Pitts2112

Members-

Posts

13 -

Joined

-

Last visited

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

Gregory reacted to a post in a topic:

Sails for Lady Nelson?

Gregory reacted to a post in a topic:

Sails for Lady Nelson?

-

Hi, Steven, Apologies from me, too, for the late reply. I don't log on very often. Thanks for the reference. Your sails look great!

-

Nirvana reacted to a post in a topic:

Twisting planks to lay flat on ribs

Nirvana reacted to a post in a topic:

Twisting planks to lay flat on ribs

-

Pitts2112 started following X-Acto knife or modeler's plane for tapering planks? , Twisting planks to lay flat on ribs , Sails for Lady Nelson? and 3 others

-

I've read every paper and watched every video I can find but haven't been able to get the hang of reliably shaping planks so they not only butt against the preceding one but also lie flat on the ribs. The twist is the part I'm having a problem with. I've tried boiling water, Chuck's drying ironing method, combination of both, all without much luck. Can someone please explain or send me a link to a source that explains/demonstrates it very clearly? Here's an example of what I'm talking about. I've sanded the edges smooth but you can see how the planks were standing off from the robs on the bottom edges resulting in the this profile after sanding.

-

catopower reacted to a post in a topic:

Jig for planing planks?

catopower reacted to a post in a topic:

Jig for planing planks?

-

robert952 reacted to a post in a topic:

Jig for planing planks?

robert952 reacted to a post in a topic:

Jig for planing planks?

-

ERS Rich reacted to a post in a topic:

Jig for planing planks?

ERS Rich reacted to a post in a topic:

Jig for planing planks?

-

JpR62 reacted to a post in a topic:

Jig for planing planks?

JpR62 reacted to a post in a topic:

Jig for planing planks?

-

Ryland Craze reacted to a post in a topic:

Jig for planing planks?

Ryland Craze reacted to a post in a topic:

Jig for planing planks?

-

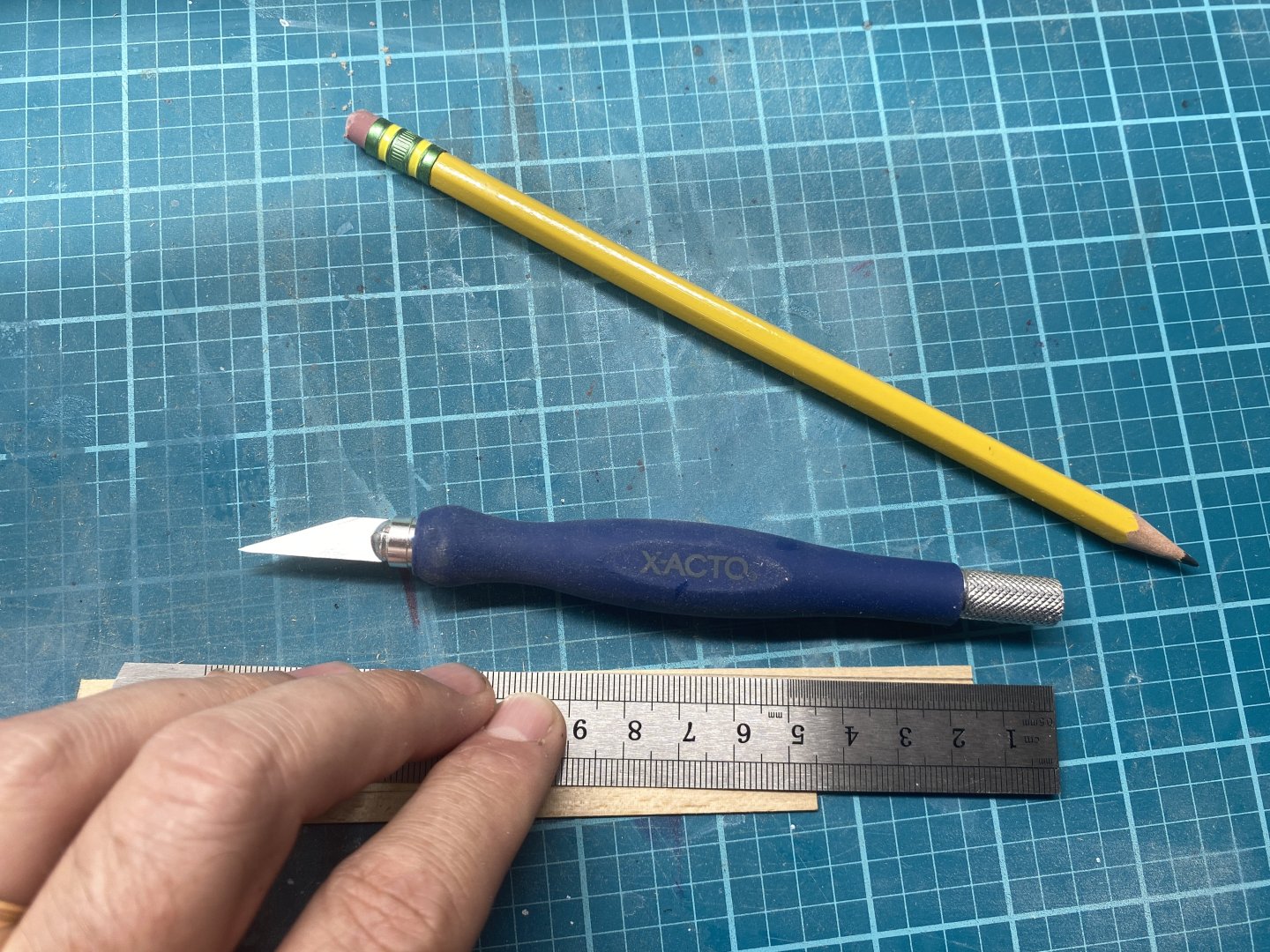

Funny you should mention that! I just picked up one of their mini planes and some chisels in the lee Valley seconds sale, delivered day before yesterday. I wish their online catalog gave a better sense of scale (it was hard to see how big/small they actually are) but I'm happy with them so far. They're the real deal - work like proper tools and everything! Pencil and scale for...scale (sorry, I didn't have a banana handy)

-

Does anyone here know if one can buy a set of sails for the Amati Lady Nelson or if there are patterns to be had to make them myself? Alternatively, is there a reason few, if any, modelers seem to put sails on this particular model? This is my first build so I'm not familiar with any issues that might be involved. Thanks very much!

-

robert952 reacted to a post in a topic:

Jig for planing planks?

robert952 reacted to a post in a topic:

Jig for planing planks?

-

robert952 reacted to a post in a topic:

Jig for planing planks?

robert952 reacted to a post in a topic:

Jig for planing planks?

-

ERS Rich reacted to a post in a topic:

Jig for planing planks?

ERS Rich reacted to a post in a topic:

Jig for planing planks?

-

Pitts2112 reacted to a post in a topic:

Jig for planing planks?

Pitts2112 reacted to a post in a topic:

Jig for planing planks?

-

Pitts2112 reacted to a post in a topic:

Jig for planing planks?

Pitts2112 reacted to a post in a topic:

Jig for planing planks?

-

Pitts2112 reacted to a post in a topic:

Jig for planing planks?

Pitts2112 reacted to a post in a topic:

Jig for planing planks?

-

Pitts2112 reacted to a post in a topic:

Jig for planing planks?

Pitts2112 reacted to a post in a topic:

Jig for planing planks?

-

Pitts2112 reacted to a post in a topic:

Jig for planing planks?

Pitts2112 reacted to a post in a topic:

Jig for planing planks?

-

Pitts2112 reacted to a post in a topic:

Jig for planing planks?

Pitts2112 reacted to a post in a topic:

Jig for planing planks?

-

What are people using out there as a jig to hold planks for edge planing tapers? I've been using a straight edge and Exacto knife flat on my workbench but I find the wood moves during the slice and I haven't figured out a good way to hold plank and straight edge in place. Photos below show my tapering tools. I use the glued-together-planks as a base to keep the straight edge at the same height as the plank surface which helps. So, I'd like to try planing instead because I think I can get more accurate and consistent tapers. But the only vice I have is a heavy bench vice and I'm using two blocks of oak as the clamping surfaces. It works but it's a bugger to line everything up since I haven't figured out how to secure any one component to another and moving the vice jaws is very cumbersome.

-

It's July 2025 and I've been working on (and off; mostly off) Amati's Lady Nelson since last Christmas. First thing I want to say is a huge thank you to this community for your very generous sharing of a wealth of information on the craft. I've spent much more time reading posts here than I have actually building the model and all of it has been a delight. I just finished the first planking, which went better than expected but I ran into a situation where I needed far more stealers on the lower hull than I expected. I suspect I didn't properly measure the length of the ribs and stern post which led to tapering too narrowly at both ends. I suspect I only measured the 10th rib and not the stern post since that's where my coverage finished when I had nearly all the planks on. I also know I didn't cut the tapers very accurately, so their actual measurements are kind of all over the shop. I partly corrected this by laying two untapered planks at the keel (garboard and next one above), then doing a very customized gap filler plank to finish the main hull. Covering the stern post required 3 very short, very pointy stealers to make up the difference. I'm pretty sure those should have been longer and more strategically placed but I didn't know I was going to need them until it was too late to plan ahead. It seems to have done the job overall just not according to standard procedure, I think. (see pictures below). Question for the group - is my assessment above correct or is this the result of some other mistake I made (or combination of mistakes)? Pics: First planking, showing wide variation in coverage toward the last couple of planks. I think I tapered too much on both ends which led to them not coming far enough down the bow and stern post and being too wavy overall. Also I think I only measured the last rib instead of the sternpost so only tapered to the end of the rib: Measured gaps between planks and keel when I only had a c9uple more planks to lay. Finished first planking with stealers laid. After sanding it came out alright, I think. Will this be good enough as a base for the second planking or do I need to do something else to it before starting?

-

- Lady Nelson

- Amati

-

(and 1 more)

Tagged with:

-

First time modeler trying to use Chuck's plank bending method on the Lady Nelson. My question is what's the technique for getting the sharp bend required on the last couple of inches of the plank to get around the first rib and into the bow? I'm getting the bend on the rest of the plank OK, but I've broken 3 of them trying to get that last bit in. I think that if I don't get the bend sharp enough then CA glue isn't going to be strong enough to hold the end of the plank in place. Any tips will be greatly appreciated!

-

Hello, all, I'm getting ready to start my first kit, the Amanti Lady Nelson. I've been absorbing the website here which is an amazing resource. I have one question about tools for tapering hull planks. My only experience with wooden models is from a couple of balsa wood aircraft when I was a kid and I remember having a really hard time getting quality results with X-Acto blades on that wood, particularly trying to make long taper cuts on thin strips. Are the planking woods in ship kits easier to work with? Would a modeler's plane give better results than a razor knife? Thanks for any tips!

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.