-

Posts

41 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by a49kid

-

Hi guys, and yes I also have a Build Thread on ‘Ships of Scale’. That is a very active Forum, and they send me notification emails every day. They are taking up a lot of my time, almost too much, can’t get any building done. And every time I come here, it takes me 10 minutes to find my Thread, maybe at 74 I’m just getting forgetful on the procedure here. Anyway I can’t spend time Posting on two forums, so I may have to end this Build Thread of the African Queen here. But will stay as a member and check on other builds here.

- 31 replies

-

- African Queen

- Billing Boats

-

(and 2 more)

Tagged with:

-

Yes continuing on with this build of the Billings African Queen, on a Very Cluttered bench......... As I have discussed above, this was a steel hull boat, but I have decided to timber plank over the plastic vacuum formed hull. I guess most smaller boats of that time were timber hulls anyway. I’m using 0.5 x 10 mm strips, and this is the first time I have done ship planking. so a big learning curve ……..lol But I’m probably not doing it in the correct or normal way. But at least all my planks go the full length of the hull. No ‘fill in’ bits here, whatever you guys call those bits. And yes I tapered the planks fore and aft. And as the planks also need to curve / bend up and down, I came up with my own solution for that. I cut thru the 10mm planks about 7mm, on the opposite edge to that that needs to curve up. But we still had the one full length plank. And yes this leaves gaps that need to be filled, the wider ones with wood filler, and the very close ones just fill with the Sand & Seal. Yes this method would be unsightly if the hull was going to be stained, But as this is going to be painted, all these expansion cuts will not be seen. It has been filled and 2 coats of sealer on it here. Will then Grey Primer it, and I suspect more imperfections will new show up, so a little more filler and primer.

- 31 replies

-

- African Queen

- Billing Boats

-

(and 2 more)

Tagged with:

-

Hi Guys, and Grant, it may seem like I haven’t been doing much boat building lately, but actually I have been. But I have taken a short rest from the filling, sanding, sealing, primer and top coat on the Queens hull. Yes I’ve been making the Drink / Gin crates, 4 of them. And all the ‘planking’ on them. It is quite a time consuming exercise. Currently waiting on some more bottles for them, will post photos when all complete. And I must say I love my cut off tool I bought a couple of weeks ago. A wooden kit you assemble, but I changed the kit blade to a UK Stanley one, it is much sharper. And for the crates, you set the stop and then cut the strip wood to all exactly the same length that you want. And the precise cutting is very very fast.

- 31 replies

-

- African Queen

- Billing Boats

-

(and 2 more)

Tagged with:

-

Finished the hull planking, and that was quite a job for a first time planker. I’m using 0.5 x 10mm strip over the plastic hull. I figured boats of that size and at that time would be timber boats. I’m now in the process of filling and sanding, and then sealer, primer and top coat, I hope you will still be able to tell it is timber planked. And I don’t care if mine is not true to the original, I would rather have a timber hull than a plastic one. I’m using this Wood Sealer, and I’m liking it. Made in the UK. But I don’t think this would be suitable for stained timber hulls. Some information on the African Queen. It was a 30-foot boat built of sheet steel in the United Kingdom, for the British East Africa Railway for service in Africa, on the Victoria Nile and Lake Albert and used from 1912 to 1968. It was originally named the L.S. Livingston, and had a diesel engine. In the movie the steam engine was just a prop.

- 31 replies

-

- African Queen

- Billing Boats

-

(and 2 more)

Tagged with:

-

Two places that sell 1:12 figures, ETSY, Melody Jane Doll House and Minimum World, Search Dolls House Figures. I wanted 2 seated figures. Very nicely painted resin molded figures, but then I modified them with my Dremell, and re painted them. So they don't look like the figures here now. I will cut and rotate Charlies arm / hand to have it on the tiller. And I have to make a big hat for Rose. Sorry no pics yet, still working on them

- 31 replies

-

- African Queen

- Billing Boats

-

(and 2 more)

Tagged with:

-

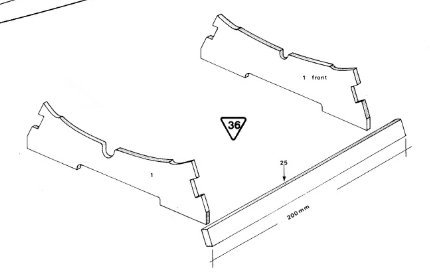

Another thing that has now annoyed me about the building instructions. They could be clearer, and more detailed drawings re the build. Yes this is only a small thing, but I would have liked to have made the stand as Billings had intended. With the joining timber going a little beyond the hull support pieces. And others have made the same mistake as me.

- 31 replies

-

- African Queen

- Billing Boats

-

(and 2 more)

Tagged with:

-

- 31 replies

-

- African Queen

- Billing Boats

-

(and 2 more)

Tagged with:

-

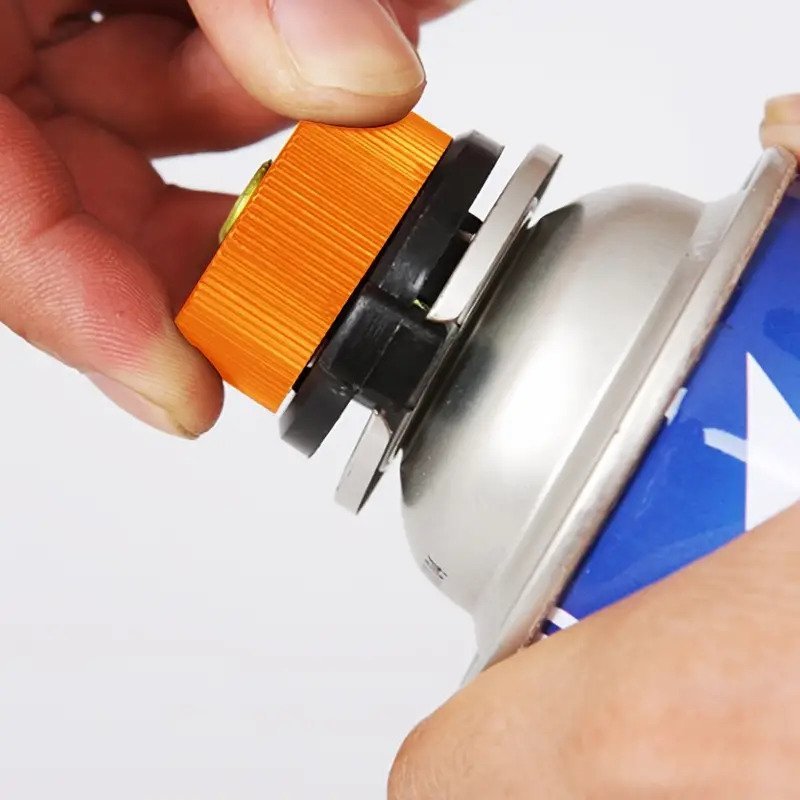

The Orange Adapter https://www.temu.com/ul/kuiper/un9.html?subj=goods-un&_bg_fs=1&_p_jump_id=894&_x_vst_scene=adg&goods_id=601099519685652&sku_id=17592229766684&adg_ctx=a-539583dc~c-18cda522~f-16258fa8&_x_ads_sub_channel=shopping&_p_rfs=1&_x_ns_prz_type=-1&_x_ns_sku_id=17592229766684&mrk_rec=1&_x_ads_channel=google&_x_gmc_account=710728018&_x_login_type=Google&_x_ads_account=2720833615&_x_ads_set=20878039836&_x_ads_id=157413511615&_x_ads_creative_id=685403347863&_x_ns_source=g&_x_ns_gclid=Cj0KCQjw2a6wBhCVARIsABPeH1snBh29I3AaBVYdpJN3fDjeaiFyjVpJb5BiXlT_u2SuRx-EUbpcPHMaAipqEALw_wcB&_x_ns_placement=&_x_ns_match_type=&_x_ns_ad_position=&_x_ns_product_id=710728018-17592229766684&_x_ns_target=&_x_ns_devicemodel=&_x_ns_wbraid=Cj4KCAjwtqmwBhBaEi4AF3g-M1SIddboT18bRk8ybYWFEoQasfKcXf4aHH4jyZ7pirs3kfi3cIFjmK_xGgJNwA&_x_ns_gbraid=0AAAAAo4mICH5hIaDH_7j0LdJpXuNnvO_R&_x_ns_targetid=pla-2087125886601&gad_source=1&gclid=Cj0KCQjw2a6wBhCVARIsABPeH1snBh29I3AaBVYdpJN3fDjeaiFyjVpJb5BiXlT_u2SuRx-EUbpcPHMaAipqEALw_wcB&is_back=1

- 31 replies

-

- African Queen

- Billing Boats

-

(and 2 more)

Tagged with:

-

The Refill Cans https://www.superbuys.com.au/4pc-butane-gas-cartridge-8oz-227g?gad_source=1&gclid=Cj0KCQjw2a6wBhCVARIsABPeH1tB2My3q7JvNvnaRRz2_H7HY1Uaml-ebw978fq8hVLHs_32mC0xTjEaAvsqEALw_wcB

- 31 replies

-

- African Queen

- Billing Boats

-

(and 2 more)

Tagged with:

-

Hi Grant, a bit of info re the Steam Plant, or do the kids call it ‘Heads Up’ Now to fire up the steam boiler, it uses Butane Gas. But you cannot fill it’s gas tank with a normal Refill gas can, a copper pipe is in the way. In the engine box the guy has supplied a 100mm brass extension tube with a screw fitting. Now you screw that pipe onto this orange adapter fitting. Then this adapter twists onto the filler can. But you need a special can, and it took me some time searching to find one. Come from Sydney, can’t buy OS as it’s “Dangerous Goods”. The Universal cans don’t work, and the red plastic nozzle is too long.

- 31 replies

-

- African Queen

- Billing Boats

-

(and 2 more)

Tagged with:

-

- 31 replies

-

- African Queen

- Billing Boats

-

(and 2 more)

Tagged with:

-

A few days ago I added a bit to the rear of the boat, (is that the stern), actually for the rudder. Put a reinforcing board on for the rudder tubing, but I slightly mucked up. I should have added the hull planking before I glued on the board. But much too hard to redo it all now re the tube locating at the bottom and at the top, where I have added a half round piece. So I have just added a bit more timber either side of the tubing, it will all look good after a little filler and it is painted And another builder was thinking like me and has done the same thing. And he is very much into realism with his weathering……………

- 31 replies

-

- African Queen

- Billing Boats

-

(and 2 more)

Tagged with:

-

Hi Todd, go the the start of this Thread, and read down, and a Lot of your questions will be answered. Including for the Steam Plant............#4034 And I have some 1:12 figures here, Dremmel modified and re painted, but I have now discovered that a guy is making some very good Humphrey and Katherine 3D figures

- 31 replies

-

- African Queen

- Billing Boats

-

(and 2 more)

Tagged with:

-

Some pics of another guys very nice African Queen, and sorry, I don't know his name to acknowledge his fine work. And it looks like it is electric powered, and probably RC.

- 31 replies

-

- African Queen

- Billing Boats

-

(and 2 more)

Tagged with:

-

Hi Grant, gjdale, how is your build going, I’m still on the hull planking, not an easy job. I had to make room for the boilers gas burner, a half round in the floor joist and some of the floor removed. And yes I drilled holes in the ply plate, to accommodate the screw heads under the Steam Engine base plate. But I’m finding it a bit disappointing here, very few replies / comments, just Likes like Facebook. In the old days Forums were very active places. Maybe they just like Square Riggers here.

- 31 replies

-

- African Queen

- Billing Boats

-

(and 2 more)

Tagged with:

-

Continuing on with this build............. I decided to plank the Queen, well I mean the Billings plastic hull doesn’t look very nautical to me. I figured boats of that size and at that time would be timber boats. Anyway, after I have filled and sanded, and then sealer, primer and top coat, I hope you will still be able to tell it is timber planked. Otherwise I should have saved all my money, time and effort on this job. I mean, will it just look like the plastic hull painted. Yea I not a big fan of doing any planking, all the calculating, measuring, trimming, sanding and gluing down. Using 0.5 x 10mm x 1mt strip I got from Float a Boat. I’m about half way thru this project. Then I thought I’d do an online search of this boat. Wow, it Was a Steel Hull …………… Anyway, it’s my boat, and I don’t care, it’s going to be a timber boat. Some information here on the African Queen, or more correctly, the Livingstone. The African Queen was a 30-foot boat built of riveted sheet iron in 1912 in the United Kingdom. For service in Africa on the Victoria Nile and Lake Albert where the movie was filmed in 1950. It was built for the British East Africa Railway and used from 1912 to 1968. The African Queen was originally named the L.S. Livingston, which had been a working diesel boat for 40 years. The steam engine was a prop, and the real diesel engine was hidden under crates and other cargo. It is now docked next to the Holiday Inn in Key Largo, FL.

- 31 replies

-

- African Queen

- Billing Boats

-

(and 2 more)

Tagged with:

-

Grant, have you had your steam engine running yet. I have not. Still trying to sort out how to fill the gas tank. And I forgot all about the brass tube piece in the box, just found it the other day. And some day I will send you a piece of this black silicon tube.

- 42 replies

-

- live steam

- radio

-

(and 2 more)

Tagged with:

-

And that front bulkhead, with the 2 louver doors, it does not really work ............ To me seems like a Billings mess up............... And remember the pole / mast is in the middle there.

- 42 replies

-

- live steam

- radio

-

(and 2 more)

Tagged with:

-

WOW, your completed planking looks great, as I have asked, what did you glue it down with. How did you work with those ridges ?? in the plastic hull, what, just somehow planked over them.

- 42 replies

-

- live steam

- radio

-

(and 2 more)

Tagged with:

-

Your planking is looking good and very neat, mine will need a good sand. What are you glueing it down with. Are they pencil lines or are there separate pieces of the planking.

- 42 replies

-

- live steam

- radio

-

(and 2 more)

Tagged with:

-

Next thing, and it looks like you have done the same thing as me, and cut them off. The rails need to go all the way to the rear, ( do they call that the Stern ) There needs to be support for the rear floor, yes I had to go back and add some rails. Poor instructions from Billings. And yes the rear bulkhead on mine did not sit down on the plastic hull........... I just pushed those bits in later.

- 42 replies

-

- live steam

- radio

-

(and 2 more)

Tagged with:

-

When I got to the point that I had to trim / sand the plastic I found the width at the top of the plastic hull, is too narrow. I added some extra wood strip. to both sides.

- 42 replies

-

- live steam

- radio

-

(and 2 more)

Tagged with:

-

Hi Grant, and you are progressing well too. Now a couple of things. Re top pic, the position of the deck, the nose piece, (I'm not a boat man) suggest glue the 2 plastic pieces together and dry fit. If you glue it in too early, it is a pain when working on the boat deck down. And check the position of the deck.

- 42 replies

-

- live steam

- radio

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.jpg.3d5b9353cfed27bc7b9ae76a2c79f07e.jpg)