-

Posts

806 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Greg Davis

-

You may have some success using a vice - after filing / sanding / cutting the first flat, put that side to one of the vice jaws and make a second flat using the top of the jaws as a guide, rotate 90 degrees and repeat, ... You may find Amazon and / or a local hobby store - even Hobby Lobby a quicker location for picking up wire and wood to finish your build. Regardless, your HMS Beagle is looking really nice! Happy New Year Greg

-

Unfortunately she has been placed on the shelf for a while - right where I see her every time I use my computer! I should get back because I really want to rig that model; however, I've gotten myself involved with a few other projects that are currently taking precedence, including a solid hull model of a pilot ship Gracie S. over on SoS, as well as a large commissioned model. So its going to be a while before another big dose of time is spent on La Couronne. Thanks for checking in - and I have been periodically taking a look at your massive Sovereign of the Seas project - such an undertaking to do what you are doing! Greg

-

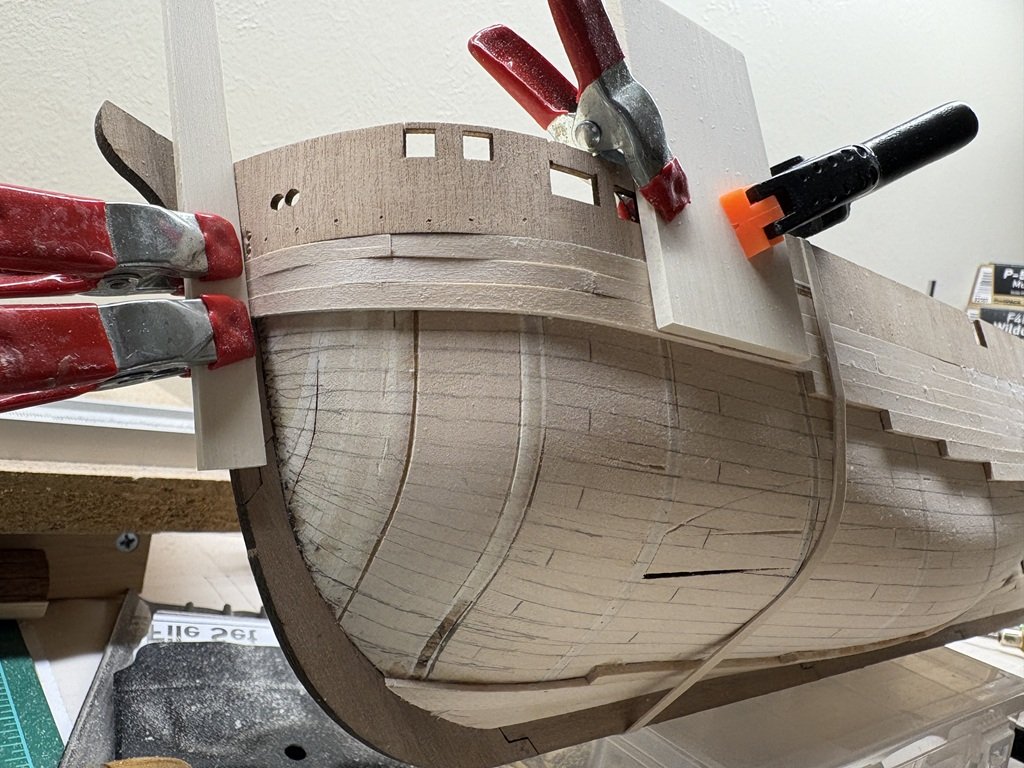

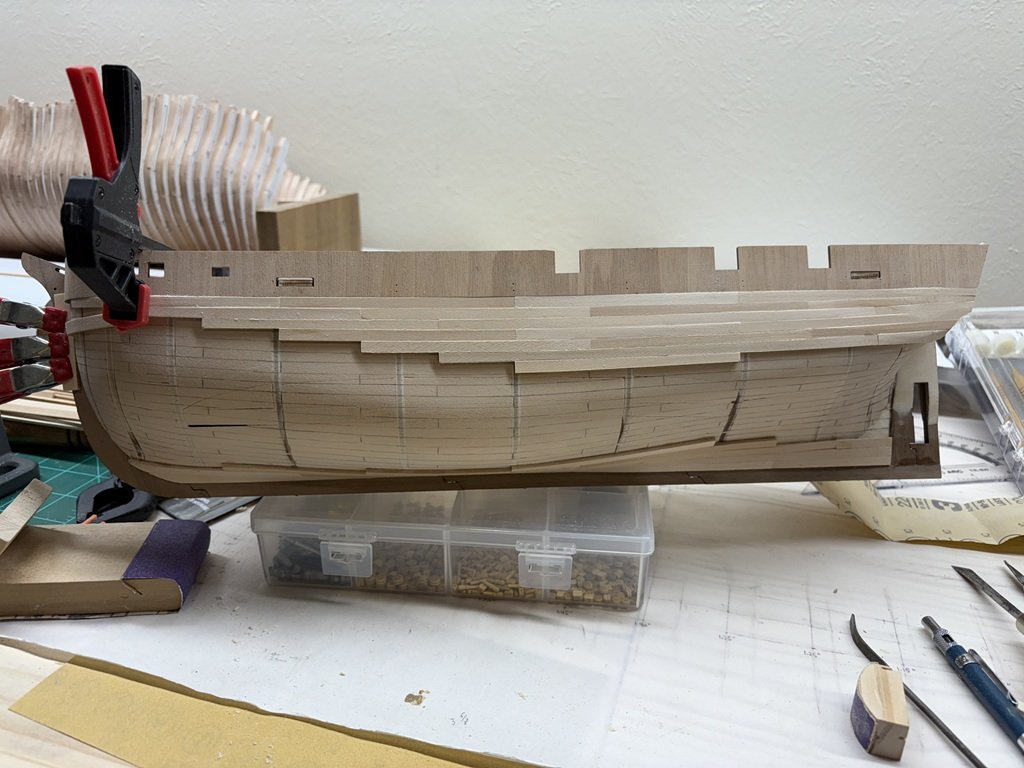

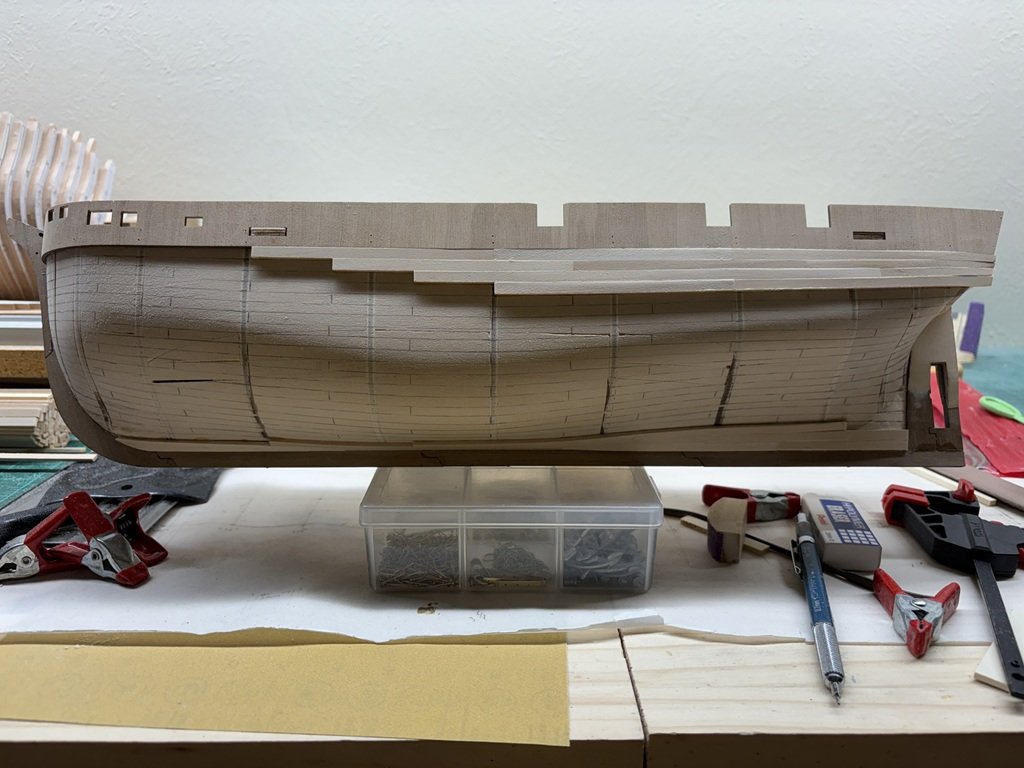

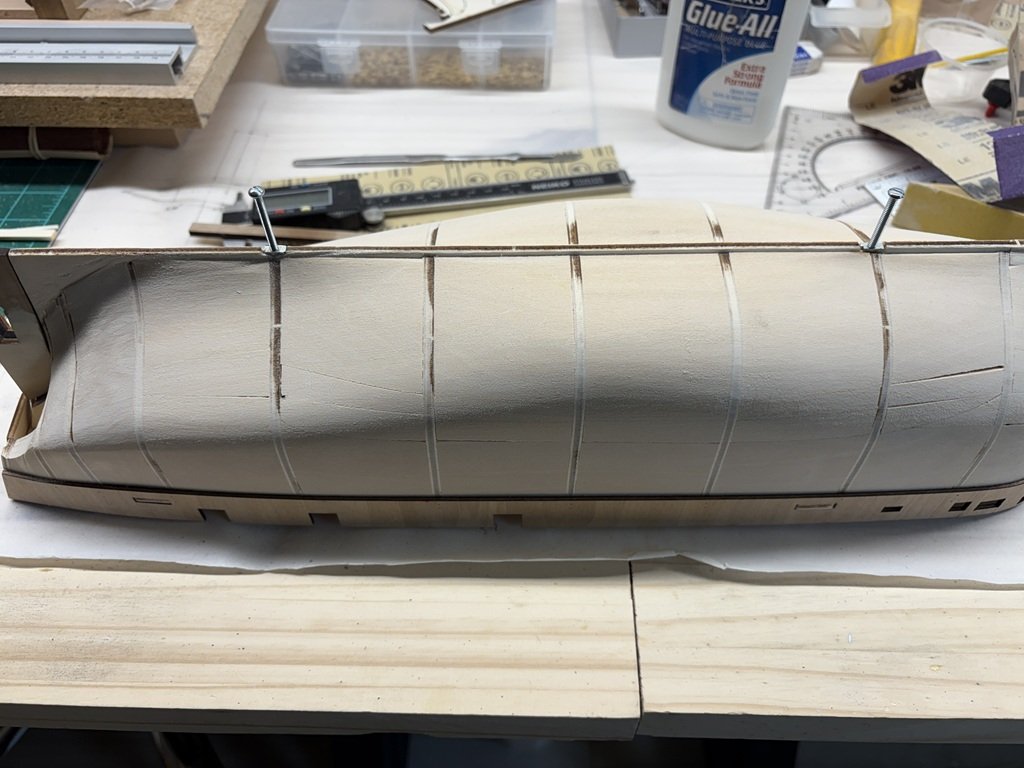

The port side planking is finally complete. It also got 15 min of smoothing before I decided it was too cold to sit outside any longer. But enough was done to get a look at what the hull is looking like now. Difficult (for me) to plank using the kit-supplied wood. A number of the planks would have been easier to fashion out of sheet wood / wider strips. There are a few 'gaps' that will need to be attended too, but all should be fine since the hull will be painted. Nevertheless, it has been a 'fun' experiment. Hopefully the starboard side will go quicker - or at least more easily! After the whole hull is planked, I'll do the rest of the sanding and get on to the ice channels. I don't foresee the need to do a second planking. Not sure when the next update will be as I think I'll be giving additional attention to a few other projects.

-

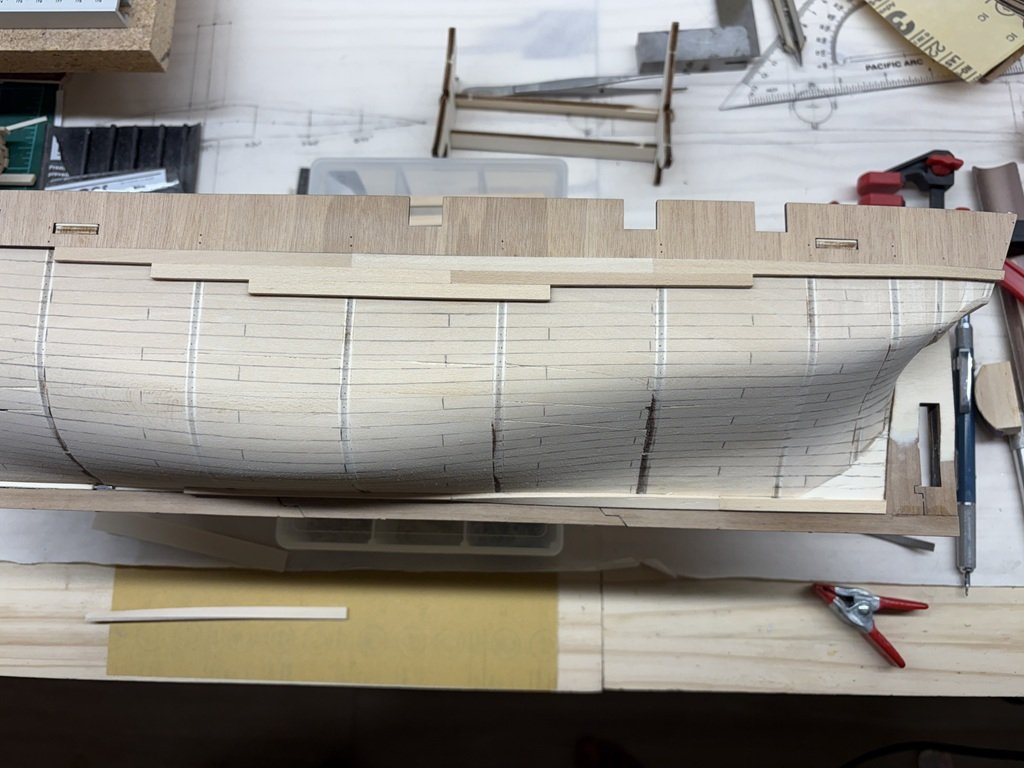

Progress - slow, but sure! One more plank and the top-to-down will meet bottom-to-top work. The plank sitting below the model has been bent in a jig to help facilitate the stern tuck planking. The jig is pretty simple; but, depending on the piece of wood, my take more than one wetting and overnight clamping iteration. The jig is very much like the one Chapelle uses to bend wales in his Ships of the American Revolution book. Here's the beginning of the tuck planking being installed:

-

A bit of progress - not as much as I had hoped for; however, I've spent a good deal of time over the past week creating a PowerPoint presentation on building model ships that will be delivered to an audience in the Learning in Retirement Program at the University of Wisconsin - Green Bay. Hopefully the talk will encourage a few to take up the hobby! Anyway, here is Terror as of this evening: Four planks are being pre-bent to take up positions near the stem and stern (top and bottom). Not too long before the top and bottom work come together! But still a lot of planks that need sharp bends. The Jameson is helping the process!

-

So far only 3 planks today ☹️. But they were hard ones that butt up against the stem. I needed to partially form each, then wet to bend, and do some more shaping before they could be attached. Once the now clamped plank dries I will be able to add quite a few planks with less difficulty going front to back and downward. Yesterday I got about 10 planks attached and cleaned up the back edge of the top 6 stakes. In the back, it is time to work on the tuck. There is quite a bit of bend in that area and I am debating the wisdom of creating a mold to bend the planks in that area.

-

Good to hear that the paint is of good quality. I agree, they are not great with instructions; either written nor with their photo collages. The builder really needs to continue to look at the pictures throughout the sheets of paper and determine a course of action. Certainly it is clear that some construction must come before others, but in some cases the builder must make adjustments and / or choices (best guesses) as they proceed. It doesn't seem that it should be that difficult for each and every model company to produce a solid set of instructions that are straightforward to follow. Its not even a question of language - I don't see that those that read Spanish would be any better off with the Occre instructions! Either way, I still think you are making very good progress with the model.

-

Good to hear the parts go together nicely! Yes, please start a log as it would be great to see your progress. The Lumber Schooner looks to be a really nice topic as well. I did buy the RC equipment along with the kit, but I'm not sure if I will use it or not. I'll PM you when / if I get to building the machine and start a log. Greg

-

I'm sorry to have been so slow to respond - I used medium CA to glue the engine castings together. Fresh CA worked well for me, but I've found that if the CA is old it is iffy in terms of the adhesion you may get. In a number of places I did need to file the castings so that the joint locations were tight to one another.

-

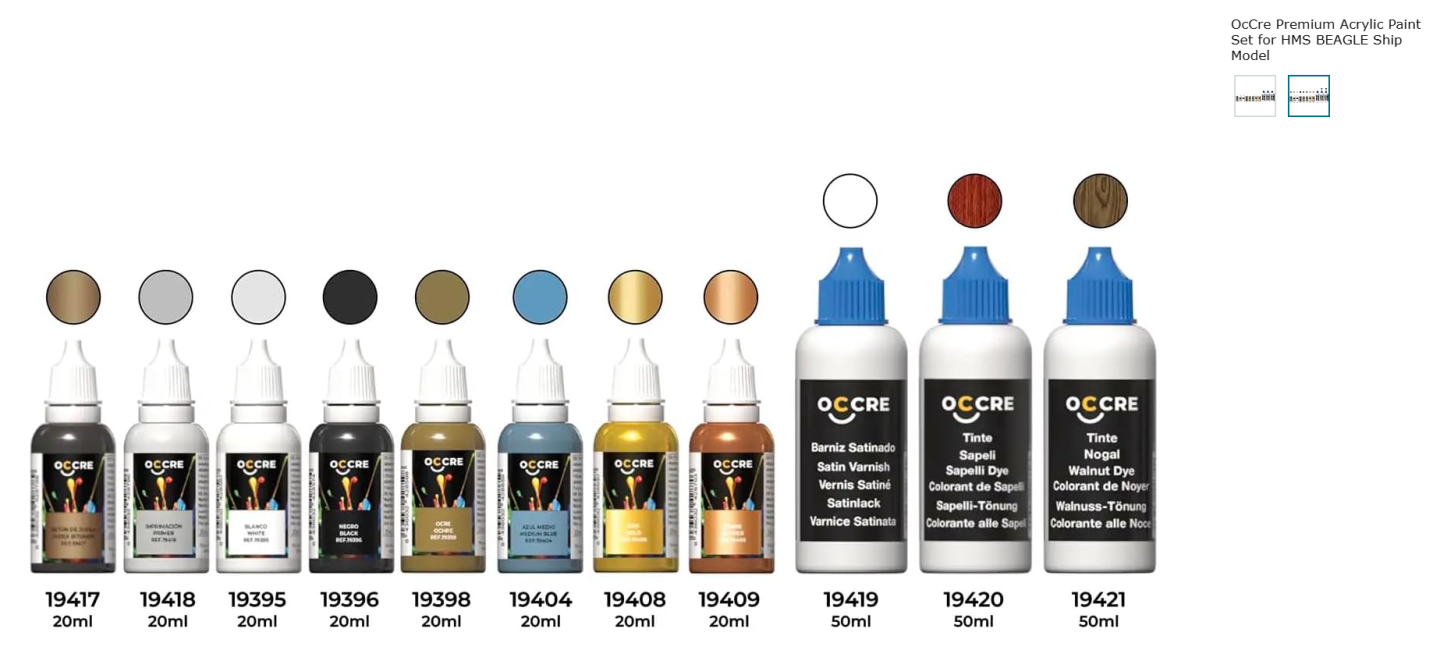

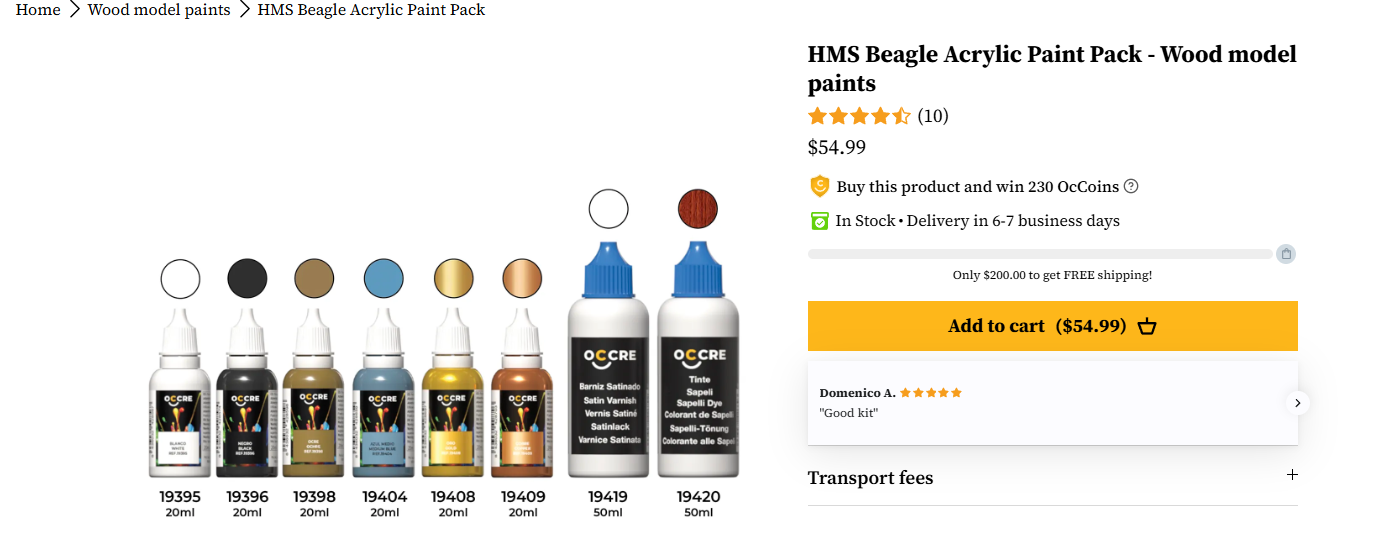

I curious as to where you obtained the paint set. Interestingly, on the Occre site, the Beagle paint set is like what you received (probably were out of the smaller vial of blue and made a substitution): But on Amazon, the Occre Beagle paint set is a bit different from what you receive. It includes the Walnut dye and two additional paint colors; also, it is a little cheaper ($51.29 with free shipping). When I first started the hobby, I did by paint sets matched with a couple of models (Model Shipways) but was rarely satisfied with what I obtained for various reasons. Similar to DonSangria, I now tend to obtain paints and stains individually as I desire them for my models. I've never used Occre (EarthMark) paints so I'll be interested to see how you like them. Currently I'm using Vallejo acrylics - they have two lines Model Color and Model Air. Model Color can be brushed and thinned for airbrushing whereas Model Air is specifically for airbrushing and does not go on very well with a brush. They offer a huge range of colors and are relatively easy for me to obtain.

-

After 3 days, 30 planks are now in place. About 85 more to go on this side. My count of planks was way off a couple of days ago - there are closer to 115 planks on each side rather than 75! Soon the work will get more challenging coming down from above as for the next diagonal from the front will have me planking right up to the stem, thus a reasonably sharp bend will need to be put into the plank. Probably as, or more, challenging work coming up aft as in two stakes I will be into the 'tuck'. Not sure if the work coming up from the bottom will be significantly harder than now. In the front strakes will need to conform to the stem. In the back everything needs to be worked up to the stern post. Some of the planks need a great deal of twist as they make there way to the back. Here's how far I had made the day before:

-

I got 9 planks shaped and installed today - so if things go well / at about this pace, i should be able to plank the hull in about 3 weeks. I'll most likely plank the complete port side and then go do the starboard planking. I will be working from bottom up and top down simultaneously with the final planks going in near the turn of the bilge. The six planks on top were easy to work, but the lower garboard strake is only partially done due to the twists in those planks. There is one more plank on the garboard strake that is being worked on currently - the one that ends at the stern. It is challenging because it twists 90 degrees in less than 4 inches. The planks that need a great deal of bending are being wetted and clamped in place to dry / take their shape. I remember rushing this process in one of my first models. In that one, planks were wetted and bent, but I failed to wait for them to be totally dry before attaching to the hull. Once they dried, I had a good number of gaps due to the wood shrinking back to its nominal dimensions; lesson learned and hopefully never repeated again!

-

The planking shift has been marked and hull planking has begun! First plank, part of the garboard has been attached. Using the provided planking material, I think there will be about 75 planks needed on each side of the hull. Some of the pieces will be hard to form near the bow and stern. Primarily due to the thickness of the material, I don't know if I will be able to get the kit wood to conform to the needed bends or if some supplemental material will be recruited - time will tell. Sometimes I find it a 'fun' challenge to see what can be done with the provided materials .

-

If the hull doesn't have too much curvature, then full length strips are not too hard to work with. As the curvature increases it becomes more difficult to wood strips in three dimensions. Working with smaller segments helps with this problem and provides a more scale-like planking of the hull. When gluing / attaching the pieces, smaller segments can be easier to get into the correct position. In either case to get a nice run of planks the pieces of wood need to vary in width to accommodate the changing distances along the hull parallel with the frames/bulkheads. This is a primary reason why a hull can't be planked using all strips of a constant width. Personally, I find it easier to first determine a hull planking pattern and then use multiple (shorter) planks in each strake.

-

I've added the rest of the keel / stem / stern structure. There are 3 mm holes thru the keel for the mounting screws to pass. I made the holes using a 3mm endmill on my mill - due to the thickness of the keel there was very little room for error so I didn't want to freehand the drilling process! Before the keel was added, I drilled holes into the false keel, made recesses, and secured a couple of nuts for the mounting screws. The nuts needed to be reshaped to not protrude out from the keel / interfere with hull planking.

-

I love the presentation - besides the great job on the model, the diorama really brings your project to life! I do have a question for you. In the background I see a Sherline lathe / mill combination; could you provide some insight on how you combined the machines? Thanks, Greg

- 62 replies

-

- Arctic Exploration

- OcCre

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.