Patrick B

Members-

Posts

74 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Patrick B

-

Thanks for the info allanyed, good think I stuck ( without making a bad word play ), with CA glue. My only concern is that I have sometimes a little bit of glue that comes out on the sides of a plank. I try to sand it until it disapeares, but I hope it won't show when I will apply the Tung oil. Anyway, here is the progress of the hull. Please inform me if you see any CA leakage.

-

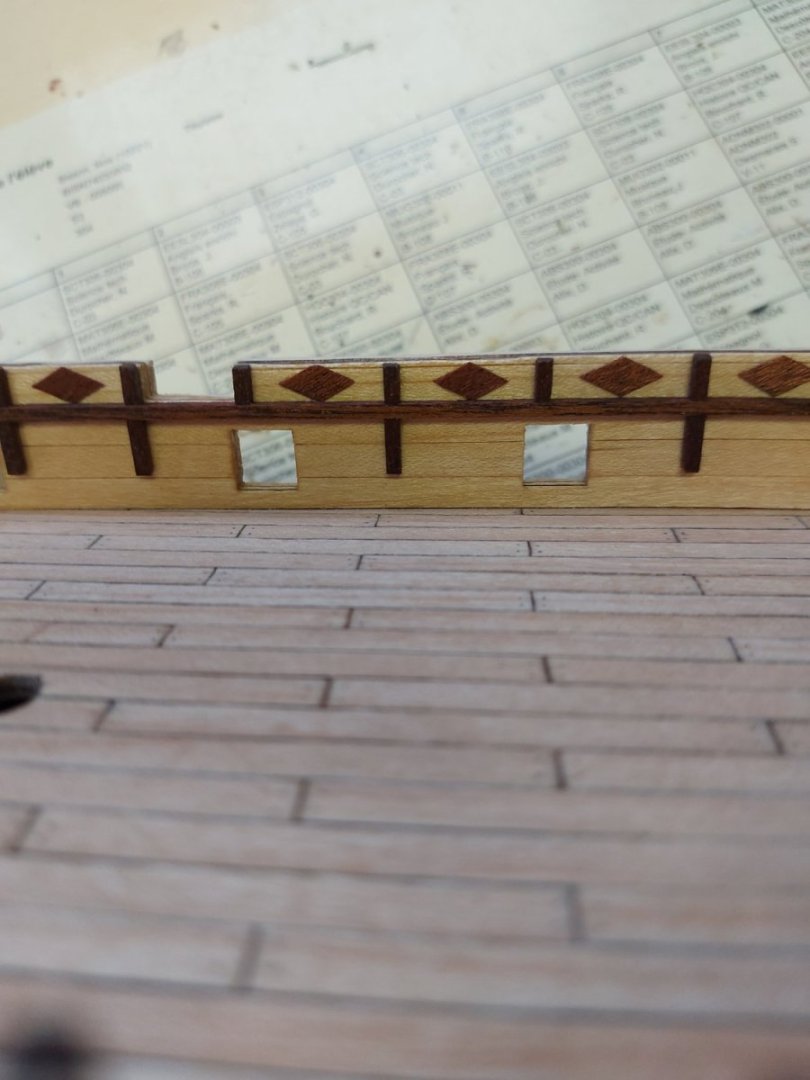

Planking update : The first side is finished planking. I am very happy with the result, as no wood filler was needed whatsoever, and little to no sanding was done too. Due to the carefull attention in the planking process, no "steps" where created. I leaved the nails in, contrarly to the popular behavior, as this didn't affect the sanding process at all. This choice was made because of the fact that I posses a nail pusher. Without it, I would have certainly took the nails off. I leaved the nails in, contrarly to the popular behavior, as this didn't affect the sanding process at all. This choice was made because of the fact that I posses a nail pusher. Without it, I would have certainly took the nails off.

-

You are right. But I still like the appearance of the 1-3-1 thwart pattern. This being my first ship, I incourage you to inform me about these interesting tricks the old sailors know. Keep in mind that I might change some other things afterwards if not too much added work is needed. I am very interested in those small tweaks that coulds make it more realistic.

-

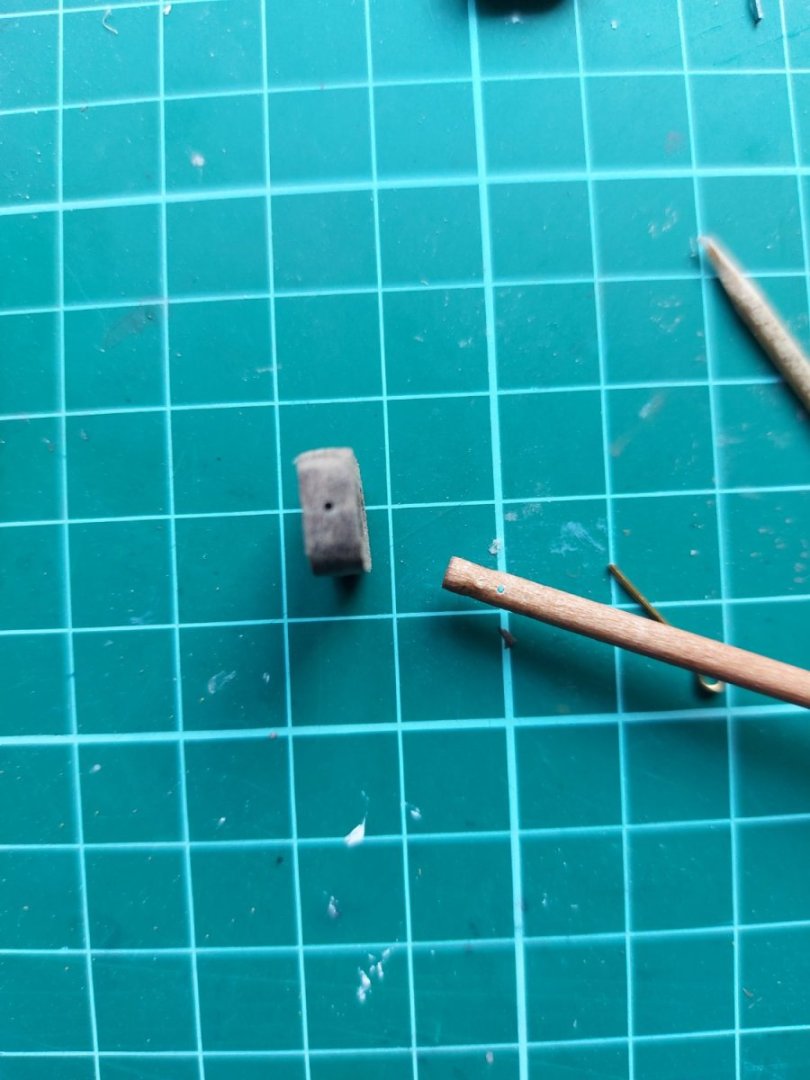

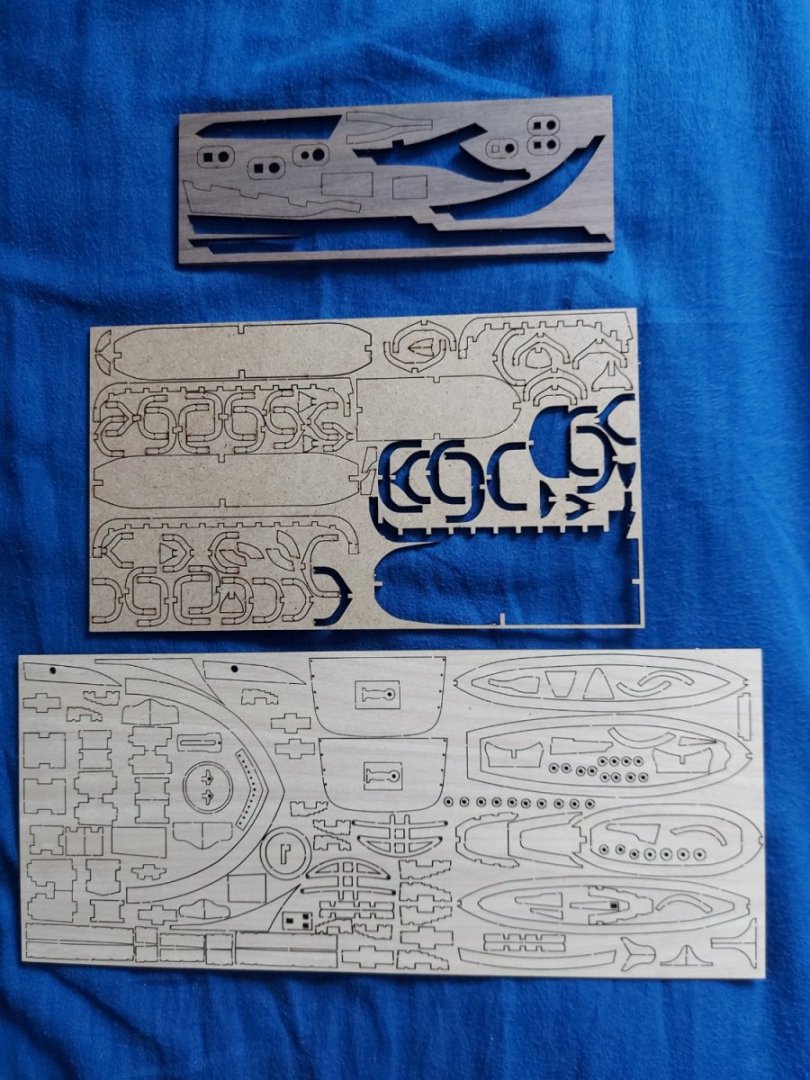

I have bought the Beagle in the last 3 month, and a couple of things have changed. -The stained plywood was changed to solid africain walnut -The other mixed sheet was changed to solid wood (unknown) -The launche's sheet was changed to mdf -The blocks have changed again to (box?) wood -The little cylinders made from brass where changed to (box?) wood also. -The stained plywood stand was changed to unstained plywood. See photos

-

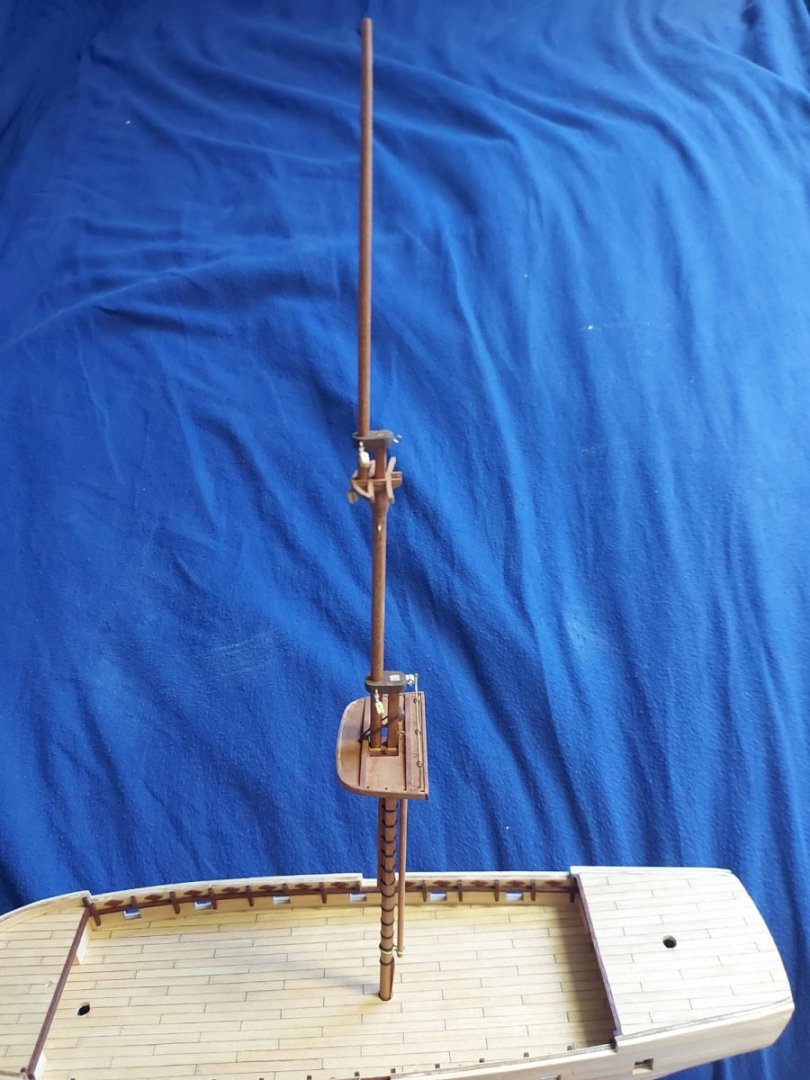

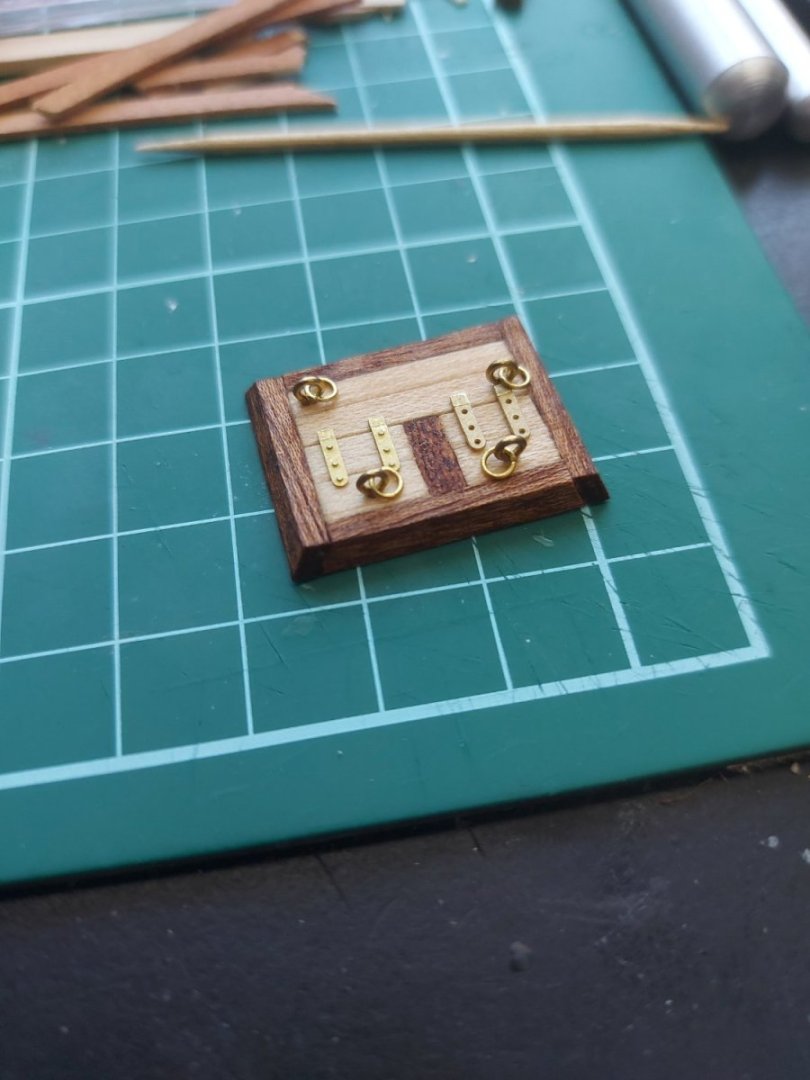

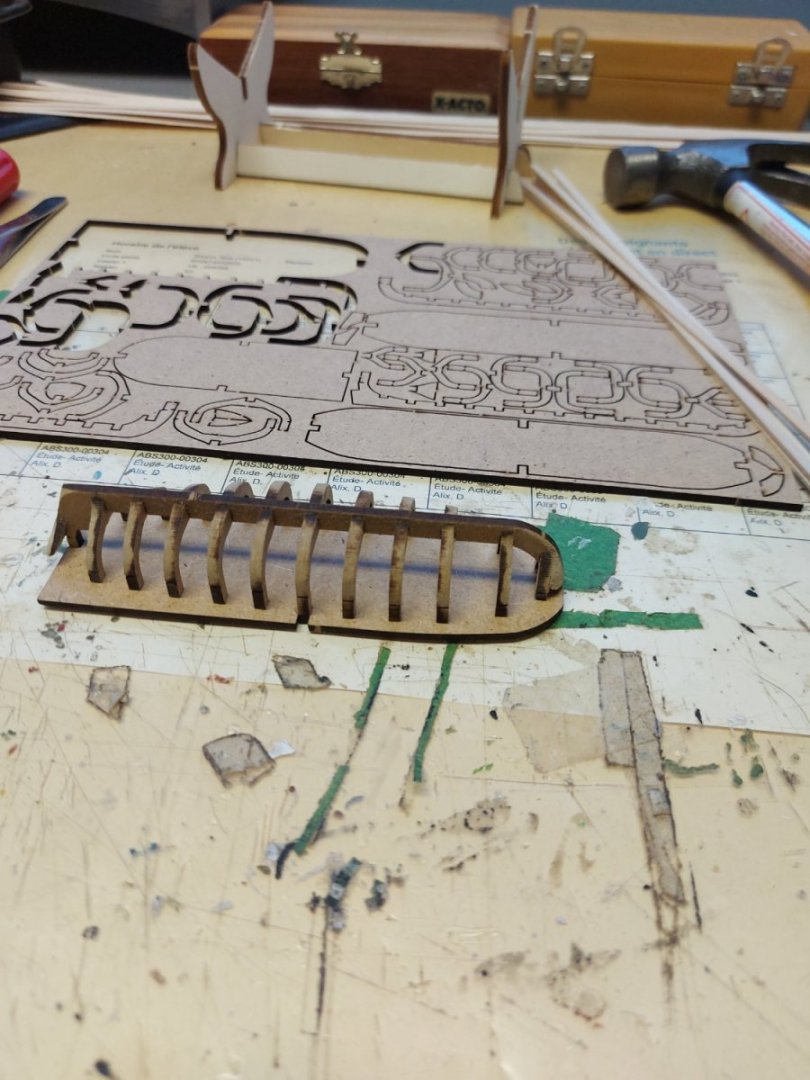

All right, I made a mistake. Not a modelling mistake tought. I went to one of my relatives, and brought the hull to show them the processus of ship building and how far I was. The thing is, I forgot it there. The good news is, I will go to this person's house again in about 2-3 weeks and I will be able to bring it back to the shipyard. In the meantime, I will be doing the several launches. Here is where I'm at for the (23 foot?) one. I don't think I will be painting it white if I do a good enought job on the hull.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.