-

Posts

400 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by kgstakes

-

Tilt Top Table by kgstakes - 1/12th scale

kgstakes replied to kgstakes's topic in Completed non-ship models

Thank you for correcting my mistake. I didn't realize that there were areas to post completed and not completed non ship type builds. Thanks again and I will try to put them in the correct posts in the future. My apologies. Kurt -

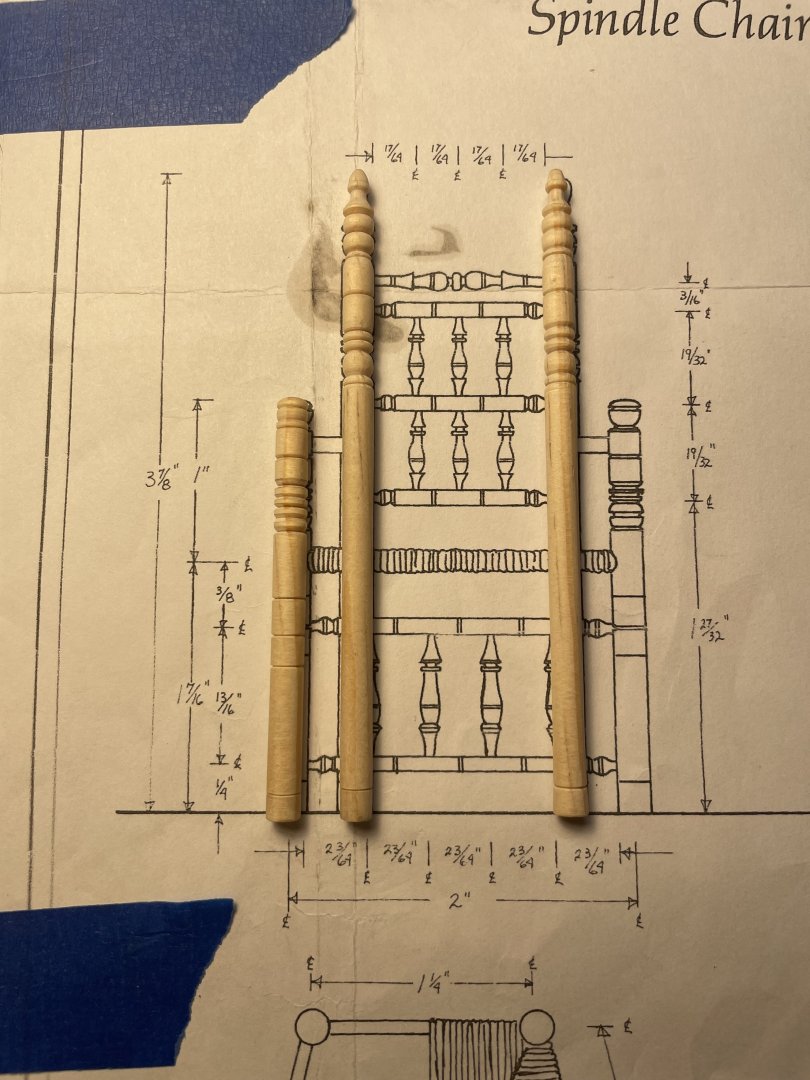

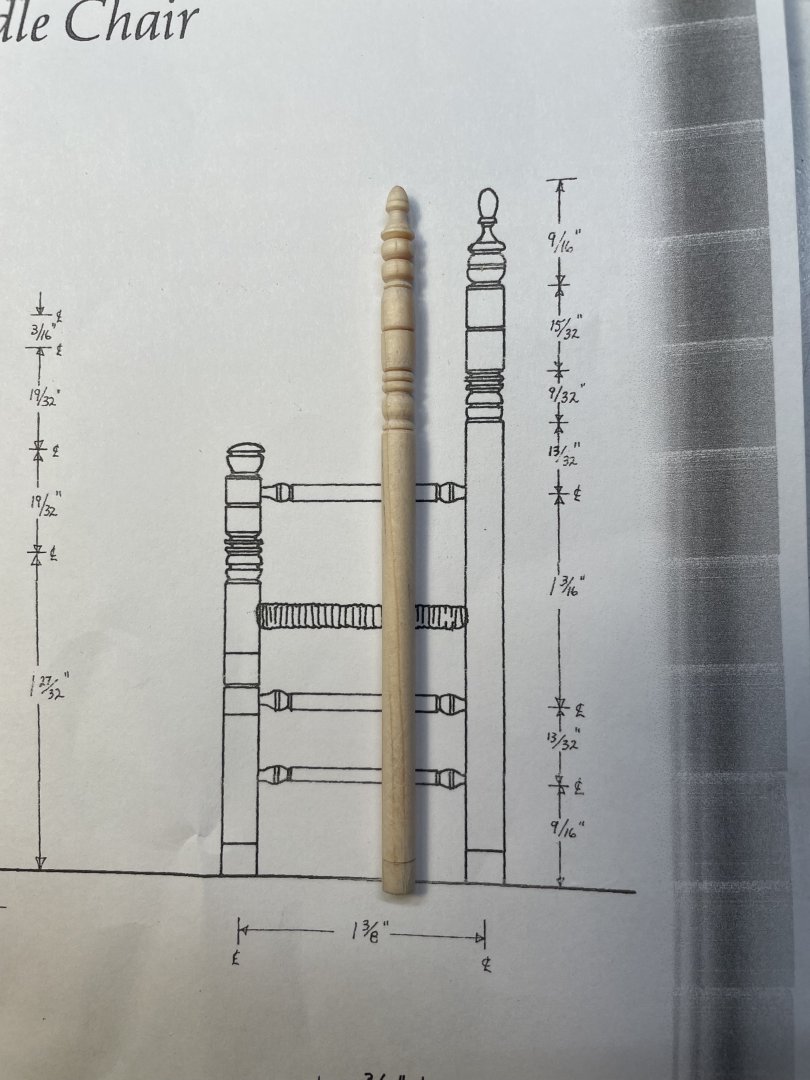

This table was the second turning on the taig lathe, after the legs for the step stool, and now I'm making the spindle chair which has a lot of turned pieces. The only other boat/ship model I have right now to build is a Midwest Chesapeake 17 Kayak 1:12. I have other projects to build before I get to the kayak, but I hope I can post what I've been doing here. Really enjoy seeing what others have done, gives me inspiration to continue to do my best and keep improving.

-

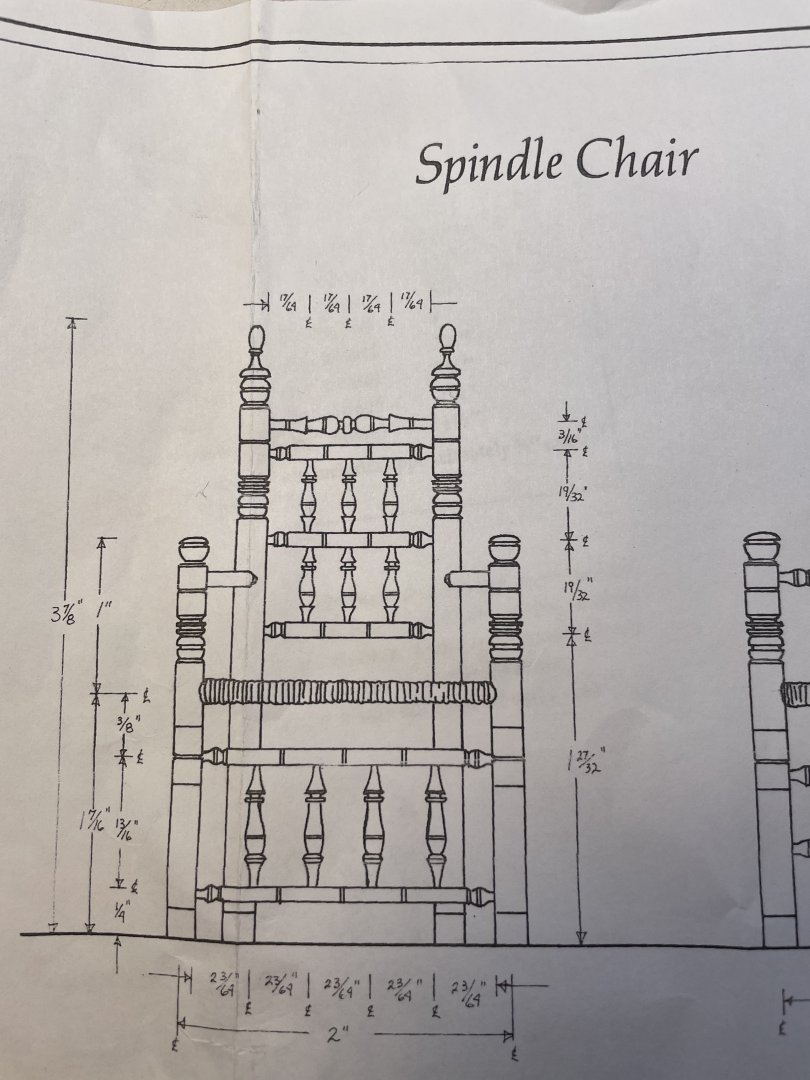

Spindle chair by kgstakes - FINISHED - 1/12th scale

kgstakes replied to kgstakes's topic in Non-ship/categorised builds

-

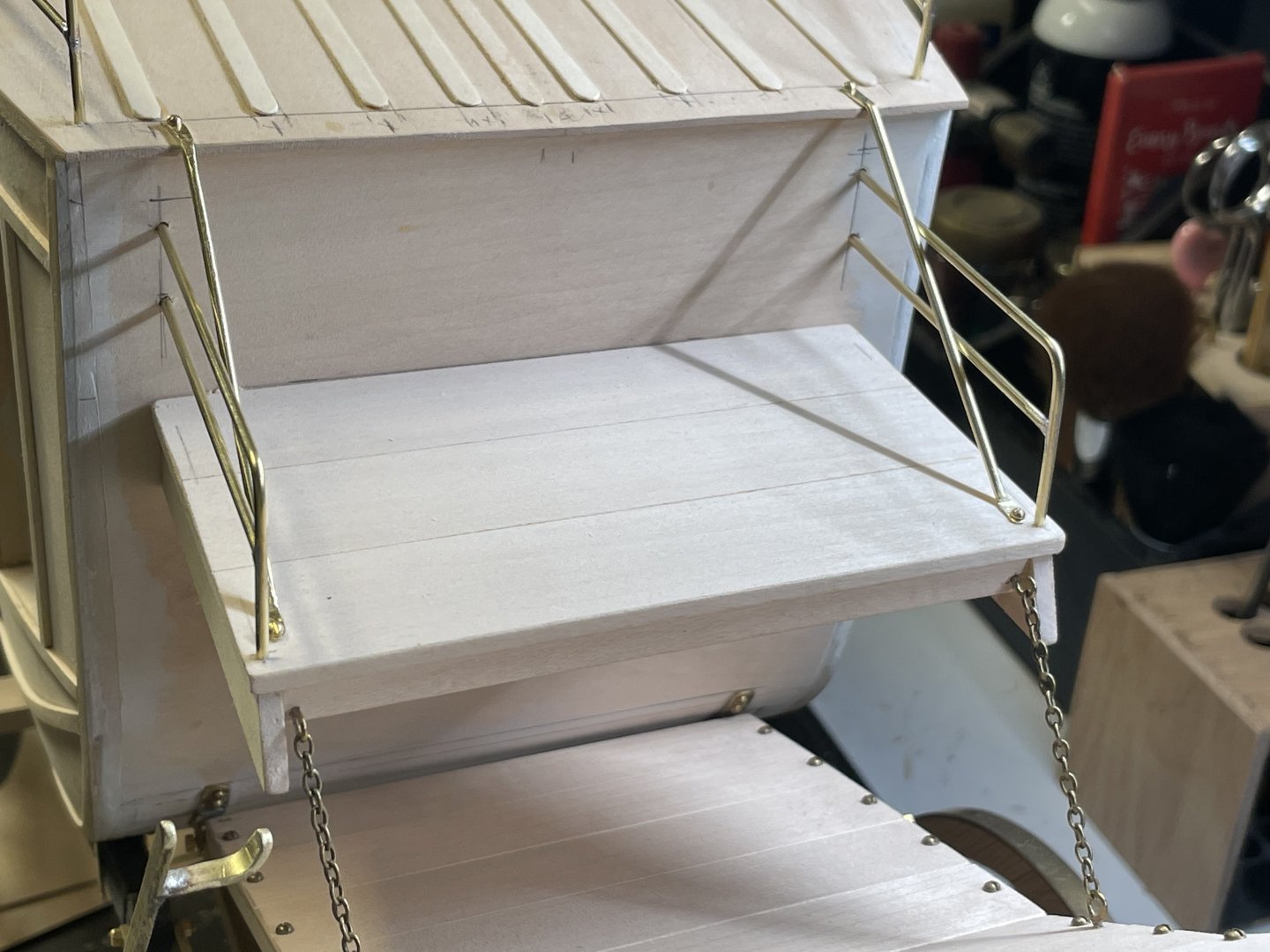

stagecoach by kgstakes - FINISHED - 1/8th scale

kgstakes replied to kgstakes's topic in Non-ship/categorised builds

Yes and I’ve met him years ago when we both had a booth (businesses) at horse events. LOL basically we were competition😁😁 in a friendly way. -

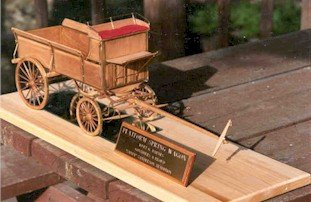

Your Doctors Buggy looks Great!! Since you've gotten a few under your belt, try scratch building one from plans. I've gotten plans for a stagecoach, delivery wagon, chuckwagon, and then I've built some from full size plans. Lots of books out there on how to build wheels and wagon boxes, undercarriage, etc. Here are a few that I've built, both from plans and from full size vehicles.

-

Mini Table Saw recommendations

kgstakes replied to captainscott's topic in Modeling tools and Workshop Equipment

For set ups on my Proxxon or for that matter, any mini tablesaw, invest in some set up blocks. I was fortunate enough to have received my father in laws gauge block set. I use it when ever I need to set up the rip fence. They are very accurate and even before I had them I used calipers to set up the rip fence. Now for cross cuts, I pretty much use a crosscut sled. I also have a 1/4 x 1/2 piece of basswood and a clamp (the ones for paper - black one) to clamp the "stop block" in place and then I can make as many cross cuts as I need. Set up time for either procedure is no longer than 5 min. if that. And to talk off the rip fence on the Proxxon, just loosen the two knobs and slide it off. Just as easy to reinstall the fence. -

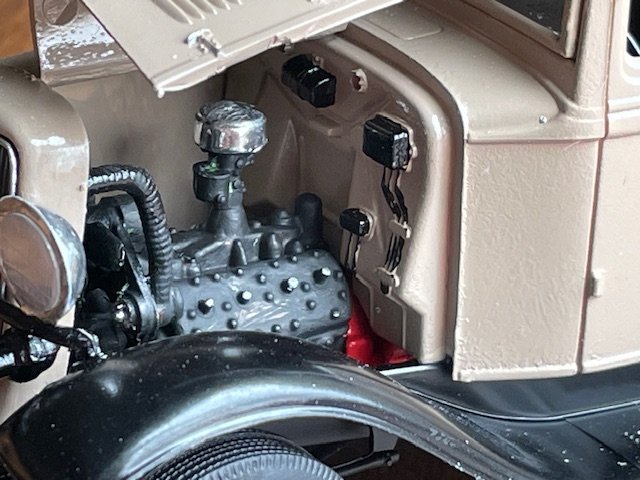

Since the riverboat build is completed I figured I do something I haven't done in 45+ years. Build a plastic kit.

-

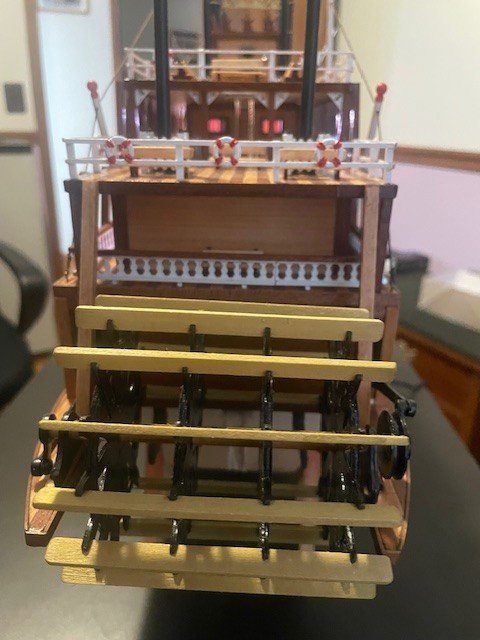

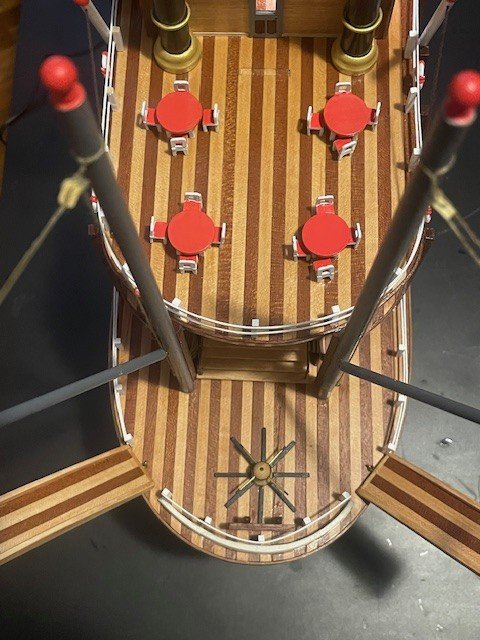

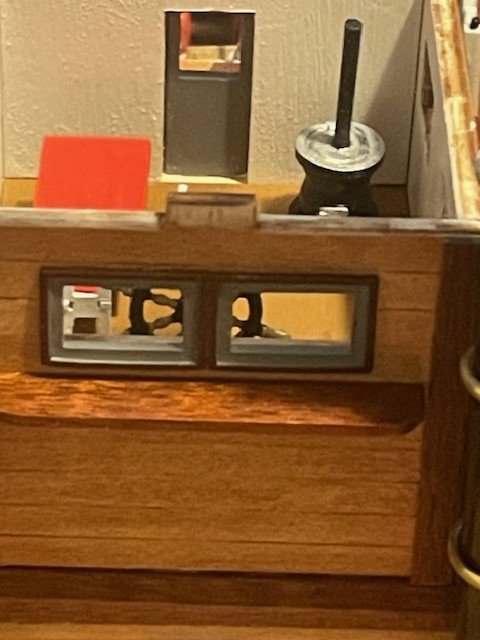

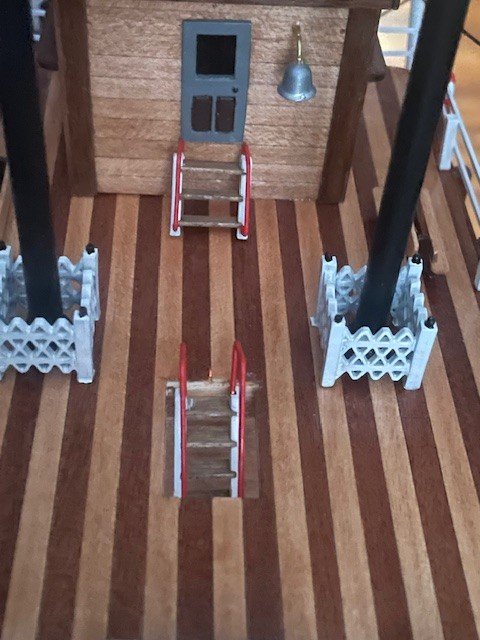

Spirit of Mississippi by kgstakes (Kurt) - OcCre - Riverboat Finished I finished the Mississippi Riverboat this afternoon. Been fun to build, had some challenges, but all in all I'm glad I purchased this kit. Modified a few things but basically built as per the instructions. Enjoy the video !! On to the next one. Kurt Mississippi Riverboat Finished Video.mov

-

Well I can say this, Nope I am never going to build a sail boat with all the rigging. I have one side done and will do the other tomorrow and then the side "tension wires" (sorry don't know what they are called). Anyway, I'm closing in on this paddle boat. Been about a year and a half since I started this project. Between my hand accident and then moving it's taken a long time to complete. Maybe tomorrow I will have it all done and then on to a base of some sort. Toying with the idea of a diorama of some sort.

-

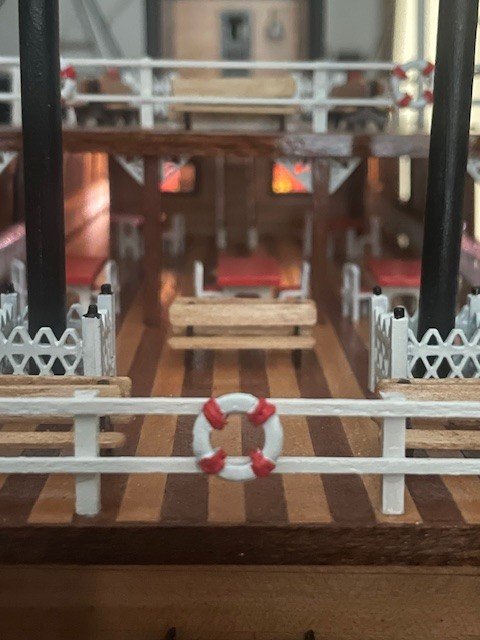

Have railings on. Decided to do a wooden railing instead of the "rope" type railing that was in the kit. Looks pretty good to me. Next the mast and the stretchers and all the rigging that goes along with that. Then I think it's pretty much finished. Then need to make a base for it to hide controller for the lighting. Might even make a diorama for it with water "river" and shorelines. We'll see.

-

Halvoric, Have you seen this website https://canoemodelkits.com/ or https://woodenboatusa.com/products/ ?? I would like to some day build one of these canoes. They look like excellent kits but have never seen them either. Some day (hopefully) I would like to build a 12' solo strip wood canoe. Don't know if that will ever happen, they are expensive kits so maybe. Always loved wooden canoes or small wooden boats for fishing or exploring. Your build as I've said before looks great!! Looking forward to seeing the finished product.

-

Hey everyone I'm looking to upgrade my old pin vise. Any recommendations? I've seen some on Amazon but I figure what better place to ask then here on tools. Let me hear what you suggest

-

Well I’ve kinda dumped the idea of a tool/model carry thingy too and from shop to house and back. Decided to organize the hobby shop and I still have tools in the house for modeling just not as many. Few pictures of the hobby shop and what I’ve done for organization.

-

Pulled the Trigger == Lathe coming

kgstakes replied to kgstakes's topic in Modeling tools and Workshop Equipment

Video of turning a taper on taig lathe. Photo of finished spoke sanded ready for next step. IMG_3104.mov -

Pulled the Trigger == Lathe coming

kgstakes replied to kgstakes's topic in Modeling tools and Workshop Equipment

Thought I would post this here about using my taig lathe. Has nothing to do with ships or building them just wanted to show what I've been up to with my lathe. I'm building a wooden wagon wheel. No particular scale, just something to hang on the wall. Still more spokes to turn but the hub is done other than the metal bands to put on it. I have half the spokes turned. This is the first time I've off set the tailstock to do a taper. Works great !! I'm using the power feed to turn the spokes. The square end of the spokes still need to be cut for the length of the spoke and then a tenon put on it to fit in the hub. I used a collet in the headstock so had to sand down the material for it to fit in the collet. Would be nice to have a 4 jaw chuck but I made due with what I had. The hub I turned using lathe tools by hand with tool rest. The holes for the spokes I did with a drill press and just eye balled vertical for each hole. 14 spokes and the finished wheel will be 12" diameter when completed.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.jpg.c120f23f64209411c0036d592a2e410f.jpg)

.jpeg.b0cf061721a98c80ac17f7d915a3febf.jpeg)

.jpeg.856d235e3e0bb568c61ae7252f40860b.jpeg)

.jpeg.5e58ac4411f4641421dd5815147e7dbe.jpeg)

.jpeg.c80d31e2fa895fda24472c5859c0cc95.jpeg)

.jpeg.72748274b18ca130c597a0c7f44d4f57.jpeg)

.jpeg.1f08449857455561c8c563b8f5d077f7.jpeg)

.jpeg.e27f3928275a010382d748ed317376a1.jpeg)

.jpeg.5f39d36d9bd638d7c196b80db14a0818.jpeg)