-

Posts

79 -

Joined

-

Last visited

About ibozev

- Birthday 02/21/1997

Profile Information

-

Gender

Male

-

Location

Velingrad, Bulgaria

-

Interests

Puzzles, Modeling, Hiking, Cycling, Music, Collecting beer bottles

Recent Profile Visitors

-

ibozev reacted to a post in a topic:

Polaris by Meekes - OcCre - 1:50 - First Build

ibozev reacted to a post in a topic:

Polaris by Meekes - OcCre - 1:50 - First Build

-

ibozev reacted to a post in a topic:

Polaris by Maid of the Mist - FINISHED - OcCre - 1:50

ibozev reacted to a post in a topic:

Polaris by Maid of the Mist - FINISHED - OcCre - 1:50

-

ibozev reacted to a post in a topic:

Polaris by Maid of the Mist - FINISHED - OcCre - 1:50

ibozev reacted to a post in a topic:

Polaris by Maid of the Mist - FINISHED - OcCre - 1:50

-

ibozev reacted to a post in a topic:

Polaris by Maid of the Mist - FINISHED - OcCre - 1:50

ibozev reacted to a post in a topic:

Polaris by Maid of the Mist - FINISHED - OcCre - 1:50

-

ibozev reacted to a post in a topic:

Polaris by Maid of the Mist - FINISHED - OcCre - 1:50

ibozev reacted to a post in a topic:

Polaris by Maid of the Mist - FINISHED - OcCre - 1:50

-

ibozev reacted to a post in a topic:

Polaris by Maid of the Mist - FINISHED - OcCre - 1:50

ibozev reacted to a post in a topic:

Polaris by Maid of the Mist - FINISHED - OcCre - 1:50

-

ibozev reacted to a post in a topic:

Polaris by Maid of the Mist - FINISHED - OcCre - 1:50

ibozev reacted to a post in a topic:

Polaris by Maid of the Mist - FINISHED - OcCre - 1:50

-

ibozev reacted to a post in a topic:

Polaris by Maid of the Mist - FINISHED - OcCre - 1:50

ibozev reacted to a post in a topic:

Polaris by Maid of the Mist - FINISHED - OcCre - 1:50

-

ibozev reacted to a post in a topic:

Polaris by Maid of the Mist - FINISHED - OcCre - 1:50

ibozev reacted to a post in a topic:

Polaris by Maid of the Mist - FINISHED - OcCre - 1:50

-

Meekes reacted to a post in a topic:

Polaris by Meekes - OcCre - 1:50 - First Build

Meekes reacted to a post in a topic:

Polaris by Meekes - OcCre - 1:50 - First Build

-

Knocklouder reacted to a post in a topic:

Polaris by Meekes - OcCre - 1:50 - First Build

Knocklouder reacted to a post in a topic:

Polaris by Meekes - OcCre - 1:50 - First Build

-

This particular mistake may not be visible at the end. I think if you're lucky enough the hole for the rudder and the rudder itself could hide it at some point. 🙂

- 28 replies

-

lemlomlem reacted to a post in a topic:

Polaris by ibozev - FINISHED - OcCre - 1:50

lemlomlem reacted to a post in a topic:

Polaris by ibozev - FINISHED - OcCre - 1:50

-

lemlomlem reacted to a post in a topic:

Polaris by ibozev - FINISHED - OcCre - 1:50

lemlomlem reacted to a post in a topic:

Polaris by ibozev - FINISHED - OcCre - 1:50

-

lemlomlem reacted to a post in a topic:

Polaris by ibozev - FINISHED - OcCre - 1:50

lemlomlem reacted to a post in a topic:

Polaris by ibozev - FINISHED - OcCre - 1:50

-

lemlomlem reacted to a post in a topic:

Polaris by ibozev - FINISHED - OcCre - 1:50

lemlomlem reacted to a post in a topic:

Polaris by ibozev - FINISHED - OcCre - 1:50

-

lemlomlem reacted to a post in a topic:

Polaris by ibozev - FINISHED - OcCre - 1:50

lemlomlem reacted to a post in a topic:

Polaris by ibozev - FINISHED - OcCre - 1:50

-

lemlomlem reacted to a post in a topic:

Polaris by ibozev - FINISHED - OcCre - 1:50

lemlomlem reacted to a post in a topic:

Polaris by ibozev - FINISHED - OcCre - 1:50

-

lemlomlem reacted to a post in a topic:

Polaris by ibozev - FINISHED - OcCre - 1:50

lemlomlem reacted to a post in a topic:

Polaris by ibozev - FINISHED - OcCre - 1:50

-

Hi James, I'm happy to hear that you've got your new keel. Indeed Occre have one of the best return and warranty polices! Unfortunately I think you made a mistake with the deck planking. You didn't have to cut the extra deck planks, which are above the holes for the ribs. The idea is to hide the ribs with the deck.

- 10 replies

-

- OcCre

- First Build

-

(and 1 more)

Tagged with:

-

Hello, Travis, and welcome to MSW! For the second layer I suggest you to read the planking materials here in the forum or to check my Polaris build log, where I tried to explain this step in a detail. I also strongly recommend you to use only PVA white glue, instead of the contact cement. This glue is suggested in the instructions, but according to most people here (me as well), contact glue is awful and it's a big mess everytime you're using it.

-

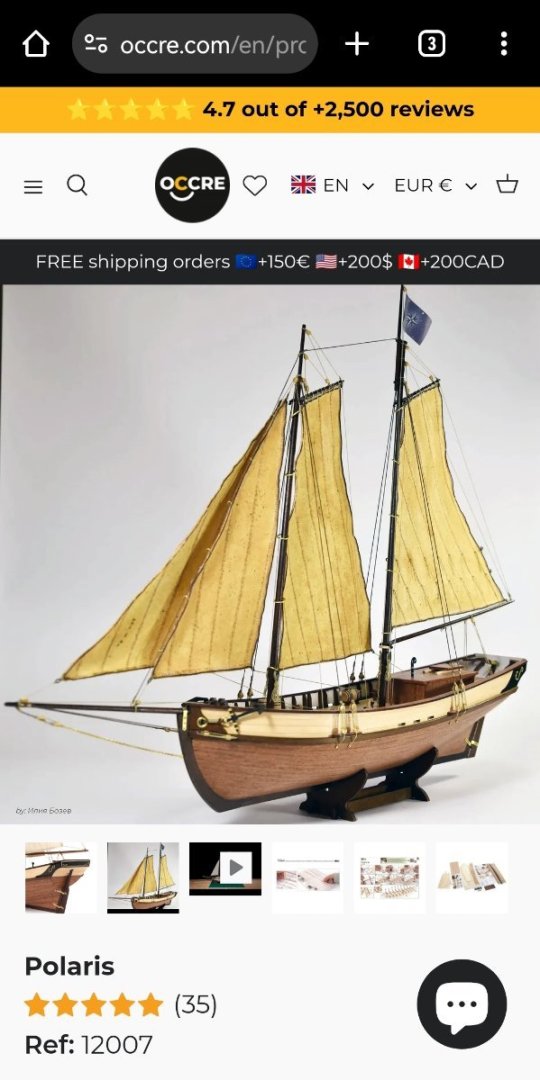

Hi everyone and Happy New 2024 Year! It's a pleasure for me to have something new to share with you! A small, but important milestone for me - one of my Polaris photos was uploaded by OcCre on their website and is now part of the official model images! You can check them here.

-

Nice job with the deck weathering! I will be looking forward to see your progress on Polaris.

-

Well done Jack, you are making a good progress! Sanding the bulkheads and lining of the hull are some of the most important and crucial things in order to prepare the hull for the first layer of planks. As you said, take your time on these steps and don't rush. On my Polaris I spent a lot of time aligning the wooden battens and strips, just to find the perfect and most symmetrical position. One advice I could give is to not oversand the bow to much and check it's fit with the stem. Do this now, not when the hull is already planked. I made this mistake and after the first layer was planked, it was very difficult to sand the bow and mount the stem.

- 28 replies

-

Thank you for all the likes and comments! An album with high quality images is already uploaded in my Profile section. This was also my first attempt to shoot with something different than a phone. 😅

-

And here we are, after 14 months my Polaris is finally finished! I certainly kept my promise from the very first post of this log, that I will make it slowly 😅. Hopefully I fulfilled at least a little the other, more important, part of my promise: "to do it well"! I want to special thank for all of the comments, likes and support through this wonderful journey! I started as a total beginner without any nautical knowledge and ended with a finished model and a lot of information and lessons learn. For sure this won't be my last model and most probably my next build will start next year at the earliest. Till then I will try to read some books about rigging, make a display case and better photos of the finished model (the last one will happen soon). ----- P.S. Now I can finally back to one of my other hobbies and celebrate it properly! Cheers!

-

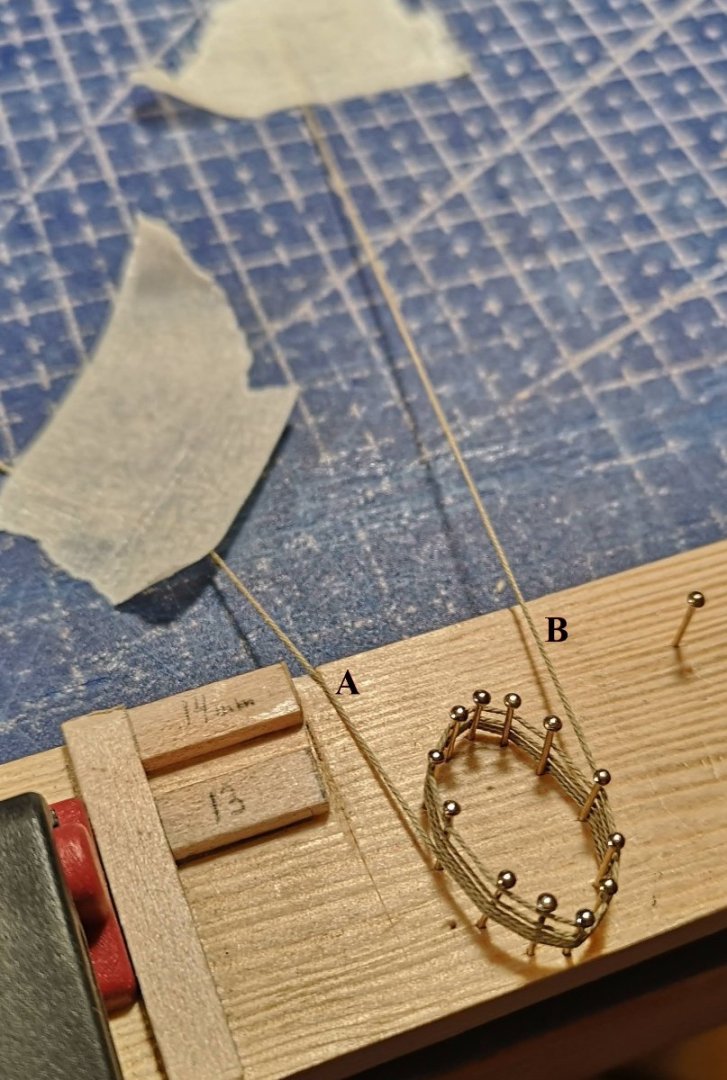

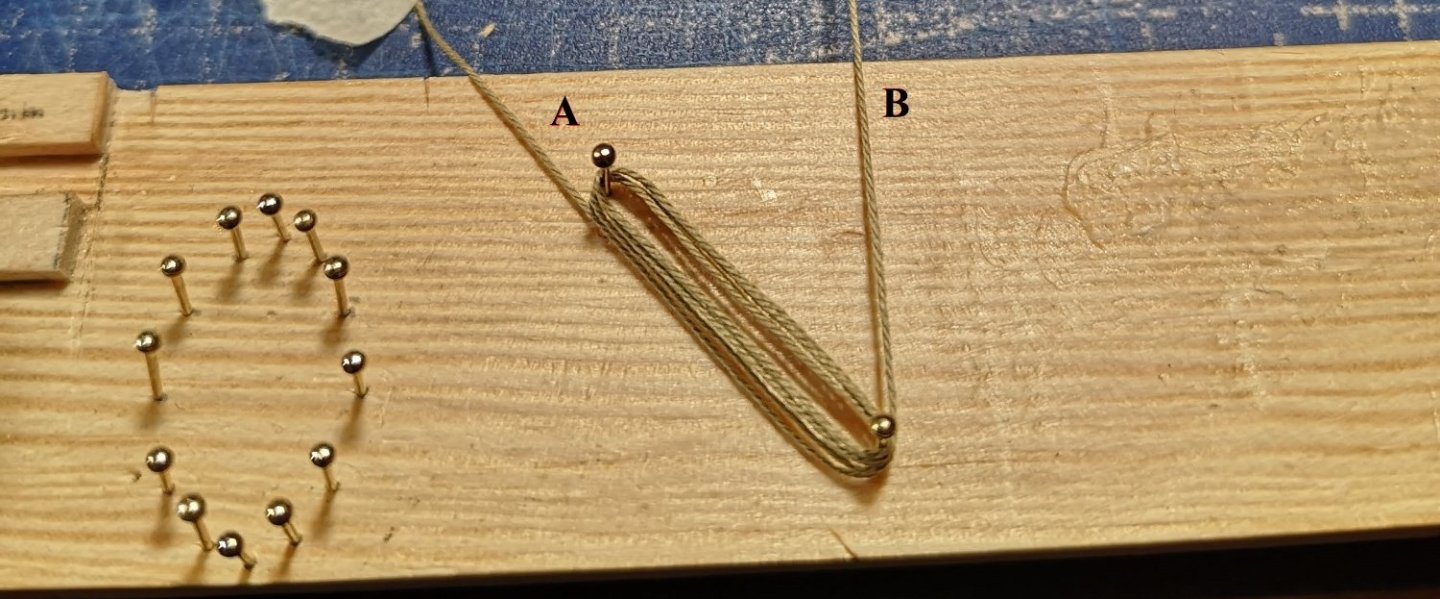

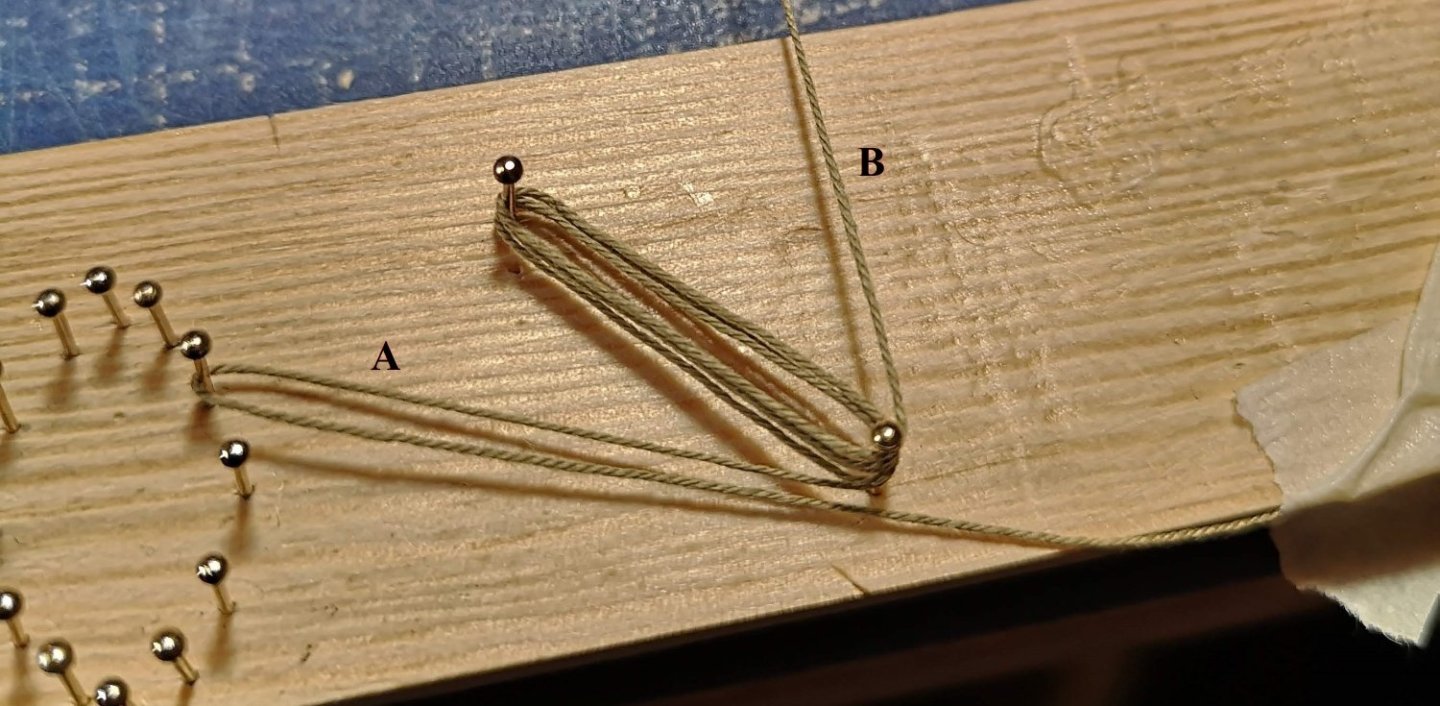

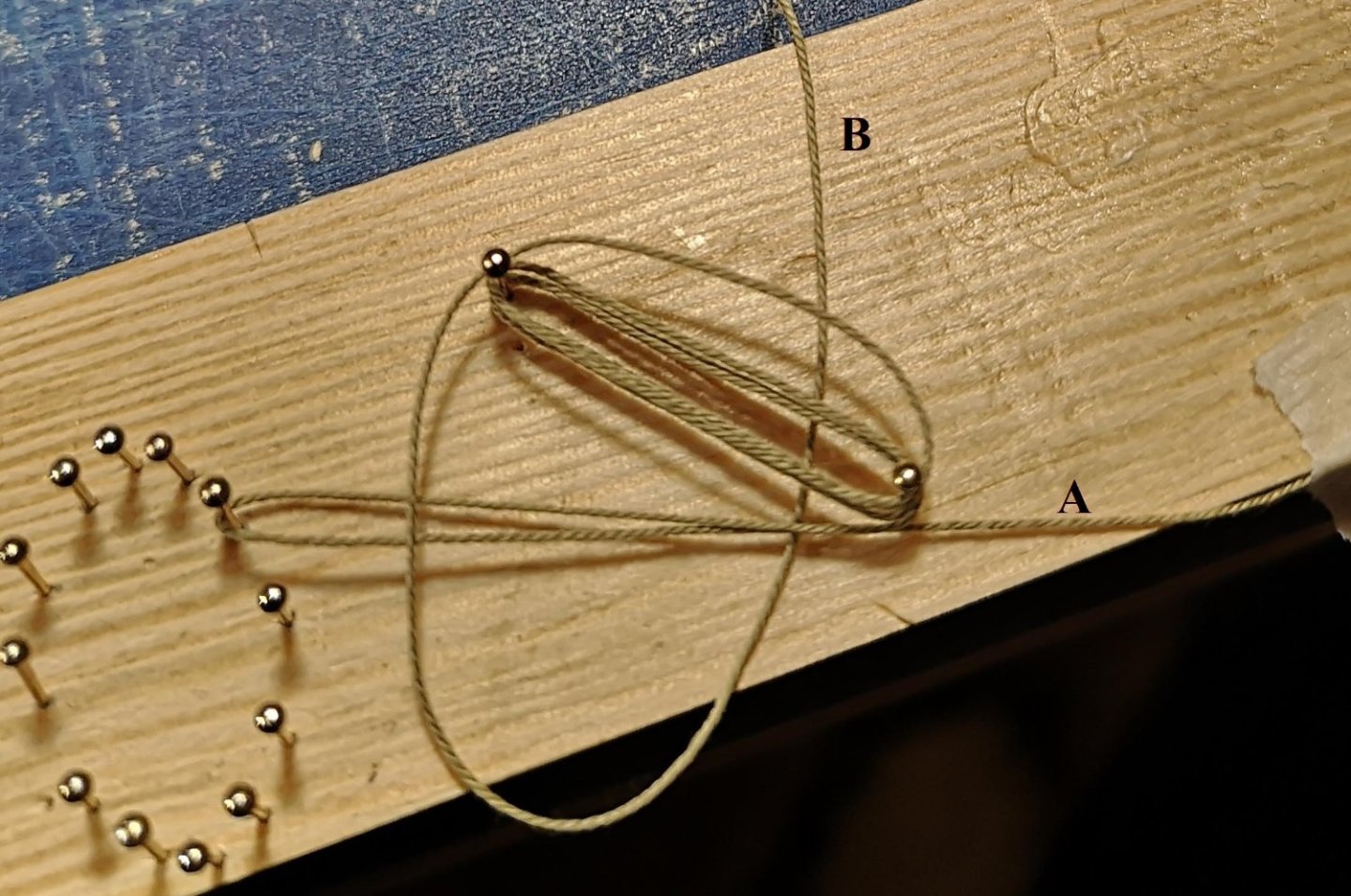

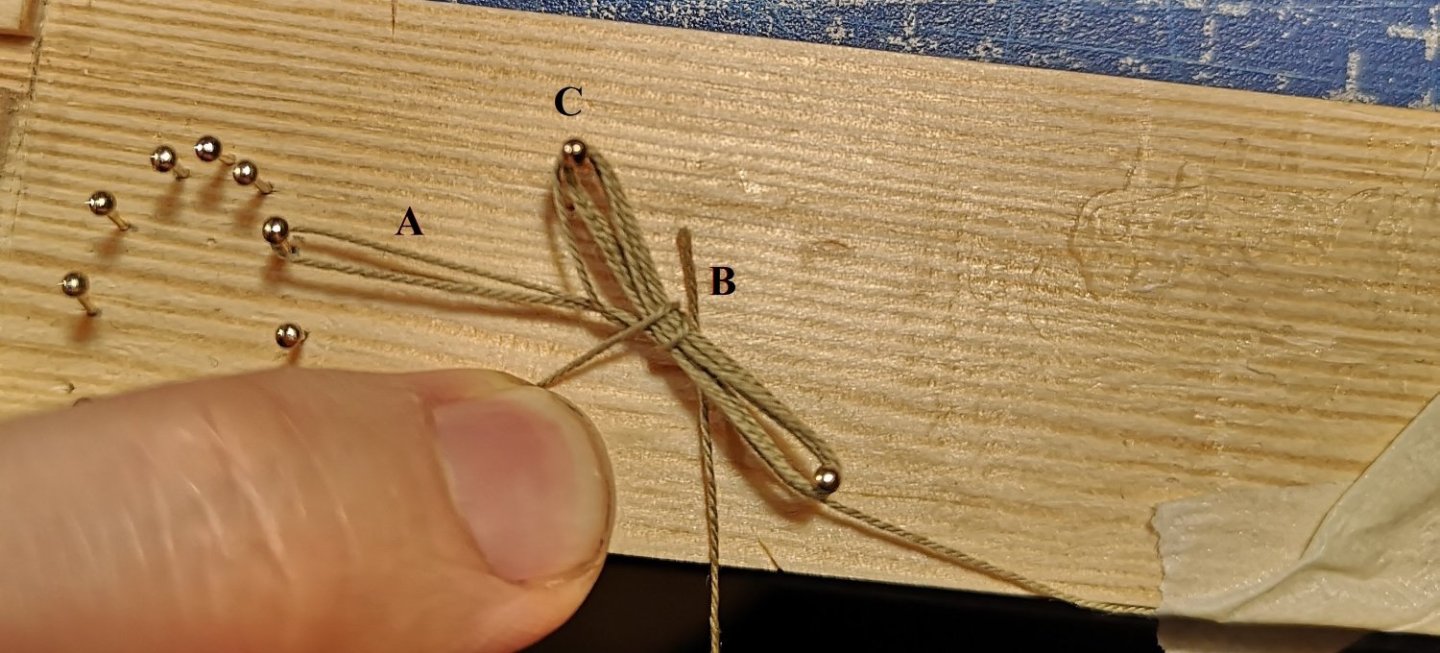

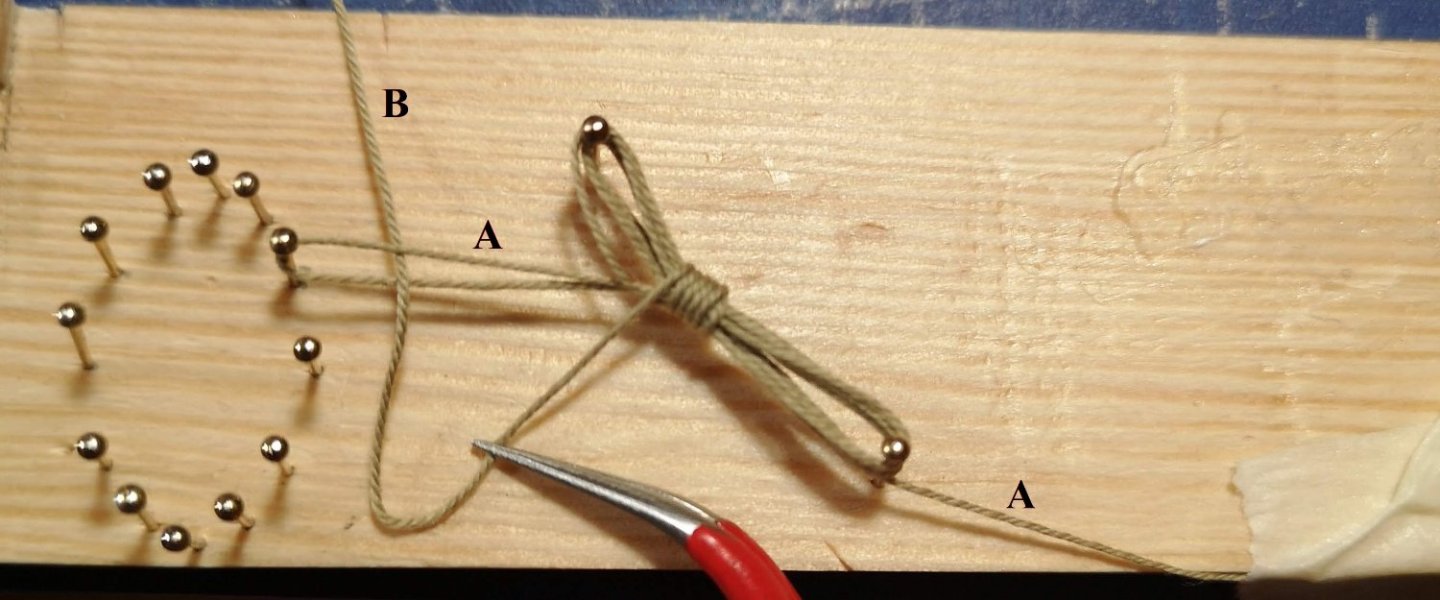

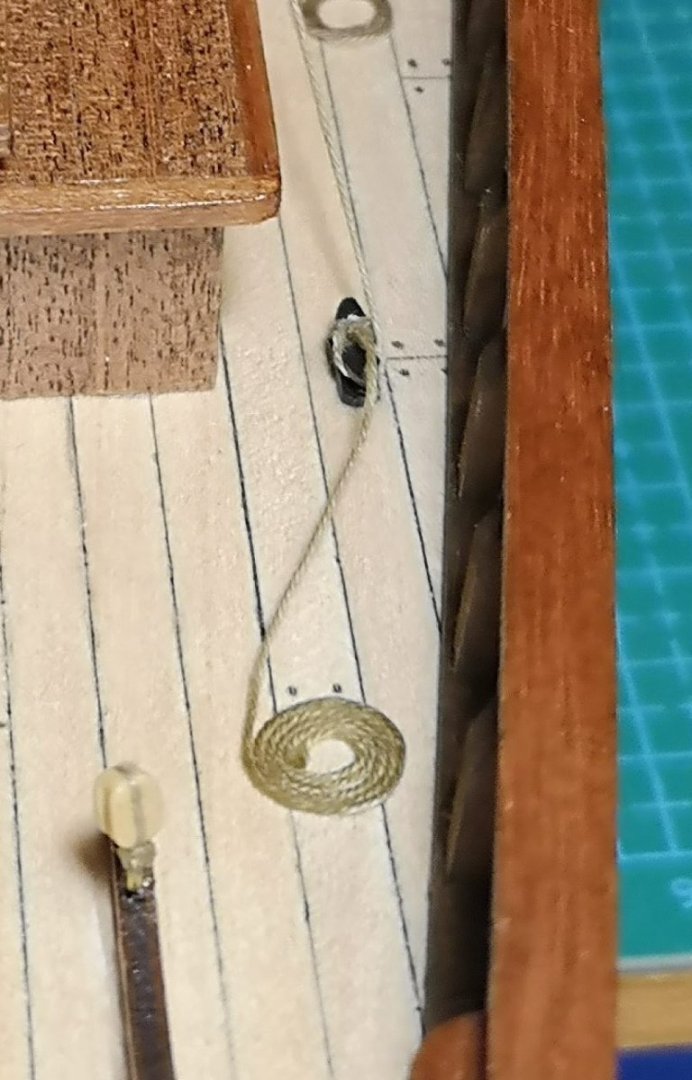

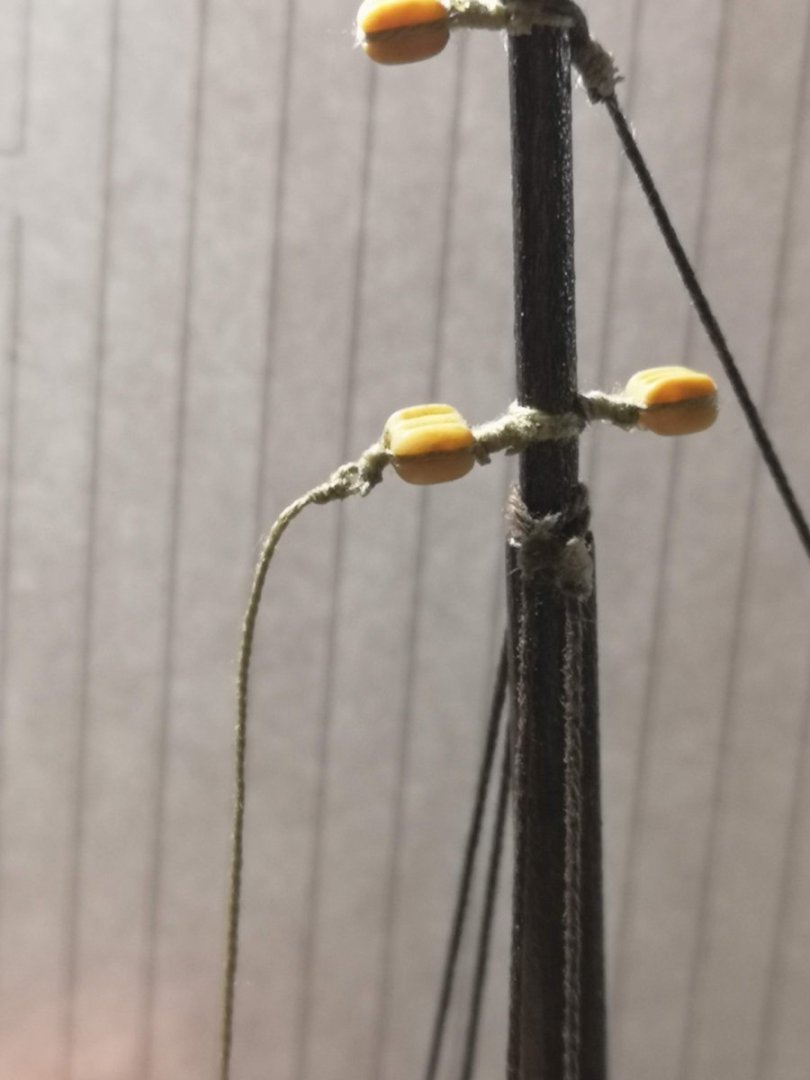

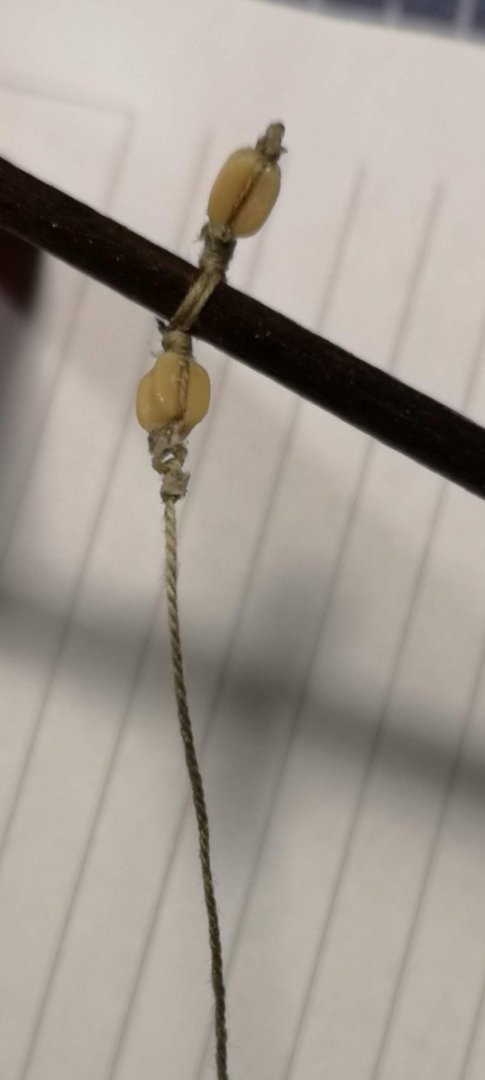

This post will be more like an improvised tutorial on making rope coils (hanks). I've read some info about coils making, watched couple of videos too, but all of the materials were about the lines belayed on the the belaying pins - something that doesn't exist in Polaris... My idea was to make something different, that I could hang on the masts cleats. So these are the steps I used: 1. First make an ellipsis jig with the desired length and shape. Then tape the starting end 'A' and make 4 or 5 rotations counter clockwise around the pins with the other end 'B'. 2. Then carefully transfer the shape to the other jig. I would say that the previous step can be skipped and use only the second jig. My initial idea for the first jig was to keep the shape somehow, in order to have rounded, not sharp ends of the coil. 3. Now make a bight with 'A', tape it again and fixed it on one of the side pins just for convenience. 4. Now begins the fun part. Take the 'B' end and reeve it counter clockwise over A's bight and below the whole coil. 5. Repeat step 4 couple of times, it is important to make every next loop towards 'C'. 6. When you are satisfied with the number of repetitions, reeve 'B' through A's loop and pull both ends. 7. A dot of CA on the backside and cut the excess. 8*. Brush the coil with diluted PVA (I decided not to do this step, but probably it will give a nice finish look). This is the final look of the coil, attached to the cleat:

-

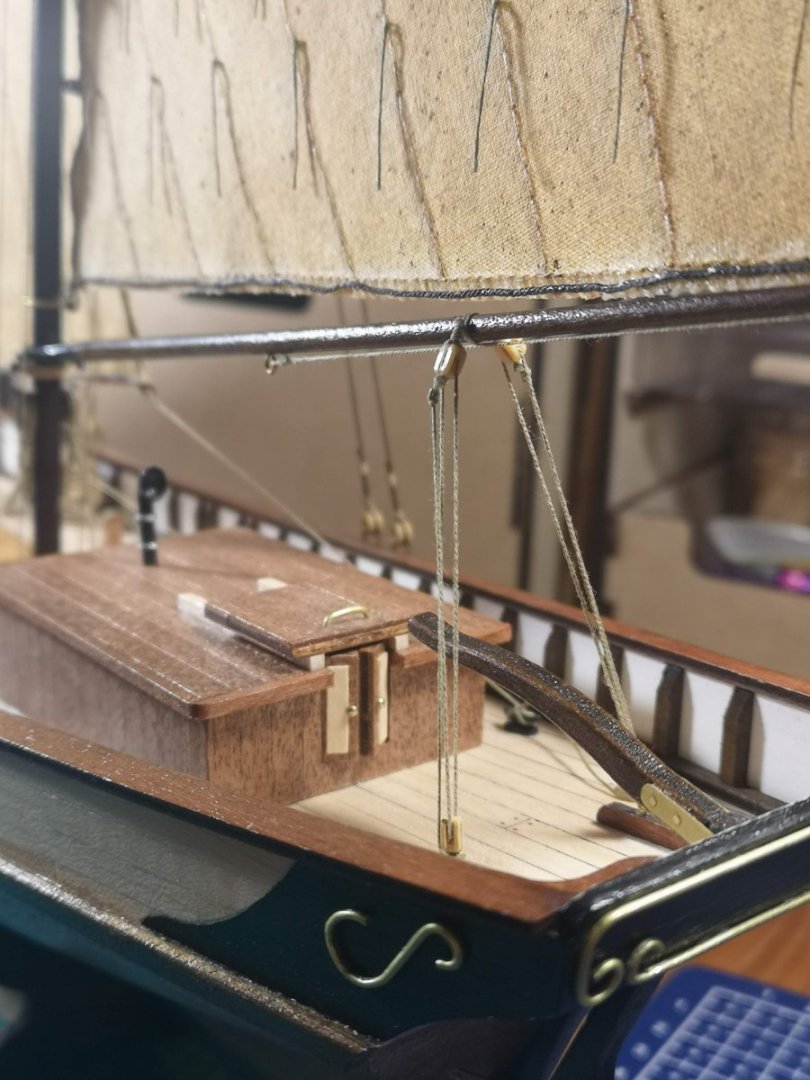

Next in the queue was the foresail. Here the rigging sequence I followed was as follow: throat halyard, gaff parrel, luff lacing, peak halyard, vang, clew line. My advice is not to glue the halyards until the luff is completely laced to the mast rings. All of the mast rings were again sewed, not pushed through the canvas. Well, that was a tricky and time consuming job, but the end result was pretty good: The clew line became better than the other two, maybe because the line was a little longer. For the mainsail the rigging sequence were: throat halyard, gaff parrel, luff lacing, peak halyard, topping lift, sheets, vang, clew line. Actually I rigged the vang before the sheets, but probably the vice versa variant would be better, I think. For me, the main sheets don't look very realistic and this is one of the many mistakes of the kit - there are no cleats or belaying pins for all of the rigging lines. As you can see on the above (and bottom) image, the boom is not perpendicular to the mainsail foot and this is a mistake I noticed later when the sail was fully mounted. With that being said, the only things left to do are the flag and the rope coils. So I can say that the end of this journey is near 🙂

-

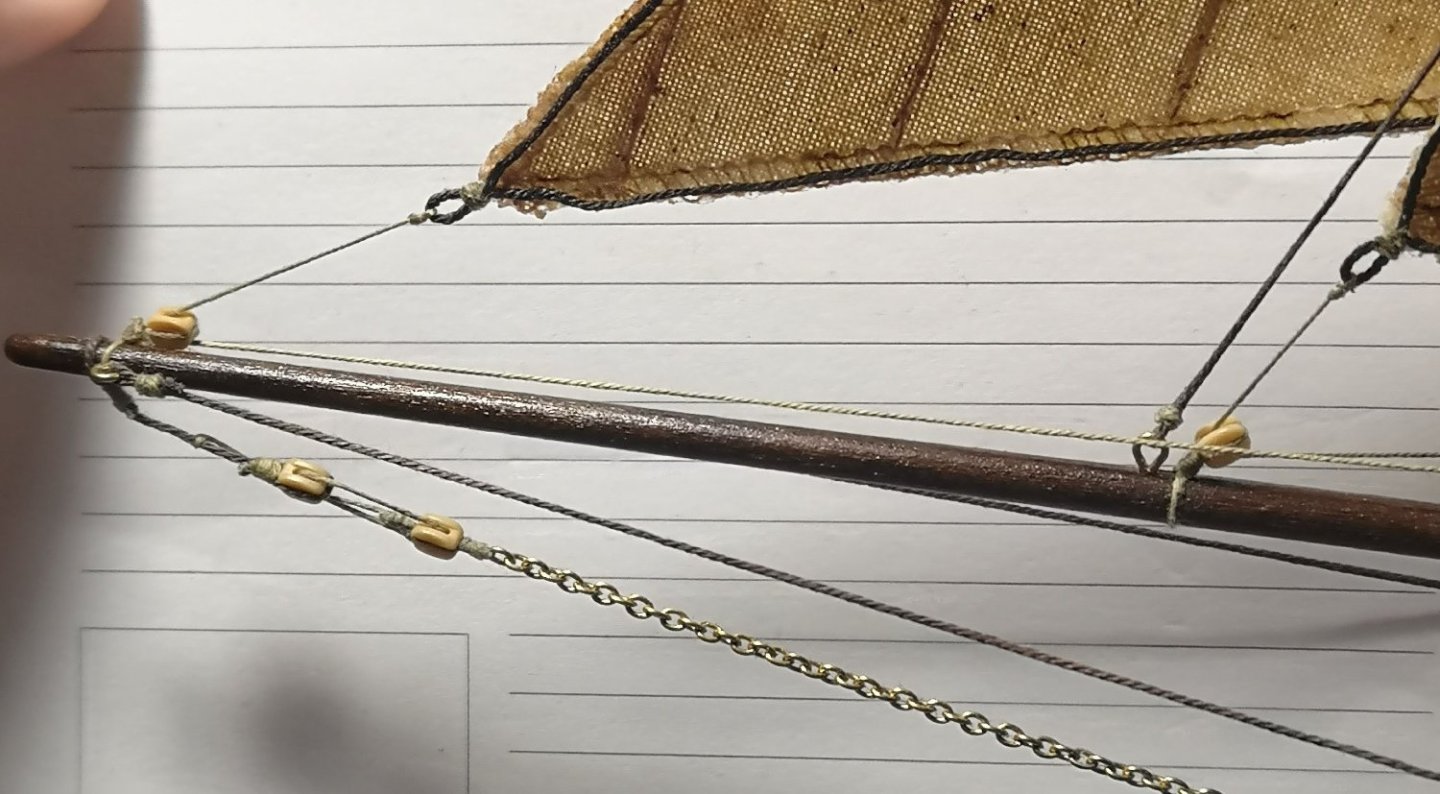

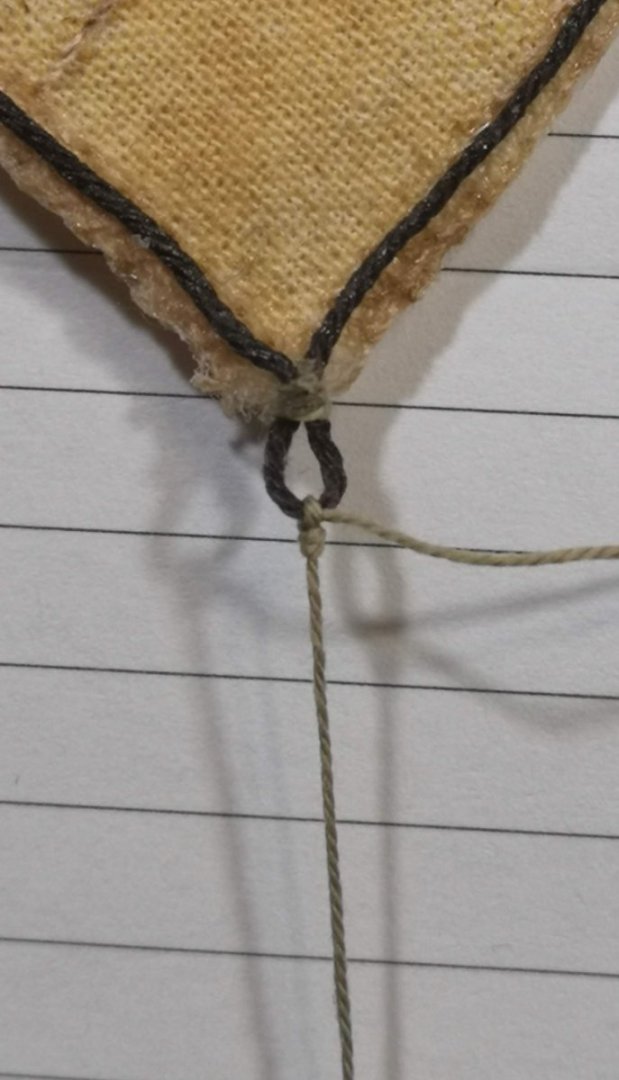

Well, it was a productive weekend and I have a lot to share. To keep the posts not too long, I will split them into several updates. After the sails were fully prepared it was time to install them and the first in the row was the jib. I clipped the halyard and tack line temporary, just to fix the sail. Then sewed all of the small rings, which I already attached to the forestay, using a simple overhand knots. I decided to sew all of the sail rings to the cloth, rather than pushing them through the sails as per the instructions. The distance between each ring was measured in advance and holes for the needle were also made. After securing the jib to the forestay, the halyard and tack line could be permanently reeved. I made a mistake here to reeve the jib sheet now, because it was very tricky to install the lines for the fore and main sails later. The better sequence probably could be to reeve all of the sheets at the end, when all sails are installed. This is how the other jib lines look installed: As you can see for the halyards I used a standard whipping, which in reality couldn't happen. But since there are a lot of factual mistakes in this kit, for me the visual appearance is more important . For the sheet lines I decided to make something interesting, which I haven't done before, but I've seen on other ships. Don't know the actual term and if it's appropriate for my Polaris, but it looks pretty good: The flying jib was installed after that in the same sequence as the jib.

-

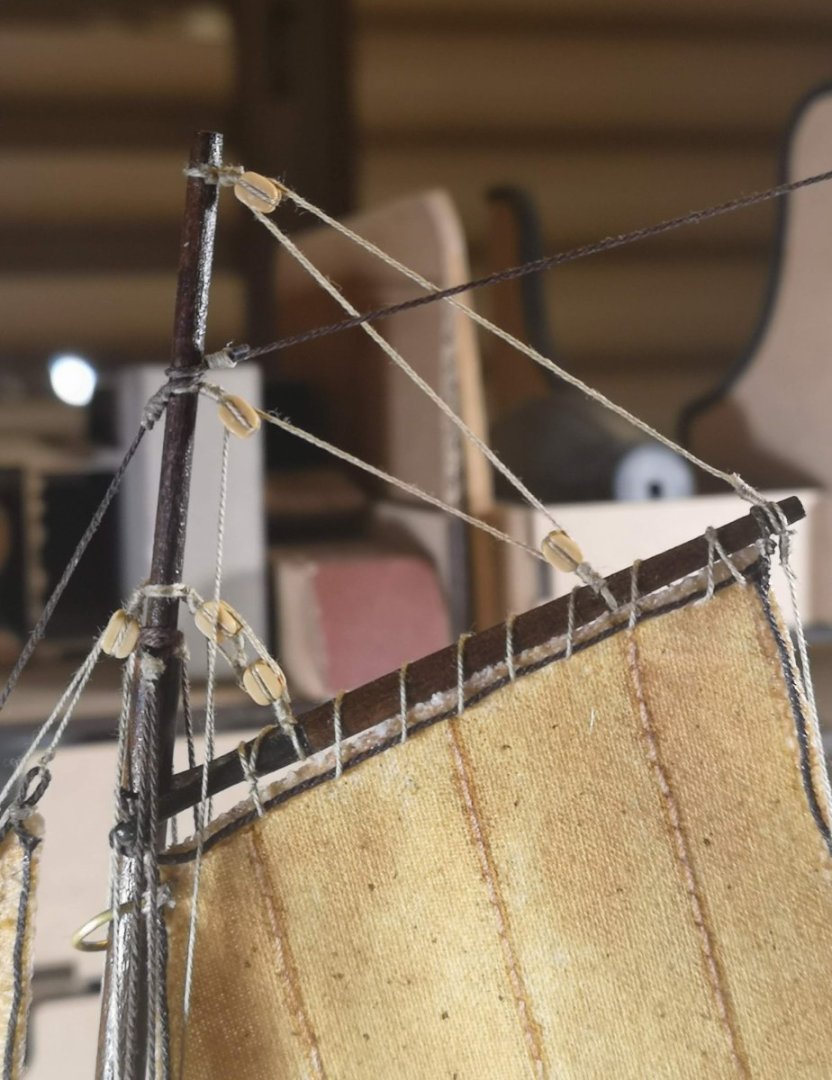

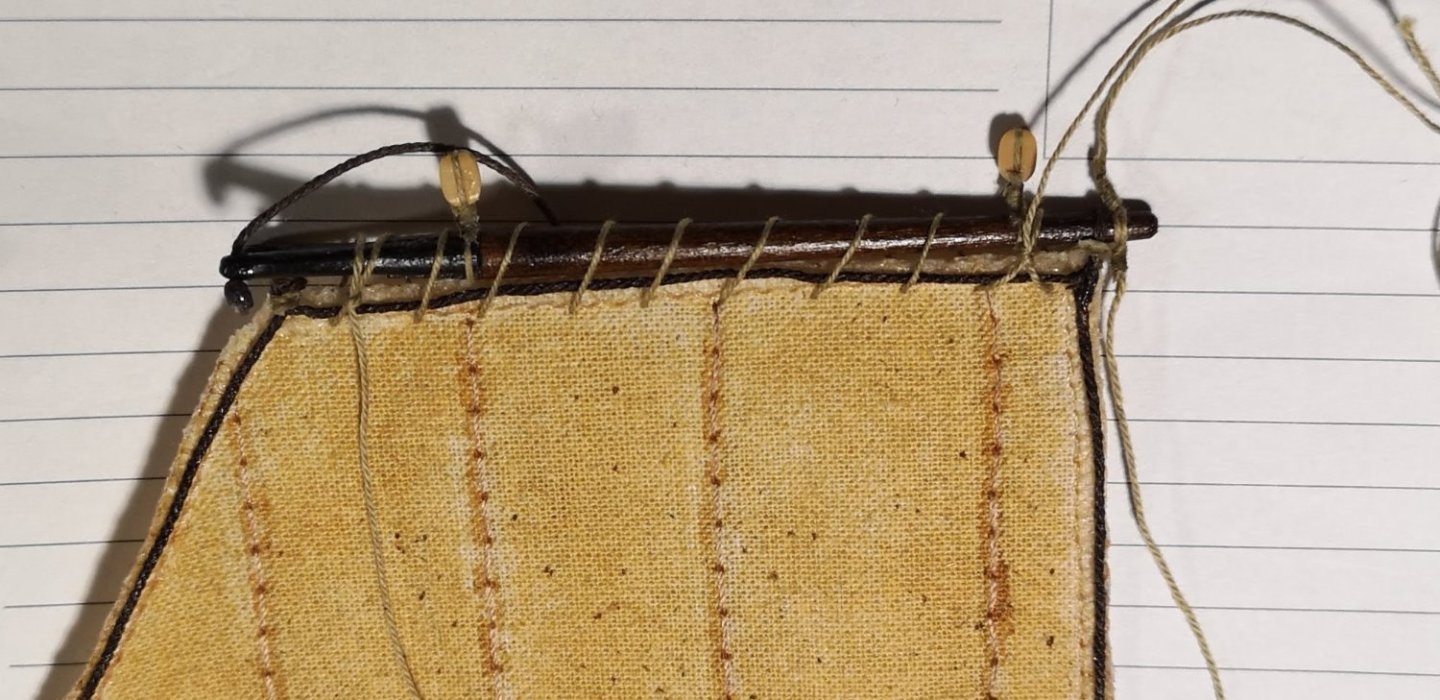

Quick update after two weeks away from the workbench. The last step before installing the sails is to prepare all of the needed running lines and to bend the sails to the gaffs. I used a halyard hitch knot to reeve all of the lines needed for jibs heads and tacks and all clew cringles. On the fore- and mainsail I didn't install other running rigging. The same knot I used also to install the lines for both throat halyards and main sheets: One advice here is to install those lines before attaching the blocks to the spars, it would be much easier. Well I didn't consider that when I built the masts and did it the hard way. I bend the sails to the gaffs using a single raw line with square knots in both ends. At this moment the vangs and peak halyards were also installed to the gaffs: And the last thing that I made before attaching the sails were to install the sails rings (don't know the actual nautical term) around the masts and on the forestay. Again, I should have done this before the standing rigging... And this is the final look of all sails (I decided to not fill them with air and leave them as they are at the moment:

-

I am still building my first model OcCre's Polaris - 1:50, the sails are almost done and are ready to be installed. I've used a Pine and Walnut dye for weathering and diluted PVA to glue the boltrope, but still thinking about the shape. I've read this wonderful topic and learnt some really nice techniques for sails making, but still cannot decide: "To fill the sails with wind or not? If yes, what would be the best method to use?". The sails I'm using are the ones provided with the kit and are made from cloth (probably cotton). I've read somewhere that the potato starch and the diluted PVA are 2 possible solutions, but I'm not familiar how to use them properly for this purpose.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.