-

Posts

22 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by jnarro

-

JAJAJJAAJJAJAJAJJAA right 20015 is a little far away! for the tree nails of the first deck I worked I indeed used wood glue but I found that the toothpick turned out in a darker color when I cut and flushed the surface, maybe because of the water of the wood glue or maybe the toothpicks brand, so that{s why i used gel CA and worked preety well., I stained the decks by tomorrow I will post a couple of images. Cheers!!!!!!

-

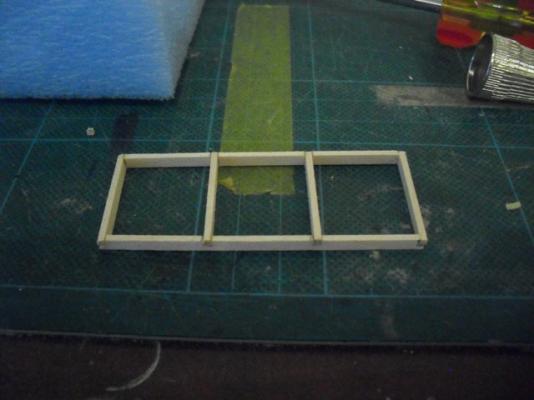

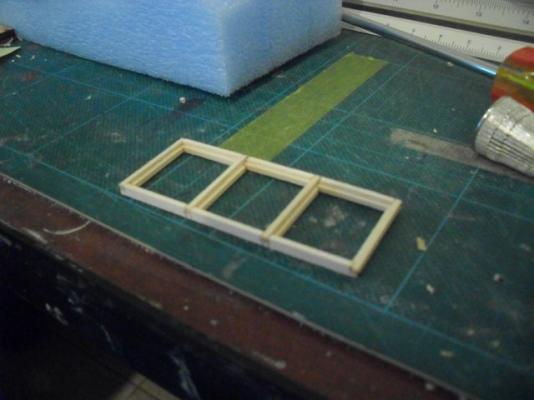

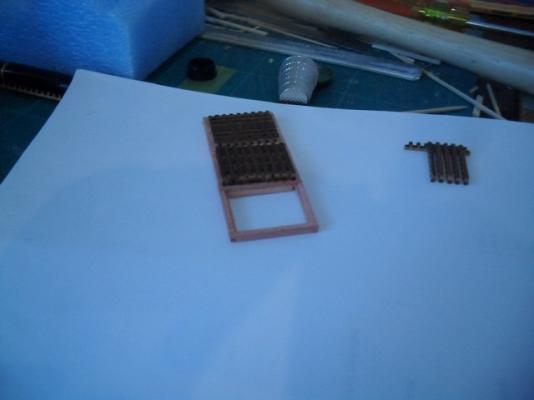

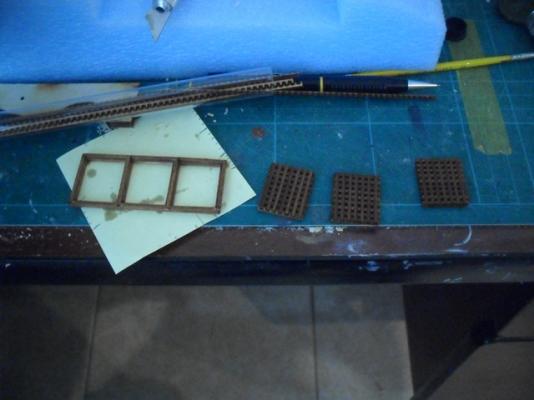

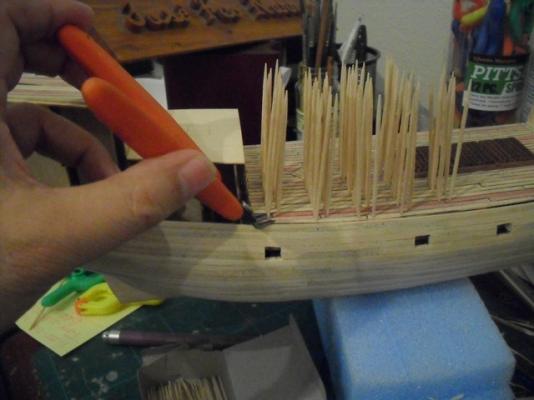

First af all, a Merry Christmas and a very very Happy 20015 for everyone!!!! For a couple of weeks I´ve been working on the decks of the ship, and following the nice instruction booklet. The first step is the building, staining and gluing the hatches, before planking. This is the main hatch: Once the glue dried, I started with the planking, slightly staining with ink several of the planks in order to weather the decks. The tree nails is something new to me, so I aked my Friend Ulises Victoria and following his advice proceeded to make the holes and insert the thootpicks with a tiny drop of CA, that was a simple step, but my problem was how to cut the toothpicks, so I decided to use my Xuron pliers and a hand made tool with a piece of wood and a chiseling blade for trimming the nails. Then I started to glue the toothpicks and cut and trimming until I finished with the three decks for this first step. After this I proceeded to lightly sand the decks with a fine sandpaper in preparation for the stain, which will be my next post. Thank you so much. Cheers

-

Hi Ulises, dear friend, what can I say? I am learning a lot watching your log, your work and craftmanship is astounding, my little Mayflower looks like a row boat compared with your monster. Cheers!!!

- 786 replies

-

- Royal Louis

- Finished

-

(and 1 more)

Tagged with:

-

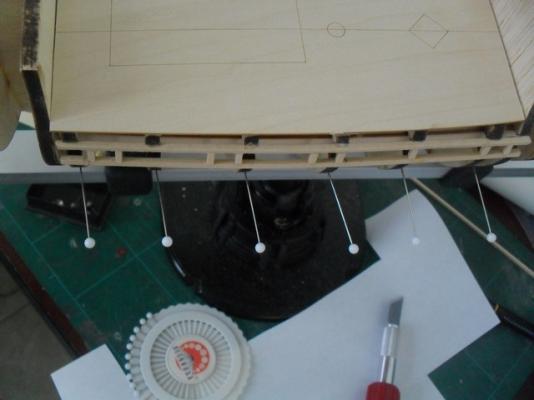

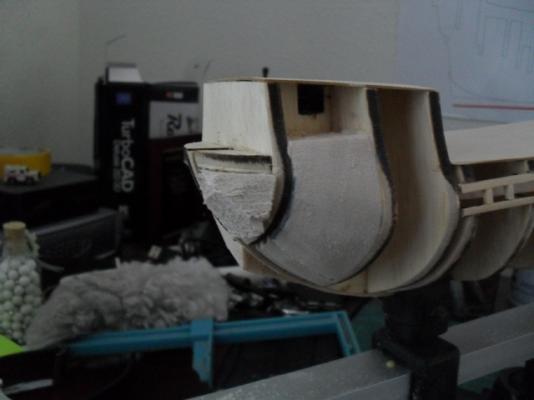

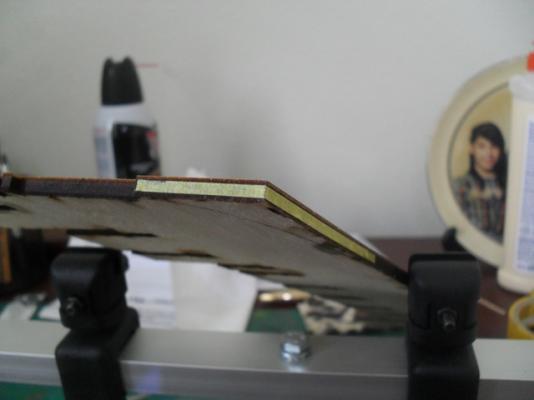

I could´nt wait more time so I started the sanding and filling of the hull. First i used a mediumg grit wood dandpaper to take all the roughness of the planks Later I apllied a layer of Elmer´s wood filler max, and let it dry all night, this is gonna be fun tomorrow! The filler color is horrible, but it makes a pretty solid fills. In the mornig the filler was dry, and ready for the rest of the sanding, a lot of powder talc like is produced by this filler and a lot of sanding so I used my Rockwell SoniCrafter to sand most of the filling. The second step was sanding with a mediumg grit sandpaper, and finnaly a fine one to finish the sanding and have a smooth surface. The Bow and the Stern need stil some trimming and filling!! The rest of the Hull is now cleaned and very smooth waiting for the second plank layer This is it until this morning!! Cheers

-

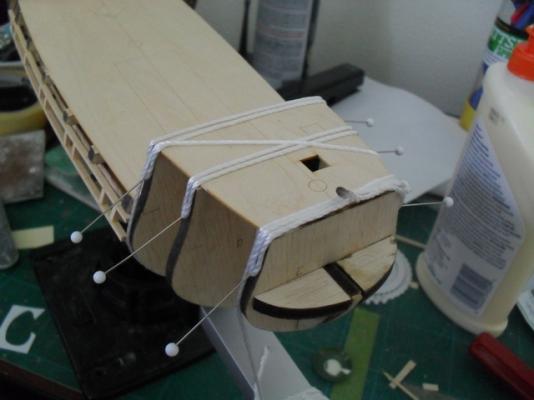

Finnally the never ending first planking layer story was accomplished, so I can prepare the hull for the next steps on the building of the Mayflower. At list I was able to keep both sides of the hull with the same number and width of the planks so this is a stone mark for me in my learning process of building a wooden ship. I will attach some images of the last planks glued. The stern view waiting for the las planks and a proper trimming once the glue dry completely The last insert for the hull Hull Completed Next step a first sanding with a medium grade sand paper to take out the roughtness, the second step will be to apply the wood filler and then a fine sanding to have a smooth surface, that{s my next job, with my little Mayflower. Any comment will be welcomed of course!!!

-

After a careful check I let the planks overnight, just to see if any movement appeared after applying the heat, so today after work every thing appeared correct so I proceeded to glue both planks to the hull. Everything appears aligned in both, the Bow and Stern I will let it dry overnight, and tomorrow will start to plan a more faster way to plank this beauty. Thank you for check this project Cheers!!!!!!

-

Finally the Plank bender from ModelExpo arrived so time for planking the hull!!!! Actually is easier than I thought, and quite fast, so I started with the two upper planks in order to really check the alignment, after soak both planks for about 2 hrs (a movie) I started the operation so important for me. I had to fix with some tape the bender and worked the plank as a video that I found in youtube.

-

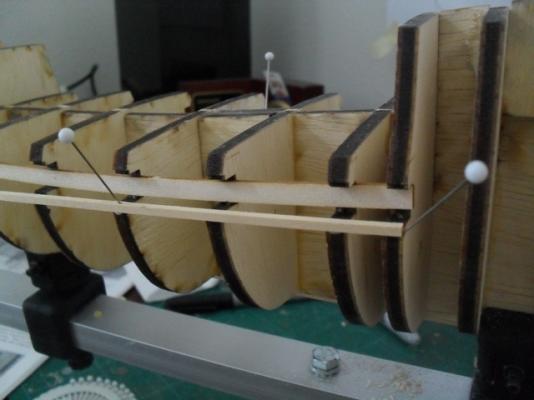

In preparation for the first layer of planking for the hull, the bulwark has to be temporary attached in order to draw the first reference marks. You may note that the bottom line of the port side bulwark is about 2mm lower than the port side, I measured both sides and I can´t find a defect in the actual building of the structure so I have to think how to fix this problem in order to have the planking correct.

-

Ulises, thanks I finished yesterday with the false decks, next will be to work on the stern and the curved joint that has me horrified but I will work on it anyway!!! Hello Midshipman, of course you can follow, feel free to make any comment when you see anything that doesn´t look right, and yes the Mayflower has 8 cannons in spite of being a Wine Merchant Vessel, is quite pretty not so large and the plans and instruction sheets are superb, check that for the Rattlesnake, any choice will be OK, the matter is that is a lot of fun!!!! Cheers!!!

-

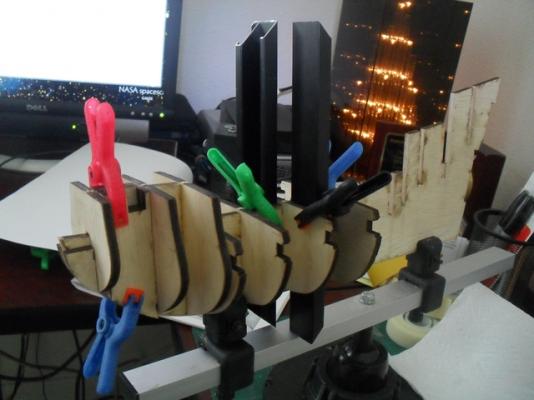

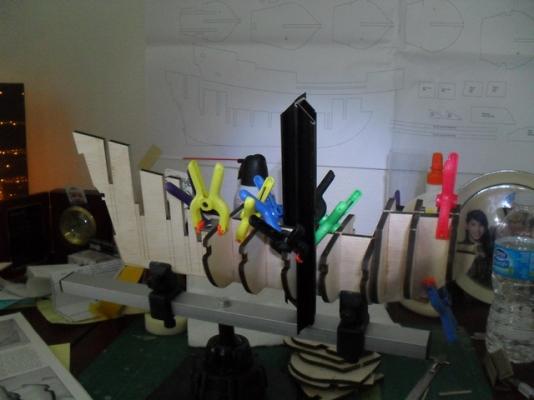

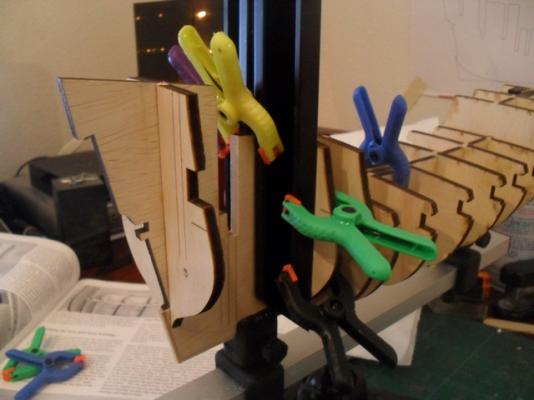

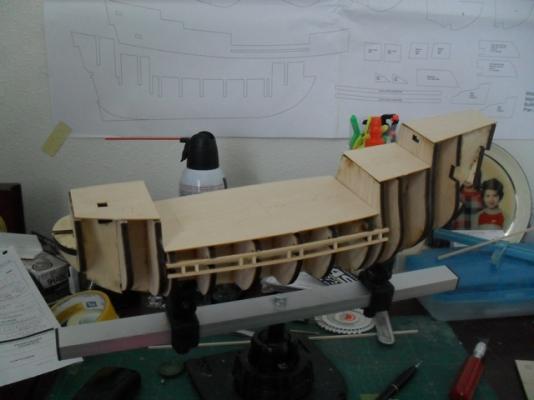

Here it goes! The nex step is gluing the bulkheads so I decided to start from Bow and work backwards to the Stern. in order to check the alignment with my drafting rule, I used a 30-60-90 degree one. As a good rookie, I made a couple of mistakes that I was able to correct on time, I am using as a primary glue the Elmer´s Carpenter, is a wonderful glue but but is an unforgiving one, once dried is like a stone. So I will start attaching the photos of the gluing process. I found that some of the bulkeads are not completely flat so I have to even the misalignment a little bit. I found that Aluminum is great for using as a tool so I am using a pair in order to secure the alignmement, those are the long black pieces. Then I discovered my first mistake; I glued the wrong bow fillers so I have to be very careful in removing them in order to glue the right ones, so in the end everything went well. Next the Port side fore fillers were sanded and attach in position; and painted black. Walking to the Stern I found that a wrong bulkhead was glued so another surgery was needed, and I think that will pose no problem at all. The last thing for the day was to dry fit and glue the dummy cannon support strips. So after a good night rest the skeleton is glued, I will reinforce it with hot glue anyway, just in case... I will continue next week, as today is Good Friday and time for meditation and thought. Thank you for passing by, any comment will be very welcome!!!! I finally was able today to keep on my Mayflower building, so I will post more images of my building process. Next step is to make the gunports, this is a little tricky issue but the plans are excellent so it only took some time. Next step is working the Stern structure and Bow eye bolt, comparing to the gun ports this is a quite easy task The dry fitting of the false decks is next, I found that the kit is very well built and some sanding needed but not a heavy sanding, so I just adjusted the bulkheads with my Dremel and after I liked the fitting I proceeded to glue the Main (false) Deck. Next will be to complete the false decks gluing, I will post more images. I need to praise the quality of the instructions and plans of this kit, I think I made the right choice for my first wood ship. Any comment will be very much appreciated!!!! It´s been so long since my last post, what a shame, a new full time job, a long everyday commute and the absolut panic because the planking moment is near!!!! I finnaly had some courage and kept the pace in my buiding this beautiful little Mayflower, so here are more images. First the false decks gluing. Then was time for the Stern planking, the first layer on the counter was so much easier than I thought, after drying I decided to apply some wood filler in order to smoothen the rounded surface. Noe was the time for the second layer of the planking, now I started to feel a little more confident in my building, after so many years of plastic modeling!! Following the advise of my friend Ulises Victoria, I shaded the sides of the planking although this part of the stern will be painted I think it will add some subtle shading effect. The planking of the stern was very interesting and funny, next is the hull planking, but... After watching some images of Ulises Victoria Royal Louis, I decided to fill some of the bulkheads of the stern and bow in order to help the first planking layer, hope this works!!!! So I just needed a fast trip to a nearby Hobby Lobby and had a couple of nice blocks of Balsa Wood, I decided Balsa because is easier of sanding and molding to the deep curves of the stern and bow. Next will be to temporary place the bulwark template to start with the first 6 rows of planking at each side, God help me!! Thank you for watching my postings.

-

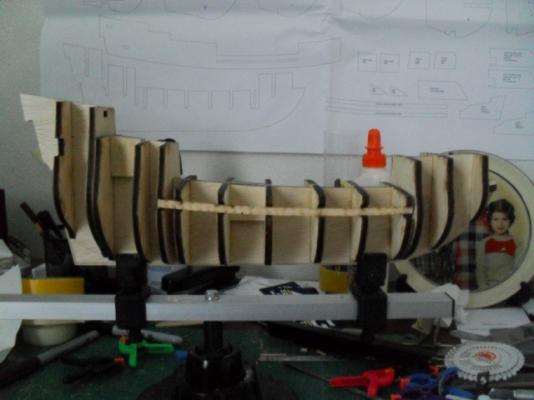

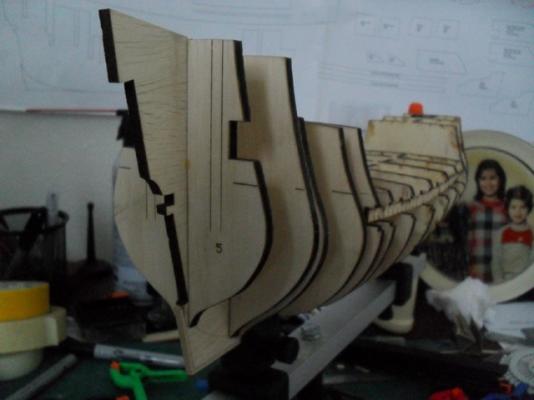

OK the first thing to do is to glue in place the Rabbet Strip, and let it sleep a whole night, this was done very easily... I´ts a very simple operation, but being my first Wood Ship I am very very careful! The next step is to Assemble the bulkheads, to be honest with this laser cuts and nice engraved lines I thought that this step were going to be an easy one but... It looked like the never ending sanding story, oh my!!!!! I decided to start from the center to the Stern first and then do the opposite, I took a lot of images as I was fitting every bulkead. Of course the first one took me almost an hour, I was trying every sand stik, and files I have , in the end a very urgent trip to the nearest Home Depot save the day! And this morning the rest of the bulkheads were fitted and waiting for the glue, so much work and I am still in page 1 of the Instruction Manual. I hope to post in the next days the bulkheads already glued Thanks for stopby and any comment will be greatly appreciated!!!!!

-

Another Big One for you Ulises, Go for it!!!!! It looks Awsome!!!

- 786 replies

-

- Royal Louis

- Finished

-

(and 1 more)

Tagged with:

-

As always the VASA is a Masterpiece, ready for the Tequila toast nex month, and waiting to see your next project!!!!

-

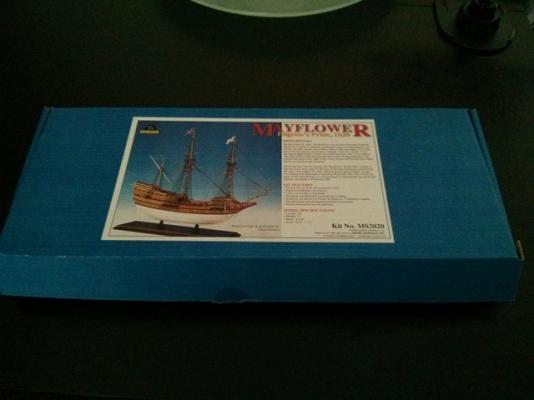

I´ve been a plastic modeler all my life and now it´s time to start a new adventure. I choose the Mayflower because it´s significant and historic value, it´s pretty and of a good size; so I hope to finish this project happily. I intend to build a decent log of the building process, all of my tools are ready I feel ready and may the force be with me... So here is the box and what it´s inside; everything seems OK, I intend to build this ship very carefully and by the book as much as possible The first thing is to glue the Rabbet Strip along the bottom of the bulkhead, but the stern has to be tapered from 3/16" to 3/32", so I decided to do this first and then glue the Rabbet Strip. For making my job easier i made a strip of yellow Masking tape 3/32" wide and glued to the bottom as much precise as I could, for an easy sanding. Then I used a Squadron Shop coarse filing stick for the sanding with a finishing touch of Micromesh 1800 (green), looks that the tapared section is ready. So far this is my beginning, next step is gluing the Rabbet Strip, I will attach in my next post this. Please any help you experts can give will be very, very much appreciated, if any of you start building plastic model airplanes I can be of help!!

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.