-

Posts

90 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by James Flynn

-

-

On 12/16/2024 at 8:07 AM, JacquesCousteau said:

That's odd, as maple is pretty frequently used--typing it in the search bar returns over 2,000 results. For examples, see:

Walnut is also frequently used, especially as a second planking material in kits, although some complain that it's too brittle or has too visible grain.

Ya I found quit a few maple and walnut after I made my post just didn't dig deep enough, I was reading in the

Wood discussion...Where to use it? Where to get it? What types are best? How to Finish it?

and didn't see any maple talked about in this desiccation then made my post I should have dug deeper.- mtaylor and JacquesCousteau

-

2

2

-

3 hours ago, JacquesCousteau said:

Nice start!

On the wood issue: Cherry is a nice wood that's cheaper some of the others that have been mentioned, if you'd like the model to look a bit darker. Rather than buying a bunch of samples and testing them out, you could look at models on this site that you like the look of and see what wood you like. If you search, you'll also find several posts about which types of wood to use. Some say that Beech does a decent job of representing oak in scale, for instance, and others like Alaskan Yellow Cedar, Holly, or other woods. Based on a quick look, Teak seems to have large visible grain which could be a problem for modeling.

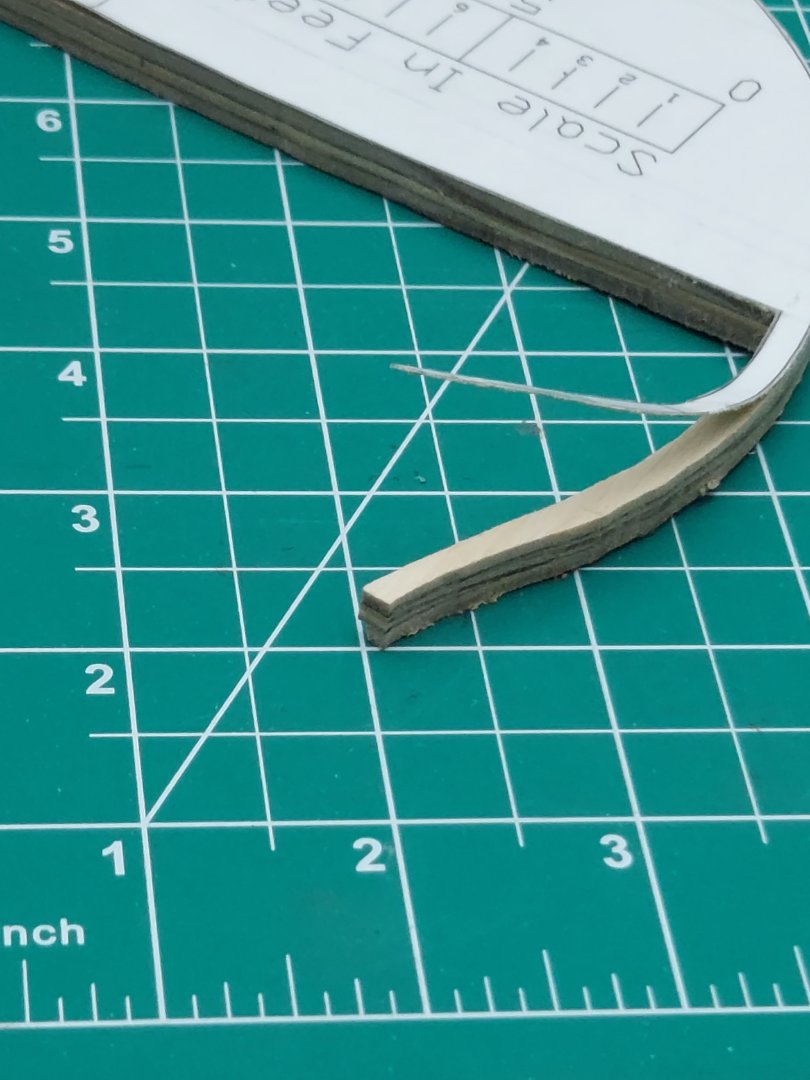

As for planking dimensions, 1/8-inch thick wood is much too thick for the curves of the hull. People generally use 1/16, 3/64, or 1/32-inch thick wood for planking--something that will easily bend. 1/32-inch curves very well but doesn't leave you with much room for sanding, 1/16-inch may be better for a model of this size. I'd recommend checking what thickness other people have used for planking similar models (such as the Winchelsea, another frigate which has a lot of build logs on this site). The width will depend on whatever was appropriate for the time and place--without doing a lot of research, you could probably just see what other people have used for similar models in this scale.

I thank you for your responce this helps me a tun. I'm thinking of using hard maple with a erly american stane for the planking and decking and black walnut for darker contrest like trim work and for the black strip on the side of the hull mainly because both have a fine grain structure but I don't see any one using maple at all can't help but wonder why from my research it seems to be a great wood stra straight grain esy to work finer grain then even boxwood can't figure why more people aren't using it.

- JacquesCousteau and mtaylor

-

2

2

-

-

2 hours ago, AnobiumPunctatum said:

I didn’t work with both timbers. In Europe lots of modellers choose pear and cherry.

Expensive is relative. You work a really long time on such a model. So the monthly costs are also for box and pear are not to high.

another quick question I have is the size wood I should use for my planking and my decking I'm thinking 1/4 wide x 1/8 thick I'm wondering because for such a small model that might be too big for 1/48 scale. I struggle with working out scale. Looking at it just seems too wide to be accurate scale. and do you know how long the bored should be to be accurate scale so I can have the right separation marks between them?

-

-

1 hour ago, vossiewulf said:

The large grain of oak is not appropriate for small ships, using oak for small scales results in ships that look like toys. Wooden ship modeling wood has always been as fine-grained as possible while holding good detail and being reasonably workable. The traditional wood used on contemporary models was European boxwood, a very fine-grained wood. It's hard to get and therefore expensive, so most modelers have turned to other fine-grain woods like pear, Castillo boxwood, cherry, or yellow cedar.

would you have an opinion on Acacia or teak

-

would any have an opinion on using acacia or teak

-

40 minutes ago, AnobiumPunctatum said:

I think it depends on your personal taste. I have looked at all the woods mentioned. Since I paint my models, I finally decided on boxwood and holly. With natural wood models, the combination of pear and boxwood also works very well. It's best to get some samples and then decide what you like best.

what would you think about teak it's supposed to be great for boats but models not sure

-

38 minutes ago, AnobiumPunctatum said:

I think it depends on your personal taste. I have looked at all the woods mentioned. Since I paint my models, I finally decided on boxwood and holly. With natural wood models, the combination of pear and boxwood also works very well. It's best to get some samples and then decide what you like best.

what would red cedar be like in your opinion?

-

34 minutes ago, AnobiumPunctatum said:

I think it depends on your personal taste. I have looked at all the woods mentioned. Since I paint my models, I finally decided on boxwood and holly. With natural wood models, the combination of pear and boxwood also works very well. It's best to get some samples and then decide what you like best.

Wow boxwood and pear exceptive and hard to get disappointing and discouraging

-

6 minutes ago, AnobiumPunctatum said:

I think it depends on your personal taste. I have looked at all the woods mentioned. Since I paint my models, I finally decided on boxwood and holly. With natural wood models, the combination of pear and boxwood also works very well. It's best to get some samples and then decide what you like best.

Know I wish I hadn't already gone out and bought all this oak, but I thank you guys for your knowledge best to know early then closer to the end, but dang I'm going to half to build the front again for the fourth time. Guess that's modeling, do it until its right. Thanks again

-

10 minutes ago, vossiewulf said:

The large grain of oak is not appropriate for small ships, using oak for small scales results in ships that look like toys. Wooden ship modeling wood has always been as fine-grained as possible while holding good detail and being reasonably workable. The traditional wood used on contemporary models was European boxwood, a very fine-grained wood. It's hard to get and therefore expensive, so most modelers have turned to other fine-grain woods like pear, Castillo boxwood, cherry, or yellow cedar.

Good to know thank you for your comment curious out of the 5 you mentioned which would stain out with the best look? I'm only planning to paint the black stripe down the side I'm wanting the rest to take a stain look.

-

-

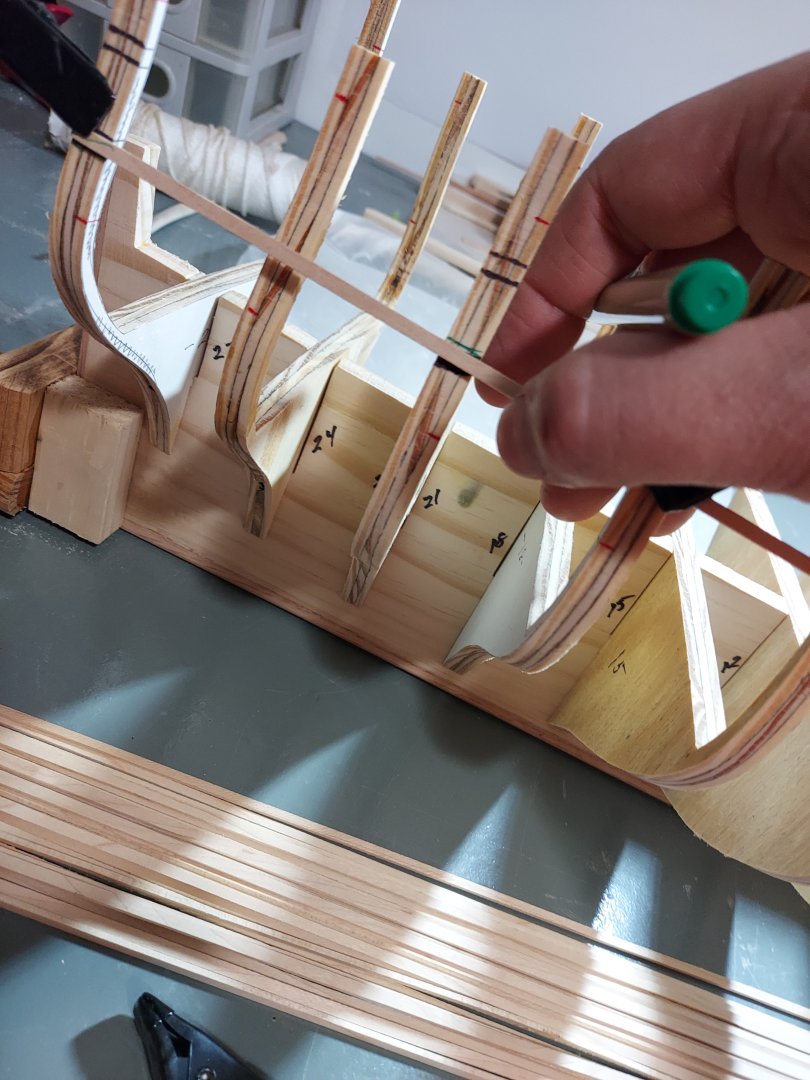

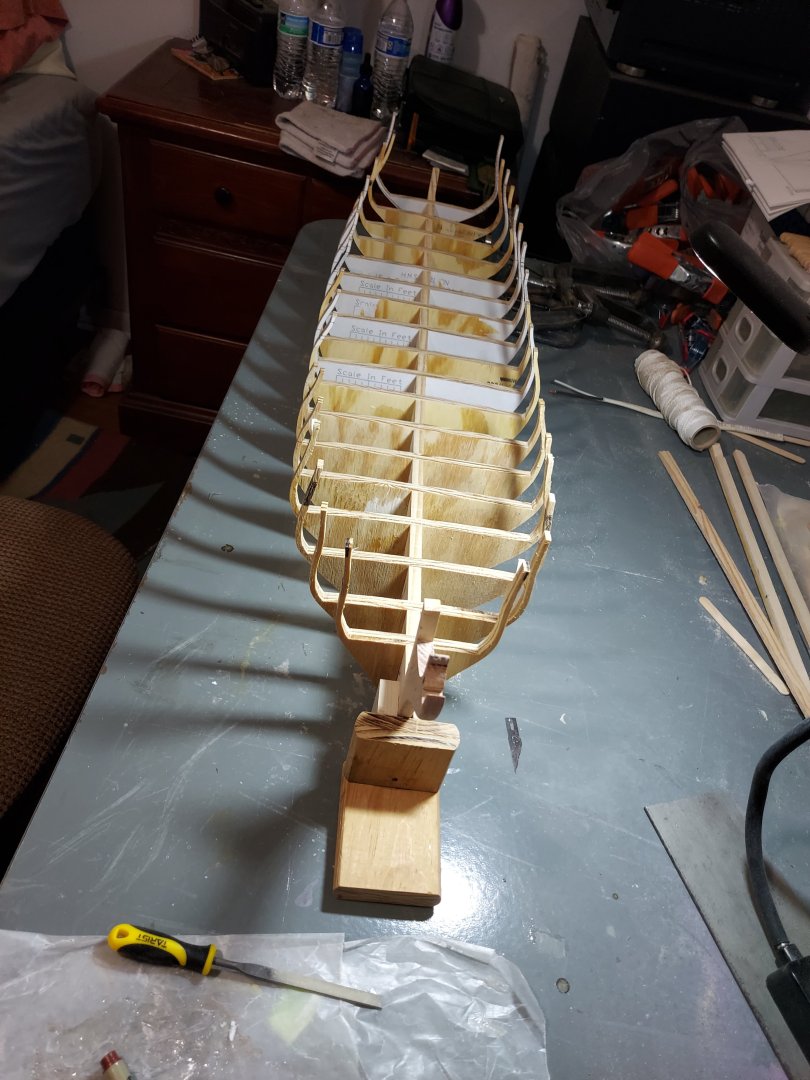

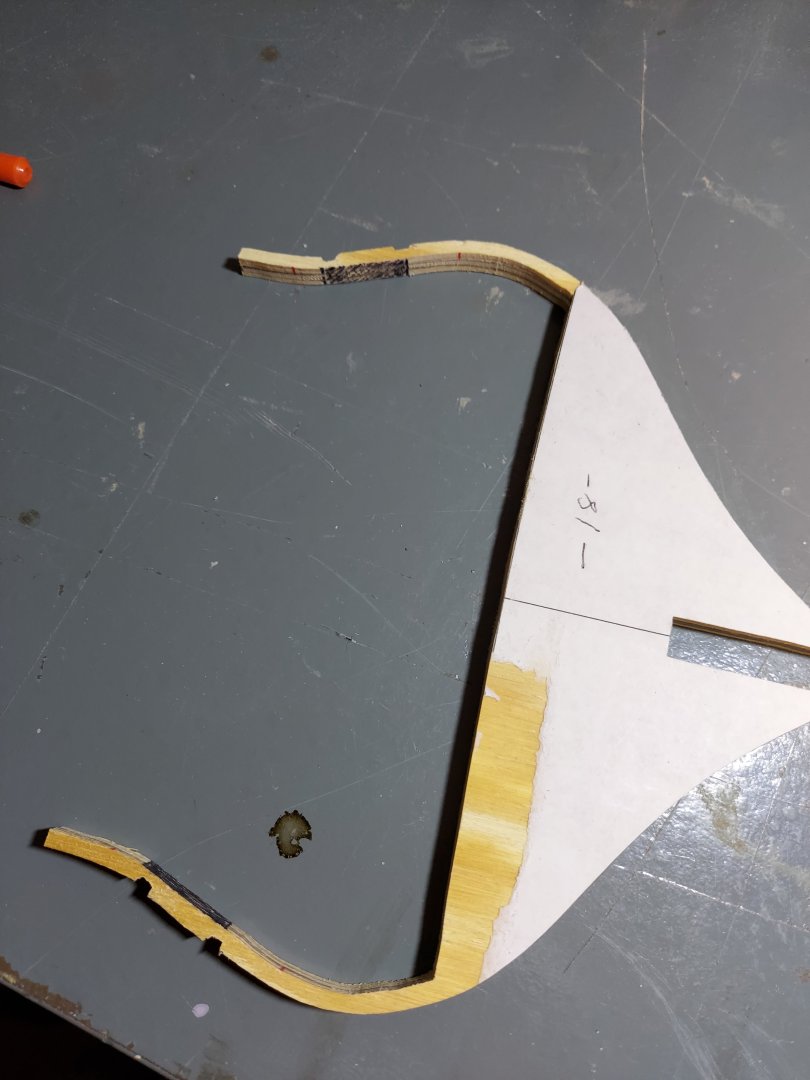

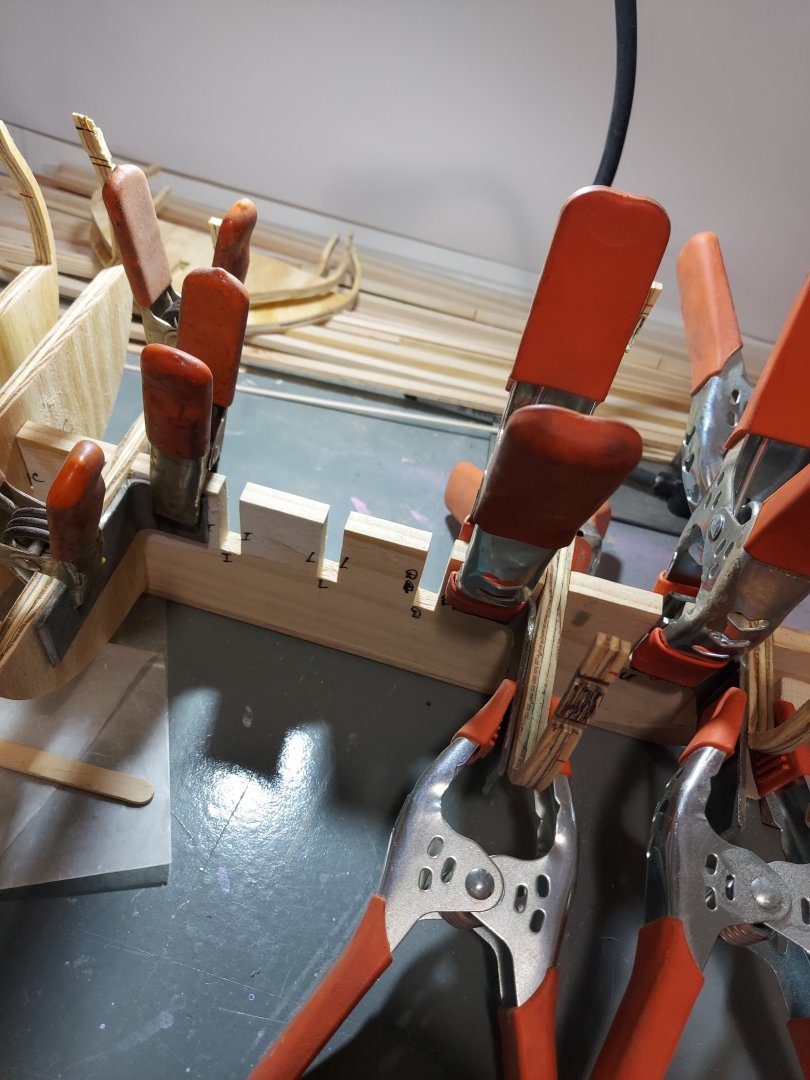

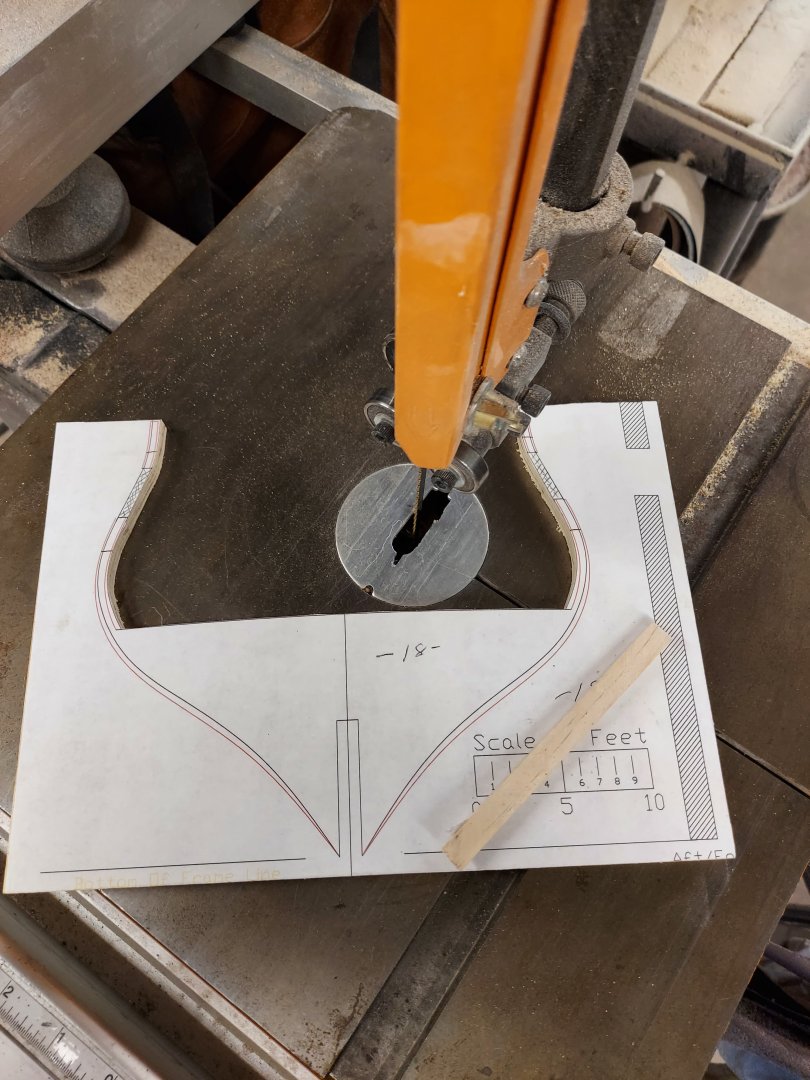

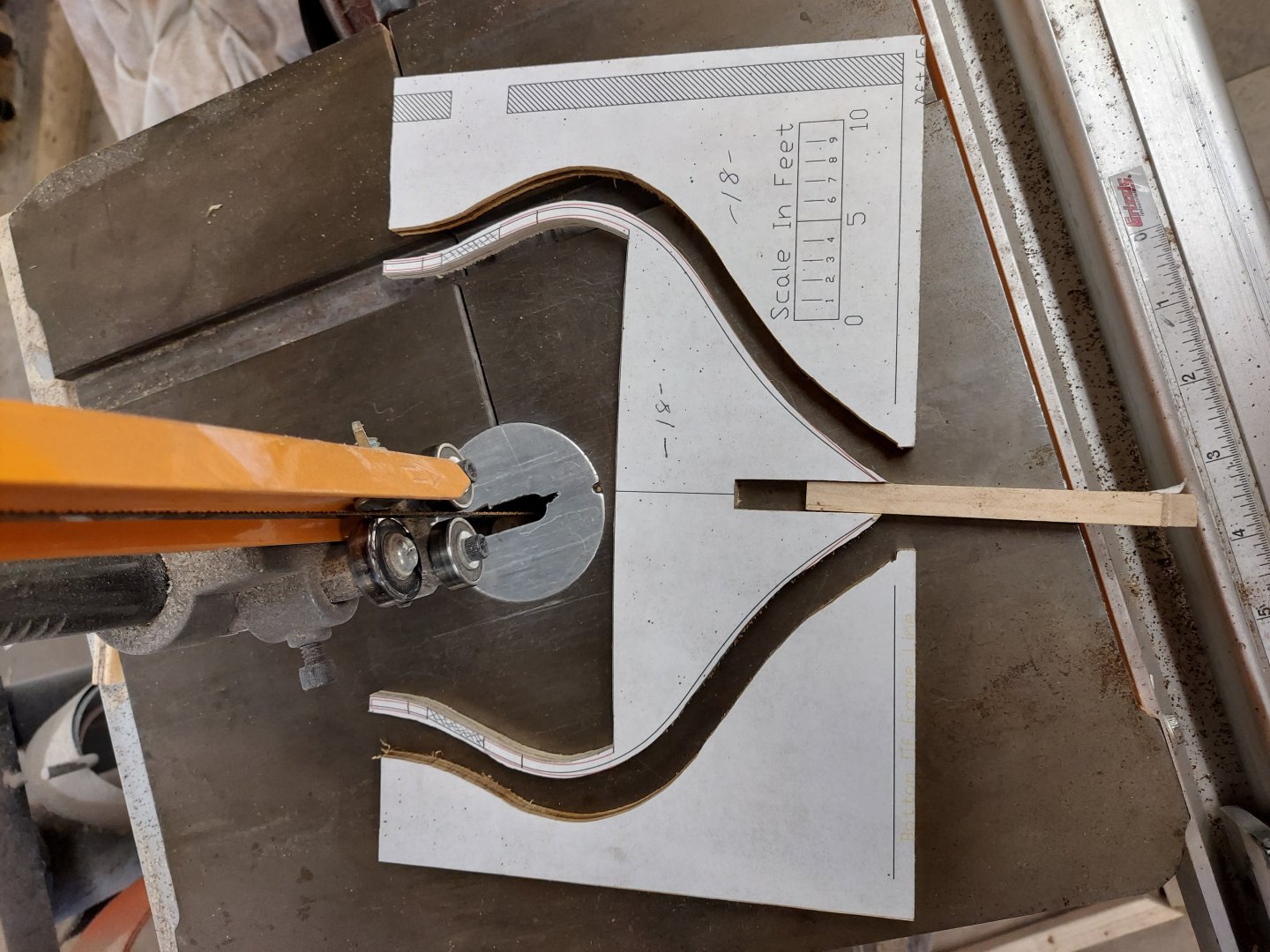

I made the front stem piece and the keel buy the POF plans but I couldn't get the fit without modifying them and after making them twice with the same results I decided I would build them off the POB plan and out of one solid piece also I wanted to build them out of oak with hopes of keeping the finish product looking true to form and I didn't really like the look of the birch anyway.

- mtaylor and JacquesCousteau

-

2

2

-

-

17 hours ago, AnobiumPunctatum said:

It's looking really good. Let a little bit more meet on the outside of the frames. This makes it easier to fair the hull after installing all frames.

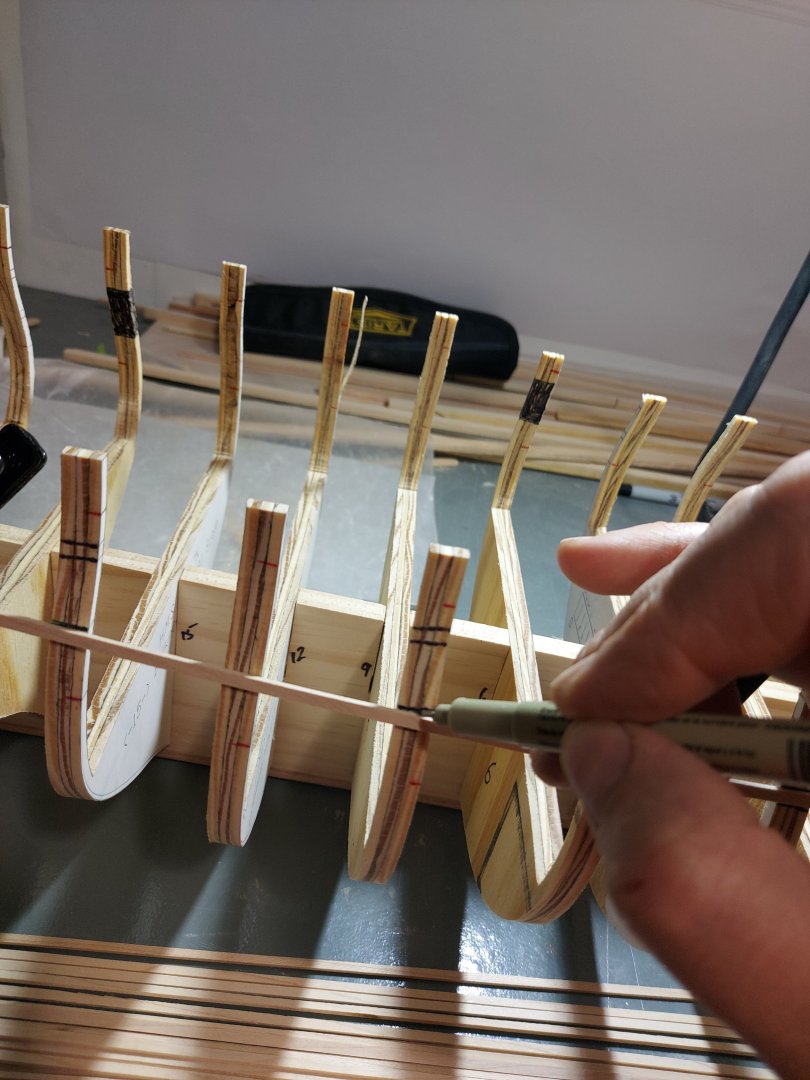

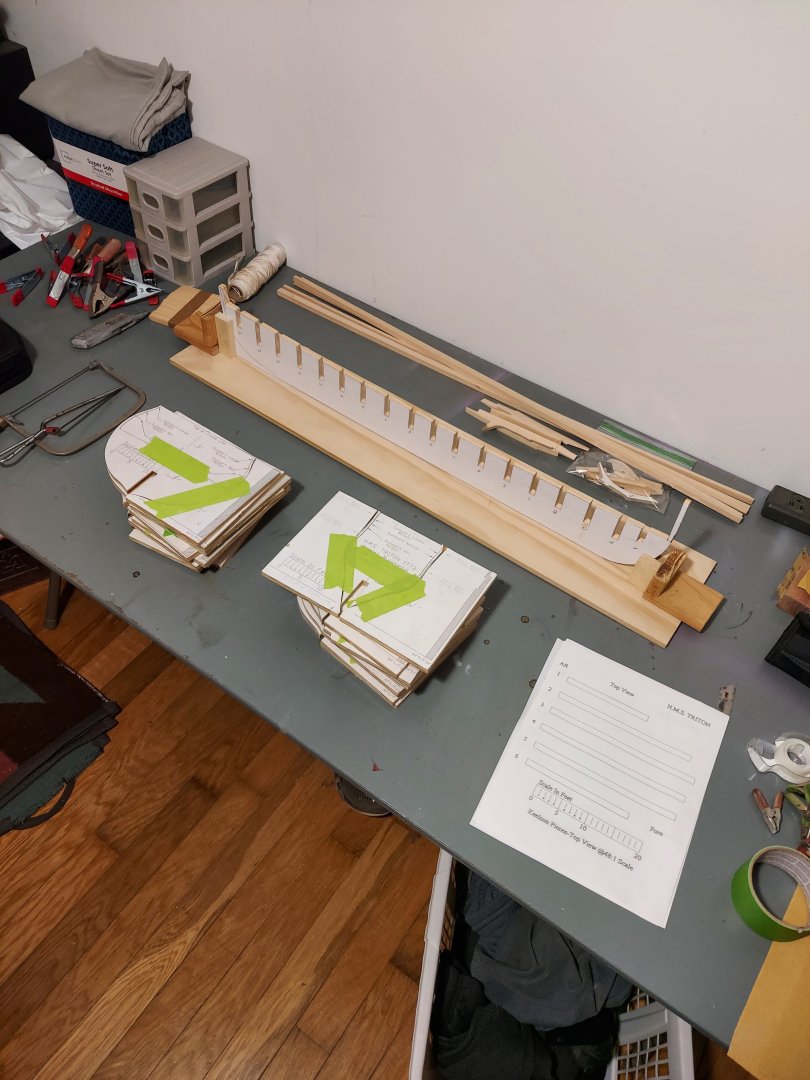

Thank you for your comments and yes, I can see exactly what you're talking about, now that I have all the frames cut and sanded and on the center board, I hope not to half to redo all that work. I'm hoping to fair just enough to give me meat enough to glue the planking on. Fingers crossed

- mtaylor and AnobiumPunctatum

-

2

2

-

- Matt D, Jorge Diaz O, mtaylor and 3 others

-

6

6

-

On 11/25/2024 at 2:52 PM, AnobiumPunctatum said:

Have a look in the log of Jorge. He describes especially the start of his project really detailed.

Looking more carfuly I think I can see how it works it looks like the gun port lintal go between the ribs from inside the hull not from outside but some of the notches are on the opposite side in the plans that's why I'm confused well hopefully it will all come together during assembly

- AnobiumPunctatum and mtaylor

-

2

2

-

8 minutes ago, James Flynn said:

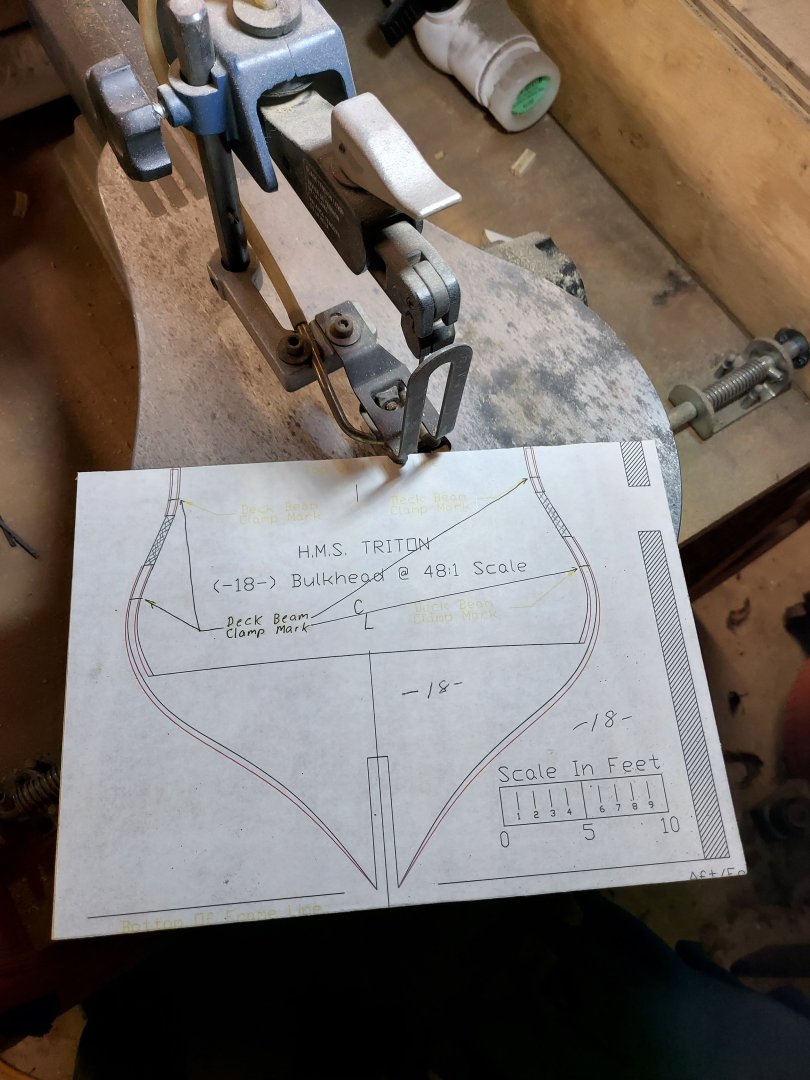

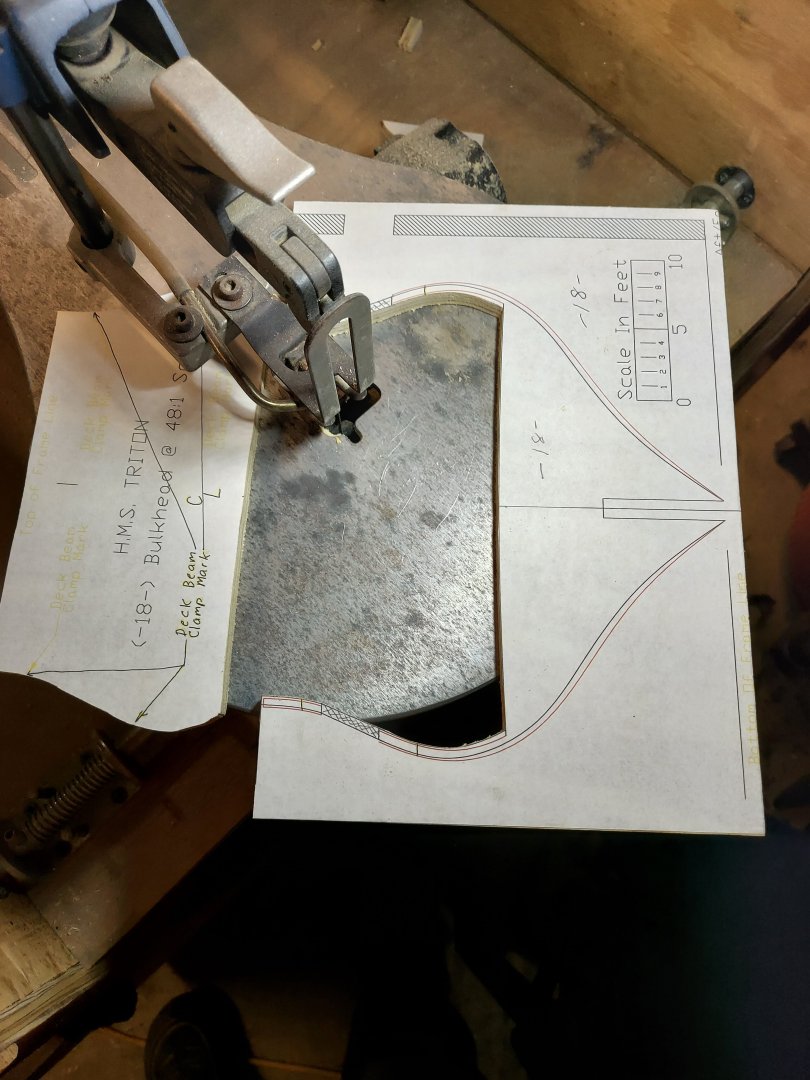

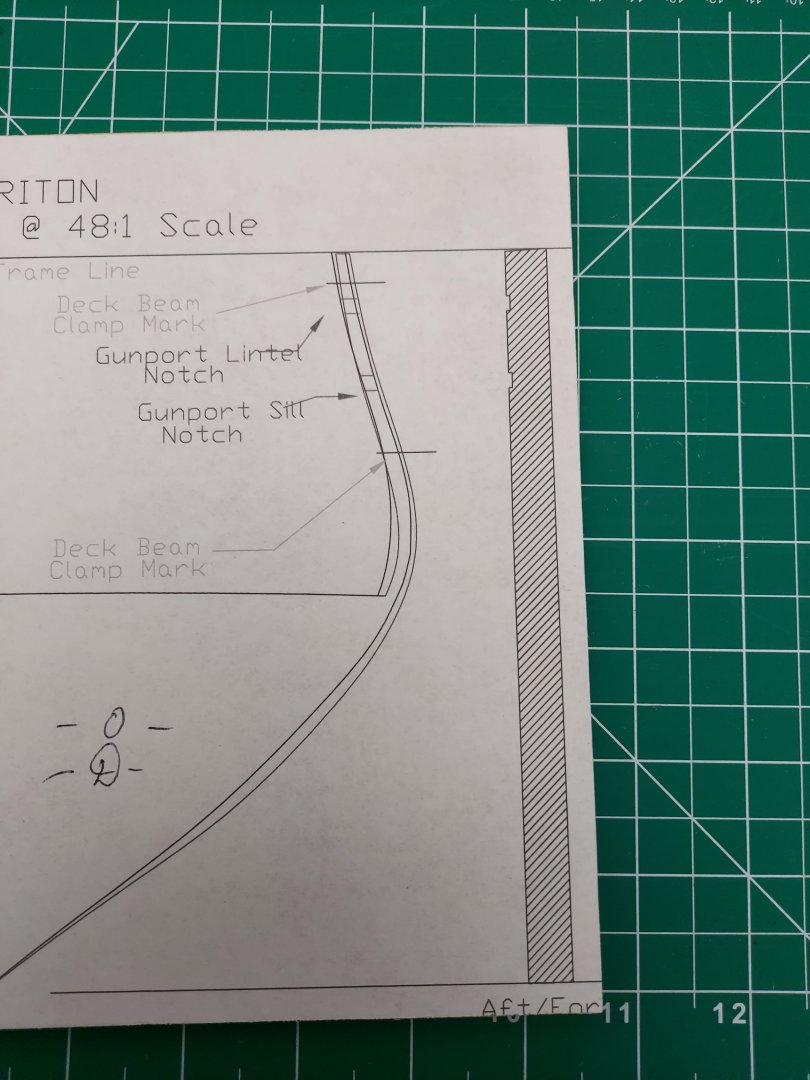

I have been following Jorge's build with a magnifying glass looking over every pic. and yes, it is a great build log verry helpful and has answered many of my questions but still I have questions for example in this pic over on the far-right side is shown a side view of this bulkhead and at the top it shows two notches cut out my question is are those notches on the outside of the ship or the inside? And If I lay the bulkhead flat down on my table face up are the notch's face up or face down but if that were the case that would make beams run across the deck from one side to the other on both the gun deck and the top deck so that can't be right.

What exactly is a gun port lintel Notch? And how is it used.

WOW I never realized just how much I didn't know about ship building. There is so much I need to learn and even though it's taking me forever to get cutting I'm having a great time with the challenge of it all. I can't white to see the progress of this thing coming together on my bench top.

To be clear I do understand the gun port is the door the gun shoot's through

-

20 hours ago, AnobiumPunctatum said:

Have a look in the log of Jorge. He describes especially the start of his project really detailed.

I have been following Jorge's build with a magnifying glass looking over every pic. and yes, it is a great build log verry helpful and has answered many of my questions but still I have questions for example in this pic over on the far-right side is shown a side view of this bulkhead and at the top it shows two notches cut out my question is are those notches on the outside of the ship or the inside? And If I lay the bulkhead flat down on my table face up are the notch's face up or face down but if that were the case that would make beams run across the deck from one side to the other on both the gun deck and the top deck so that can't be right.

What exactly is a gun port lintel Notch? And how is it used.

WOW I never realized just how much I didn't know about ship building. There is so much I need to learn and even though it's taking me forever to get cutting I'm having a great time with the challenge of it all. I can't white to see the progress of this thing coming together on my bench top.

- GrandpaPhil and mtaylor

-

2

2

-

On 11/23/2024 at 1:08 AM, AnobiumPunctatum said:

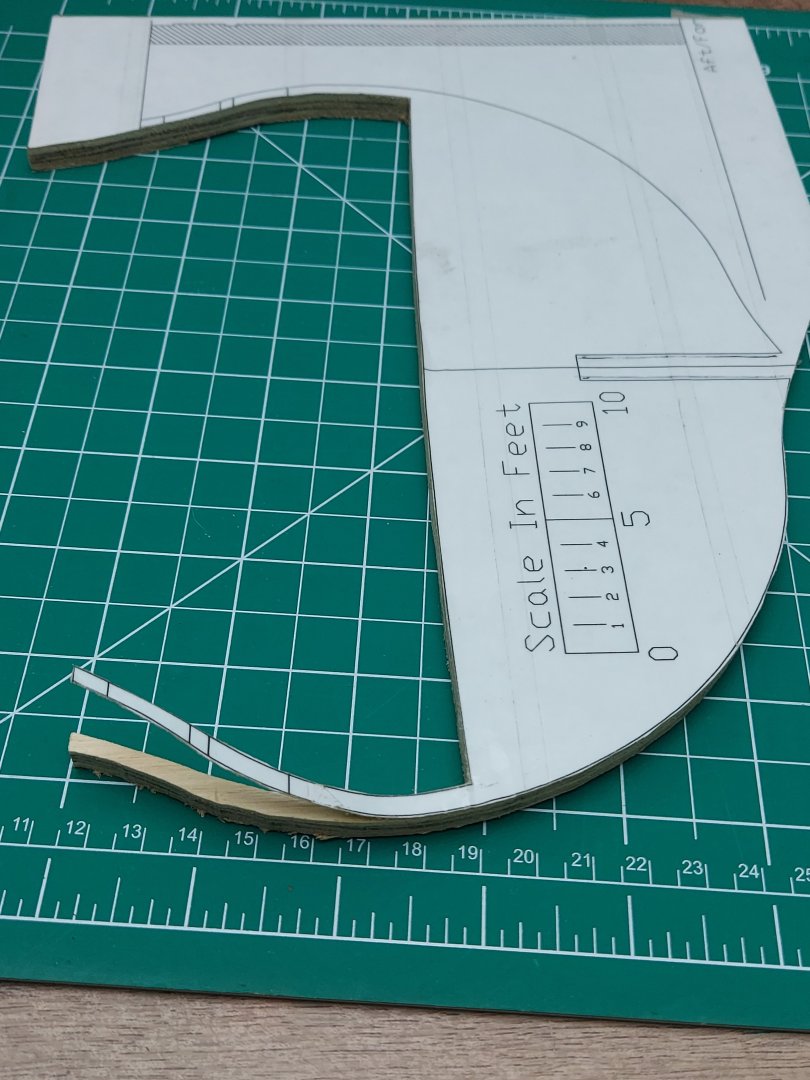

If you print the parts of the model check on your program that the scale of the printout is 100% and not fitted to sid or something similiar. You can check the scale of each print out with the ruler shown on every PDF. It is given the length of 10 feet in the scale 1/48. In metric scale it's exact 63.5mm. Don't worry about your thoughts. It's the beginning of a really long journey. For me the MSW project was also the start in scratch building.

If you have not much experience I can recommend the cross section as a really good entry point. It hase the same scale as the full hull build but is much less complicated.

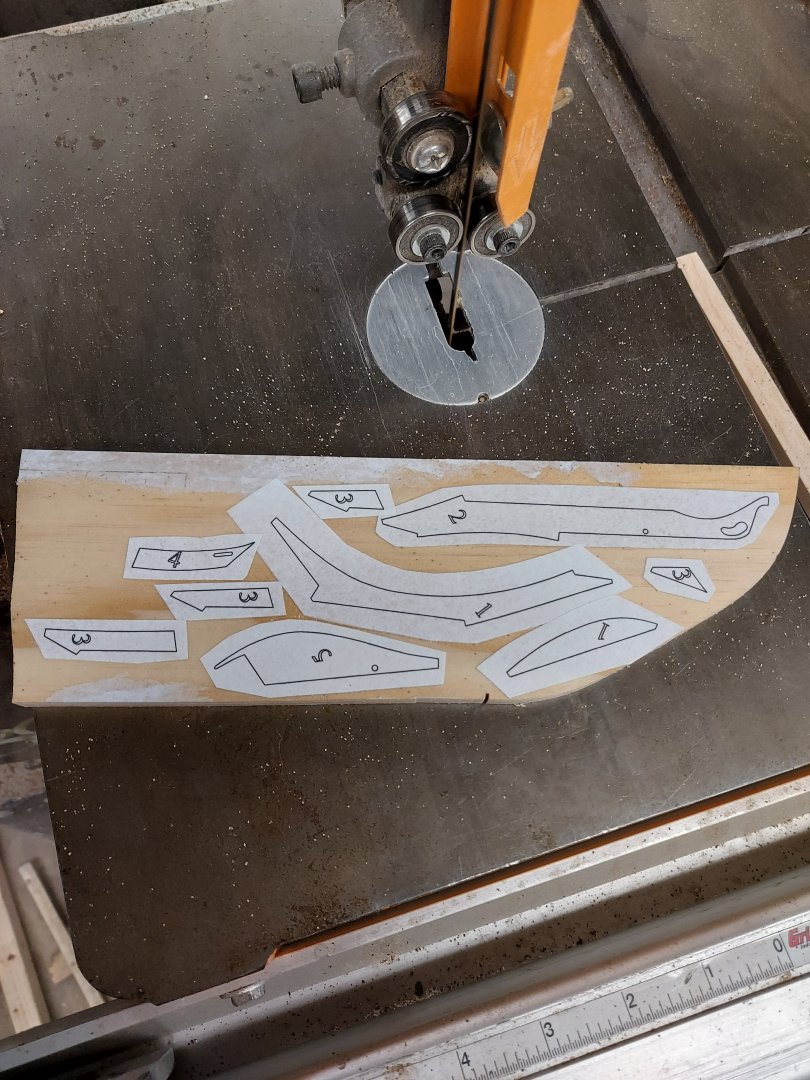

Wow I'm looking at all these plans there are so many of these prints I have no idea what they are or where they go Might be calling on you if that's ok. All the window pieces and keel and fore deadwood pieces it's all mixed up in the way they put them in order and some of which I'm not sure were or what it is. Understand I will do my due diligence and try looking as much up as I can find before asking for help. Again, I thank you

-

On 11/23/2024 at 1:08 AM, AnobiumPunctatum said:

If you print the parts of the model check on your program that the scale of the printout is 100% and not fitted to sid or something similiar. You can check the scale of each print out with the ruler shown on every PDF. It is given the length of 10 feet in the scale 1/48. In metric scale it's exact 63.5mm. Don't worry about your thoughts. It's the beginning of a really long journey. For me the MSW project was also the start in scratch building.

If you have not much experience I can recommend the cross section as a really good entry point. It hase the same scale as the full hull build but is much less complicated.

Also, another question I have when I printed the plans, I ended up with what looks like 4 decks, and I was thinking there is supposed to only be 3 I got plans of the Quarter deck fore castle deck which in my thinking is the top exposed deck, then the gun deck, and then the lower deck but I also got one called the for and after platforms which shows the sail room carpenters store room, Gunnards store room< Boatswains store room, slop room,- - - -

Is this the verry bottom of the ship which only becomes relevant with the POF construction or is all this how the lower deck is laid out?

-

On 11/23/2024 at 1:08 AM, AnobiumPunctatum said:

If you print the parts of the model check on your program that the scale of the printout is 100% and not fitted to sid or something similiar. You can check the scale of each print out with the ruler shown on every PDF. It is given the length of 10 feet in the scale 1/48. In metric scale it's exact 63.5mm. Don't worry about your thoughts. It's the beginning of a really long journey. For me the MSW project was also the start in scratch building.

If you have not much experience I can recommend the cross section as a really good entry point. It hase the same scale as the full hull build but is much less complicated.

Ok I'm pretty sure I understand everything you are telling me; I would like to say Thank you for taking time to chat with me about my build it means allot I'm thinking everything is in good shape the way it printed its just my lack of understanding with all this. I have build a few boats and from plans much like these but all of those had all the work done all I had to do was cut and glue with this there's allot of things to consider and I just want to try my best to get things as correct as posable in the beginning foundation of the build in an attempt to avoid future problem's as I get deeper into the ship. Origenaley in the beginning I was thinking 3/8 might be too big to build my frames out of but I went and got a piece of 1/4 and cut it out and the uprights look to small, and flimsy was wondering would you recommend I use 1/4 or the 3/8'' stock?

-

21 hours ago, AnobiumPunctatum said:

If you like to use thinner bulkheads you have to rework the cutout in the centerboard. Forwards from middle bulkhead (0) you have to change the fore edge of the cutout and backwards the after edge.

Then everything should work again. What is the thickness of the centerboard?

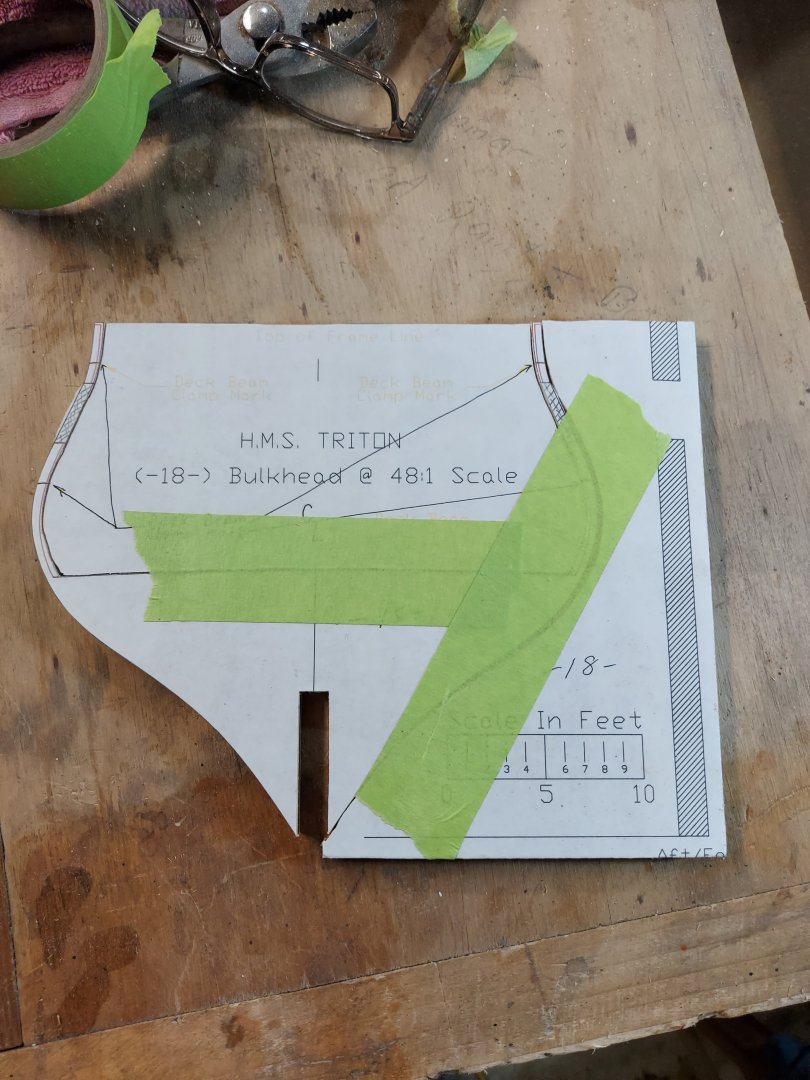

What I'm really worried about is the bulkhead size did my print come out correct or is something bad wrong

.thumb.jpg.33c8f22a320beaf80129c687067a735b.jpg)

HMS Triton by James Flynn - POB - Beginning My learning of the construction of ships of the line

in - Build logs for subjects built 1751 - 1800

Posted · Edited by James Flynn

Thank you very much for taking the time for me I appreciate it.