-

Posts

73 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by uscharin

-

Yup, I have a strong flashlight at the ready and have used it often. Also, the parts are rarely found where you think they went. Anymore, I try to sweep the floor between sessions to help my odds. I have spent hours on some replacement parts only to find them the next day. The purist in me wanted to draw/paint the scroll work directly onto the ship but it's gotten harder for me to keep my hands still enough. I can print out several copies of my design and if I mess up on one, I just move to the next. I would otherwise need to fix mistakes on the ship before making a new attempt. At my age I'm now cutting myself a little slack.

- 100 replies

-

- Cutty Sark

- Sergal

-

(and 1 more)

Tagged with:

-

Played around with my decal paper today and the results were disappointing. First thing I did was scale and bend the design in Photoshop until it fit the ship. I would cut out the paper version and apply to make sure it fit properly. First thing I noticed was just how good the paper version looked, to the point I almost didn't bother with the decal paper. The toner almost perfectly matched the hull paint. But, I have the decal paper so wanted to see how it would work. After printing out my design on the laser printer the first thing I noticed was the toner got partially picked up and smeared by the outfeed roller. Toner adhesion is terrible, at least with my printer. You can very easily scratch off the toner by dragging your fingernail across the surface. For sure, you would have to seal this work once you transfer your design. Even though the decal paper didn't look that good I went ahead and tried to apply gold to the scroll work. I initially tried to use my nib pen using some gold paint (I couldn't find any gold ink) and that went badly as the pen tip would quickly foul. It also proved a little difficult to apply paint to the glossy decal surface. The pen would probably have worked great if I had ink. It was at this point I tried to apply the gold paint to the paper version, which was a lot easier but would bleed a little, so the design was not as crisp as I was hoping for. Never-the-less, it didn't look all that bad. I used an old brush that I trimmed to a point and thinned the paint with a little mineral spirit. I ended up using some of the gold paint out of my new Ultra Fine (0.5mm) Pilot paint pen, which turned out to be useless. The tip was too wide and every time you pressed the tip down to feed more paint the line would get wider. I almost went w/o the gold as I'm actually not sure the carving was gilded at this point in time. In fact, I still lean in that direction. Longridge did his work in gold so maybe it was gold. Really hard to tell with B&W photos. I carefully applied water-thin CA around the edges of the paper using a wire loop. I went around it twice letting the CA completely wick up behind the paper. You had to be a little careful as too much CA would melt and flow the paint. I might later go back around with some black paint but honestly without a bright spotlight on it, as in the picture below, you would have no idea there was a paper edge. I also applied silicone to my little lifeboat form. I used alcohol but mineral spirits would likely have been better. It needs to completely cure before I try to apply my planking, which I might try to start tomorrow. Funny how you will see things in pictures that you might not otherwise notice. For example, it jumped out at me in my last post that the hull needed more fairing.

- 100 replies

-

- Cutty Sark

- Sergal

-

(and 1 more)

Tagged with:

-

I like that table. Maybe it's time for me to go shopping. Your ship is looking great! She has a very "authentic" and natural look. Ron

- 186 replies

-

- Flying Cloud

- Mamoli

-

(and 1 more)

Tagged with:

-

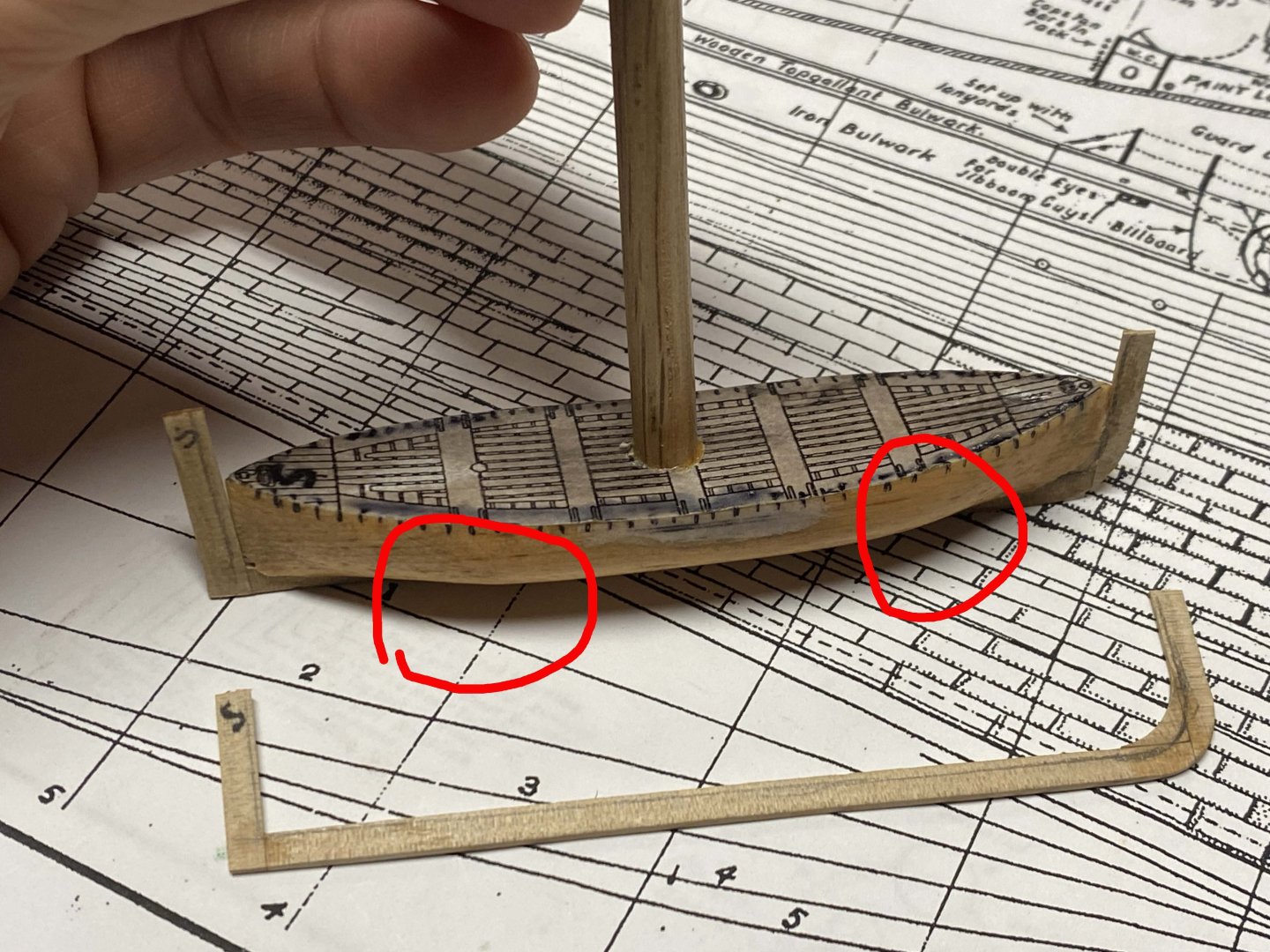

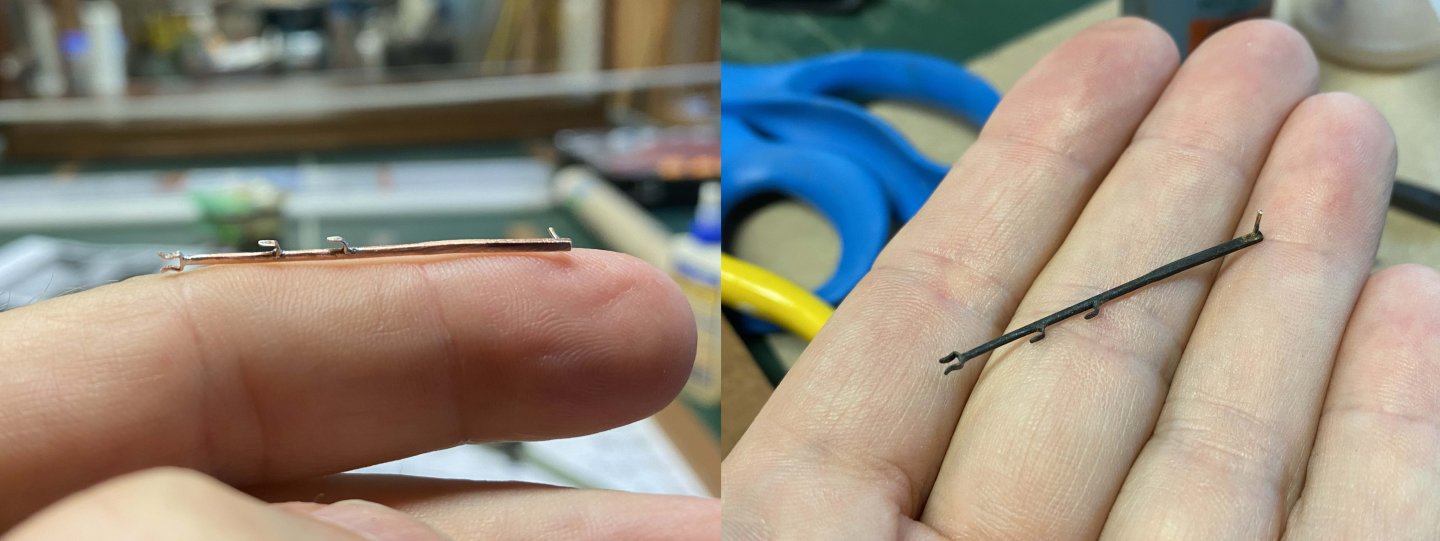

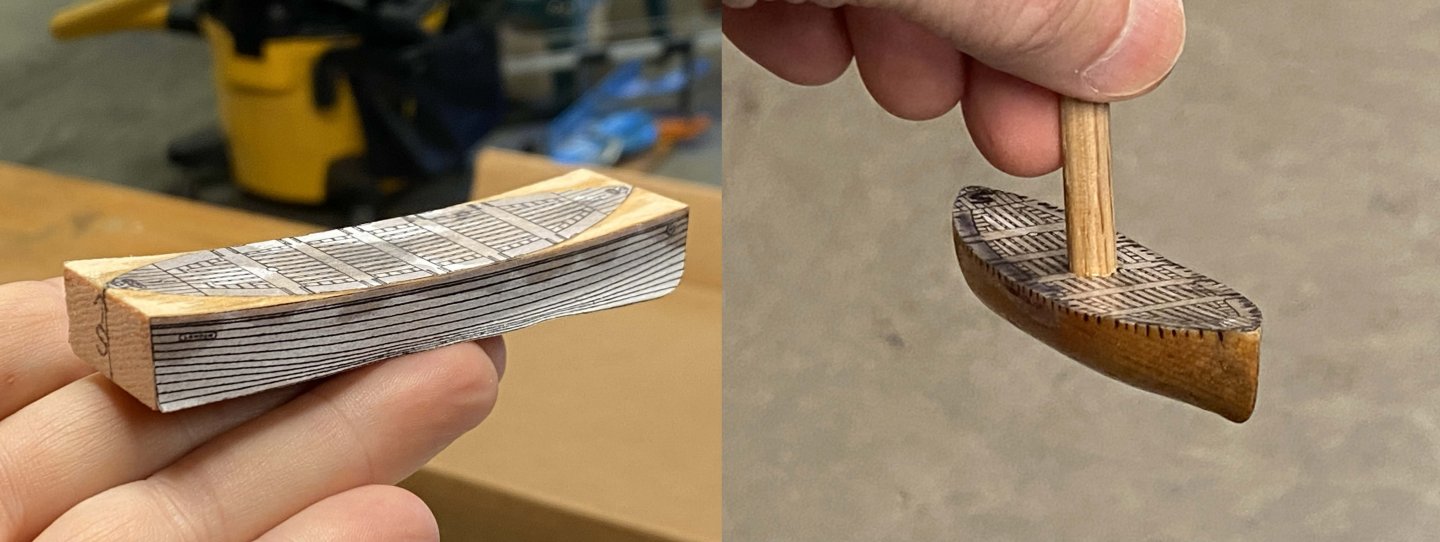

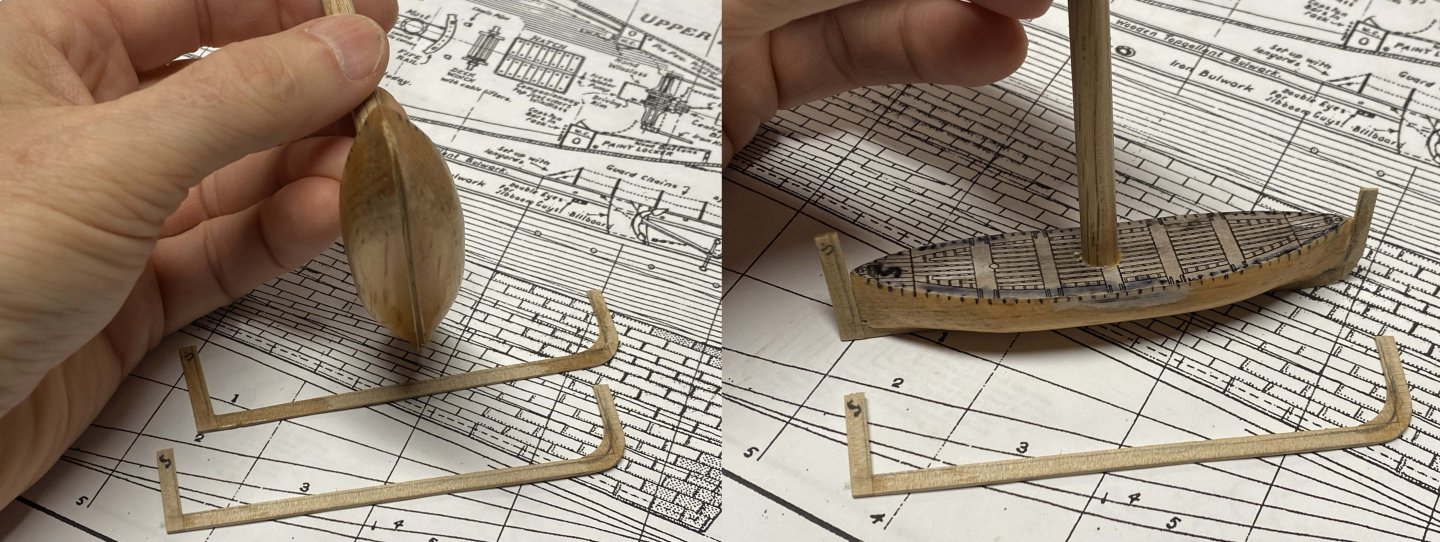

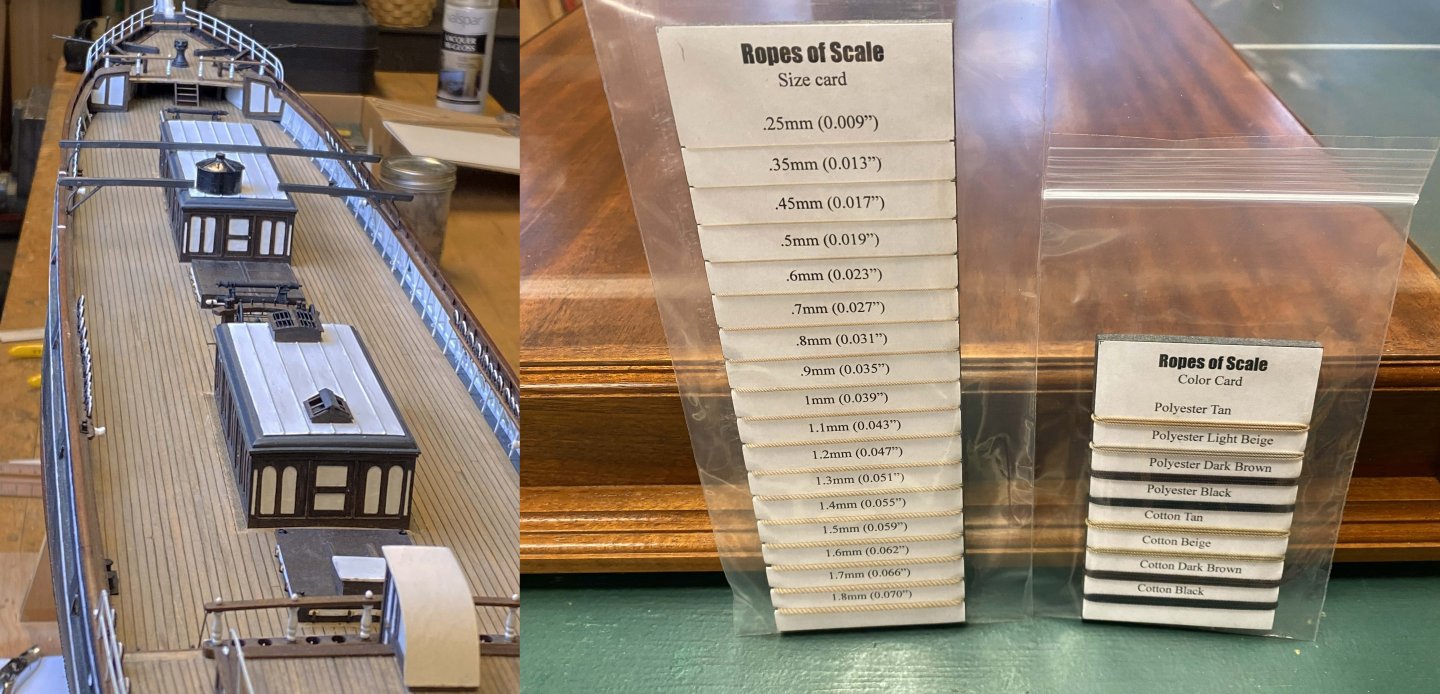

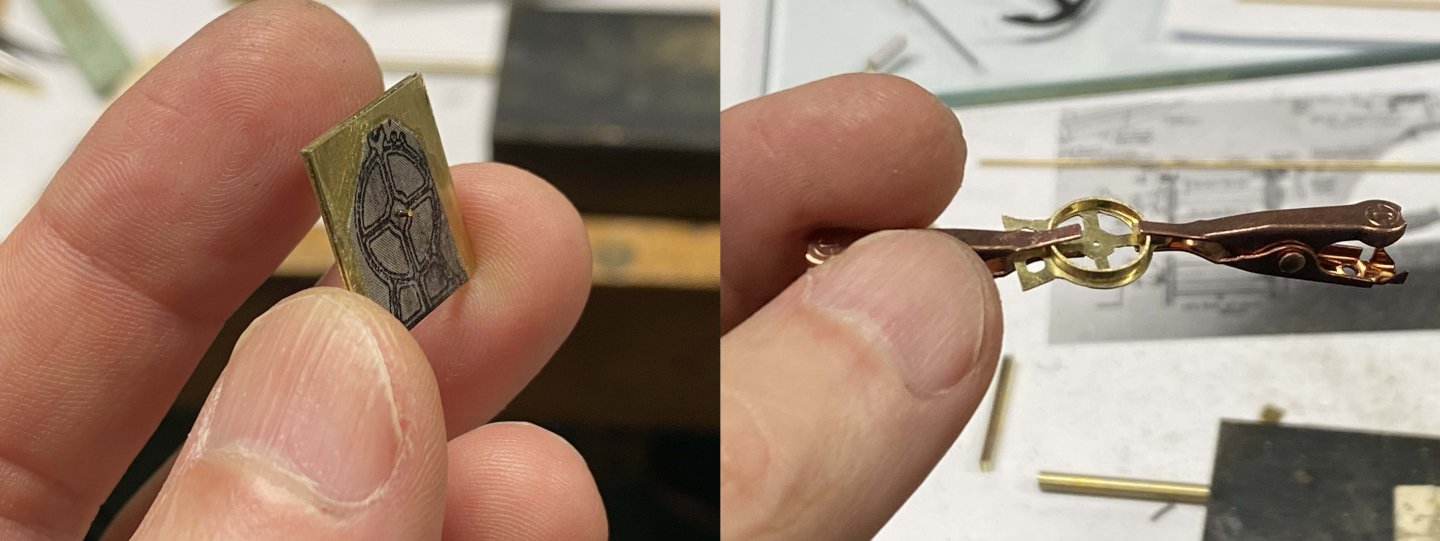

Have been simultaneously working on a number of smallish jobs that are not all completed. Multitasking is not an efficient way to work. The reality is some of my current tasks are not much more than a series of experiments to see what works. Framing the masts: Pretty straight forward but took a surprising amount of time to measure out and remove decking, then color some replacement wood to match decking. The mast diameters are not enough to fill in between frames but when a weather skirt is applied that will cover things up. Unfortunately, my old-work masts will need to be completely rebuilt as there is just too much wrong with them. After the framing was complete, I started gluing down all the items I have been making... chicken prisons, winches, etc. Something always goes wrong at this stage and the big oops this time was one of the chicken coops took a ride down the throat of my shop vac. It could have been worse. Although I made the whiskers and dolphin striker a while back, I had to remove them as they would surely get broken off in the course of modeling. I refitted them on the ship but will take them back off until I get to the rigging. Made out of soft copper wire hammered out to shape. The hammering process turns the Cu hard and not easily bent. Soldering on the clips was an exercise in patience. Mounting the anchors: There are, of course, several ways to display the anchors. While at Falmouth the anchors were stored on deck and the anchor chains used as mooring points, and that never changed. Every picture I have from that period shows the anchors simply laying on the deck with only a protective board under each fluke and not lashed down. As a practical matter, I did lash down the anchors as they would otherwise be constantly moving about. Longridge displayed his model that way, even if it wasn't exactly as it was. In the right-hand picture below, you can see how the almost identical anchor is stored on the deck of the Polly Woodside. I also attached the anchor chains, again, even though that was not how it was in reality. It's simply a matter of practicality. I had to make a couple small shackles out of brass to make the connections. Sections of the railings could be temporarily removed to allow the anchors to be stored on deck. I need to somehow detail that in a way people don't keep asking me how they got the anchors under the railings. Lifeboats and storage skids: This is one of those jobs that is ongoing and outcome uncertain where the lifeboats are concerned. It took some time to figure out the exact locations of skids, as they were moved forward at some point while in the hands of the Portuguese. I have no published plans for this so had to stare at pictures until I felt I got it right. One big difference is that the distance between skids was narrowed, and a section of the aft skid bridge was cut out to accommodate the water tank. The lifeboats are currently a work in progress and am working out the process as I go. I started out making a mold for the shell out of soft pine. I printed out scaled drawings to help and that makes this so much easier. I then made a pair of keels that get notched into the mold. I made the keels very oversized so after the planking is done, I can then shape the keels down to the proper depth. My next step is to coat the mold with silicone so it will be much harder for over-applied CA to grab the mold. To do this I'll dissolve some 100% silicone caulking in isopropyl alcohol, or maybe mineral spirits. CA does not stick well, or at all, to silicone. I've been looking for over various materials to use as planking and in the end, I'll likely use a paper product to achieve the look and scale. That'll be fun. Bow carvings: Concurrent to all these projects is I'm still trying to figure out how to apply the bow carvings in a way that I'll believe. My latest effort was to see if I could reproduce the design in etched brass or copper foil. You can find various methods to apply etch resistant designs from the internet. The easiest and cheapest method I found was to print your design on glossy paper with a laser printer. From there you can transfer the design either by heat (cloths iron) or melt it on with nail polish remover. Straight acetone will work but tended to dry to fast. Once the design is pressed on and the acetone is mostly dry you can peel off the paper. That part seemed to work pretty well except when I tried to sponge off the paper whiskers stuck to the toner, I discovered the toner did not adhere all that well. I later determined that how you clean the metal is VERY important. Initially I simply scoured the surfaces with 0000 steel wool. Turns out that leaves a faint oily residue which guarantees failure. You need to use detergent and water as a final step and then don't touch any part of the surface. I tried using straight acetone as a final rinse but that didn't work well at all. Don't use cellophane tape to hold down your designs. It will melt and leave a gooey mess. As you can see, this process is quite doable. I took this rather thick brass test plate and soaked it in 30% ferric chloride for about an hour and was surprised to see the edges were still quite sharp around the toner resist that was still intact. I sprayed the back of the plate with lacquer to keep it from getting eaten. For some reason I didn't take a picture of that. If I do this again, I'll use thin copper foil and see what happens. As a possible alternative to etching, I just got in the mail some water-slide decal sheets. I have prepared some jpeg files to print out to see how it works. My plan is to print out the design with a black background. From there I will use an ultra fine pen nib (of which I have) and follow the design with gold ink. I can then cut out the design and apply to the ship. We'll see how that goes. I have other ideas on how to use this product but need to see first-hand what can be done. It's a process of discovery. I'm starting to think about rigging so recently ordered a sample pack from Ropes of Scale. They make some really nice stuff. Having the samples in hand is going to make my decisions on which sized to use so much easier.

- 100 replies

-

- Cutty Sark

- Sergal

-

(and 1 more)

Tagged with:

-

Hi Kevin, Glad I'm not alone in my fears. Your winch kits sure started to look good to me and when I went back to look them over, they were all gone! I took it as a sign. Ron

- 100 replies

-

- Cutty Sark

- Sergal

-

(and 1 more)

Tagged with:

-

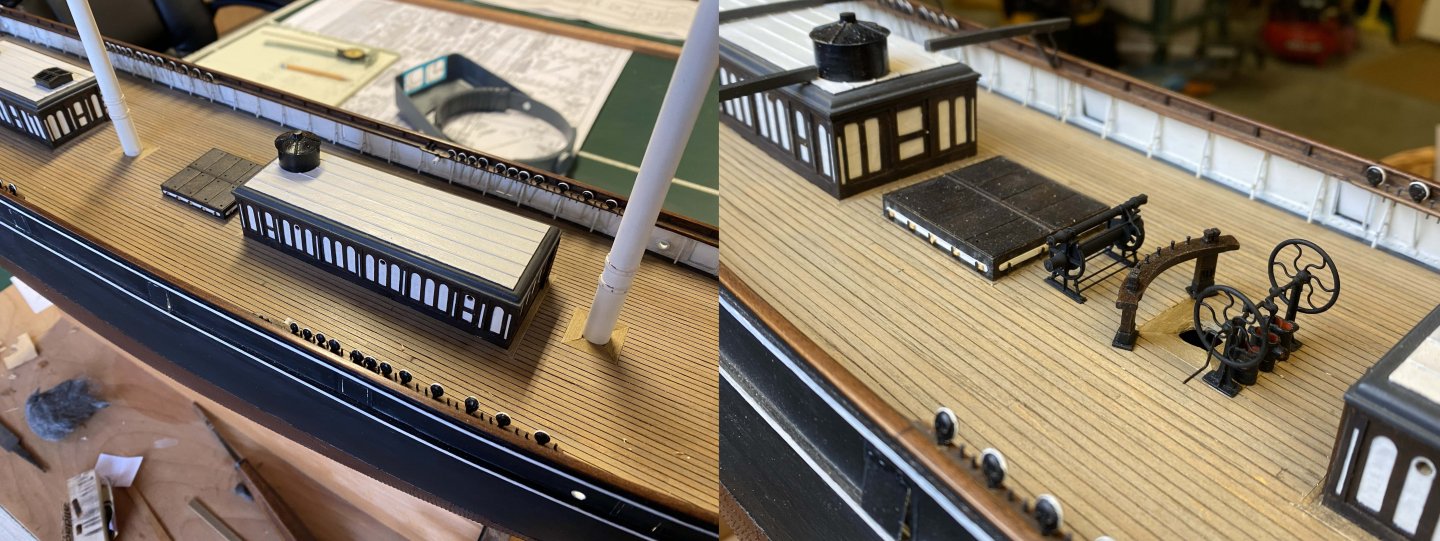

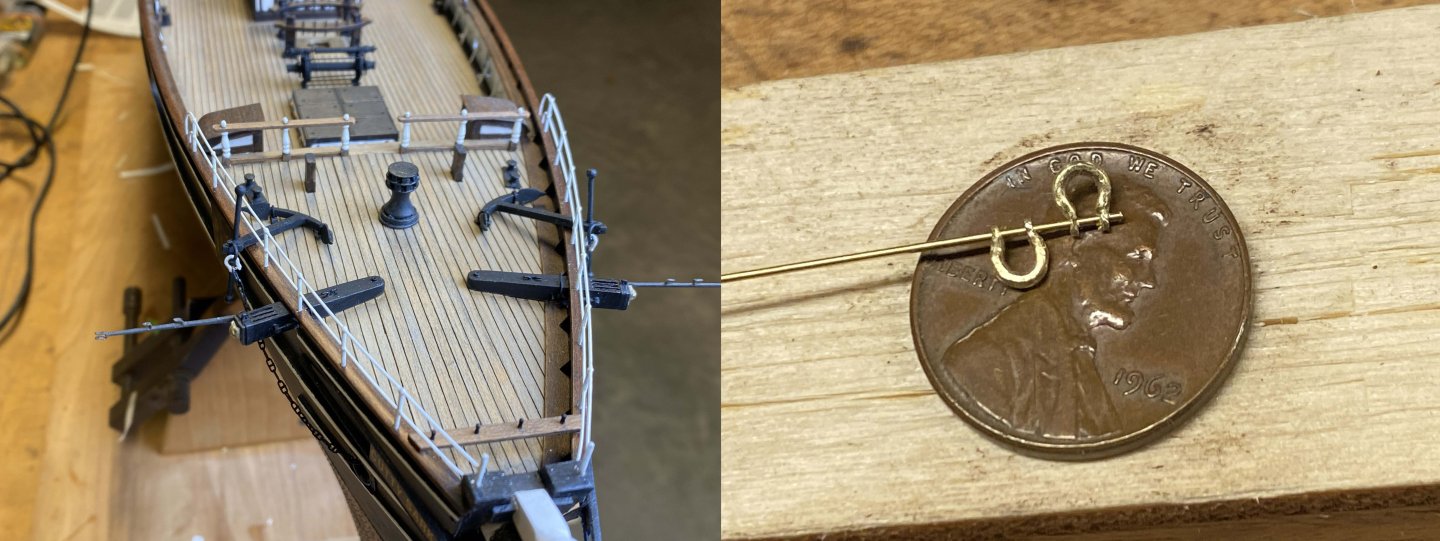

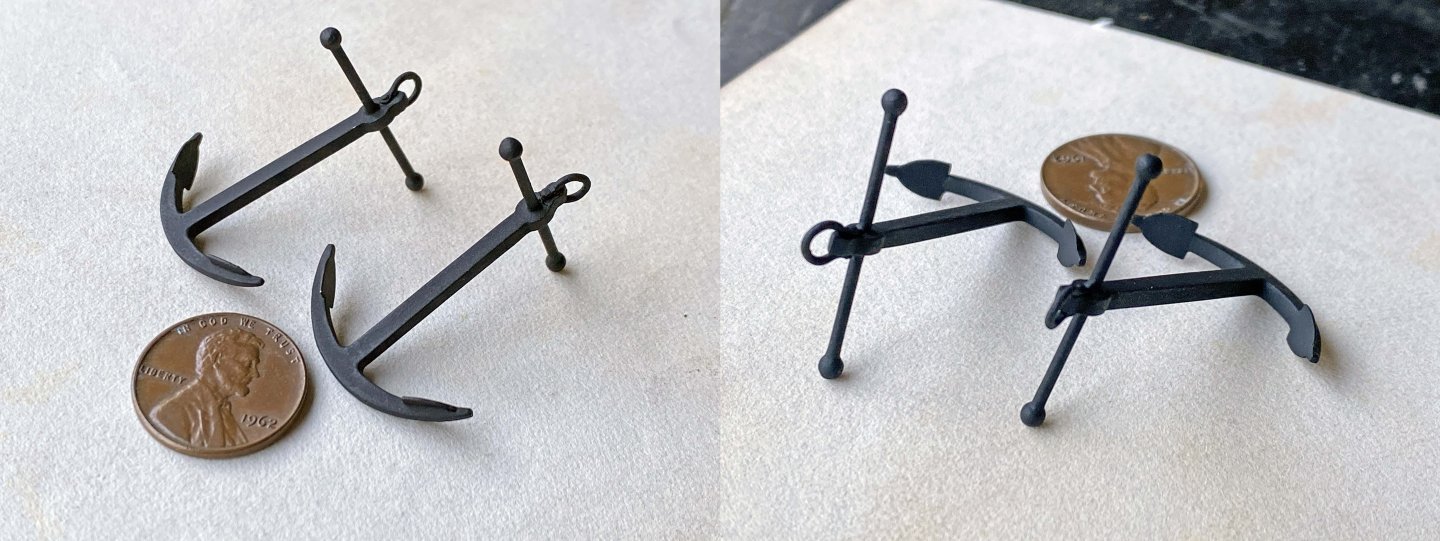

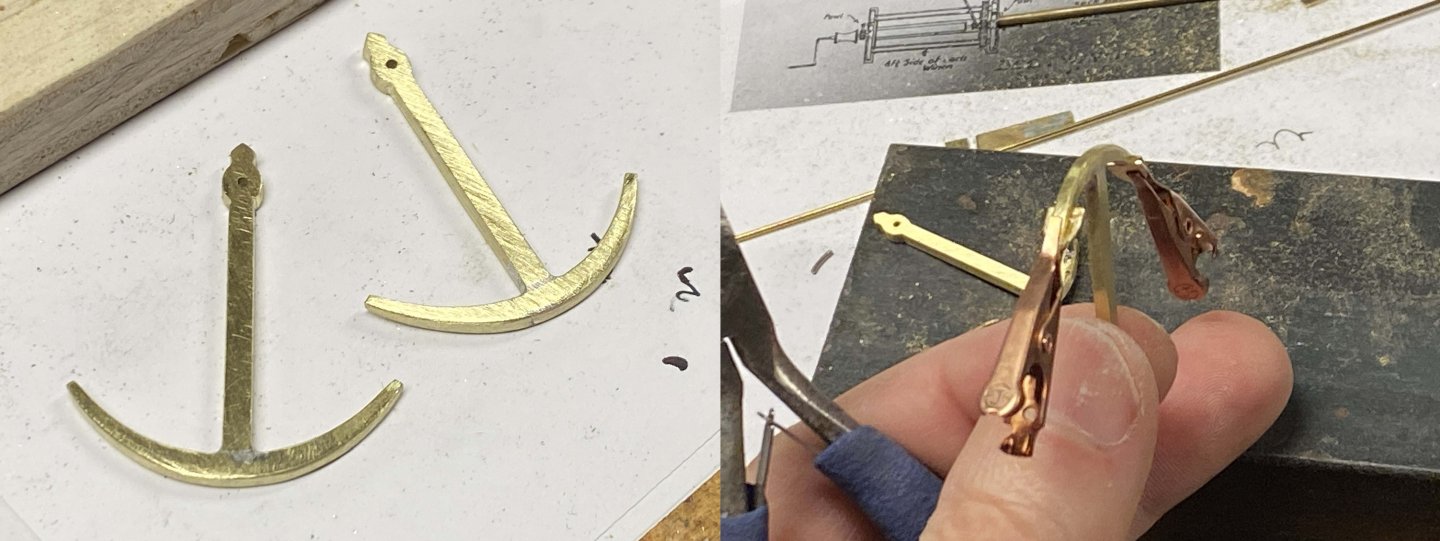

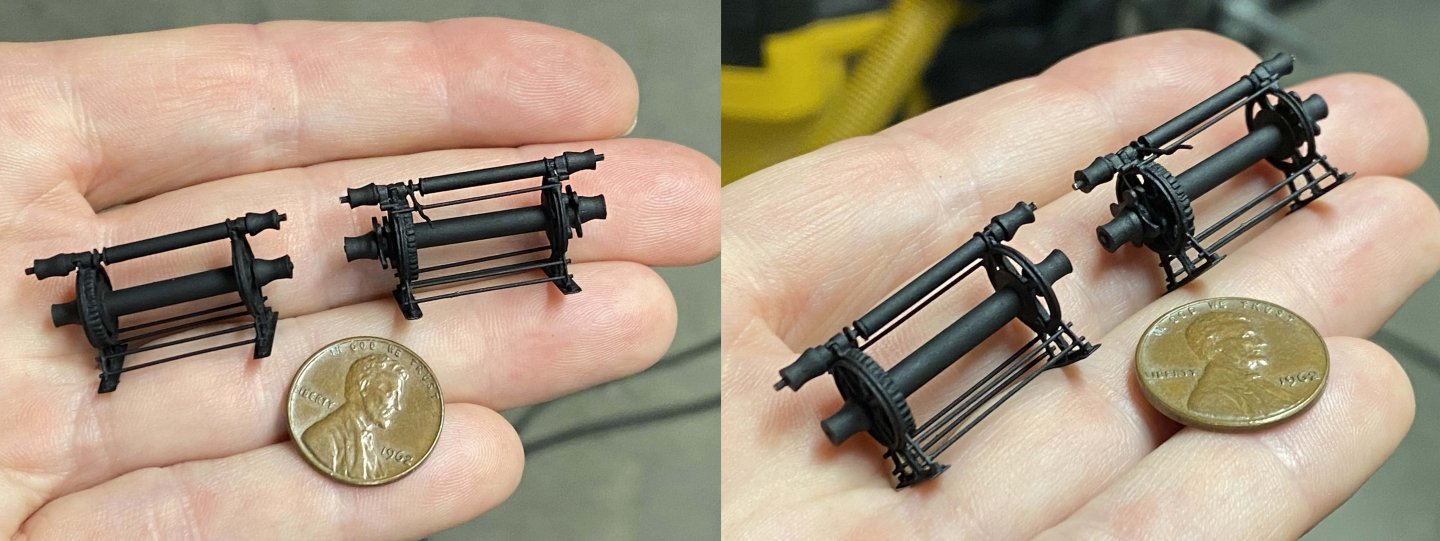

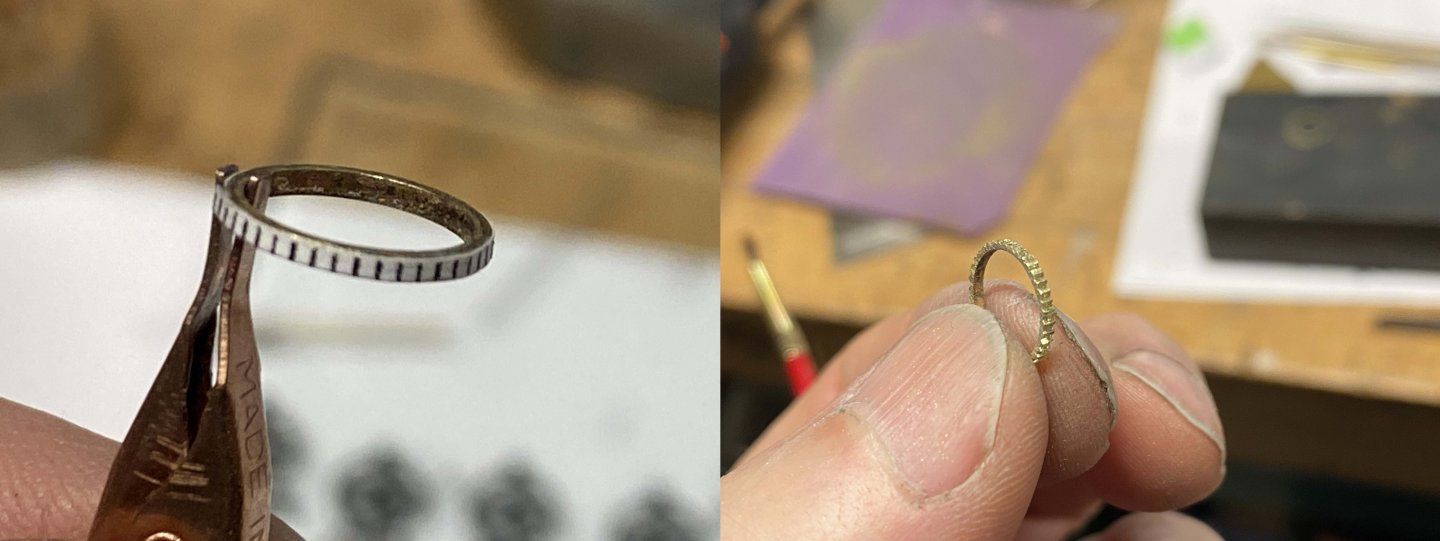

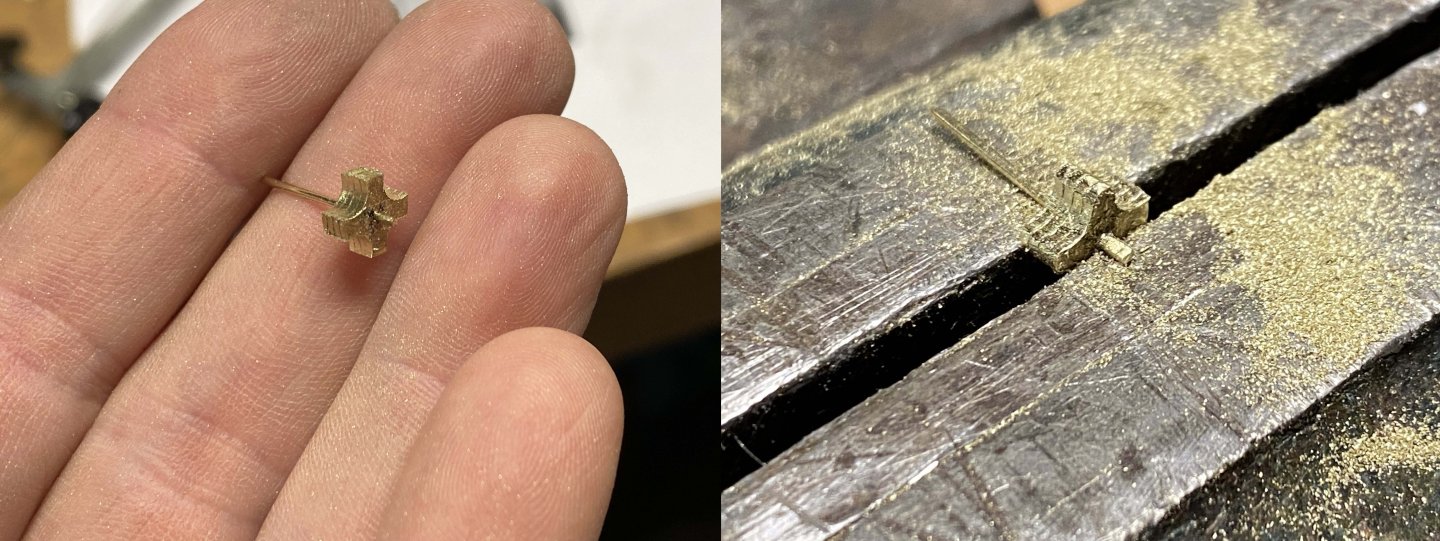

Just today finished the two deck winches and it was a hard slog. Proved to be far, far more of a challenge than the bilge pump. I didn't think that was possible. In the end I'm happy with the overall results; maybe not so happy with the gear rings. The gear rings look OK, and in fact from about a foot away you can't resolve individual teeth. Most of the construction is in brass with some ribs and outboard hubs being in wood. To replicate the outer cast iron supports I sandwiched four pieces of 0.1mm sheet brass and glued them together with CA. I also pinned for good measure and then glued a scaled image of the supports on both outer faces as a guide. From there I pierced the inner captive areas with a drill and hand filed to a rough opening. Using a jewelers saw I trimmed the outer areas then rough filed. To start forming the ribbing I cut narrow pieces of tubing for both faces of each support. The tubing I had on hand was a little too small so split the rings and wedged open to hit the correct diameter before soldering. Once the rings were in place I then filed them down to the appropriate depth. The brass feet were next, which are soldered in place. Wood was used to make the remaining ribs for the same reason I used wood on the bilge pump supports in post #80. The gear rings were next and proved very difficult. I tried a number of approaches, and nothing worked as well as simply free hand cutting them using a paper template. I definitely got better at it with practice, but still far from perfection. To make the rings I cut slices of the same tubing I used for the support ribs and then soldered an additional layer of brass to get a thicker wall. I counted 84 teeth on the original CS winch main gear ring, which was going to be impossible for me to pull off. I ended up making a template for 40 teeth, which my printer was happy with and in practice could accommodate my smallest razor saw. The second of the two rings turned out way better than the first and I'm sure if I had the patience to make more the results would have been progressively better. My biggest problem was the paper template would keep tearing up and off with each fresh saw cut and made precision almost impossible. If I ever do this again, I'll epoxy the paper on instead of using CA. Of course, the alternative would be to invest a few thousand $ in clock gear cutting equipment and accessories and spend a few months learning how to use it... or resin print. The top and bottom inner drums are made with brass (original is wood), while the outer drums are wood which I turned on my hand held Dremel tool. The two deck winches differ a little. The forward winch has a pair of wildcats (pocket drives) on the main outer hubs for pulling up the anchor chain slack before dropping into the chain lockers. Of course, the wildcats were useless after the Portuguese installed a new windlass. Like with the end supports, I sandwiched small pieces of brass plate together rather than cut each individually. The two pictures below illustrate some rough filing. Hard to tell, but I'm starting to round off the ears in the second picture. I have yet to glue down any of the bollards, fife rails, bilge pump, or winches. I think in the coming days I'll need to stop making things and start installing. Truth is, I find installing this stuff pretty stressful. There is always the risk of getting positions wrong, smearing glue, etc. Before I started work on the winches, I made the anchors. They turned out pretty nice. At some point in CS's history, and I don't know when or how, the starboard anchor was fitted with a wooden stock. My personal theory is one of the original iron stock arms broke off or at least became seriously weakened. The wooden stock would have been a good solution. I find the wooden stock to be quite awkward and looks out of place, even though that is how it existed at Falmouth. I finally decided to restore the anchor to its original condition, and I'll sleep just fine. Nothing complicated here, just cut out the shanks and arms then solder together. You can't tell from the second picture, but I filed a pocket for each fluke so the palms are flush with the arms. I hand-formed the terminal balls from brass rod using my Dremel. Drilling the holes was a little bit of a pain and a couple escaped in the process. Tinning the entire ball surface with solder almost completely filled in all surface imperfections.

- 100 replies

-

- Cutty Sark

- Sergal

-

(and 1 more)

Tagged with:

-

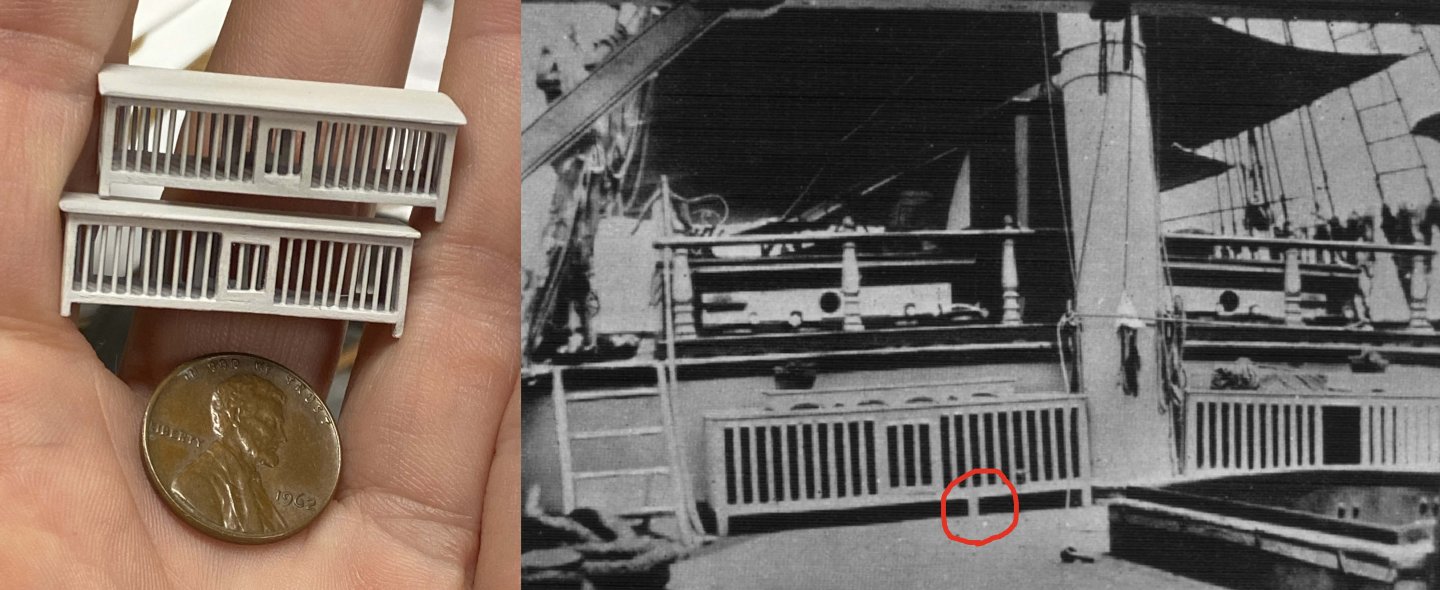

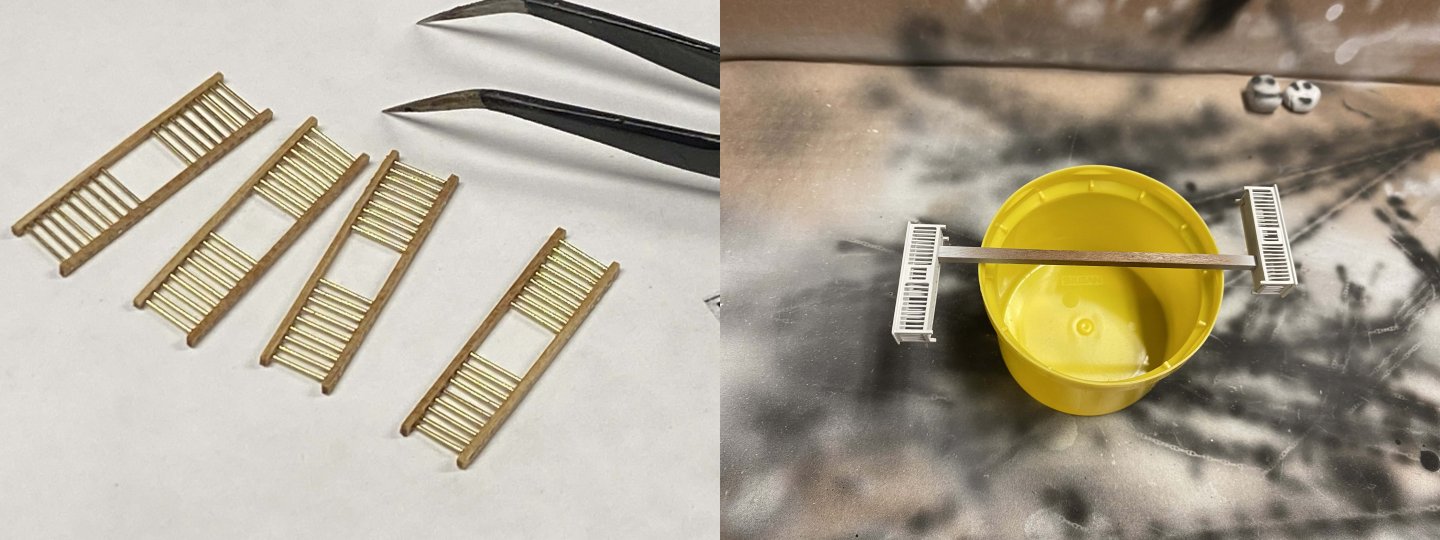

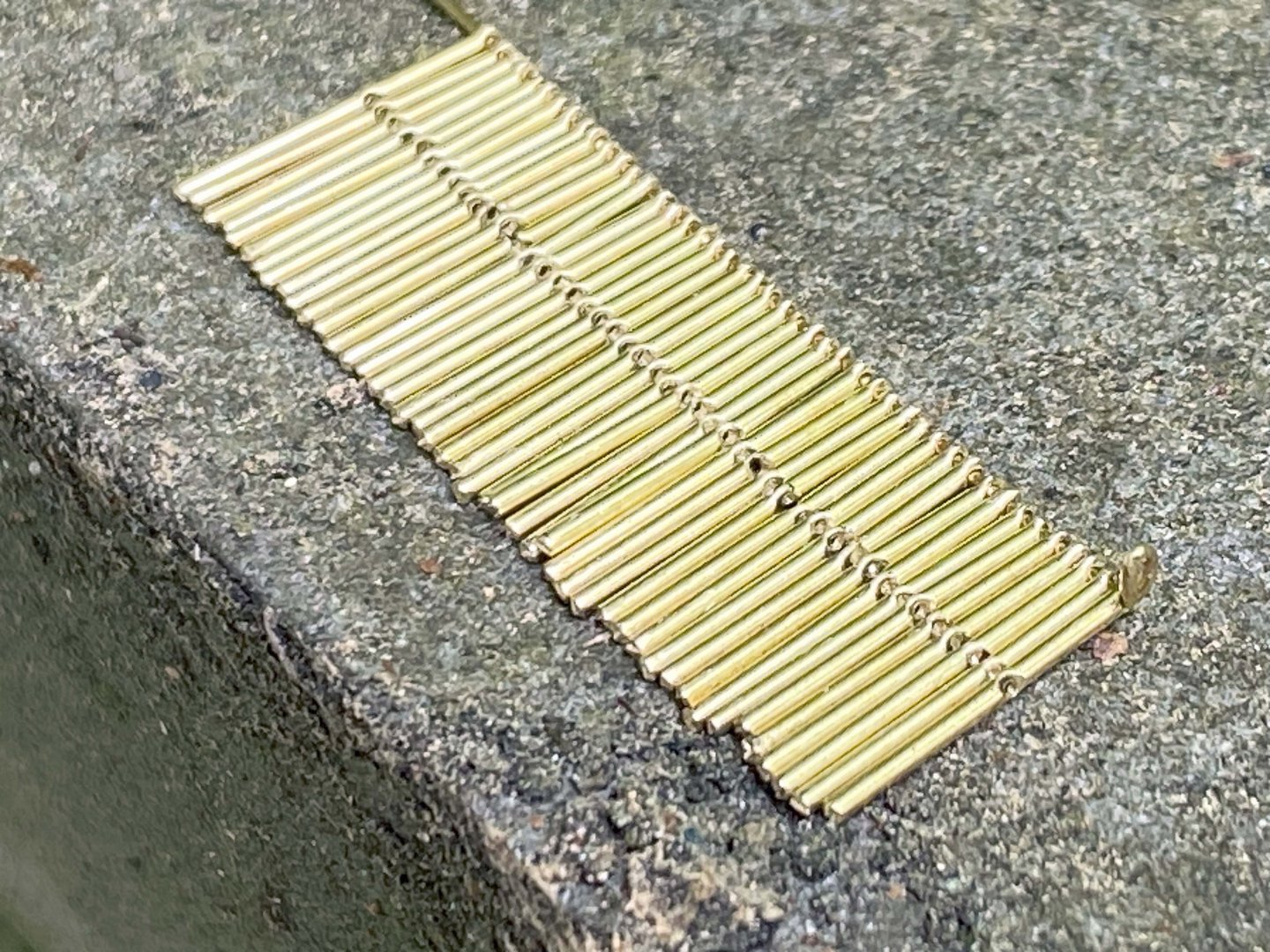

After the bilge pump I needed to do something relatively easy. I'm happy to say the hen coops turned out well and are ready to be installed. The coops were widened at some point before arriving at Falmouth. The current CS restoration/reproduction has them close to their original as-built size. You can see in this early Falmouth image that there is an extra foot. This extra foot marks the original outside corner and was no doubt still in place in order to support a weak rail splice. I made up bar panels and glued to rectangular wood tops and bottoms. Hard to believe the coops consumed over two feet of 0.45mm brass rod. I had to tack-glue the coops to a stick in order to spray paint them. The original coop bars were made out wood and were square(ish). One of my sons was recently in London on business and took time out to visit the CS. He reports it was a great experience to see it in person, something I have yet to do. The "water" dome that the ship sits in always leaves me unsettled. The effect looking up at the ship from within is quite grand. On the exterior, it looks like she is sitting on a water balloon that is about to burst. It is absolutely not complimentary to the lines of the ship and find that very unfortunate.

- 100 replies

-

- Cutty Sark

- Sergal

-

(and 1 more)

Tagged with:

-

Haha, yes, I'll enjoy making them, but it will also likely be a little painful. The iron end castings are where the real work will be. Thanks for the compliment. Just finished looking over your 3d printed CS offerings. Really nice prints and the resolution looks really good. Must be a pretty nice printer. If you offered your parts in my scale I might have been tempted. Kevin, your CS model looks great but I'm sure your Victory is soaking up all you time and effort. Ron

- 100 replies

-

- Cutty Sark

- Sergal

-

(and 1 more)

Tagged with:

-

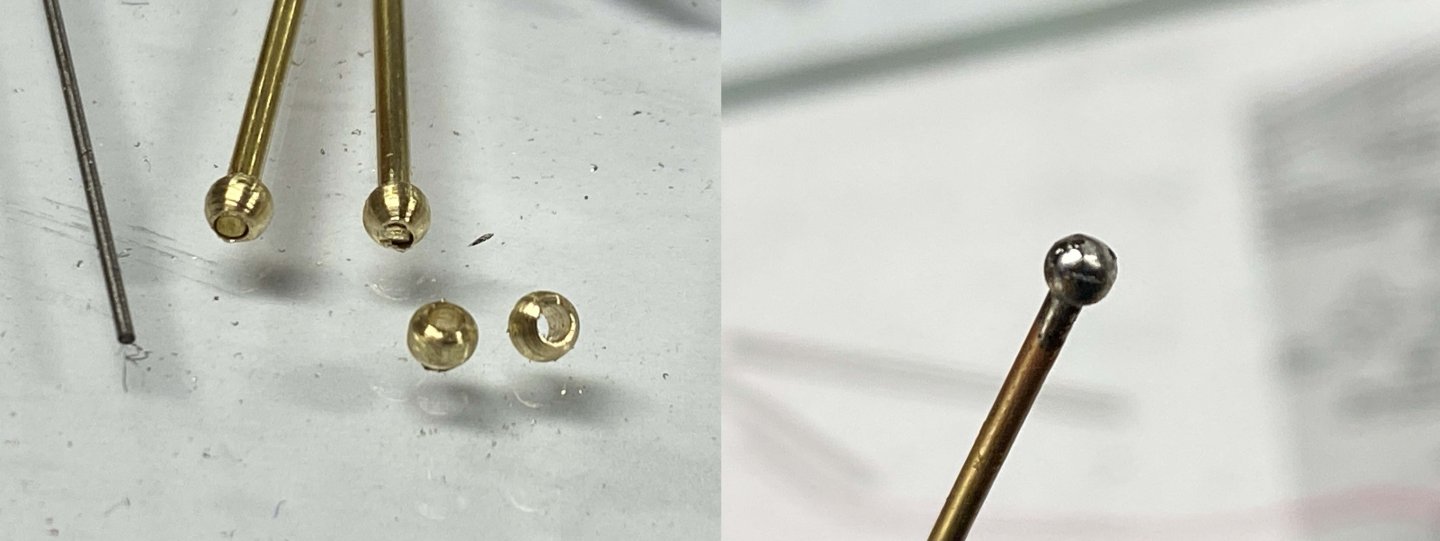

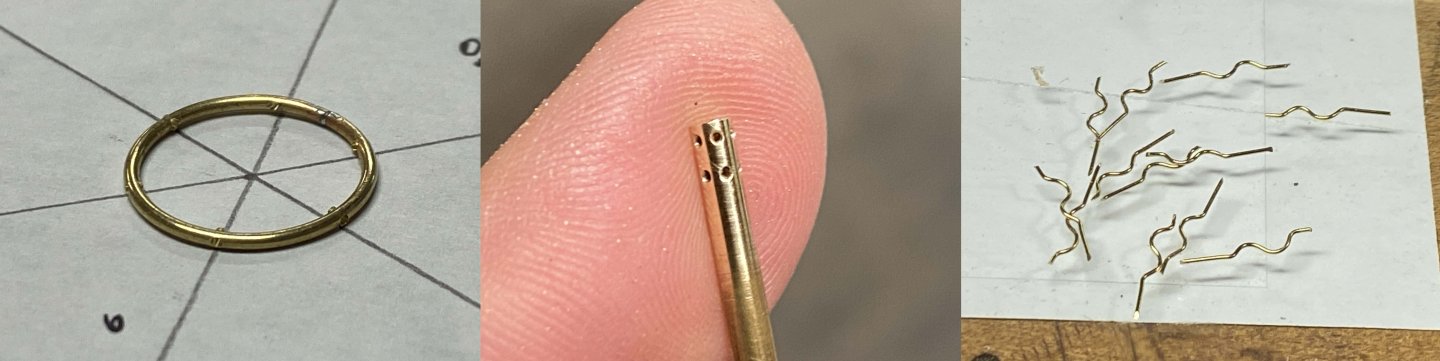

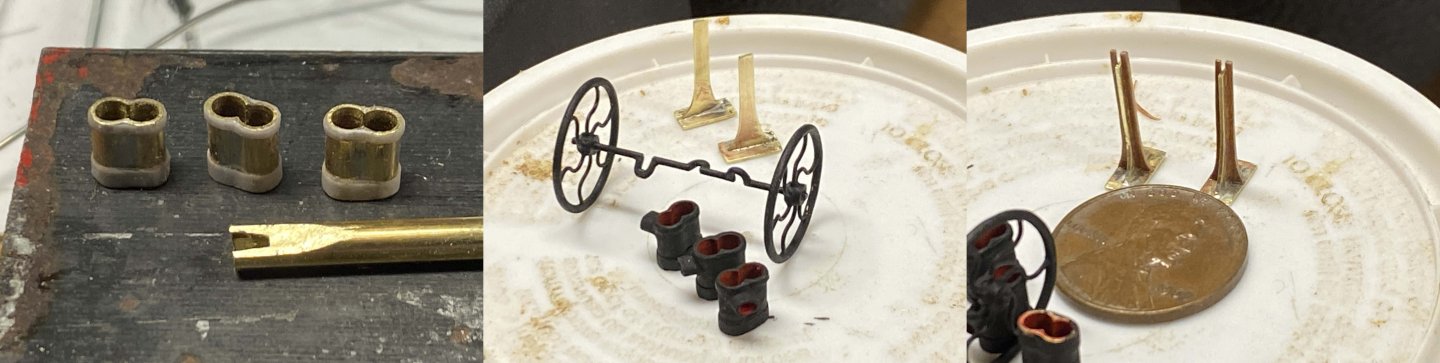

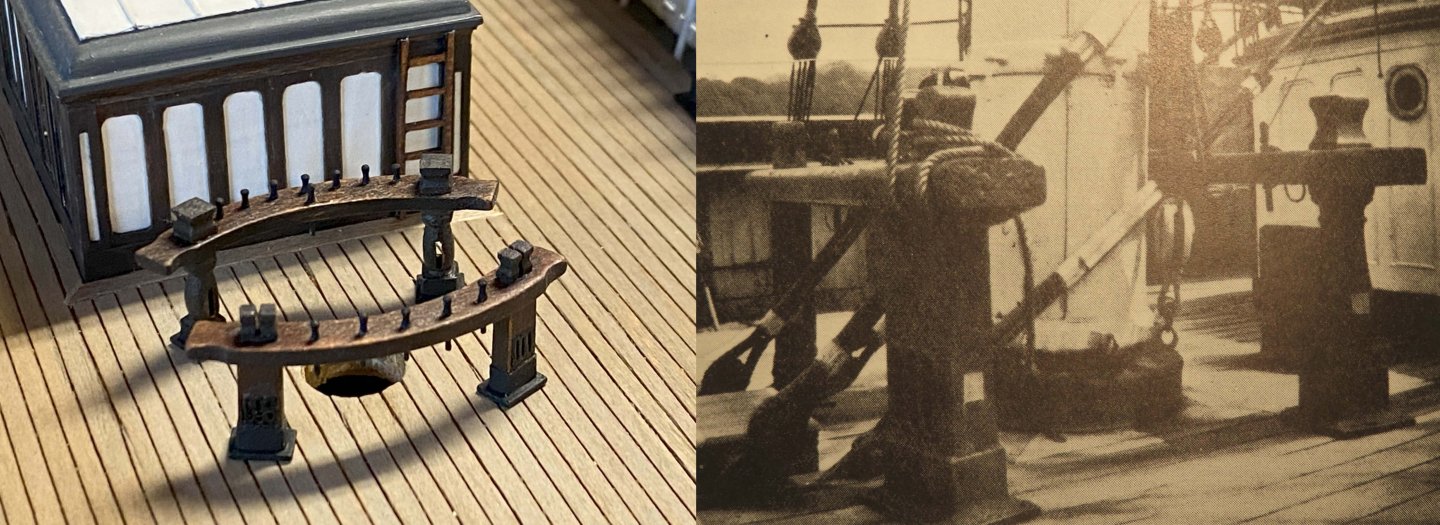

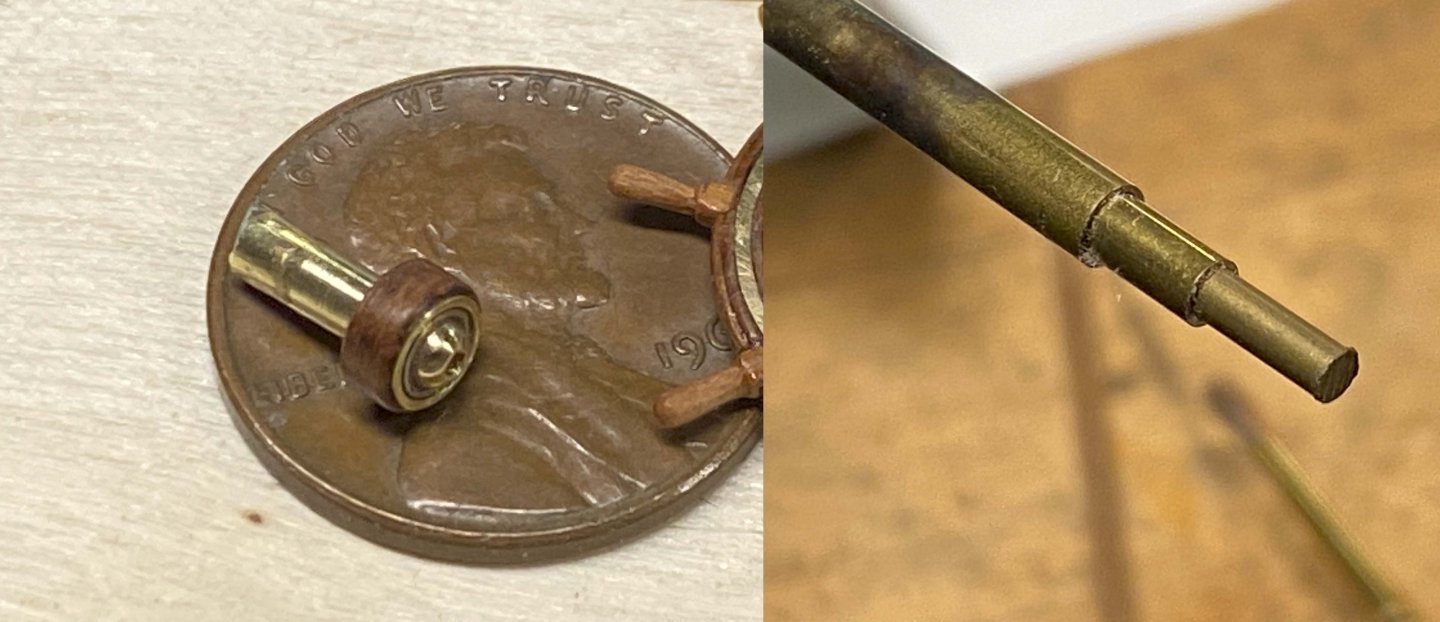

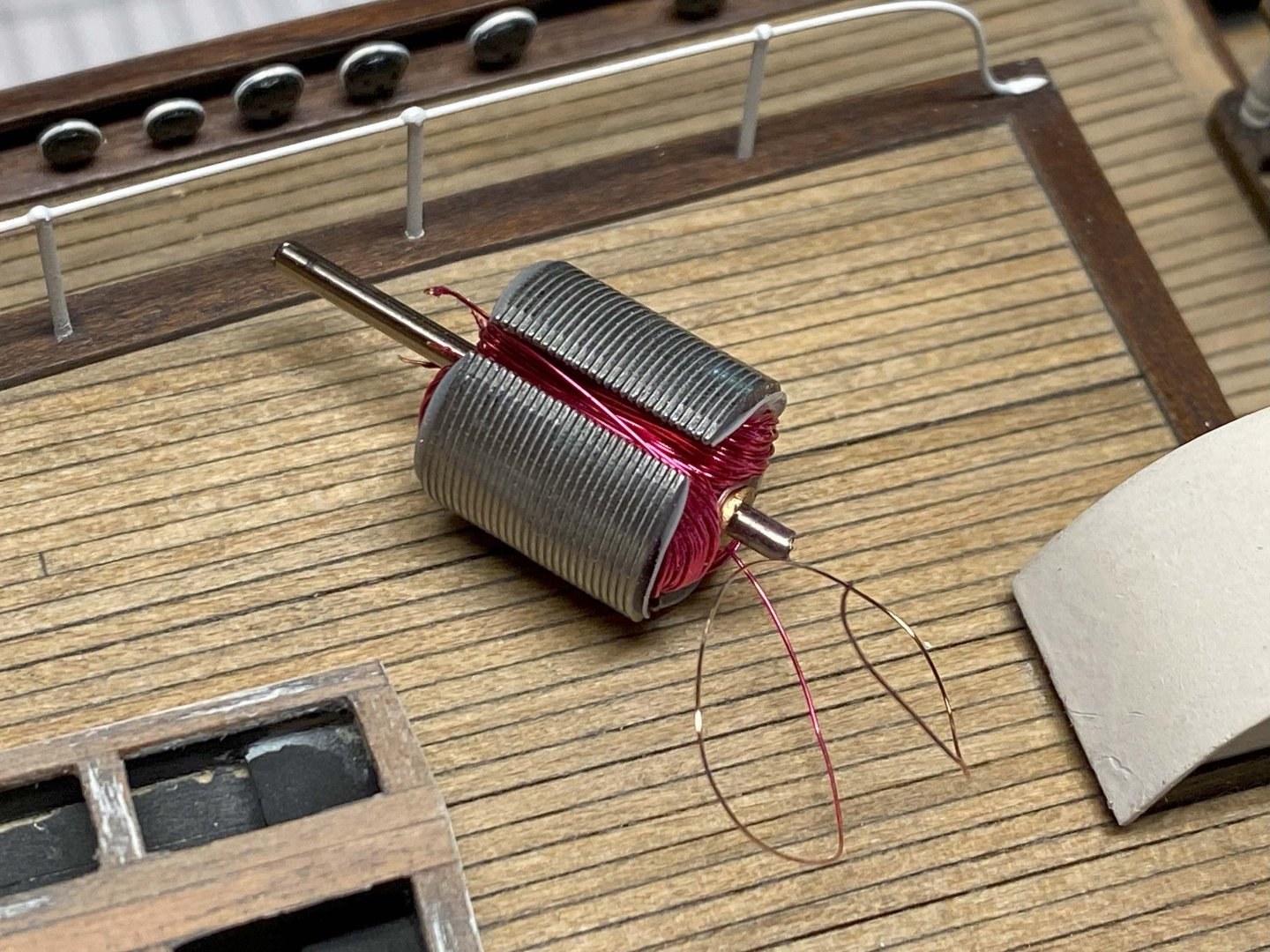

Can't believe this little bilge pump took me three weeks to build, but it did. Turned out to be pretty challenging. Most of the parts took me at least two attempts to make and I had to walk away several times to gather myself. In the end, I have something I can live with. I think my next task will be the chicken coops before tackling the deck winches. As with the fife rails, the pump is not glued down yet. I'm waiting until the masts can be set in place to help with positioning. Most of the pump is made out of brass. The wheels were perhaps the greatest challenge. What you see below is how I managed it. I first formed a ring out of brass wire and then drilled holes to receive the spokes. I then made the hubs by drilling receivers for the brass spokes in solid brass rod. I kept both hubs together, as you see in the middle pictures, until I could lace the spokes and solder. After the first wheel was finished I parted it from the rod and moved to the second. In my first attempt at this I cut the hubs out first which was disaster as it was pretty much impossible for me to manipulate the hub while lacing the spokes. Leaving the hubs attached to a rod make it much easier as I had something to hang onto during the assembly. The pump cans came next. I filed a face on a brass tube (see first picture) and then cut sections that then got soldered together in pairs. That worked out great. The iron support posts were pretty tricky but was able to make mostly out of brass (middle picture). The problem came when trying to solder the opposing ribs. The part would heat up too fast causing the entire assembly to fall apart. The solution was to glue in wood and then shape (third frame).

- 100 replies

-

- Cutty Sark

- Sergal

-

(and 1 more)

Tagged with:

-

Congratulations! Glad you have it under glass and really like how you did the sails. You can be proud. Ron

- 42 replies

-

- Cutty Sark

- Sergal

-

(and 1 more)

Tagged with:

-

Most of this update is work done about a month ago, at which point I had to stop ship building and tend to a couple domestic projects before the weather shuts me down. I had to chainsaw up and split two very large trees that blew down this last spring. I then restructured an external wall in my house so I could install two new windows. Everything seems to happen in threes, so it was no surprise when my geothermal heat pump broke down needing some significant attention. All of that is behind me now and today I am just resting my bones and thinking about ships. Bollards. Made all of them out of brass, which is very suited to the task. As usual, I didn't appreciate how much work they were going to be. There is a dozen of them in total, some very small that mount to the main deck rail and the biggest ones that mount on the main deck. The largest ones on the main deck, in reality, also can serve as vents. I added a picture of some men restoring the brass screw vents. I had intended to add unpainted brass caps to my bollards but decided not to when I realized they were painted over with black paint at early Falmouth. A lot of brass was painted over at that point in time to save on maintenance. Fife Rails. It is often said that it is important to research the period in time that you intend to model. Over a ships history so much can change and that is especially true of CS. The fife rails are a good example of this. The as-built arrangement of main deck fife rails is different than what you would see in today's restoration and again different than what you would have seen at early Falmouth. At Falmouth the foremast was flanked by two rails, one square-posted (fore), the other round-posted (aft). The main mast had one (fore) square posted rail, where the as-built arrangement would have had an additional aft mounted square-posted rail, which apparently ended up going to the foremast when the Portuguese owned the ship. In today's restoration the round-posted fife from the foremast is now aft of the main mast and bilge pump. The early Falmouth arrangement was no doubt executed by the Portuguese, and probably when it was re-rigged as a barkentine. Wish I had more pictures to share of my work. I seem only to have pictures of how I made the square-posted sheave escutcheons. The square-posted version has three sheaves on each post where the round ones have a single sheave, which I have yet to complete. I have not glued down the rails yet as I'm still not sure of the spacing from the masts. I included a ca1922 picture provide by Longridge of the foremast arrangement at Falmouth. It looks to me that the aft rail sits closer to the mast, but not sure. Originally, the round-posted rail was located where the square-posted fife sits. It was brought to my attention that the binnacle would have been kept polished and I had to agree, even though I'm sure its maintenance would not have been up to seaworthy standards. I tried my best to polish it without breaking it off and then lacquered it. At some point I'm going to shave down the wheel grips a bit as they are simply too big for my liking. Here are a couple overviews of the ship. Getting there... slowly.

- 100 replies

-

- Cutty Sark

- Sergal

-

(and 1 more)

Tagged with:

-

Hello Julie, Am enjoying your work as you come at this sort of project with a unique background and diverse skill sets. I find it very interesting and refreshing. Had never considered using hide glue on my model. Personally, I use a variety of adhesives but mostly 5-minute epoxy and some CA. I have used hide glue for decades on various restoration projects, primarily veneering. For sure it has many advantages, but convenience is not one of them. I'm curious how the hide glue works for you in ship modeling. Keep up the fine work! Ron

-

Haha. Yes, I asked the young cadets where it was stowed, and they had trouble finding it. I'll take pictures for a later post, but I did my best to brighten it up without breaking it. I then coated with lacquer to slow or arrest tarnish. It does look more "right." For such a small part, a little dark contrast helps give it dimension and that is still the case as I could not get into all the crevices. My feeling is that when the cadets were on board they would have been charged with such tasks as polishing the brass, if only occasionally. I have one picture of the binnacle in early Falmouth that shows it with large blotches of corrosion. B&W pictures can be hard to interpret, however. I'm happy with how it now looks and so is my wife (which has good taste is such things). Bob, your Staghound is moving along at warp speed. Meanwhile, I must have spent the last two days just making bollards. The accumulation of detail is really starting to bring her to life. Alway feel inspired by your attention to detail.

- 100 replies

-

- Cutty Sark

- Sergal

-

(and 1 more)

Tagged with:

-

You are right, of course. Don't know what I was thinking. Thanks for sobering me up! I'll be sure to feature the polishing results in my next update and am sure it will really improve the look. Ron

- 100 replies

-

- Cutty Sark

- Sergal

-

(and 1 more)

Tagged with:

-

Seemed like a good point to share some work. July was a super busy month for things other than CS. August has so far been relatively quite so have spent time working on smallish details that are important but are hugely time consuming. Makes progress feel very slow. The original binnacle is quite tall in real life at approx. 2 feet. The original stayed on the CS deck while at Falmouth and during this time was occasionally repositioned. I profiled the binnacle body on my 1/2" electric drill, from a brass fastener I found in my junk pail. The head turned out a little too big so proportions are a little off. No big deal. I soldered on the exterior parts and then blackened. I scoured off most of the black to get something that looks tarnished. My wife says it needs to be brighter so will probably comply. I floated some clear epoxy in the view port cavity to look like glass. Making the floor grate that the helmsman would stand on was quite difficult. The only way I could make this was by printing out on paper a scaled grid and then tack parts to it with CA. This helped a great deal with keeping the spacing close to correct. When it came time to cross-cut the grating I glued two strips of scaled grid to the front and then used a jewelers saw to make the cuts free-hand. Should have used a small razor saw as there was too much flex to the jewelers blade allowing for some drift. Still, it worked out. Once all the wood pieces were in place I peeled off the paper backing and sanded out. I intentionally made the whole assembly thicker to allow for sanding. Up to recently I never considered that these grates were very important in keeping the deck from getting worn down, in addition to improving footing. I made a ladder for each of the two main deck houses. They are super small so used the same technique as with the grating. I'm showing the paper peels that came off almost intact. I stained and then sealed all the wood with shellack before assembly which no doubt helped with paper release. You can see in this image one of the four mooring pipes I put in days ago. Made three sets of steps, one for the forecastle and two that lift you to the poop deck. Tried pretty hard to get the stair profiles to look right. Before I could fit the forecastle steps I had to install my Walker windlass and make the forward hatch (formerly a companionway). I also had to paint the brass studded chain which would have been a nightmare without my airbrush. Hand painting that small chain would have looked terrible. As the model progresses I will judicially add some weathering powders to the chain. I added two chain pipes to my windlass, wrapped the chain onto the wildcats (pocket drives) and then glued in place. The windlass serves only to hold the chain ends as you can not see it without a borescope. I could have completely left it off the boat but as I have said before, it is important to me to have it there. I also installed the poop smoke stack. At this point in her life the stack was not in use and is cut back and capped.

- 100 replies

-

- Cutty Sark

- Sergal

-

(and 1 more)

Tagged with:

-

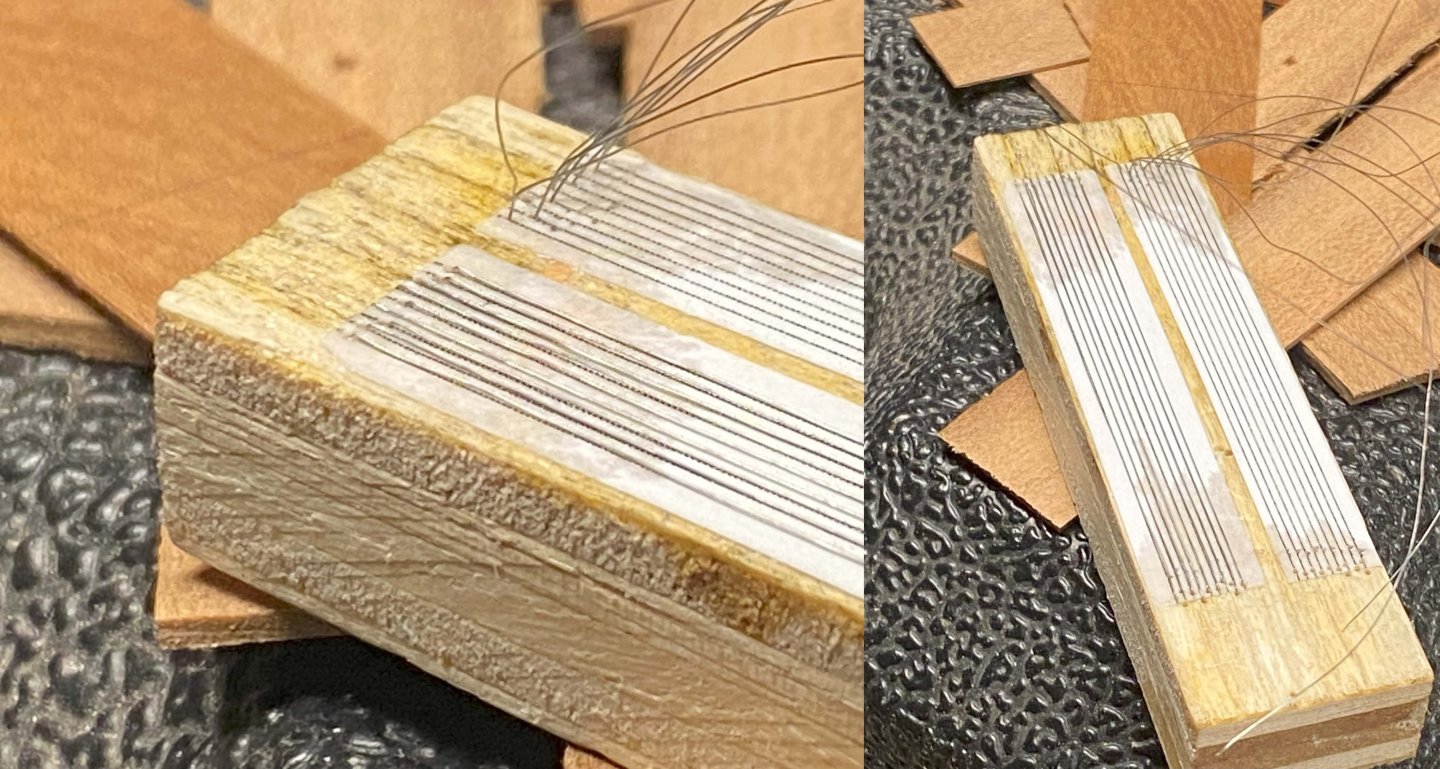

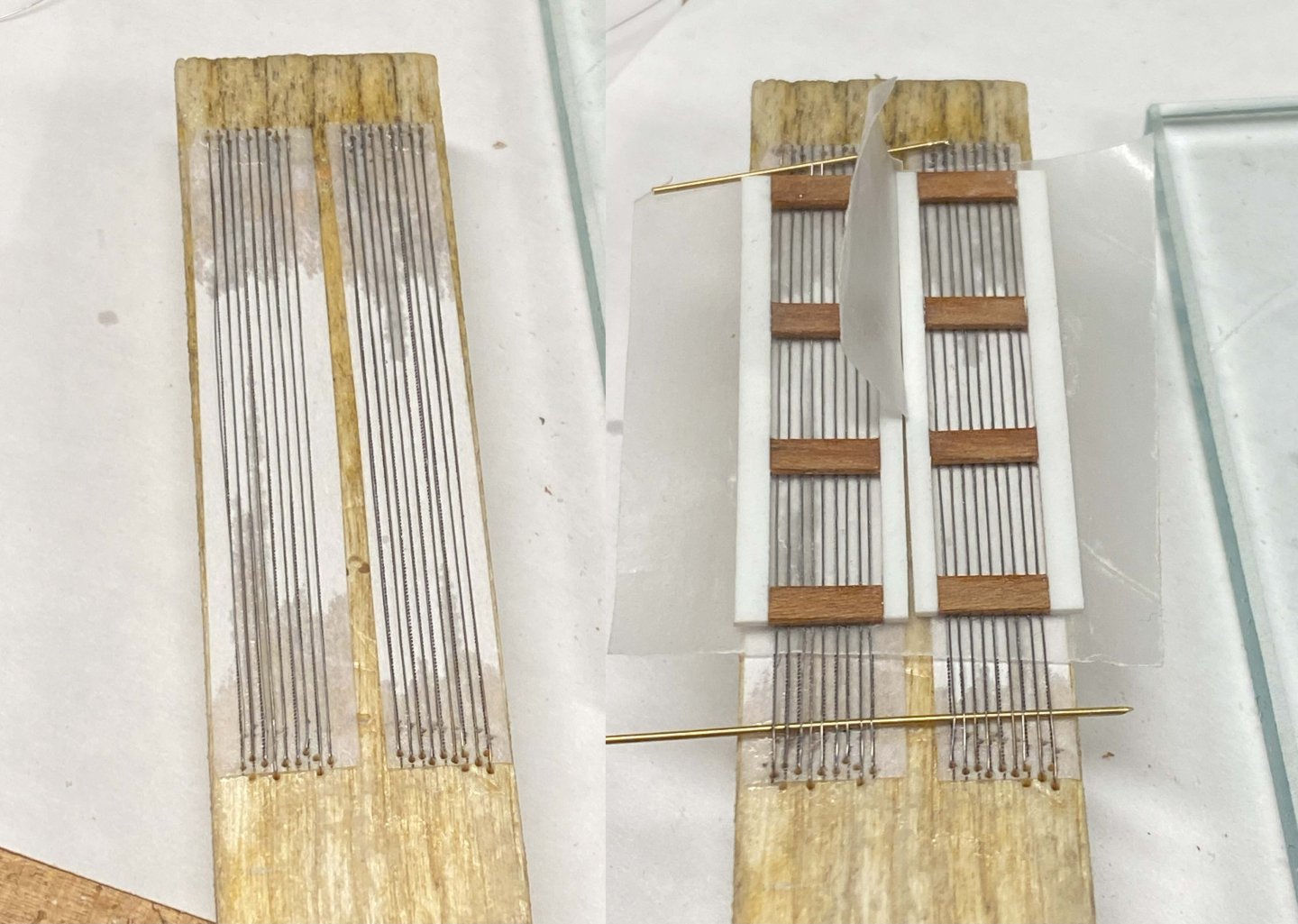

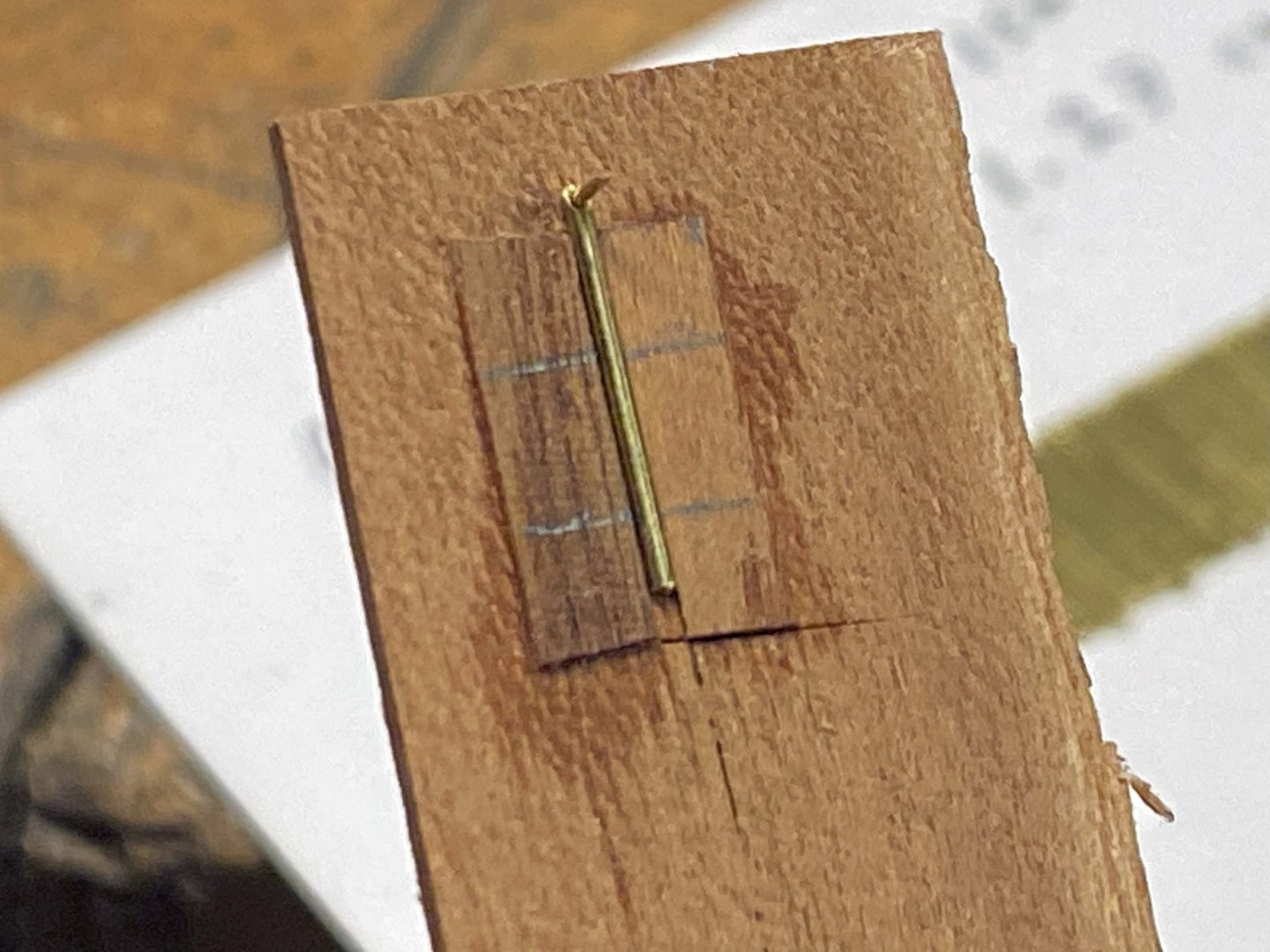

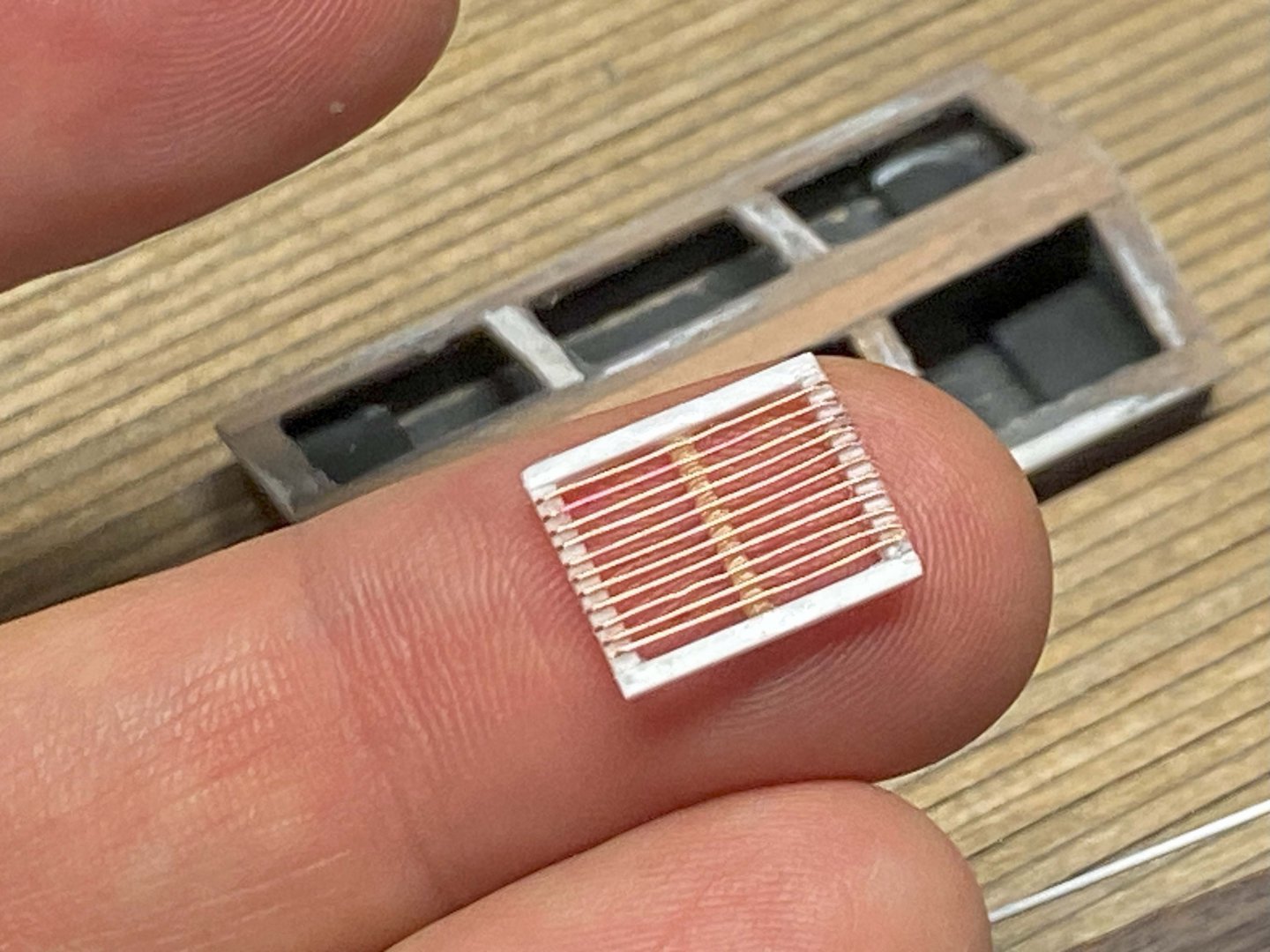

Fourth time the charm? This will be short. After placing my new helm on the CS, something simply did not look right. Turns out the poop skylight I had just finished redoing was way too large. It made everything around it look wrong. Proportionally it was not too bad unto itself, but the overall size was way too big. I did not check the dimensions against Campbell's plans, which was a huge mistake. Of course, smaller is harder. The big problem was reproducing the metal protective bars. The fine electric motor wire I used in my last attempt was now far too big. I ended up sacrificing an old USB cable to harvest the fine wire within. Of course, the fine wire was a nightmare to work with. The bars add a great deal to the look so really wanted to have that modeled. This is what I had to do: These closeup pictures make the wire look not so bad. Reality is, it was like working with baby's hair. I tried all sort of ways to stretch this wire into a pattern so I could then glue it to the panels. I tried double-sided tape, etc., to hold the wire into position but it always allowed too much creep. I printed out two paper patterns with spacing that I felt would work and then glued to a piece of plywood. I then drilled holes at either end to insert the wire and then soak with CA. On one end the holes go all the way through the wood so I could gently pull the wire taut and then fix with CA. This method worked fairly well but several of the wires broke during the process so had to redo them. At the end, some wires ended up slacker than others. I re-tensioned the wires by using a couple small brass rods. I then slid a piece of wax paper under the wires and then pressed down the skylight panels while introducing CA under the wood stiles. A very tedious process but got away with it. Once the glue had set up, I cut the panels away with a razor blade. The wire spacing could be improved a little after-the-fact by pushing the wire around with a needle. The results are not bad but still need to clean up the bars a little and try to straighten/space them a bit. The new skylight tuned out to be ~20 percent smaller, which magically made everything look and feel much more balanced.

- 100 replies

-

- Cutty Sark

- Sergal

-

(and 1 more)

Tagged with:

-

Thanks, Peter. The wheel was a real challenge. I will absolutely not try to improve on it, as I sometimes will do. Tough to be a perfectionist. I'm starting to get antsy to move on to masts and rigging. Love how your CS is coming along and looks really close to being finished. Are you going to case it? I hope so. Ron

- 100 replies

-

- Cutty Sark

- Sergal

-

(and 1 more)

Tagged with:

-

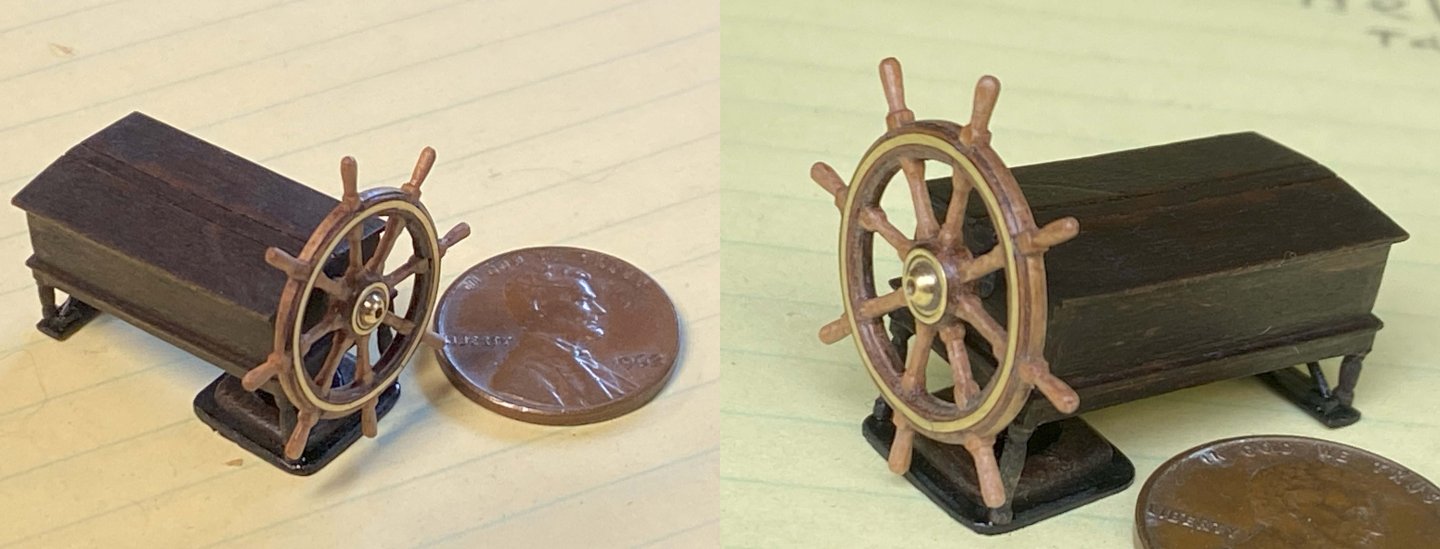

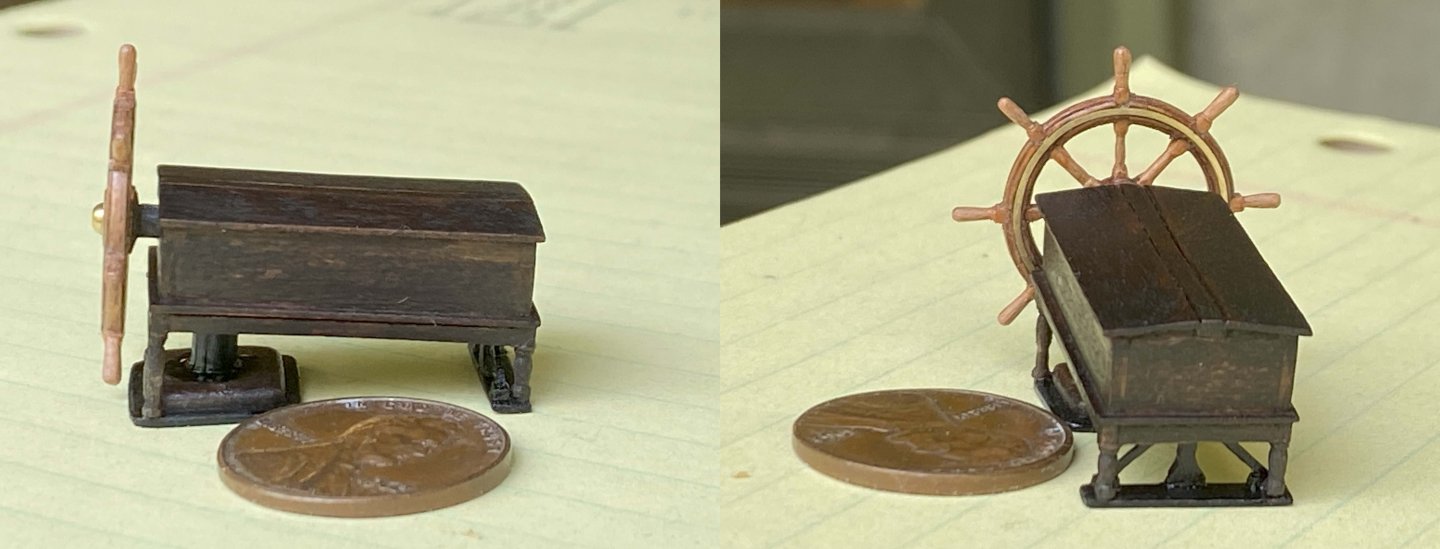

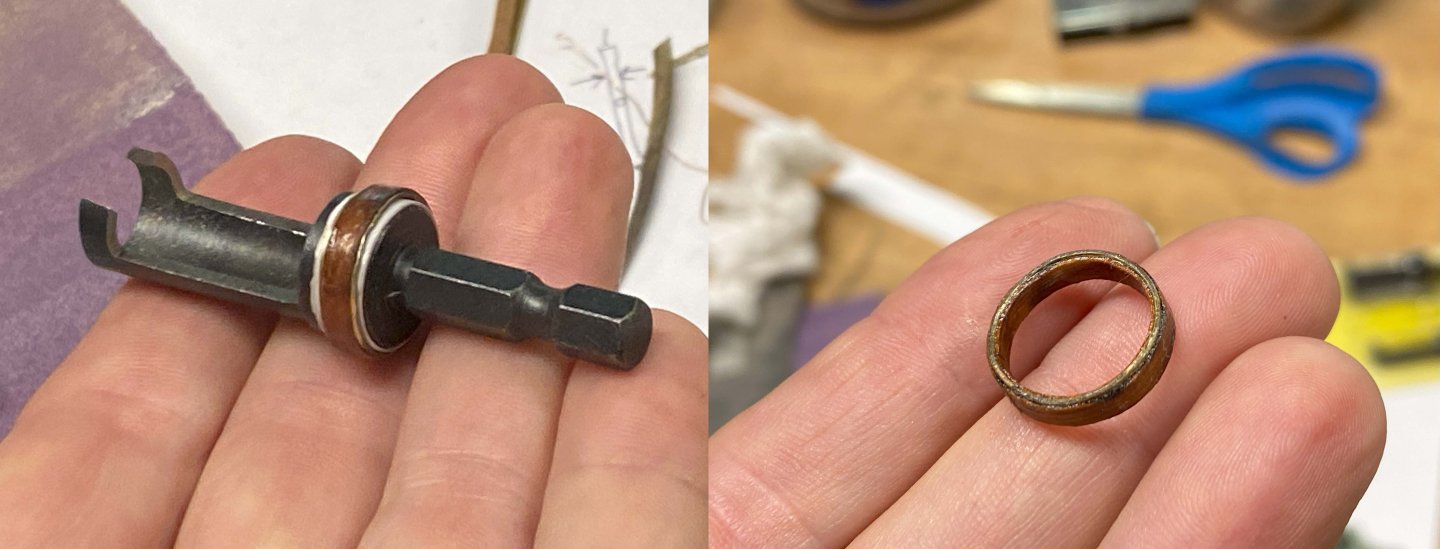

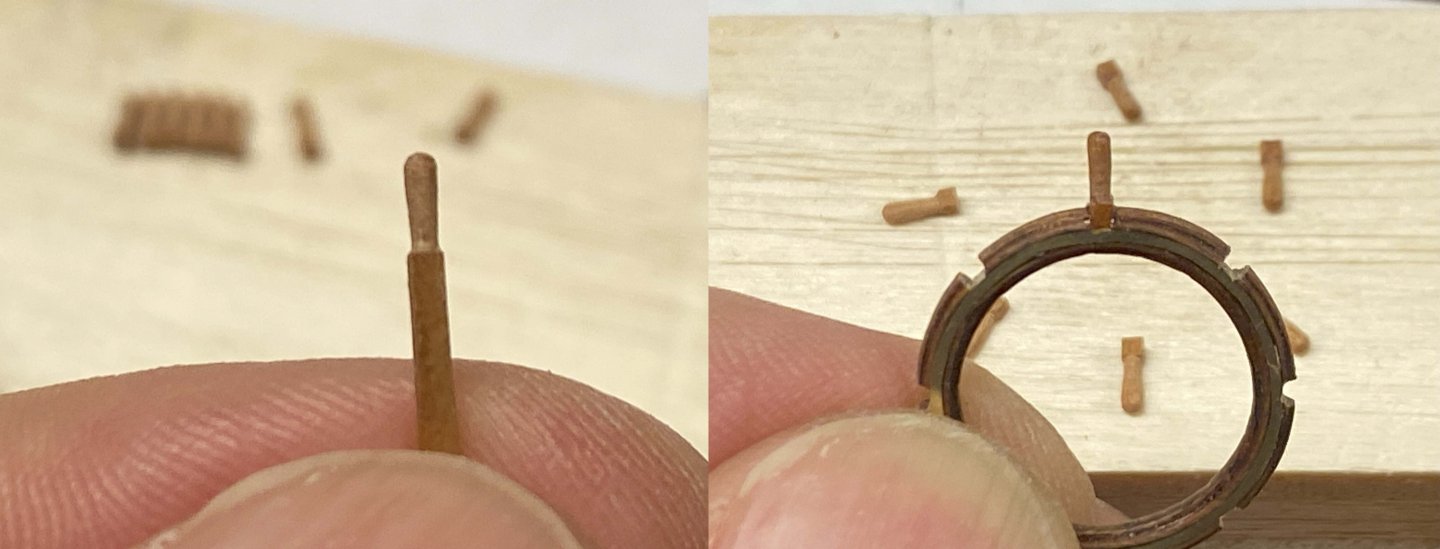

Lots going on around the house this last couple of weeks. Lightning took out a lot of my electronics and black bears have added my home to their rounds. Electronics have all been repaired or replaced but I have not figured out how to keep the bears out of my cultivated raspberry patch. The cold war has begun. Despite all the recent drama, I have managed to model the CS helm. Maybe it's me but the ship's wheel is one of those features that I invariably look at first when viewing a model. It needs to feel realistic enough that I can smell the salt. For that reason, I poured a lot of sweat into this. Lacking modern conveniences such as a small lathe and mill, I knew this was going to be painful. I used the Campbell drawings to guide me in addition to LOTS of pictures, both old and new. The feet on the steering mechanism enclosure are turned in my model, as they were at early Falmouth. My guess is the legs were original to the ship. At some point in later Falmouth the legs were replaced with square ones as seen today. There was also an emergency tiller arm under the enclosure that I decided not to include as you simply would not see it. The emergency tiller had two eyelets that could be hooked up to tackle to steer. The brass facing on the CS wheel is a highly recognizable element and I definitely wanted to somehow create that. My best bet was to hammer out some brass rod and then form a ring. In order to hammer the brass flat, I had to repeatedly anneal the brass by heating to red and quenching in water. It would otherwise become so springy from hammering that it would become unworkable. I used a plug cutter as a mandrel to form the brass ring and also keep it stable while I glued a 0.5mm thin cherry strip over the outside surface. Once that was done I did the same thing on the interior face. Once the outside lamination had set up the ring became very dimensionally stable. I made the ring assembly quite wide and needed to be file dressed down to final dimension. Once that was done I laminated an additional layer inside and out with slightly narrower cherry strips. Altogether, this mimics the original wheel construction. Making the grips and spokes was a massive headache. I made up 1mm square "sticks" for this purpose and tried to turn the profiles using my hand held Dremel tool. I don't know what the slowest RPM is on this tool, but it proved to be way too fast causing the frail sticks to self-destruct. The solution was to hand carve each one. Not too bad as there are only 8 grips. I used a razor blade and tiny files and did all the work free hand. Naturally, there is a lot of variability between each part but not enough for my eye to easily catch it. After the grips were made I cut notches on the wheel using nothing more than a razor blade. The hub is made up of two brass tubes and a solid bar which I happened to have on hand. Forming the central cap was done on my Dremel. I had to skin over the hub with more 0.5mm cherry and that turned out to be one of the more difficult tasks. I used a soldering iron to heat-bend the strips for the outer wheel, but heat alone would not work over a 2mm radius. So, I soaked a strip in ammonium hydroxide overnight and then made a couple wraps over a scrap piece of brass tubing of the same diameter. Once dried the wood held its shape and could then easily be glued into place. As an aside, I have recently read a few posts critical of the use of ammonia for bending wood. Personally, I have used ammonium hydroxide in general wood working for decades with absolutely no issues. Ammonia gas dissolved in water gives you ammonium hydroxide. Wood in general is slightly acidic, so soaking in ammonium hydroxide will neutralize the acidity (think paper document deacidification). The ammonia goes off as a gas leaving water that then evaporates. I would rather risk the wood being slightly alkaline over acidic. I ended up making the spokes free handed as well. Given their size, adding much detail by hand was almost impossible for me. Interestingly, the Campbell drawing of the wheel illustrates a different spoke turning profile than the original. I attached the spokes to the wheel the same way as the grips. It became painfully obvious that trying to install the spokes with the hub in place was going to be far too difficult. Instead, I glued in the spokes and then carefully radius the ends with a file until the hub fit. Sounds difficult but ended up being quite easy. Just had to be very careful and use a backing so the spokes don't break out.

- 100 replies

-

- Cutty Sark

- Sergal

-

(and 1 more)

Tagged with:

-

Rob, thanks for the complement. Means a lot coming from you as I respect your work immensely. Taking a few days off then will decide what to work on next.

- 100 replies

-

- Cutty Sark

- Sergal

-

(and 1 more)

Tagged with:

-

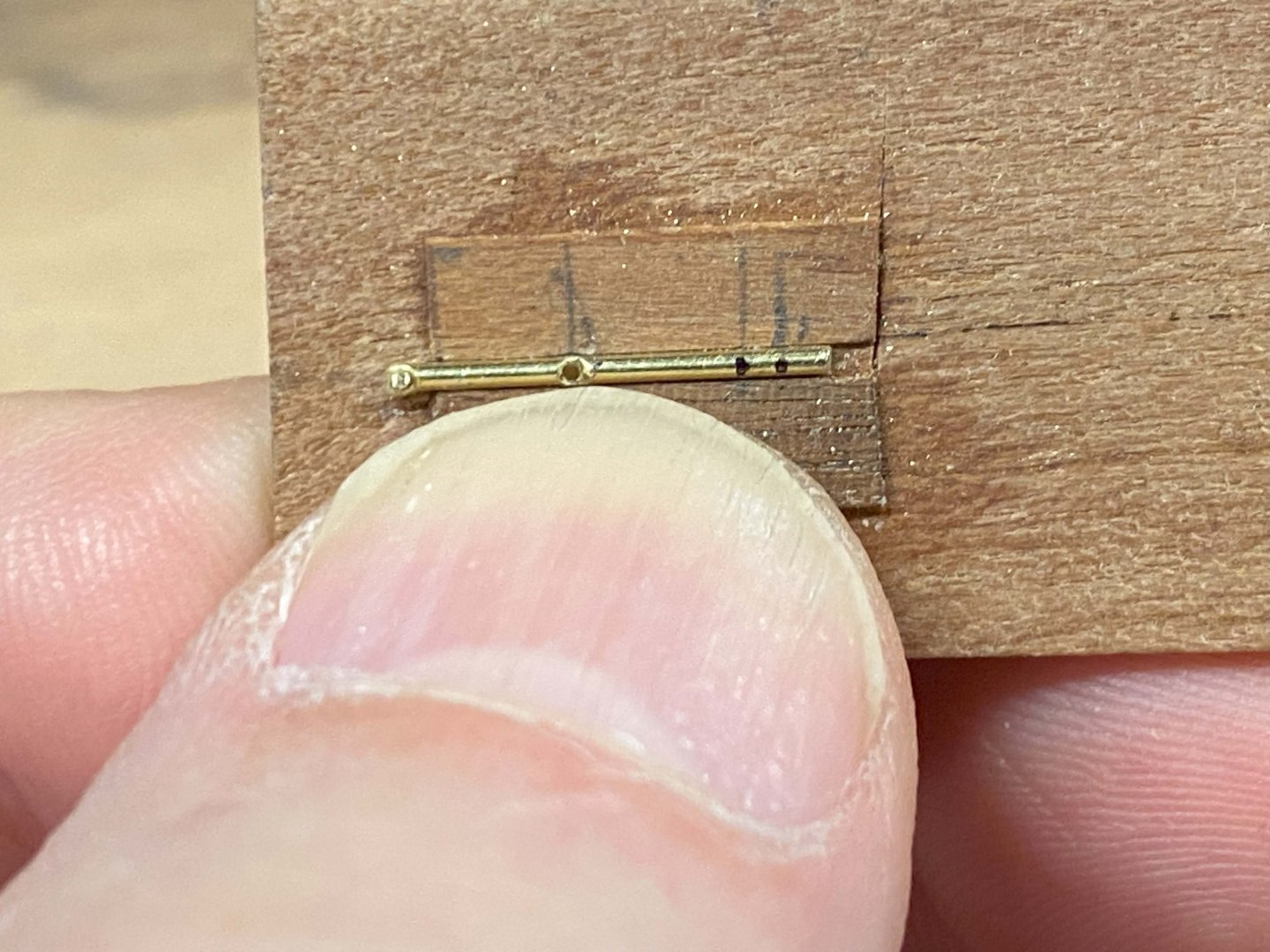

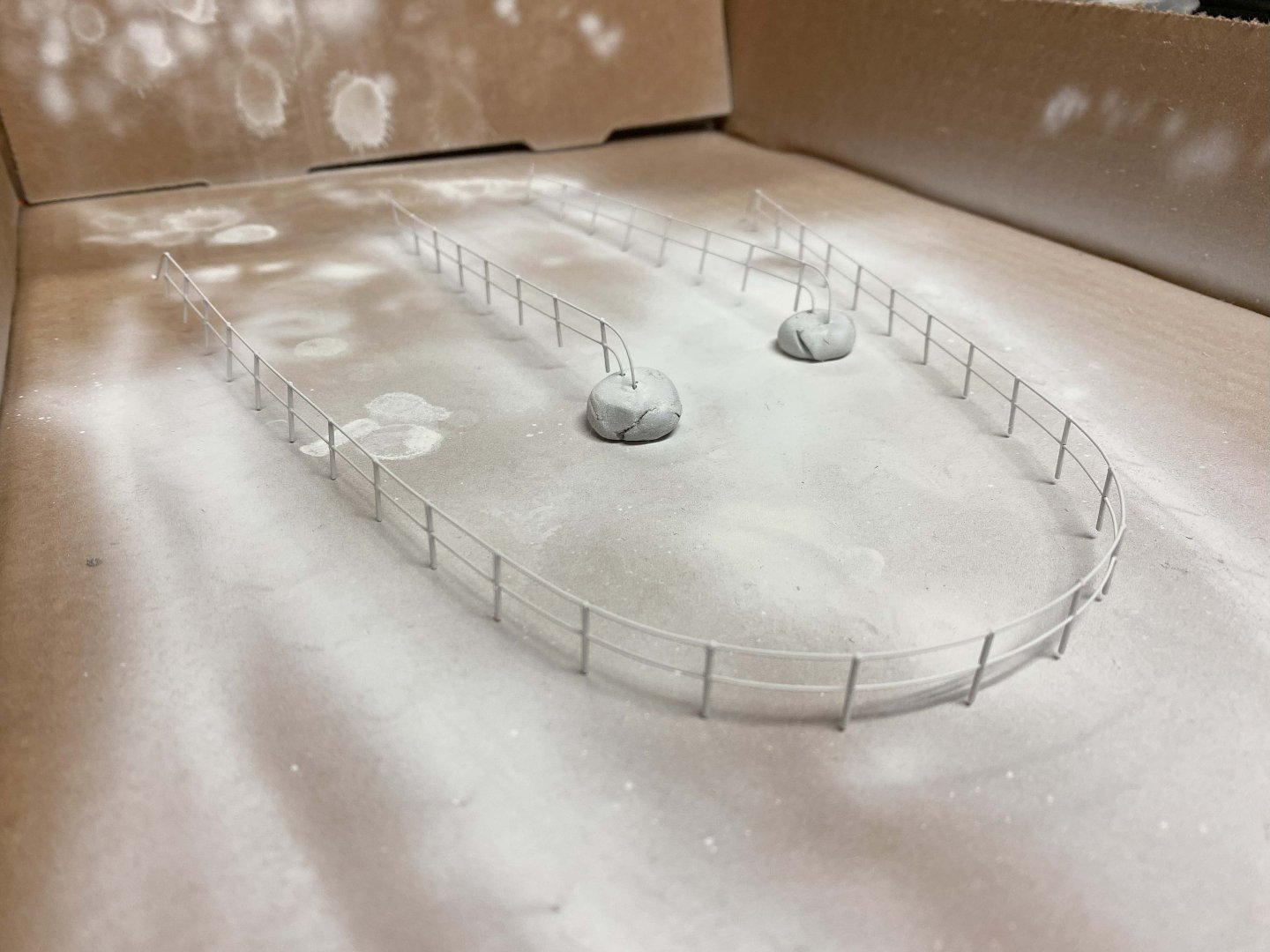

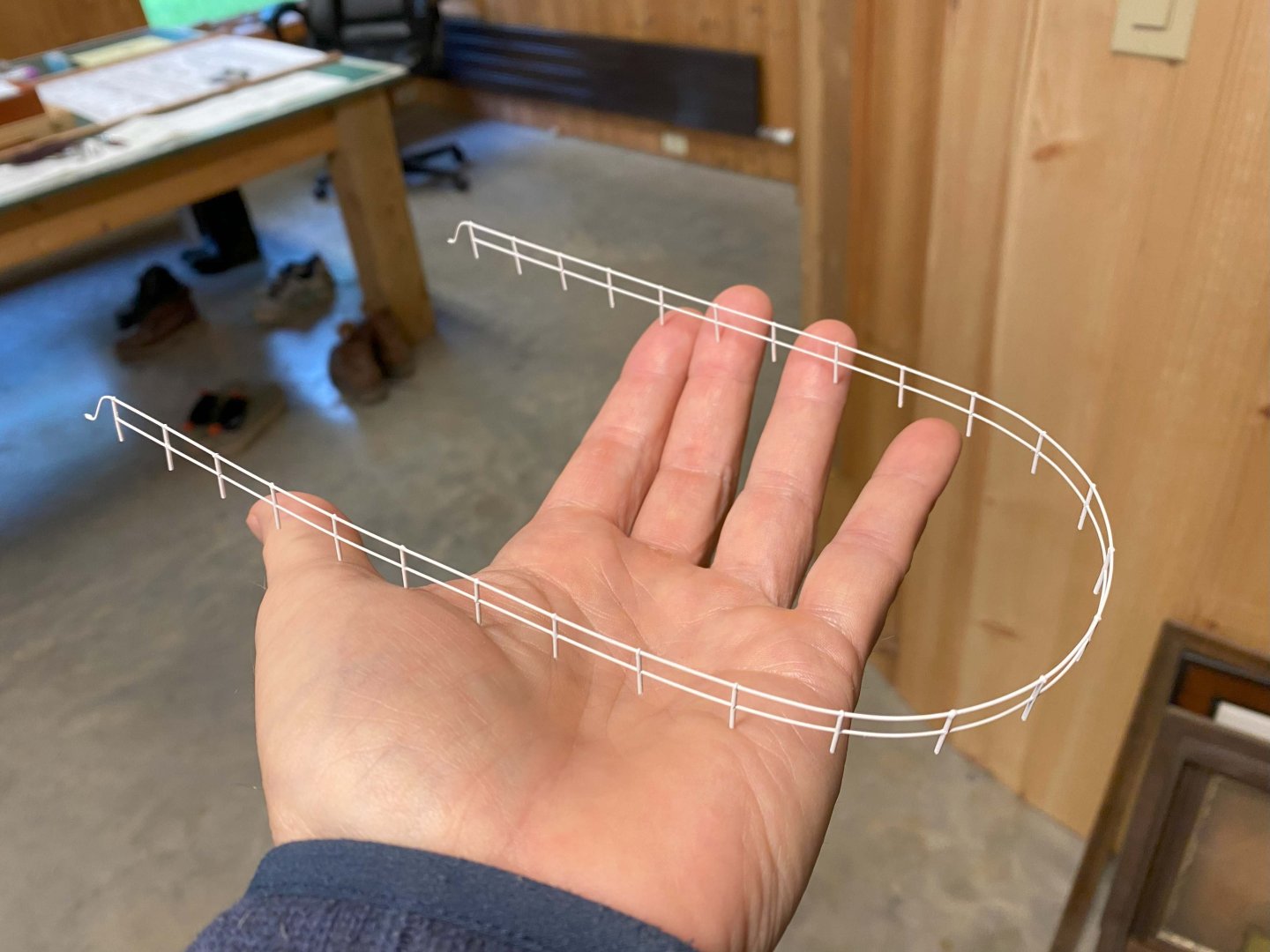

Finished the outer railings and am happy that is behind me. The job required a little trial and error but worked out in the end. Started out making all the stanchions using the same methodology as in post #48. This wasn't so bad. Trying to accurately place the second course rail turned out to be the trick. Like with the top rail I wanted to evenly, and symmetrically, crimp the brass rod before drilling. This would make it easier to drill the second hole and also give the solder a place to build up to yield something of a spherical look. My attempts at flattening the junction with a punch sort of worked but was far from repeatable and definitely not symmetrical. I ended up partially sacrificing a small pair of end nippers to do the crimping. I gradually ground out a gap in the jaws until I could crimp the rod to what looked like a good depth. Trial and error. The tool worked exceptionally well. Next came drilling the hole, which for the second rail is 0.45mm. Top rail is 0.5mm. As was suggested to me, I made up a prick punch out of a 1/16" HSS drill bit. I ground the end to a sharp point. Trouble was, the target is so small I could not accurately guide the punch to the correct spot due to shadows, my eyesight, fingers in the way, etc. More importantly, even lightly striking the punch would tend to fold the rod at the flat and seriously weaken the intersection. In the end I had little choice but to free hand the drilling. Took a while and only ruined about 3 stanchions in the process. I made a little jig to hold the stanchions for locating second railing hole. Kind of crude but made a really nice crimp. The crimp. The process elongated the stanchion by 1mm. I also added a reference mark that would be top of wood rail and one for total length. Pretty small. Looks like a string of firecrackers. Before trimming to length. I pressed each stanchion into a drilled hole (no glue) and then strung the wire rails. On a tight radius I had to feed the stanchions on one at a time. Once everything was in place I went around and soldered each intersection. Once everything is soldered, I could carefully remove the whole assembly to file imperfections and paint. It was surprisingly durable. Once painted I simply reinstalled.

- 100 replies

-

- Cutty Sark

- Sergal

-

(and 1 more)

Tagged with:

-

Correct. Specifically, early Falmouth just following Dowman's re-rig/restoration. Been thoroughly enjoying your Staghound project. I have learned a great deal. Also, very glad you are feeling better. Kidney stones are no joke.

- 100 replies

-

- Cutty Sark

- Sergal

-

(and 1 more)

Tagged with:

-

Another cold, wet day so decided to reno some recent work. Some of you may have noticed I tend to re-do a lot of my work. For sure, that is true. The poop skylight just looked too crude after a successful railing job, so attempted an upgrade, in situ. Same process as in last attempt except more experienced this time and also found some fine wire in my e-waste bucket, a small electric motor. I harvested the wire (0.16mm OD) which is far thinner than used in my last attempt and scales much, much better. Again, the "rods" were placed free handed. Tracking between rods look much better this time. Very hard on my neck muscles. Now that I'm happy with the skylight I will go back to working on the railings.

- 100 replies

-

- Cutty Sark

- Sergal

-

(and 1 more)

Tagged with:

-

Thanks for the tip. I think your approach will be needed for the outer two-course railing. My biggest challenge is not to let the hole distance between top and mid rail to fluctuate. The railing would end up looking terrible. I'll need to make or order something I can use as a mini punch and fabricate a fixture to hold the little stanchions from rolling around. I see this as a two-stage process where I'll use a small flat tipped punch to slightly flatten the intersection and then mark drill locations. I'm starting to feel better about this.

- 100 replies

-

- Cutty Sark

- Sergal

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.