-

Posts

137 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Stuka

-

Off to a good start Danny! About the planking question, There are diffirent approaches to it. Some like to create equally divided sections where you use battens on the hull. Myself I measured the length of the bulkheads using a thin piece of paper which in my case was around 6cm long. I then placed this on each bulkhead and wrote down the length of it. After I looked for the bulkheads in the middle section where the length started to decline towards the fore and aft. Cause this is where the tapering would start of the plank eventully meeting the end of it. How far the tapering goes depends on the length of the final and first bulkead divided by the amount of planks you can fit. And I try to follow the rule of not having a plank go below 2.5mm in width due to risk of it cracking once you put the pin through it. Now there are probably alot of better guides out there and threads or even advice from the veterans of this site as I myself has only planked two ships. So I consider myself still new to it but best of luck to your build!

-

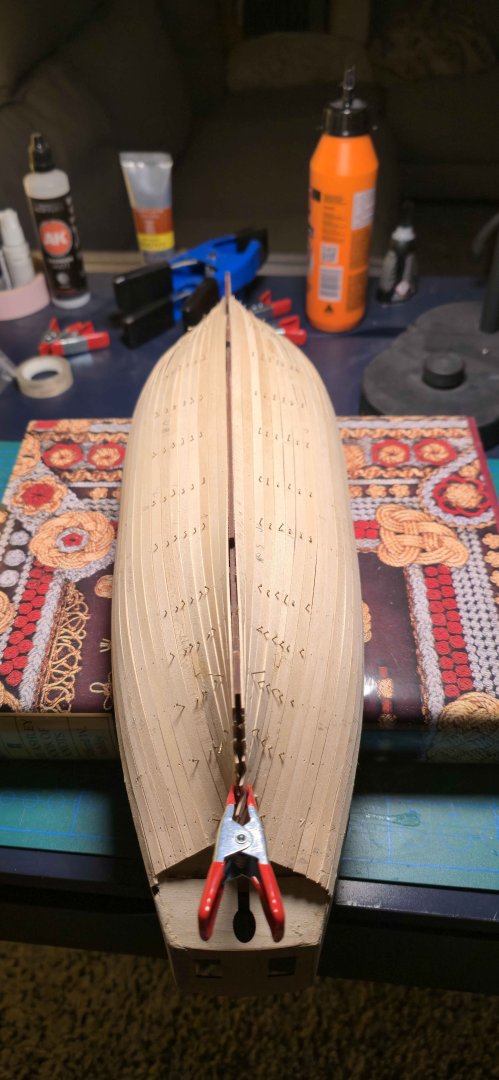

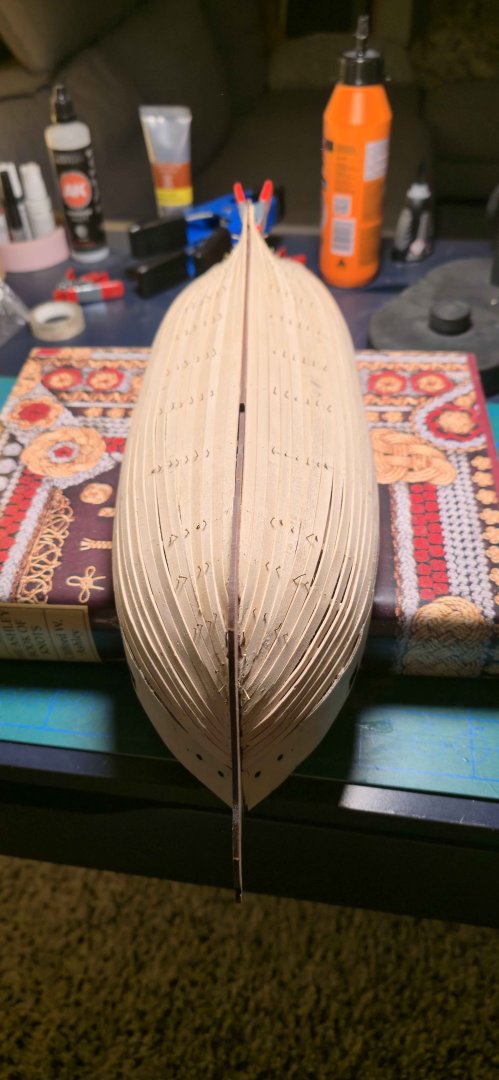

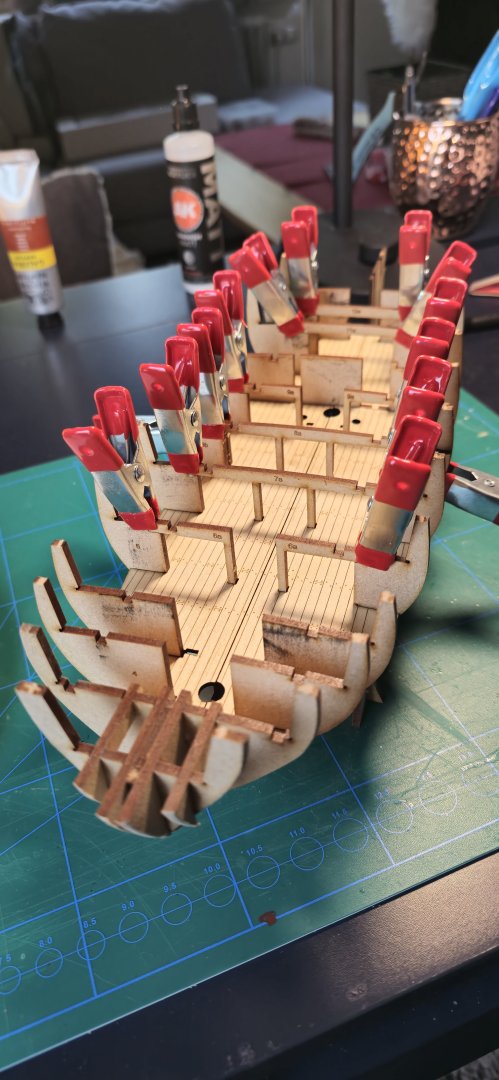

Hello again! I have been gone for half a year almost now with this build as I was procrastinating and felt low motivation due to some of the early planking results. However last two weeks my motivation built up to finally get this ship into seaworthyness, So now many planks later the first layer has been planked. Far from perfect Im afraid as I got the clinkering effect on some of the planks which I still dont really know how to counter. Some stealers where used in the aft and the final plank which Had do be sanded to fit like a puzzle piece took very long as I had to make one for each side of the Speedy. Hopefully I can really get the sanding done good with some filler to get that smooth surface, Cause I would really like the second plank layer to fit like a glove. But I suppose I cant expect to much as this is only my second model even though I wish I could do it like some people on this forum can.

-

First pair of planks on, I used the plank taper suggested by Craig. And then I will probably use stealers to balance eventual gaps on the stern/stem. This gap has me worried and its caused to my knowledge by my lack of sanding on the bulwark ears causing the pattern to stick out somewhat. Had some ideas to counter it as getting some wood filler on the bulkheads most affected by this gap. But it didnt turn out to well for me so instead i will just sand and use woodfiller and hopefully cover some of it in the second planking layer.

-

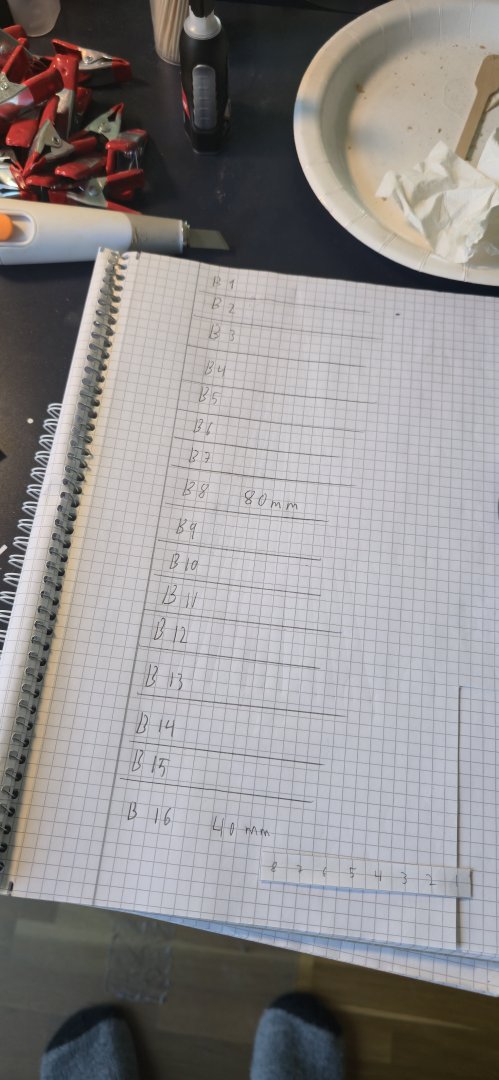

Hello Been quite busy lately im afraid, But hopefully things will settle down now for some time so I can get some progress going which have been lacking im afraid. I just sanded the remaining bulkheads and got my tick strip ready so im starting to measure the bulkhead lengths which im writing up as I go. Even though I have done one planked model now before I still get confused with where I should stop measuring the length for the stem (Bulkhead 1) area aswell as the stern one (Bulkhead 16). Marked in yellow I have the bulkheads themselves marked. The red area represents my confusion as if I should account for this area when tapering the plank widths or if I should just focus on the bulkheads themselves.? I was afterall hoping to read up some more before starting to plank this one as I would want it to become somewhat better than my Sherbourne. Most importantly I also want to better understand all the variables one should consider with the measurements for plank width on each bulkhead. Anyways plan is otherwise to now measure all the bulkheads and find out where the plank width decreases drastically compared to the full length one at 80mm (16 planks). From there I will taper the planks accordingly. I might also put up tickmarks on each bulkhead but since im unsure of how to measure the stern/stem as I previously stated I feel I dont yet understand it completely.

-

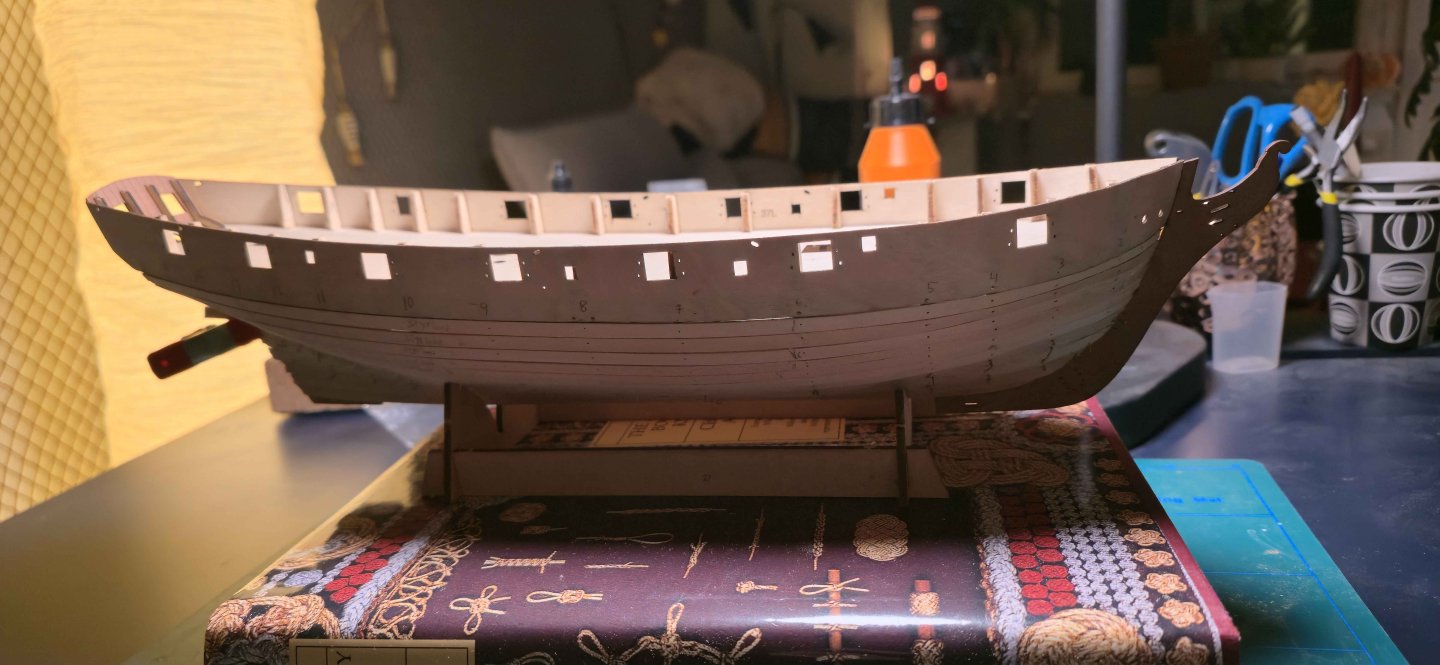

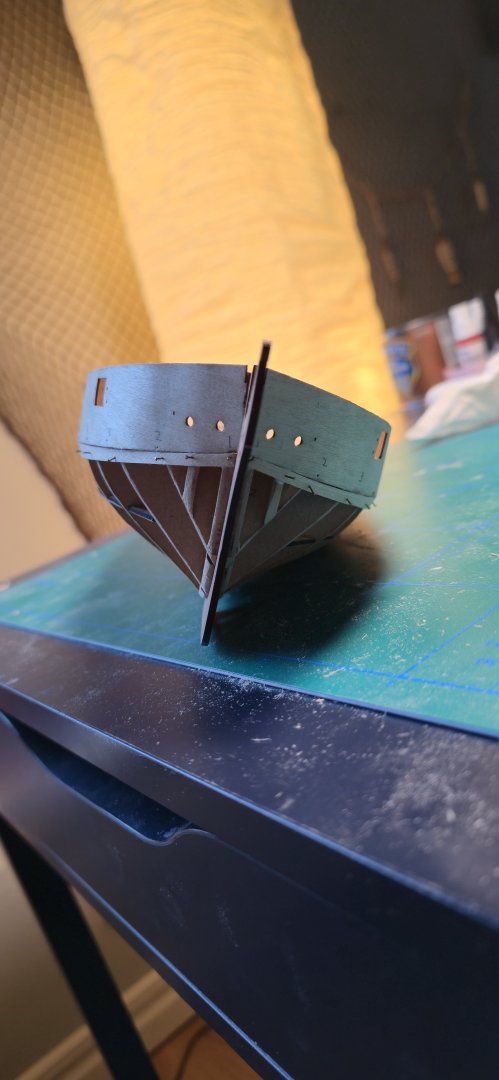

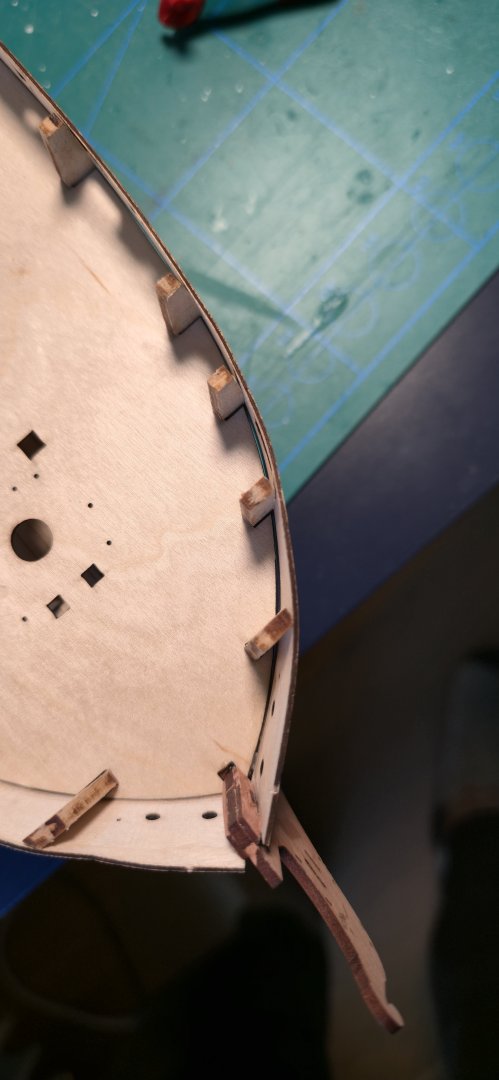

Hello, Im currently trying to mend my inner bulwark that I glued on arpund a 1 week ago. In certain areas its not completely flush with the hull so im thinking of solutions like extra PVA or even filler. The few gaps there are are very small but I hope they wont pose a serious problem. Getting the pattern seated with the indicator line for the deck proved a little challenging as everytime it was correct with the deck the bulwark was off by the stern for example. But eventually I got it on. Think from here I will use wood filler and then advance to planking as im not really sure pulling off the bulwark pattern and redoing it would be of any real change besides maybe just offering an oppurtinity for me to maybe break the part by mistake haha. But if anybody with more experience think I should redo it I will consider it. Other than this smooth progress but slow due to my work schedule.

-

I dont know how others approached it but I did no serving on the shroud lines. I only did some rookie "seizings" on some areas.

- 177 replies

-

- Sherbourne

- vanguard models

-

(and 3 more)

Tagged with:

-

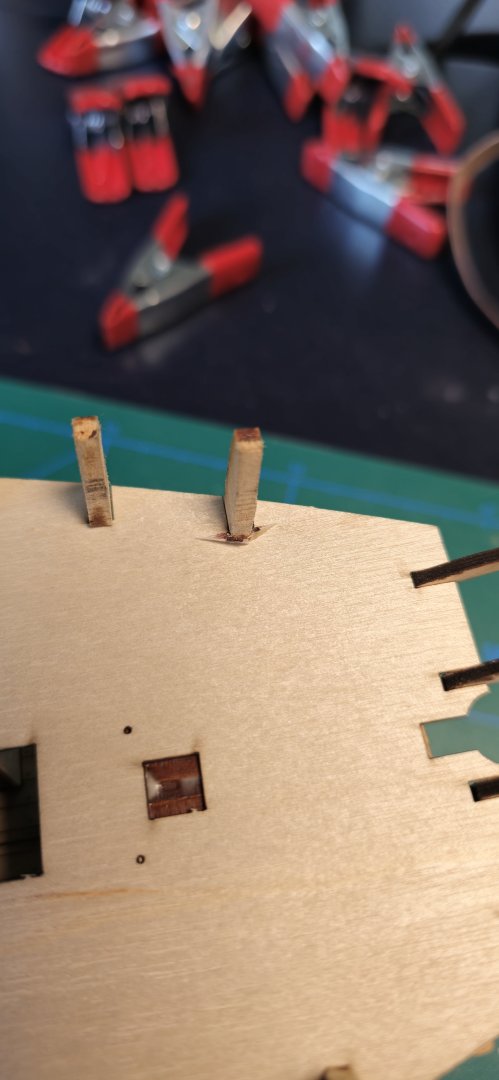

So Today I glued on the false upper deck. This was fairly straightforward although with alot of caution taken. I dryfitted the falsedeck around 3 times and I sanded the bulkhead ears where I saw resistance when I tried to dryfit the deck. Then I glued on and went for it pressing slowly on the points of tension with my thumbs carefully as to not break anything. It went pretty good I would say even though I did get some tiny "woodskin" that started to peel off in one spot close to the aft by one bulkhead. The damage in question very minor and no cracks or anything in the deck Before all this when I was brushing diluted PVA on the lower deck. I noticed this area that is discoloured and I might be overthinking this but since im not that experienced in wood. This isnt any rot or something that can spread right? You cant see a trace of it on the upper side of the lower deck so it seems small. Other than that smooth building so far 👍

-

Thanks alot Craig for all the times you came with good advice.

- 129 replies

-

- vanguard models

- Sherbourne

-

(and 1 more)

Tagged with:

-

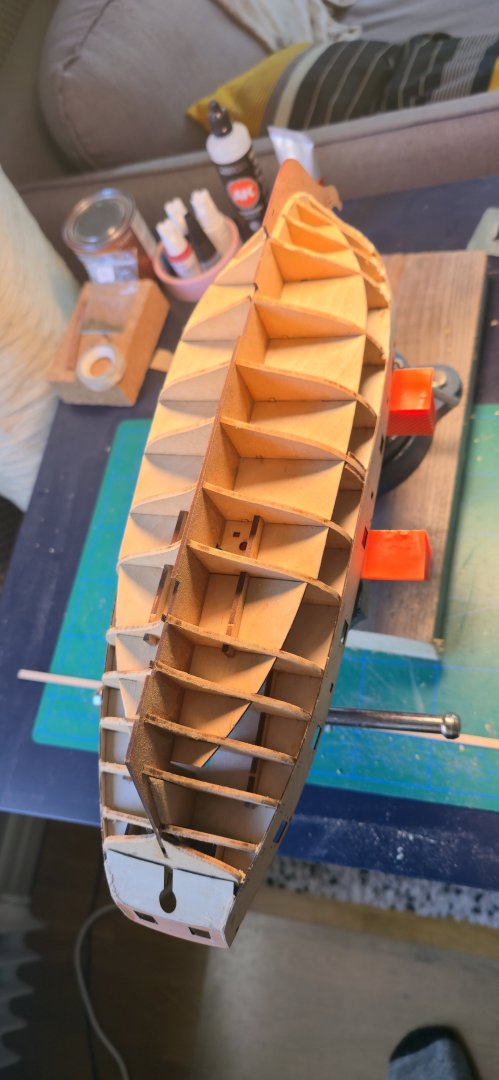

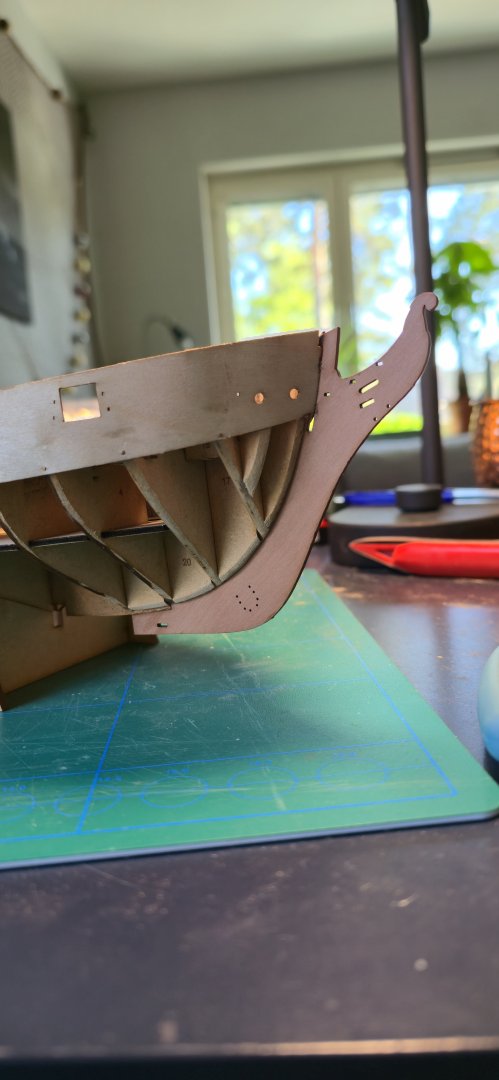

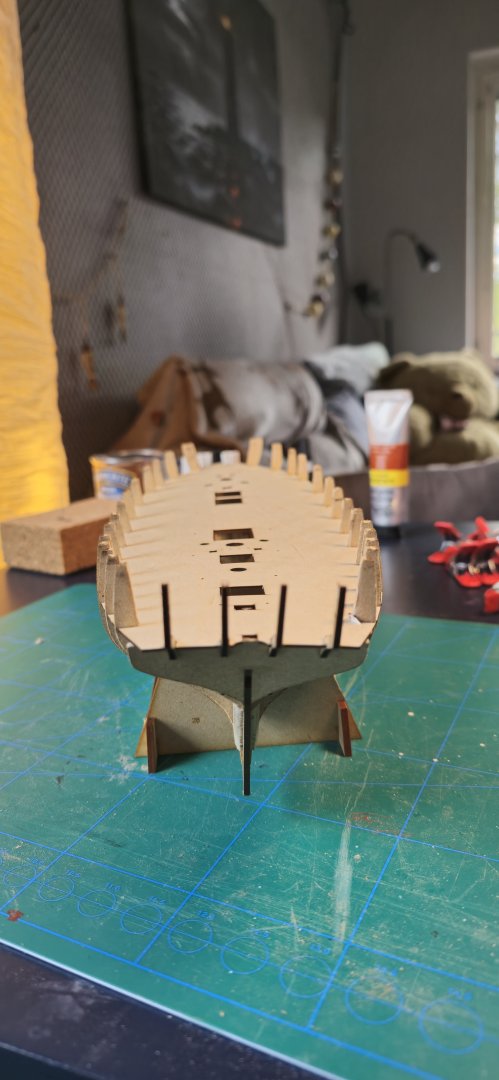

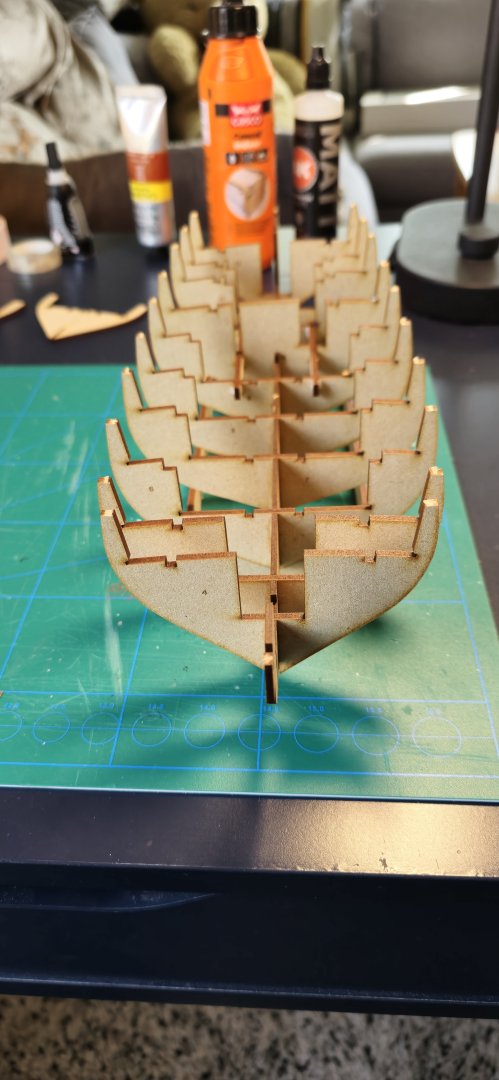

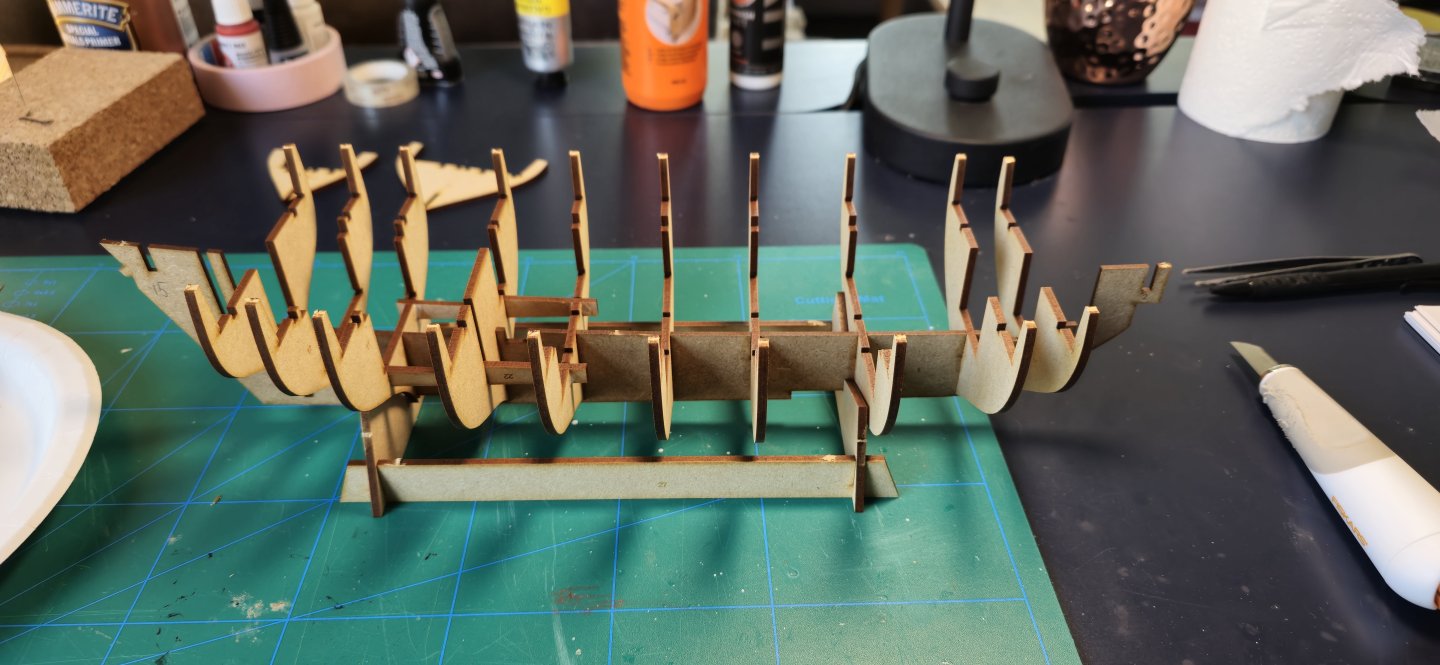

Well one thing led to the next and suddenly I have assembled alot of bulkheads along with supporting bulk/ deck beams. I also glued on the lower deck. So far the Speedy is much bulkier than my Sherbourne and it keeps getting bigger. Not even all the bulkheads are attached yet so it will be exciting to see how big it becomes in comparasion.

-

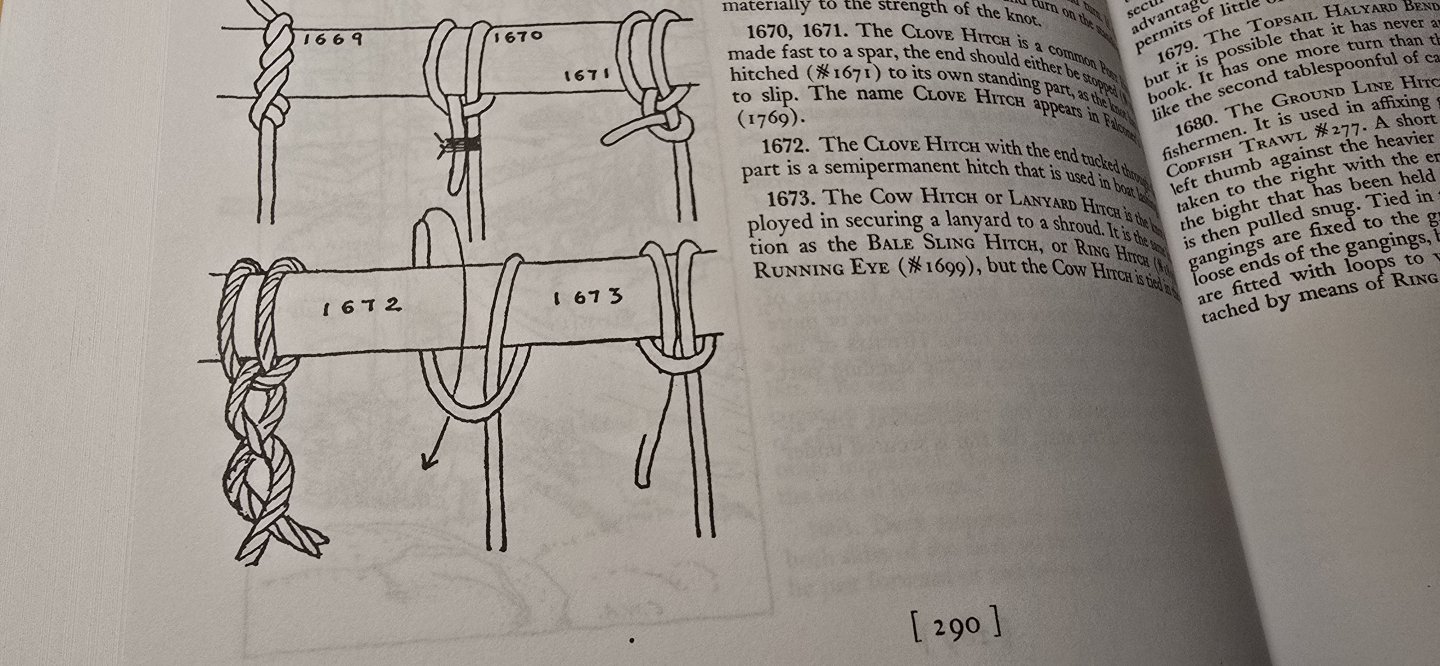

Now I dont know exactly what would be the accurate knot to use, But I personally took the Cow hitch from "Ashleys book of knots" for my Sherbourne. It looks like this.

-

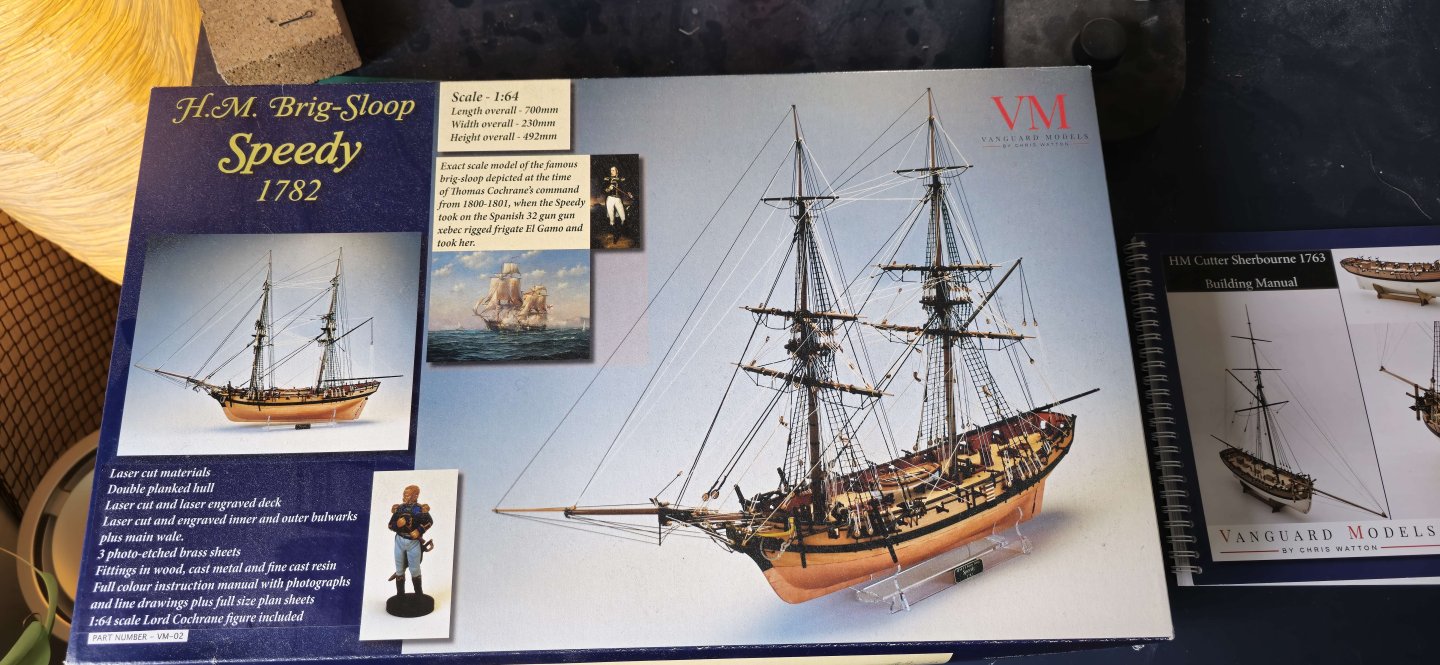

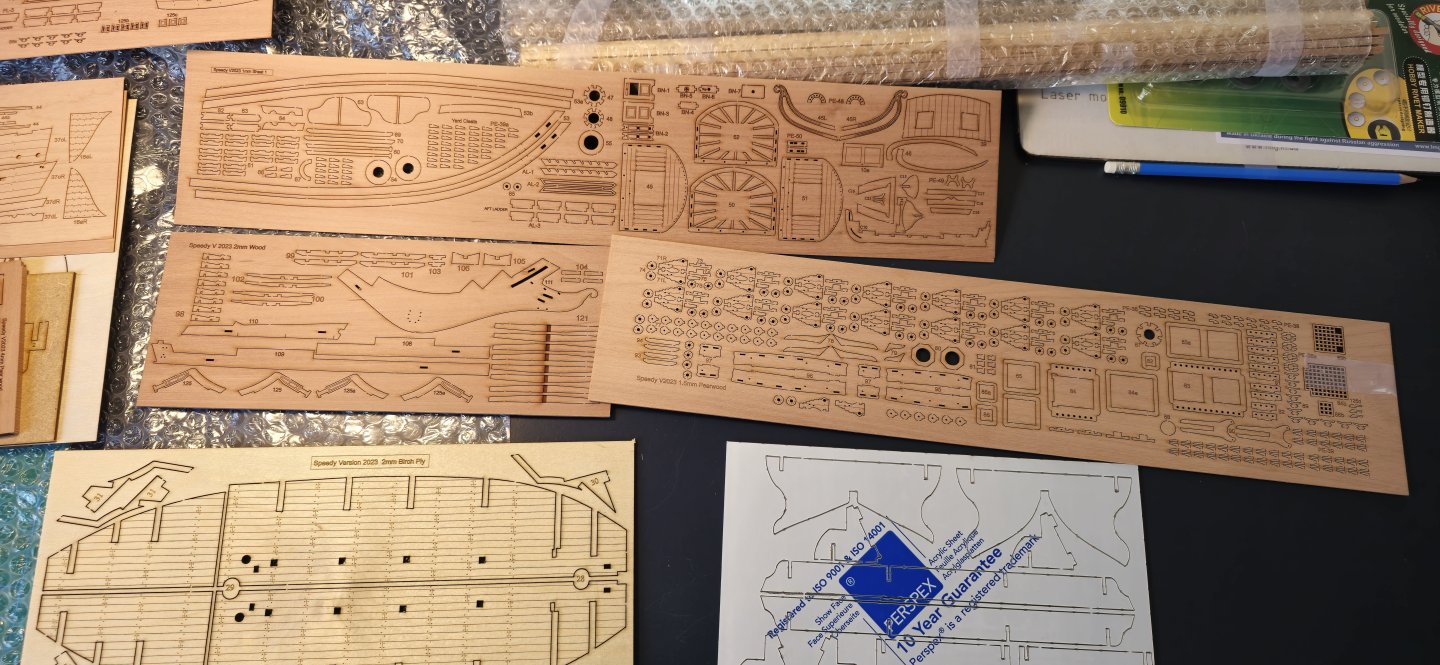

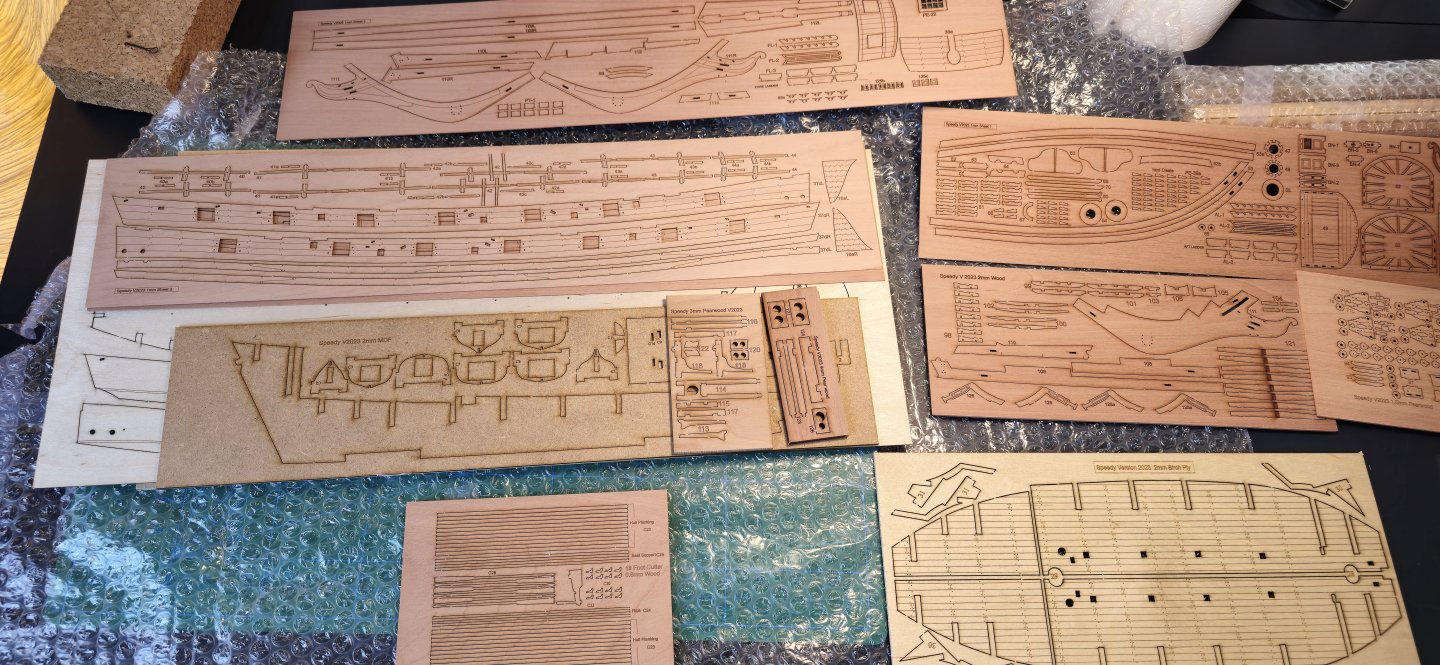

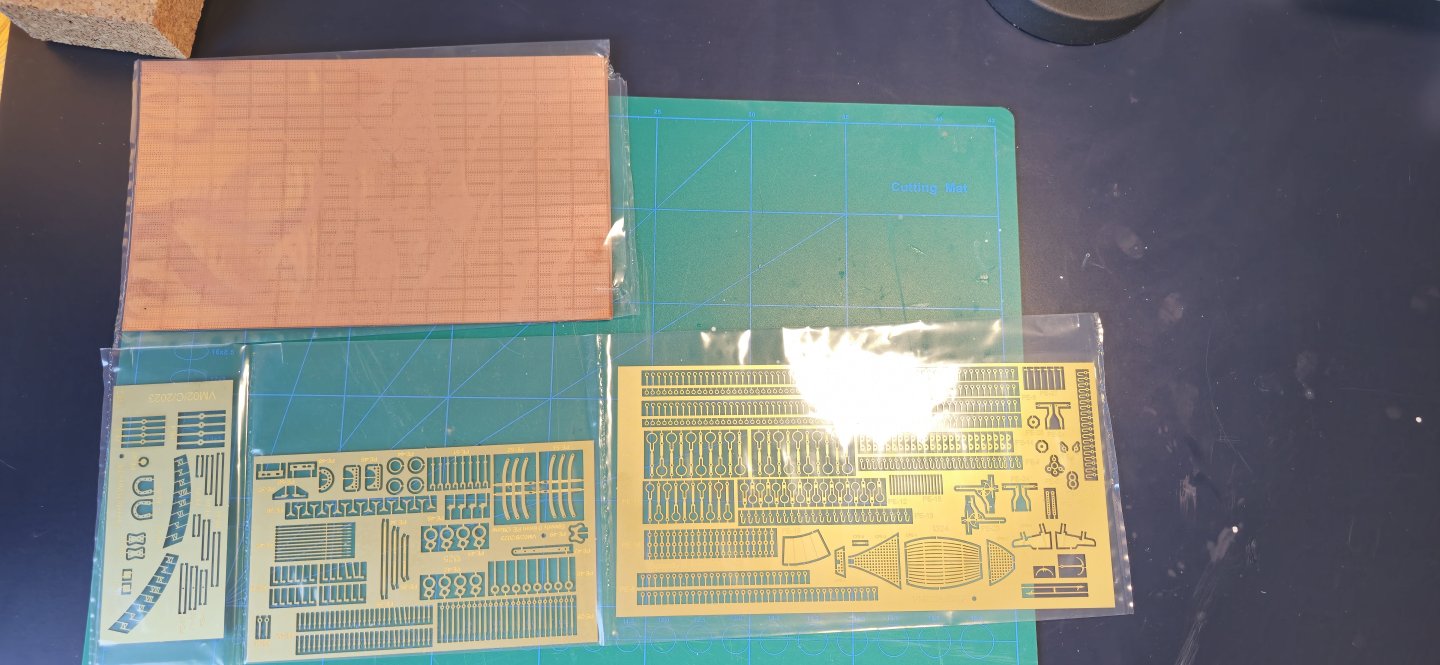

Back on the horse This is the 2023 special version of Vanguards Speedy which comes with some extras as copper plates and machined walnut blocks which look very nice so I hope my rigging can do them justice. Here are some photos from the content in the box, Now my workspace is limited so I couldnt fit all the material but here is most of it. Then we have the fittings The machined walnut blocks is another world apart from the normal blocks like that I got on the Sherbourne so im very happy about them. Entering this kit I now know how much time goes into just a little rigging and two ratlines. Therefore im sort of dreading it when I will eventually have to attach all the rigging on this one I suspect it will be quite a challange one which I hopefully can tackle. Now onto the building

-

Hey Palmerit I wanted to get back to what I said earlier about the top thimble blocks being incorrect. After now having finished this model I will say I was wrong in that. The instructions are correct regarding the rigging so ignore my statement about it. I guess I must have been confused with something about it. So no need to worry as long as you follow the plan sheets all will be good 👍.

- 177 replies

-

- Sherbourne

- vanguard models

-

(and 3 more)

Tagged with:

-

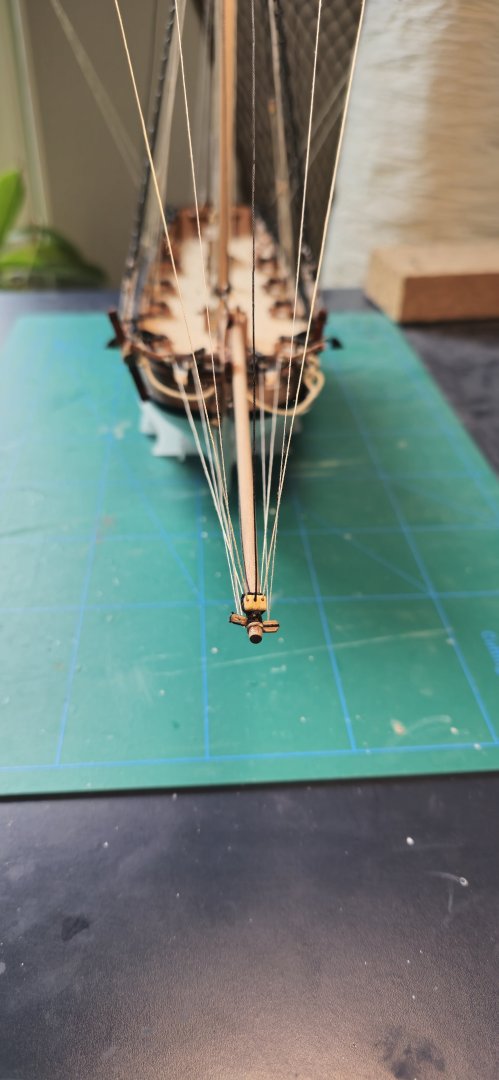

Finally Finished Did the bowsprit rigging, backstays and yard lines aswell as I today just finished the anchors knots which were not the best but works the part I guess. I had some trouble finding a good anchor knot due to the hawserope being very thick. But eventually I got something and it does the job. It has been a learning and problemsolving jorney definitely but now I hope I can transfer that experience onto me next project which is the Vanguard Speedy.

- 129 replies

-

- vanguard models

- Sherbourne

-

(and 1 more)

Tagged with:

-

Thanks Craig, I did read the manual that watered down PVA glue is supposed to be used on the ratlines but I wanted to try CE cause how fast it settles. The downside is the marks the CE leaves on the knots so next time Il try the PVA solution.

- 129 replies

-

- vanguard models

- Sherbourne

-

(and 1 more)

Tagged with:

-

Finally got the ratlines done Oboy for a first timer this wasnt hard but very time consuming. 7-8 hours it took me to get both sides done. That has me thinking how long it will take on bigger models with more ratlines like my speedy haha. Now I dont know if thats normal how long it took for me but I used CE on every knot so it wouldnt come undone. I can finally see the light in the tunnel as its Backstays, bowsprit and Ancor rigging left pretty much.

- 129 replies

-

- vanguard models

- Sherbourne

-

(and 1 more)

Tagged with:

-

I have now attached the deadeyes. I had a little trouble with them as I had accidently wrapped the shroud lines before attaching them meaning I had to redo the deadeyes for one side again. Rookie mistake there. In other news it was fairly smooth tomorrow il attempt at starting the ratlines so let see how that goes. As for attaching the shrouds to the deadeyes I used a bent brasswire so each deadeye got the same distance of sorts. Then i put CE glue on the deadeye and wrapped around the shroud line before pinching it with a needle pliers. This technique worked pretty well but did have some troubles with excessive Ce glue sometimes needed. Got to work on my techniques.

- 129 replies

-

- vanguard models

- Sherbourne

-

(and 1 more)

Tagged with:

-

More rigging has been done now. I wanted to make all the inner rigging done first before doing the shrouds as I thought that it will be easier that way. Its starting too look like something which Im happy about even though the small imperfections. Next up I believe is the shrouds which will be challenging I think but hopefully it goes well.

- 129 replies

-

- vanguard models

- Sherbourne

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.