HumphreyG

Members-

Posts

10 -

Joined

-

Last visited

-

mtaylor reacted to a post in a topic:

What Wax To Use On Rigging Line

mtaylor reacted to a post in a topic:

What Wax To Use On Rigging Line

-

Technically yes. It is mostly a combination of microcrystalline wax and mineral spirits. Both of which are derived from petroleum. However, that description can be misleading and you need to be careful in what you infer from calling it a petroleum product. The mineral spirits quickly evaporate, and the wax is heavily refined so that it is actually very inert. It is unlikely to react and is well established in its use in museums which are very careful in the care and preservation of artifacts.

-

mtaylor reacted to a post in a topic:

Drawing center lines

mtaylor reacted to a post in a topic:

Drawing center lines

-

Canute reacted to a post in a topic:

Drawing center lines

Canute reacted to a post in a topic:

Drawing center lines

-

Canute reacted to a post in a topic:

Making lifeboat small mast for 1:200 Yamato

Canute reacted to a post in a topic:

Making lifeboat small mast for 1:200 Yamato

-

Stuntflyer reacted to a post in a topic:

Drawing center lines

Stuntflyer reacted to a post in a topic:

Drawing center lines

-

Drawing center lines

HumphreyG replied to Stuntflyer's topic in Modeling tools and Workshop Equipment

There are center funding rulers. They are fairly inexpensive (around $10-15). Basically the rules just extend out in opposite directions from the center. You just check both sides read the same. Saves you from doing the math in you head. That would help you quickly find the center and then set the marking gauge off that. -

mtaylor reacted to a post in a topic:

Making lifeboat small mast for 1:200 Yamato

mtaylor reacted to a post in a topic:

Making lifeboat small mast for 1:200 Yamato

-

Olaf reacted to a post in a topic:

Making lifeboat small mast for 1:200 Yamato

Olaf reacted to a post in a topic:

Making lifeboat small mast for 1:200 Yamato

-

Making lifeboat small mast for 1:200 Yamato

HumphreyG replied to Olaf's topic in Metal Work, Soldering and Metal Fittings

Another option would be phosphor bronze wire. It's a bit stiffer than brass, which can helpful at his diameter, and it still solders great. You can buy it straightened. (There are probably other sources, but this is the one I am personally most familiar with.) https://www.tichytraingroup.com/Shop/tabid/91/c/n_wire/Default.aspx However I opted to buy it on a spool and straighten it. You get a fairly inexpensive wire straighting tool that does a decent job straighting the wire. The pulling method mentioned above should also work, but does change the diameter a little and makes the wire stiffer (which can be good or bad). -

HumphreyG started following Hull modeling with Blender , SS Blagoev (ex Songa )1921 by Valery V - scale 1:100 - Soviet Union , Sylvan Scale Models N Scale anchor windlass and 6 others

-

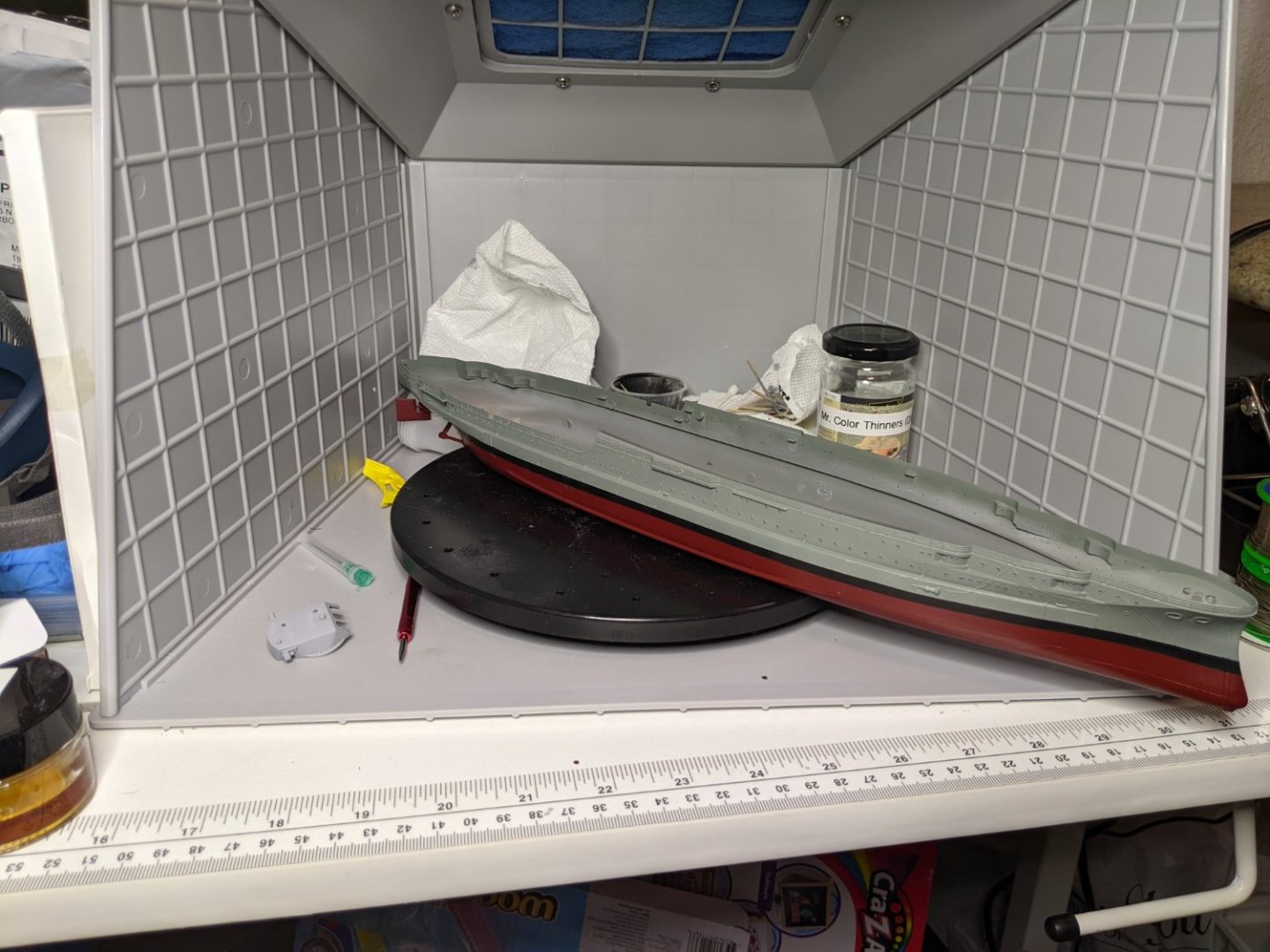

I am curious to see your progress on this model. I have another of Sylvan's models (a 1:160 tramp or EFC design 1020 freighter). I have not started on mine yet. I was noticing the vertical lines in the resin hull. My model has the same vertical lines. I am still trying to decide if I should sand the hull flat (removing the plate details). Do you have any plans to remove those lines? Im not confident in getting putty to effectively conceal them.

-

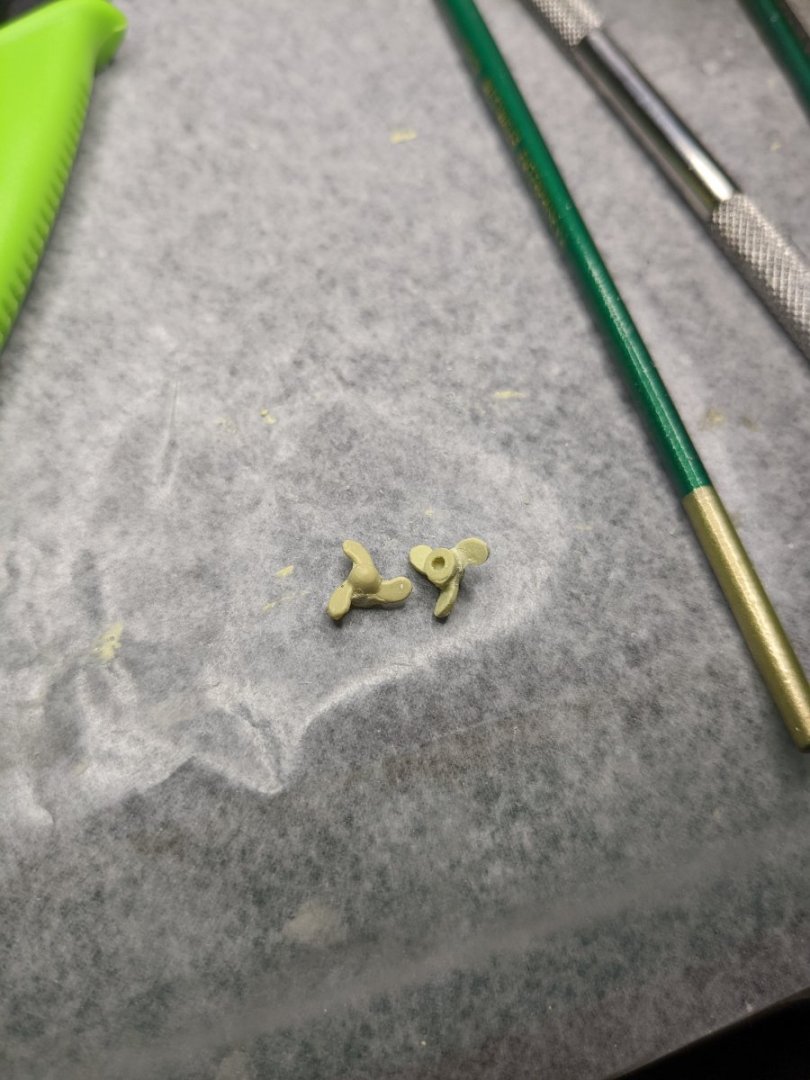

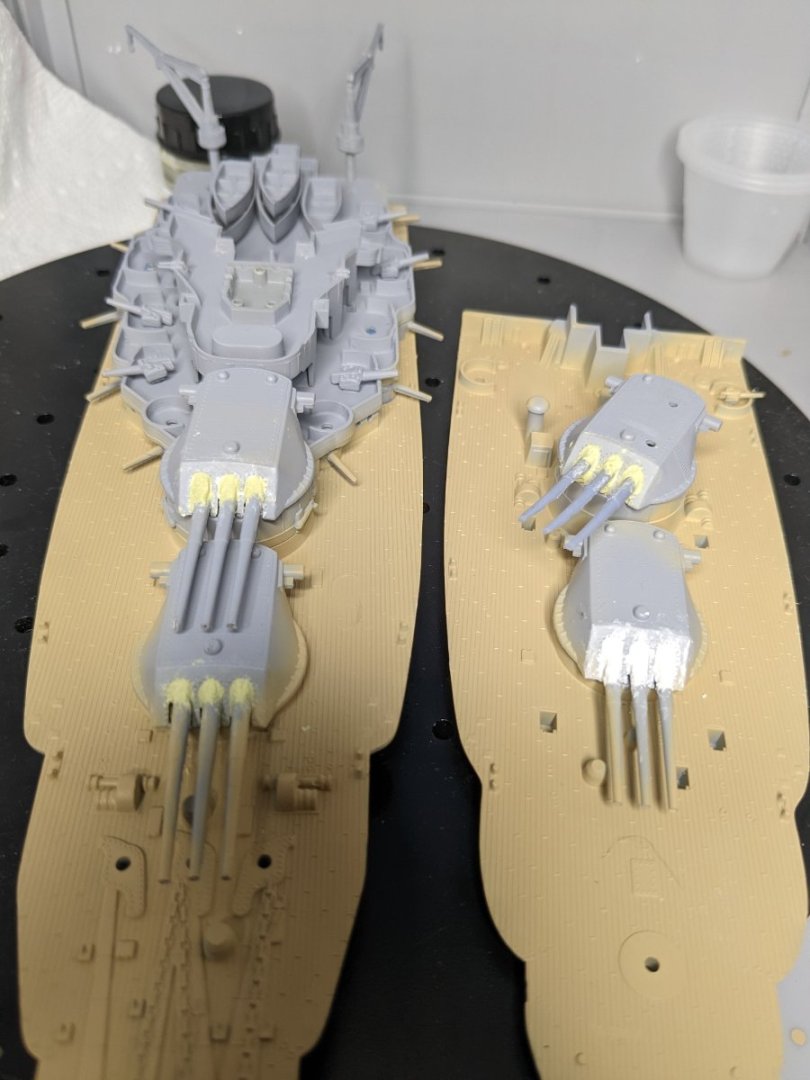

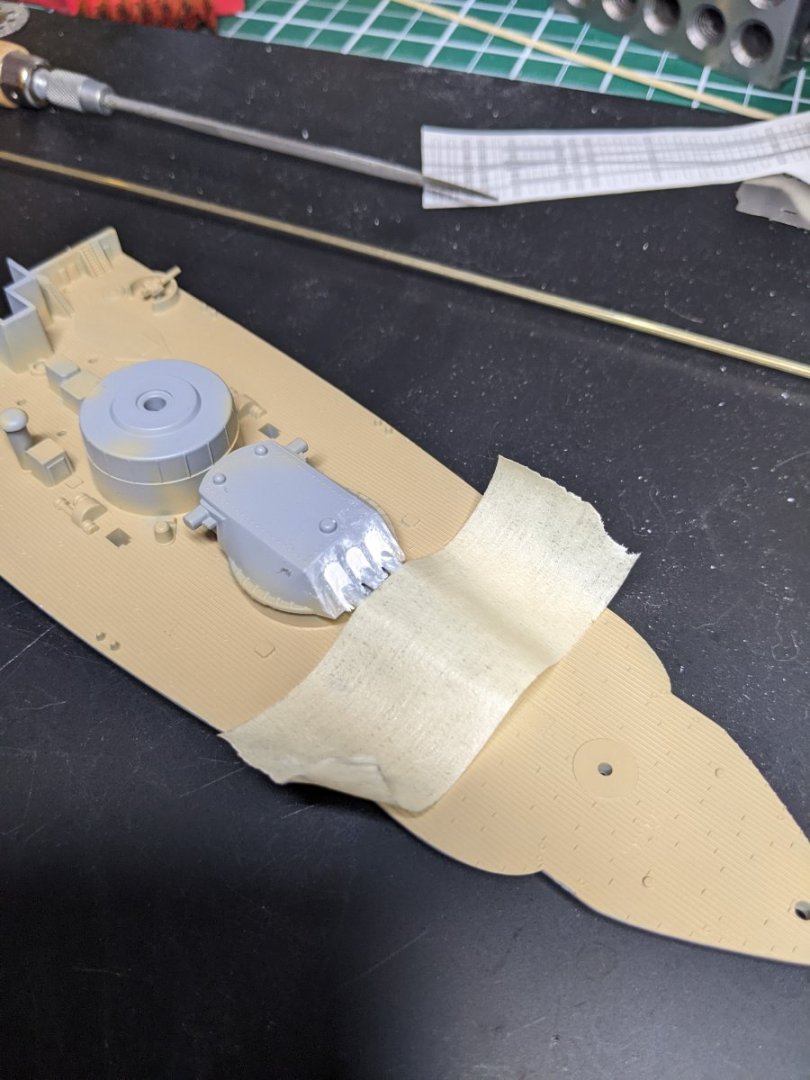

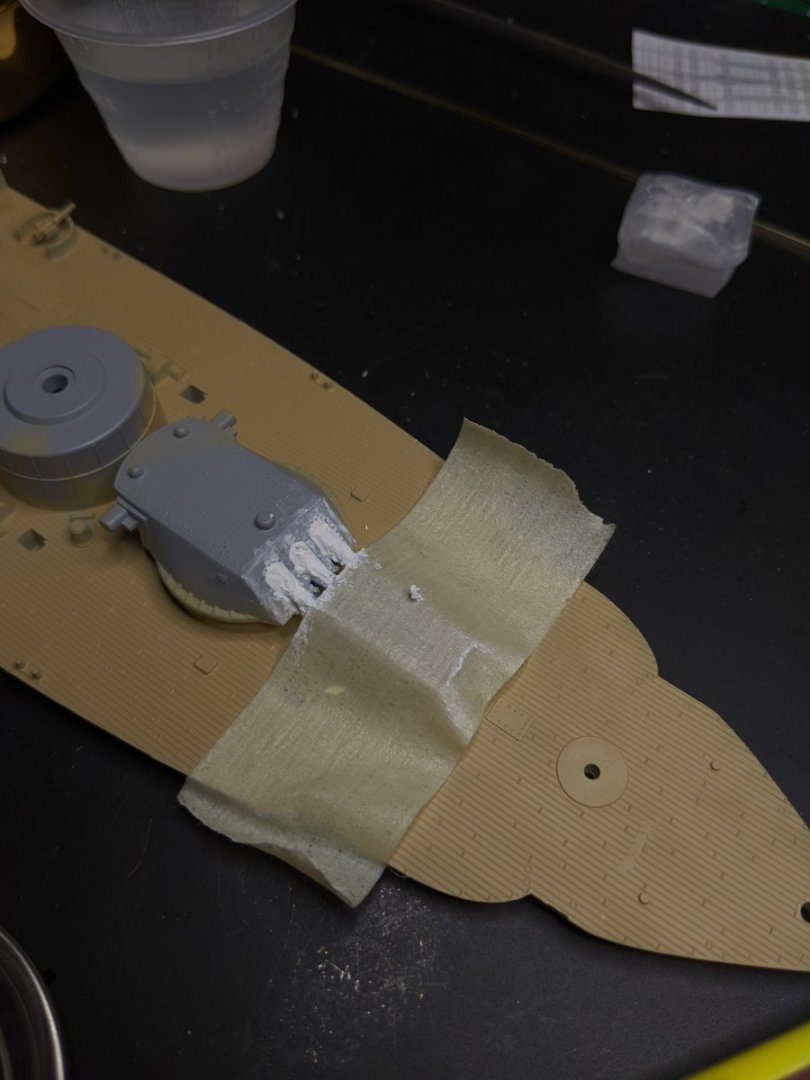

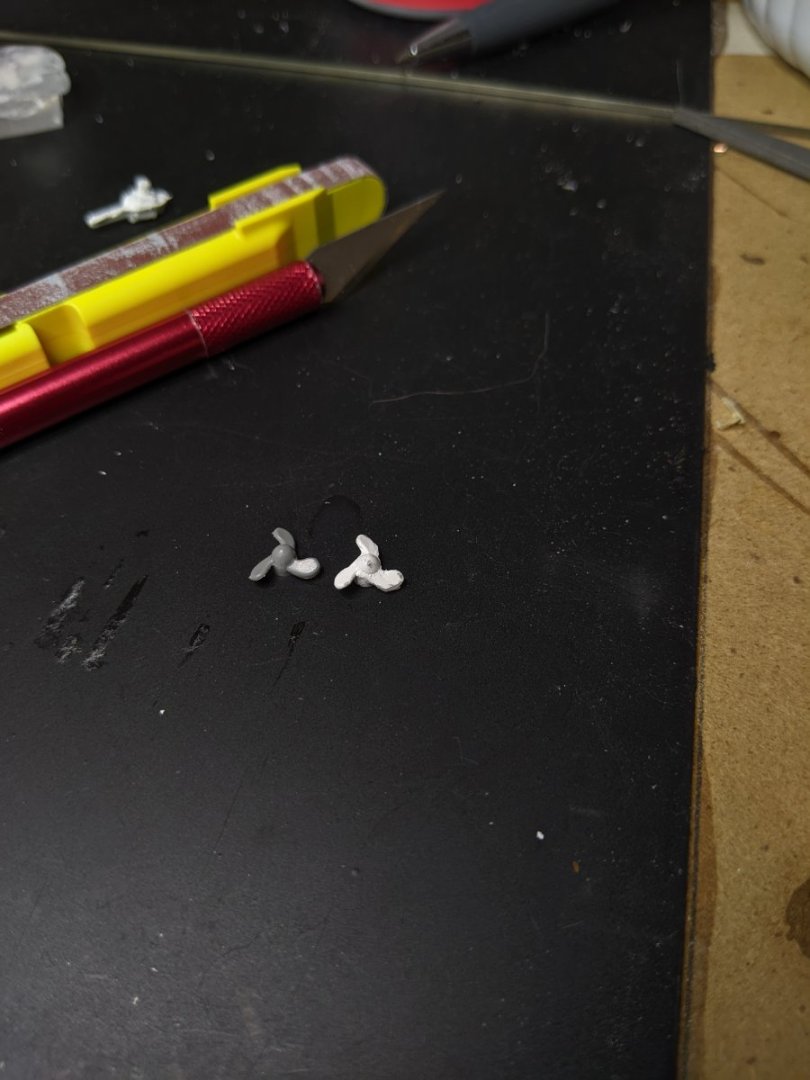

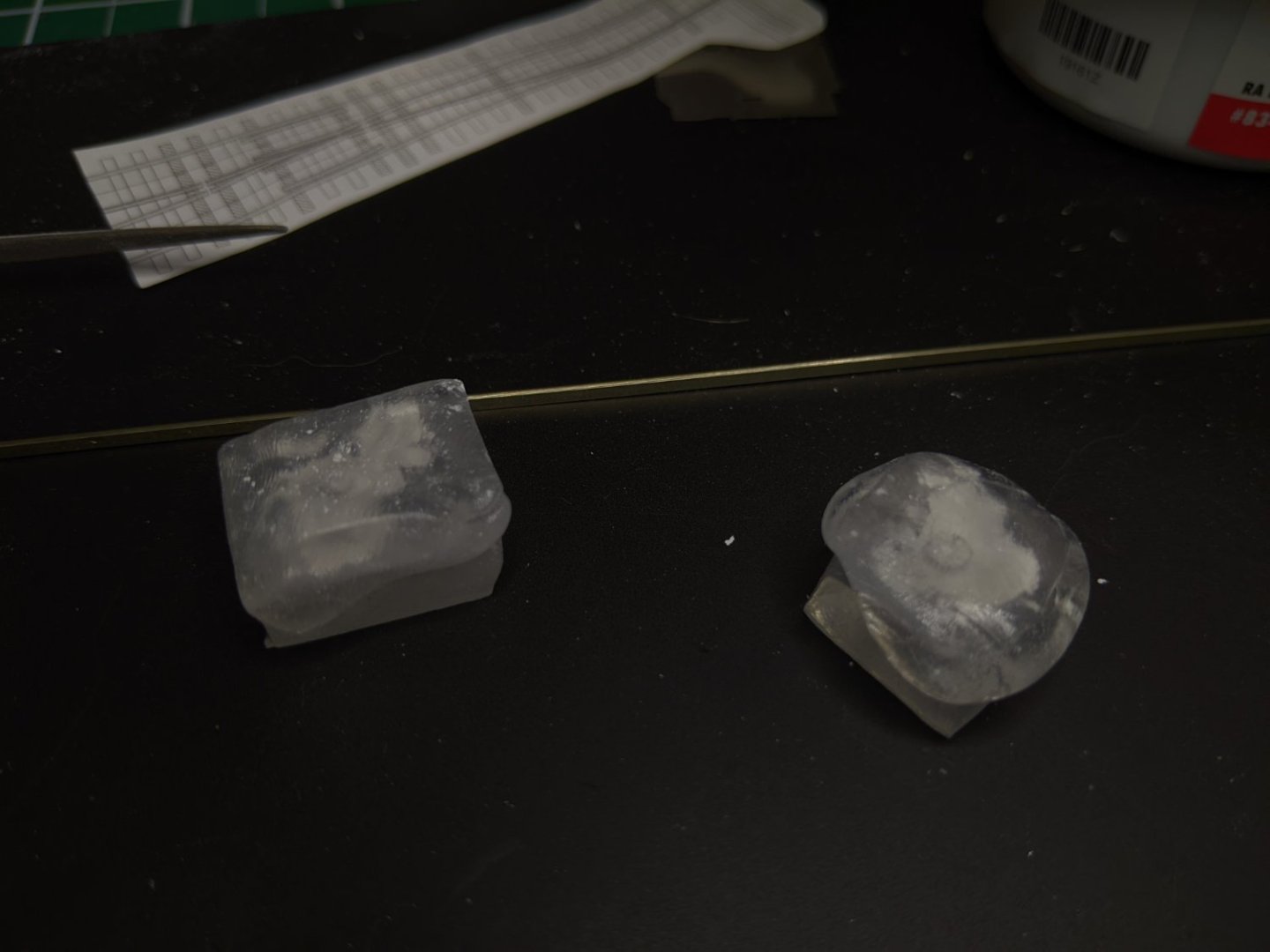

I found the white milliput to be very crumbly, even when dry. I tried the standard and that seems to be much more durable. I had to remake the 2 propellers. With a but more experimentation, I found a makeup applicator worked well for forming the blast bags. I have a bunch for applying flux for solder. They were nice and small, daily stuff and held a little water. The capstan with the kit were very poorly molded, so I decided to make a new one. I use my freedom to turn down a styrene rod. I used a hacksaw and files for tools.

-

My progress is quite slow. The next kit I am planning is a resin kit, so I'm not sure it will be much cleaner then this one. This week I put a base coat on the decks. I also started using milliput to fill in the blast bags. For my first time working with milliput I think it turned out alright. I have lost a few pieces of the kit, so I decided to use it as an opportunity to practice casting some parts. I used oymaru to make the molds. It will soften in hot water. I then put the milliput into the molds. There is a lot of flash, but with a little cleaning the parts seem to turn out ok.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.