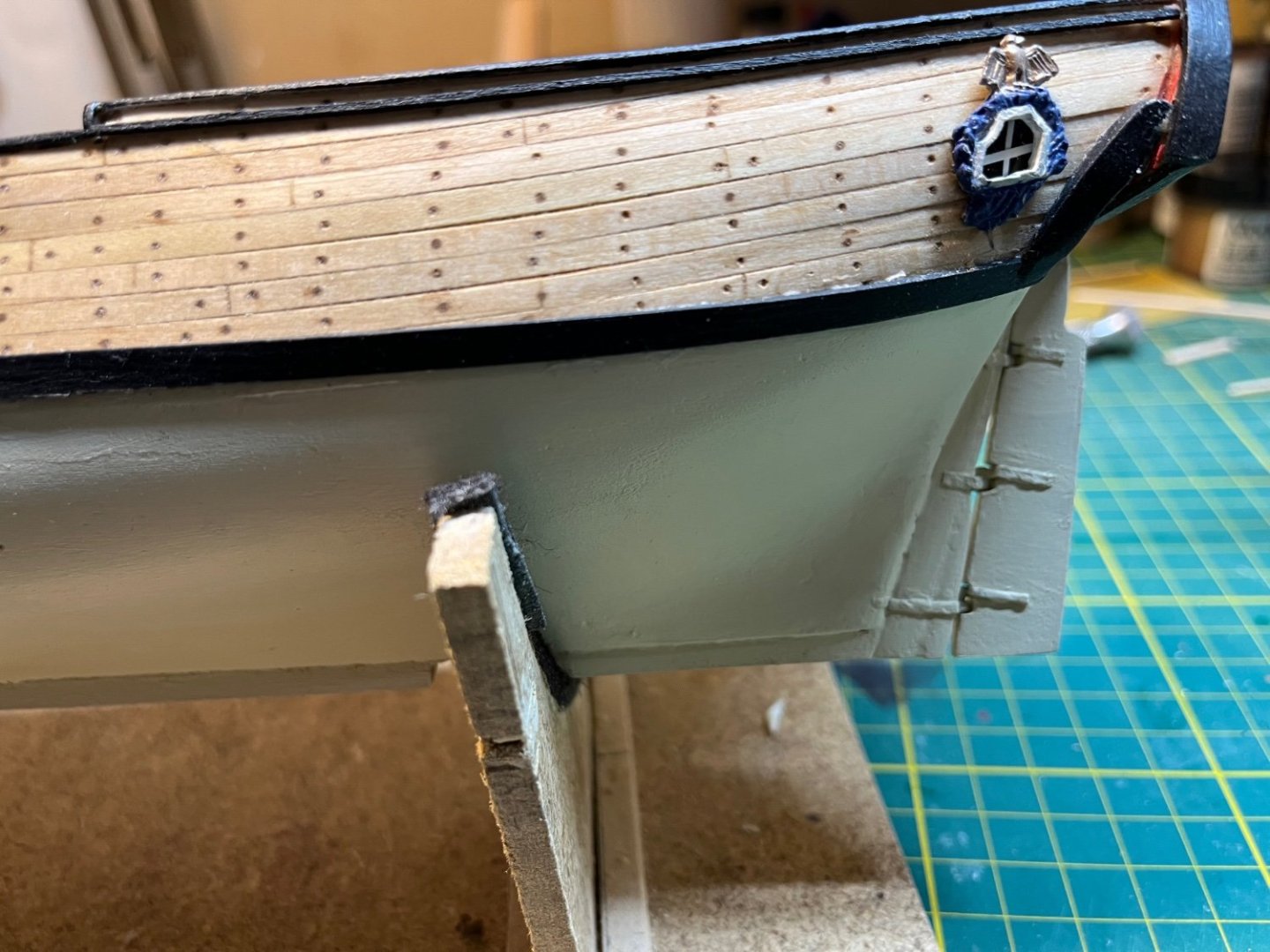

More planking. Used the same technique as the hull planking: drilled holes for trenails, filled them with darker wood filler (“golden oak”) and finished with tung oil. The filler darkened some with the tung oil. Having fun with this part! Moving forward. -

Sultana by DanB - Model Shipways - 1:64

DanB replied to DanB's topic in - Kit build logs for subjects built from 1751 - 1800

Rudderattached! Started planking the deck and painted the places where the gratings and ladder will be black.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.