-

Posts

139 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by flutlo6180

-

Thanks Allan! I appreciate the explanation and the sketch which does make it much clearer. You are correct, I've installed all the blocks thus far the same way - upside down. As you say, it is a small detail, and I'm not sure if I will go back and redo them, but I will give that some thought, Regardless, I will make the change going forward.

-

Based on Thukydides guidance, I've started to redo the deadeyes. Doing so did mean I needed to replace several shroud lines and I am finding it less daunting that I originally thought to be working on building the mast while it is stepped. With all the rework I've done on this build it seems like I am building her twice, but I am learning a lot and enjoying the journey.

-

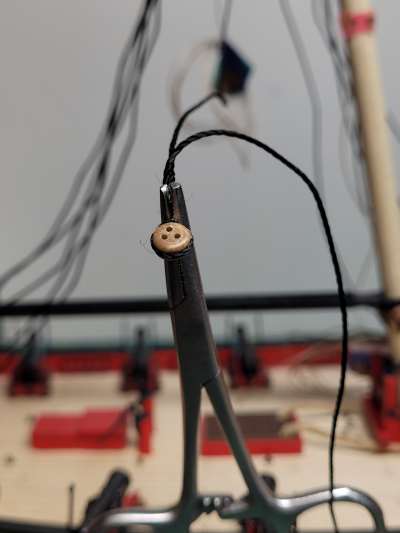

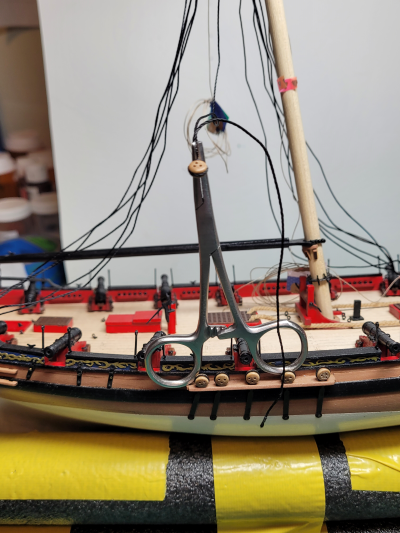

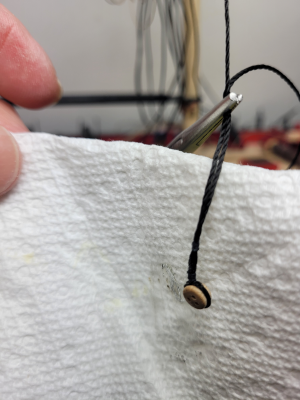

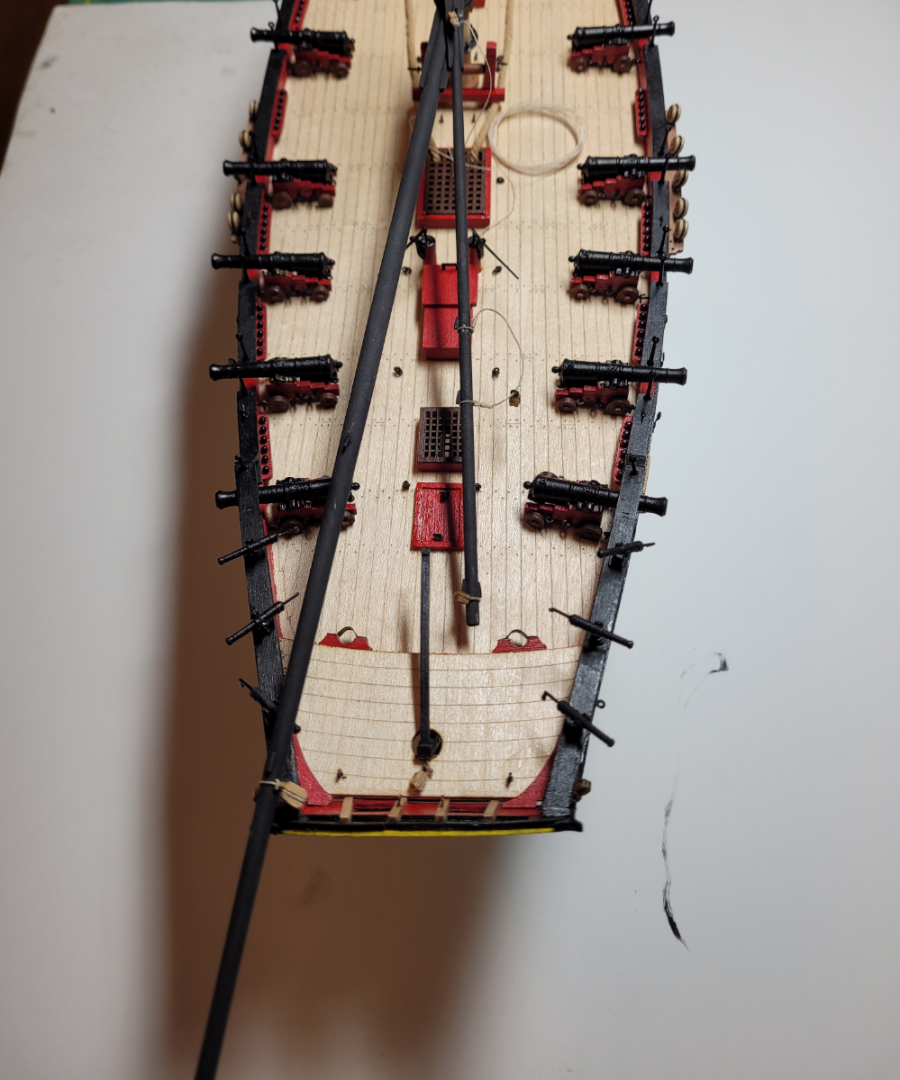

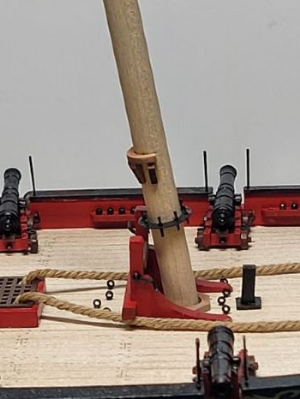

The first item of rigging is complete with the driver boom install. I rigged the boom with the mast off the hull which turned out to be a good idea. During my first attempt at raising the boom I realized that the parrels would not slide above the lower mast cleats and the block for the main yard so I had to remove the block and retie the parrels. With the boom in position, I wound up running the line the wrong way through a couple of blocks and had to pull the line back and rerun through the blocks in the correct orientation. Redoing my work was much easier without the mast stepped. The sheets for the boom are hanging loose for now. I did change my mind and decided to step the mast prior to installing the yards. With the mast seated I am now working on rigging the main shroud deadeyes. The results of my first attempt were dreadful so I did some quick research on rigging deadeyes. That led me to a picture of a deadeye rigging jig in a post in the Masts, Rigging and Sails forum by hornet (https://modelshipworld.com/uploads/monthly_01_2017/post-1505-0-68284800-1483318896.jpg).. I had the materials on hand and made one of my own. Using the jig to place the upper deadeye in to position, grabbing the shroud line with hemostats just above the deadeye and resting the handle base of the hemostat on the chain plate was a much easier approach. The end result turned out much better than I had anticipated. With the deadeye connected to the shroud I connected the two together in 0.5mm rope. I'll clip the rope later. The building sequence in the manual seems to show the shroud cleats installed after all the shrouds are connected. I think it may be easier to install the cleats after I finish connecting each shroud and am wondering if there are any drawback to using this sequence.

-

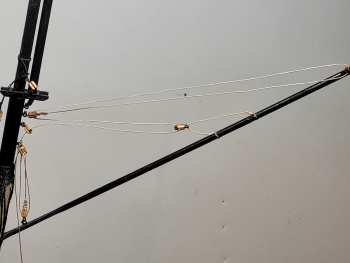

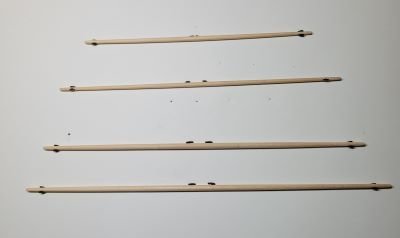

Completed painting the yard and attaching the blocks. I discovered that one of the shrouds shorter than I wanted and I suspect it will make it more challenging to connect the line properly to the deadeyes. Replacing the shroud now seems like my best way forward, and once that step is complete I will start affixing the yards to the mast.

-

Continuing to make progress with both the main and driver booms complete. Finished shaping the yards and installing the fittings prior to painting. And began installing the shrouds. After having to rebuild the stern, I am concerned about breaking something as I make progress on the rigging. I have decided to build as much of the main mast as possible with the mast separate from the hull as that approach affords more flexibility to get a better orientation for building while I am still working on developing my skills. My intent is to get the shrouds tied to the mast and the yards installed before I step the mast and finish the rigging.

-

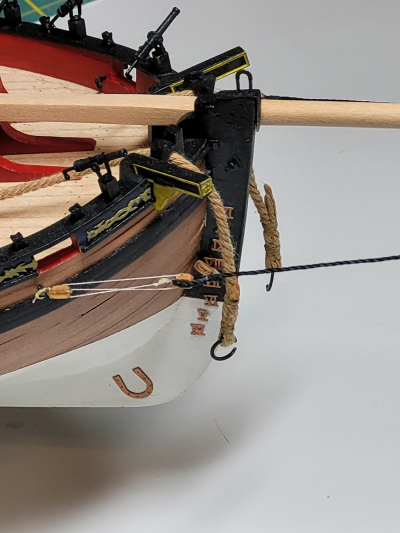

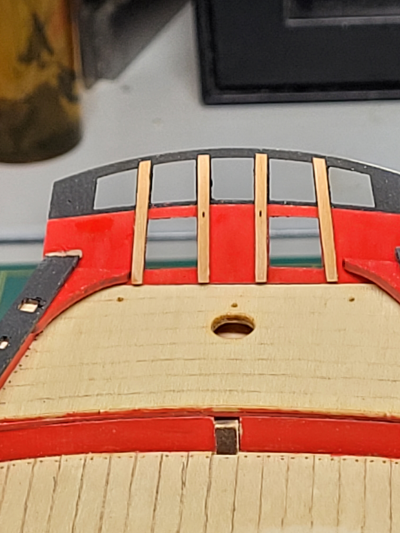

My grandson got to my build last August and broke off the transom, both port and starboard upper rough tree rails, and the transom knees which was quite disheartening to say the least. I had to walk away for what turned out to be an extended break before I got back to the shipyard to rebuild the damaged pieces. I started on rebuilding in late November and am overall pleased with the effort. Here are the photos of the rebuild. Fortunately, the swivels were not installed. I'm glad to say that I am reenergized and excited to be working on shaping the mast pieces, bow sprit, and the main and driver booms (and thinking about the next build).

-

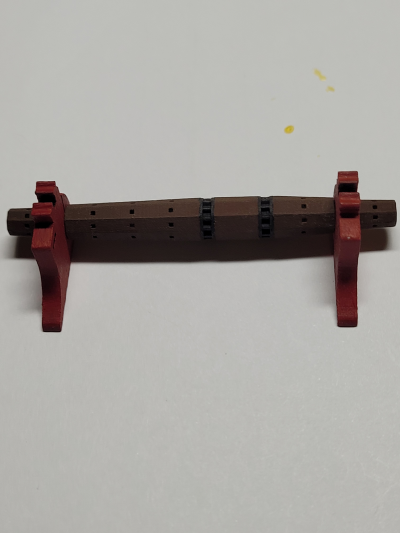

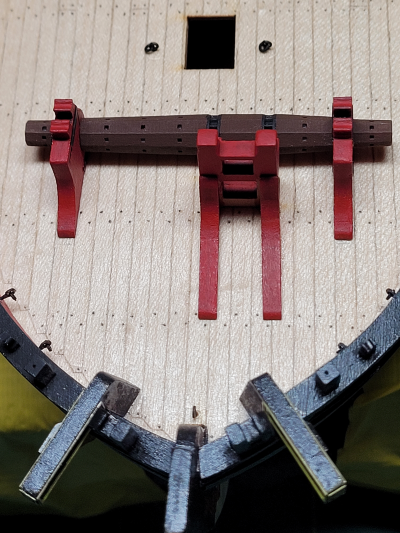

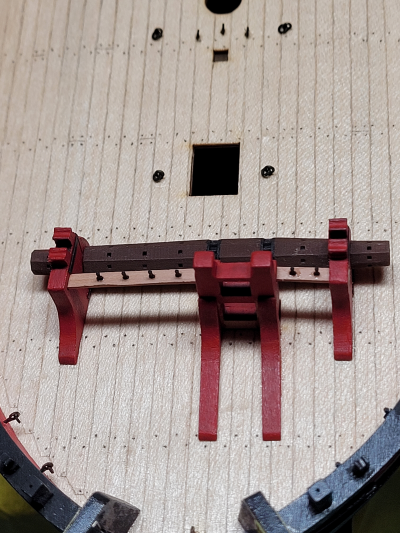

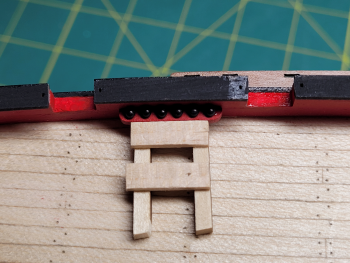

With the rudder installed the outer hull is essentially complete and marks a significant milestone for this build. I was worried about getting a good alignment when installing the assembly but I'm pleased with the final look. Getting started on the deck fixtures starting with the winch assemble. Final installation including the pin rails and pins.

-

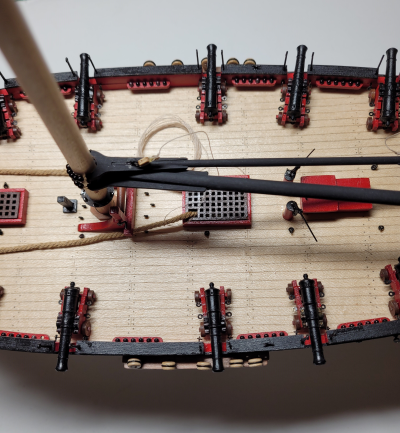

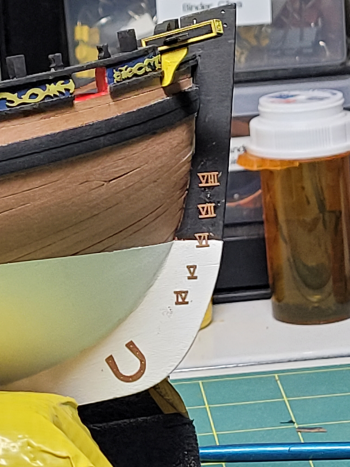

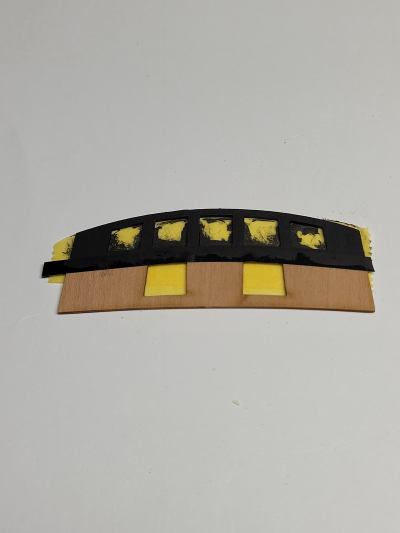

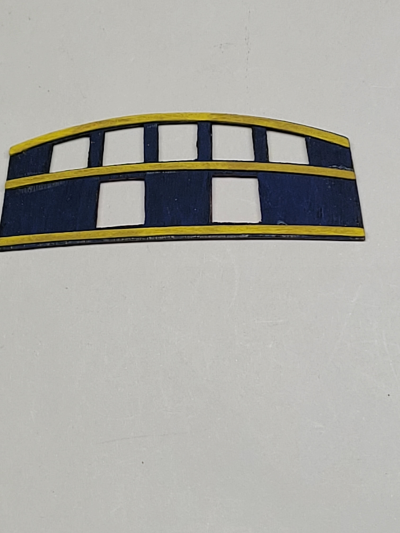

A couple of productive days in the shipyard where I finished the frieze work and the rest of the outer hull. My first attempt at placing the draft markings had them spread too far apart as shown in the first picture, so I removed them and reinstalled. You can see the results in the finished hull picture. With the outer hull complete except for the rudder, I moved on to the shot garland and cannon. To get the shot garland at a consistent 3mm height above the deck I made a small jig which also made it easier to adjust the lateral position and press the pieces into place for the glue to set. I decided it would be easier to glue the cannon balls to the shot garland before placement and that sequence worked out well. Then I assembled and placed some of the cannon on the port side to see what how it all looked together. I am pretty excited and overall pleased with how Alert is coming together. My challenge now is that I and want to spend more time on the build then on other items around the house that require my attention.

-

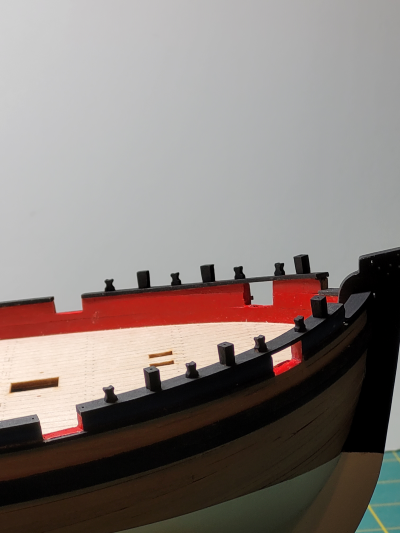

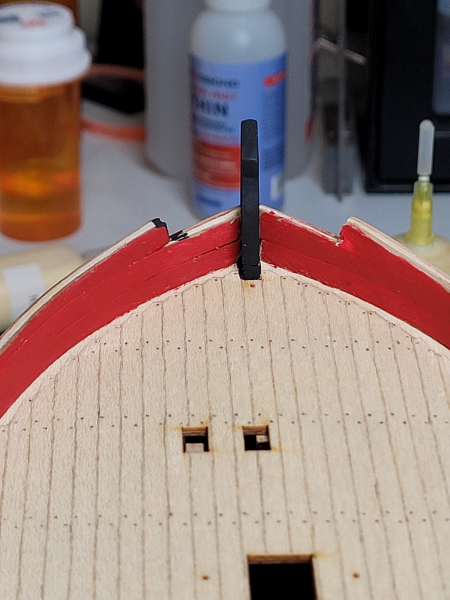

With the top cap and tree railings installed it is beginning to look like a ship. It took a bit of patience to get the swivel post and timberheads shaped to fit into their respective slots, but overall I'm pleased with the result. Trying to shape the PE for the mizzen step block assemblies was quite frustrating. Annealing the PE helped, but I still managed to break off one of the tabs at the score line when working to insert the pins. Fortunately, I was able to get the parts installed with the help of a little Cyano. You can see the difference in the top view of the starboard assembly if you look closely. Although I don't think the flaw will be noticeable with some touch up black paint on the PE and pin heads I would have preferred to replace the part. Clearly I need to go slower and improve my technique when shaping PE, but with the parts so delicate it seems that breaking a piece is always somewhat likely (and there is a lot of shaping for the cannon straps coming up). Is their a tool I should consider getting to be able to cut replacement PE parts like this from the PE sheet scrap??

-

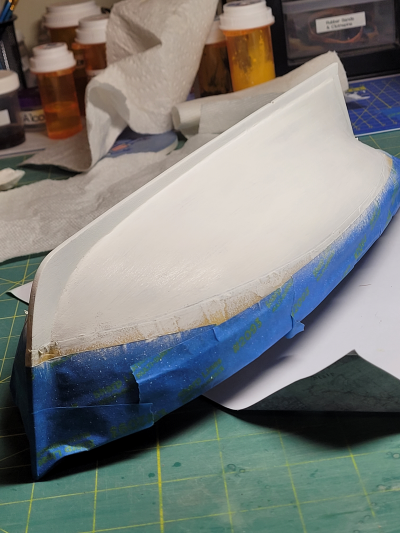

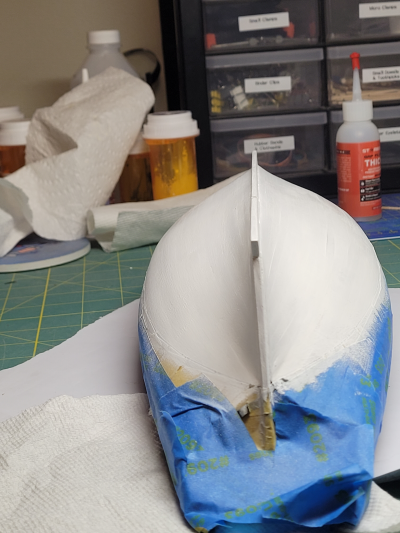

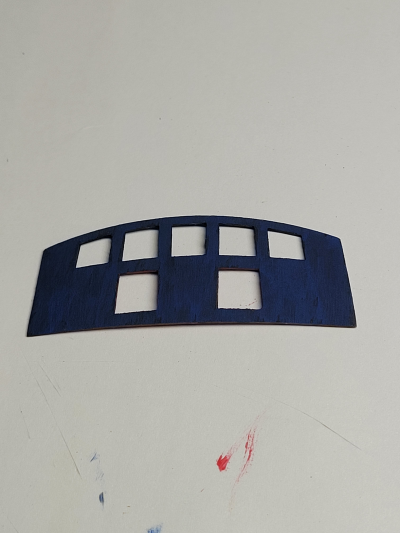

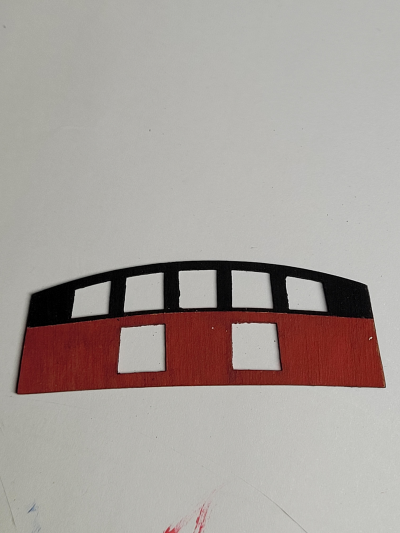

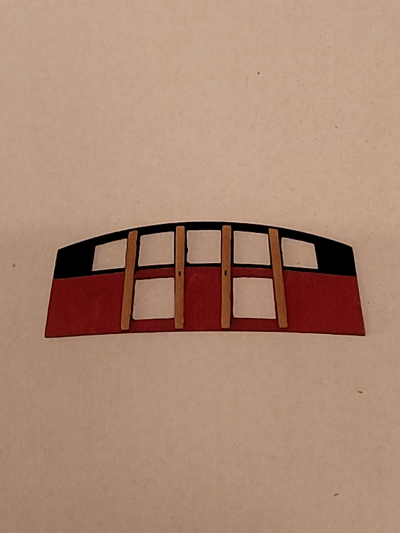

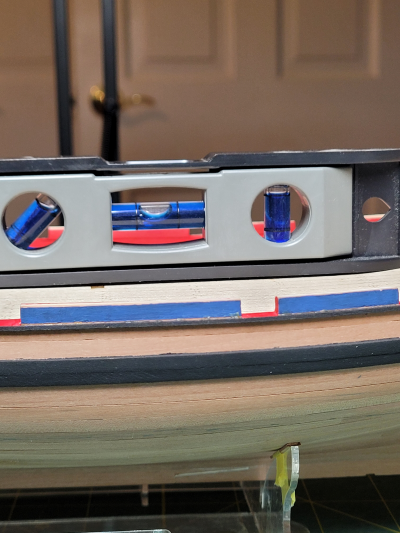

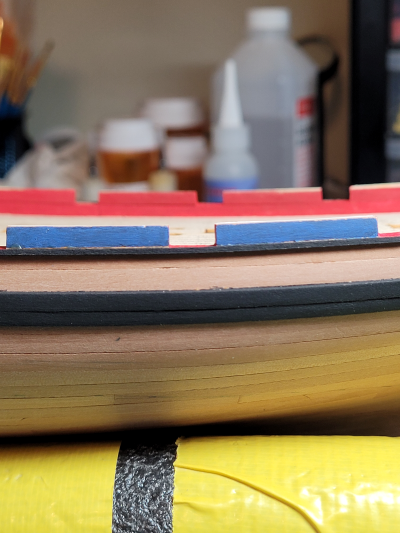

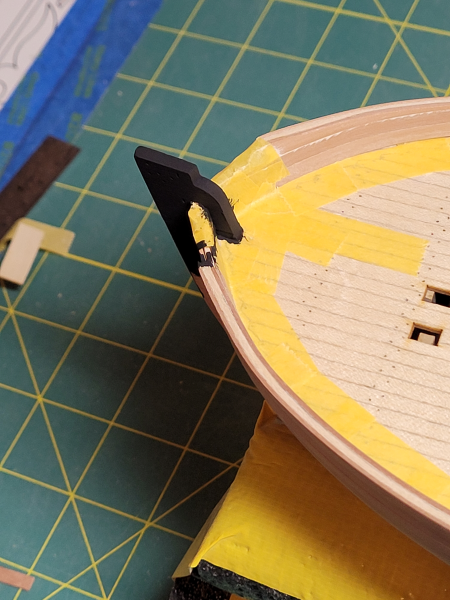

After getting the comments from Glenn and Thukydides (thanks again), I was able to layout the waterline and get the bottom painted. I'm glad I took my time and asked for some guidance as the result looks pretty good (at least in my opinion). With the waterline complete, I moved on to the transom. I used thin detailing tape to get a clean line between the black top and red bottom. And managed to get the transom assembly installed without breaking anything. On to the the top cap and railings.

-

Thanks Glenn. Adding some additional reference points should help to better visualize how the line should look. Thanks Thukydides. The apparent difference in the picture stems from the right hand side being painted and the other side unpainted. I appreciate you sending the link to your log post and the data point on the stern dragging a bit on cutters.

-

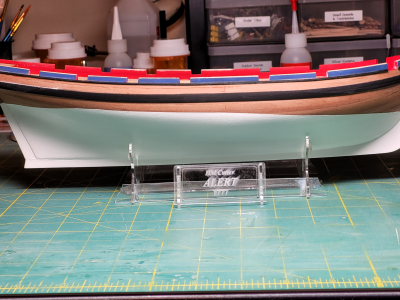

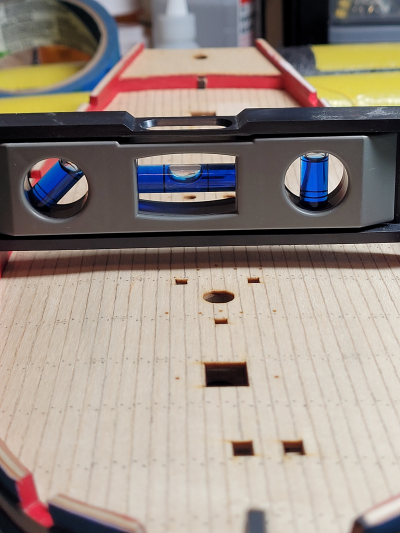

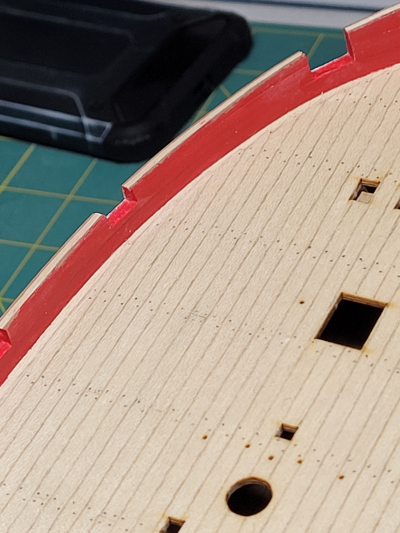

The build is coming along nicely with the progress made the past few days. I was able to install and pain the main wale. Painting between the gun ports is also complete with the strake at the bottom edge of the gunports painted and installed. I decided to wait to install the cap rail until after the waterline is drawn and the bottom painted to avoid the chance of breaking anything. The waterline is proving to be more of a challenge then I expected. I'm using an Amati waterline marker but the result looked really off with the hull placed in the proper location on the acrylic stand. I checked the table and it was level in both direction but the hull was way off level fore and aft. You can see how far back the notch is in the second photo to get to level. The waterline look better after leveling the hull but I am still not convinced it is correct. Clearly there is some proficiency involved with using the marker which I have yet to achieve. I have two questions I'm hoping someone can answer. First, should the hull be level fore and aft or placed correctly in the stand before scribing the waterline? Second, How far below the main wale should the waterline fall at its highest point amidships?

-

Applying the paint to the inner bulwarks provided a great feeling of progress. Getting the gun ports cutout and painted was even better. I did run into 2 issues where the planking layer section between gun ports came off - not sufficiently edge glued during planking. Fortunately nothing broke and I was able to fix the issues with a quick bead of cyano. Any errors is placement are going to show up when I install the top cap and I have my fingers crossed that won't be an issue.

-

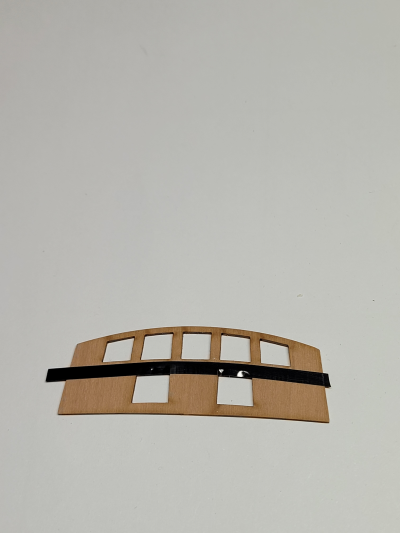

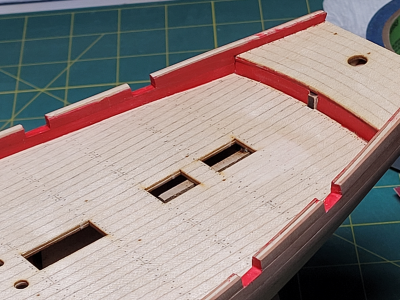

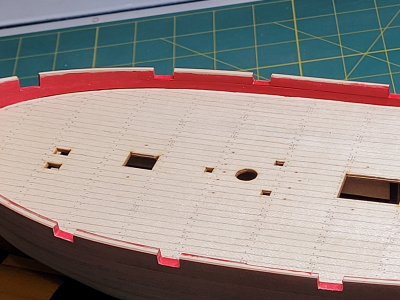

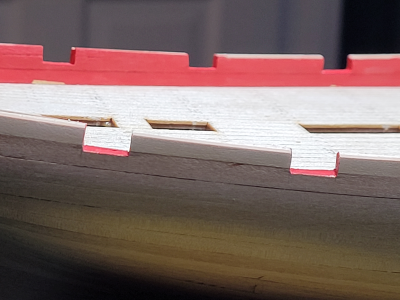

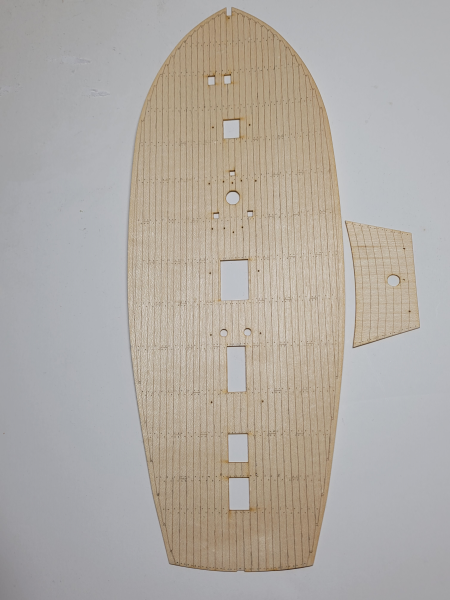

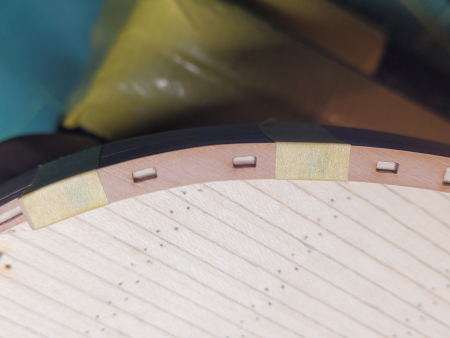

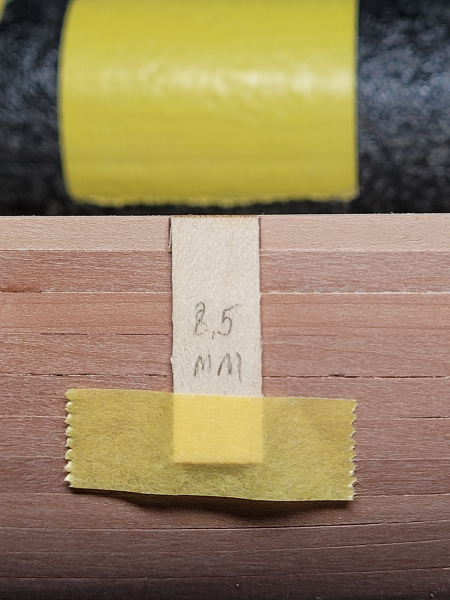

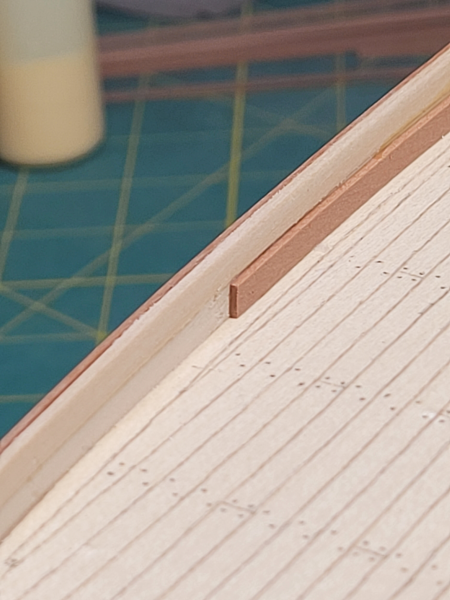

A good day in the shipyard with the decks installed and the seams and nails marks darkened with pencil. The instructions say to line the inner bulwarks before installing the deck, but those were written with the decks being planked and not the full deck cutout. Installing the lining first would have meant taking 1 mm from each edge so I installed the decks first and then added the lining. I think an added benefit is this arrangement hold the deck edges flat and guard against curling up over time. With the decks installed and inner bulwark lined, it was time to move on to marking out the gunport locations with the cap rail taped in place. To make it easier to get the ports straight I took one of the scrapes from the deck openings and made an 8.5 mm template which worked well. I just made an error marking the 4 mm and 6 mm gunport depths which tells me that its time to shut down the build for the day and cutting the gunport openings will need to wait until later. Overall, I am pleased with the progress made this weekend.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.