-

Posts

400 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by kgstakes

-

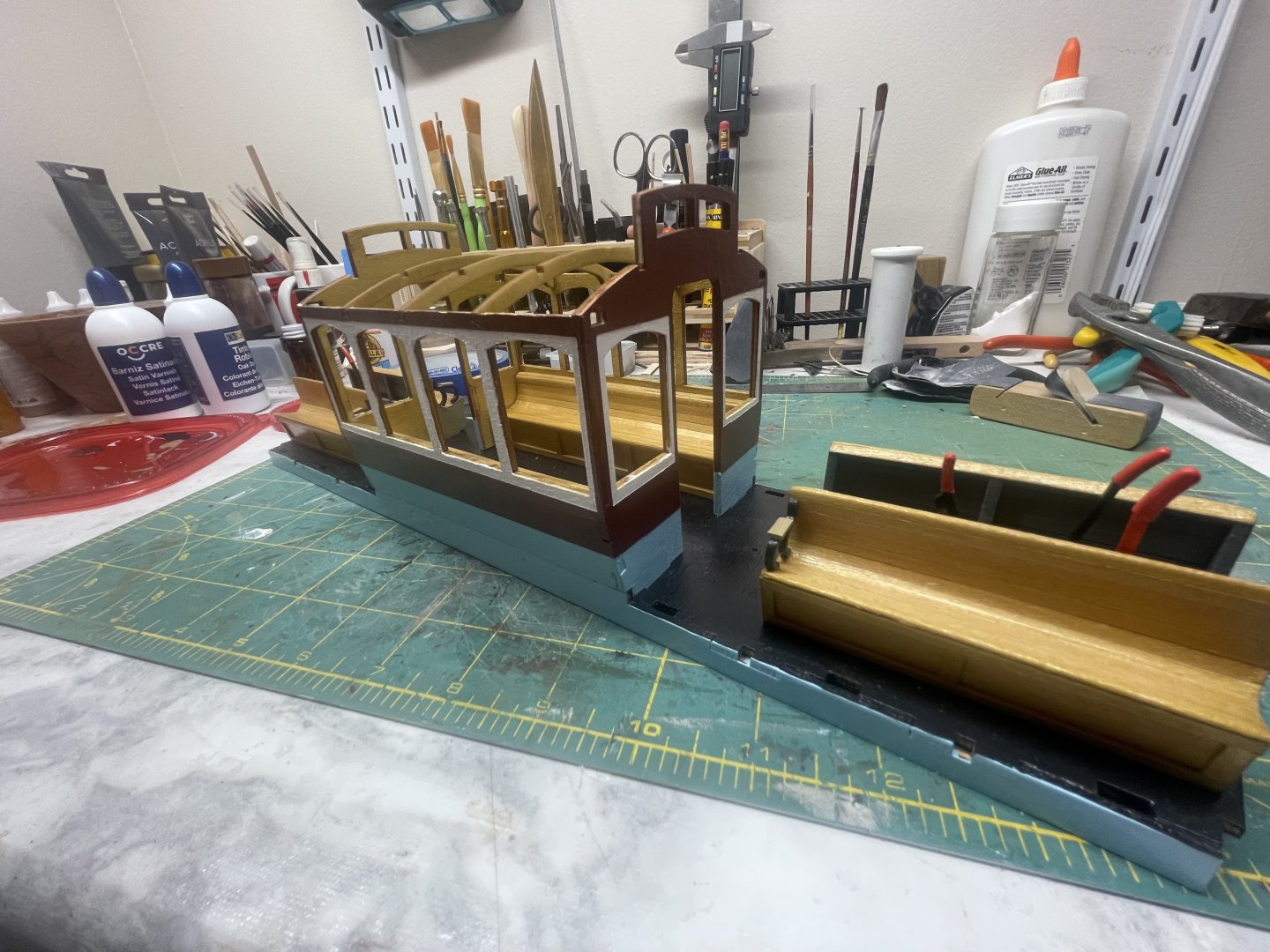

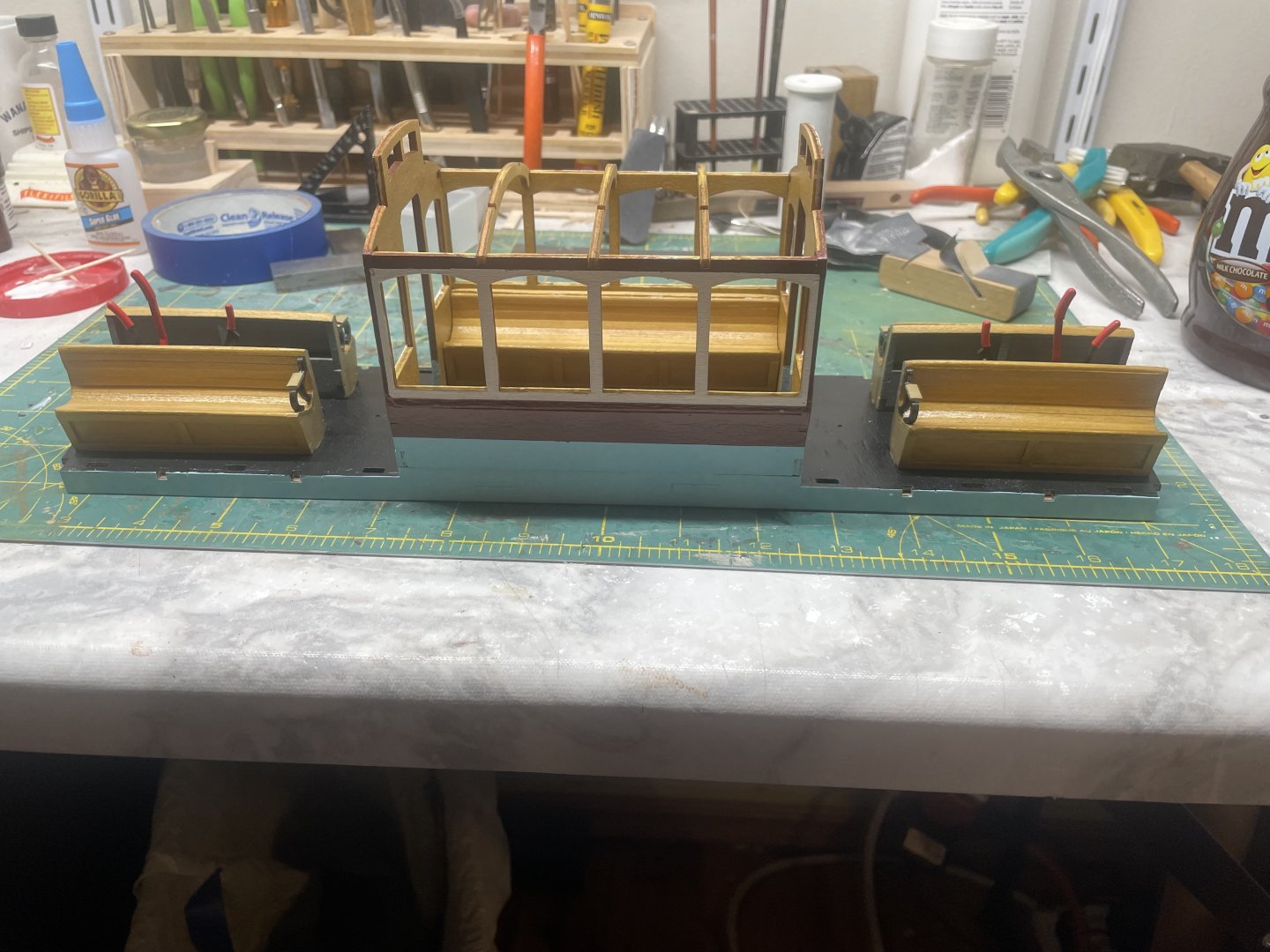

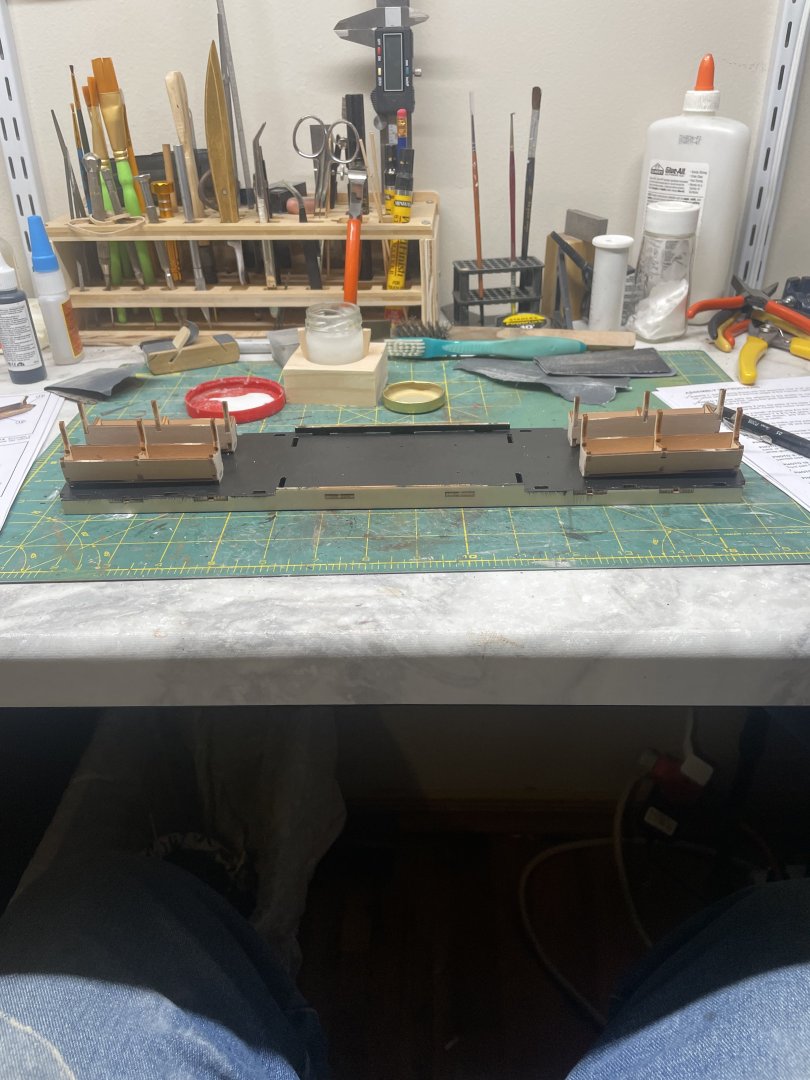

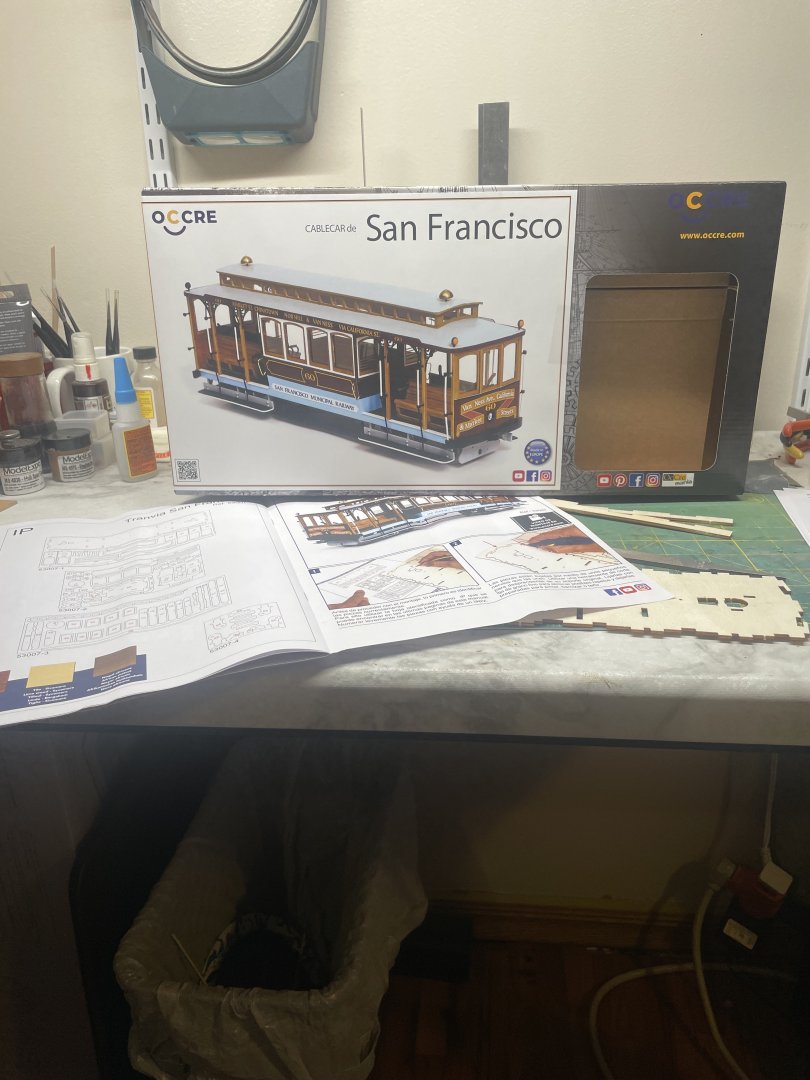

San Francisco cable car by kgstakes - FINISHED - OcCre

kgstakes replied to kgstakes's topic in Non-ship/categorised builds

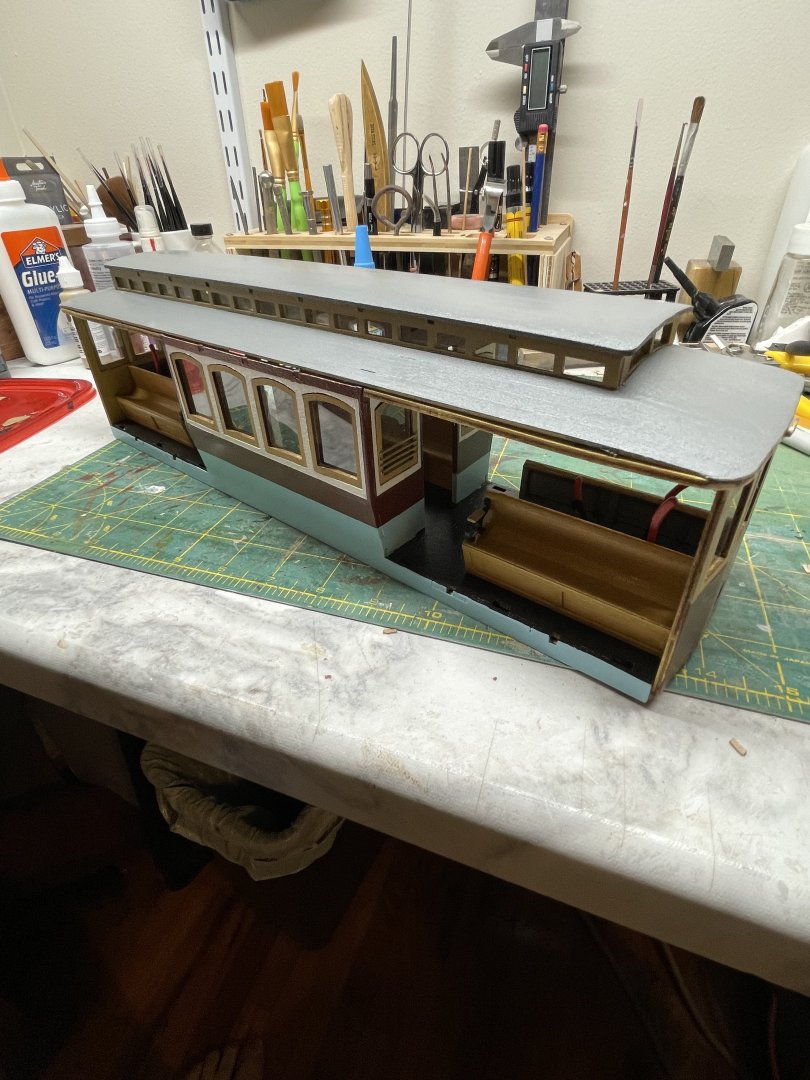

Finished the roof and some inside details over the weekend. Next a few details and then the trucks. Nice build straight forward. -

San Francisco cable car by kgstakes - FINISHED - OcCre

kgstakes replied to kgstakes's topic in Non-ship/categorised builds

Started the roof this morning we’ll see what sticks and what adjustments may have to be made. Compound curves are always a pain. Soak the wood lots of glue and clamps and let dry. See what happens afterwards. -

San Francisco cable car by kgstakes - FINISHED - OcCre

kgstakes replied to kgstakes's topic in Non-ship/categorised builds

-

San Francisco cable car by kgstakes - FINISHED - OcCre

kgstakes replied to kgstakes's topic in Non-ship/categorised builds

-

San Francisco cable car by kgstakes - FINISHED - OcCre

kgstakes replied to kgstakes's topic in Non-ship/categorised builds

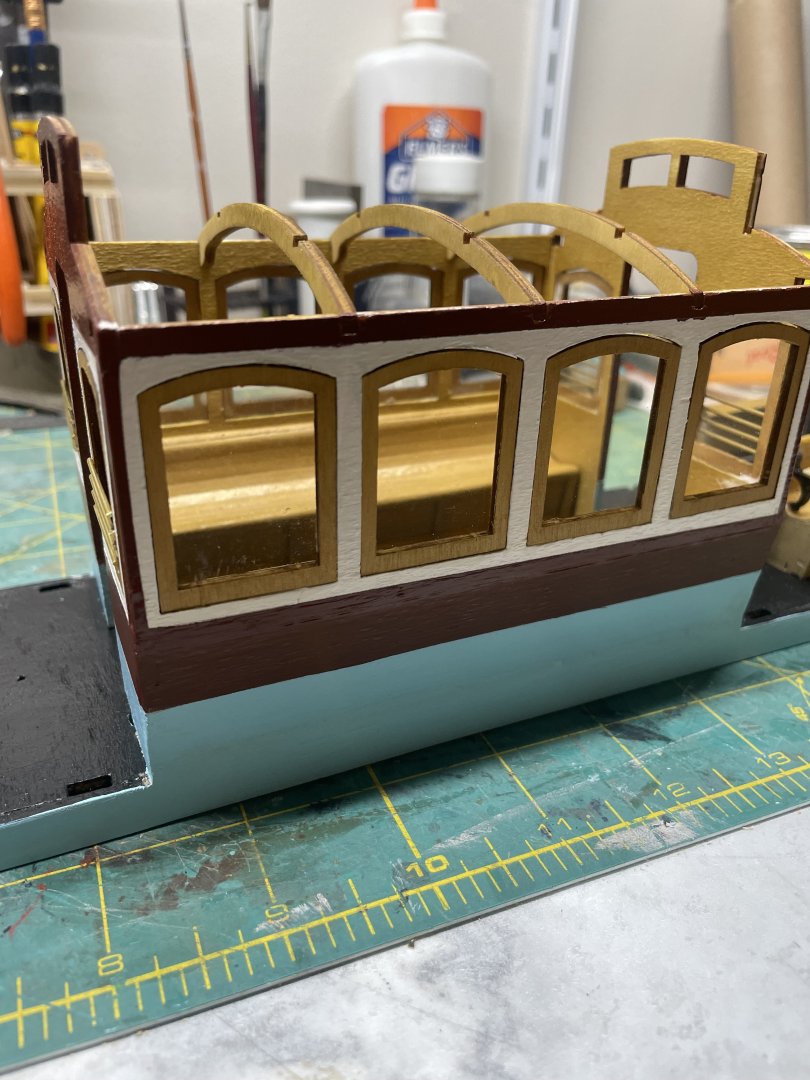

Got some work done before everyone wakes up this morning. I’ll be doing the same as the sides fill the seams and repaint the ends even though there is a sign that will cover it, I’d like to have a smooth transition between the panels and hopefully the sign will lay down better than not doing anything at all. We’ll see when that time comes. Enjoy the pictures and have a great weekend. Wife and I are celebrating our wedding anniversary today (17 years) so no more modeling today😭😂😂. -

San Francisco cable car by kgstakes - FINISHED - OcCre

kgstakes replied to kgstakes's topic in Non-ship/categorised builds

-

San Francisco cable car by kgstakes - FINISHED - OcCre

kgstakes replied to kgstakes's topic in Non-ship/categorised builds

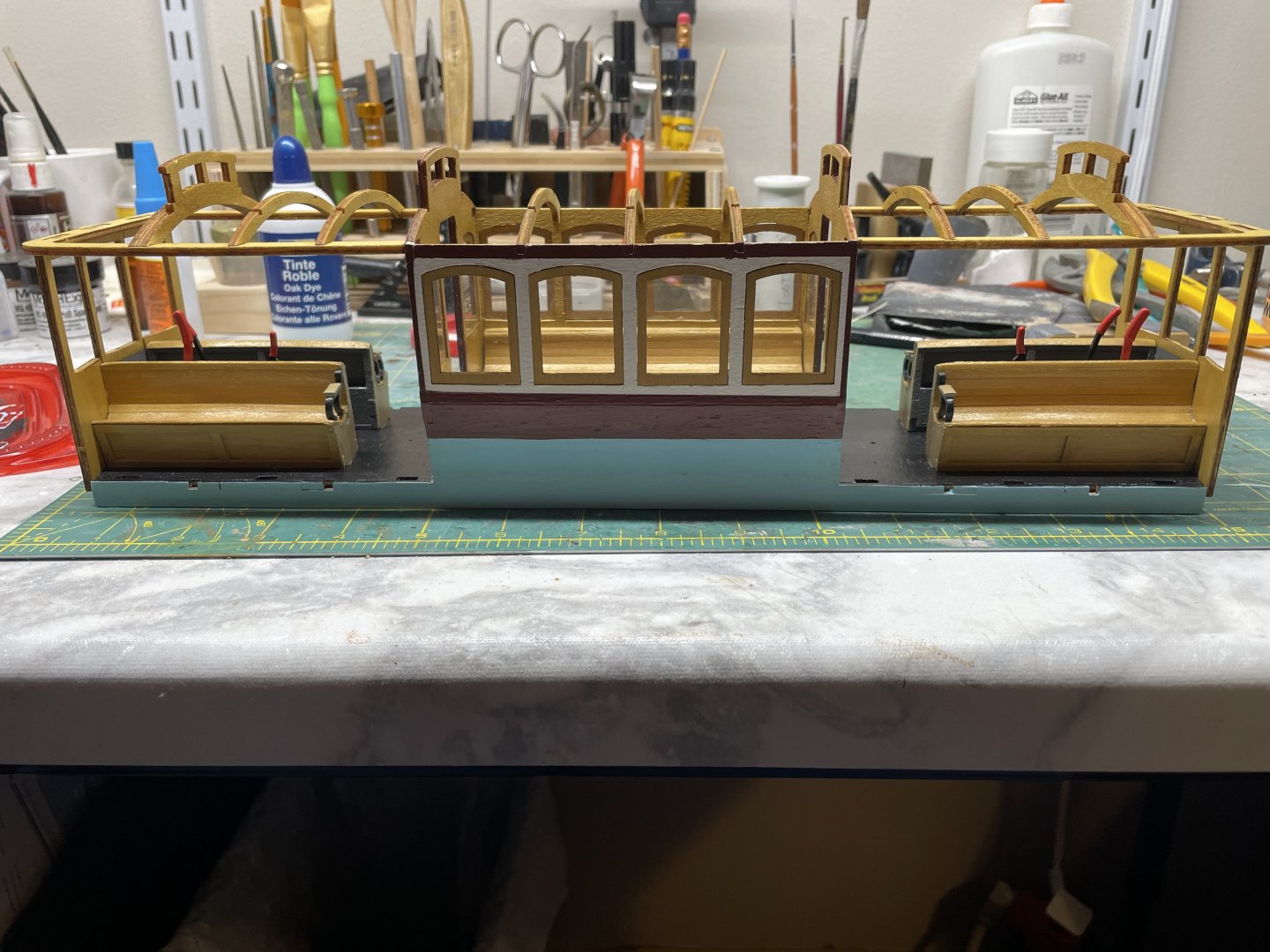

Working on the cable car today. The one thing I will be doing before I go any farther is fill in the areas that you can see the tab and slot connections. Will make the model look better when finished. I don’t like seeing those on the sides of the car. 🤔🤔🥺 -

Buckboard by kgstakes - Model Trailways - 1/12 scale

kgstakes replied to kgstakes's topic in Completed non-ship models

Actually I've built full size buckboards and they are very comfortable to ride in. The ones I've built have no springs between the body (floor) and the axles, only under the seat. This is my personal buckboard. I made my own brackets (see pic) that attached the seat spring to the seat and to the floor. Made a very comfortable ride, both for the horse and driver. I used 1/2" square stock for the curved braces for the dash which was heated in my forge and then twisted and then ends hammered flat and punched holes for bolts. -

Buckboard by kgstakes - Model Trailways - 1/12 scale

kgstakes replied to kgstakes's topic in Completed non-ship models

From what I've read about stagecoaches, they were built to travel long distances and the throughbraces for the suspension was to help the horses (easier on the horses) than on the passengers. Yes, you did get bounced around in them, even today if you ride in a stagecoach at any speed it's a rough ride for the passengers. The throughbraces (leather suspension) was to give the horses a little "give" when they were pulling the load. Hard to explain the way it works but hopefully you understand what I'm trying to say about the suspension of the coach. The body basically "rocked" back and forth and it was easier on the horses. Kurt -

San Francisco cable car by kgstakes - FINISHED - OcCre

kgstakes replied to kgstakes's topic in Non-ship/categorised builds

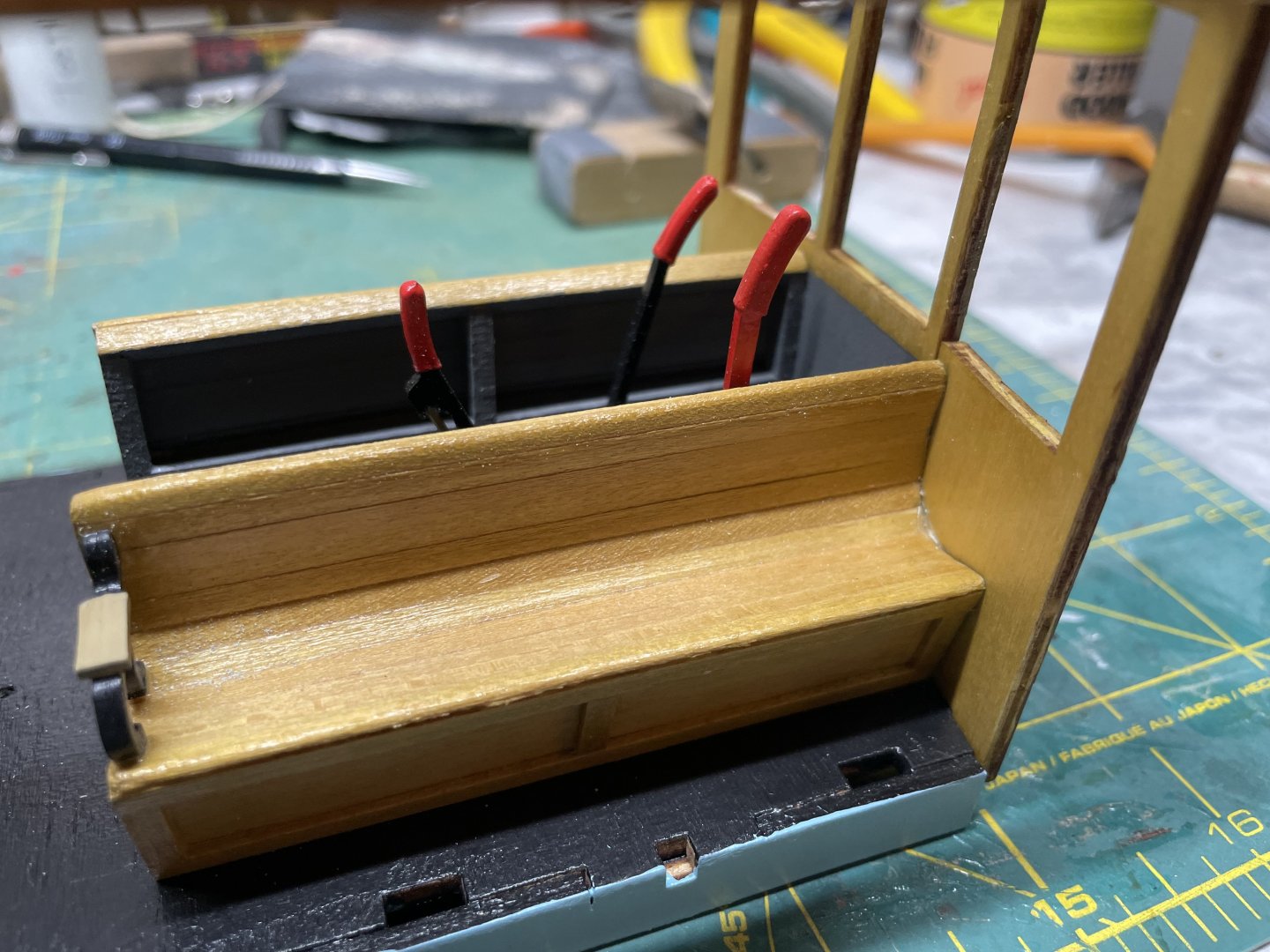

Little more progress today. Been slow going but I'm also remodeling/finishing the basement at the same time so that takes priority over modeling. Pictures show test fitting everything before I start on the "cabin" area (painting, windows, doors, etc. Benches still need some touch up and finial coat of clear finish. Been a pretty straight forward build - wish the picture directions were in English but with the text directions, I can follow and go by the pictures. -

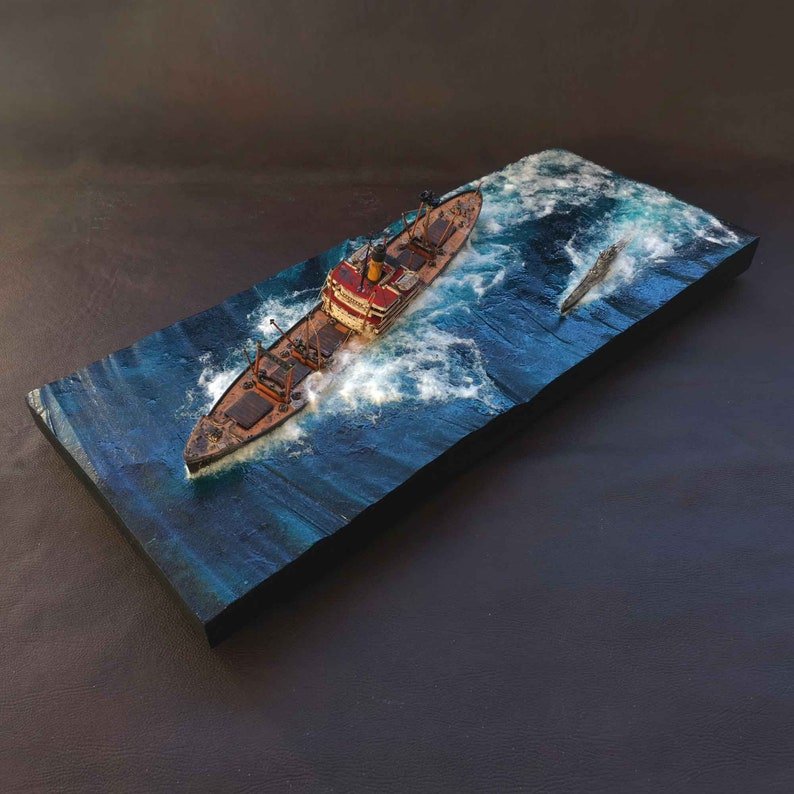

Not sure whether this is the right category to ask this but do any of you done a diorama where the ship is modeled in resin or some other “water”. Have you ever modeled a ship sinking or under attack maybe like a torpedo in the water just about ready to hit the ship or has and then you’ve done other effects to mimic a direct hit? I’ve seen some one do this and didn’t know if anyone here has done anything like that. Found this on the web for an example of what I’m talking about.

-

For being a small scale ship I’m surprised at the detail it has. Great build and love the paint work you’ve done. i haven’t built any war ships and i always admire the people that do and can do such an excellent job at painting them. Nicely done!!

-

San Francisco cable car by kgstakes - FINISHED - OcCre

kgstakes replied to kgstakes's topic in Non-ship/categorised builds

Some work was done yesterday not much just enough to get me feet wet. the seats are just sitting there not attached yet. -

San Francisco cable car by kgstakes - FINISHED - OcCre

kgstakes replied to kgstakes's topic in Non-ship/categorised builds

OOPS my bad. Thank you for the correction 🙂 -

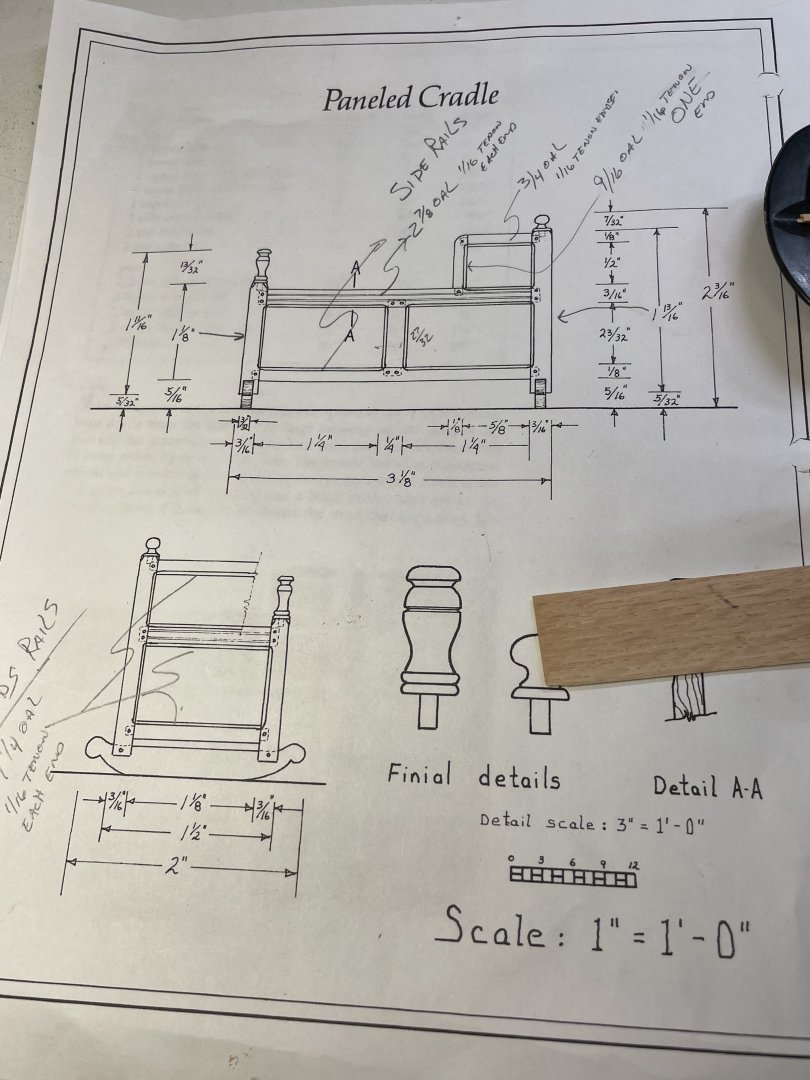

Cradle by kgstakes - FINISHED - 1/12 scale

kgstakes replied to kgstakes's topic in Non-ship/categorised builds

-

Cradle by kgstakes - FINISHED - 1/12 scale

kgstakes replied to kgstakes's topic in Non-ship/categorised builds

-

Cradle by kgstakes - FINISHED - 1/12 scale

kgstakes replied to kgstakes's topic in Non-ship/categorised builds

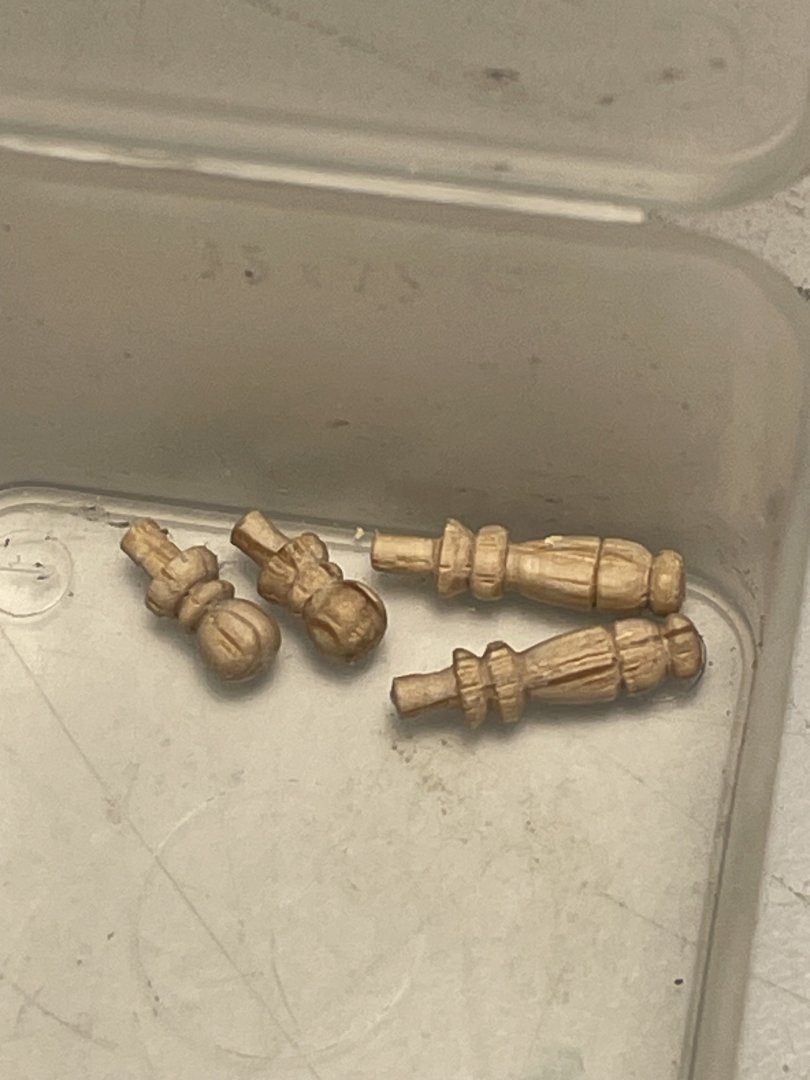

Progress on the cradle build. Dadoes and tenons working out good, few more panels and then the rockers on the bottom and it’ll be ready for finish work. -

Work area pictures only

kgstakes replied to Johnny Mike's topic in Modeling tools and Workshop Equipment

Here is my model workshop it’s the office of my workshop. I don’t use it as an office anymore so I turned it into my model workshop. the video is of my miniature workshop but it has changed a little bit since this was taken. IMG_3122.mov -

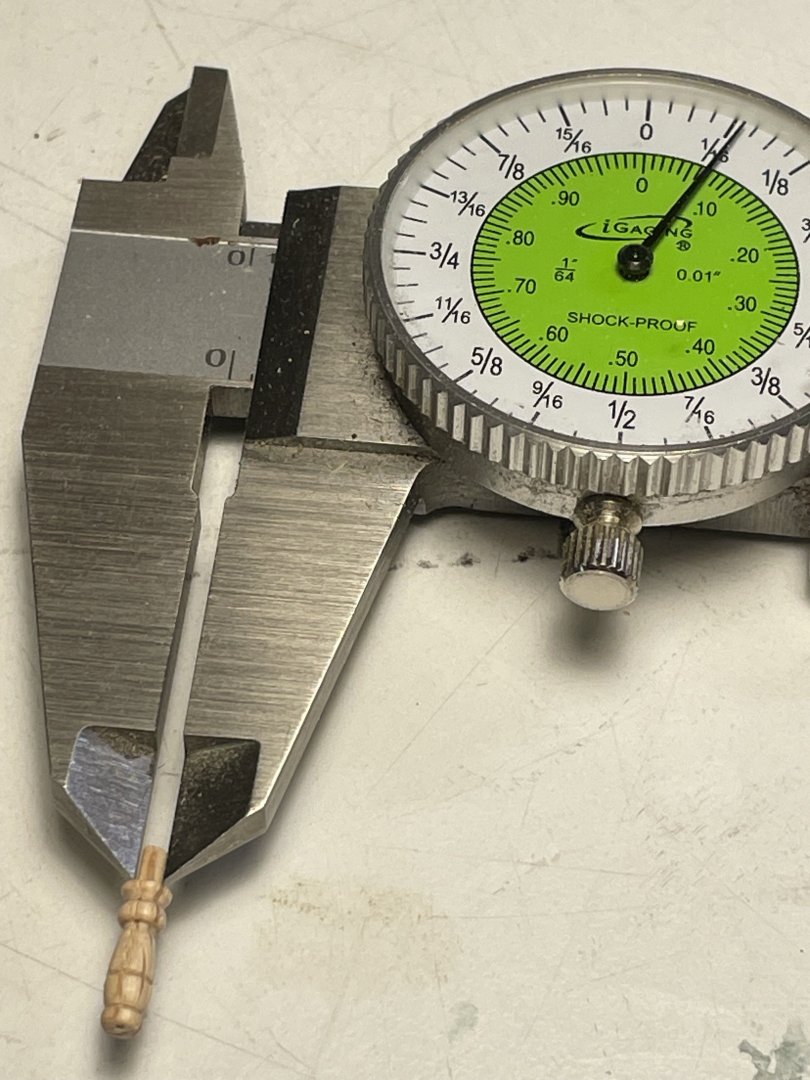

Now before you all congratulate me this cradle is 1/12 th scale. Oh heck no too late in life for that!!🤣🤣🤣 Anyway, milled up all the rough stock for this little cradle. Turned the finials this morning and next is cutting all the parts out of the stock I made up and do all the mortise and tenons then make the panels and assemble. i milled up some rift cut red oak so there should be lots of nice grain pattern in this project.

-

Buckboard by kgstakes - Model Trailways - 1/12 scale

kgstakes replied to kgstakes's topic in Completed non-ship models

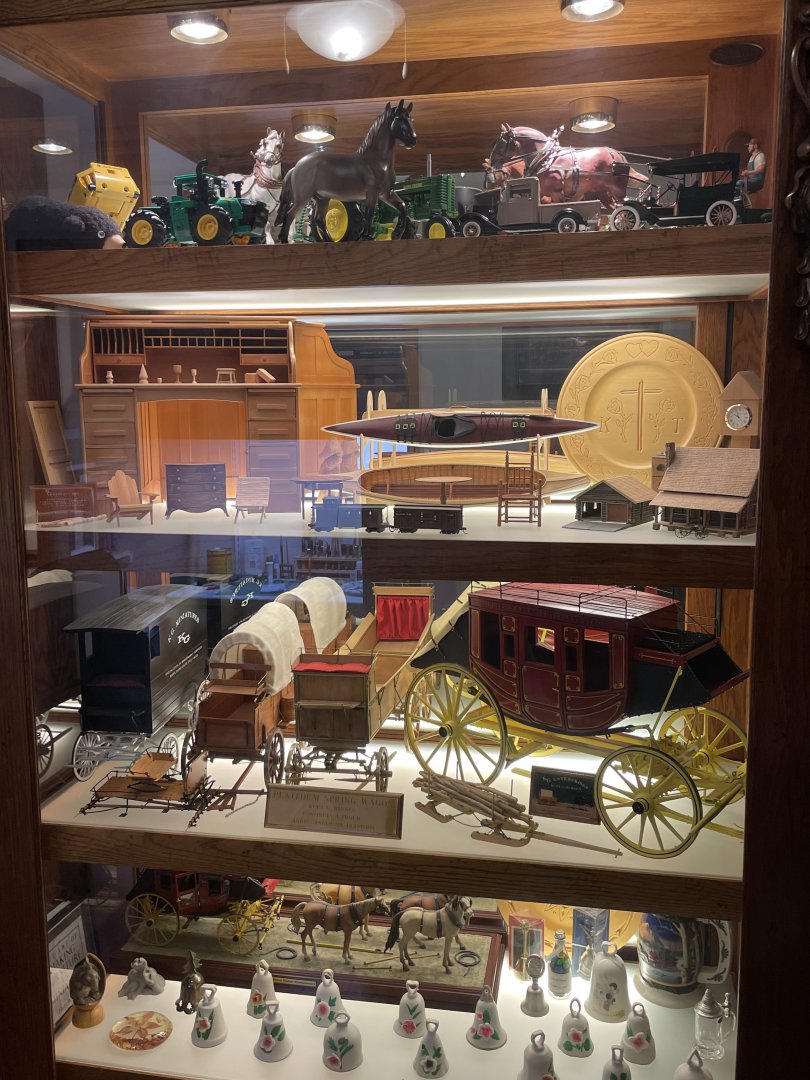

Not to worry that stagecoach that is in the display case (picture) took me 10 years to complete. Work on it put it away work on it put it away. i think you have time 🤣🤣 -

I just finished the buckboard by model trailways. It's an easy kit and something different from scratch building a wagon. The kit went together good, some areas could be better and I wish they would of included "real nuts, bolts, washers" instead of just cast bolts and fake square nuts, both out of scale. I used brass nuts, bolts, washers, as I would if scratch building a wagon. Other than that, the kit is a good kit. Enjoy the pictures.

-

You did a very nice job at sanding out all the burned spots. I have a heck of a time with that. Some parts I can get really well and there are other areas that just seem to be really burned in. But you're doing a heck of a job on that longboat. Great job !!!

- 38 replies

-

- 18th Century Longboat

- Model Shipways

-

(and 1 more)

Tagged with:

-

Nice kit! And thank you regarding paint recipes. i use masters touch artist paints and have had good results when painting cars and trucks 1900-1930’s. Just love those style of automoblies. sometimes I’ll use hobby paints but for the money and ease of use with both brush and airbrush I find the artist colors do quite well for me anyway. Again thanks for info on the “recipes”. I’ll look them up and see what I can do too.

-

Finished the Chesapeake 17 Kayak this morning. i don’t know if anyone else has built this but i had a hard time with the buckles and actually gave up and used some buckles I had made for me for my 1/8 th scale stagecoach. Makes it look a little like a Santa Clause Kayak but hey I have buckles on the straps for the hatches.🤣🤣 Here are some pictures of the finished model.

- 7 replies

-

- Chesapeake 17

- kayak

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.