halvoric

NRG Member-

Posts

84 -

Joined

-

Last visited

-

Tim Moore reacted to a post in a topic:

Canadian Canoe by halvoric - Midwest Products - 1:8

Tim Moore reacted to a post in a topic:

Canadian Canoe by halvoric - Midwest Products - 1:8

-

yvesvidal reacted to a post in a topic:

Canadian Canoe by halvoric - Midwest Products - 1:8

yvesvidal reacted to a post in a topic:

Canadian Canoe by halvoric - Midwest Products - 1:8

-

halvoric reacted to a post in a topic:

Canadian Canoe by halvoric - Midwest Products - 1:8

halvoric reacted to a post in a topic:

Canadian Canoe by halvoric - Midwest Products - 1:8

-

halvoric reacted to a post in a topic:

Canadian Canoe by halvoric - Midwest Products - 1:8

halvoric reacted to a post in a topic:

Canadian Canoe by halvoric - Midwest Products - 1:8

-

ccoyle reacted to a post in a topic:

Canadian Canoe by halvoric - Midwest Products - 1:8

ccoyle reacted to a post in a topic:

Canadian Canoe by halvoric - Midwest Products - 1:8

-

Paul Jarman reacted to a post in a topic:

Canadian Canoe by halvoric - Midwest Products - 1:8

Paul Jarman reacted to a post in a topic:

Canadian Canoe by halvoric - Midwest Products - 1:8

-

Ryland Craze reacted to a post in a topic:

Canadian Canoe by halvoric - Midwest Products - 1:8

Ryland Craze reacted to a post in a topic:

Canadian Canoe by halvoric - Midwest Products - 1:8

-

druxey reacted to a post in a topic:

Canadian Canoe by halvoric - Midwest Products - 1:8

druxey reacted to a post in a topic:

Canadian Canoe by halvoric - Midwest Products - 1:8

-

druxey reacted to a post in a topic:

Canadian Canoe by halvoric - Midwest Products - 1:8

druxey reacted to a post in a topic:

Canadian Canoe by halvoric - Midwest Products - 1:8

-

druxey reacted to a post in a topic:

Canadian Canoe by halvoric - Midwest Products - 1:8

druxey reacted to a post in a topic:

Canadian Canoe by halvoric - Midwest Products - 1:8

-

Timmo reacted to a post in a topic:

Canadian Canoe by halvoric - Midwest Products - 1:8

Timmo reacted to a post in a topic:

Canadian Canoe by halvoric - Midwest Products - 1:8

-

king derelict reacted to a post in a topic:

Canadian Canoe by halvoric - Midwest Products - 1:8

king derelict reacted to a post in a topic:

Canadian Canoe by halvoric - Midwest Products - 1:8

-

halvoric reacted to a post in a topic:

Norwegian Sailing Pram by Venti - FINISHED - Model Shipways - 1:12

halvoric reacted to a post in a topic:

Norwegian Sailing Pram by Venti - FINISHED - Model Shipways - 1:12

-

halvoric reacted to a post in a topic:

Canadian Canoe by halvoric - Midwest Products - 1:8

halvoric reacted to a post in a topic:

Canadian Canoe by halvoric - Midwest Products - 1:8

-

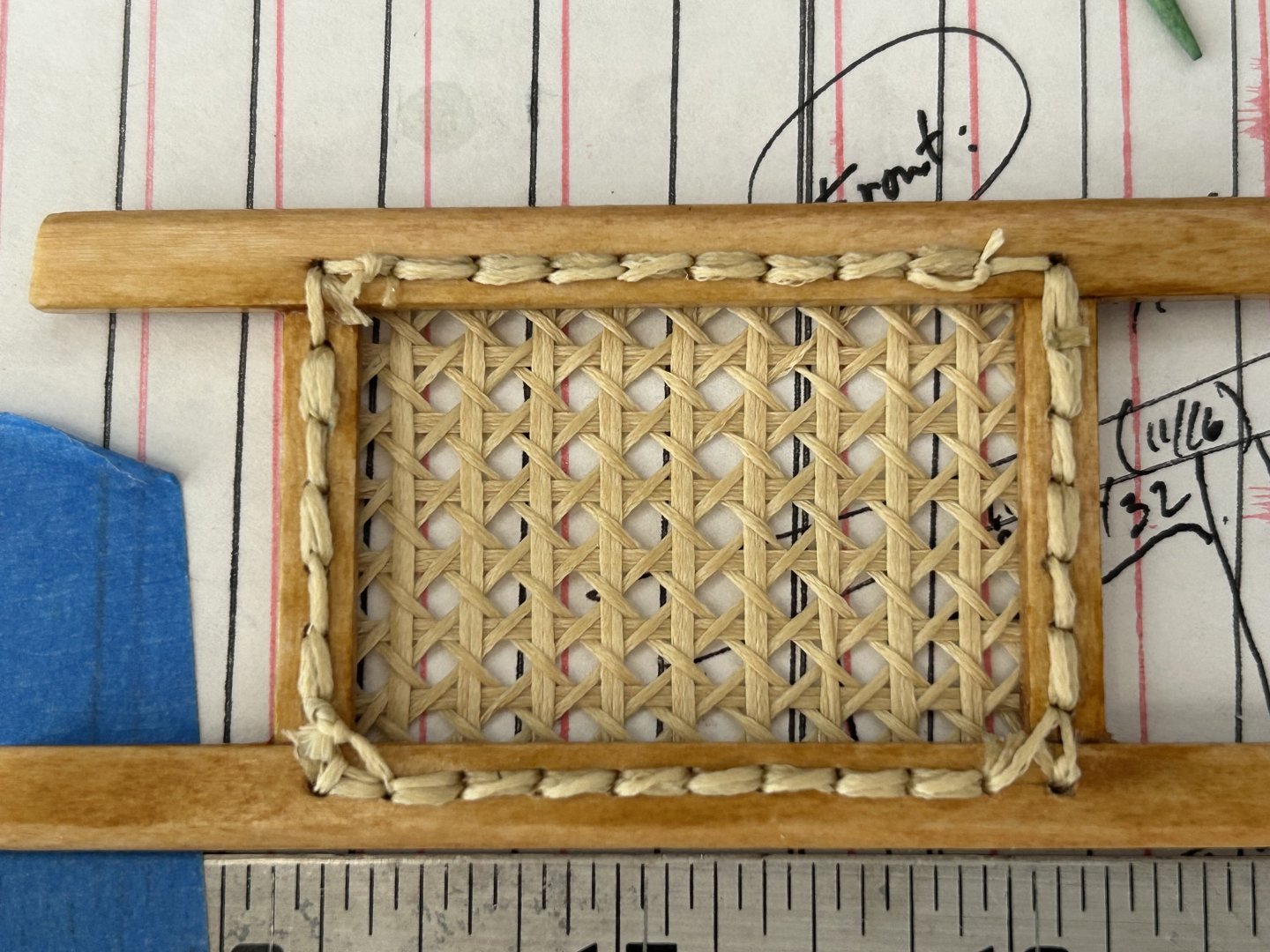

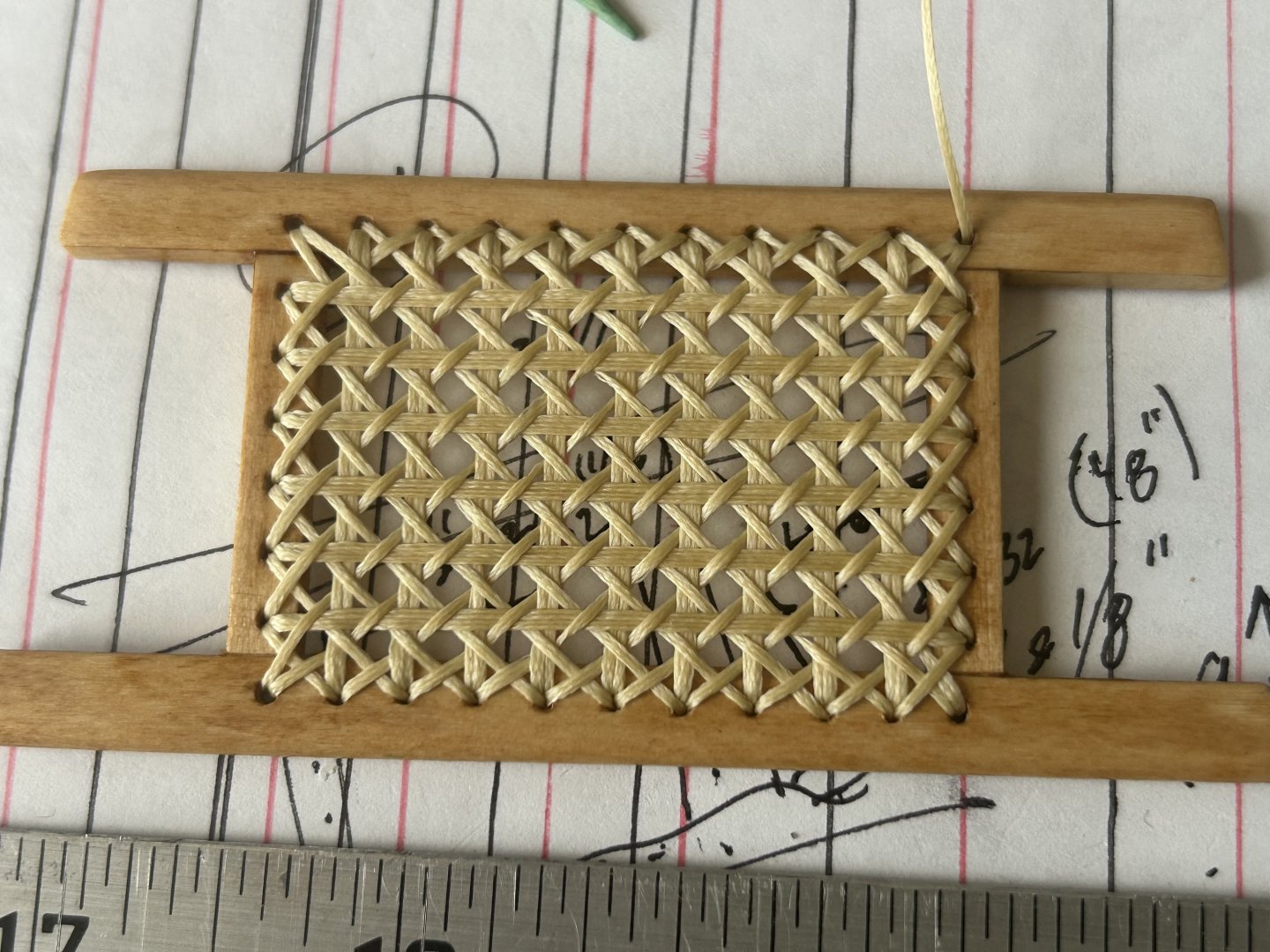

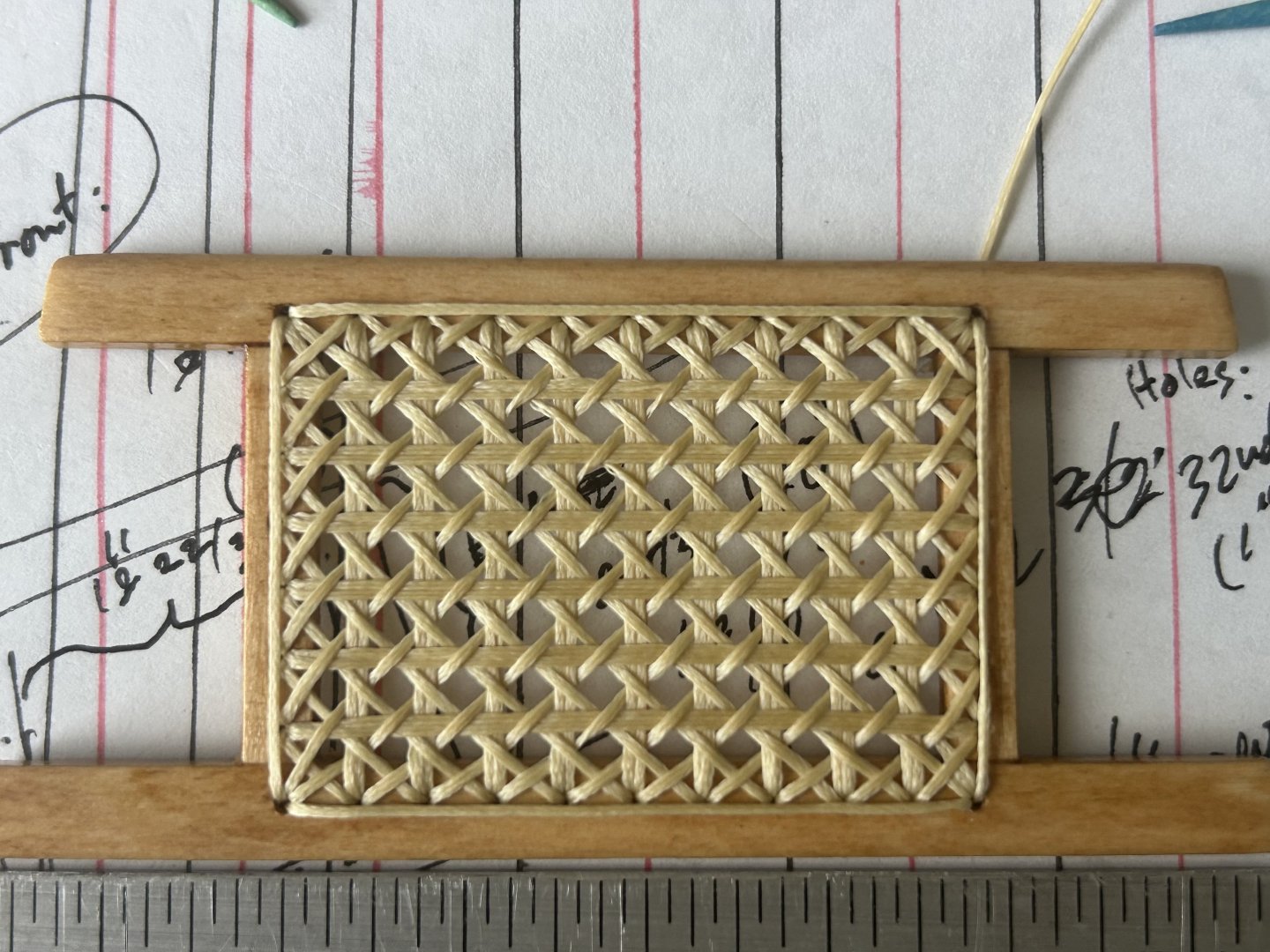

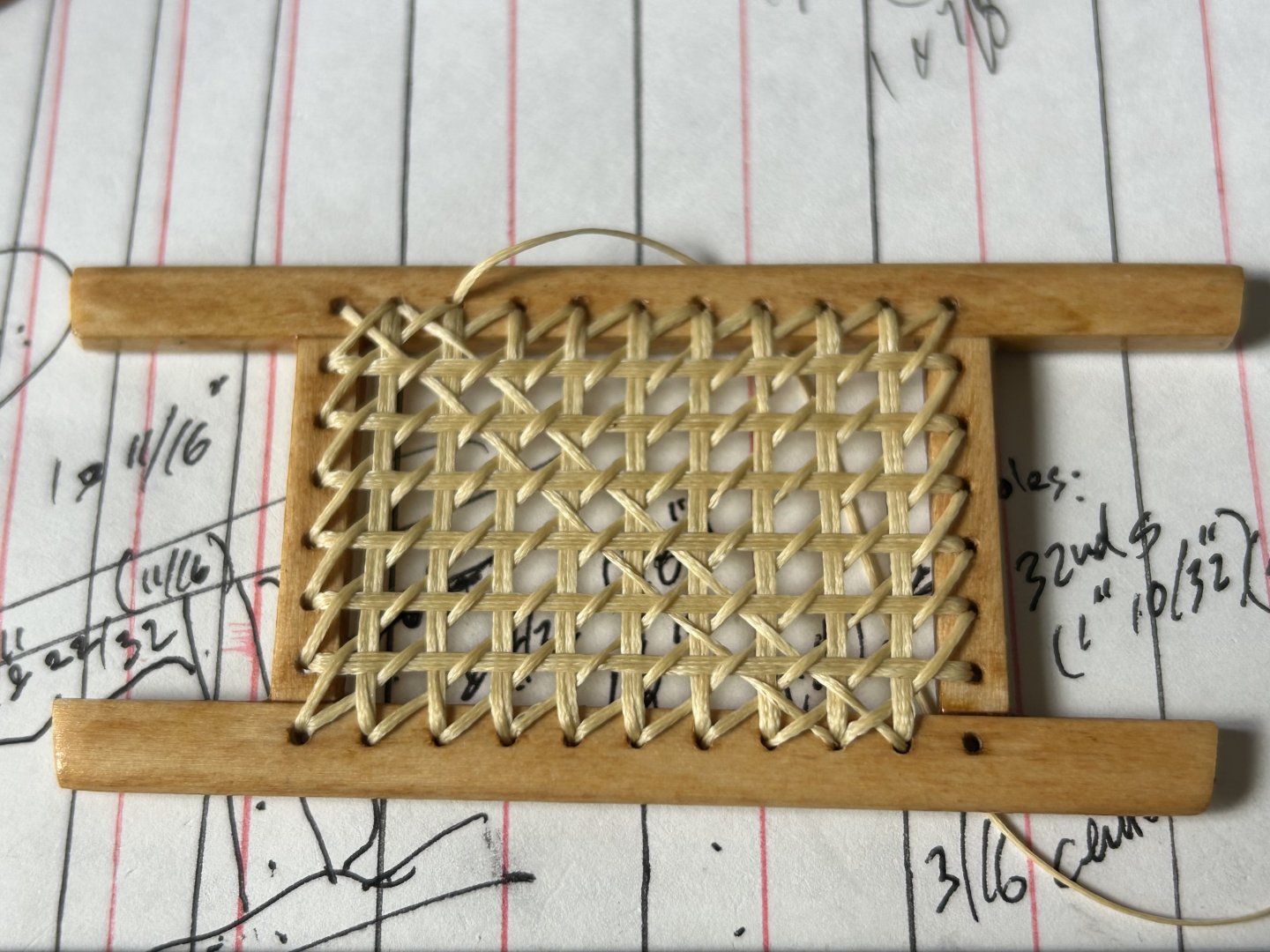

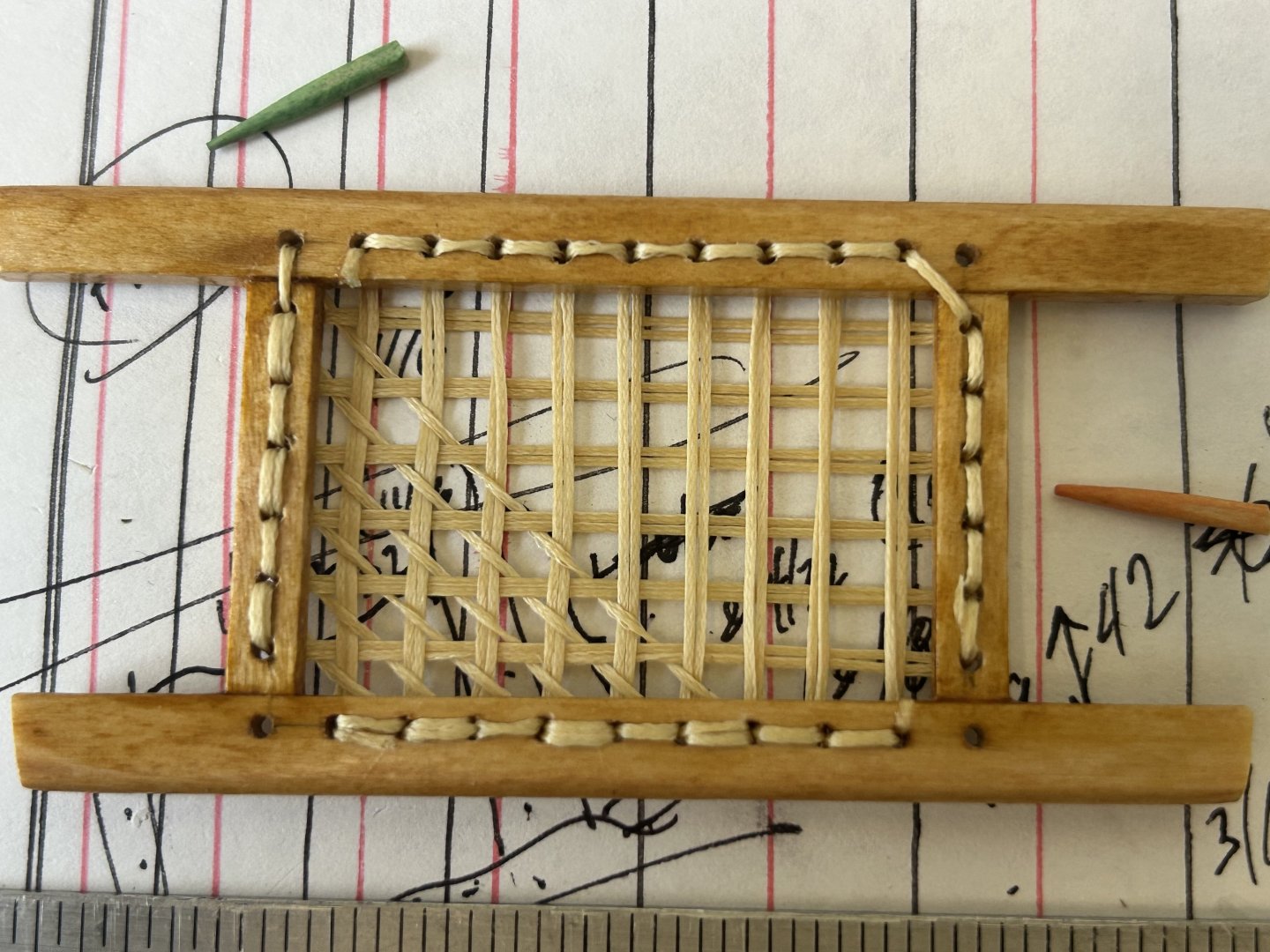

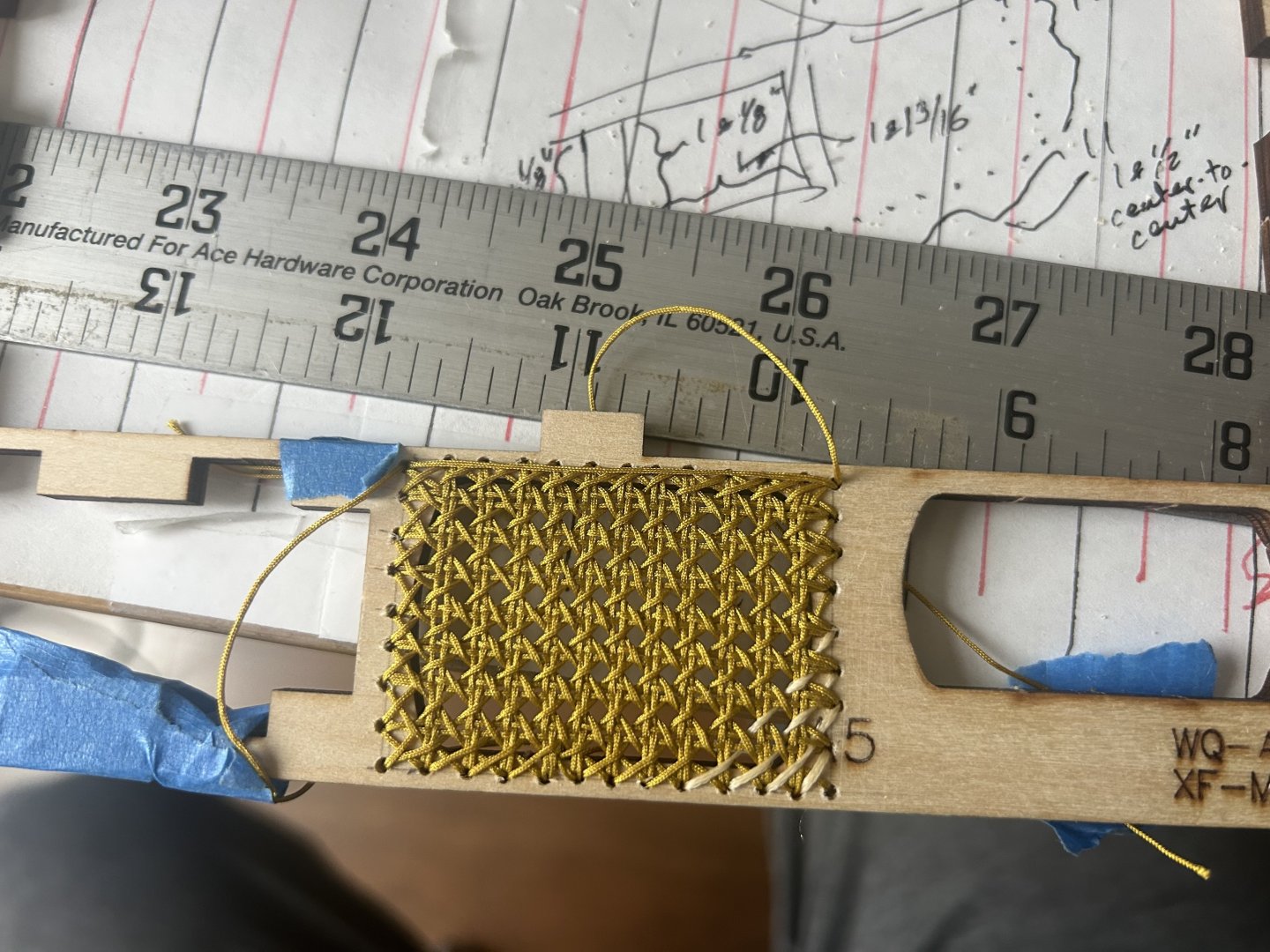

Here is the seat with the second diagonal step completed. Notice there is a missing strand in the upper left corner—I will pick that up when I string the “couching” strands that are to cover the holes and make a nice border. And here I have run the couching strands and corrected the missing corner. All that remains is to run tie-down loops through every (or every other) border hole. Hopefully I can do that without too much drama.

-

halvoric reacted to a post in a topic:

Annapolis Wherry by Landlubber Mike - FINISHED - Chesapeake Light Craft - 1:8

halvoric reacted to a post in a topic:

Annapolis Wherry by Landlubber Mike - FINISHED - Chesapeake Light Craft - 1:8

-

halvoric reacted to a post in a topic:

Canadian Canoe by halvoric - Midwest Products - 1:8

halvoric reacted to a post in a topic:

Canadian Canoe by halvoric - Midwest Products - 1:8

-

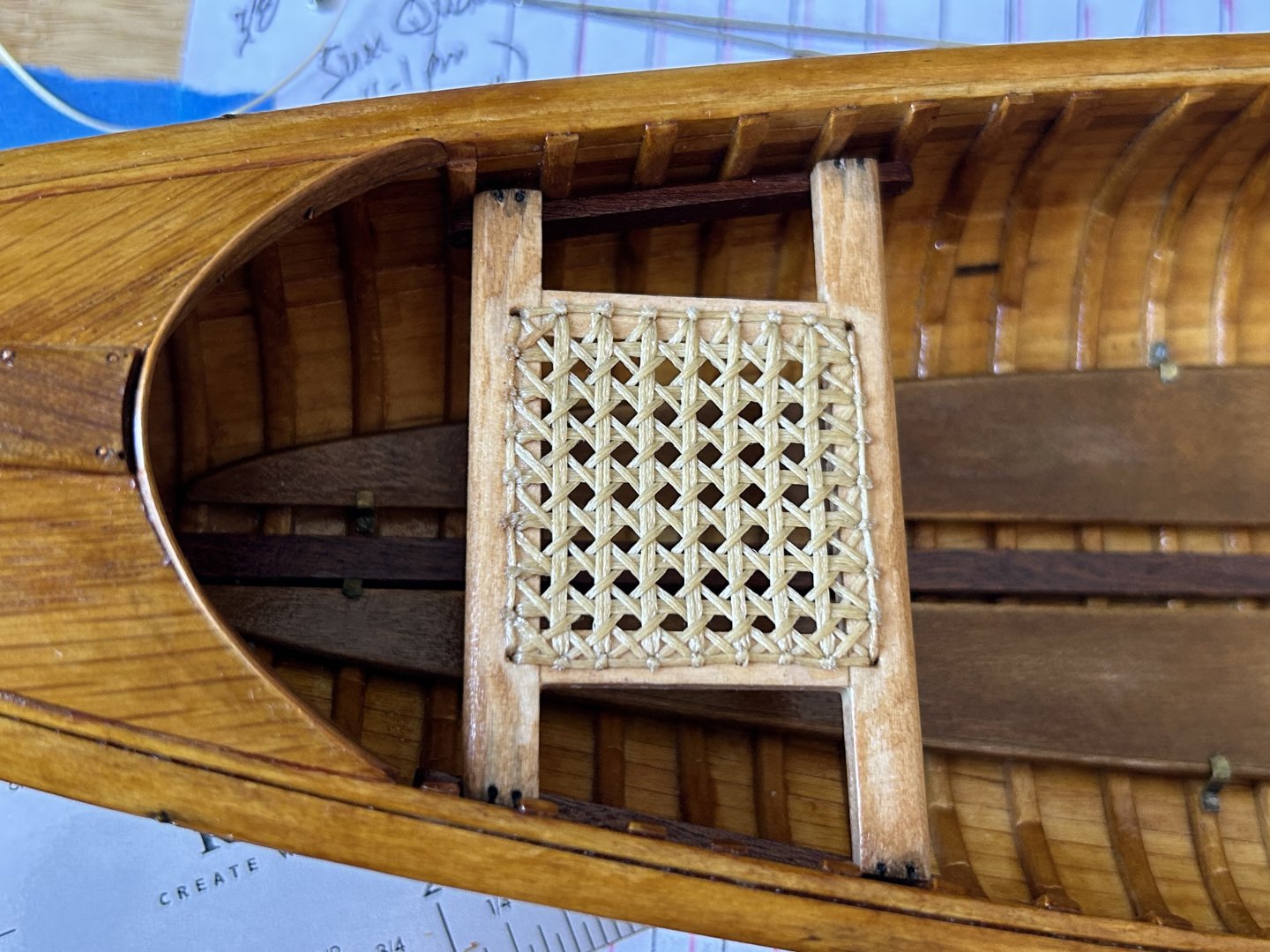

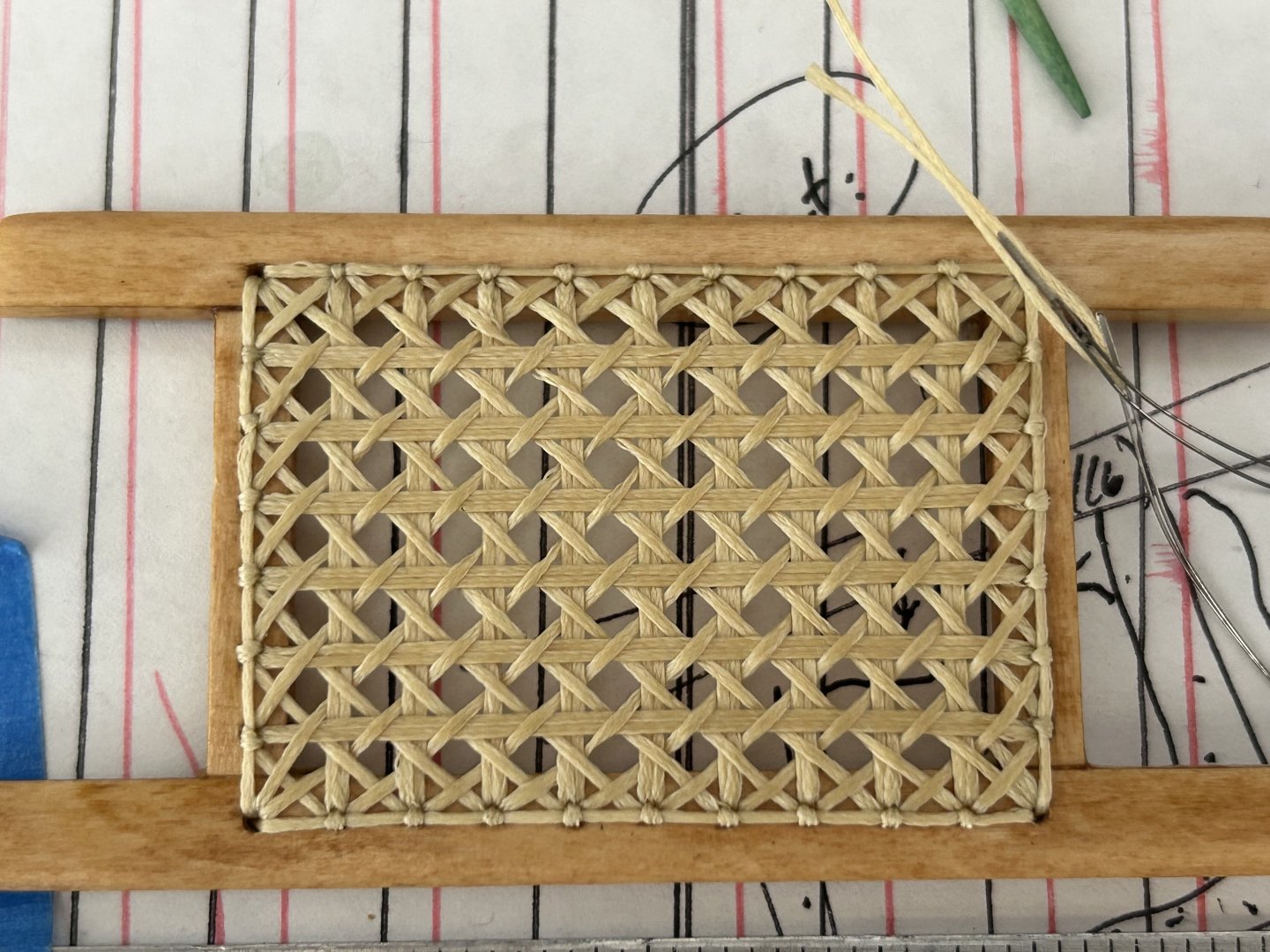

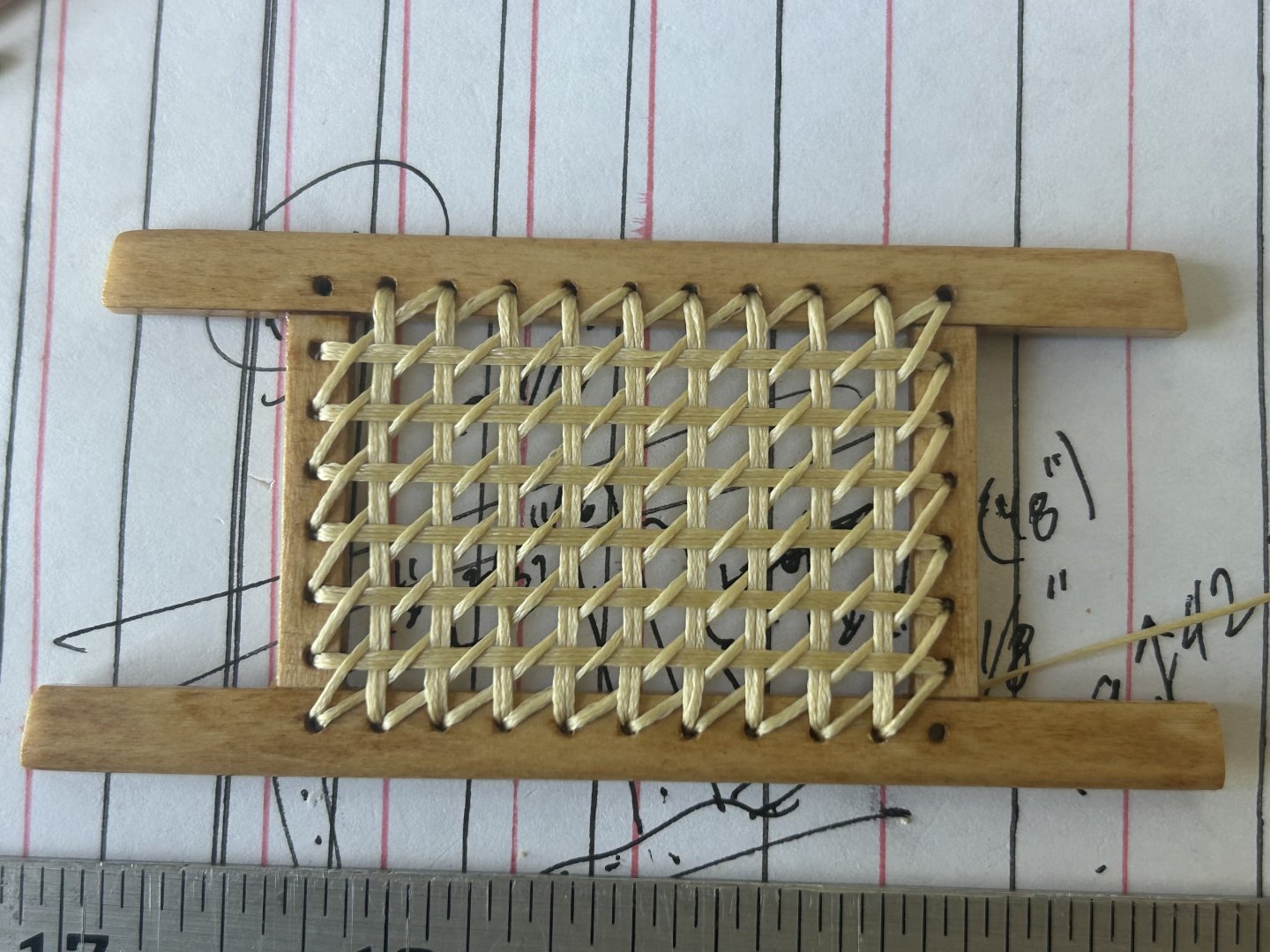

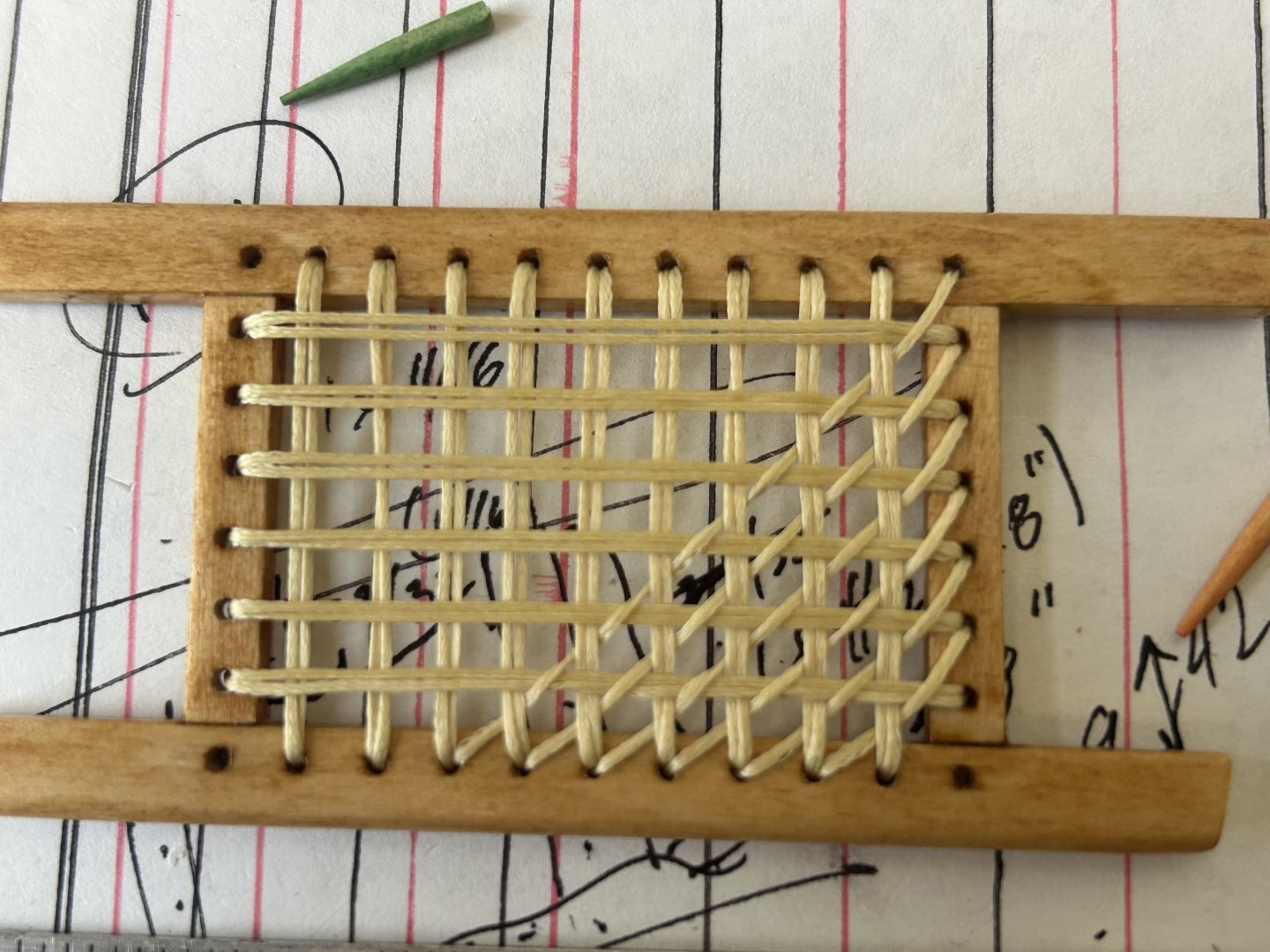

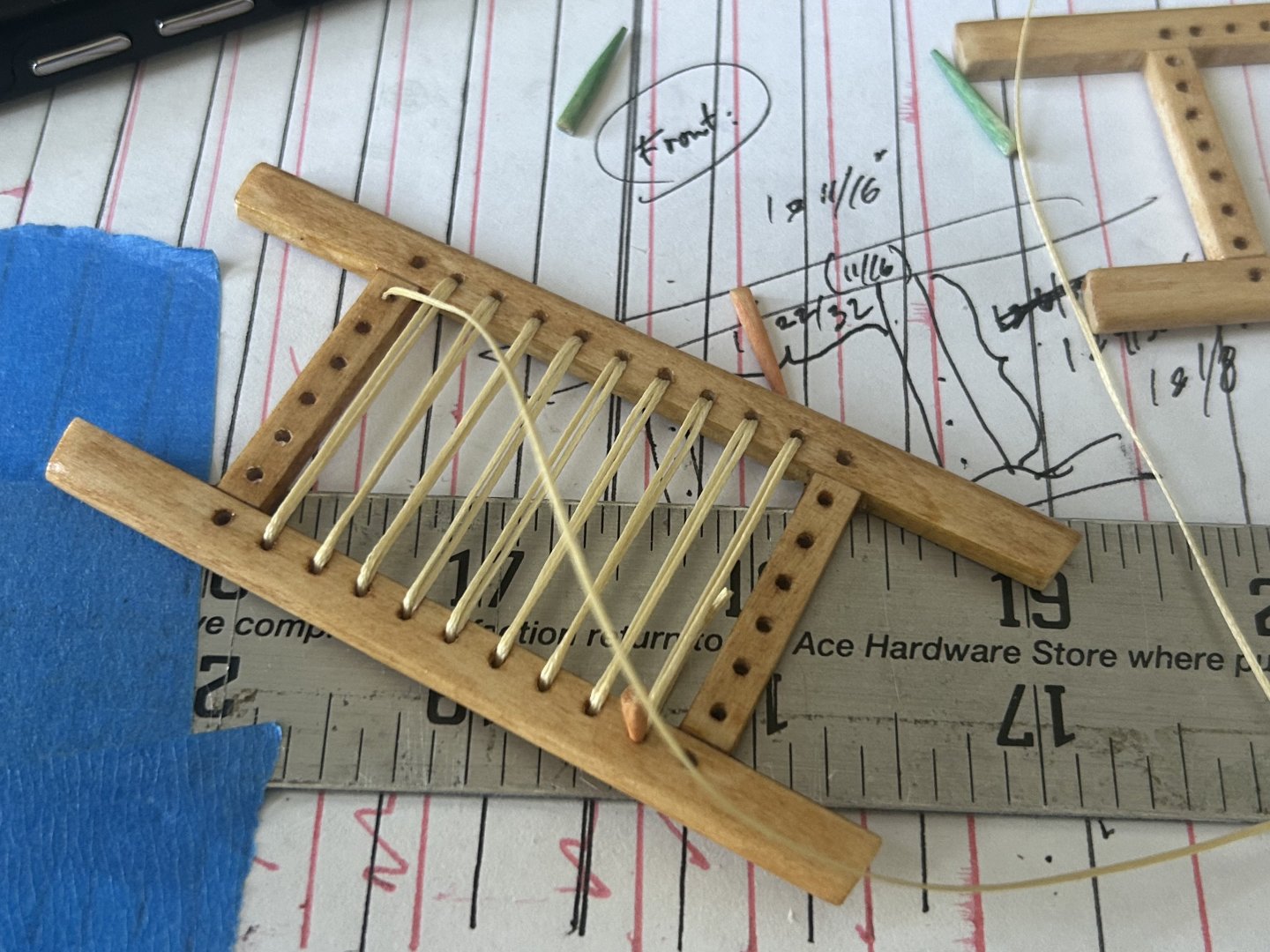

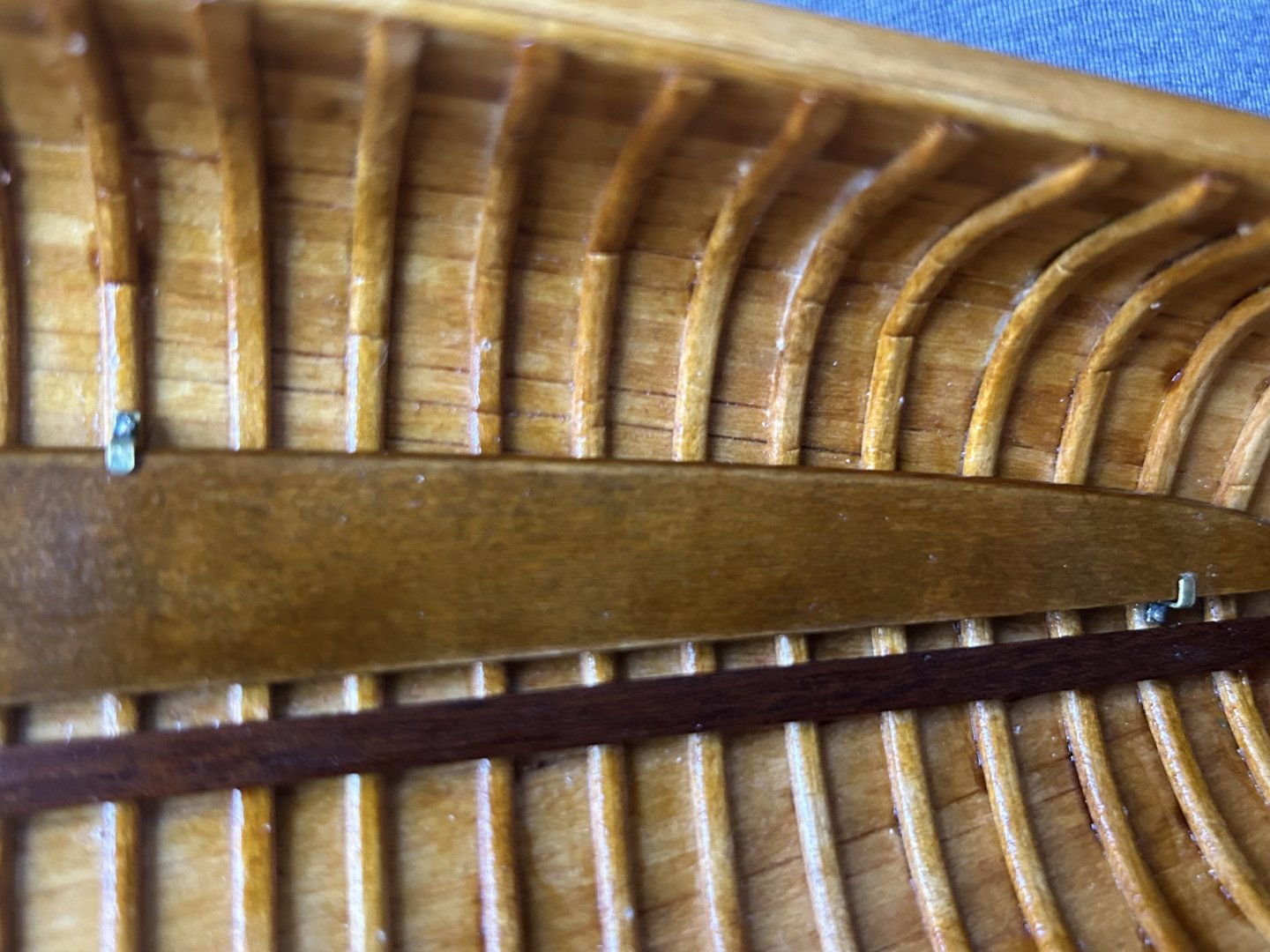

Doing the (larger) front seat first: Verticals and horizontals completed, diagonals about 20% complete: Trying to keep it neat on the underside: See lessons learned from the underside of my test weave: The sharp-eyed may notice a subtle difference in the pattern between the test (traditional warp-and-weft pattern) and the current seat weave (the Peterborough “quick” pattern). This is intentional and based on my research (and great debt owed to Mike Elliott’s “This Old Canoe” books). There was also a Chestnut Canoe Co. version of the “quick” pattern. What the two quick patterns have in common, and in contrast to the traditional pattern, is that they skip the weaving that normally happens in the fourth step of the vertical/horizontal matrix. The difference between the Chestnut and Peterborough quick patterns is quite subtle and is just in the last diagonal step (which strands the diagonal goes over versus under). And now you know more than you will ever need to (or wanted to) about canoe seat caning patterns. 😆

-

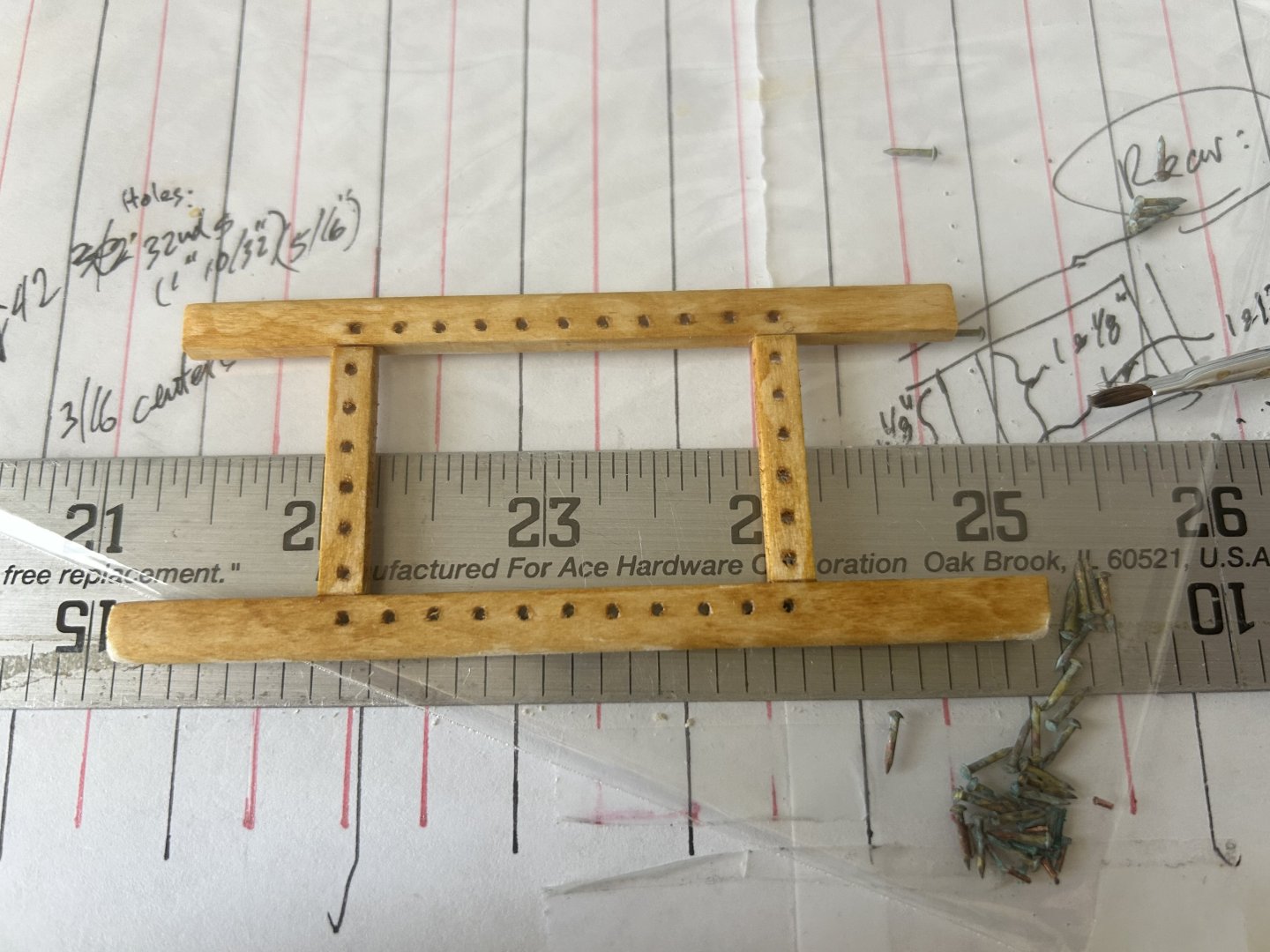

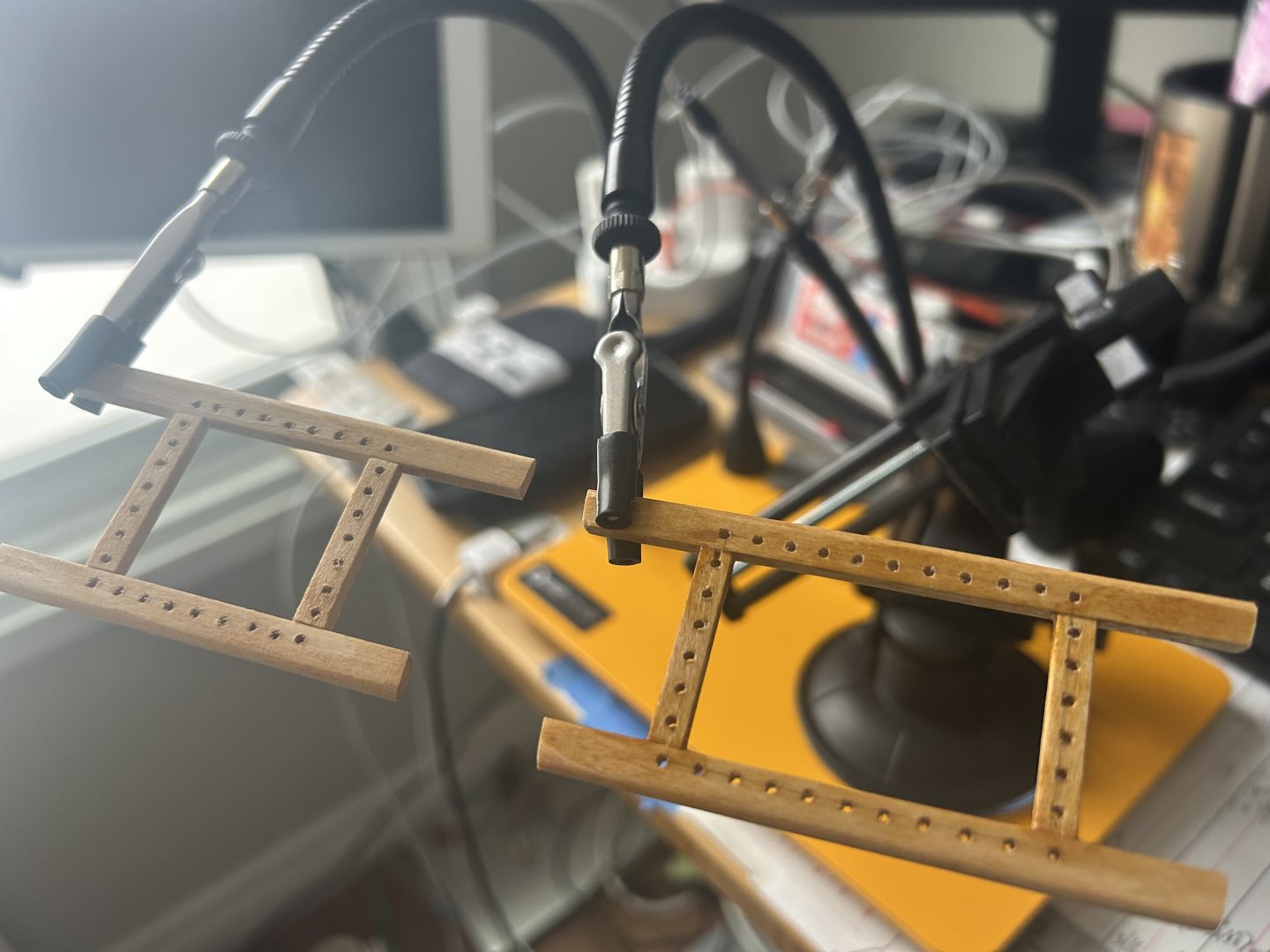

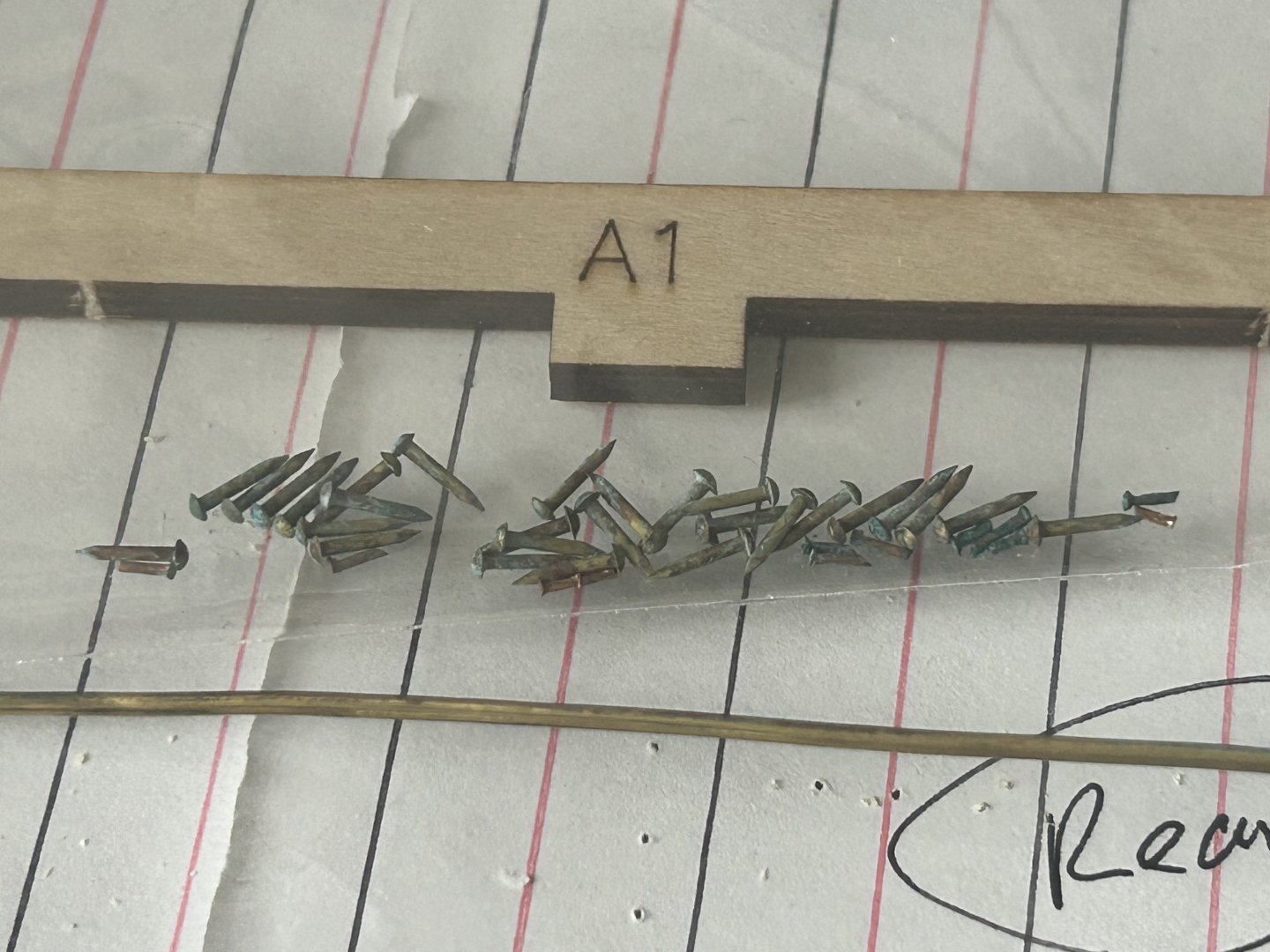

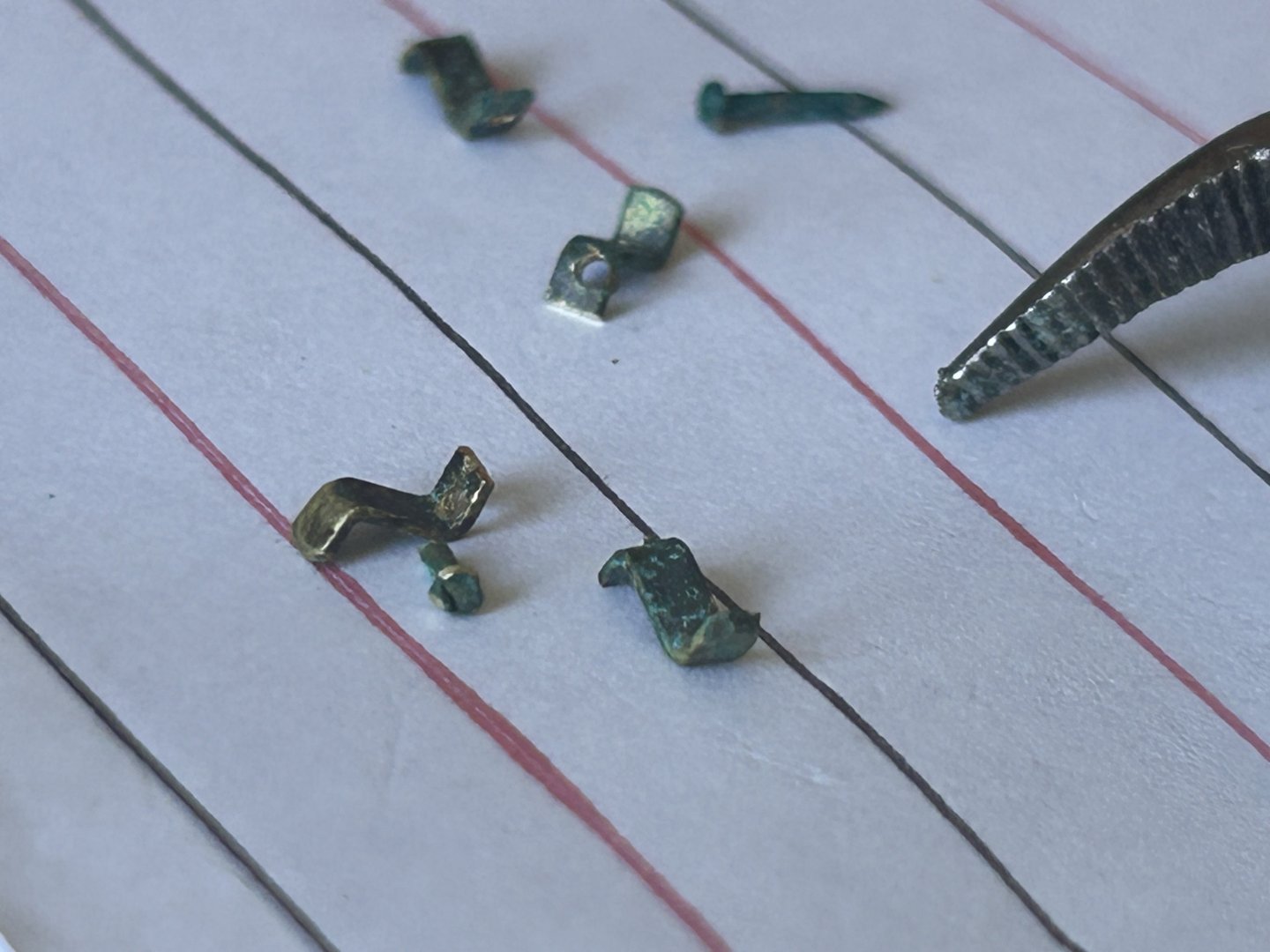

It’s taken me a while to plan out exactly how to manage the seats (basswood, with a light stain, and a semi-gloss clear lacquer varnish) and seat supports (3/32 x 3/16 mahogany), and to settle on the sizes and hole patterns for the caning. Still not sure if I’ll be happy with the scale (thinking they may read as a bit oversized), but if not perfect I can always re-make them with another 30 hours of meticulous labor (😆). Another batch of screws/bolts will be needed for the seat supports, and some tiny screws for the brass keel strip, which has been weathered/patinated, just needs straightening. Here is the test warp & weave caning job at scale, although I will be using the flat waxed linen thread (visible in lower right corner) rather than the gold woven thread. Already screwed up the front seat (was supposed to be 9 rows high by 11 wide, somehow I only made 8 rows high).

-

halvoric reacted to a post in a topic:

Norwegian Sailing Pram by MBerg - FINISHED - Model Shipways - 1:12

halvoric reacted to a post in a topic:

Norwegian Sailing Pram by MBerg - FINISHED - Model Shipways - 1:12

-

halvoric reacted to a post in a topic:

Norwegian Sailing Pram by MBerg - FINISHED - Model Shipways - 1:12

halvoric reacted to a post in a topic:

Norwegian Sailing Pram by MBerg - FINISHED - Model Shipways - 1:12

-

halvoric reacted to a post in a topic:

Norwegian Sailing Pram by MBerg - FINISHED - Model Shipways - 1:12

halvoric reacted to a post in a topic:

Norwegian Sailing Pram by MBerg - FINISHED - Model Shipways - 1:12

-

halvoric reacted to a post in a topic:

Canadian Canoe by halvoric - Midwest Products - 1:8

halvoric reacted to a post in a topic:

Canadian Canoe by halvoric - Midwest Products - 1:8

-

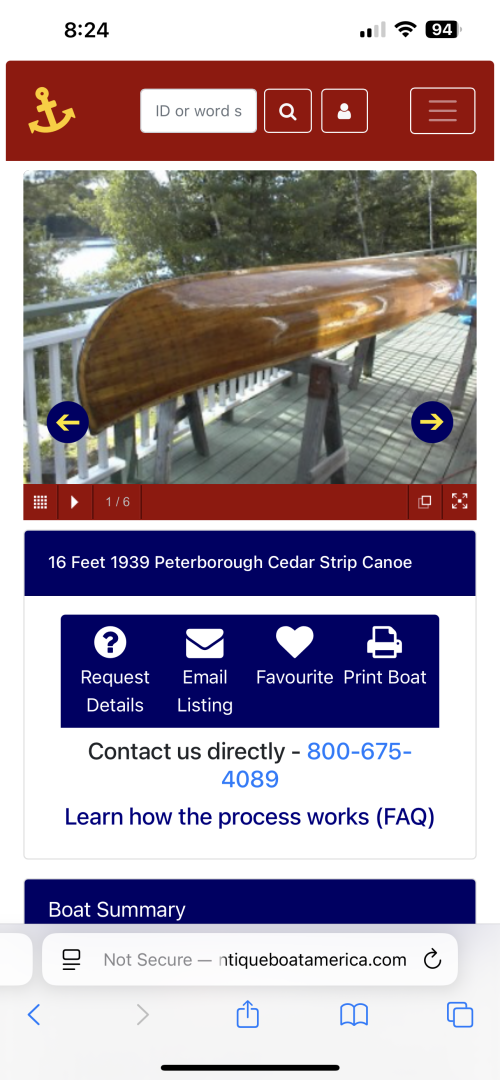

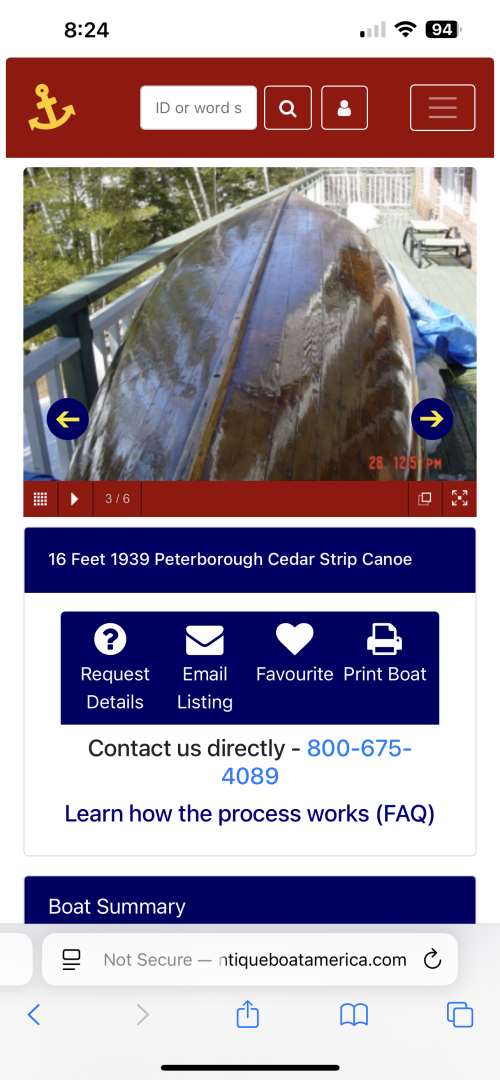

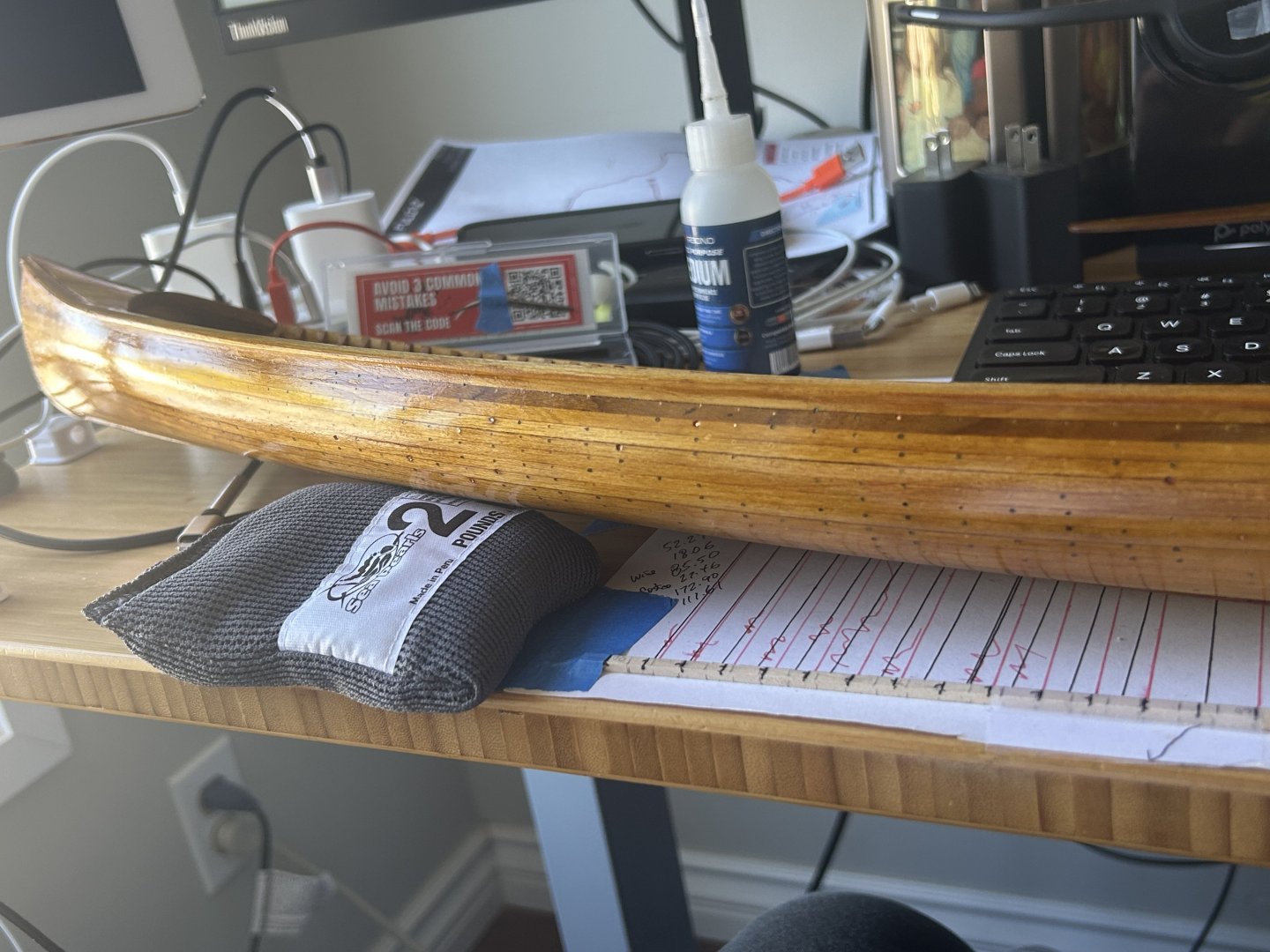

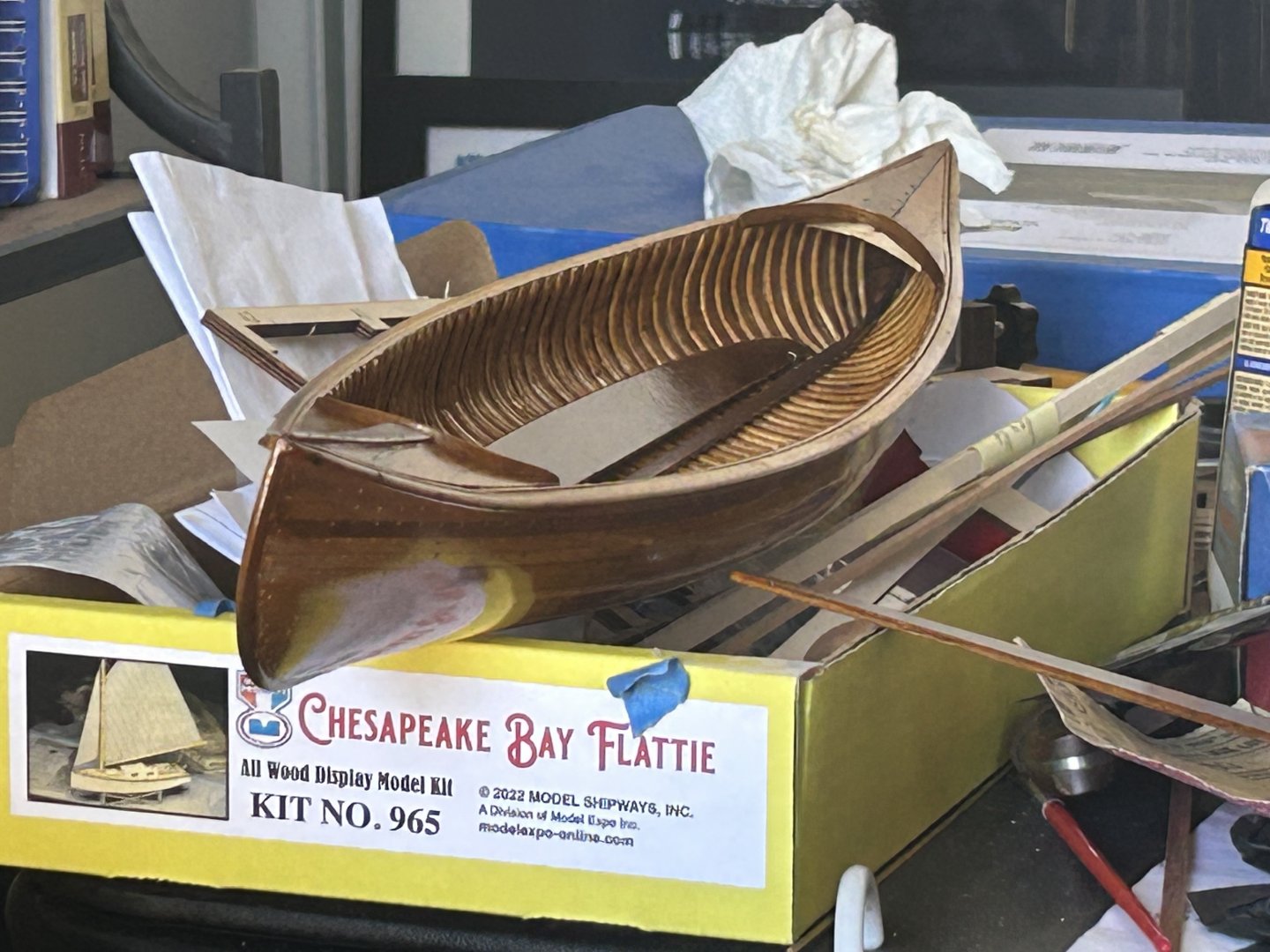

Now both floorboards are in and the hull polish is “done” (it’s hard to resist adding a micron or two more and then buffing it out again). Had to add a few coats to one side as my very last floorboard bracket screw hole popped all the way through. Oops. And I’ve found one more reference canoe online, this one with the glossiest finish I’ve seen yet. Makes me feel a bit more “scale”. Now for a lot of measuring twice and cutting once as I decide where the two seats and single thwart and their mounting pieces need to go. Not really looking forward to caning the seats as it is remarkably tedious work. But worth it I hope.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.