-

Posts

1,015 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Ferrus Manus

-

-

- Keith Black, mtaylor, GrandpaPhil and 1 other

-

4

4

-

Would you like to do some research on the real ship?

-

10 hours ago, Isaiah said:

I’m just confused because the plan before your drawing has a straight bow, but then you said you’re redesigning to make a straight bow?

The plan shown was not my own. It was a representation of what I wanted my bow to look like. I redesigned my own bow to reflect the online image. That picture is likely a photocopy, my designs are all drawn on paper with pencil. Go back and look at the original side profile of the boat. I hope that answers your question.

- Isaiah and Keith Black

-

2

2

-

Thank you for the recommendation. I will have to look into it. While this is a pilot cutter, other similar boats like the Lizzie Annie are equally valuable resources. The shallow hull sets the Devin Collins apart from other pilot cutters, and from what I've seen, all pilot cutters are unique.

- GrandpaPhil and Keith Black

-

2

2

-

Why don't you start the build log for the Sherbourne and do some research while you wait? That's what I do.

-

Another possibility that avoids the brass pin inserts is to cut a square hole at the edge of the planking at regular intervals (probably every other frame, will be determined after planking is on-ship) and insert the stanchions into the cutouts in the deck. A third option is to use JB-Weld on the bottoms of the stanchions. The first plank on the stanchions, directly above the wale, will be glued to the wale as well as the stanchions, increasing the structural soundness of the entire system.

- mtaylor and Keith Black

-

2

2

-

20 minutes ago, Isaiah said:

I thought the first drawing already has a straight bow? Me the beginner is confused.

The drawings you're looking at are not my drawings or plans, but rather a representation of how the bow should look on my vessel.

- mtaylor and Keith Black

-

2

2

-

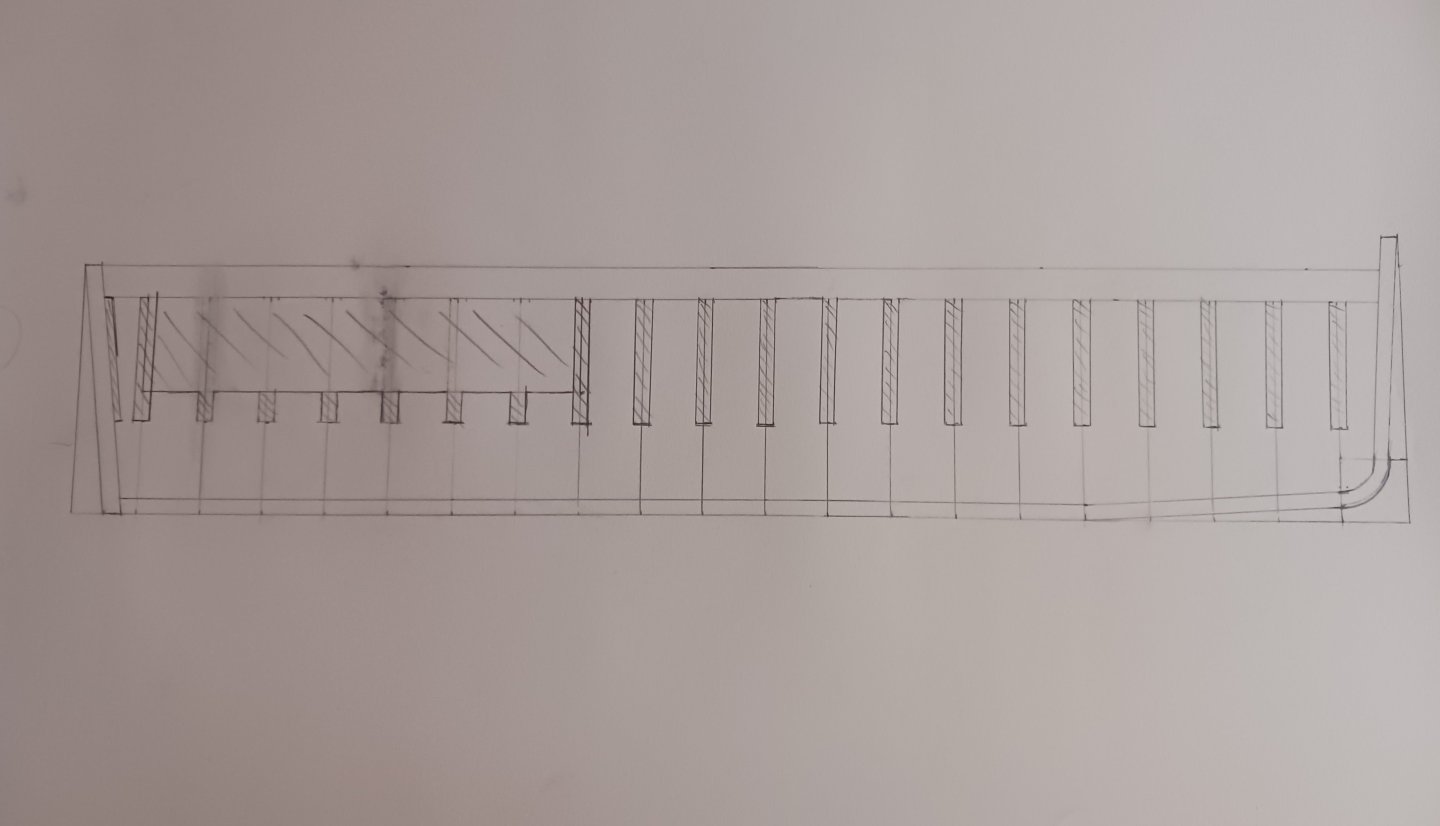

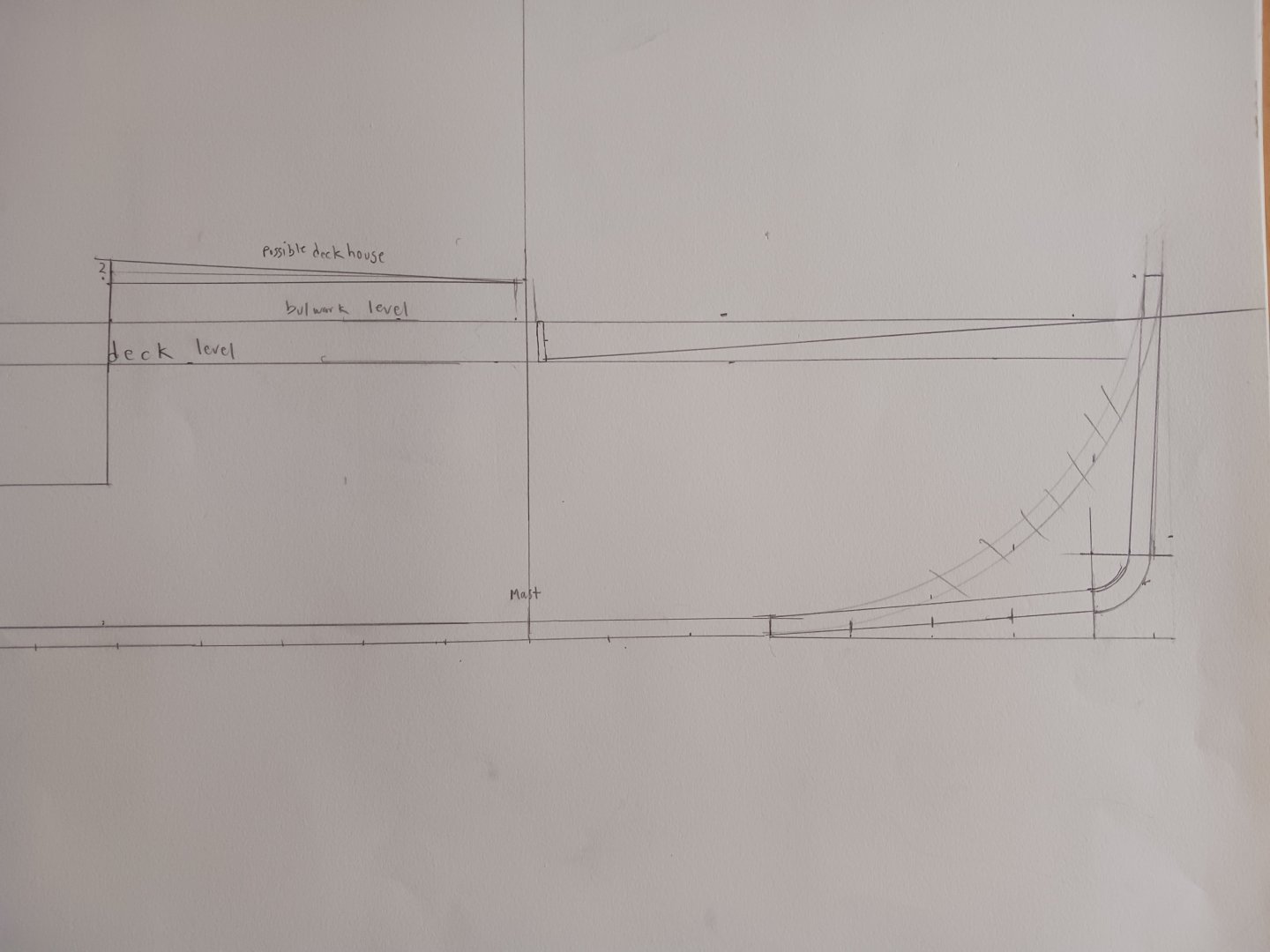

I have reevaluated the positioning of the main wale on the boat. I have also come up with a different way of attaching the stanchions for the upper bulwarks that does not require the wale to be above deck-level. The deck will be planked off-ship (this is non-negotiable as I already have working plans for that) and laid down on the tops of the frames. Then, with each frame still exposed, the stanchions will be positioned on top of the deck. This opens up new avenues for the scupper designs. Some smacks have an open area at deck level for water runoff, while others have proper scuppers. I will likely go the latter route.

The Lizzie Annie has an unplanked area at deck level...

...while the cutter Kochi has proper scuppers.

The plan is to drill holes and insert brass pins connecting the stanchions to the hull. The reason for this, apart from the scupper issue, is that the interiors of these cutters' upper bulwarks usually remain unplanked. Thus, the stanchions are to remain exposed when the upper bulwarks are planked and painted. I have rarely ever seen the main wale above deck level on an English smack.

- mtaylor and Keith Black

-

2

2

-

- mtaylor, GrandpaPhil and Keith Black

-

3

3

-

Now, I am thinking of redesigning the stempost and lengthening the keel. It's not too late to do this, as I haven't designed the stempost frames yet. I will likely redesign it to reflect the bow shapes of the era.

The straight-vertical bow will help with the planking process.

- mtaylor, Isaiah, GrandpaPhil and 1 other

-

4

4

-

This is the pilot cutter Pellew, a vessel that is significantly larger than either the Lizzie Annie or the Devin Collins. A point of note is the topmast stay and the fact that the jib is still on a traveler. This eliminates the need for furling ropes or manropes on the bowsprit. The second stay and taller mast both exist because the Pellew has a standing gaff topsail. I am sticking with a jackyard topsail as is flown on the Lizzie Annie.

- mtaylor, GrandpaPhil and Keith Black

-

3

3

-

- GrandpaPhil, Isaiah and mtaylor

-

3

3

-

-

I have decided to reduce the rig in the interest of saving space for display. The intended display location is a bedroom-turned-library. This provides a unique challenge owing to the size of the model.

Thus, the length of the bowsprit will probably be halved, or thereabouts. The height of the mast will likely be reduced by about 6 inches, and the length of the boom will extend not more than two inches from the transom. This is all subject to change, and should not be considered an exact science. The jackyard topsail will have to stay, assuming the rig is to be set. If the sails are to be furled, however, (which would be easier for me, and might even look better, but would sacrifice the WOW factor) then the height of the topsail yard stops being a factor.

- Isaiah and GrandpaPhil

-

2

2

-

Apologies for the stalled progress on this build. I realized an error I will have to fix on the designs for the first 4 or 5 frames- I didn't draw the cutout for the cockpit!

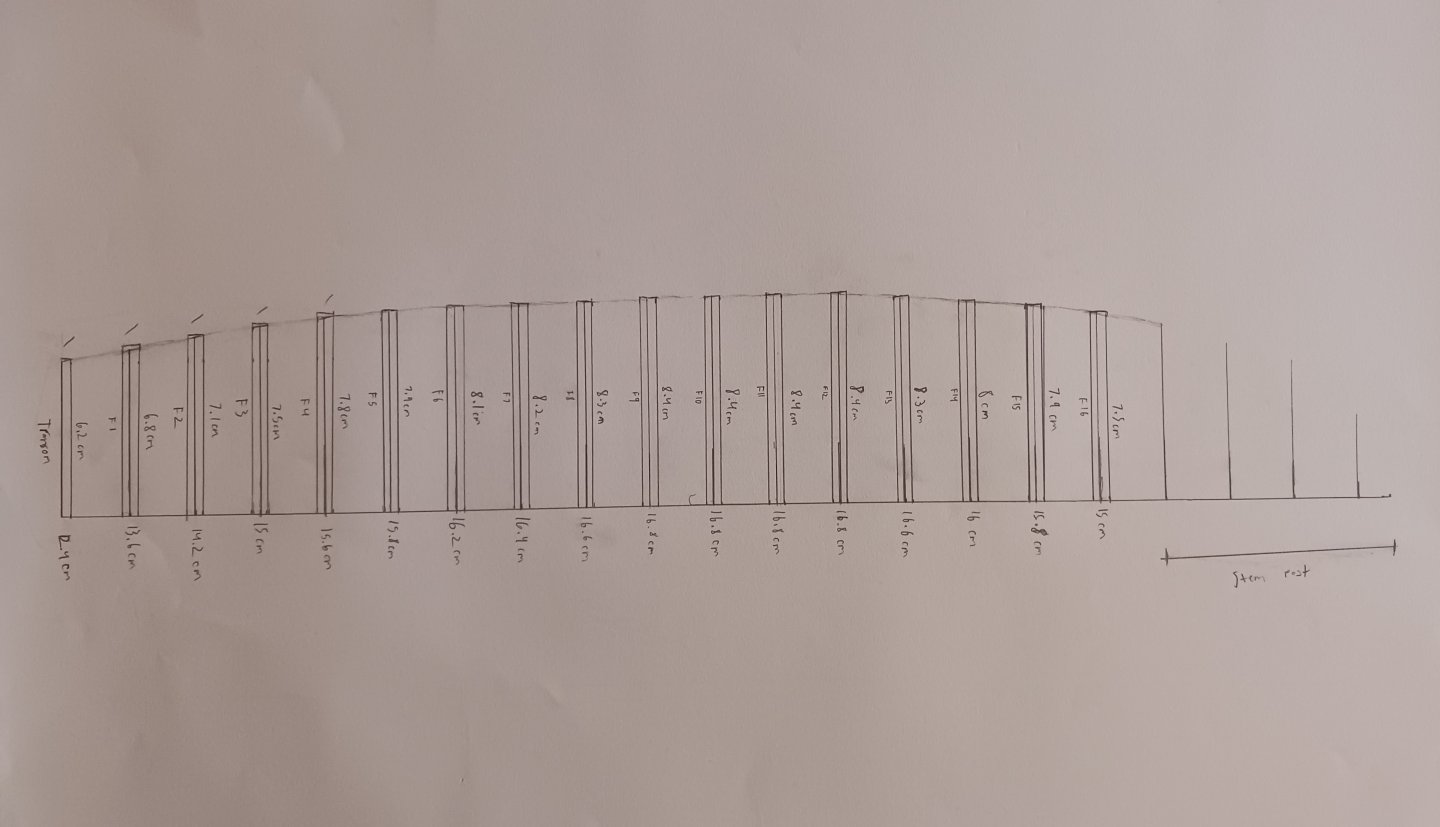

Anyways, the show will hopefully continue soon. The keel will be easy to design, as well as the rest of the frames up to the beginning of the stempost. There are, I believe, 4 stempost frames. I do not believe these vessels had any kind of cant frames or hawse pieces. It wouldn't need them, as this is a small vessel.

I have changed my design for the shroud turnbuckles- they will be attached directly to either the outside of the hull or the top of the cap rail. I might buy my own pre-cut planking material for at least the deck.

I have been recommended a hand planer to assist with the extensive fairing at the bow.

-

-

Belay to the port side bulwark if possible, not the deck.

-

-

-

@GGibson If he wants to see a list of a specific member's builds, he can just go to that person and ask them for a list. This community is all too happy to show others their builds. I tried your technique, and the issue is someone might have posted in one or multiple non-build log forums, or may be referenced in logs other than their own.

-

You should probably make stuff like this out of brass in the future, because it's easier to work with and can be chemically blackened.

-

-

-

Don's wood. The framing, false keel, and likely a significant amount of the planking will be made from Don's wood. He is basically sending me raw materials, and I'm sending them back in the form of a model ship. I will be using a lot of my own materials and fittings, however. I will be buying my own blocks, rigging line, brass, turnbuckles, shackles, chain, cloth, etc.

HM Armed Cutter Sherbourne 1763 by Isaiah - Vanguard models - 1:64

in - Kit build logs for subjects built from 1751 - 1800

Posted

An accurate build is a good looking build. When it comes to ships, usually accuracy equates to beauty pretty well.